Coated Al and F co-doped single crystal lithium manganate positive electrode material as well as preparation method and application thereof

A single-crystal lithium manganate and cathode material technology, applied in battery electrodes, structural parts, electrical components, etc., can solve problems affecting the performance of material capacity, improve normal temperature cycle performance and rate discharge performance, suppress lattice distortion, The effect of reducing lattice distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

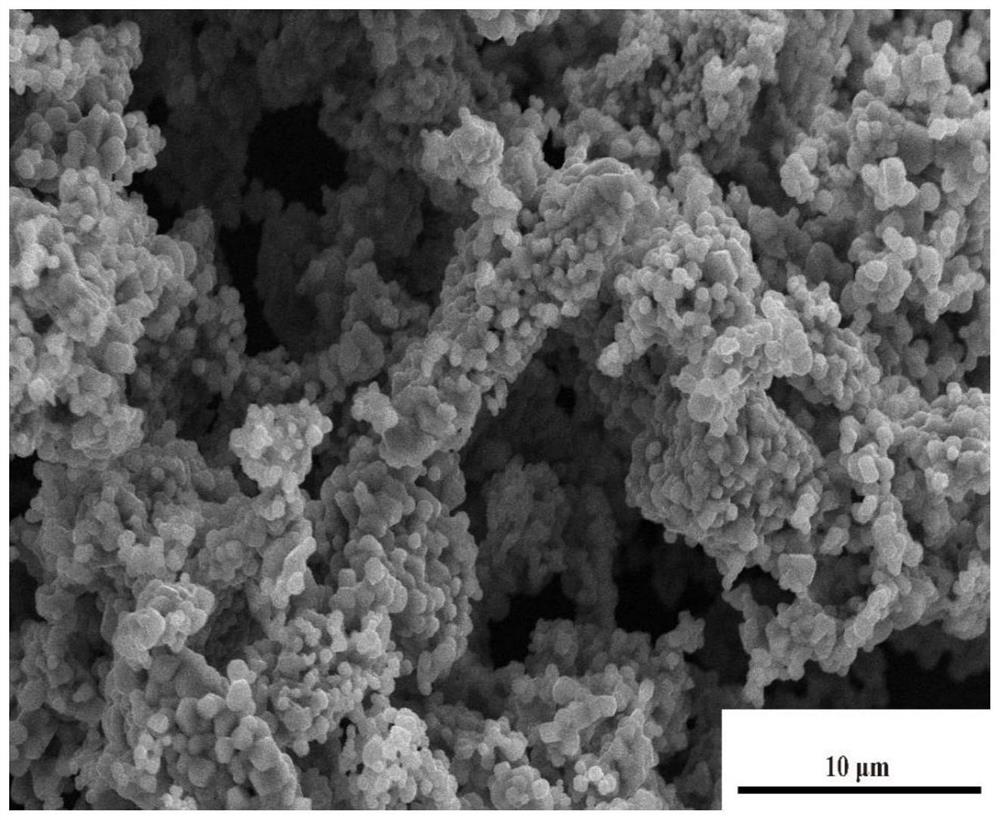

[0033] This embodiment provides a clad Al, F co-doped single crystal lithium manganate, and the general chemical formula of the single crystal lithium manganate is [Li 1.03 Al 0.01 Mn 1.99 (O 3.995 F 0.01 )]·[Nb 2 O 5 ] 0.01 , the single crystal lithium manganate includes a lithium manganate inner core Li 1.03 Al 0.01 Mn 1.99 (O 3.995 F 0.01 ) and Nb 2 O 5 cladding.

[0034] This embodiment also provides a method for preparing the above-mentioned single crystal lithium manganate positive electrode material, and the preparation method includes the following steps:

[0035] (1) According to the molar ratio of Al:Mn:F=0.02:1.98:0.01, weigh β-MnO 2 , Al(OH) 3 and LiF, using deionized water as solvent and PEG2000 as emulsifier, mixed and ball-milled in a planetary ball mill for 6 h to make a uniform slurry;

[0036] (2) Granulate by spray dryer, control the solid-liquid ratio to be 1:1.2, the air outlet temperature to be 120 °C, the feed rate to be 20 mL / min, and th...

Embodiment 2

[0042] This embodiment provides a method for preparing the above-mentioned single crystal lithium manganate positive electrode material, and the preparation method includes the following steps:

[0043] (1) According to the molar ratio of Al:Mn:F=0.01:1.99:0.01, weigh β-MnO 2 , Al(OH) 3 and LiF, using deionized water as solvent and PEG4000 as emulsifier, mixed and ball-milled in a planetary ball mill for 6 h to make a uniform slurry;

[0044] (2) Granulate by spray dryer, control the solid-liquid ratio to be 1:1.2, the air outlet temperature to be 120 °C, the feed rate to be 20 mL / min, and then dry at 120 °C;

[0045] (3) Sintering at 500 ℃ for 9 h in air atmosphere, cooling, pulverizing and sieving to obtain doped β-MnO 2 ;

[0046] (4) According to the molar ratio Li:Mn:La=1.02:1.99:0.02, weigh Li 2 O, doped β-MnO 2 and coating agent La 2 O 3 , high-energy ball milling for 3 h to obtain lithium manganate precursor;

[0047] (5) Sintering at a high temperature of 780 ...

Embodiment 3

[0050] This embodiment provides a method for preparing the above-mentioned single crystal lithium manganate positive electrode material, and the preparation method includes the following steps:

[0051] (1) According to the molar ratio of Al:Mn:F=0.01:1.99:0.01, weigh β-MnO 2 , Al(OH) 3 and LiF, using deionized water as solvent and PPG as emulsifier, mixed and ball-milled in a planetary ball mill for 6 h to make a uniform slurry;

[0052] (2) Granulate by spray dryer, control the solid-liquid ratio to be 1:1.2, the air outlet temperature to be 120 °C, the feed rate to be 20 mL / min, and then dry at 120 °C;

[0053] (3) Sintering at 500 ℃ for 12 h in air atmosphere, cooling, pulverizing and sieving to obtain doped β-MnO 2 ;

[0054] (4) According to the molar ratio Li:Mn:Zr=1.02:1.99:0.02, weigh LiOH, doped β-MnO 2 and coating agent ZrO 2 , high-energy ball milling for 3 h to obtain lithium manganate precursor;

[0055] (5) Sintering at a high temperature of 750 °C for 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

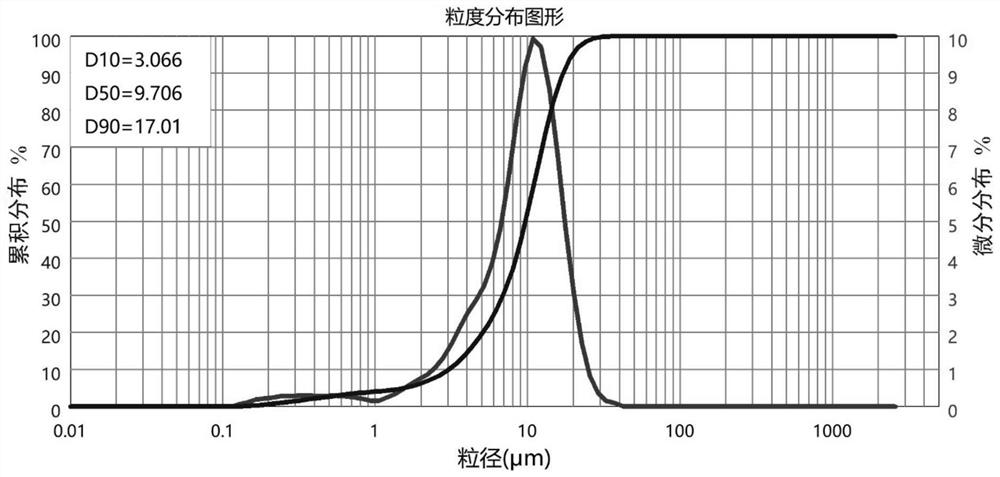

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com