Method for selectively leaching voluble metal in copper refinery cinder

A technology for copper refining slag and valuable metals, which is applied in the fields of environmental protection and non-ferrous metallurgy, can solve the problems of incomplete leaching and poor filtration performance, and achieve the effects of good filtration performance, low cost and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

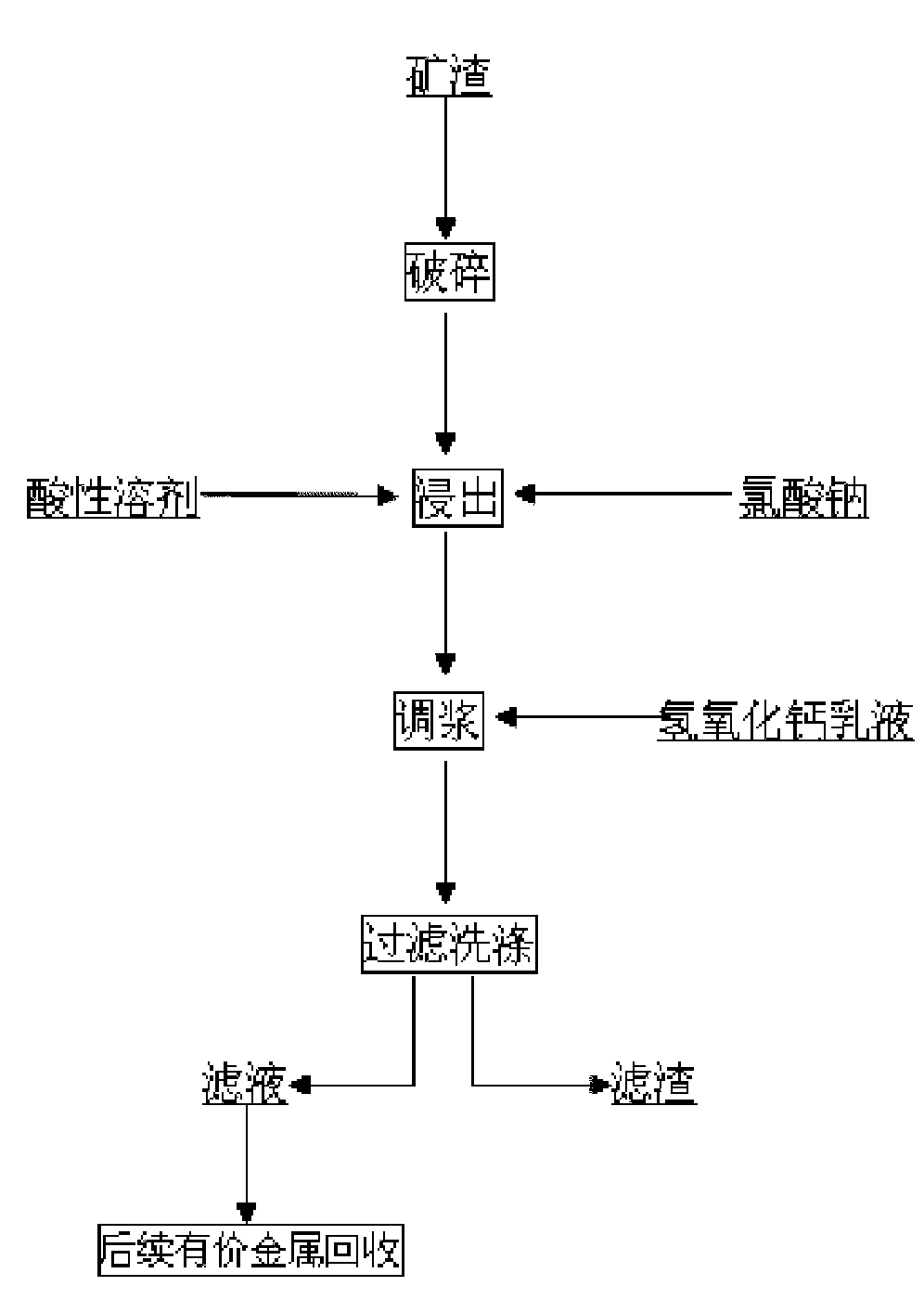

Method used

Image

Examples

Embodiment 1

[0025] Slag I from African copper smelting contains 1.6% Cu, 1.2% Co, 6.7% Zn, 21% Fe, and 18% Si. Phase analysis shows that the slag metal is distributed in the form of ferrite and silicate. Grind the slag through a 100-mesh sieve, add 7kg of sodium chlorate per 100kg of slag, use 0.7mol / L sulfuric acid, control the liquid-solid ratio to 10:1, mechanically stir, the reaction temperature is 75°C, and the leaching reaction time is 3 hours. Calcium emulsion sizing, sizing time 3 hours, control end point pH 2.1, aging at 95°C for 0.5 hours, filtration, hot water washing, good filtration performance, copper, cobalt, zinc leaching rates were 90.1%, 98.2%, 98.1% %, the silicon and iron leaching rates are lower than 3.5%, 0.02%, and the slag yield is 216.4kg / 100kg slag.

Embodiment 2

[0027] The slag from African copper smelting II contains 15.4% Si, 28.4% Fe, 4.0% Co, 1.4% Cu, 1.7% Zn, Al3.22%, 0.05% Ni, the phase analysis of the slag metal is silicate, ferrite form exists. Grind the ore through an 80-mesh sieve, add 10kg of sodium chlorate per 100kg of slag, use 0.5mol / L sulfuric acid, liquid-solid ratio 15:1, mechanically stir, reaction temperature 95°C, leaching reaction time 2 hours, use calcium hydroxide Emulsion sizing, sizing time 2.5 hours, control end point pH value 1.9, aging at 95°C for 0.5 hours, filtration, hot water washing, good filtration performance, copper, cobalt, zinc leaching rates were 89.3%, 98.1%, 98.0% , The leaching rate of aluminum, silicon, and iron is lower than 31%, 3.3%, and 0.1%. The amount of slag produced is 186.3kg / 100kg slag.

[0028]It can be seen from the above examples that the method of adding sodium chlorate sulfuric acid system for leaching-calcium hydroxide emulsion and slurry adjustment can effectively leach val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com