Lithium primary battery and method for producing same

A battery and lithium alloy technology, applied in the field of lithium primary batteries, can solve problems such as separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

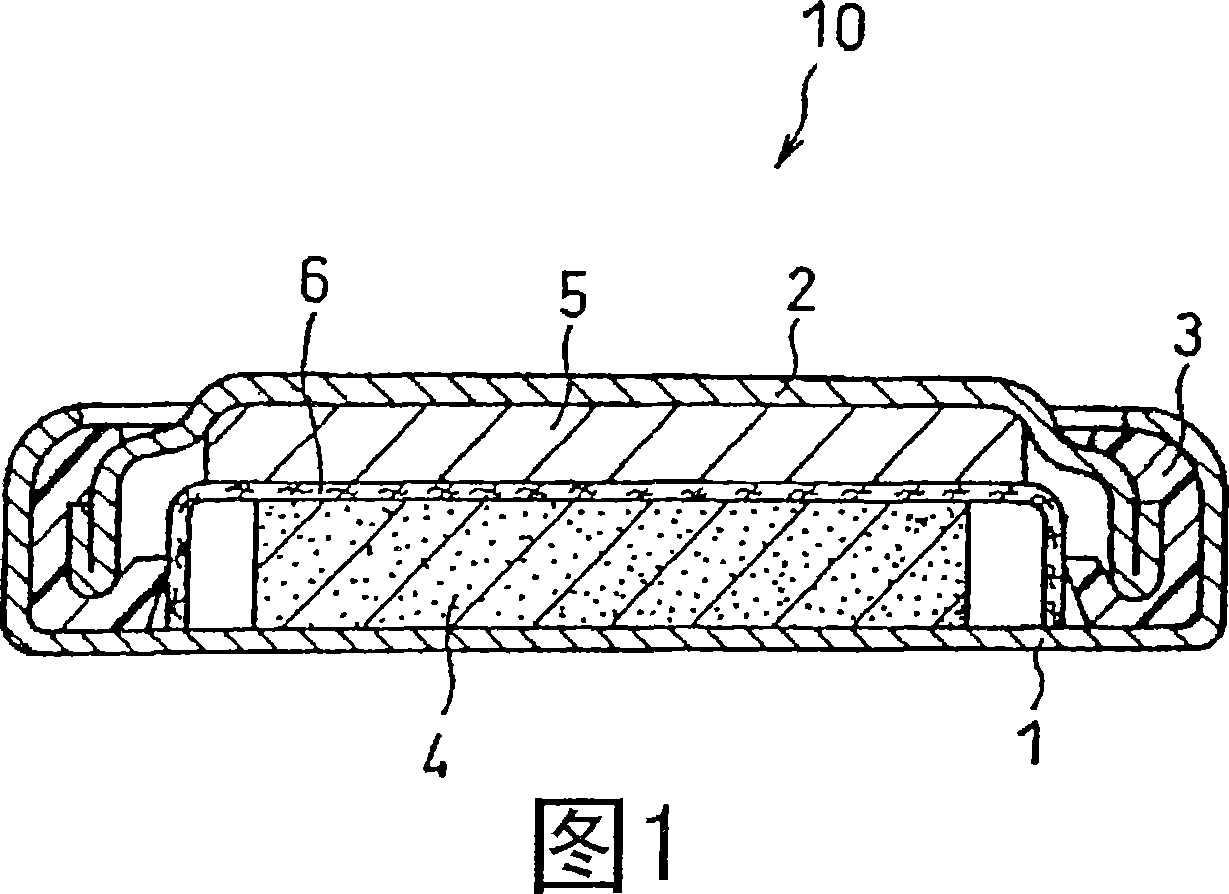

preparation example Construction

[0096] An example of the production method of the negative electrode of the coin cell is given in detail. In an argon glove box, dry carbon black was sprayed on a lithium metal sheet and the sheet was heated to approximately 200°C with a hot plate. At this time, carbon black is impregnated with molten lithium to form a composite of carbon black and lithium. Alternatively, carbon black can be sandwiched between a pair of lithium metal sheets and heated to about 200°C. Heating is preferably performed under a reduced pressure of 100 Pa or less to accelerate the impregnation of carbon black with molten lithium. In addition, a molten mixture was prepared by heating lithium flakes and carbon black powder, and stirring them in an inert atmosphere to accelerate homogeneous mixing.

[0097] Then, the composite of lithium and carbon black was pressed into a sheet using a small roller press installed in an inert atmosphere, and the thickness of the sheet was made uniform. When the thi...

Embodiment 1A

[0123] (i) Preparation of positive electrode

[0124] For the positive electrode active material, petroleum coke was fluorinated and used as fluorinated graphite. Fluorinated graphite, acetylene black (conductive material) and styrene-butadiene rubber (SBR) (binder) were mixed at a solid content weight ratio of 100:15:6, and a mixed solution of water and ethanol was used as a dispersion medium Knead them well. After the resulting mixture was dried at 100° C., the mixture was compression-molded into a disc shape by using a predetermined mold and a hydraulic press, thereby obtaining a positive electrode.

[0125] (ii) Preparation of negative electrode

[0126] Lithium metal was used as the negative electrode active material, and acetylene black (AB) prepared by Denki Kagaku KogyoKabushiki Kaisha was used as the amorphous carbon material. The average particle size of the primary particles of acetylene black is 0.04 μm, and the BET specific surface area is 60m 2 / g. The acety...

Embodiment 2A

[0133] A negative electrode was prepared in the same manner as in Example 1A, except that the negative electrode preparation atmosphere was changed to an airtight container with a vacuum degree of 100 Pa or less. Prepare 10 coin cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com