Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Inhibition of decomposition reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

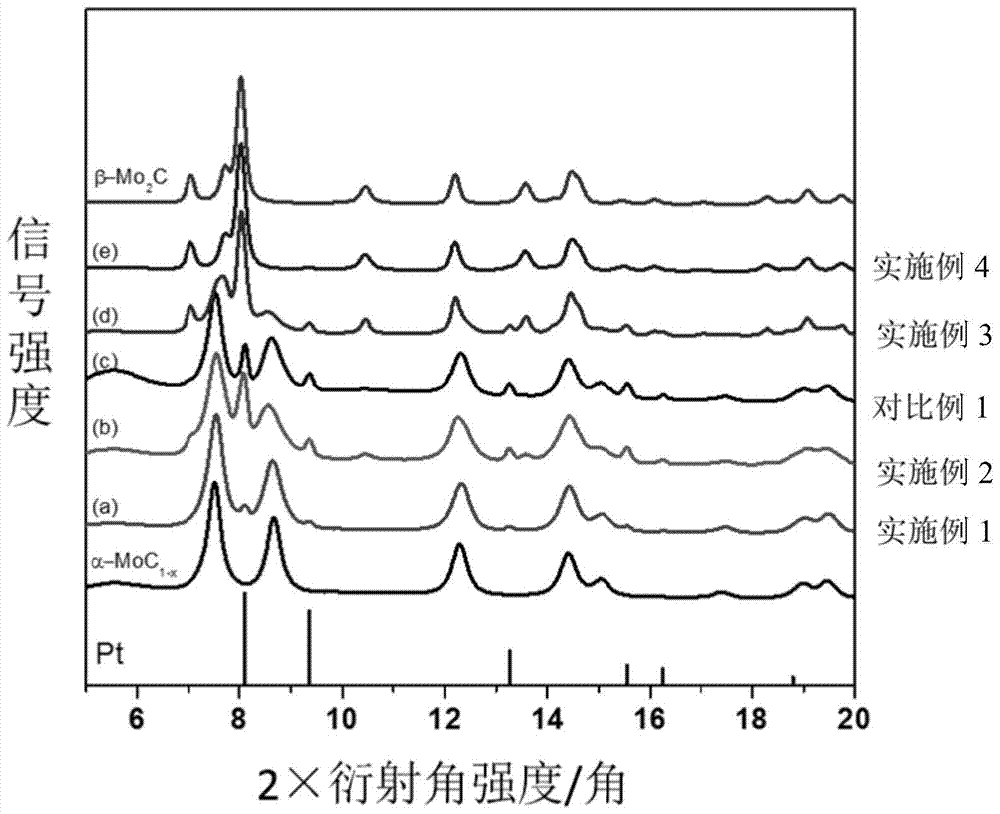

Pt/alpha-MoC1-x supported catalyst, and synthesis method and application thereof

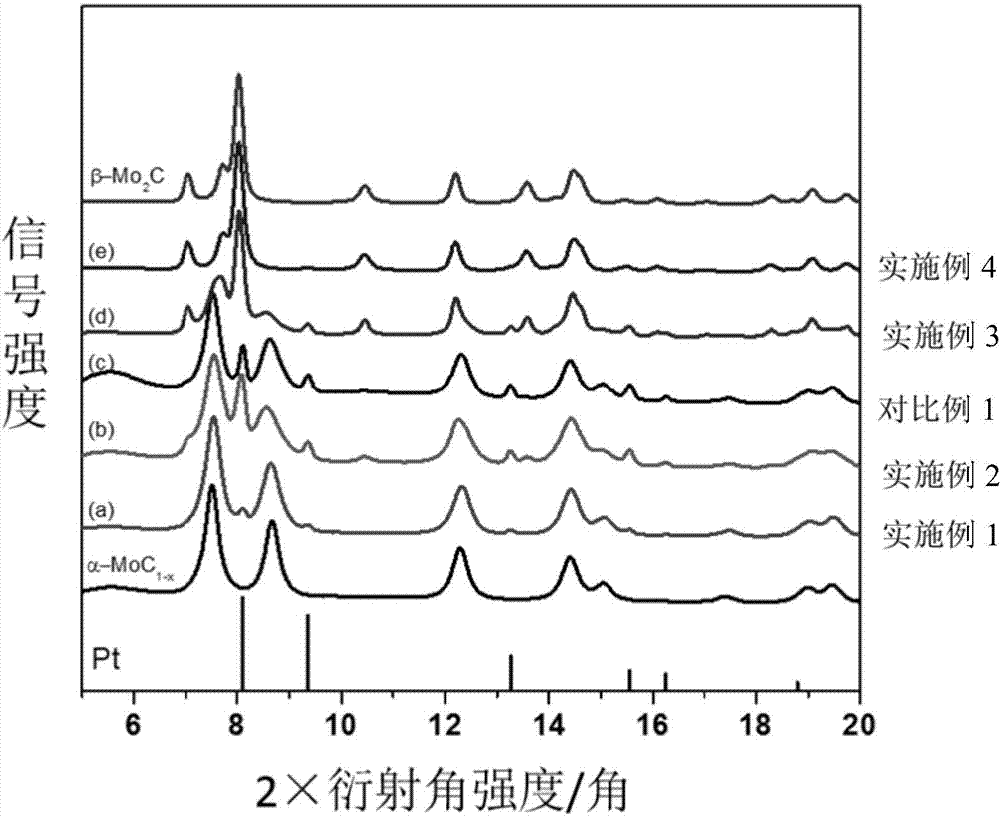

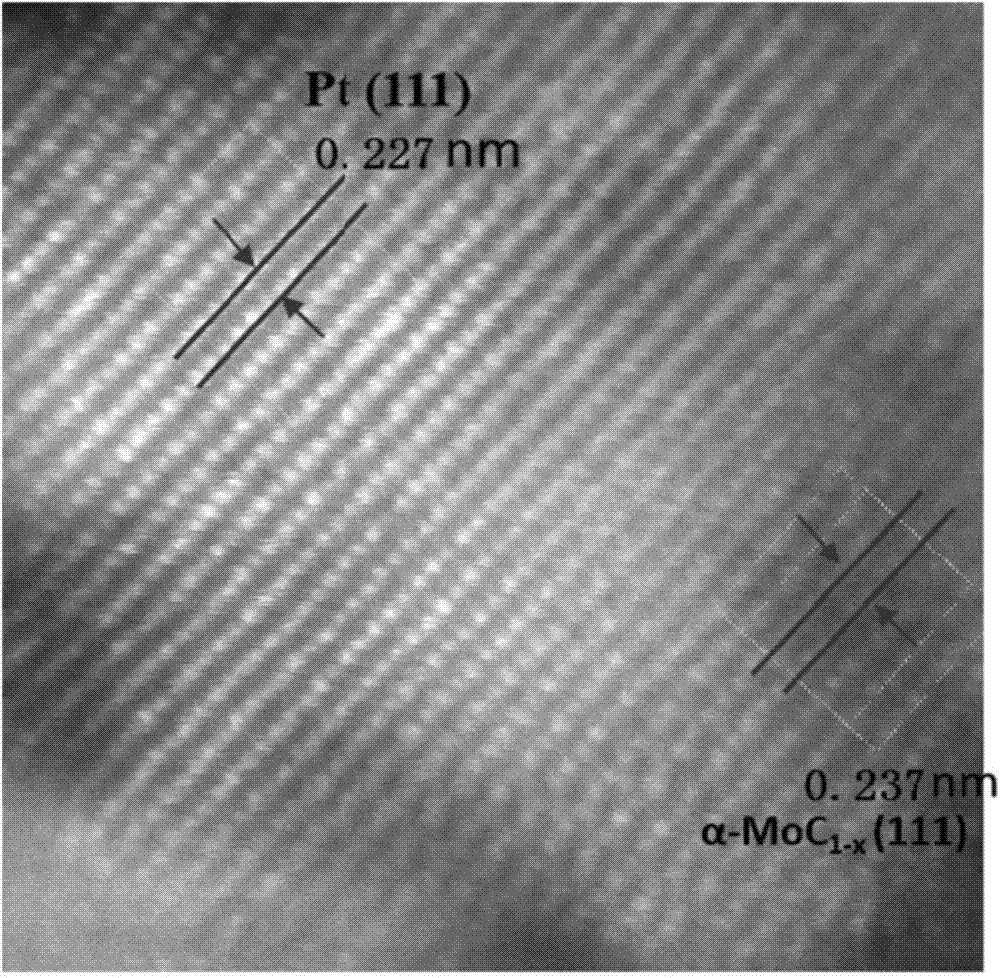

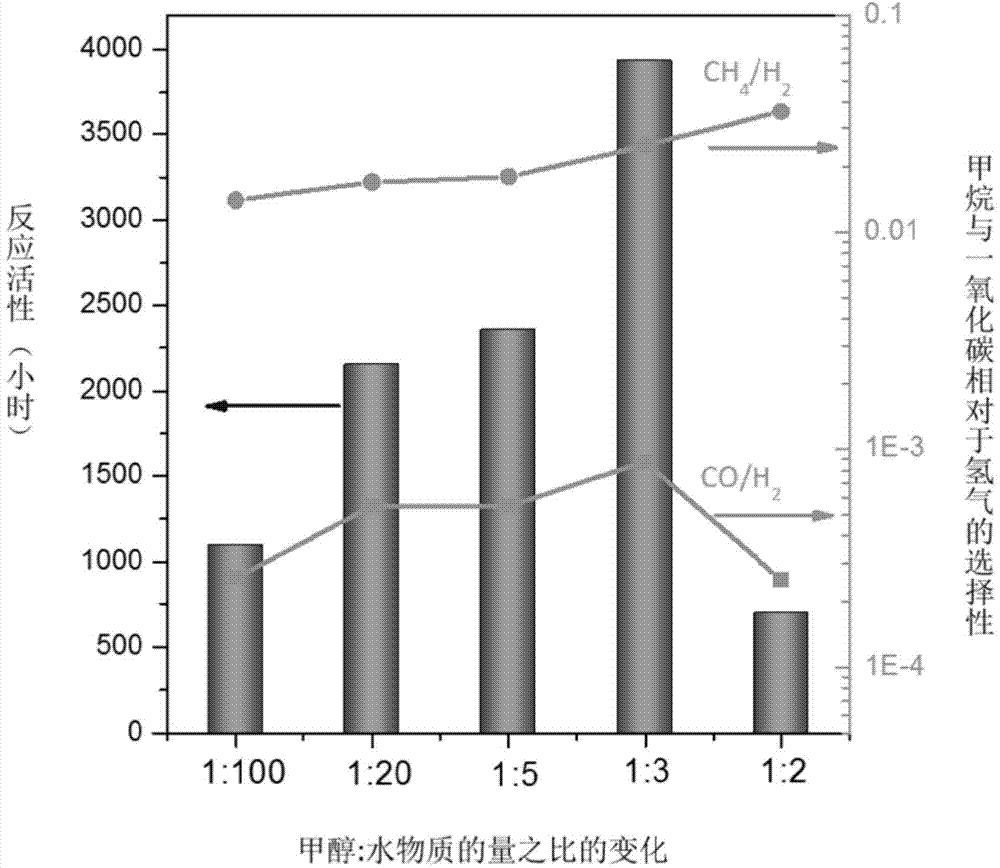

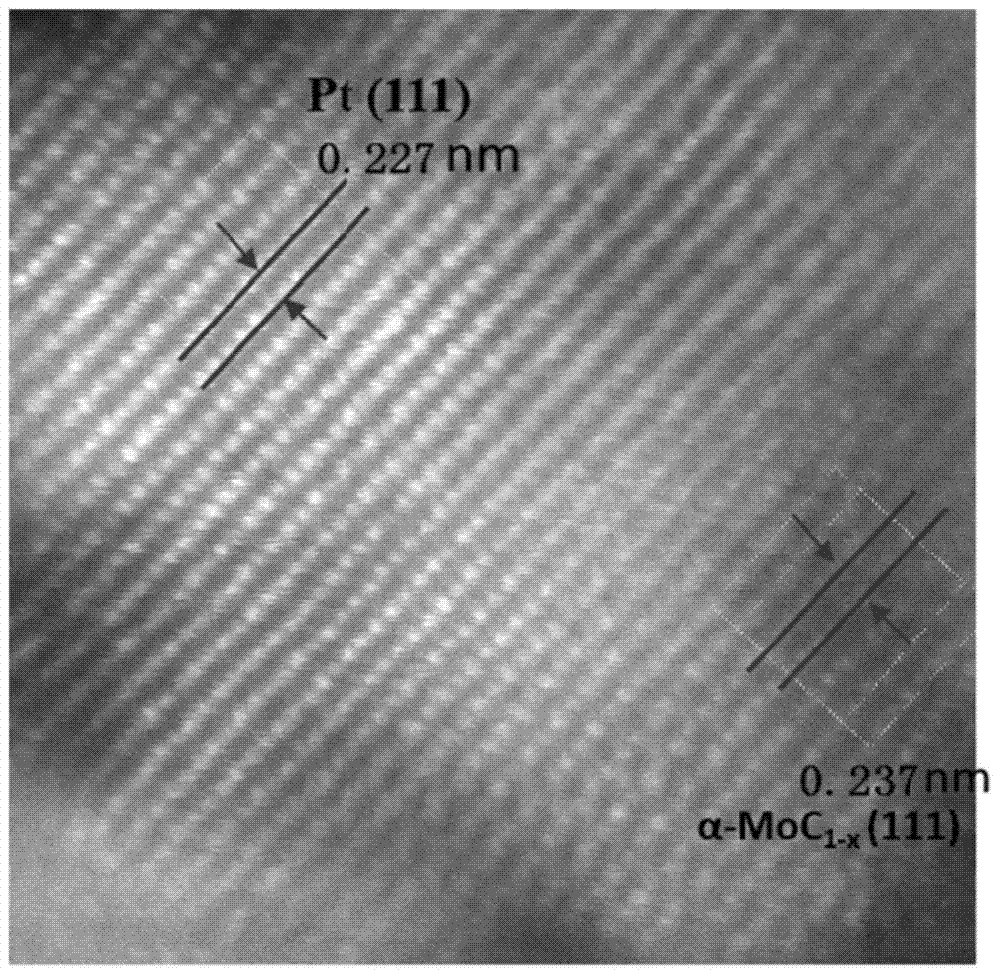

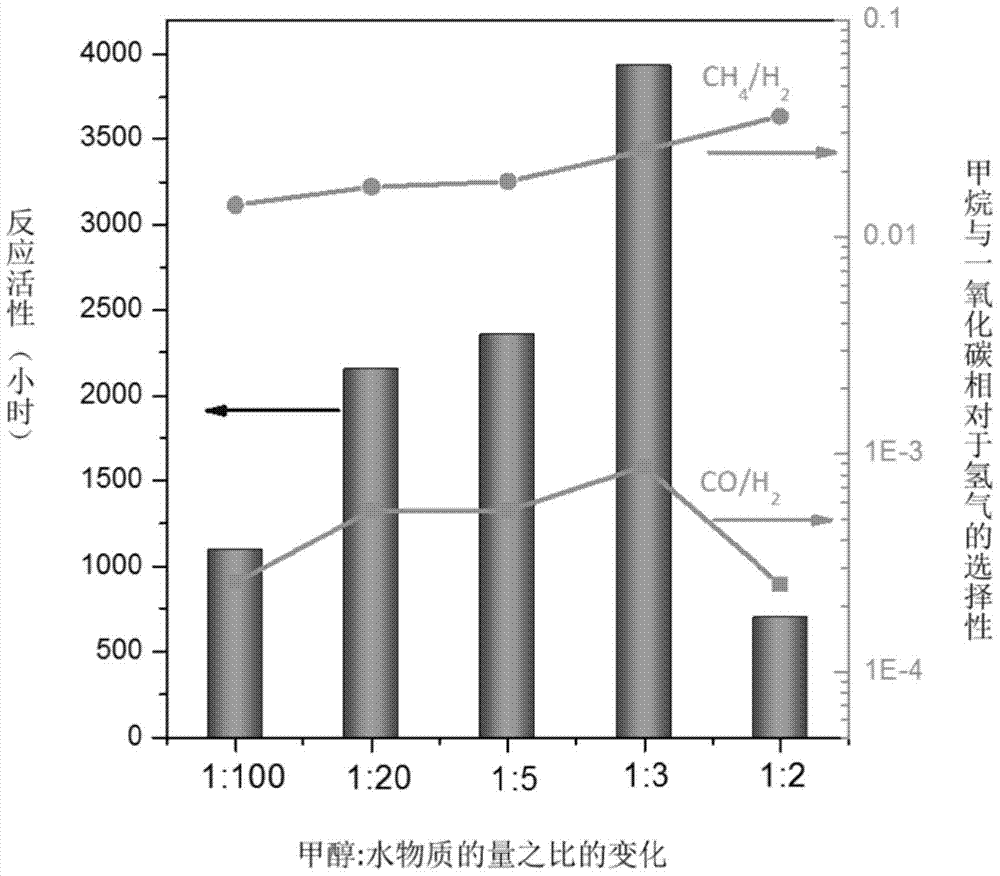

ActiveCN104707636AHigh activityLow selectivityHydrogenMetal/metal-oxides/metal-hydroxide catalystsPlatinumHydrogen

The invention discloses a Pt / alpha-MoC1-x supported catalyst, and a synthesis method and an application thereof. The method comprises the following steps: dissolving a platinum precursor salt in water, dipping the obtained solution to a MoO3 supporter, stirring until dryness, placing the obtained solid in a 40-60DEG C vacuum drying box, drying, carrying out programmed heating on the dried solid in a muffle furnace to 400-500DEG C, maintaining the temperature at a highest value for a certain time to obtain Pt-MoO3, and carbonizing the obtained solid in a certain proportion of carbonizing gas atmosphere to obtain the Pt / alpha-MoC1-x supported catalyst. The Pt / alpha-MoC1-x supported catalyst used as a good catalyst for preparing hydrogen through low temperature (150-190DEG C) water phase reforming of methanol has better catalysis activity than Pt supported oxide supporters and Pt supported non-pure MoC supporters, and has high stability in stimulation of a truth approaching system.

Owner:PEKING UNIV

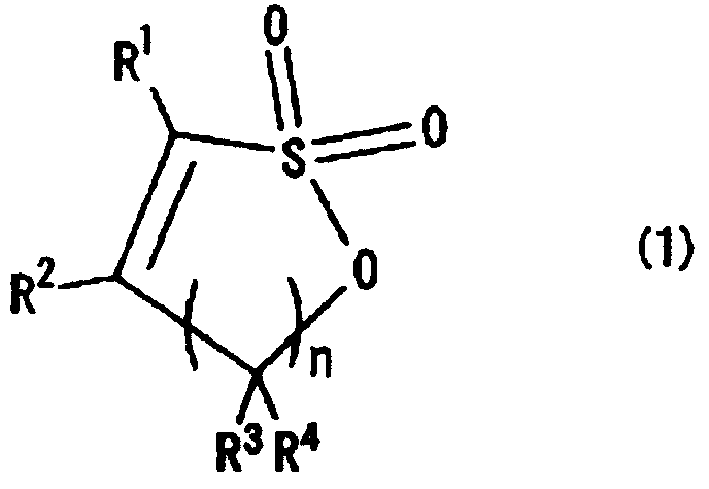

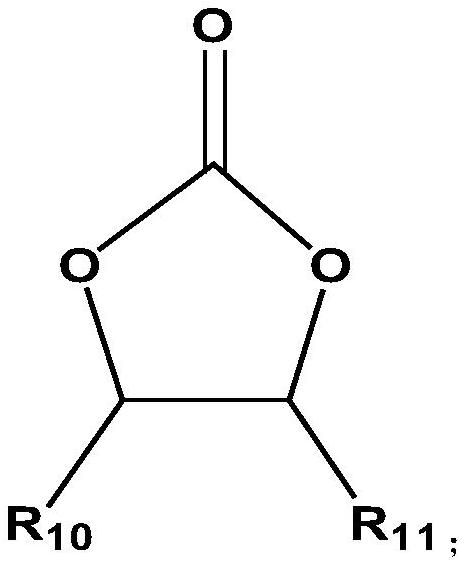

Additive for electrolytic solution, non-aqueous elecrolytic solution using said additive and secondary cell

InactiveCN1474476AImprove life characteristicsHigh flash pointSecondary cellsDecompositionPhysical chemistry

The purpose of this invention is to provide an electrolyte capable of suppressing decomposition of a solvent on he negative pole, suppressing energy reduction, gas and load charcteristic going worse to provide a nonaqueous electrolyte providing excellent load property and low temperature property to the battery, and provide a secondary battery containing the electrolyte and additives for it characterizing in containing unsaturated sultone nonaqueous electrolyte and secondary battery using this electrolyte and its additives composed of same compositions.

Owner:MITSUI CHEM INC

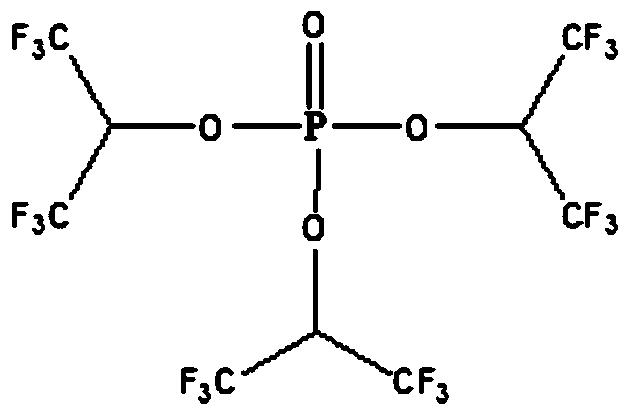

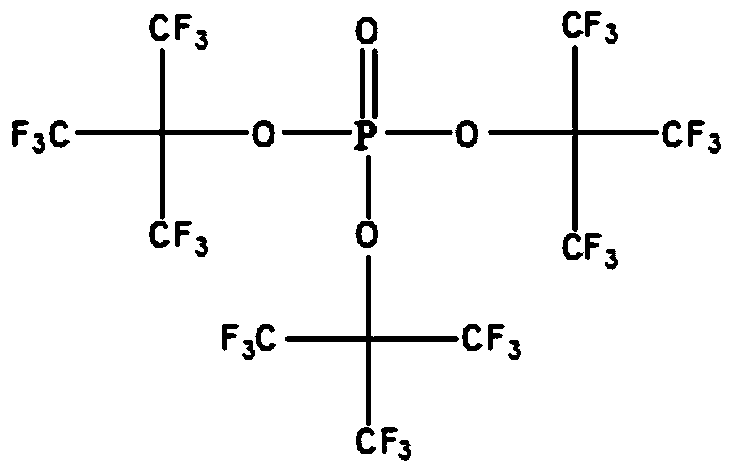

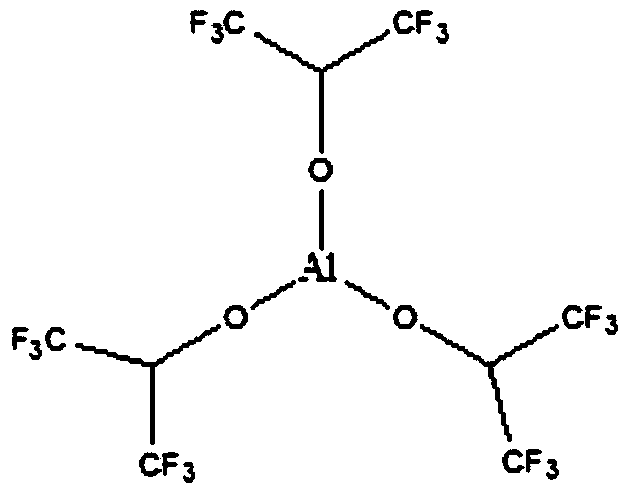

High voltage lithium-ion battery electrolyte and lithium-ion battery

InactiveCN103633369AInhibition of decomposition reactionsReduce exposureSecondary cellsHigh voltage batterySolvent

The invention discloses a high voltage lithium-ion battery electrolyte which is composed of an electrolyte solute, a solvent and an additive agent, wherein the additive agent comprises a positive electrode film formation additive agent and a conventional additive agent; the positive electrode film formation additive agent is at least one selected from HFiP, PFBP and Al (HFiP); the conventional additive agent is one or more selected from VC, FEC, VEC, 1, 3-PS and PST. The high voltage lithium-ion battery electrolyte can obviously improve the cycle performance and the storage performance of a high voltage battery. In addition, the invention further discloses a high voltage lithium-ion battery.

Owner:SHENZHEN SONGDING TECH

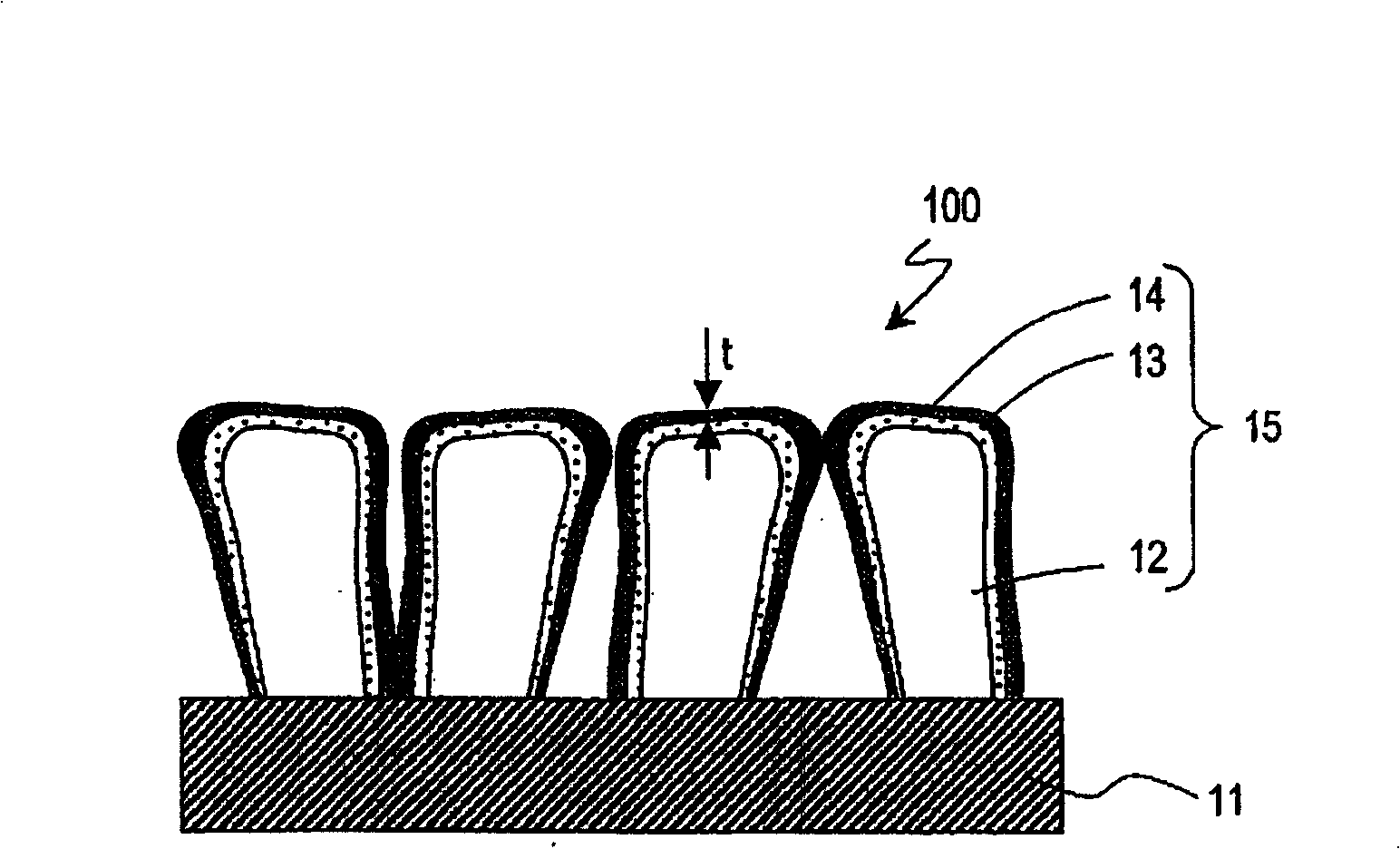

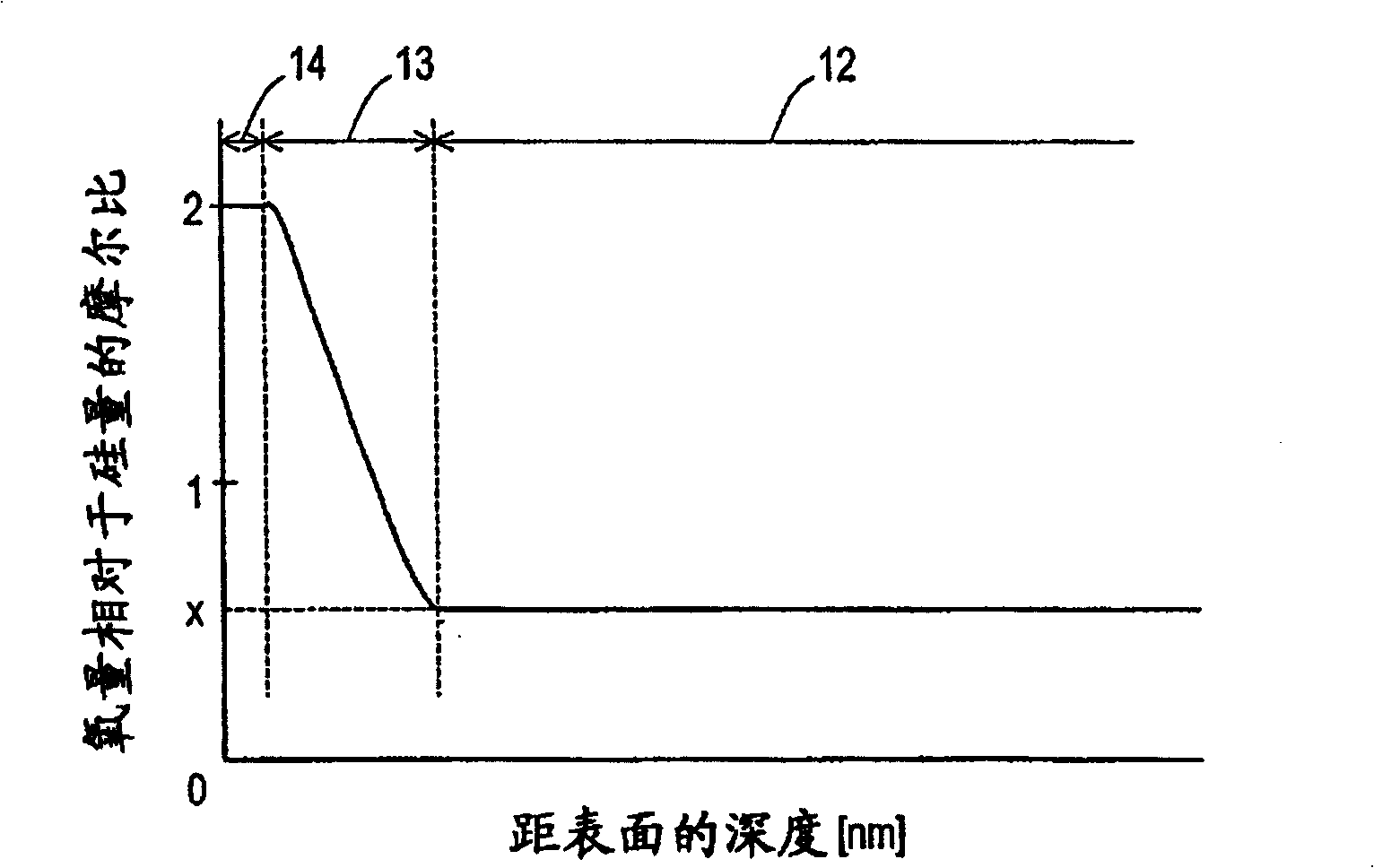

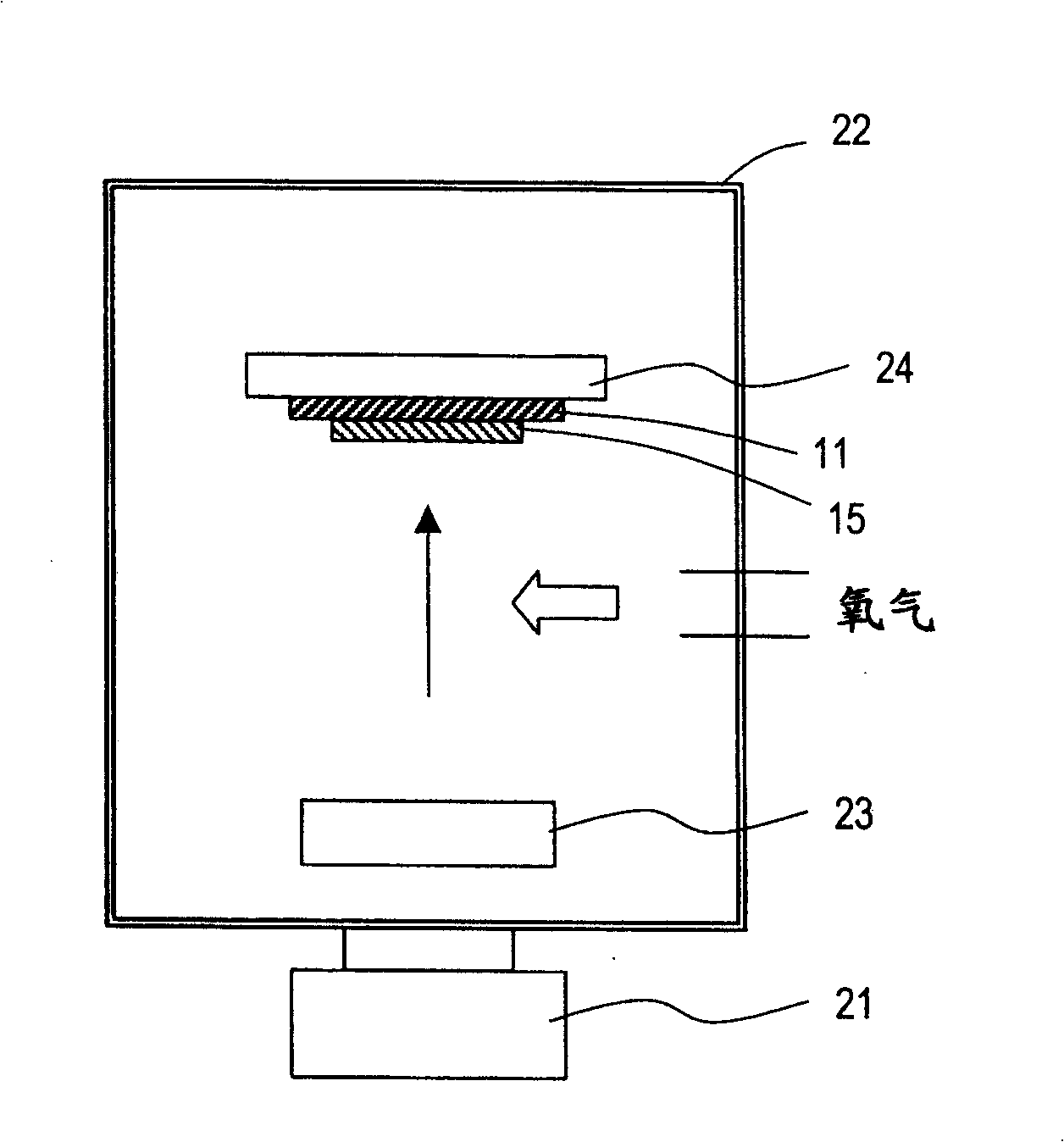

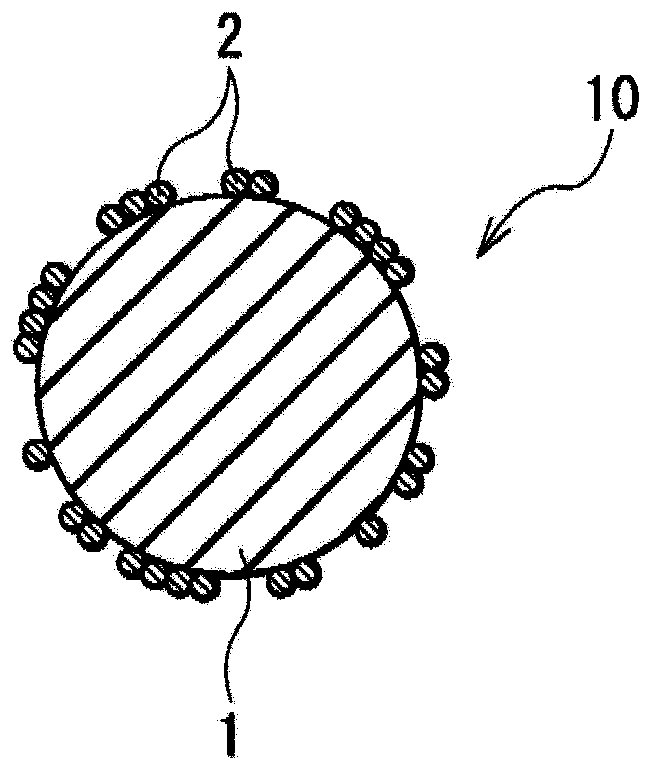

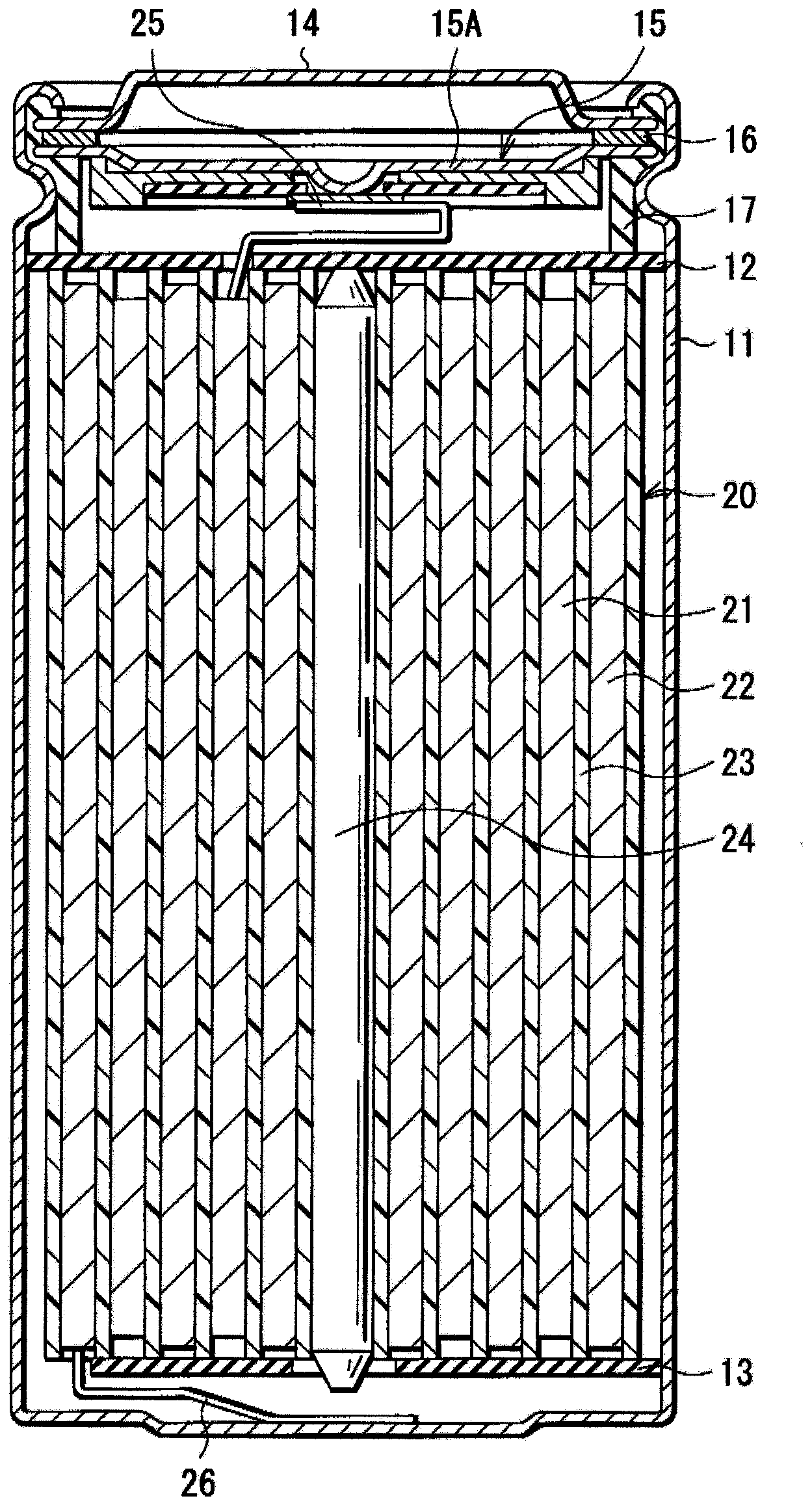

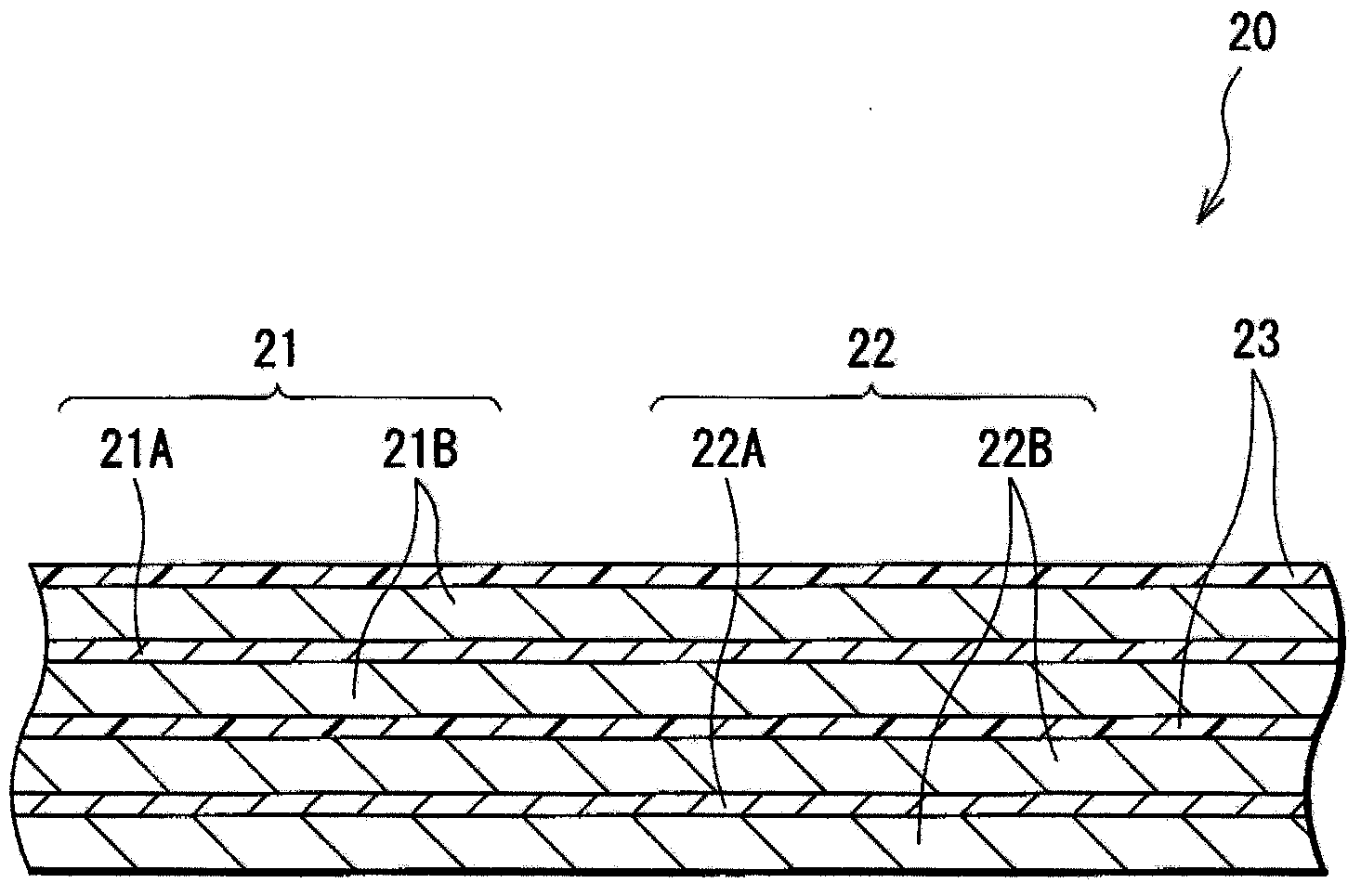

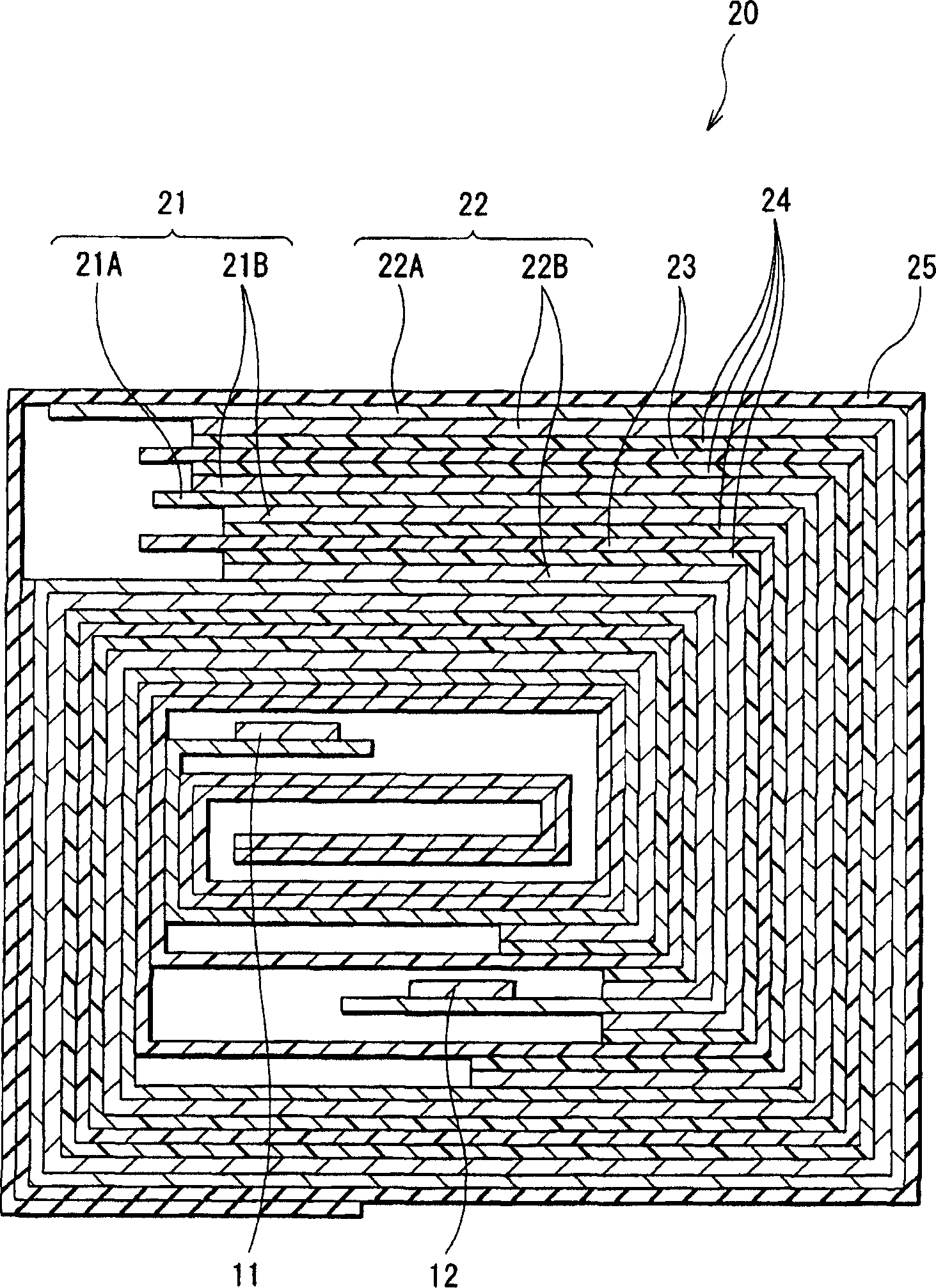

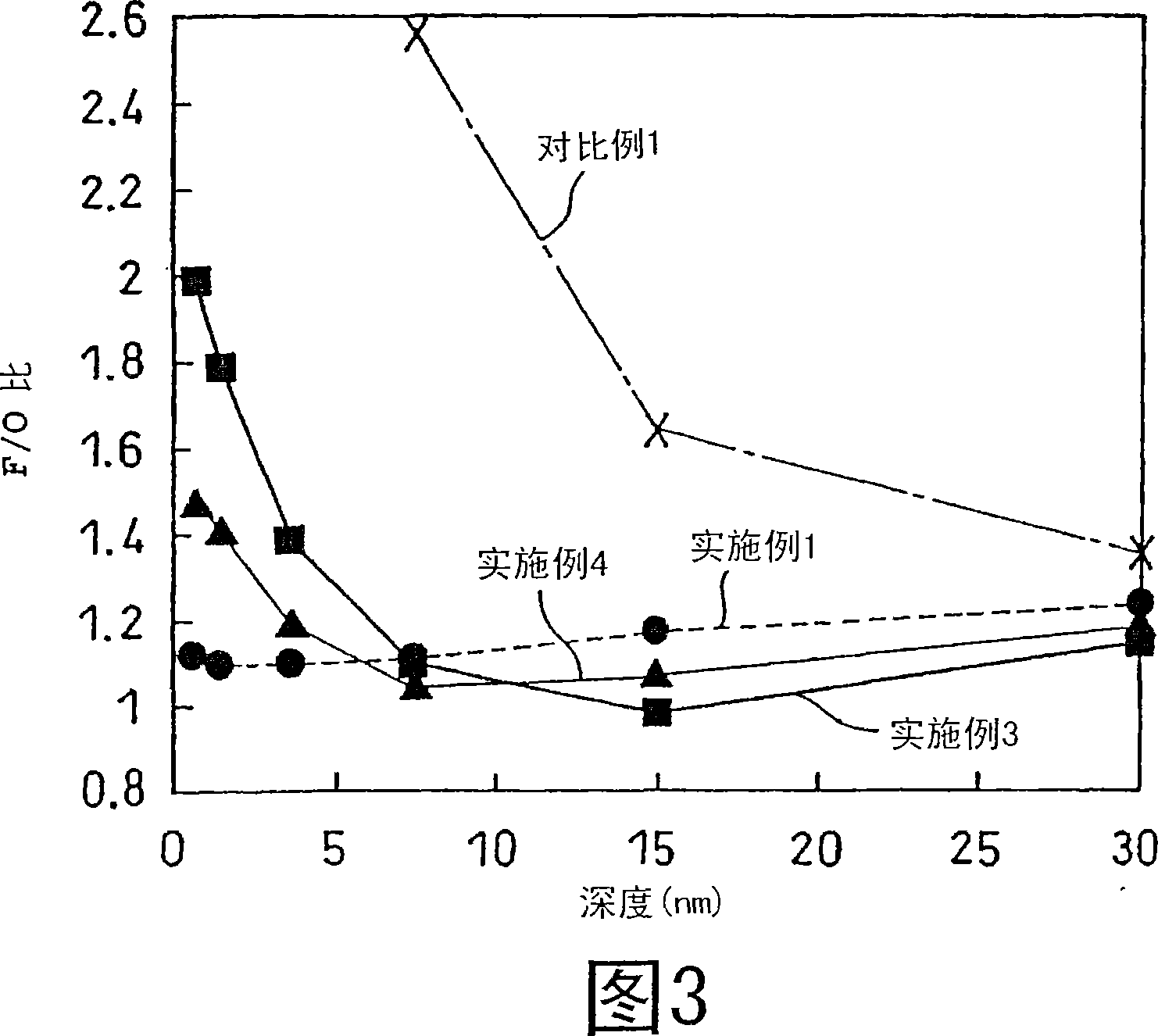

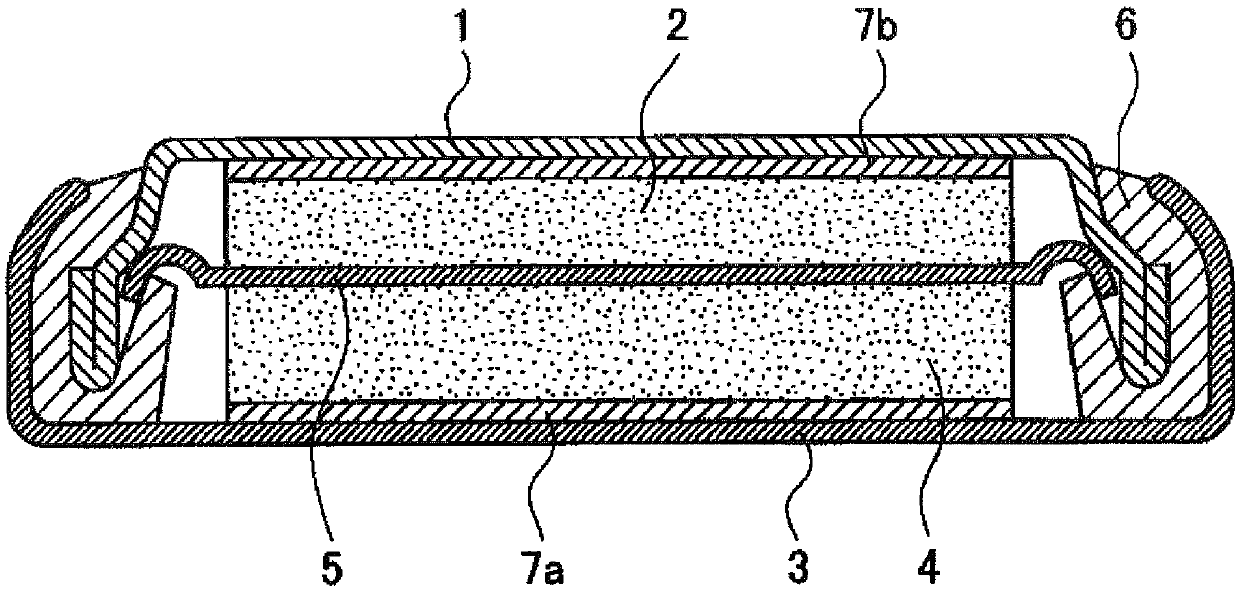

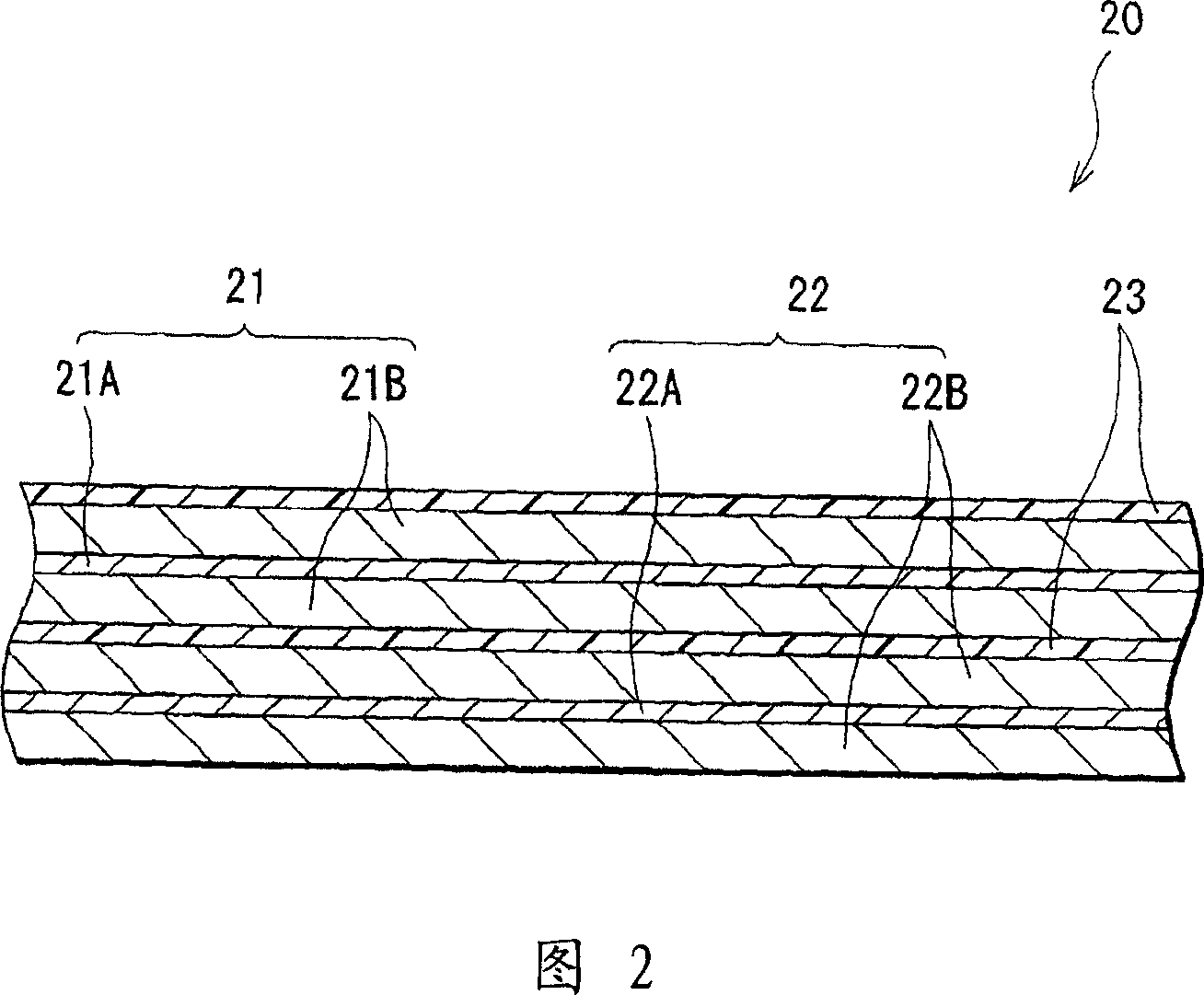

Negative electrode for lithium secondary battery, method for producing same, and lithium secondary battery comprising such negative electrode for lithium secondary battery

ActiveCN101356670AImprove charge and discharge cycle characteristicsInhibition of decomposition reactionsElectrode manufacturing processesElectrode carriers/collectorsLithiumChemical composition

Disclosed is a negative electrode (100) for lithium secondary batteries which comprises a collector (11), a negative electrode active material (12) supported by the collector (11) and having a chemical composition expressed as SiOx (0.1<= x<= 1.2), and a cover layer (14) formed on the negative electrode active material (12) and having a chemical composition composed of silicon dioxide. The cover layer (14) has a thickness of more than 1 nm and not more than 10 nm.

Owner:PANASONIC CORP

ANODE MATERIAL, ANODE, BATTERY, AND METHODS OF MANUFACTURING the anode material, the anode and the battery.

ActiveCN104143625AEmbedded firmlyGood chemical stabilityFinal product manufactureSecondary cells manufactureAlkaline earth metalElectrical battery

An anode and battery including the anode capable of improving the cycle characteristics while securing the input and output characteristics is provided. The battery includes a cathode, an anode, and an electrolytic solution. The anode includes an anode active material layer on an anode current collector, wherein the anode active material layer includes an anode active material capable of intercalating and deintercalating an electrode reactant, wherein a thickness of the anode active material layer ranges from 60 μm to 120 μm, and wherein the anode active material includes a carbon material and at least part of a surface is covered by a covering, the covering including at least one of an alkali metal salt and an alkali earth metal salt.

Owner:MURATA MFG CO LTD

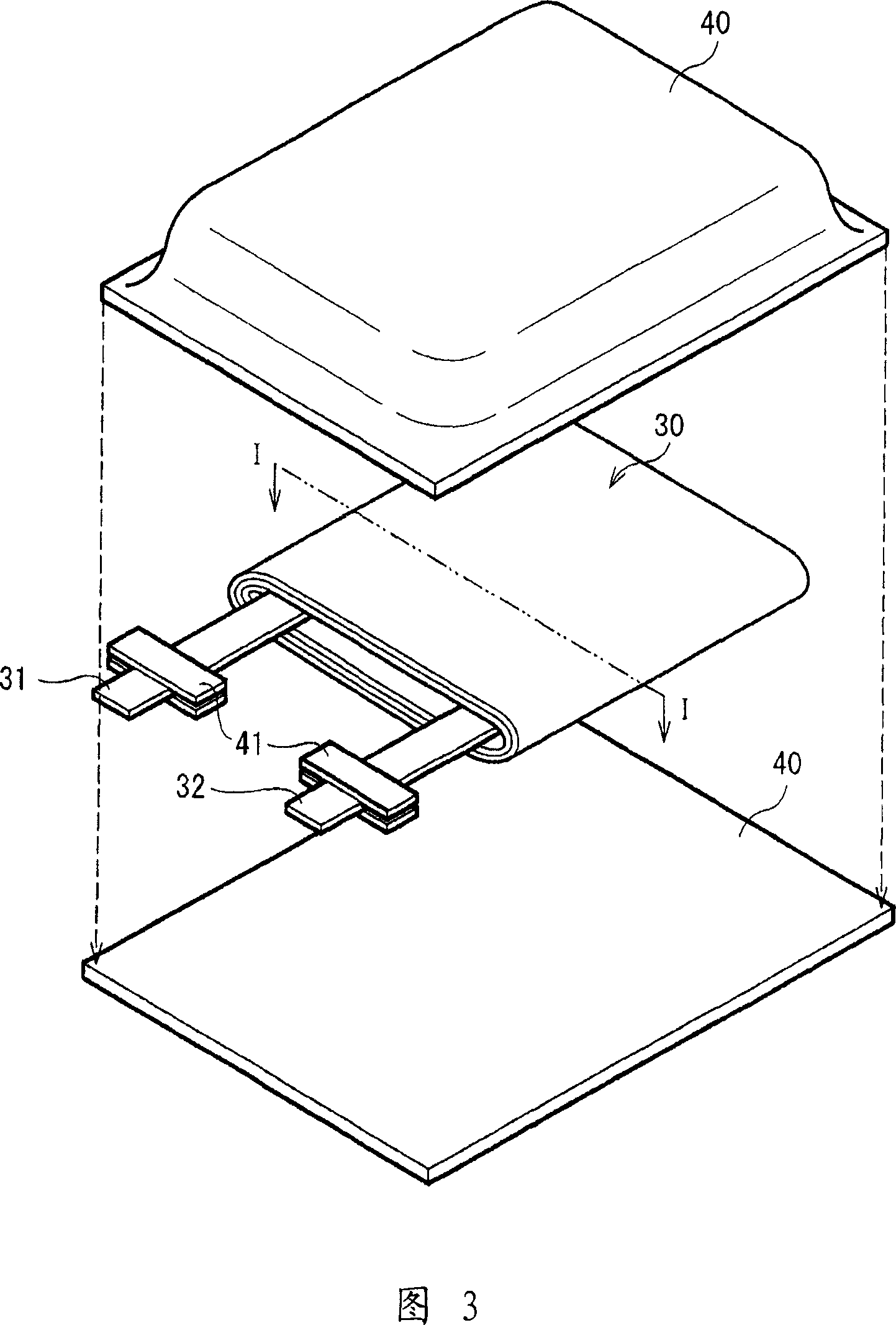

Battery

InactiveCN1744369AInhibit swellingInhibition of decomposition reactionsLi-accumulatorsElectrolysisDecomposition

A battery capable of inhibiting decrease in capacity and inhibiting swollenness even in hot environment is provided. A battery comprises a cathode, an anode and an electrolyte inside a film exterior member. The electrolytic solution contains carboxylate ester or ketone, in which a third alkyl group is directly bonded to a carbonyl group. Thereby, decomposition reaction of the solvent in the cathode is inhibited.

Owner:SONY CORP

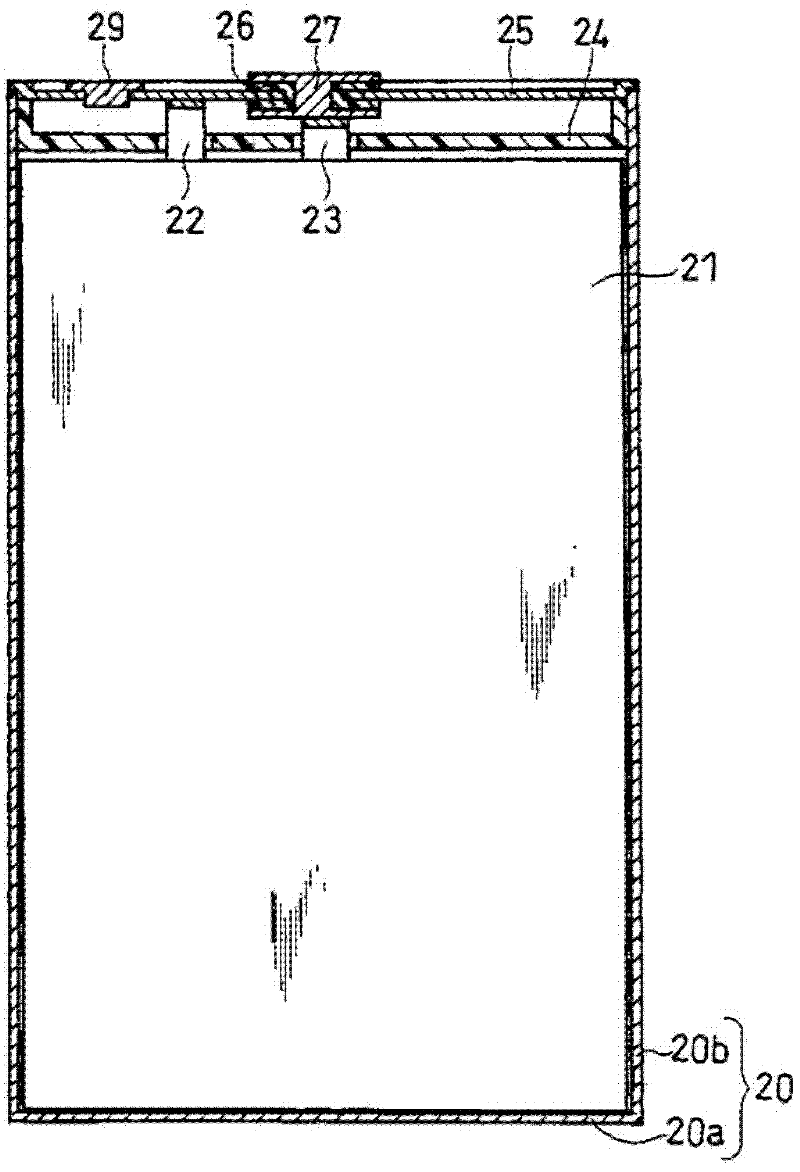

Lithium primary battery and method for producing same

ActiveCN101065864AReduce reaction overvoltageImprove discharge performanceOrganic electrolyte cellsPrimary cell electrodesSurface layerLithium metal

Disclosed is a lithium primary battery comprising a positive electrode, a negative electrode, an organic electrolyte solution and a separator interposed between the positive electrode and the negative electrode. The negative electrode contains a negative electrode active material, and the negative electrode active material is composed of at least one substance selected from the group consisting of lithium metal and lithium alloys. At least the surface layer of the negative electrode is composed of a composite material of an amorphous carbon material and the negative electrode active material, and the surface layer is arranged opposite to the positive electrode via the separator. Such a lithium primary battery is highly reliable and excellent in large current discharge characteristics at low temperatures and storage stability at high temperatures.

Owner:PANASONIC CORP

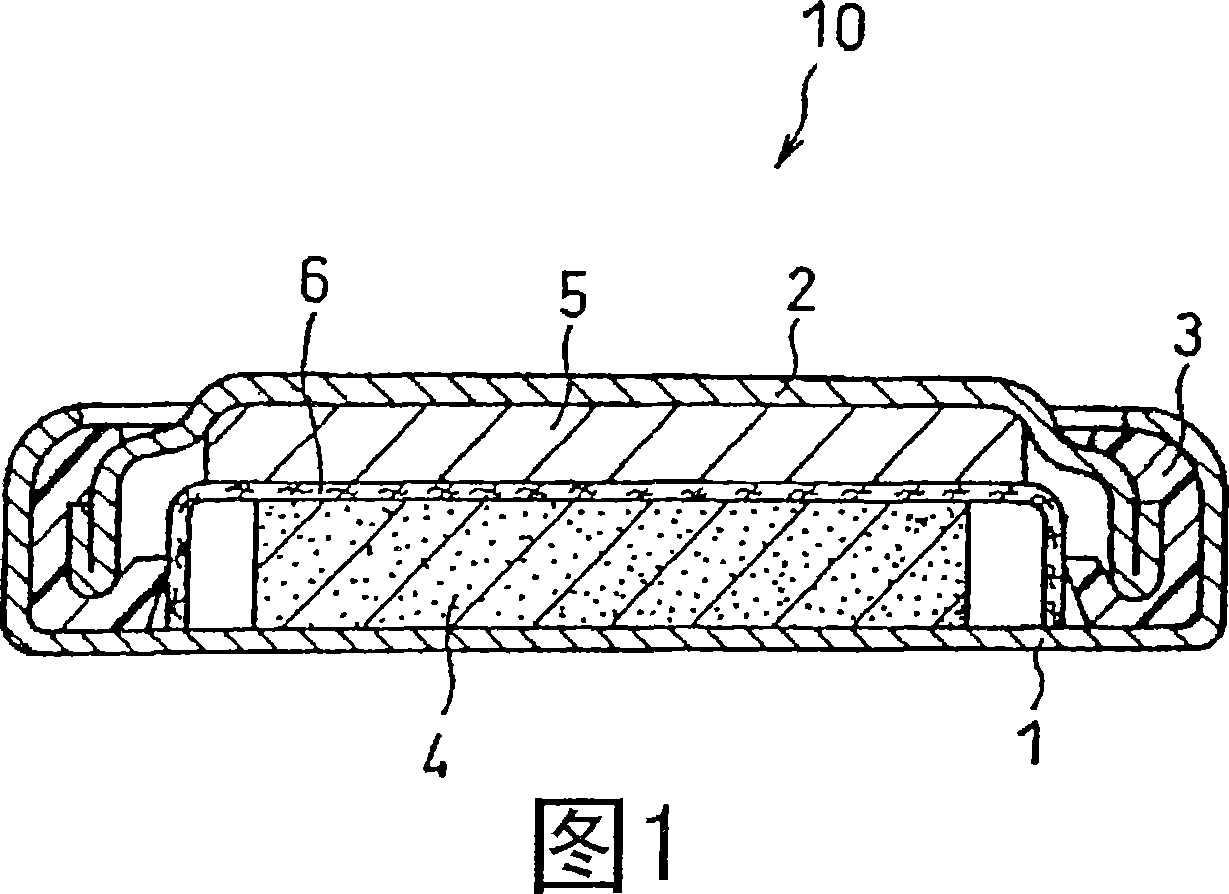

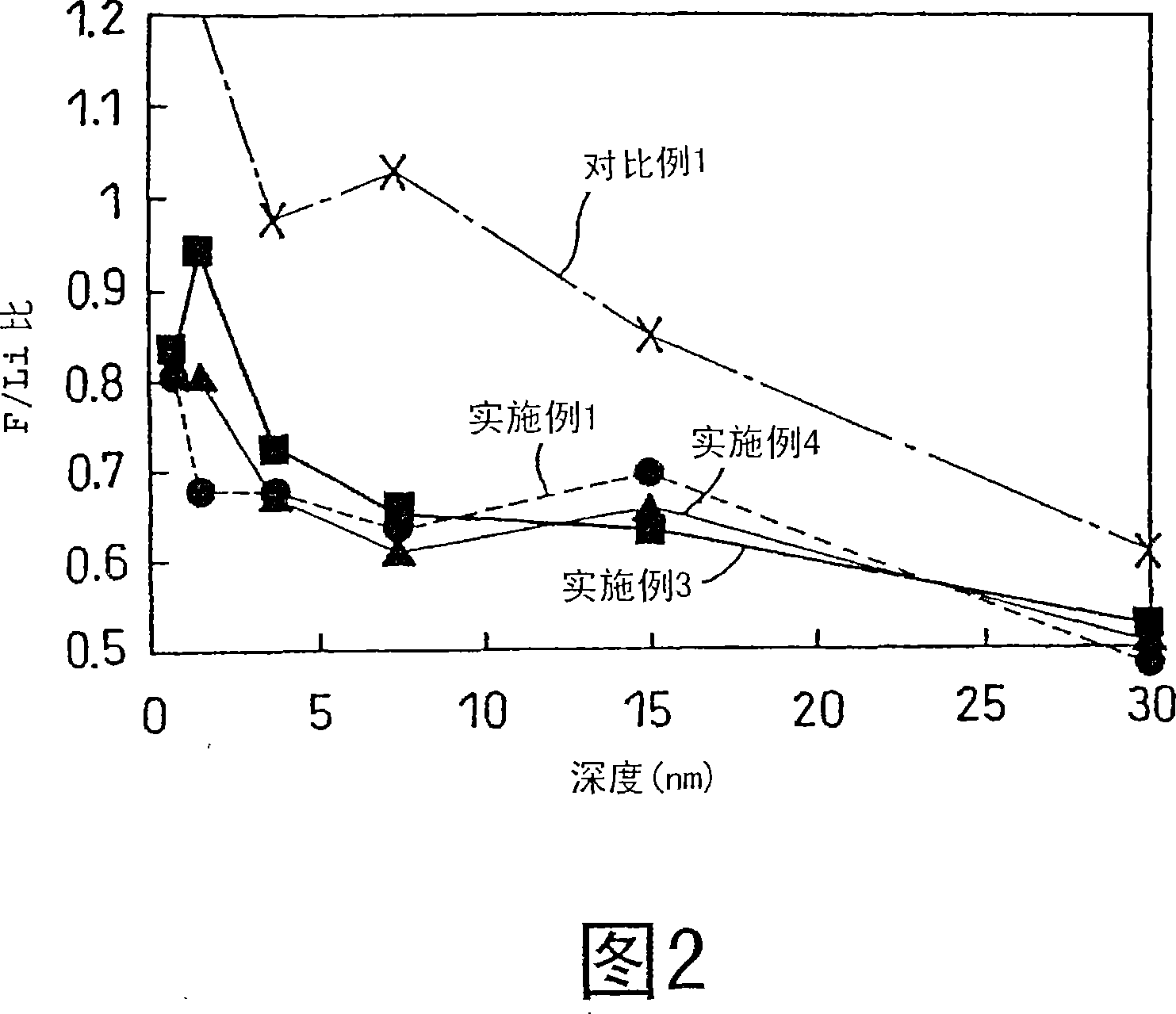

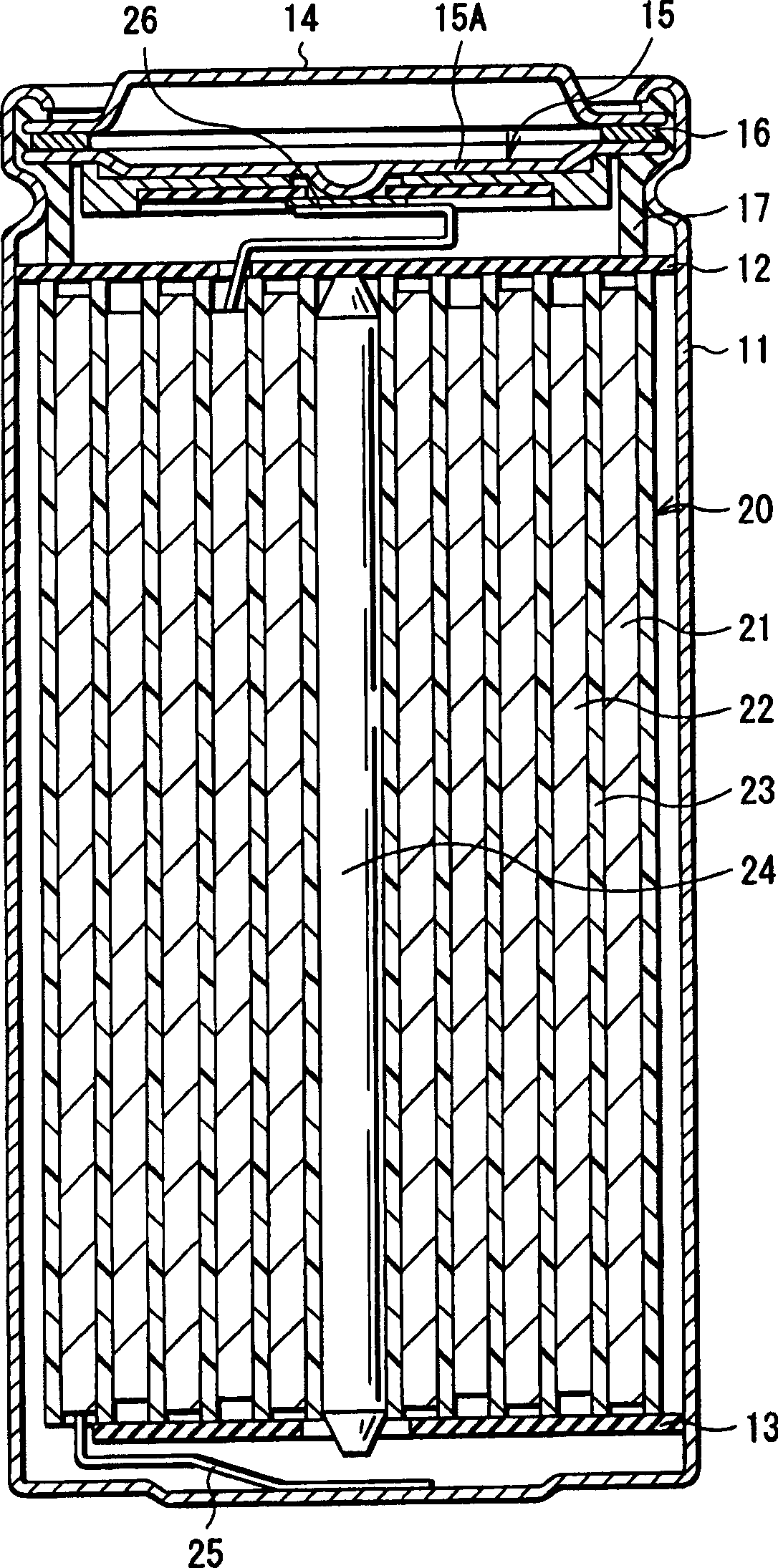

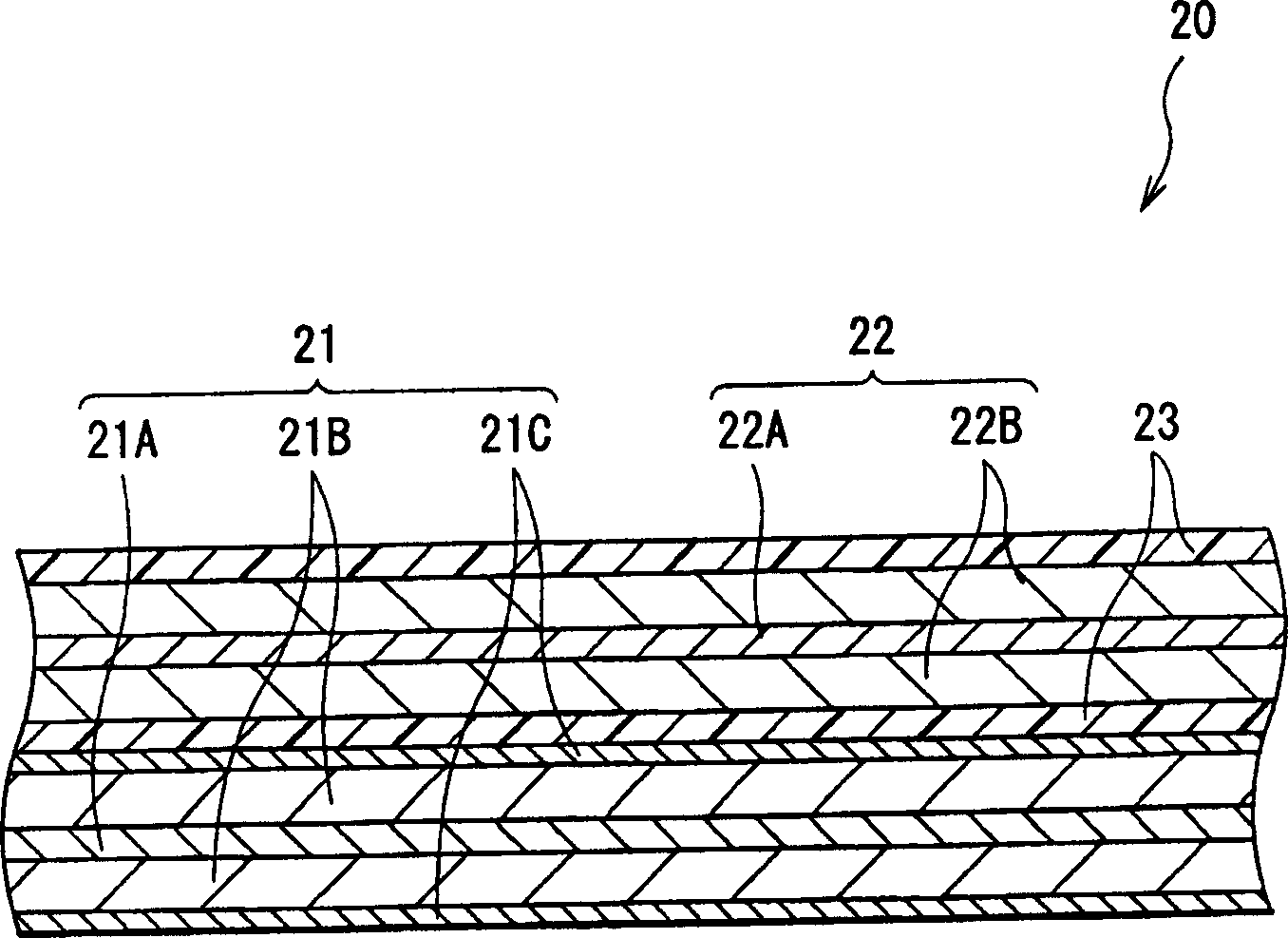

Battery

ActiveCN1794511AInhibition of decomposition reactionsExcellent cycle characteristicsElectrode manufacturing processesActive material electrodesChemistryDecomposition

A battery capable of improving battery characteristics such as cycle characteristics is provided. A coating layer containing lithium fluoride and lithium hydroxide is provided on the surface of the negative electrode active material layer. The ratio between lithium fluoride and lithium hydroxide is within a range in which the Li2F+ / Li2OH+ peak intensity ratio obtained in cation analysis by time-of-flight secondary ion mass spectrometry is 1 or more. The anode active material layer contains a substance containing Si or Sn as an element as an anode active material. Oxidation of the negative electrode active material layer is suppressed by this coating layer, and decomposition reaction of the electrolytic solution is suppressed.

Owner:MURATA MFG CO LTD

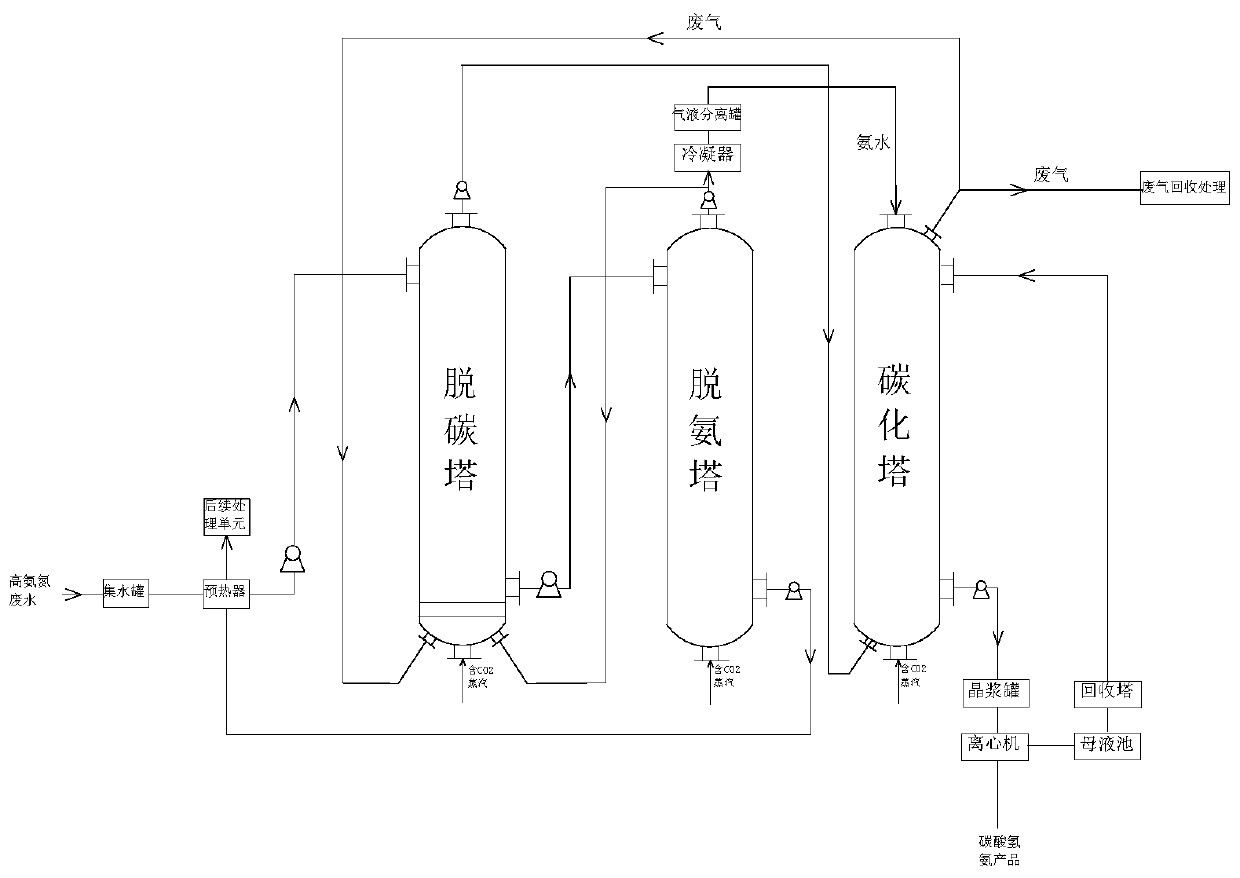

Ammonia recovery method of high-ammonia-and-nitrogen waste water

ActiveCN109879510APrecipitation completePrevent sedimentation and scalingWater contaminantsAmmonium carbonates/bicarbonatesRecovery methodHigh concentration

The invention discloses an ammonia recovery method of high-ammonia-and-nitrogen waste water, and belongs to the technical field of sewage treatment. The ammonia recovery method comprises the steps: firstly, the high-ammonia-and-nitrogen waste water passes through a decarburization tower where carbon-dioxide-containing steam and ammonia-containing steam are introduced, and calcium and magnesium ions in the waste water are removed; then the high-ammonia-and-nitrogen waste water passes through a deamination tower, steam-stripping deamination is carried out at 80-90 DEG C, ammonia and nitrogen inthe waste water enter a steam phase, high-concentration ammonia-containing mixed steam is formed and collected at the top of the deamination tower, one part of the ammonia-containing mixed steam flowsback to the decarburization tower, and the remaining part of ammonia-containing mixed steam is introduced into a condenser to be condensed and then subjected to gas-liquid separation; and finally, effluent of the deamination tower enters a subsequent treatment facility to be subjected to biochemical treatment, separated ammonia water enters a carburization tower where the carbon-dioxide-containing steam is introduced, and ammonium bicarbonate is formed and serves as a recycled product. By adopting the method for high-ammonia-and-nitrogen waste water treatment and ammonia recovery, the deamination effect and ammonia recovery efficiency of the high-ammonia-and-nitrogen waste water can be improved greatly, and additionally treatment equipment can further be prevented from being scaled.

Owner:TONGJI UNIV

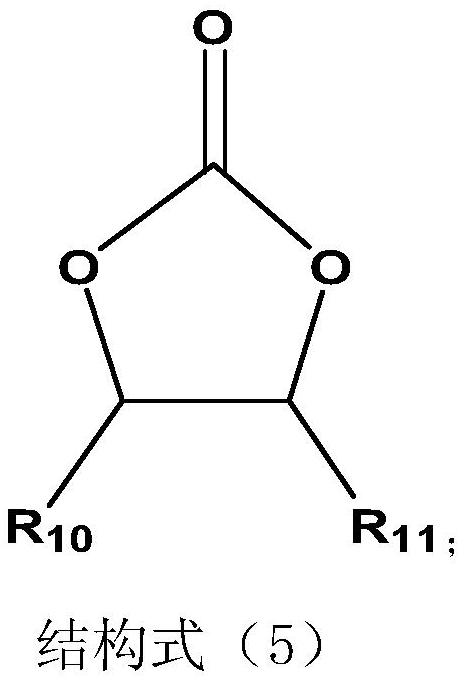

Electrolyte and lithium ion battery using same

ActiveCN104466251AInhibition of decomposition reactionsInhibit side effectsSecondary cellsOrganic electrolytesOrganic solventDouble bond

The invention provides an electrolyte which comprises a nonaqueous organic solvent and lithium salt, wherein the nonaqueous organic solvent contains chain carboxylic ester, a chemical structural formula contains C=C double-bond cyclic carbonate, and the C=C double-bond cyclic carbonate contained in the chemical structural formula is not more than 1% in percentage by weight in the electrolyte. The electrolyte provided by the invention can be used for a long time under the condition of high voltage, can be used in a lithium ion battery, can normally work for a long time under the condition that working voltage is higher than 4.35V and ensures the high-temperature property of a battery.

Owner:DONGGUAN AMPEREX TECH +1

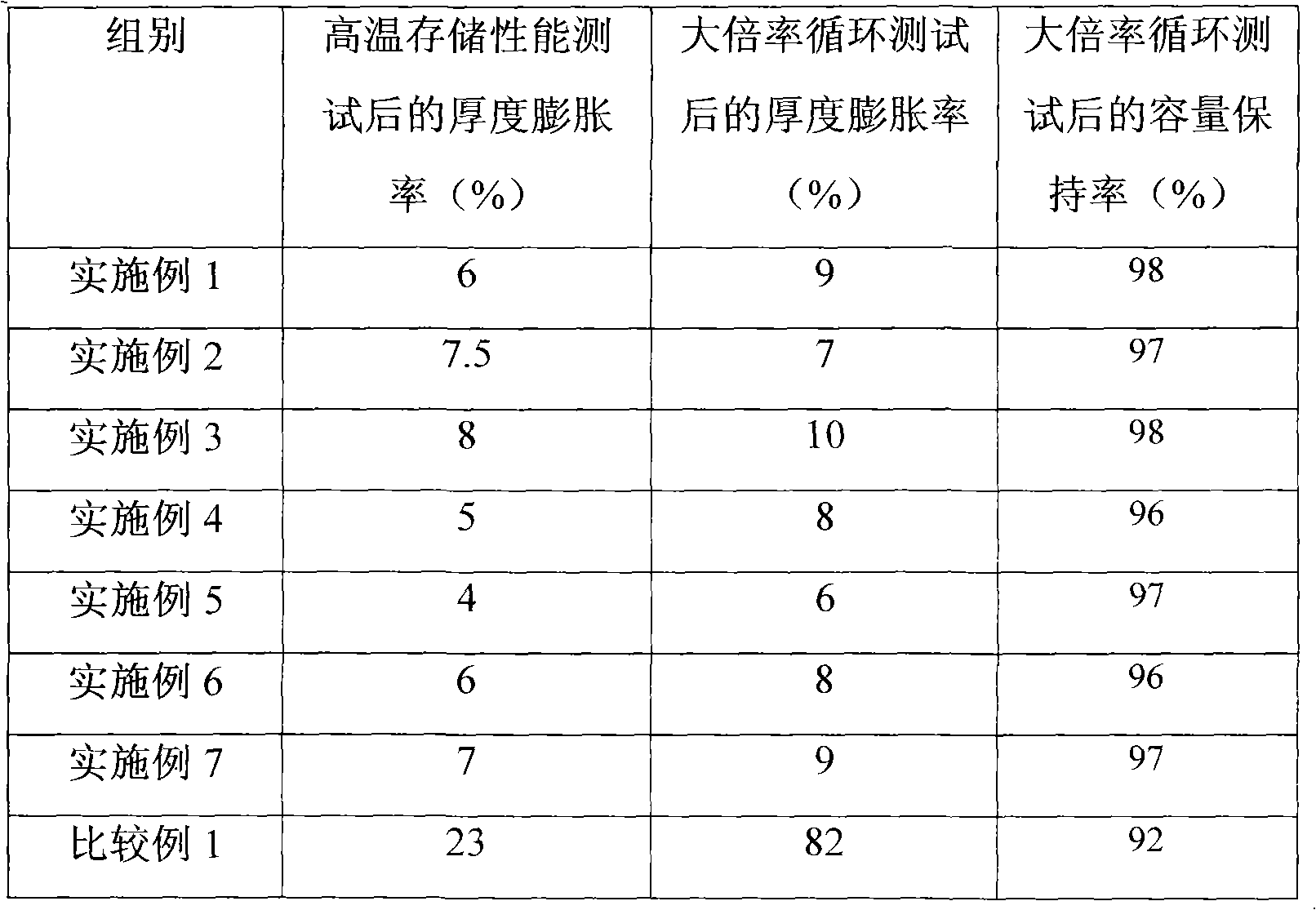

High-temperature-resistant high-voltage electrolyte of high-nickel lithium ion battery

PendingCN112216870AReduce exposureAvoid decompositionSecondary cellsOrganic electrolytesDifluorophosphateElectrolytic agent

A high-temperature-resistant high-voltage electrolyte of a high-nickel lithium ion battery is composed of a composite electrolyte lithium salt, an organic multi-component solvent and an additive, andthe composite electrolyte lithium salt is at least two of lithium hexafluorophosphate, lithium perchlorate, lithium difluorophosphate, lithium bis (fluorosulfonyl) imide, lithium bis (oxalato) borate,lithium difluoro (oxalato) borate, lithium difluoro (oxalato) phosphate and the like. The electrolyte lithium salt and the additive in the electrolyte participate in positive electrode film formationat the same time to hinder contact between the electrolyte and an electrode, so that decomposition reaction between the electrolyte in a high-potential region and an active substance is inhibited, and the storage and cycle performance of the lithium ion battery at high temperature and high voltage is improved.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

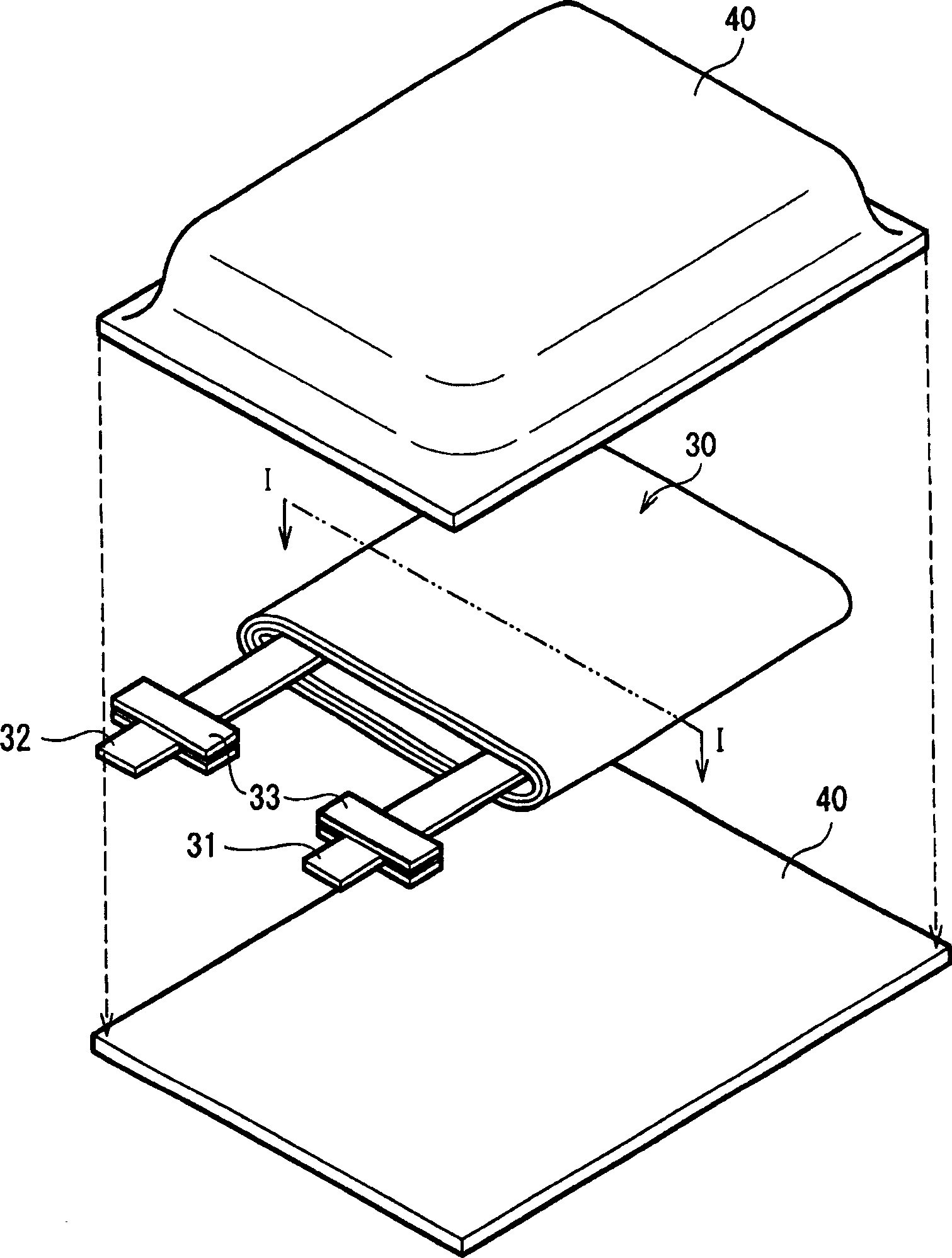

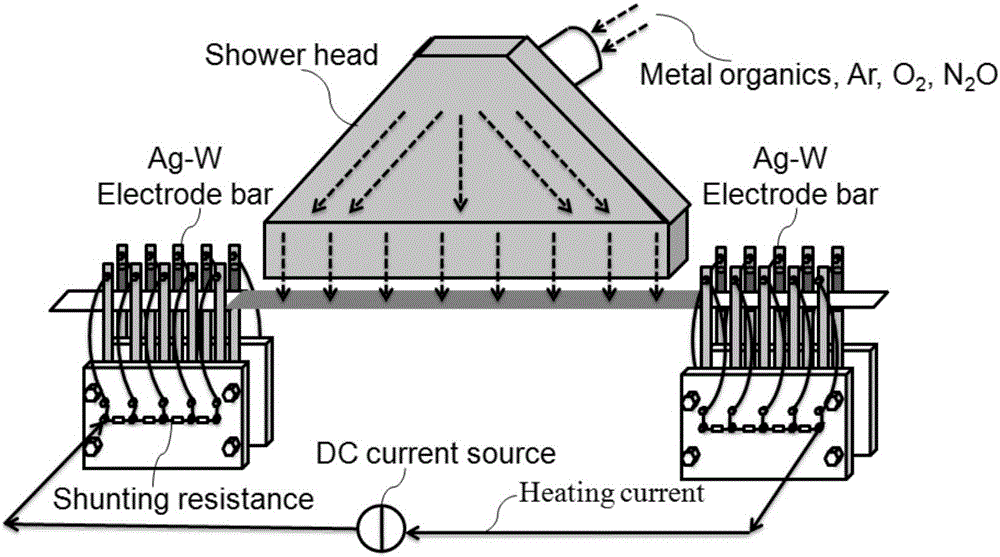

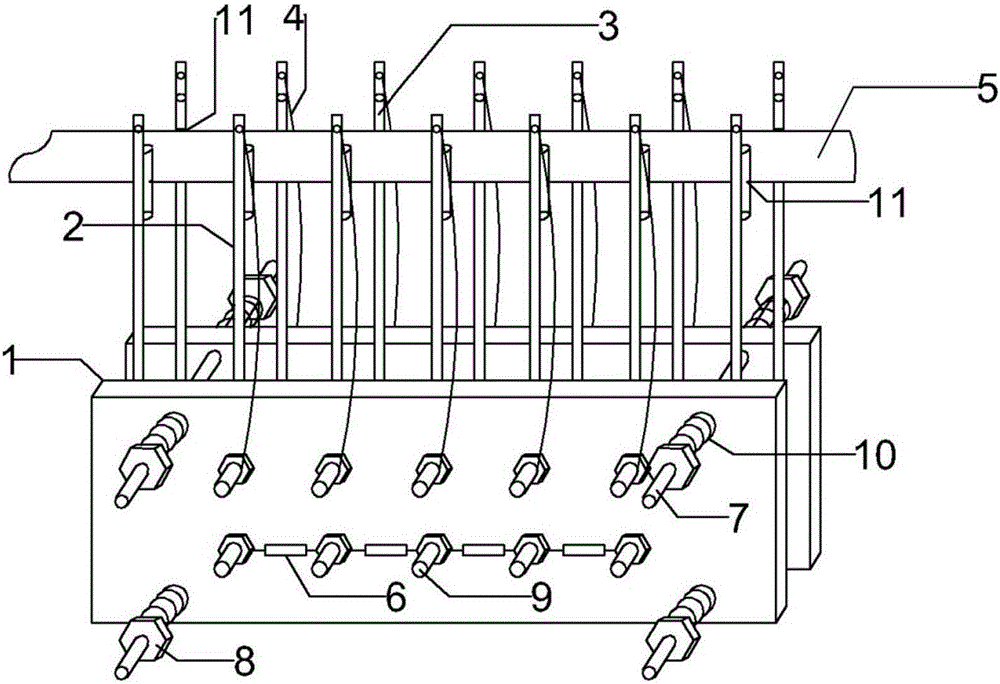

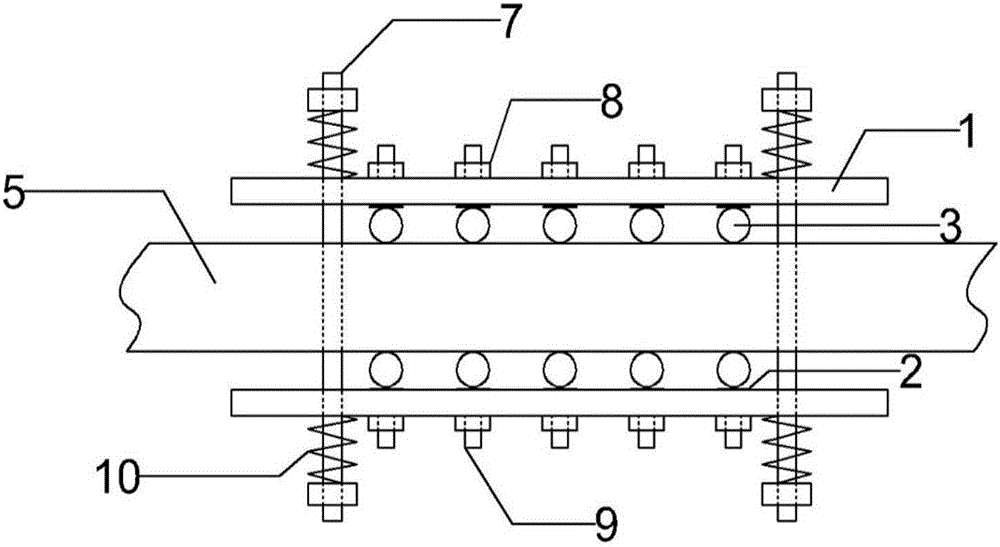

Heating device for high-temperature thin film deposition

InactiveCN106521457AImprove efficiencyEnables continuous roll-to-roll preparationVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceOptoelectronics

The invention belongs to the technical field of thin film preparation, and particularly relates to a heating device for high-temperature thin film deposition. The heating device comprises two electrode assemblies, wherein current I is led onto a metal substrate base band from two edges of the metal substrate base band through electrodes and flows on the metal substrate base band; the metal substrate base band (Hastelloy with high electrical resistivity and the like) is heated up under the action of self resistance to reach the temperature required for YBCO growth; and a deposition area is positioned between the two electrode assemblies. The heating device is simple in principle and structure, quick in heating and high in energy efficiency, can be used for heating a banded metal substrate or a banded metal substrate on which a (conductive or insulating) buffer layer is prepared, and can realize continuous winding preparation of single-faced or double-faced YBCO long strips through eliminating discharge caused by poor contact between the electrodes and the base band.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

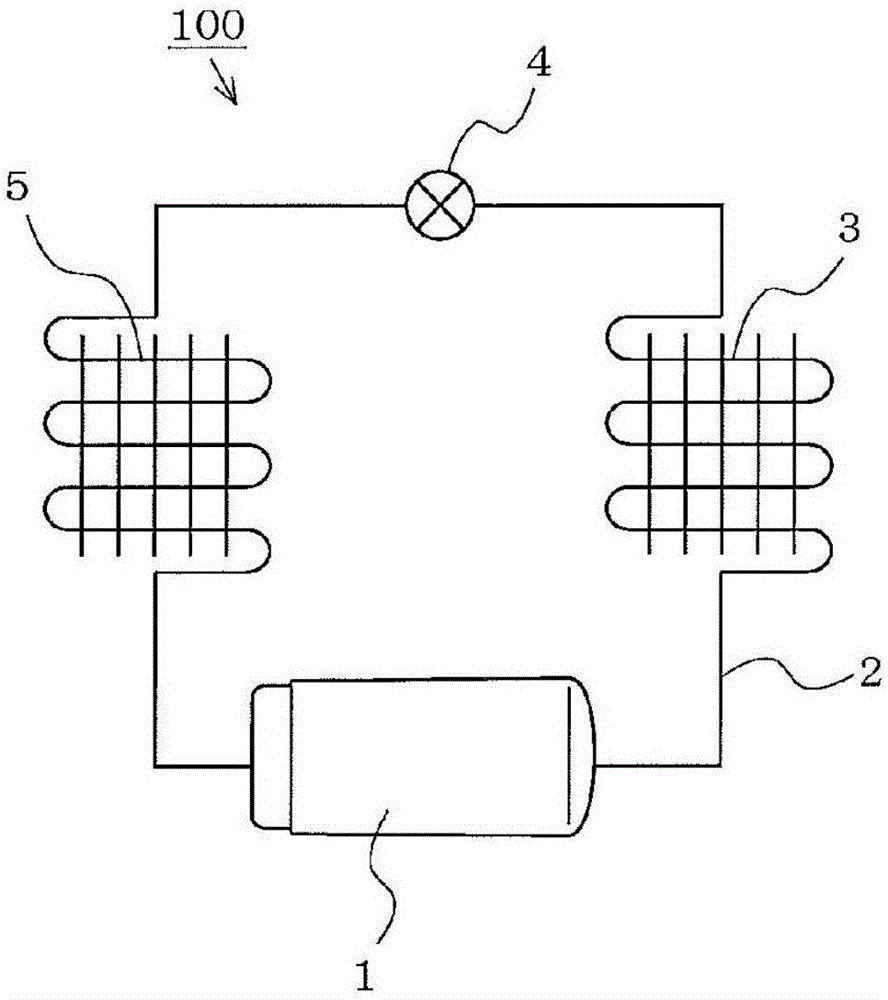

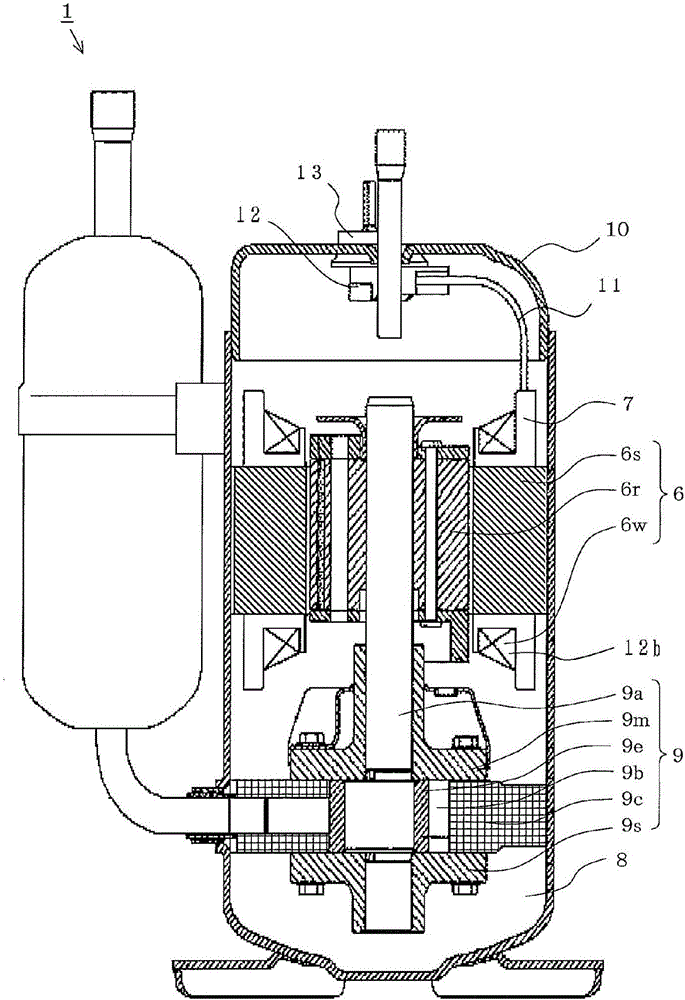

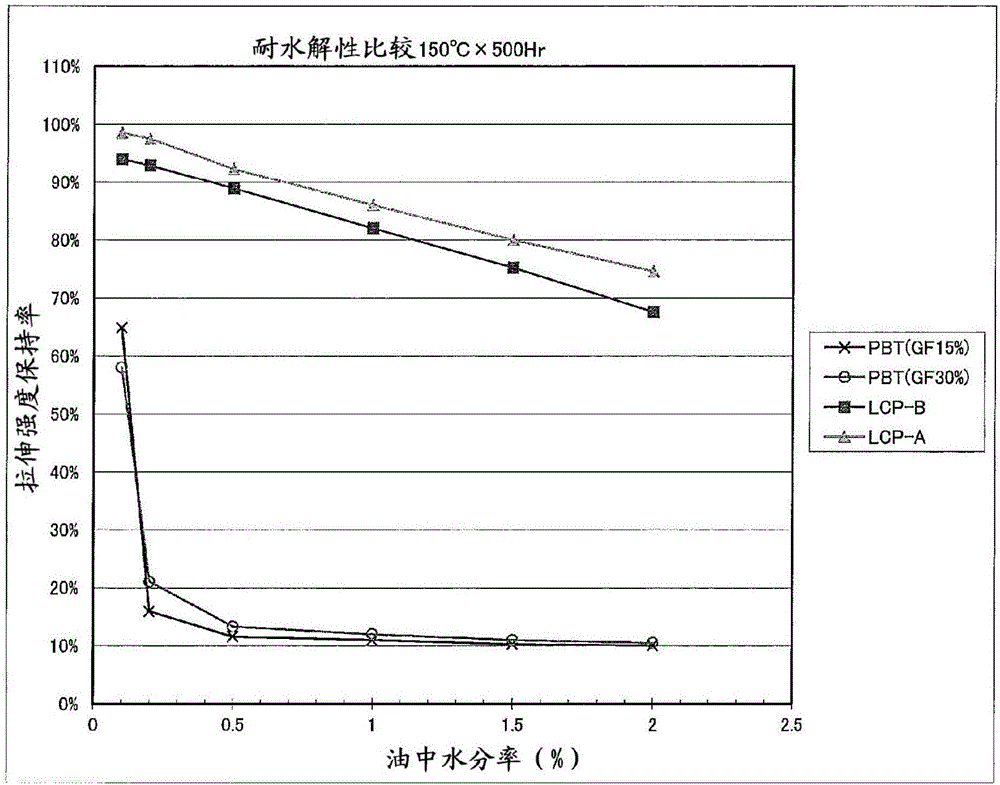

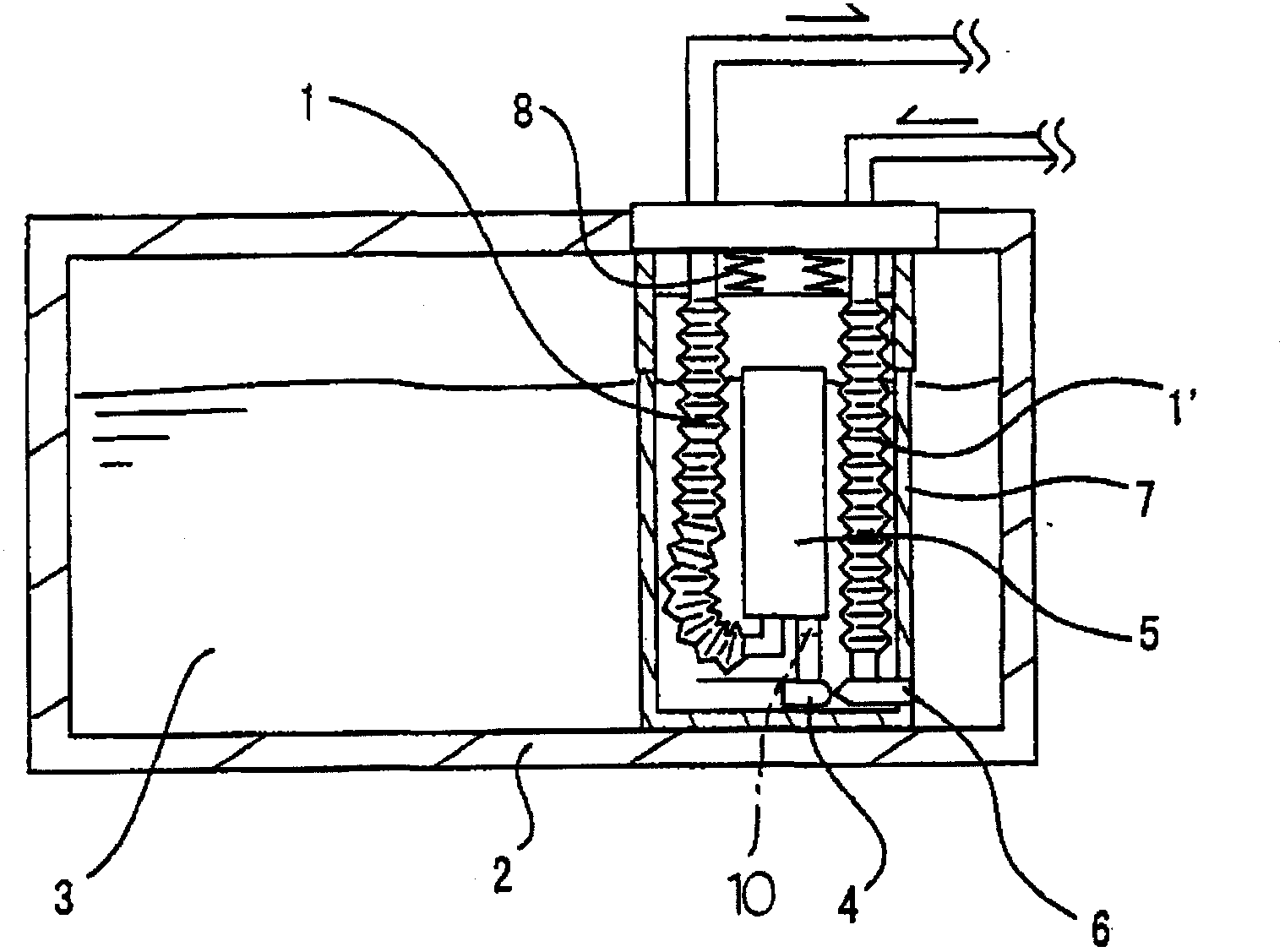

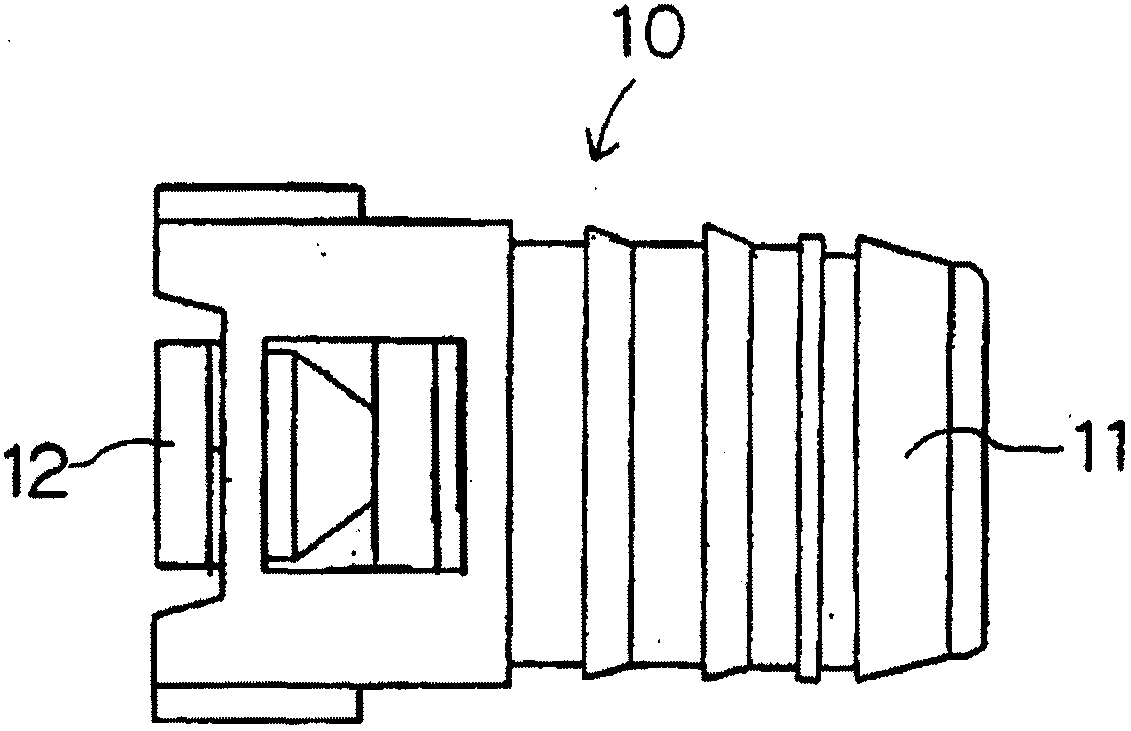

Heat pump device

ActiveCN106164606AImprove long-term reliabilityGood effectCompressorPositive displacement pump componentsPolyesterEngineering

Provided is a heat pump device achieving long term reliability by using an insulating material that is not readily hydrolyzed. An electric motor (6) of a compressor (1) comprises a stator (6s) that is fixed to a sealed container (10) and on which a winding wire (6w) is wound with an insulating material (7) therebetween, and a rotor (6r) that is surrounded by the stator (6s). The insulating material (7) is a wholly aromatic liquid-crystal polyester (LCP) in which a main molecular chain is formed by bonding by ester bonds a monomer of para-hydroxybenzoate (PHB) as an essential component and another monomer of just ingredients having a benzene ring, and the saturated water content for the refrigeration oil is 2% or lower in 80% relative humidity at 40DEG C for 24 hours. That is, a chemical species that supplements active radicals that cause the decomposition reaction is generated by using a flame retardant in order to suppress the explosive decomposition reaction of an ethylene-based fluorohydrocarbon.

Owner:MITSUBISHI ELECTRIC CORP

Negative electrode for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery

InactiveCN102292852AInhibition of decomposition reactionsInhibit swellingCell electrodesSecondary cellsDecompositionUltimate tensile strength

The negative electrode for the non-aqueous electrolyte secondary battery includes a negative electrode core material and a negative electrode mixture layer attached to the negative electrode core material. The specific surface area of the negative electrode mixture layer is 2.2-3m2 / g, and the bonding strength between the graphite particles coated with water-soluble polymer is more than 14kgf / cm2. A nonaqueous electrolyte secondary battery including this electrode can suppress decomposition of nonaqueous electrolyte components caused by the reaction between graphite particles and the nonaqueous electrolyte, and thus has excellent charge and discharge efficiency.

Owner:PANASONIC CORP

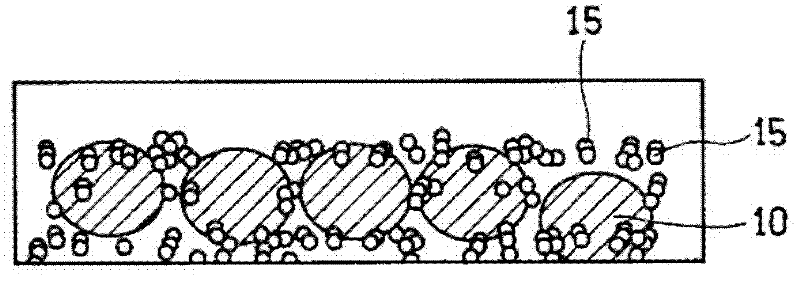

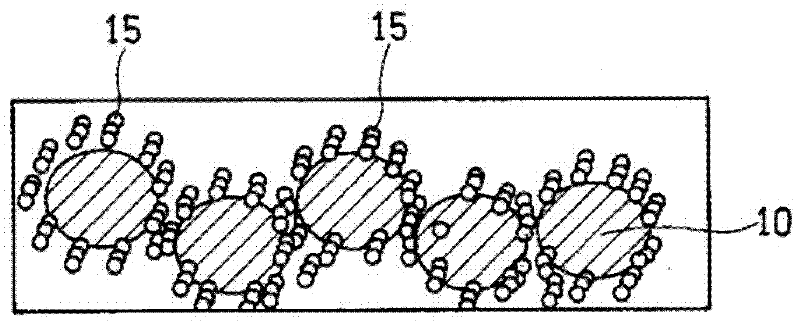

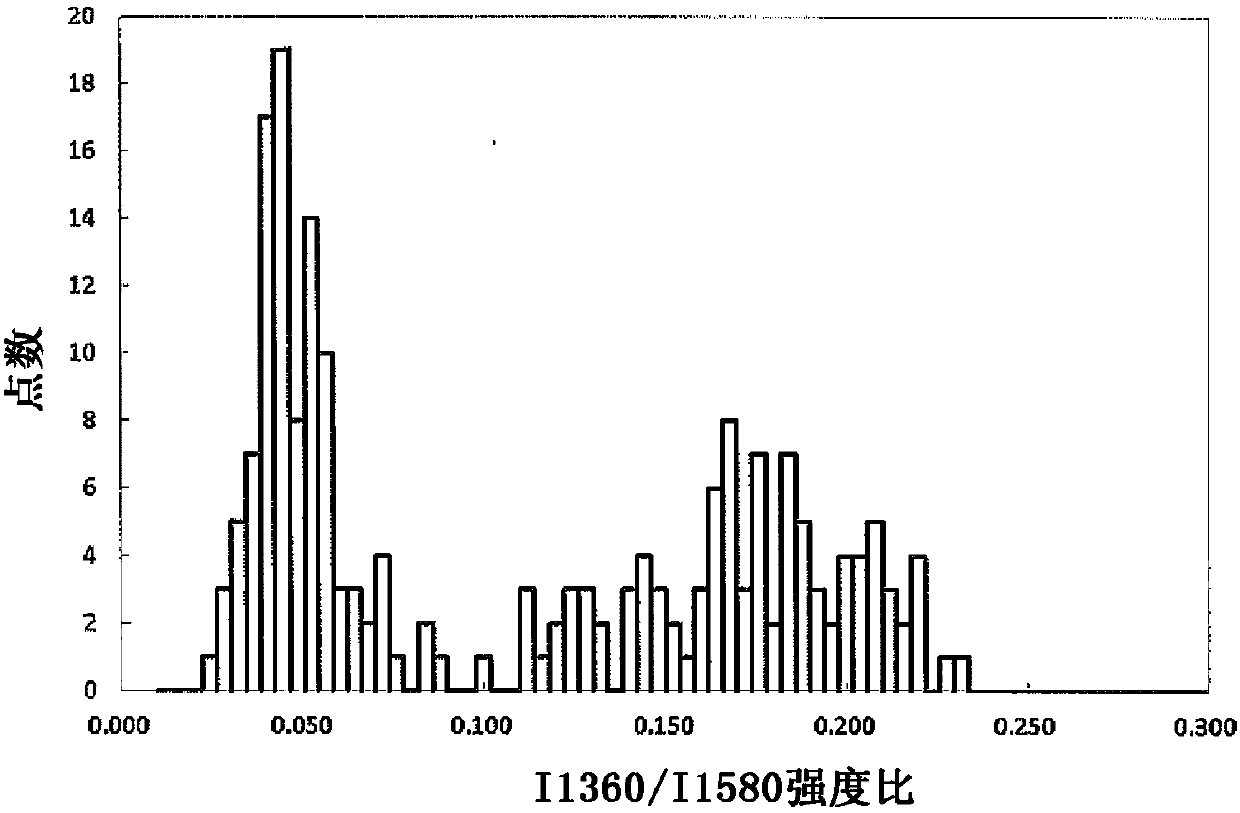

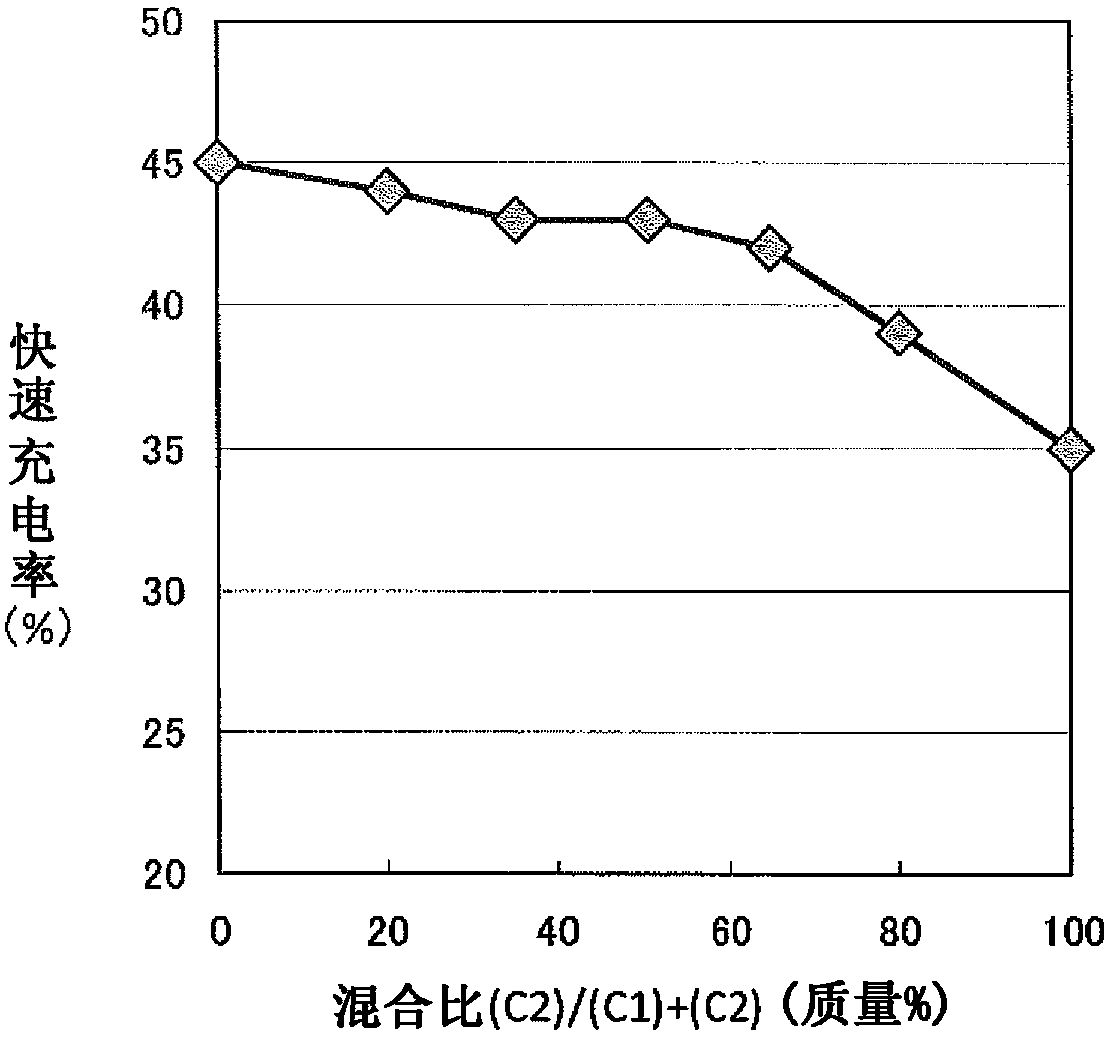

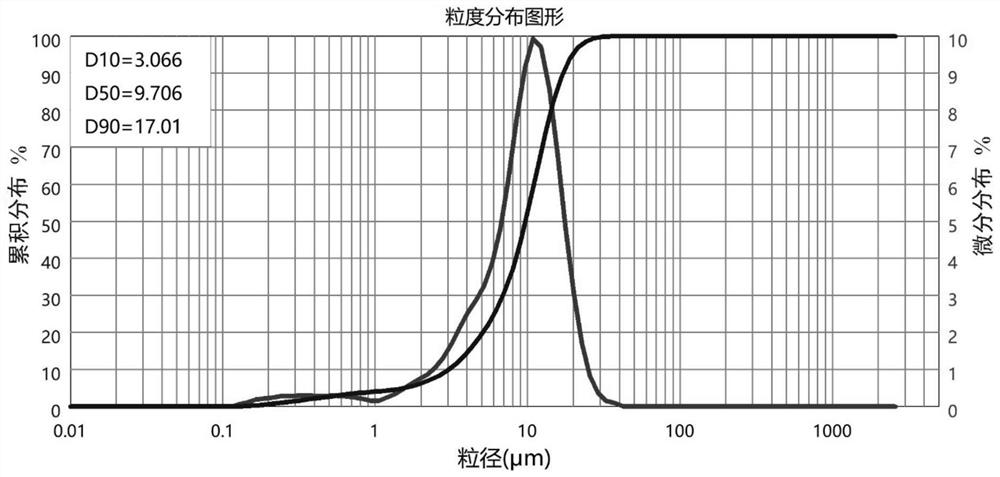

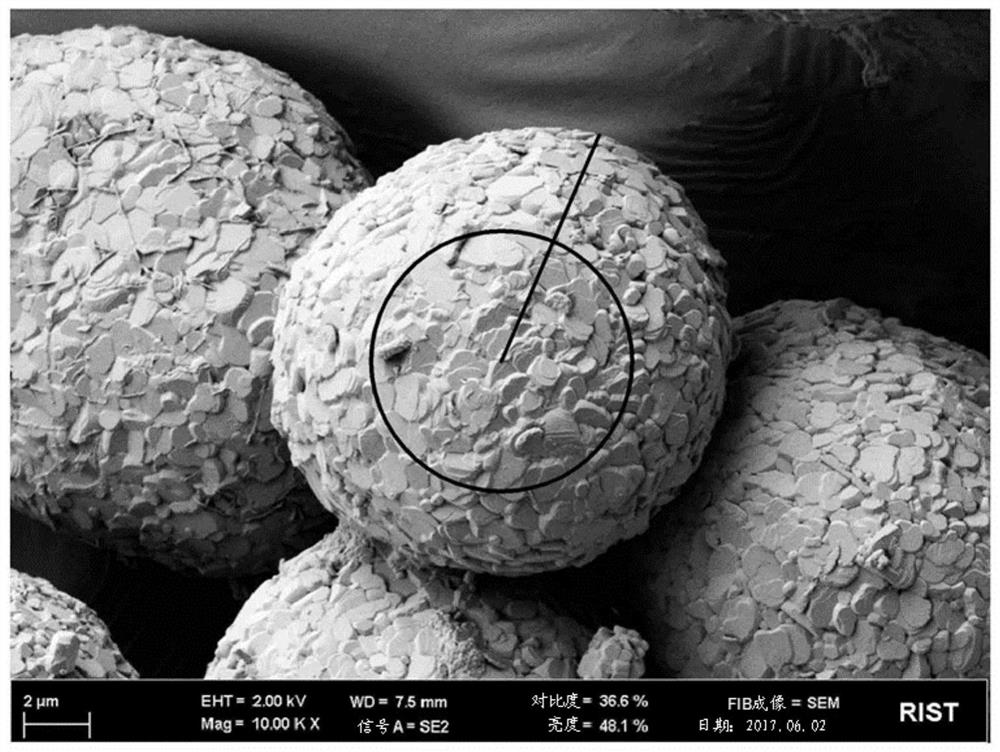

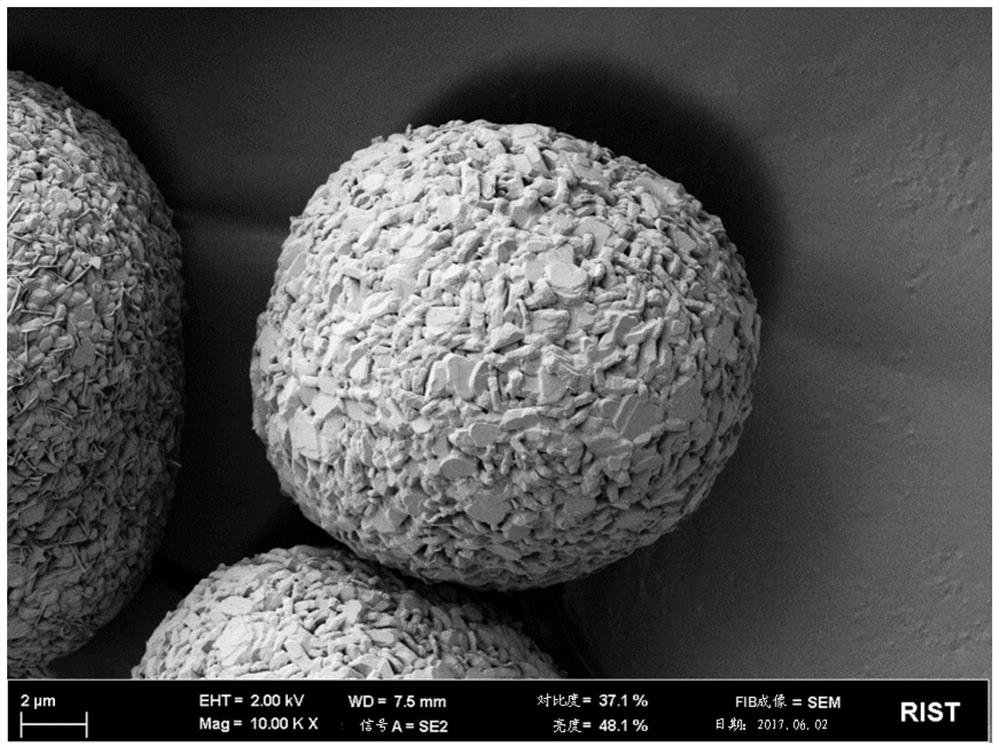

Graphite particles for lithium ion secondary battery negative electrode materials, lithium ion secondary battery negative electrode and lithium ion secondary battery

ActiveCN107078288AHigh crystallinityImprove discharge capacityGraphiteCell electrodesDischarge efficiencyLithium

Provided are: a negative electrode material which has at least one of excellent initial charge / discharge efficiency, excellent high-rate charge characteristics, excellent high-rate discharge characteristics and excellent long-term cycle characteristics; a negative electrode which uses this negative electrode material; and a lithium secondary battery. Graphite particles for lithium ion secondary battery negative electrode materials, which are a mixture of composite graphite particles (C1) that comprise carbonaceous material (B1) within spheroidized graphite particles (A) having spherical or generally spherical shapes and / or on at least a part of the surfaces of the spheroidized graphite particles (A) and composite graphite particles (C2) that have a graphite material (B2) within the spheroidized graphite particles (A) having spherical or generally spherical shapes and / or on at least a part of the surfaces of the spheroidized graphite particles (A). In this connection, the mixture satisfies the following requirements (1)-(5). (1) The interplanar spacing (d002) of a carbon network surface layer is 0.3360 nm or less. (2) The tap density is 1.0 g / cm<3> or more. (3) The average particle diameter is 5-25 [mu]m. (4) The average aspect ratio is 1.2 or more but less than 4.0. (5) The pore volume of pores having a diameter of 0.5 [mu]m or less as determined by means of a mercury porosimeter is 0.08 ml / g or less.

Owner:JFE CHEMICAL CORP

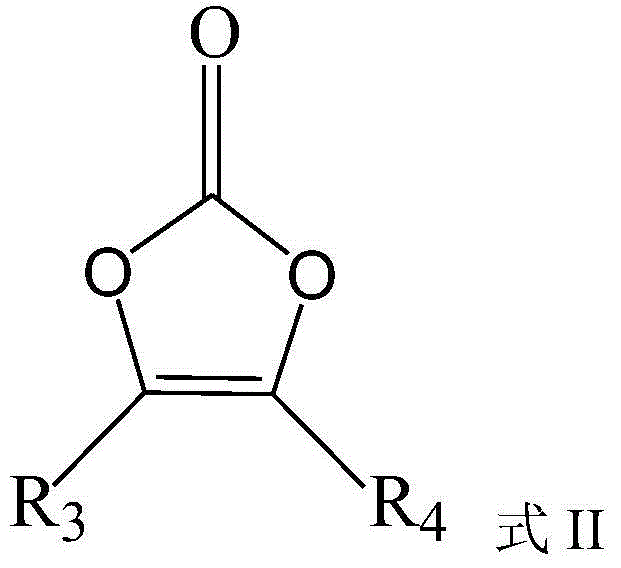

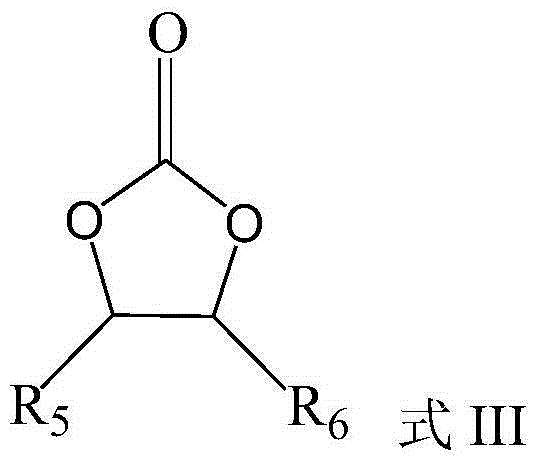

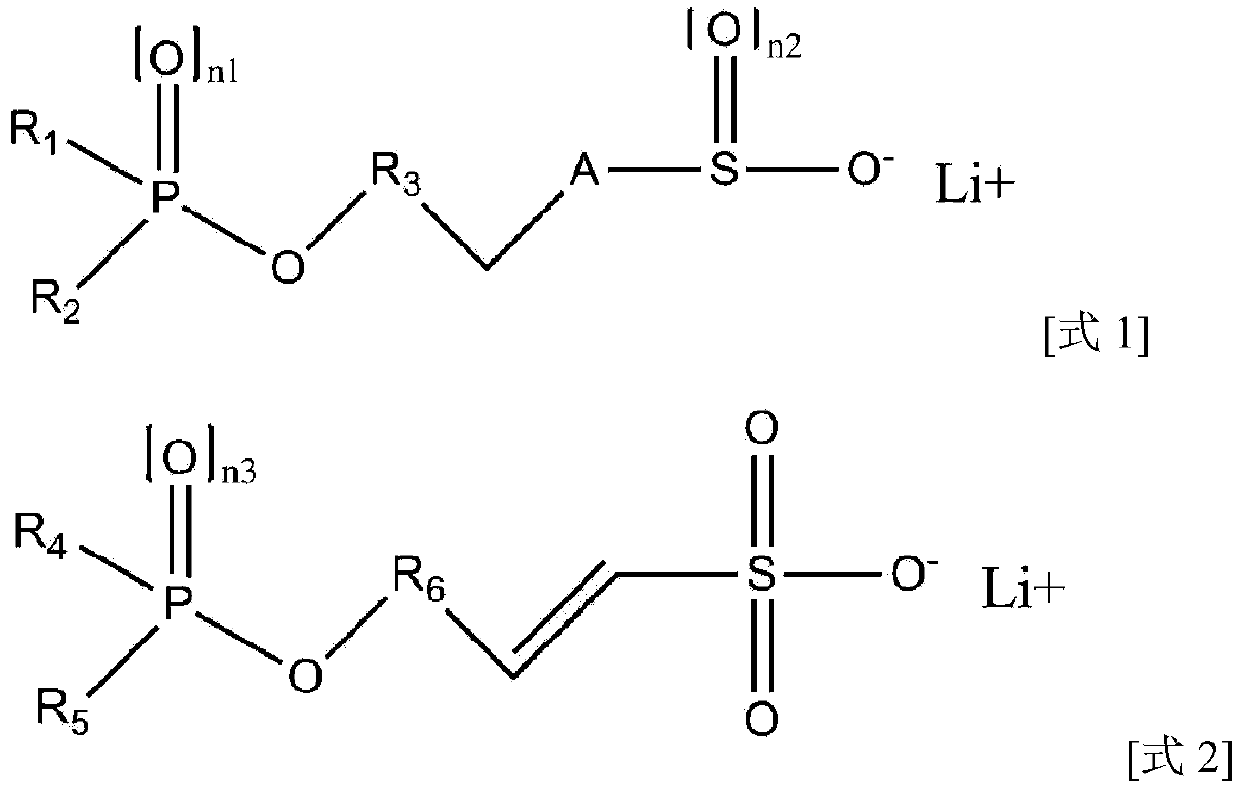

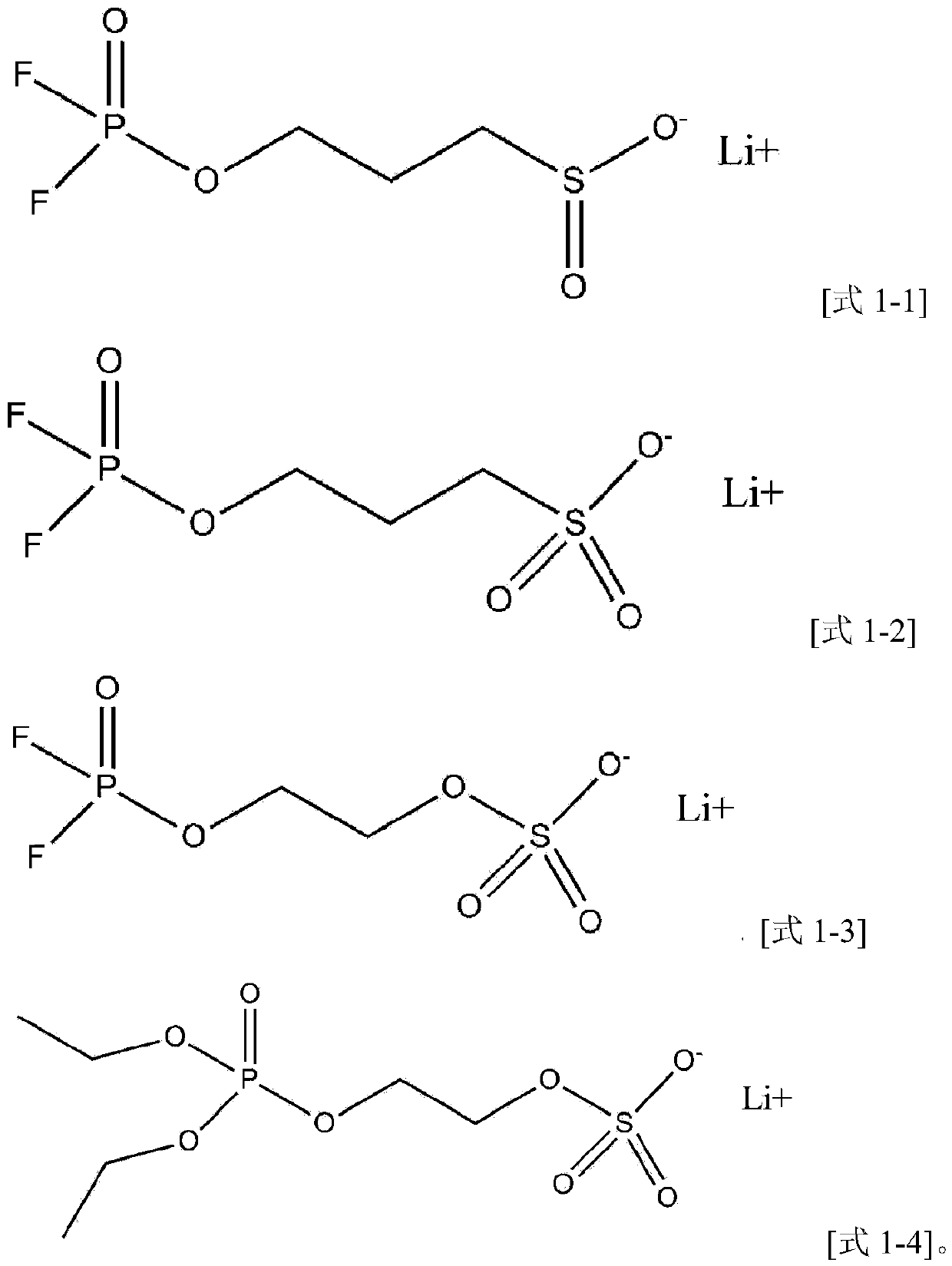

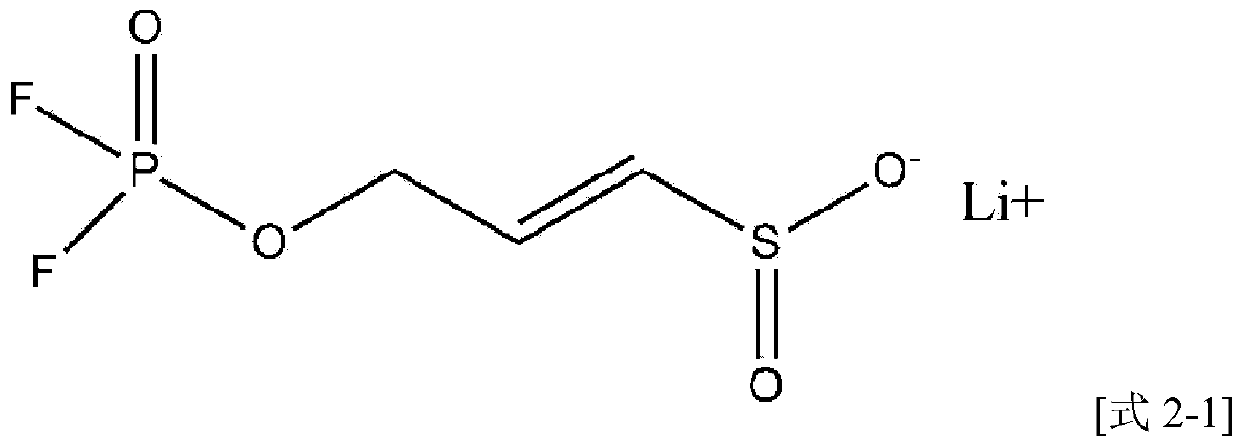

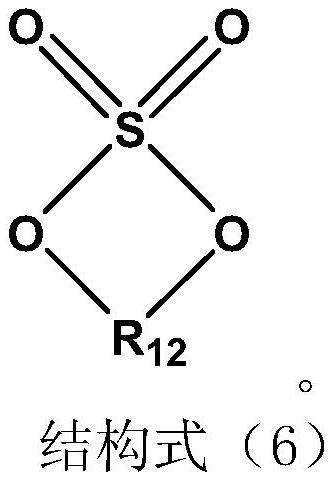

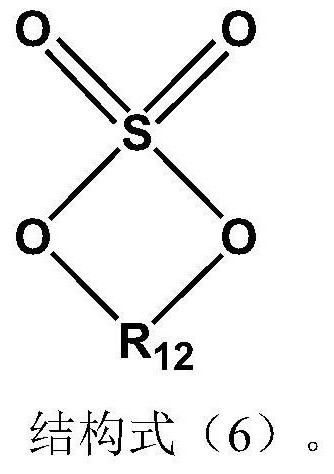

Additive, non-aqueous electrolyte for lithium secondary battery comprising same, and lithium secondary battery comprising same

ActiveCN110574213AInhibition of decomposition reactionsImprove life characteristicsElectrolytesLi-accumulatorsPhysical chemistryAqueous electrolyte

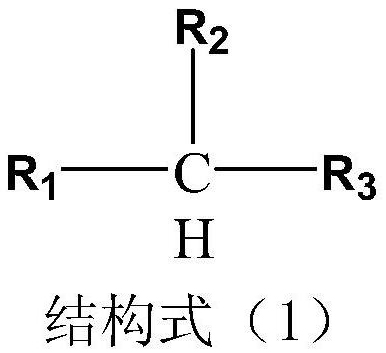

The present invention relates to an additive comprising at least one compound selected from the group consisting of compounds represented by chemical formulas 1 and 2; and a non-aqueous electrolyte for a lithium secondary battery and a lithium secondary battery which comprise the same.

Owner:LG ENERGY SOLUTION LTD

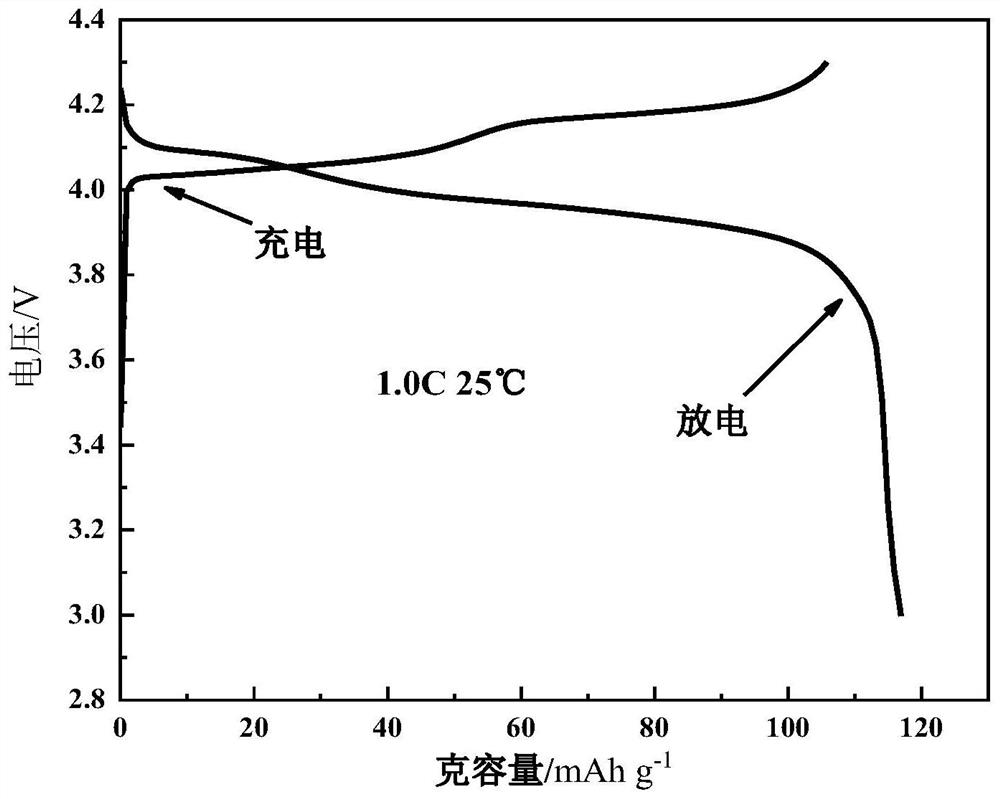

Lithium-ion secondary battery and anode material and manufacturing method thereof

ActiveCN102683663AReduce reactivityInhibition of decomposition reactionsCell electrodesTitaniumElectrolyte

The invention belongs to the technical field of lithium-ion secondary batteries, and in particular relates to an anode material for a lithium-ion secondary battery. The anode material comprises lithium titanate particles, wherein lithium cobaltate is coated on the surface of the lithium titanate particles and has the chemical formula of LixCo1-yMyO2; and the mass ratio of the lithium cobaltate to the lithium titanate particles is (0.1-10):(90-99.9). Compared with the prior art, the anode material has the advantages that the lithium cobaltate is coated on the surface of the lithium titanate particles, and the content of high-catalytic activity trivalent titanium on the surface of the lithium titanate can be reduced, so that the reaction activity of the surface of the lithium titanate on catalytic decomposition of electrolyte is effectively reduced; meanwhile, a compact coating can react with the electrolyte to form a surface passivation film, a contact interface between the surface of the lithium titanate and the electrolyte is reduced to a certain degree, the reaction between the electrolyte and the lithium titanate is correspondingly reduced; and moreover, the passivation film has high stability at high temperature, so that the battery is prevented from bloating at high temperature.

Owner:NINGDE AMPEREX TECH

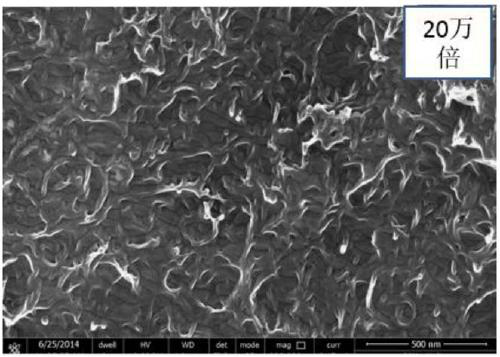

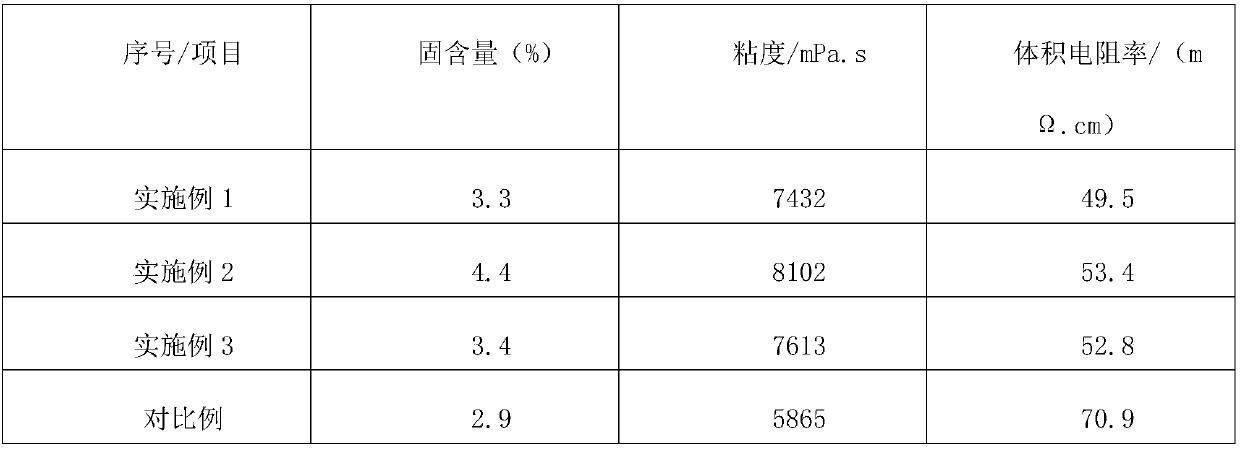

Solid capacitor carbon foil nano conductive carbon paste and preparation method thereof

ActiveCN111105932ARelatively large areaMany surface atomsElectrolytic capacitorsNon-conductive material with dispersed conductive materialCarbon nanotubeAcetamide

The invention relates to solid capacitor carbon foil nano conductive carbon paste and a preparation method thereof. The solid capacitor carbon foil nano conductive carbon paste comprises a polymer carrier and a nano conductive carbon fiber system dispersed in the polymer carrier, wherein the polymer carrier is formed by mixing an adhesive, a polymer solvent and a processing aid; the nano conductive carbon fiber system comprises a carbon nano tube and an acidified carbon nano tube acidified by a mixed solution of concentrated nitric acid and concentrated sulfuric acid; the adhesive is one or more of polyester acrylic resin, waterborne polyurethane resin, epoxy acrylic resin and polyurethane resin; the polymer solvent is several in butyl cellosolve, polyoxyethylene alkyl phenyl ether, methylbenzyl alcohol, N, N-dimethylformamide and terpilenol. The nano conductive carbon fiber system is dispersed in the polymer carrier, so that the microscopic coverage compactness of a carbon layer is improved; and the solid capacitor carbon foil nano conductive carbon paste is suitable for a solid capacitor carbon foil, protects a current collector, prevents the surface of the aluminum foil from being oxidized or corroded, and greatly reduces the ESR of a solid capacitor.

Owner:南通宇华新材料科技有限公司

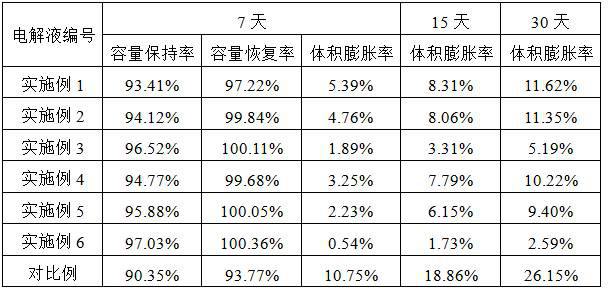

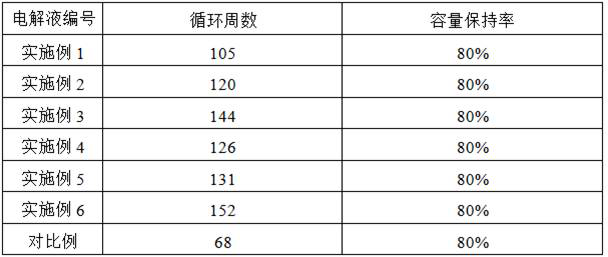

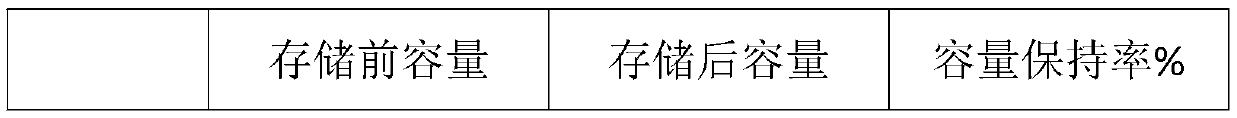

Electrolyte solution capable of improving high temperature cycling and storing performances of lithium secondary battery

InactiveCN103022561AImprove high temperature circulationImprove featuresSecondary cells servicing/maintenanceGamma-ValerolactoneLithium-ion battery

The invention discloses an electrolyte solution capable of improving high temperature cycling and storing performances of a lithium secondary battery. The electrolyte solution is prepared by lithium salt, an organic solvent and an addition agent, wherein the electrolyte solution also comprises a high temperature film-forming agent; the high temperature film-forming agent is one or any combinations of delta-valerolactone, gamma-valerolactone, gamma-caprolactone and epsilon-caprolactone; and the mass percentage of the high temperature film-forming agent accounts for 0.5%-15% of the total amount of the electrolyte solution. The high temperature film-forming agent is added into the electrolyte solution of the lithium secondary battery, a passivating film with excellent stability can be formed on the surface of a lithium secondary battery positive pole, a contact interface of the positive pole and the electrolyte solution can be improved, the decomposition reaction of the electrolyte solution on the positive pole material in the high temperature is inhibited, and the disadvantages that the existing lithium secondary battery is quick in storage capacity loss, low in recovery rate and quick in battery thickness swelling when being used under high temperature environments are overcome, so that the high temperature cycling and storing performances are improved.

Owner:TIANJIN LISHEN BATTERY

Anode active substance and battery

InactiveCN101075670AReduced responseExcellent cycle characteristicsNegative electrodesLi-accumulatorsLithiumFerric

An anode active material with a high capacity capable of providing superior cycle characteristics and a battery using it are provided. An anode contains an anode active material capable of reacting with lithium. The anode active material contains at least tin, iron, and carbon as an element. The carbon content is from 11.9 wt % to 29.7 wt %, and the iron ratio to the total of tin and iron is from 26.4 wt % to 48.5 wt %. Thereby, while a high capacity is maintained, the cycle characteristics are improved.

Owner:SONY CORP

Preparation method of lithium ion battery with long storage performance

InactiveCN111276755ADissolution inhibitionGood electrode stabilityCell electrodesFinal product manufactureElectrolytic agentPhysical chemistry

The invention provides a preparation method of a lithium ion battery with long storage performance, an active substance in a positive electrode in the lithium ion battery is LiCo0.97Al0.1Mg0.2O2, andthe positive electrode also comprises polyaniline accounting for 2-3% by mass of the active substance; the negative electrode of the lithium ion battery is a graphite negative electrode and can be selected from natural graphite or artificial graphite; the chain carbonate in the electrolyte of the lithium ion battery accounts for less than 20% of the total volume of the electrolyte, and the electrolyte comprises an additive composed of dimethyl sulfoxide (DMSO), trifluoroethyl phosphonic acid (TTFP) and hexylbenzene (CHB). The preparation method comprises the following steps: stacking a positive electrode, a diaphragm and a negative electrode to prepare a battery cell, placing the battery cell in a battery shell, injecting liquid, and performing formation, wherein the formation comprises aconstant-voltage charging process under a predetermined voltage, and the lithium ion battery obtained by the preparation method disclosed by the invention can be stored for a long time without capacity attenuation, and has good storage performance.

Owner:钱起

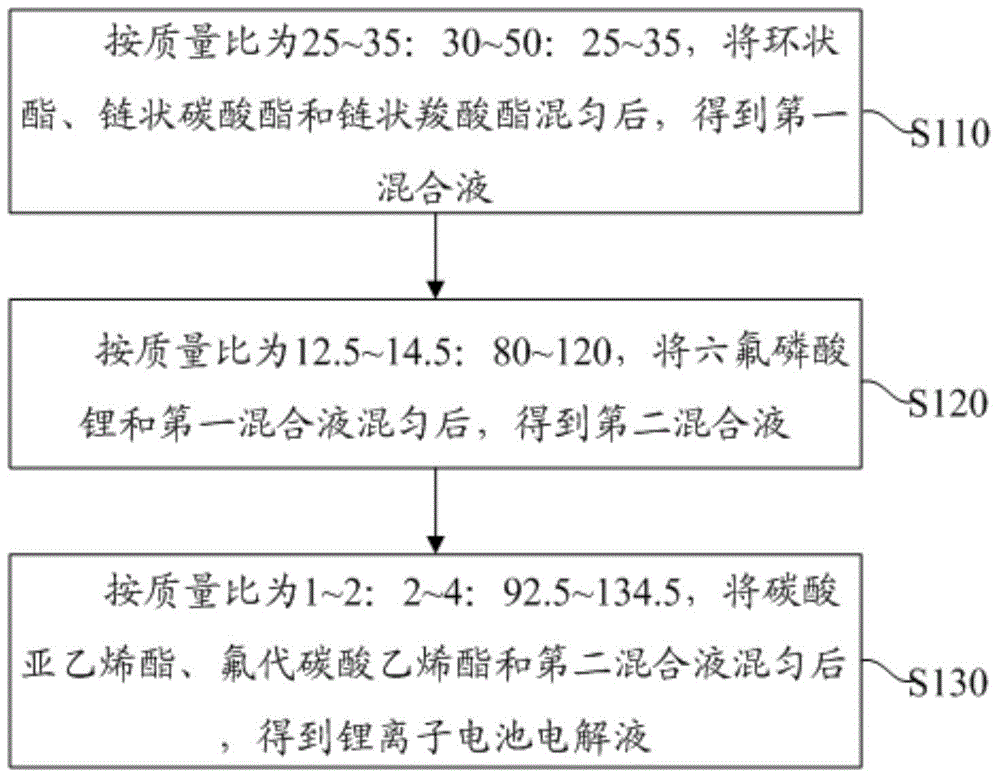

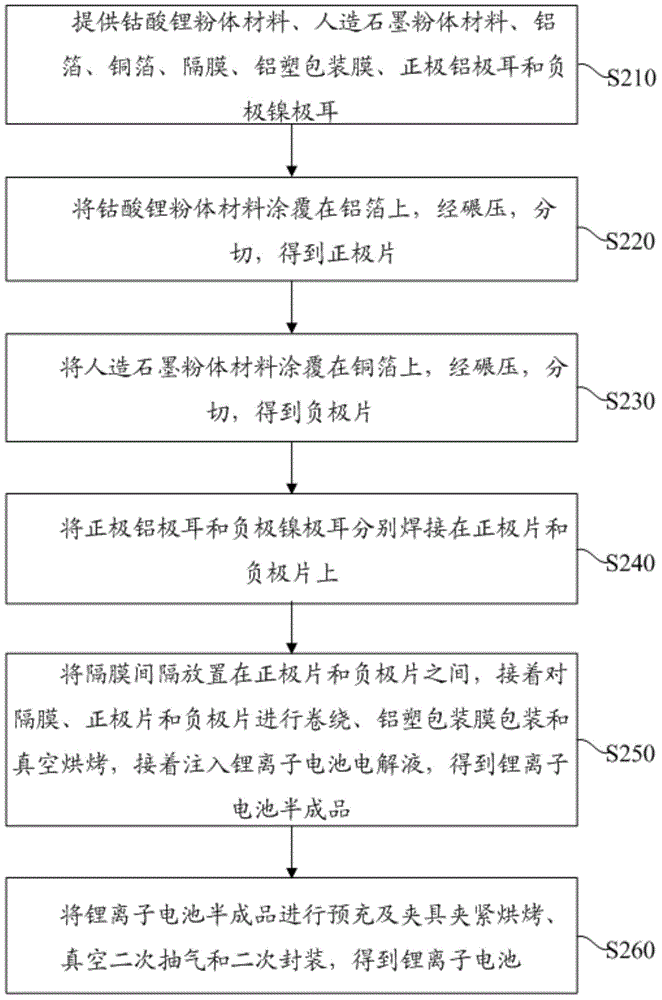

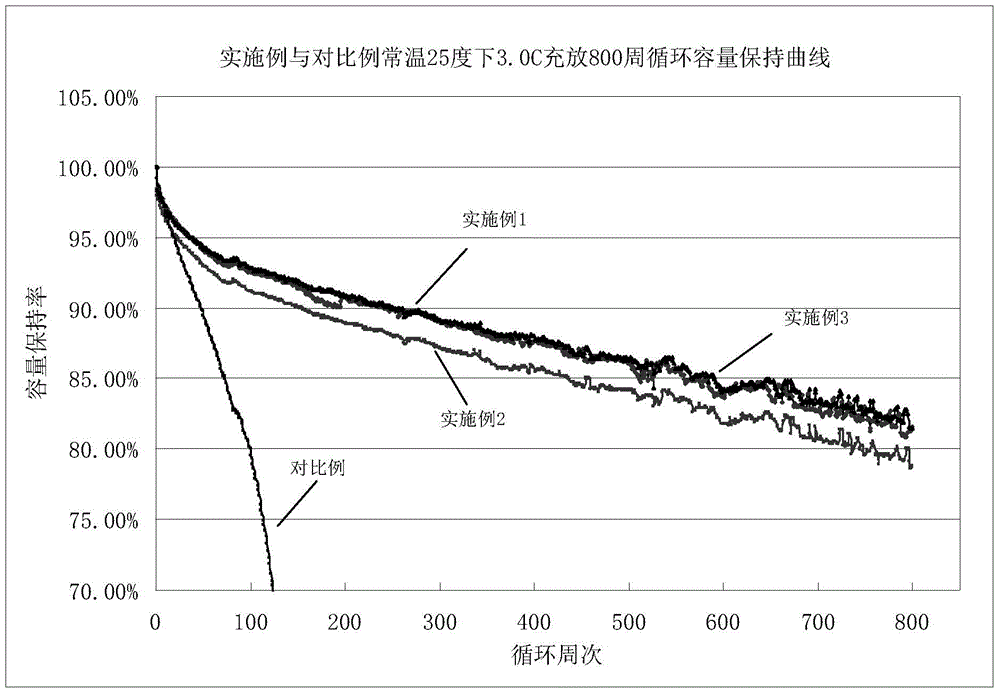

Lithium ion battery electrolyte and preparation method thereof, and lithium ion battery

InactiveCN105489933AImprove charge and discharge rateInhibition of decomposition reactionsSecondary cellsVinylene carbonateLithium electrode

The invention relates to a lithium ion battery electrolyte, which comprises, by mass, 25-35 parts of a cyclic ester, 30-50 parts of a chain carbonate, 25-35 parts of chain carboxylic acid ester, 12.5-14.5 parts of lithium hexafluorophosphate, 1-2 parts of vinylene carbonate, and 2-4 parts of fluoroethylene carbonate. According to the present invention, with the application of the lithium ion battery electrolyte in the lithium ion battery, vinylene carbonate and fluoroethylene carbonate can form the SEI film with characteristics of high density and stable structure on the electrode material, such that the adsorption of the lithium ions migrating between the positive electrode and the negative electrode on the electrode material surface during the charging and discharging process can be avoided to increase the concentration of the migrating lithium ions so as to improve the number of the charges moving between the positive electrode and the negative electrode within the per unit time of charge and discharge so as to improve the charging and discharging rate of the lithium ion battery. The present invention further discloses a preparation method of the lithium ion battery electrolyte, and a lithium ion battery using the lithium ion battery electrolyte.

Owner:EVE HYPERPOWER BATTERIES INC

pt/α‑moc 1‑x Supported Catalyst and Its Synthesis and Application

ActiveCN104707636BHigh activityLow selectivityHydrogenMetal/metal-oxides/metal-hydroxide catalystsPlatinumReal systems

Owner:PEKING UNIV

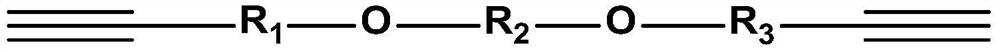

Lithium ion battery non-aqueous electrolyte, lithium ion battery and manufacturing method

PendingCN112186247AGood low temperatureImprove cycle performanceFinal product manufactureSecondary cellsElectrolytic agentPhysical chemistry

The present invention discloses a lithium ion battery non-aqueous electrolyte, which comprises an electrolyte lithium salt, a non-aqueous organic solvent and an additive, and according to the mass percentage content in the lithium ion battery non-aqueous electrolyte, the additive comprises a component A, a component B and a component C, and the component A accounts for 0.1-3%; the component B accounts for 10%-80%; the content of the component C is 0.1%-3%; the component B can improve the oxidative decomposition potential of the electrolyte, can form a passivation film on the surface of the negative electrode, and improves the cycle performance of the electrolyte; the component A can effectively inhibit the precipitation of cobalt from the lithium cobalt oxide positive electrode, and the component C can form a sulfur-containing compound on the negative electrode to improve the morphology of the negative electrode passivation film and effectively reduce the impedance of the negative electrode passivation film. The invention provides a lithium ion battery non-aqueous electrolyte which is good in high-temperature cycle characteristic, low in gas production in high-temperature storage and good in low-temperature performance. The invention further provides a lithium ion battery comprising the lithium ion battery non-aqueous electrolyte and a manufacturing method for manufacturing thelithium ion battery.

Owner:CHONGQING VDL ELECTRONICS +1

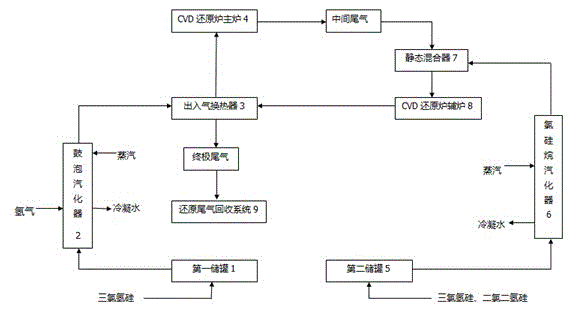

Polysilicon production technology

ActiveCN106276912AInhibition of decomposition reactionsReduce spawn rateSiliconHydrogenDichlorosilane

The invention provides a polysilicon production technology. The polysilicon production technology comprises mixing refined trichlorosilane and hydrogen according to a ratio to obtain a raw material, orderly treating the raw material through a bubble vaporizer, an inlet and outlet gas heat exchanger and a CVD reduction main furnace, mixing refined trichlorosilane and dichlorosilane according to a ratio to obtain an accessory material, treating the accessory material through a chlorosilane vaporizer to obtain accessory material gas, through the CVD reduction main furnace, producing polysilicon from the raw material gas obtained by the bubble vaporizer, mixing the side product as intermediate tail gas and the accessory material gas through a static mixer, feeding the mixed gas into a CVD reduction accessory furnace, carrying out a reaction process on the intermediate tail gas and the accessory material gas on the surface of a silicon core in the CVD reduction accessory furnace to obtain polysilicon, carrying out heat exchange between the side product as finished tail gas and the raw material gas through the inlet and outlet gas heat exchanger, and feeding the mixed gas into a reduced tail gas recovery system. The polysilicon production technology improves a polysilicon generation rate and a deposition rate and reduces the material total amount of the finished tail gas.

Owner:巴彦淖尔聚光硅业有限公司

Lithium ion battery non-aqueous electrolyte, lithium ion battery and preparation method of lithium ion battery non-aqueous electrolyte

PendingCN114142085AReduce capacityIncrease the oxidation decomposition potentialFinal product manufactureElectrolyte accumulators manufactureElectrolytic agentOrganosolv

The invention discloses a non-aqueous electrolyte of a lithium ion battery and a manufacturing method of the non-aqueous electrolyte. The electrolyte provided by the invention is good in low-temperature performance, good in high-temperature cycle characteristic and less in gas production in high-temperature storage. Comprising an electrolyte lithium salt, a non-aqueous organic solvent and an additive, according to the mass percentage content in the non-aqueous electrolyte of the lithium ion battery, the additive comprises a component A, a component B and a component C, and the component A accounts for 0.1-3%; the content of the component B is 10%-80%; the content of the component C is 0.1%-3%; the component A can effectively inhibit cobalt element from being separated out of a lithium cobalt oxide positive electrode, and side reaction is reduced; the component B can improve the oxygenolysis potential of the electrolyte, can form a passive film on the surface of the negative electrode, and improves the cycle performance of the electrolyte; and the component C can form a sulfur-containing compound on the negative electrode to improve the morphology of the negative electrode passivation film and effectively reduce the impedance of the negative electrode passivation film.

Owner:CHONGQING ZIJIAN NEW ENERGY CO LTD +1

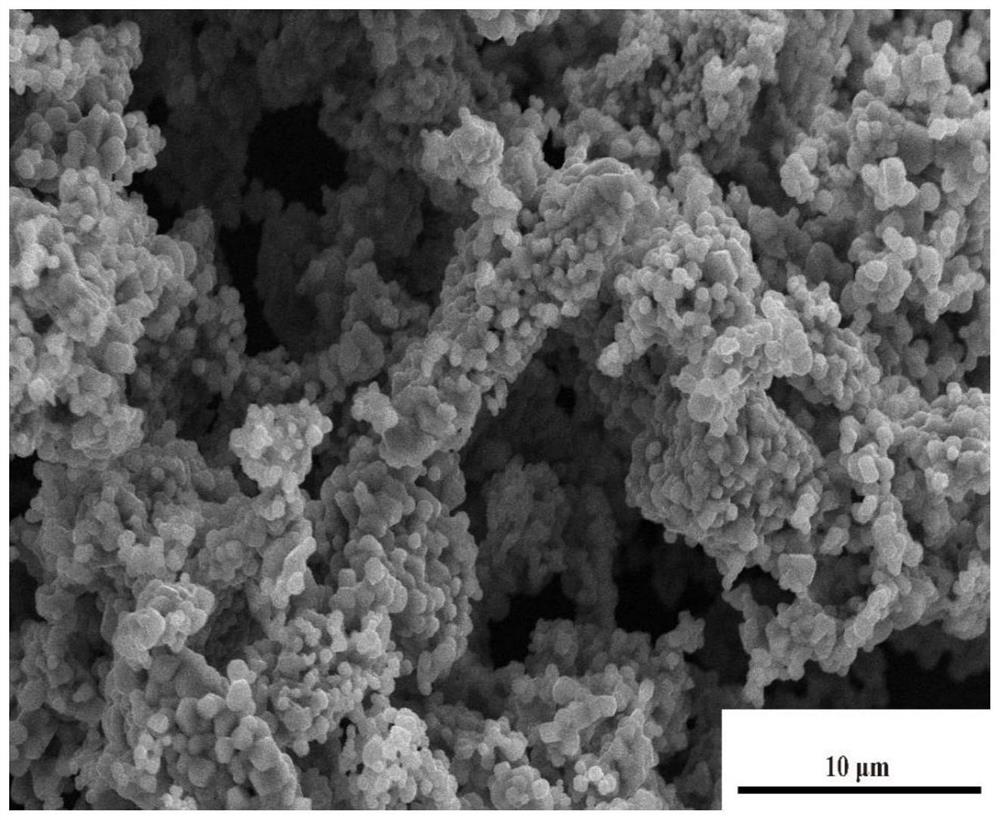

Coated Al and F co-doped single crystal lithium manganate positive electrode material as well as preparation method and application thereof

PendingCN114784236AReduce shufflingDecrease phenomenonSecondary cellsPositive electrodesElectrolytic agentManganate

The invention relates to a coated Al and F co-doped single crystal lithium manganate positive electrode material as well as a preparation method and application thereof, and belongs to the technical field of preparation of battery positive electrode materials. The preparation method comprises the following steps: introducing doping elements Al and F into beta-MnO2 in a planetary ball milling manner, sintering to generate doped beta-MnO2, mixing the doped beta-MnO2, a lithium source and a coating agent, and carrying out secondary sintering to obtain the single-crystal lithium manganate positive electrode material. The lithium manganate is doped and coated by adopting specific elements, so that the crystal structure of the lithium manganate positive electrode material can be stabilized, the dissolution of Mn and the side reaction between an active substance and an electrolyte are inhibited, and the specific capacity, the first charge performance and the cycle performance of the single-crystal lithium manganate are improved.

Owner:安徽格派新能源有限公司

Lithium ion battery non-aqueous electrolyte and lithium ion battery containing non-aqueous electrolyte

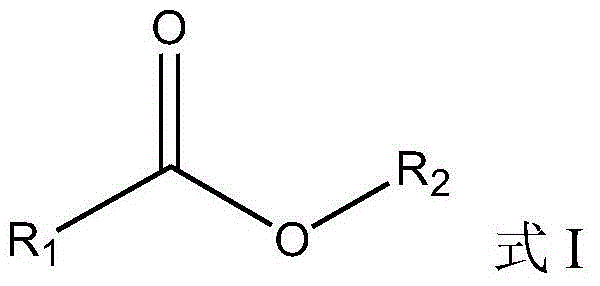

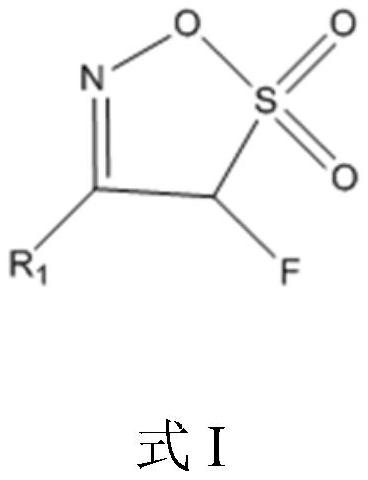

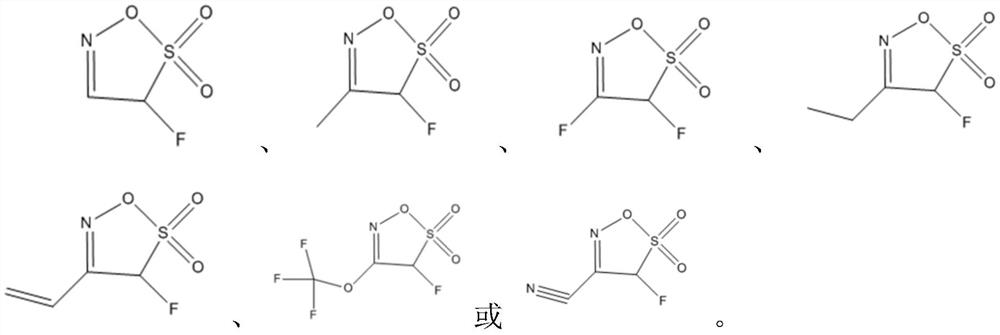

ActiveCN111883833AImprove cycle performanceInhibition of decomposition reactionsSecondary cellsOrganic electrolytesElectrolytic agentAqueous electrolyte

The present invention provides a lithium ion battery non-aqueous electrolyte and a lithium ion battery. The lithium ion battery non-aqueous electrolyte comprises a compound additive having a structurerepresented by the following formula I, the additive can effectively inhibit the decomposition reaction of a solvent on a positive electrode and a negative electrode, and can rapidly generate a protection film on the positive electrode and the negative electrode, and the electrolyte is prevented from reacting with an electrode material, so that the electrolyte is more stable in the battery, and the cycle performance and the high-temperature storage performance of the lithium ion battery can be effectively improved.

Owner:XIANGHE KUNLUN NEW ENERGY MATERIALS CO LTD

Cathode active material, method for preparing same, and lithium secondary battery comprising same

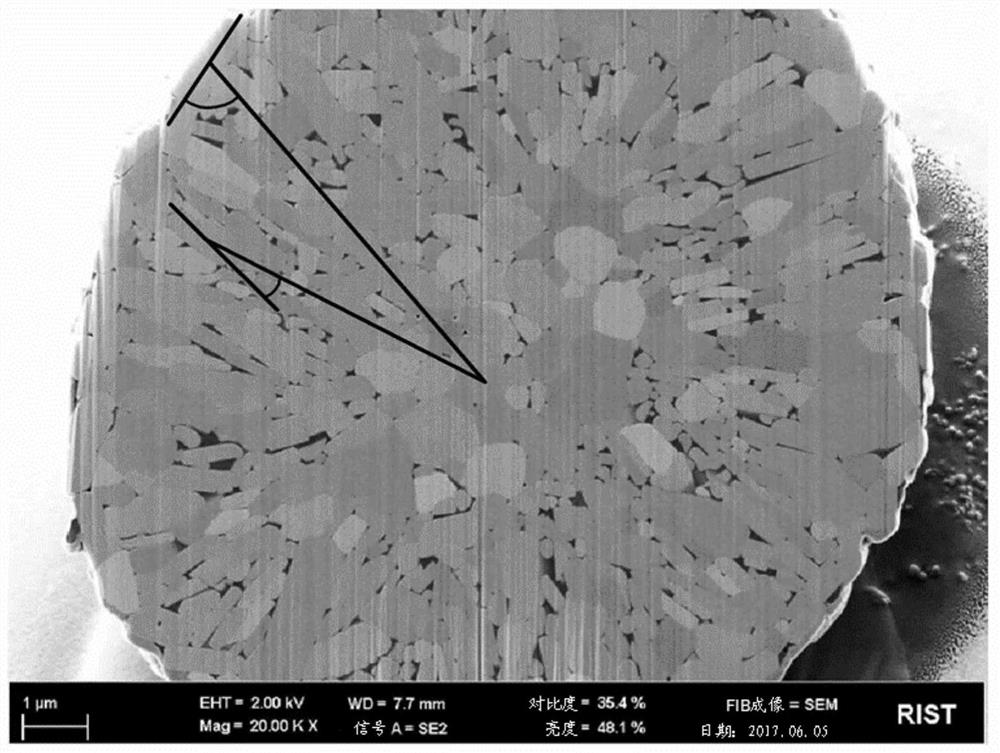

PendingCN112997338AInhibition of decomposition reactionsImprove thermal stabilityPositive electrodesLi-accumulatorsLithium metalElectrical battery

The present invention relates to a cathode active material, a method for preparing same, and a lithium secondary batter comprising same. The present invention can provide a cathode active material, which has lithium metal oxide particles in the form of secondary particles each comprising primary particles, wherein the surface of the secondary particle comprises plate-shaped primary particles each satisfying that the smaller angle of the angles between the c axis of the plate-shaped primary particle and a straight line connecting an imaginary point of the center of the plate-shaped primary particle and the center point of the secondary particle is 70-90 DEG.

Owner:浦项控股股份有限公司 +2

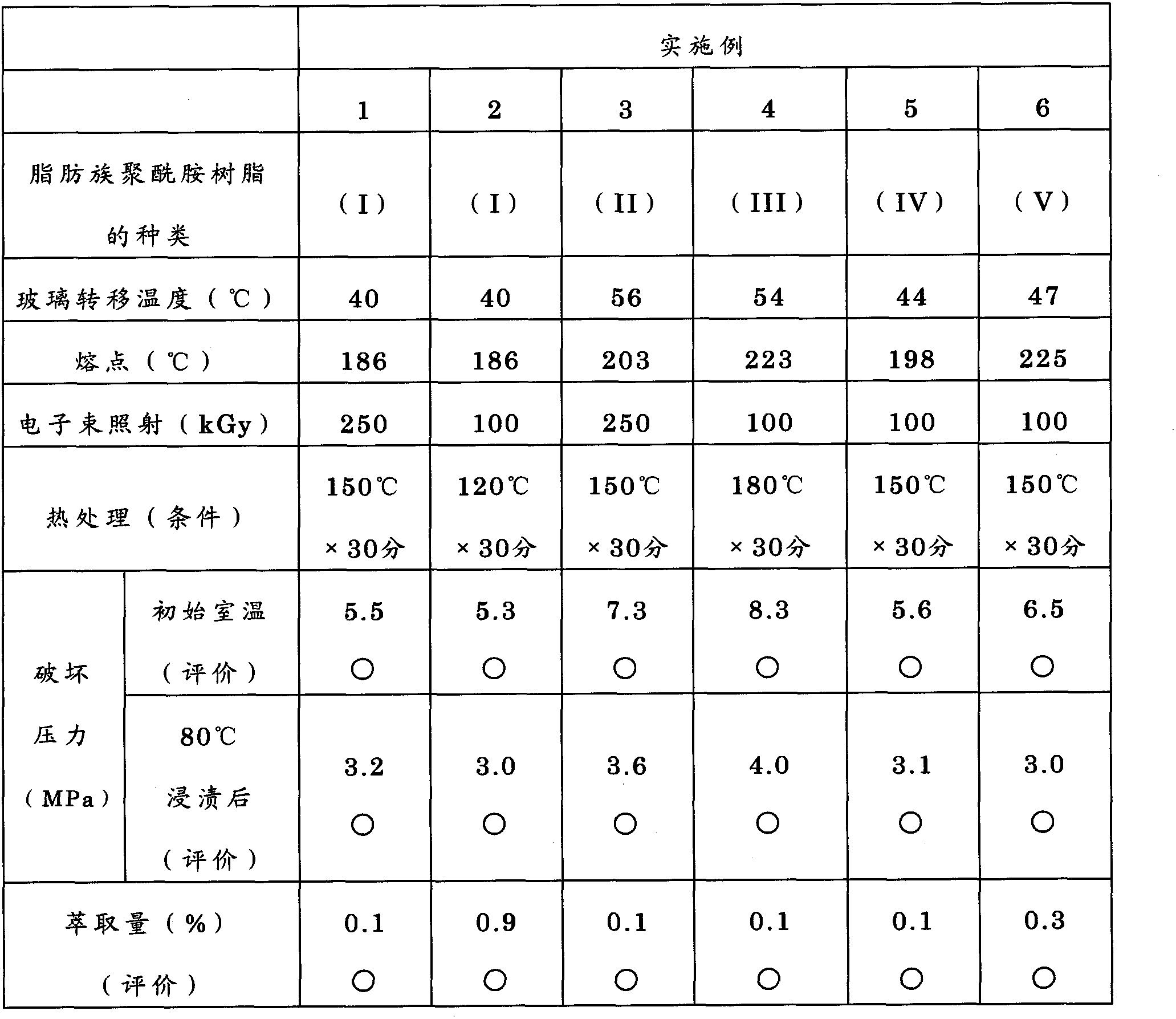

Automobile fuel in-tank tube and method of manufacturing same

InactiveCN102317062AWell toleratedInhibition of decomposition reactionsMachines/enginesFlexible pipesPolyamideMethanol

Disclosed is an in-tank tube with superior pressure resistance performance. A monolayer structure automobile fuel in-tank tube (1) is disposed within a fuel tank (2), and comprises a configuration of absorbing the displacement of the fuel tank (2) and the oscillations of a fuel pump (5). The automobile fuel in-tank tube (1) is formed in a monolayer structure from a resin material, the primary constituent thereof being an aliphatic polyamide resin, said in-tank tube (1) further comprising a pressure-resistant characteristic (X) described hereinafter: (X) The pressure at the time the in-tank tube breaks or comes apart from test pipes, i.e., the breakage pressure, is greater than or equal to 2.8MPa, when the in-tank tube, after immersion in testing fluid [Fuel C: Methanol = 85:15 (based on volume)] for 168 hours at 80 degrees C, is then filled with silicon oil as a pressurizing medium, and a pressure resistance test is carried out at room temperature with both ends of the in-tank tube blocked with the test pipes, at a pressurization speed of 1.0MPa / min.

Owner:TOKAI RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com