Negative electrode for nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery

A non-aqueous electrolyte, secondary battery technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as lower battery charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] (a) Preparation of negative electrode

[0072] Process (i)

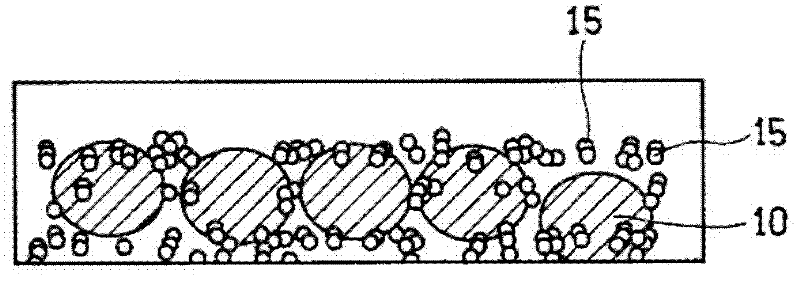

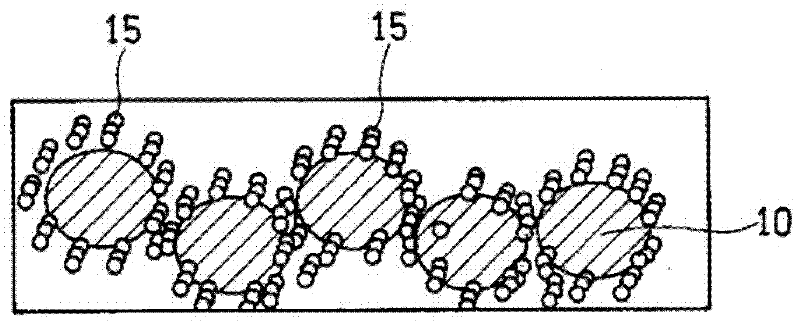

[0073] First, carboxymethylcellulose (hereinafter referred to as CMC, molecular weight: 200,000, degree of etherification: 0.7) which is a water-soluble polymer was dissolved in water to obtain an aqueous solution having a CMC concentration of 0.7% by weight. The viscosity at 25° C. of an aqueous solution having a CMC concentration of 0.7% by weight was measured with a B-type viscometer and found to be 1.5 Pa·s. The natural graphite particles (the average particle size is 18 μm, the average circularity is 0.92, the specific surface area is 4.8m 2 / g) 100 parts by weight and 100 parts by weight of the CMC aqueous solution were mixed, and the mixture was stirred while controlling the temperature of the mixture to 25°C. Then, the mixture was dried at 80° C. for 5 hours to obtain a dry mixture. In the dry mixture, the amount of CMC was 0.7 parts by weight per 100 parts by weight of graphite particles.

[0074]...

Embodiment 2

[0117] A negative electrode was produced in the same manner as in Example 1, except that the dried coating film was rolled with a calender roll at a linear pressure of 40 kgf / cm in step (iii). A lithium ion secondary battery was fabricated in the same manner as in Example 1 except for using this negative electrode. The same evaluation as in Example 1 was performed on the negative electrode and the battery.

Embodiment 3

[0121] A negative electrode was fabricated in the same manner as in Example 1, except that the dried coating film was rolled with a calender roll at a linear pressure of 60 kgf / cm in step (iii). A lithium ion secondary battery was fabricated in the same manner as in Example 1 except for using this negative electrode. The same evaluation as in Example 1 was performed on the negative electrode and the battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com