Negative electrode for lithium secondary battery, method for producing same, and lithium secondary battery comprising such negative electrode for lithium secondary battery

A lithium secondary battery and manufacturing method technology, applied in the direction of electrode manufacturing, secondary batteries, battery electrodes, etc., can solve the problems of lithium detachment, irreversible capacity increase, etc., achieve the suppression of decomposition reaction, excellent charge and discharge cycle characteristics, high Effect of charge and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] 1. Fabrication of negative electrode active material layer

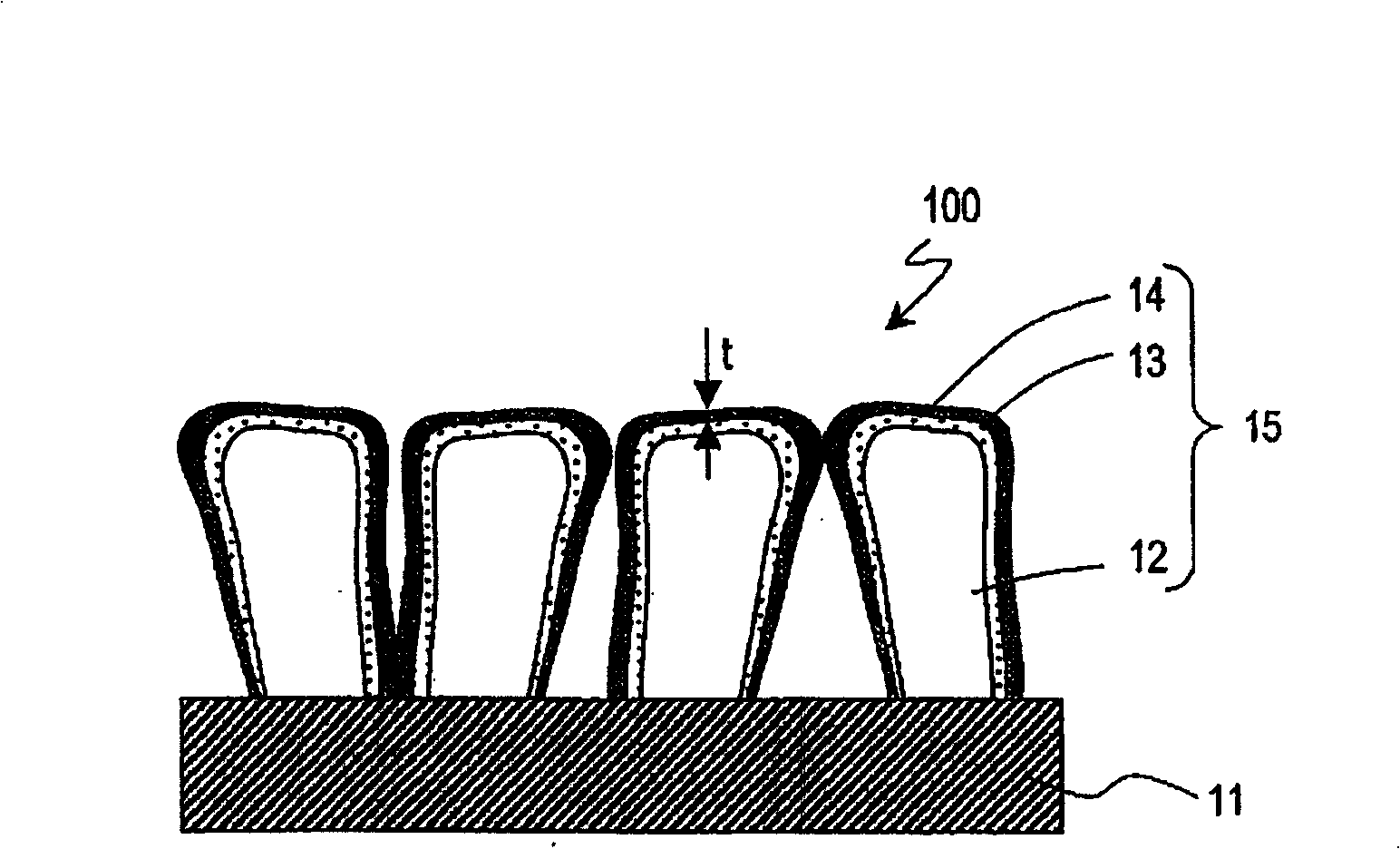

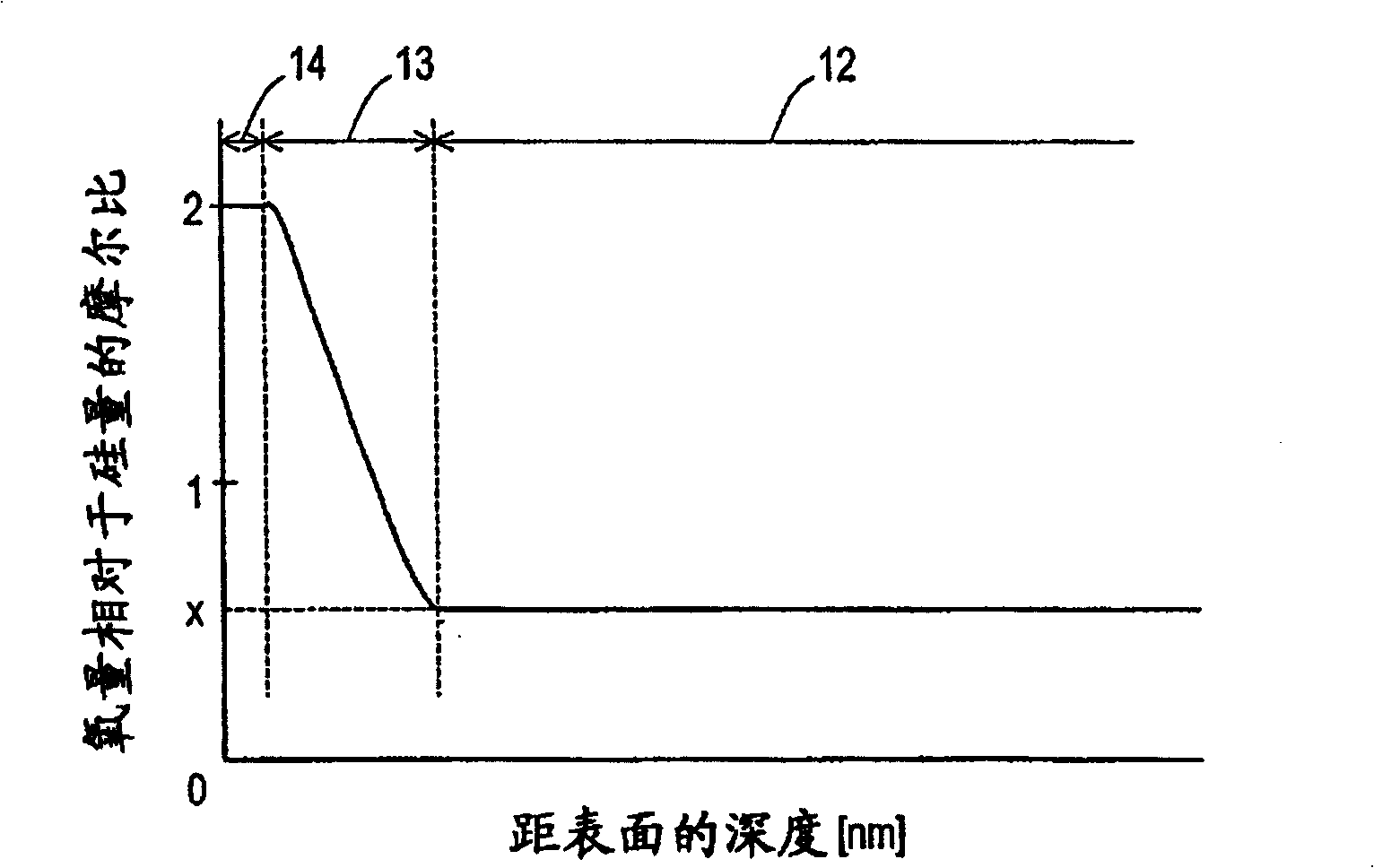

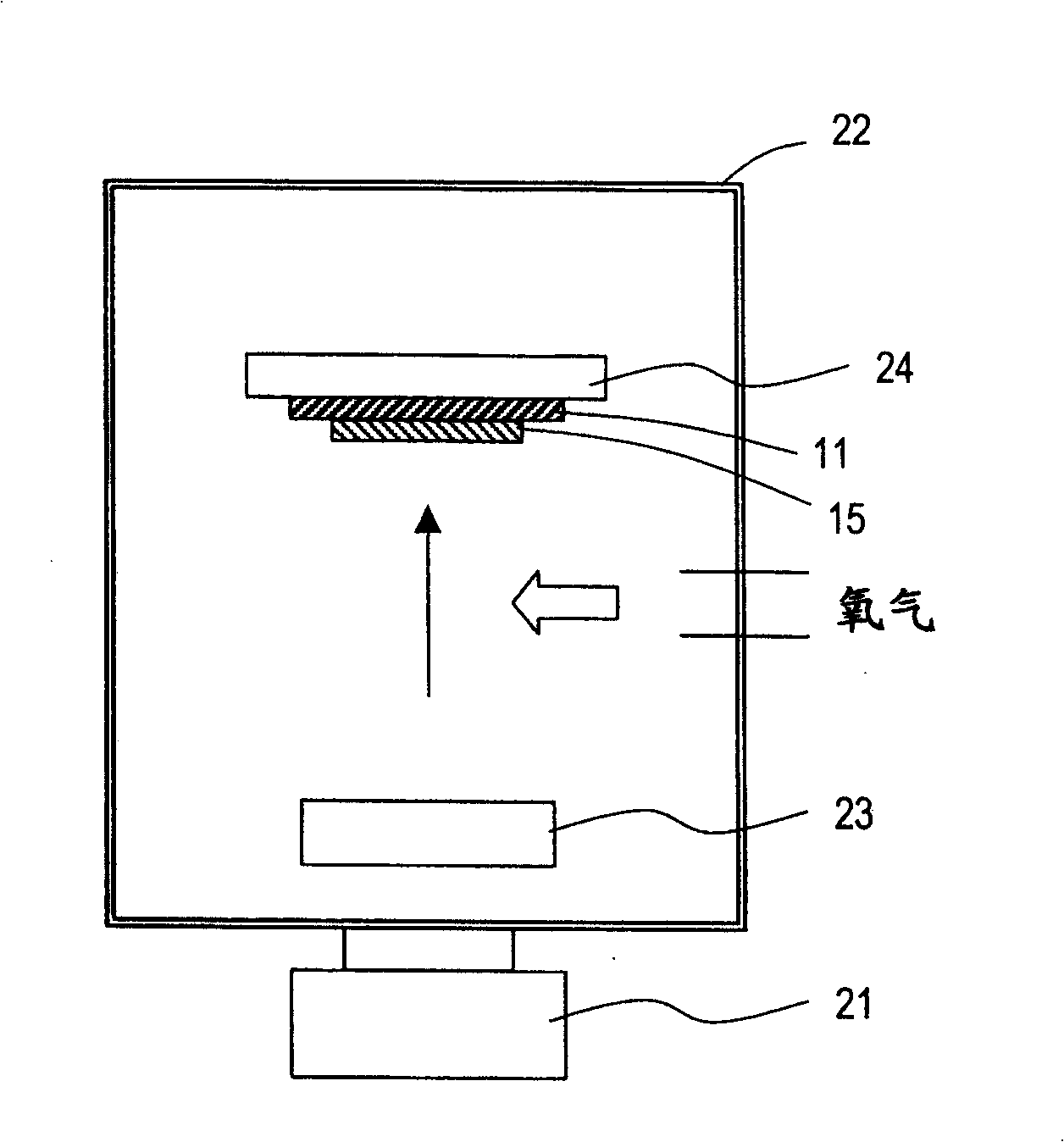

[0125] First, use the image 3 In the manufacturing apparatus of the structure shown, the negative electrode active material layer was formed on the surface of a current collector. The production method will be specifically described.

[0126] Add silicon flakes (more than 99.99% of purity) in advance in the carbon crucible 33 that is arranged in the vacuum chamber 22, after the pressure in the vacuum chamber 22 is set at 0.005Pa, introduce oxygen with the flow rate of 70 sccm, vacuum chamber 22 The pressure inside is set at 0.13Pa.

[0127] Then, electron beams were irradiated from an electron gun to the above-mentioned silicon wafer under the conditions of a voltage of −9 kV and an EB current of 400 mA to melt silicon and vapor-deposit it on the current collector 11 facing the carbon crucible 23 . A copper foil having a thickness of 50 μm was used as the current collector 11 . This vapor deposition was c...

Embodiment 2

[0145] When the film thickness (thickness of the negative electrode active material body) reaches 10 μm, the oxygen flow rate is increased from 70 sccm to 90 sccm, except that, the negative electrode active material layer and the coin-type battery of Example 2 were produced in the same manner as in Example 1. . Next, the measurement of the oxygen concentration of the negative electrode active material layer and the evaluation of the charge-discharge characteristics of the coin-shaped battery were performed by the same method as in Example 1, and the results thereof will be described.

[0146] For the negative electrode active material body (SiO2) in the negative electrode active material layer of embodiment 2 x ) as a result of fluorescent X-ray analysis, the x value was 0.59.

[0147] In addition, X-ray photoelectron spectroscopy will be used to measure Si in the depth direction of the negative electrode active material layer of Example 2. 2P The binding energy results are ...

Embodiment 3

[0176] 1. Fabrication of negative electrode active material layer

[0177] In this example, a negative electrode active material layer was produced using a vapor deposition apparatus (manufactured by ULYAC Co., Ltd.). First, refer to Figure 16 The configuration of the vapor deposition apparatus used in this example will be described.

[0178]The vapor deposition device 50 includes a chamber 56 and an exhaust pump (not shown) for exhausting the chamber 56 . Inside the chamber 56 are provided with: a fixing table 54 for fixing the current collector 51, a pipe 53 for introducing oxygen into the chamber 56, a nozzle 52 for injecting oxygen connected to the pipe 53, and a nozzle 52 for injecting oxygen into the chamber 56. The surface of the electrode 51 is supplied with an evaporation source 55 of silicon. In addition, although not shown, an electron beam heating unit for evaporating the material of the evaporation source 55 is also provided. The pipe 53 is connected to an ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com