Preparation method of lithium ion battery with long storage performance

A lithium-ion battery and storage performance technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of storage performance affecting battery continuous use performance, generation of metal dendrites, capacity attenuation, etc., and achieve storage performance improvement , good electrode stability, and the effect of inhibiting decomposition reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

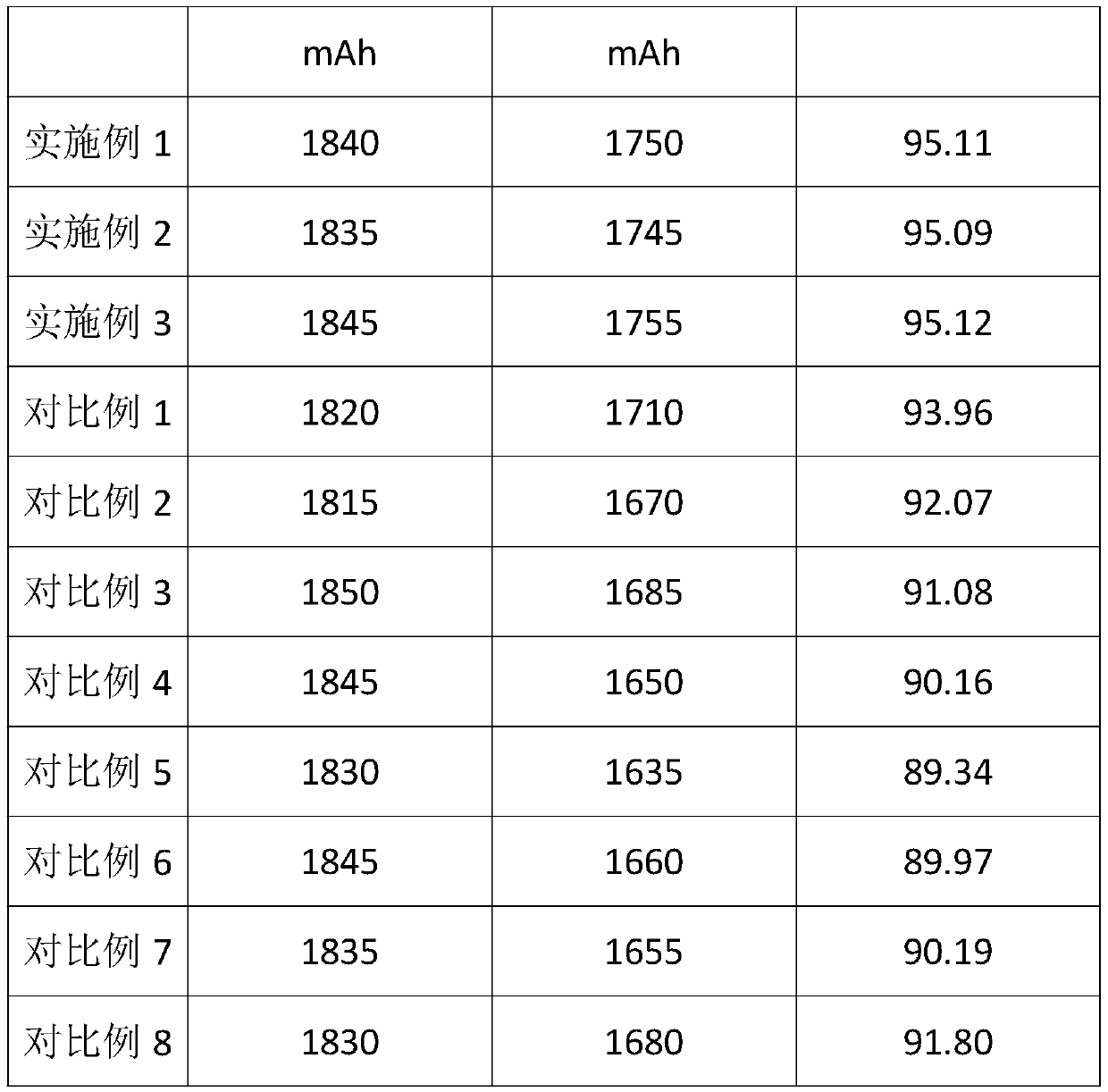

Embodiment 1

[0030] 1) Laminate the positive electrode, diaphragm, and negative electrode to form a battery cell, place it in the battery case, inject liquid, and let it stand for 2 hours. In the electrolyte, dimethyl sulfoxide (DMSO) is 0.8% by volume, trifluoroethylphosphine Acid (TTFP) is 1.5% by volume; Hexylbenzene (CHB) is 2.2% by volume;

[0031] 2) Pulse charging to 3.75V, pulse current 0.02C, pulse time 60s, interval 5s;

[0032] 3) Charge at a constant voltage of 3.75V until the charging current is less than 0.01C;

[0033] 4) Stand still for 1h;

[0034] 5) Adjust the battery temperature to 40°C, and charge again at a constant voltage of 3.75V until the charging current is less than 0.01C;

[0035] 6) Aging at 40°C for 3 hours;

[0036] 7) adjust to room temperature;

[0037] 8) 0.1C constant current charging to 4.2V, and then 4.2V constant voltage charging until the charging current is less than 0.01C;

[0038] 9) Charge and discharge cycle 3 times with 0.1C constant curre...

Embodiment 2

[0041] 1) Laminate the positive electrode, diaphragm, and negative electrode to form a battery cell, place it in the battery case, inject liquid, and let it stand for 2 hours. In the electrolyte, dimethyl sulfoxide (DMSO) is 1.2% by volume, trifluoroethylphosphine Acid (TTFP) is 2.0% by volume; Hexylbenzene (CHB) is 2.6% by volume;

[0042] 2) Pulse charging to 3.80V, pulse current 0.1C, pulse time 30s, interval 2s;

[0043] 3) Charge at a constant voltage of 3.80V until the charging current is less than 0.01C;

[0044] 4) Stand still for 1h;

[0045] 5) Adjust the battery temperature to 50°C, and charge again at a constant voltage of 3.80V until the charging current is less than 0.01C;

[0046] 6) Aging at 50°C for 3 hours;

[0047] 7) adjust to room temperature;

[0048] 8) 0.1C constant current charging to 4.2V, and then 4.2V constant voltage charging until the charging current is less than 0.01C;

[0049] 9) Charge and discharge cycle 3 times with 0.1C constant curren...

Embodiment 3

[0052] 1) Laminate the positive electrode, diaphragm, and negative electrode to form a battery cell, place it in the battery case, inject liquid, and let it stand for 2 hours. In the electrolyte, dimethyl sulfoxide (DMSO) is 1% by volume, trifluoroethylphosphine Acid (TTFP) is 1.8% by volume; Hexylbenzene (CHB) is 2.4% by volume;

[0053] 2) Pulse charging to 3.78V, pulse current 0.05C, pulse time 40s, interval 3s;

[0054] 3) Charge with a constant voltage of 3.78V until the charging current is less than 0.01C;

[0055] 4) Stand still for 1h;

[0056] 5) Adjust the battery temperature to 45°C, and charge again at a constant voltage of 3.78V until the charging current is less than 0.01C;

[0057] 6) Aging at 45°C for 3 hours;

[0058] 7) adjust to room temperature;

[0059] 8) 0.1C constant current charging to 4.2V, and then 4.2V constant voltage charging until the charging current is less than 0.01C;

[0060] 9) Charge and discharge cycle 3 times with 0.1C constant curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com