High-temperature-resistant high-voltage electrolyte of high-nickel lithium ion battery

A lithium-ion battery and ion battery technology, applied in the electrolyte field of lithium-ion batteries, can solve the problems of capacity loss, side reactions, battery swelling, etc., to improve high temperature performance and cycle performance, inhibit decomposition reaction, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

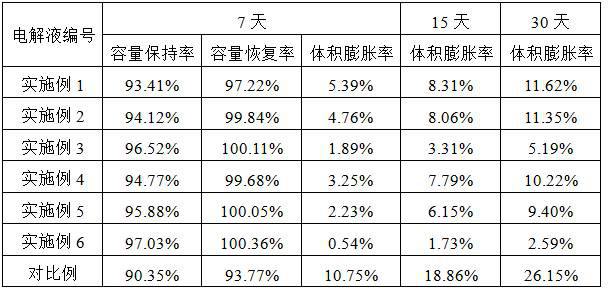

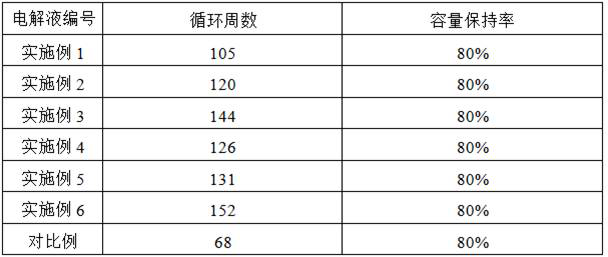

Examples

Embodiment 1

[0016] The composition of the electrolyte in this embodiment is: the lithium salt part adopts a mass fraction of 13.75% LiPF 6 , 1%LiPO 2 f 2 and 2% LiFSI; the solvent part adopts EC, PC, DEC, EMC, DMC, and the corresponding mass percentage is 25:5:20:45:5; the additive part adopts mass fraction of 0.8% VC, 0.4% PS.

[0017] The mixing of the electrolyte is carried out in a closed environment with a water oxygen content of ≤1ppm; just mix well (the same below).

Embodiment 2

[0019] The composition of the electrolyte in this embodiment is: the lithium salt part adopts a mass fraction of 13.75% LiPF 6 , 1%LiPO 2 f 2 and 2% LiFSI; the solvent part adopts EC, PC, DEC, EMC, DMC, and the corresponding mass percentage is 25:5:20:45:5; the additive part adopts mass fraction of 0.8%VC and 0.2%VEC respectively , 0.4%PS, 0.3%PST.

Embodiment 3

[0021] The composition of the electrolyte in this embodiment is: the lithium salt part adopts a mass fraction of 13.75% LiPF 6 , 1%LiPO 2 f 2 and 2% LiFSI; the solvent part adopts EC, PC, DEC, EMC, DMC, and the corresponding mass percentage is 25:5:20:45:5; the additive part adopts mass fraction of 0.8%VC and 0.2%VEC respectively , 0.4%PS, 0.3%PST, 0.3%TAP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com