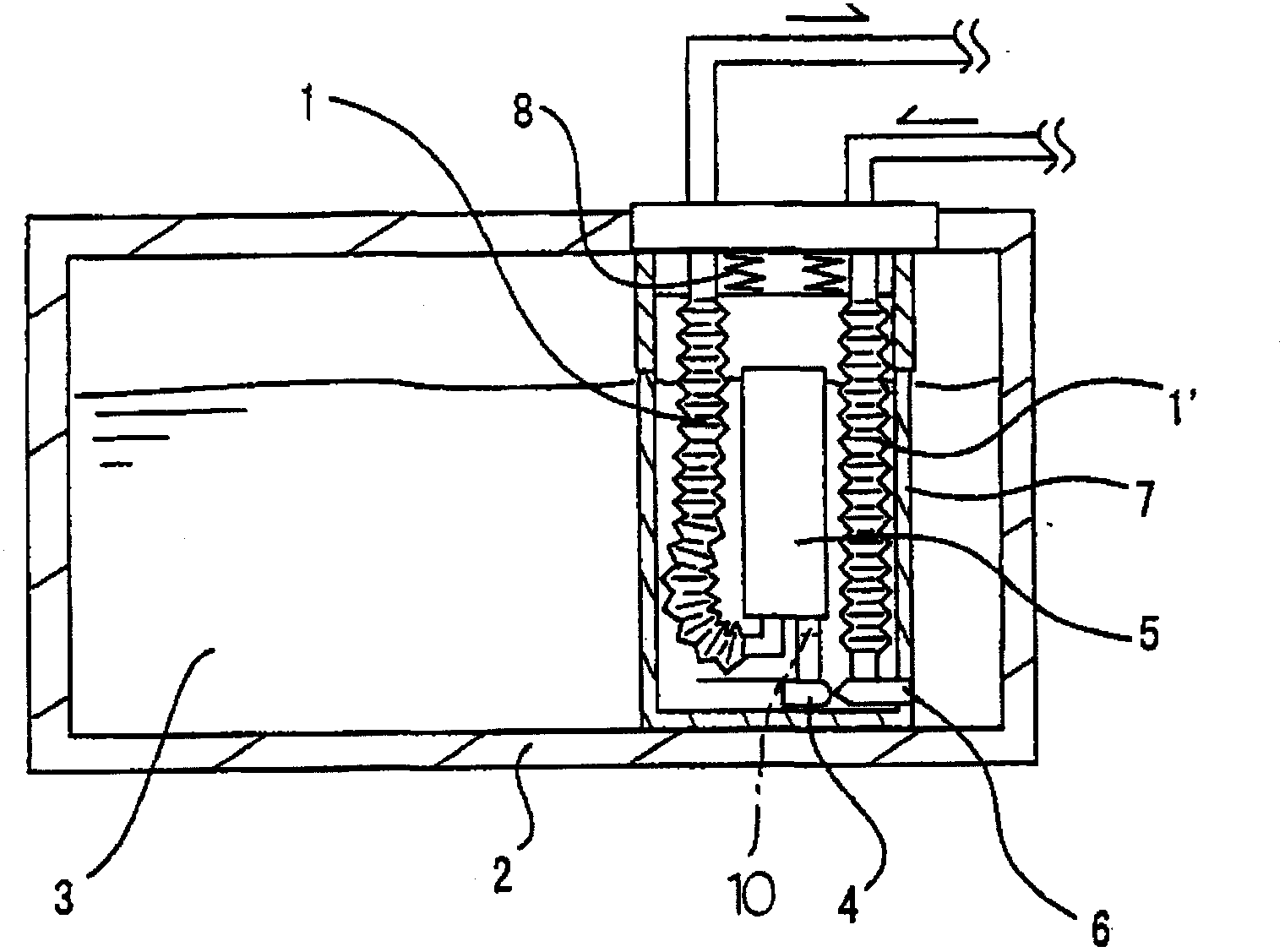

Automobile fuel in-tank tube and method of manufacturing same

A manufacturing method, fuel tank technology, applied in the direction of liquid fuel feeder, application, hose, etc., to achieve excellent resistance, inhibit decomposition reaction, and prevent clogging of injectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

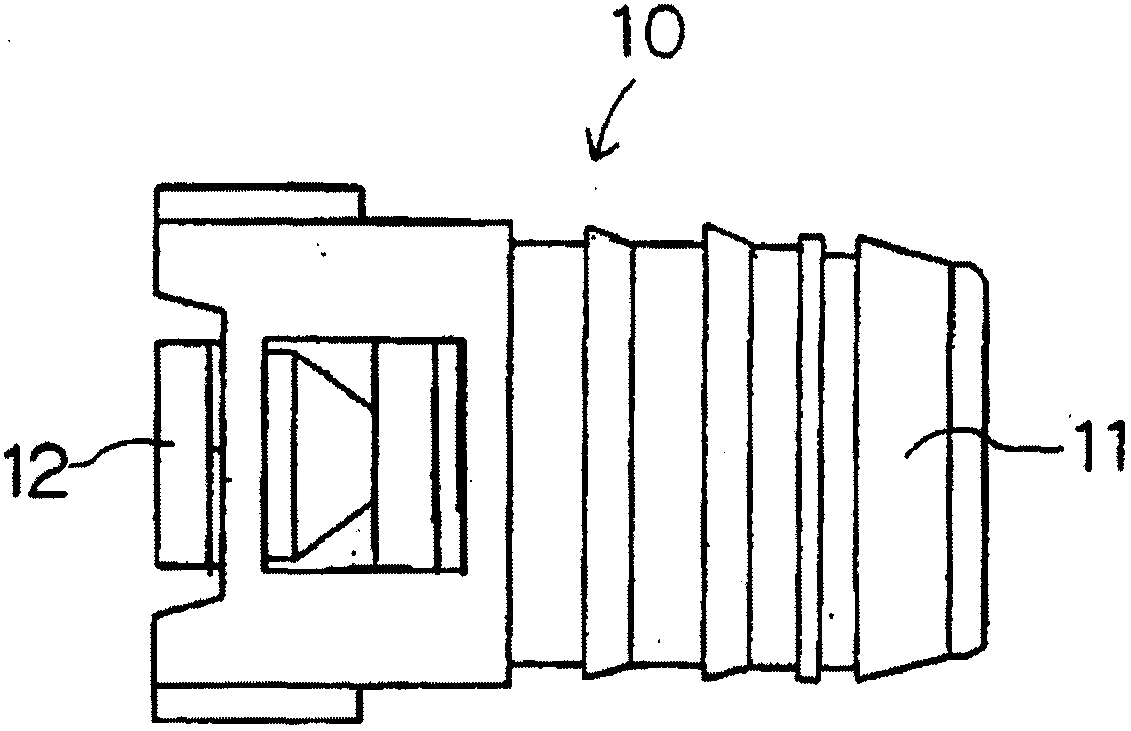

[0067] Aliphatic polyamide resin (I) that is polyamide 11 is extruded into a tube shape (inner diameter: 6mm, outer diameter: 8mm), and then vacuum forming corrugator (vacuum forming corrugator) (manufactured by Japan "Korma" Co., Ltd. , model 120HS) to form a corrugated structure (corrugated structure part: 150mm, outer diameter of valley / peak outer diameter = 7mm / 10mm, pitch length: 3mm) (straight parts at both ends: 10mm, inner diameter of straight parts at both ends: 6mm, Outer diameter: 8mm). Next, it is irradiated with an electron beam (a dose of 250 kGy), and cut into a predetermined length (180 mm in length) by a cutter or the like. Next, put the cut tube into a heat treatment furnace (made by Japan "Espec" company, PV(H)-212), and heat-treat it (150°C x 30 minutes), thereby producing a box-in-box tube (with the above-mentioned inner diameter, outer diameter ).

Embodiment 2~6

[0068] (Examples 2-6, Comparative Examples 1-4)

[0069] Inner tubes were produced as in Example 1 except that the type of aliphatic polyamide resin, the conditions of electron beam irradiation and heat treatment, etc. were changed as shown in Tables 1 and 2 below.

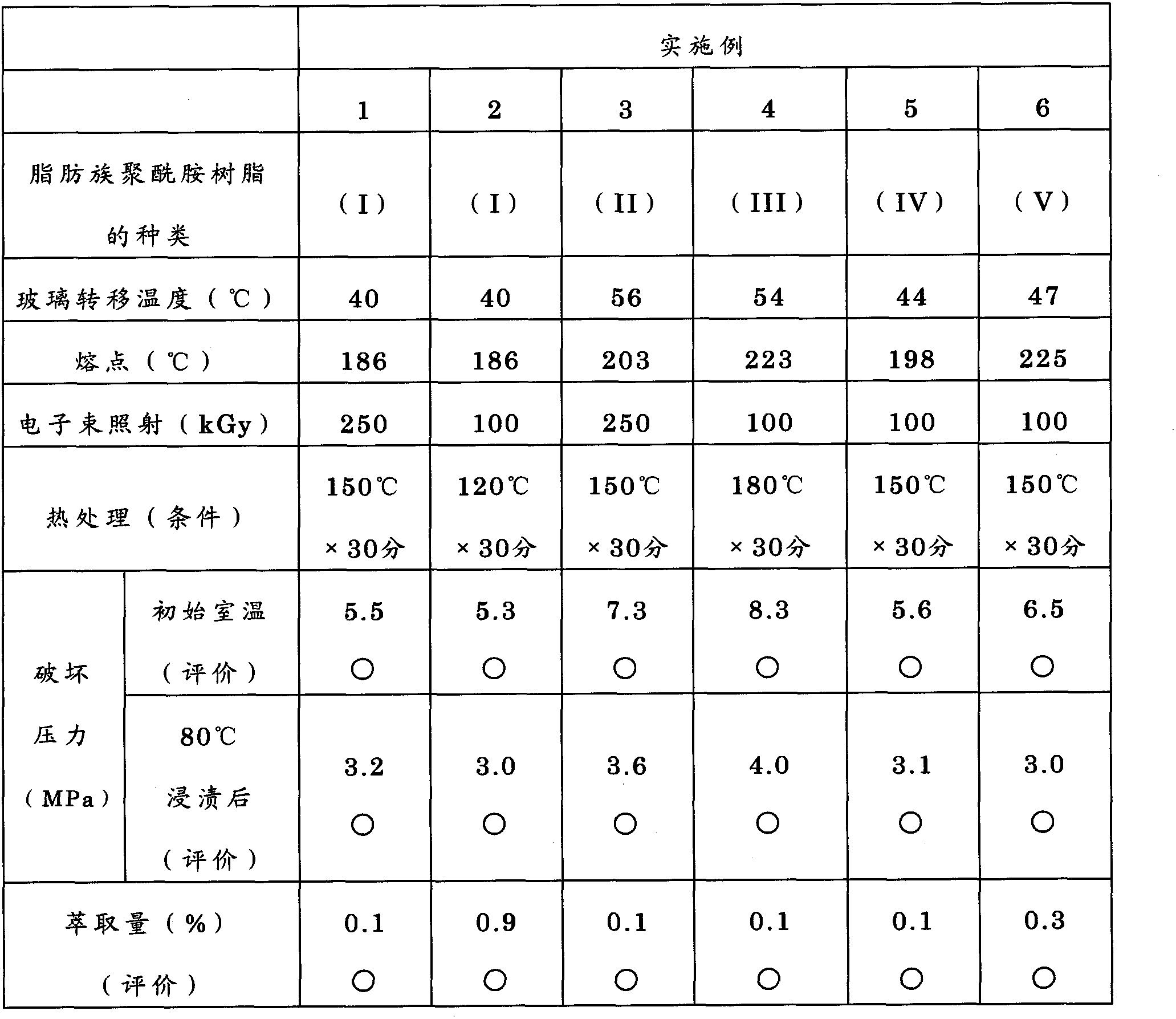

[0070] Table 1

[0071]

[0072] Table 2

[0073]

[0074] Using the tank tubes of Examples and Comparative Examples obtained in this way, each property was evaluated according to the following criteria. These results are shown together in Table 1 and Table 2 above.

[0075] (breaking pressure)

[0076] (initial room temperature (23°C))

[0077] Fill the tube in the box with silicone oil as a pressurized medium, use the test pipe to plug both ends of the tube in the box, and conduct a pressure test at room temperature (23°C) at a pressure increase rate of 1.0MPa / min to measure the rupture of the tube in the box Or the pressure when the test pipe is disconnected (destroying pressure).

[0078] In the ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com