Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Increase vulcanization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

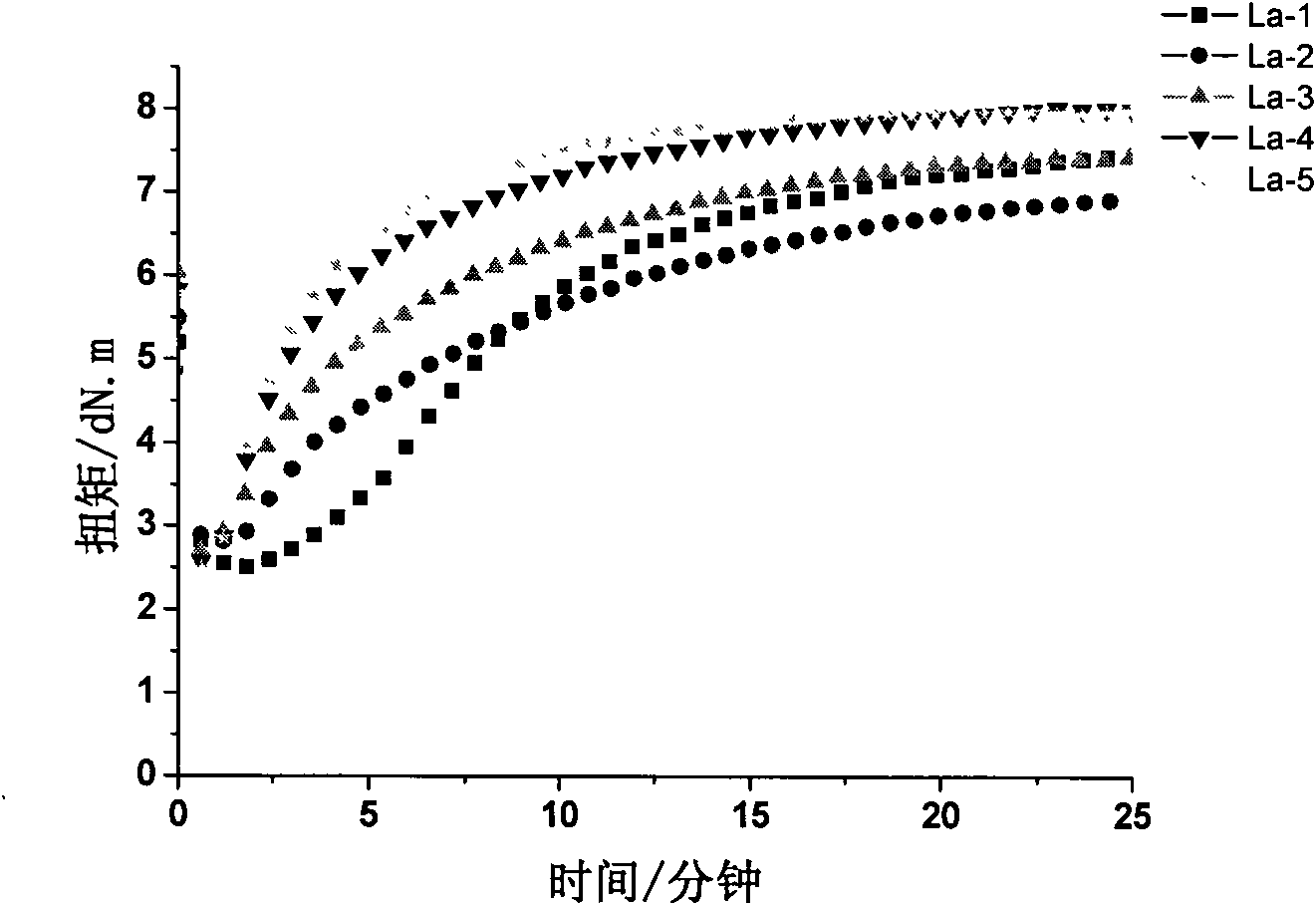

Rare earth rubber vulcanization accelerator, and preparation method and application thereof

ActiveCN101962452ASignificant vulcanization acceleration effectAccelerated vulcanization acceleration effectOrganic chemistryRare-earth elementVulcanization

The invention discloses a rare earth rubber vulcanization accelerator, and a preparation method and application thereof. The accelerator is prepared by compounding rare earth ions and carboxylic acid substituted dithiocarbamate, wherein the rare earth ions may be one or the mixture of more than one of 14 rare earth elements, except promethium which is a radioactive element, with the atomic numbers of 57 to 71 in the periodic table of elements. The rare earth vulcanization accelerator of the invention is added into a rubber formula without adding the vulcanization active agents of stearic acid and zinc oxide to achieve good vulcanization effect and prepare a rubber composite material with high comprehensive mechanical properties which are remarkably superior to those of the accelerator zinc diethyl dithiocarbamate (ZDC) commonly used in industry at present in the same proportion, is a carbamate rare earth compound of primary amine, does not produce nitrite in a vulcanization process, and is environmentally-friendly.

Owner:SOUTH CHINA UNIV OF TECH

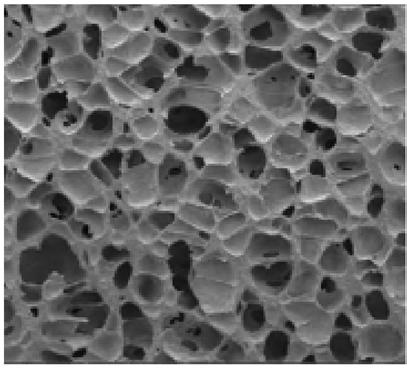

Porcelainized fireproof and heat insulation foamed silicone rubber and preparation method thereof

The invention discloses porcelainized fireproof and heat insulation foamed silicone rubber and a preparation method thereof. The rubber comprises the following raw materials in parts by weight: 100 parts of base rubber, 10 to 60 parts of porcelain forming filler, 0.1 to 0.5 part of a platinum catalyst, 0.5 to 1.5 parts of silicone oil, 2 to 10 parts of a foaming agent, 0.1 to 0.5 part of a vulcanizing agent, and 0.1 to 0.4 part of a vulcanization accelerator. The foamed silicone rubber has good ceramic effect, does not have surface cracks, is hard in texture, keeps a complete foam structure, ensures that the volume retention rate is 85% or higher, and is excellent in fireproof performance.

Owner:WUHU YANGZHAN NEW MATERIAL TECH SERVICE CO LTD

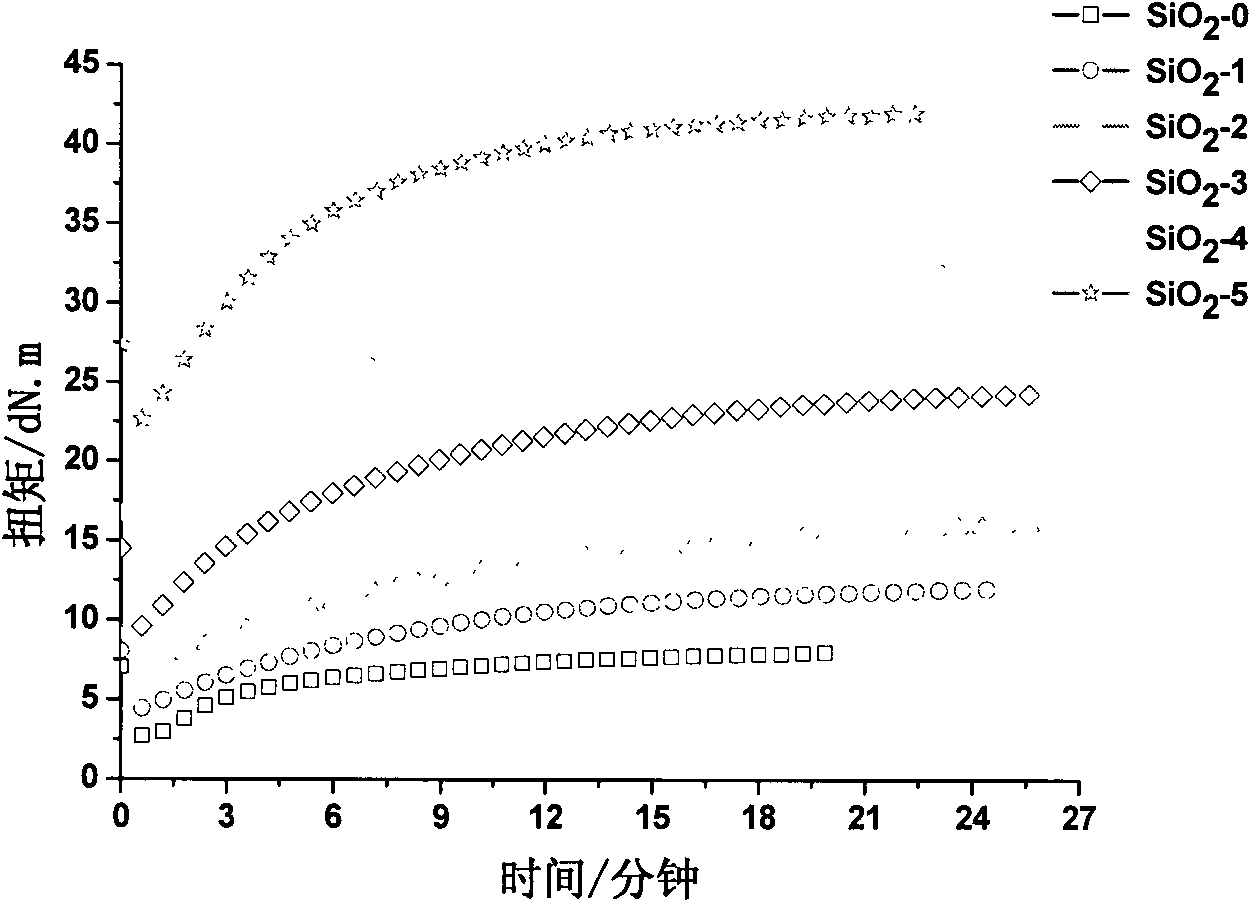

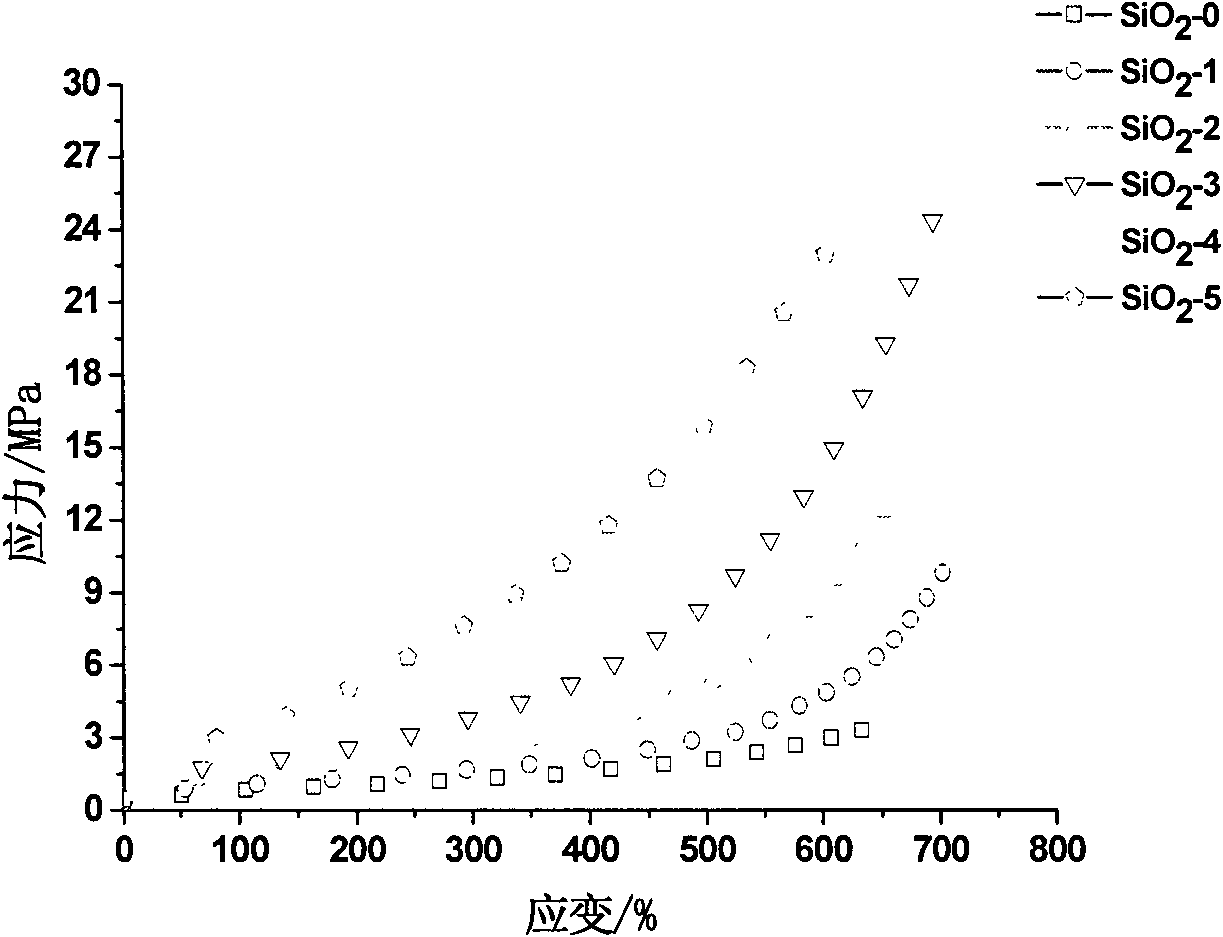

Low hydroxyl content white carbon black and preparation method thereof

The invention relates to a low hydroxyl content white carbon black and a preparation method of the low hydroxyl content white carbon black. The preparation method comprises the following steps: 1) preparing a reaction base solution with the pH of 7.0-10.5 at the temperature of 65-99 DEG C; 2) adding concentrated sulfuric acid and a sodium silicate solution to conduct a precipitation reaction, wherein the temperature of the precipitation reaction and the temperature of the reaction base solution are the same, keeping the pH of a system to 7.0-10.5 constant; 3) regulating the pH and post-processing to obtain the white carbon black. The white carbon black is low in hydroxyl content, the density of hydroxyl is less than 3 / nm<2>, the white carbon black is excellent in dispersity, the white carbon black is taken as a reinforcing agent to prepare a rubber, the excellent reinforcing effect is shown, the vulcanizing rate is increased, the vulcanizing time of the rubber material is shortened, and the processing performances and the mechanical property of a rubber compound are improved.

Owner:WUXI HENGCHENG SILICON IND CO LTD

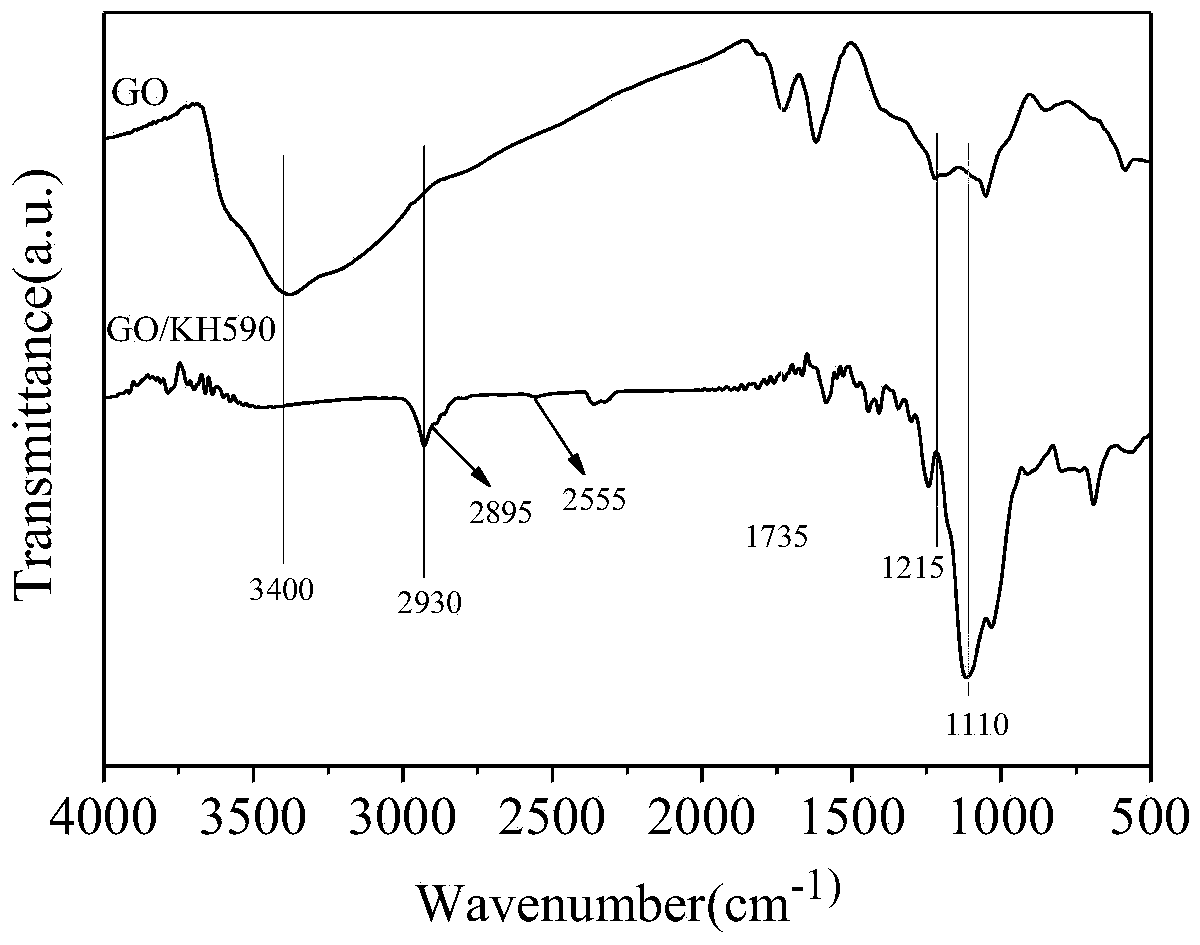

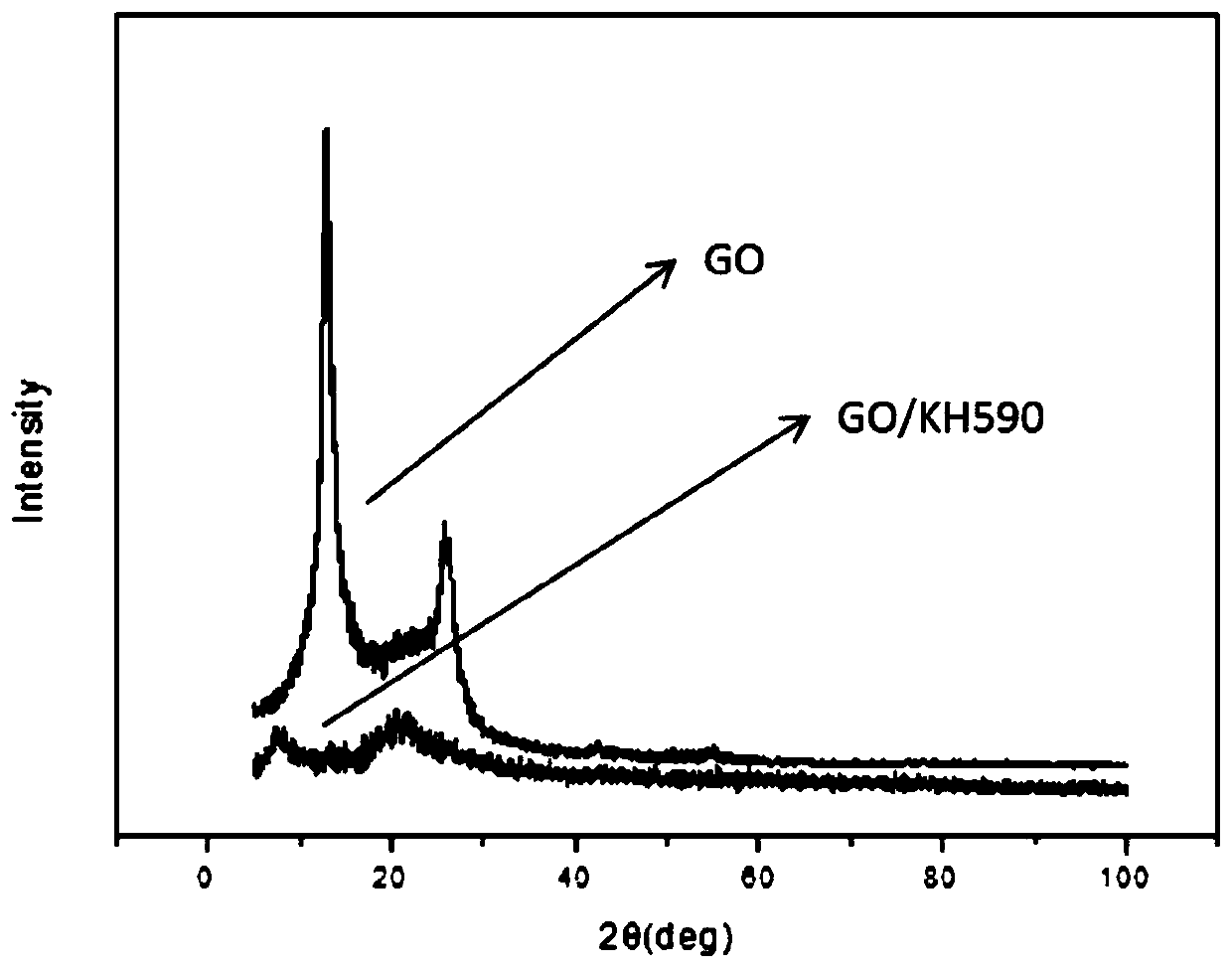

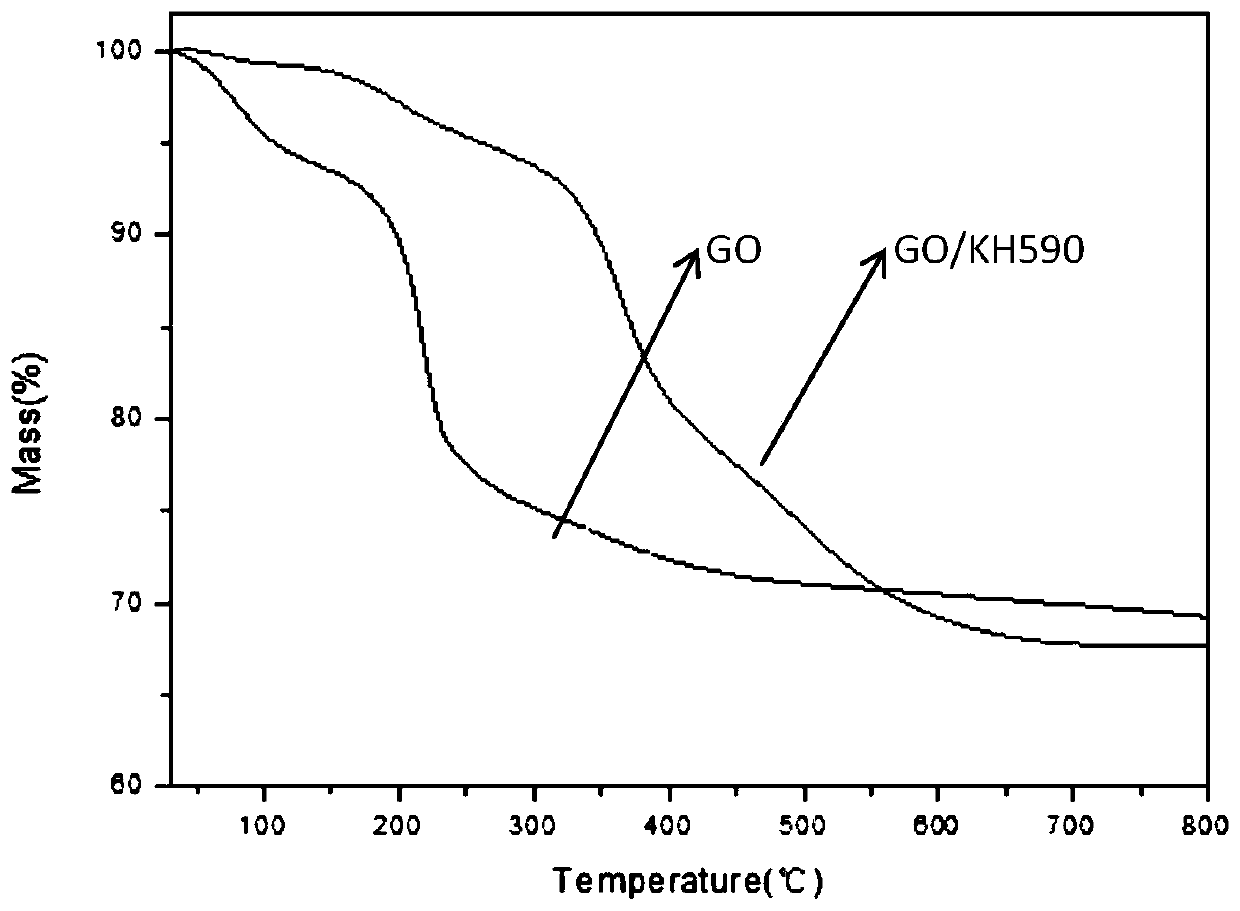

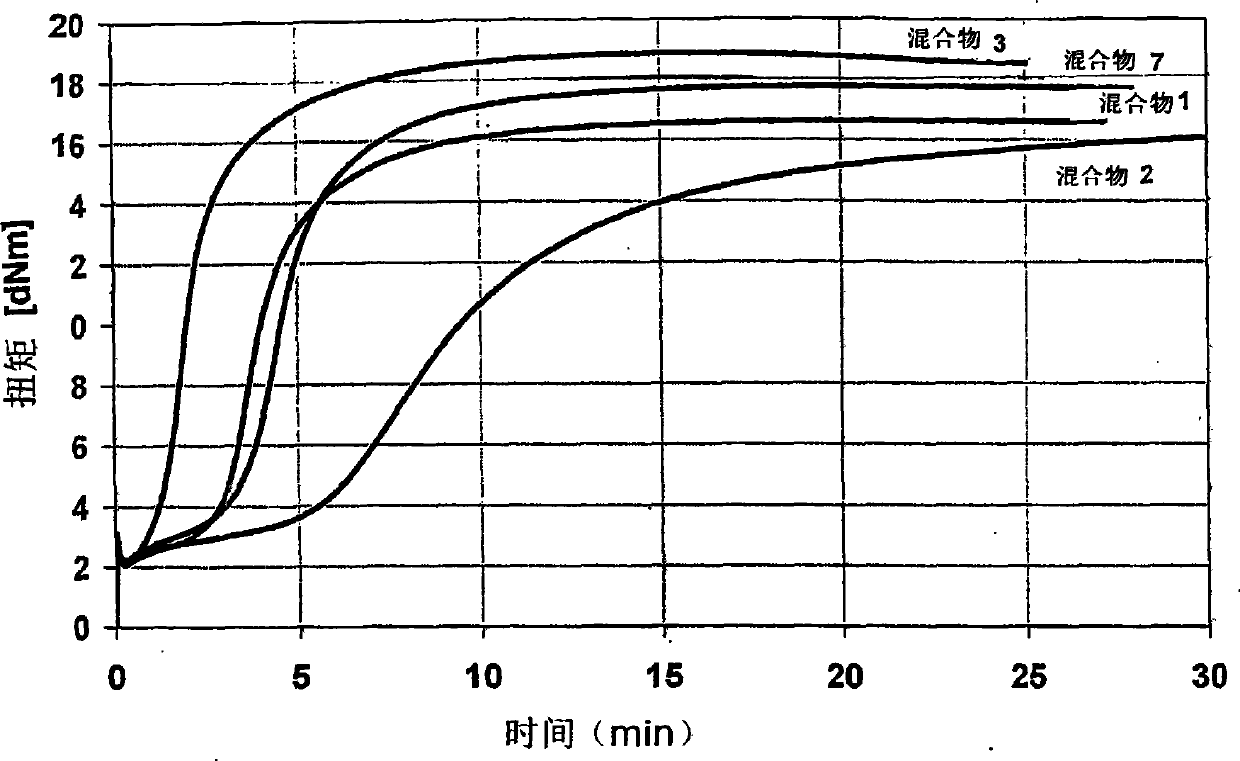

Graphene modified nitrile rubber and preparation method thereof

ActiveCN110343299ASolve the problem of poor high and low temperature resistanceImprove mechanical propertiesNitrile rubberPolymer science

The invention belongs to the technical field of graphene rubber composite materials, and provides a graphene modified nitrile rubber and a preparation method thereof. The graphene modified nitrile rubber is prepared from the following components in parts by weight: 70-90 parts of a nitrile rubber, 10-30 parts of a modified graphene oxide-carboxyl nitrile rubber master batch, 1.5-2 parts of a vulcanizing agent, 0.5-2.0 parts of a vulcanizing accelerator, 3-5 parts of a vulcanizing activator, 1-3 parts of a plasticizer, 1-2 parts of an antioxidant and 20-30 parts of fillers; and the modified graphene oxide-carboxyl nitrile rubber master batch is prepared from the modified graphene oxide and further prepared from carboxyl nitrile rubber latex, wherein mercapto-siloxane after hydrolysis reactswith the graphene oxide by being subjected to dehydration synthesis, and the modified graphene oxide is obtained. Through the technical scheme, the problem of poor high and low temperature resistanceof the nitrile rubber in the prior art is solved.

Owner:石家庄贝克密封科技股份有限公司 +1

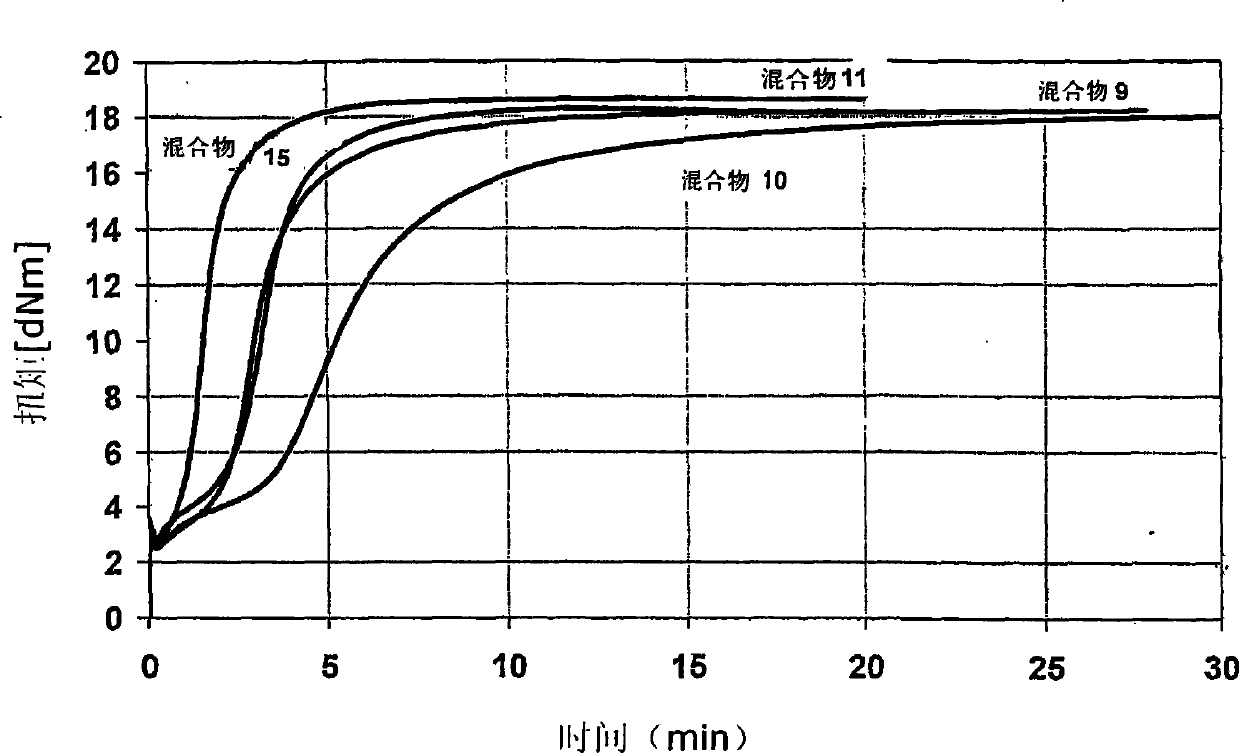

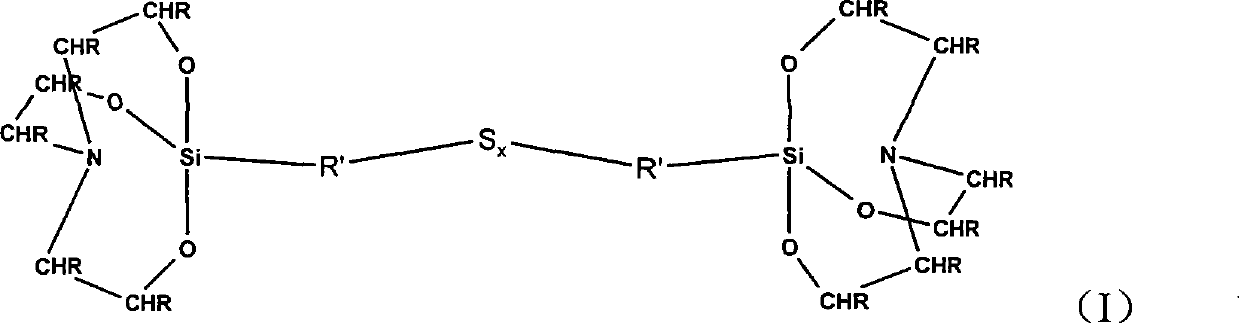

Rubber mixtures

InactiveCN101374899ALess quantityLow processing hazardGroup 4/14 element organic compoundsPolymer scienceTransesterification

The invention relates to rubber mixtures, comprising at least one rubber, a filler, an organosilicon compound of the formula I one rubber accelerator and one co-accelerator. The rubber mixtures are prepared by mixing at least one rubber, a filler, an organosilicon compound of the general formula I, one rubber accelerator and one co-accelerator. The rubber mixtures can be used for production of mouldings . The invention further relates to a process for preparation of the organosilicon compound of the formula I via transesterification.

Owner:EVONIK DEGUSSA GMBH

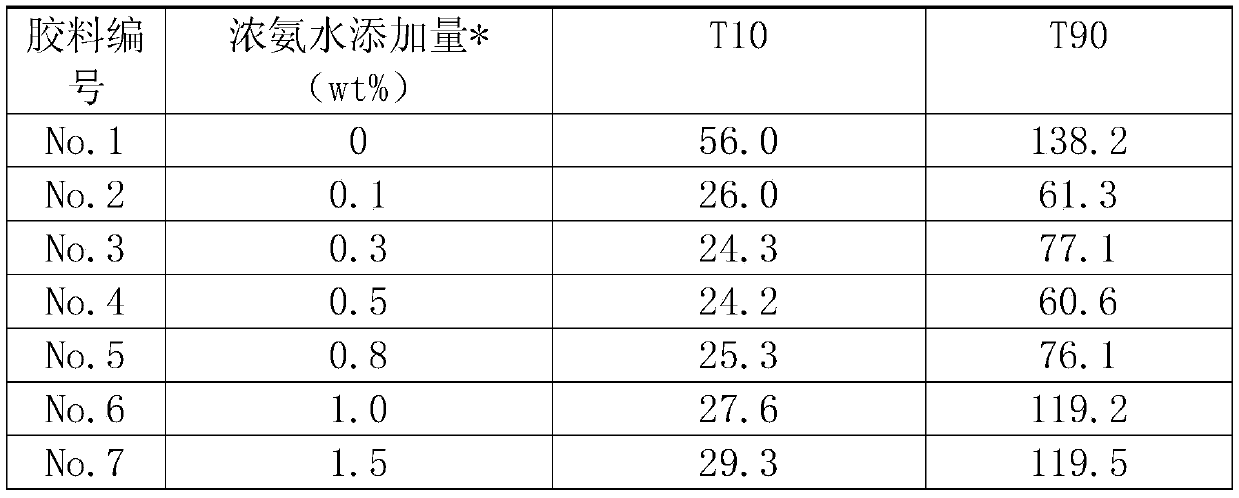

Vulcanization method of addition silicone rubber

ActiveCN109929127AImprove vulcanization characteristicsIncrease vulcanization rateCross-linkVulcanization

The invention discloses a vulcanization method of addition silicone rubber. Ammonia is a common well-supplied and low-cost inorganic compound, and ammonia gas is introduced into water to obtain ammonia water. Some carbon dioxide is introduced into the ammonia water to obtain carbonized ammonia water. The addition type silicone rubber is synthetic rubber which is vulcanized by hydrosilylation reaction to form a cross-linked network. According to the method, the ammonia, the ammonia water, the carbonized ammonia water or liquid ammonia is added into the addition silicone rubber to change the vulcanization characteristic of the addition silicone rubber, the vulcanization rate of the addition silicone rubber is increased by the method, the vulcanization temperature is reduced, the vulcanization time is shortened, the production efficiency is improved, and meanwhile, the method facilitates hot vulcanization compound molding of silicon rubber and low softening point materials (such as thermoplastic ABS, PMMA, PC / ABS and PC).

Owner:NANTONG MEMTECH TECH +1

High-performance modified styrene butadiene rubber composition

The present invention discloses a high performance modified styrene butadiene rubber composition. The high performance modified styrene butadiene rubber composition is prepared from the following raw materials: styrene butadiene rubber, epoxidized natural rubber, a carbon nano-tube, modified montmorillonite, nano aluminium nitride, precipitation-method white carbon black, modified boehmite, nano aluminium hydroxide, nano magnesium hydroxide, stearic acid, sulfur, zinc oxide, organic silicon peroxide, polyvinyl alcohol, diphenyl phosphate, lanthanum stearate, an anti-aging agent RD, an anti-aging agent NBC, an anti-aging agent 4010NA, diethyl dithiocarbamate zinc, dithiocarbamate cerium formate glutamate, an accelerant DM and triethyl citrate. wherein a modifier of the modified boehmite is a mixture comprising one or more of methacrylic acid, itaconic acid, sorbic acid, maleic acid, arachidonic acid and linoleic acid. The high-performance modified styrene butadiene rubber composition provided by the present invention has high strength, good abrasion resistance, and excellent heat resistance and weather resistance.

Owner:合肥市再德高分子材料有限公司

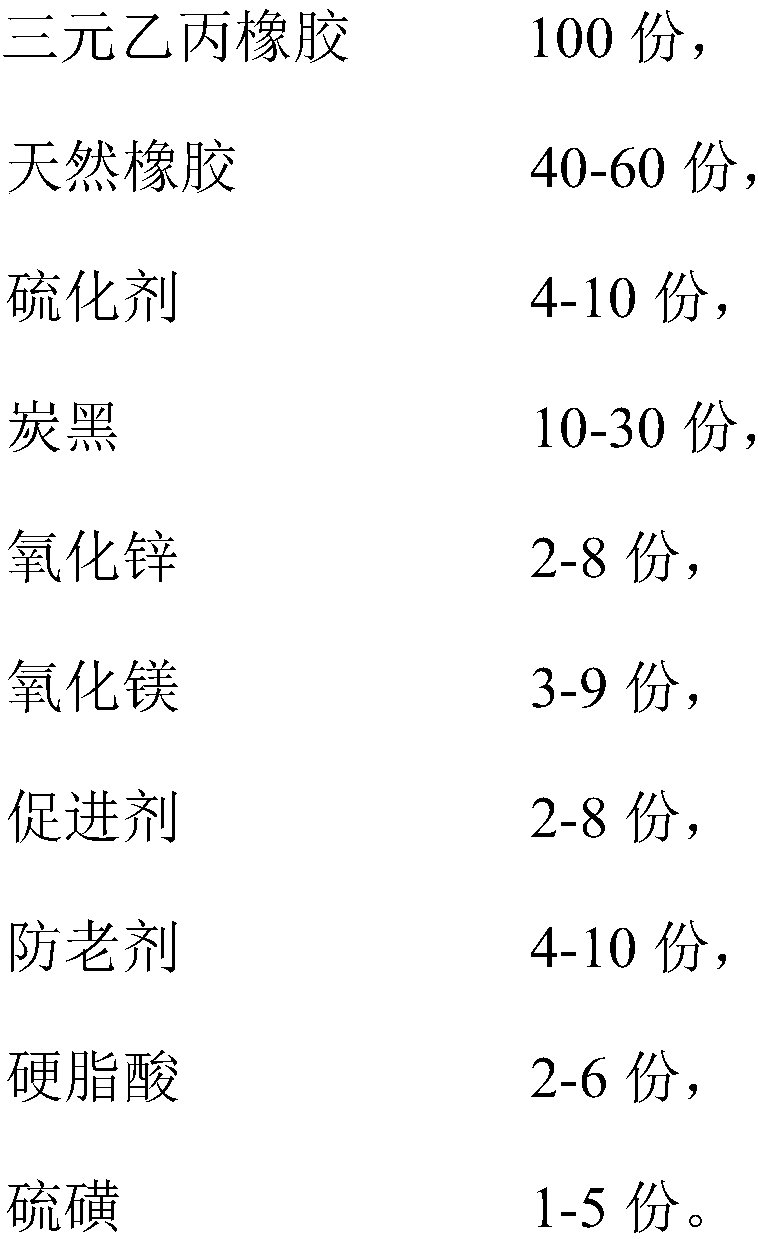

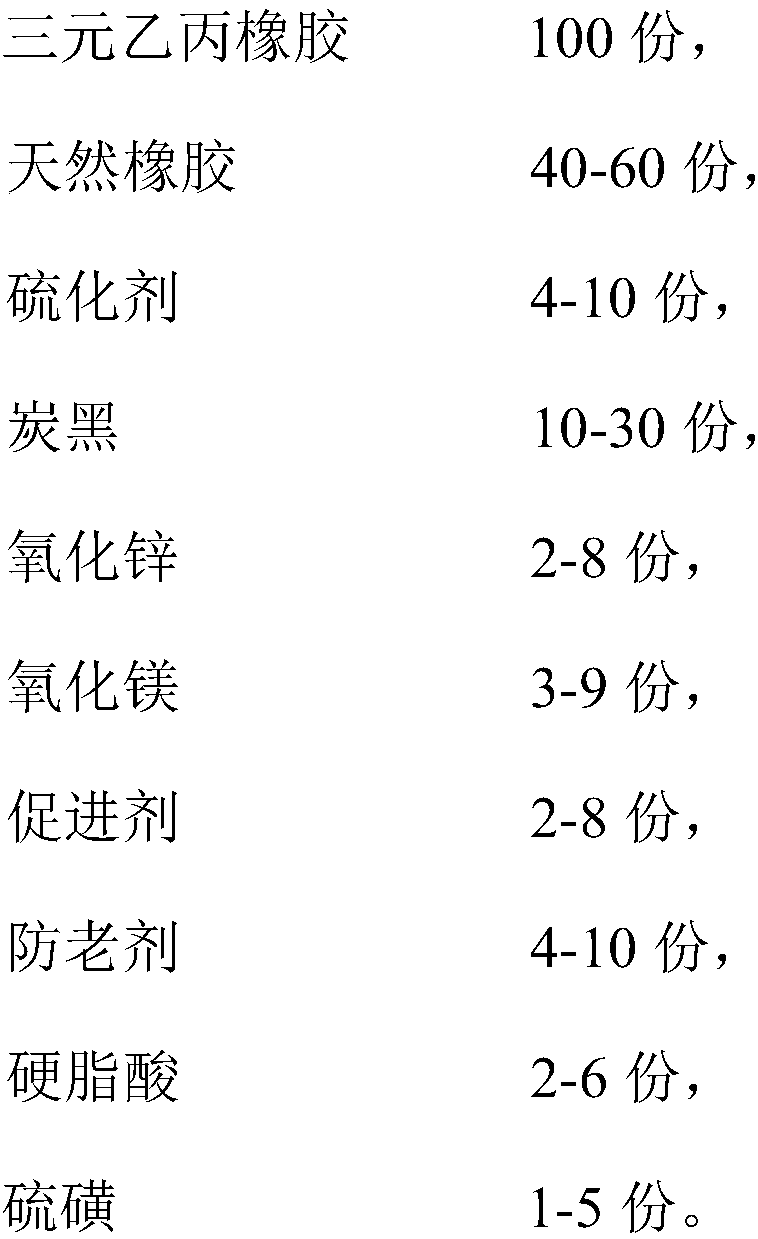

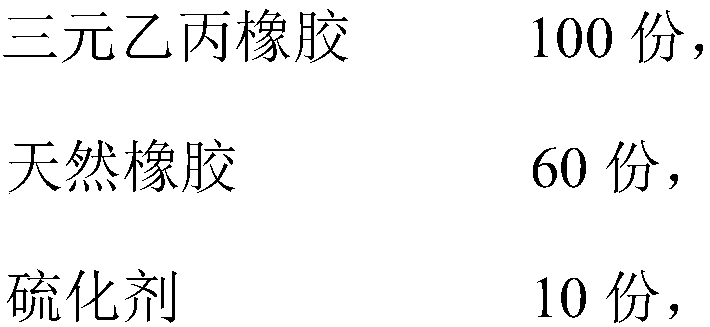

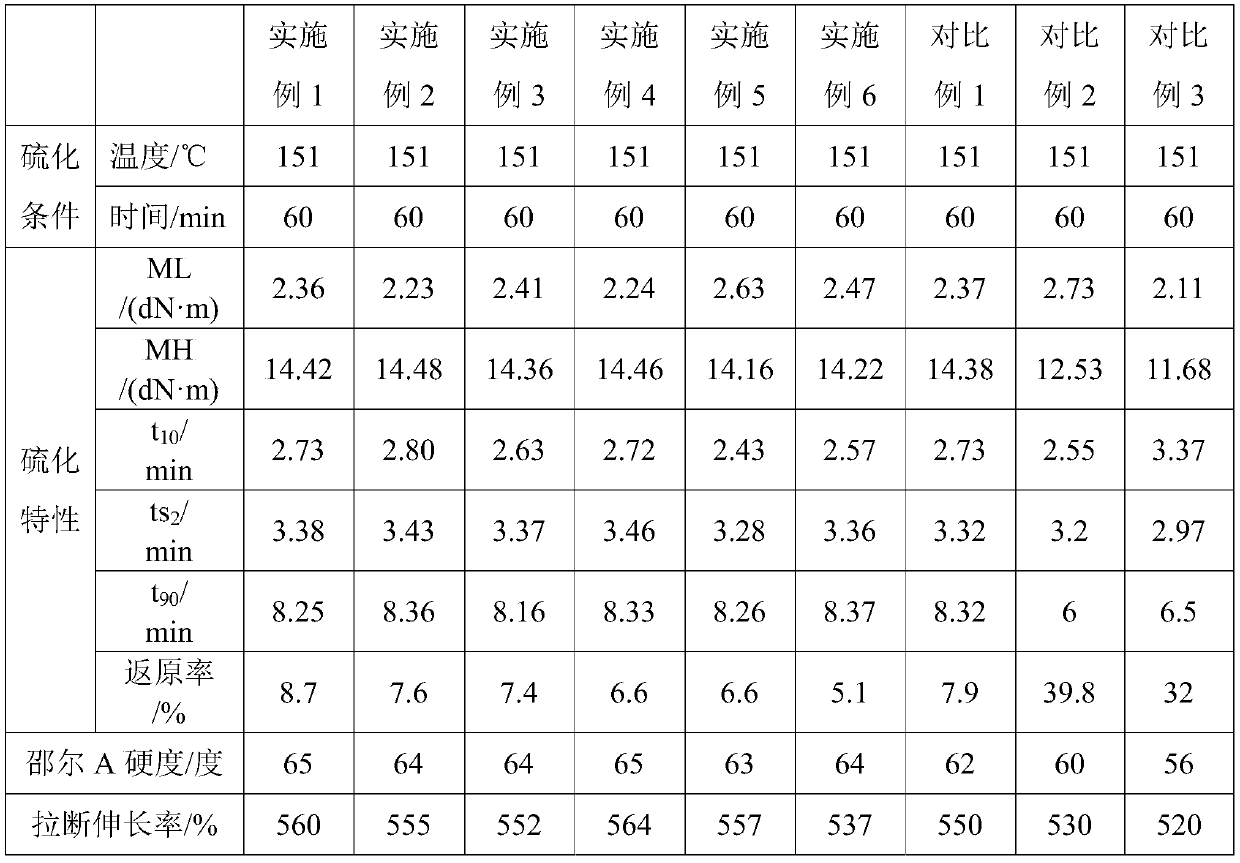

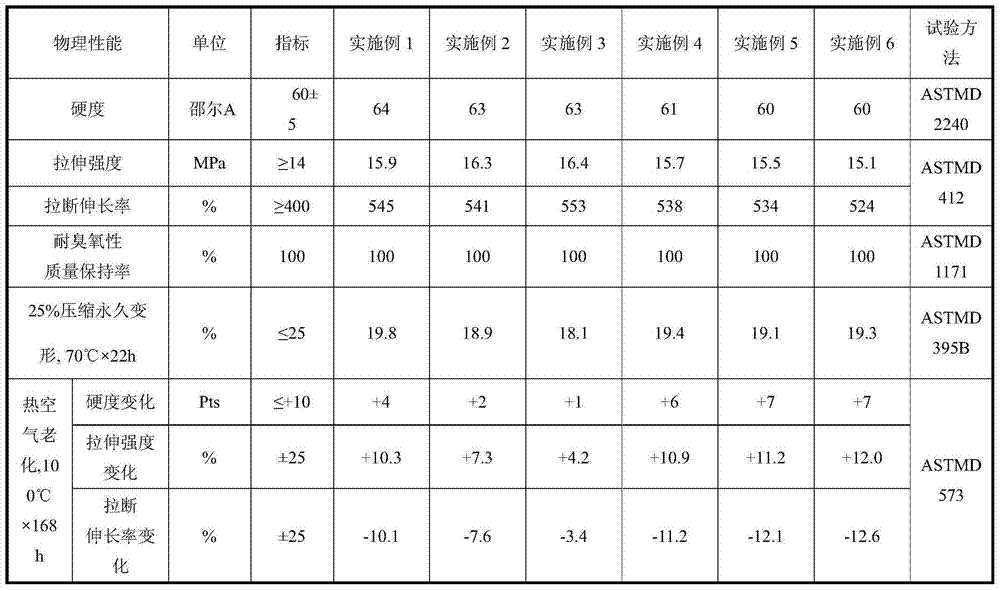

EPDM/ natural rubber combined ageing-resistant rubber and preparation method thereof

InactiveCN108841090AExcellent compression recovery performanceReduce surface tensionBulk chemical productionVulcanizationPolymer science

The invention discloses an EPDM / natural rubber combined ageing-resistant rubber and a preparation method thereof. The method comprises the following steps: (1) preparing EPDM masterbatch; (2) preparing natural masterbatch; (3) mixing EPDM / natural rubber; and (4) vulcanizing the rubber compound and a vulcanizing agent for 20-60min in a vulcanizing machine in order to form to obtain the ageing-resistant rubber. According to the method, a supercritical carbon dioxide technology is carried out, the PEDM / natural rubber mixed rubber is subjected to supercritical treatment before vulcanizing, so that the compatibility and the co-vulcanization performance of the two-phase rubbers can be extremely improved, and the vulcanizing rate of the rubber compound is effectively increased; and the obtained rubber realizes the effective combination of the outstanding performances of the EPDM / natural rubber; the prepared rubber is outstanding in ageing resistance and mechanical performance and meets the performance demand of various special environments to a sealing material.

Owner:NINGGUO ZHENGDAO RUBBER & PLASTIC PARTS

Preparation method of antisepsis and anti-inflammation lubrication-type condom containing natural cinnamyl aldehyde

InactiveCN103213226AEliminate odorAntibacterialMale contraceptivesCoatingsPolymer sciencePolymer chemistry

The invention relates to a preparation method of an antisepsis and anti-inflammation lubrication-type condom containing natural cinnamyl aldehyde. The preparation method of the antisepsis and anti-inflammation lubrication-type condom containing natural cinnamyl aldehyde particularly comprises the following steps of: coating cinnamyl aldehyde directly on a natural emulsion condom or butyronitrile emulsion condom finished product, or adding and dispersing a certain amount of cinnamyl aldehyde together with other conventional burdening uniformly into the natural emulsion or butyronitrile emulsion in raw material prevulcanization process of the natural emulsion condom or the butyronitrile emulsion condom; then steeping and forming a natural emulsion glove condom or a butyronitrile emulsion condom which comprises natural cinnamyl aldehyde by a conventional forming technology; and then performing edge curling, chloridizing, foam-washing, rinsing and drying, thereby obtaining a finished product. The condom prepared by the method has the function of antisepsis and anti-inflammation, lubricating and skin protection; and meanwhile cinnamyl aldehyde can emit fragrant flavor, and can eliminate peculiar smell secreted by human bodies, is simple in technology, is low in cost, also saves resources, and improves the production efficiency.

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

Environment-friendly rubber vulcanizing activator, and preparation method and application thereof

The invention discloses an environment-friendly rubber vulcanizing activator, and a preparation method and application thereof. The vulcanizing activator comprises, by mass, 1-6 parts of C2-C6 polyalcohol, 1-5 parts of C2-C6 fatty acid polyol ester, 2-5 parts of C8-C18 fatty acids and 1-4 parts of zinc oxide. The prepared vulcanizing activator is added to rubber instead of the zinc oxide, so thatthe crosslinking density and tensile strength of the vulcanized rubber are improved, the Mooney viscosity thereof is lowered, and the processing property and wear resistance thereof are improved; meanwhile, the zinc content is reduced by 50-62% as compared with that of a zinc oxide vulcanizing system.

Owner:SOUTH CHINA UNIV OF TECH

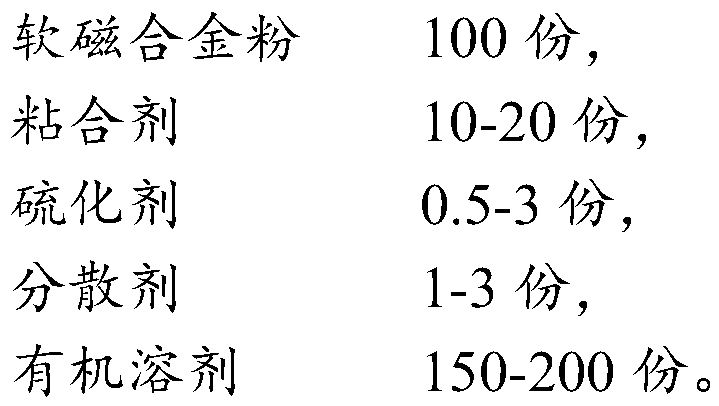

High-temperature-resistant high-permeability wave absorbing sheet and preparation method thereof

InactiveCN110669266AImprove permeabilityImprove high temperature resistanceLamination ancillary operationsLaminationPolymer scienceOrganic solvent

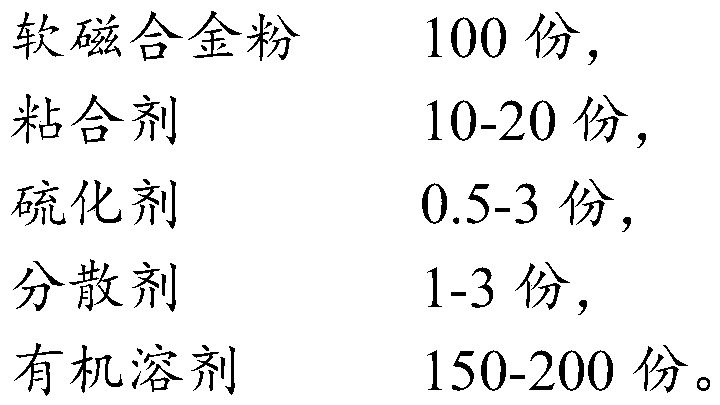

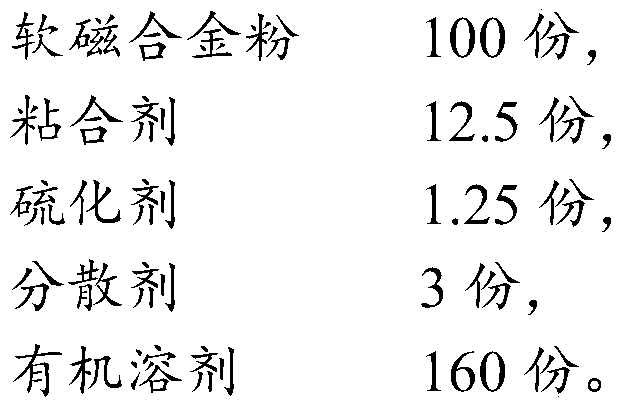

The invention discloses a high-temperature-resistant high-permeability wave absorbing sheet and a preparation method thereof. The wave absorbing sheet comprises, by weight, 100 parts of soft magneticalloy powder, 10-20 parts of an adhesive, 0.5-3 parts of a vulcanizing agent, 1-3 parts of a dispersant and 150-200 parts of an organic solvent. The wave absorbing sheet has high magnetic conductivityand high-temperature resistance, can be stably used for at 120 DEG C a long time, and has a longer service life than wave absorbing sheets which can only be used at 80 DEG C in the prior art.

Owner:江门江益磁材有限公司

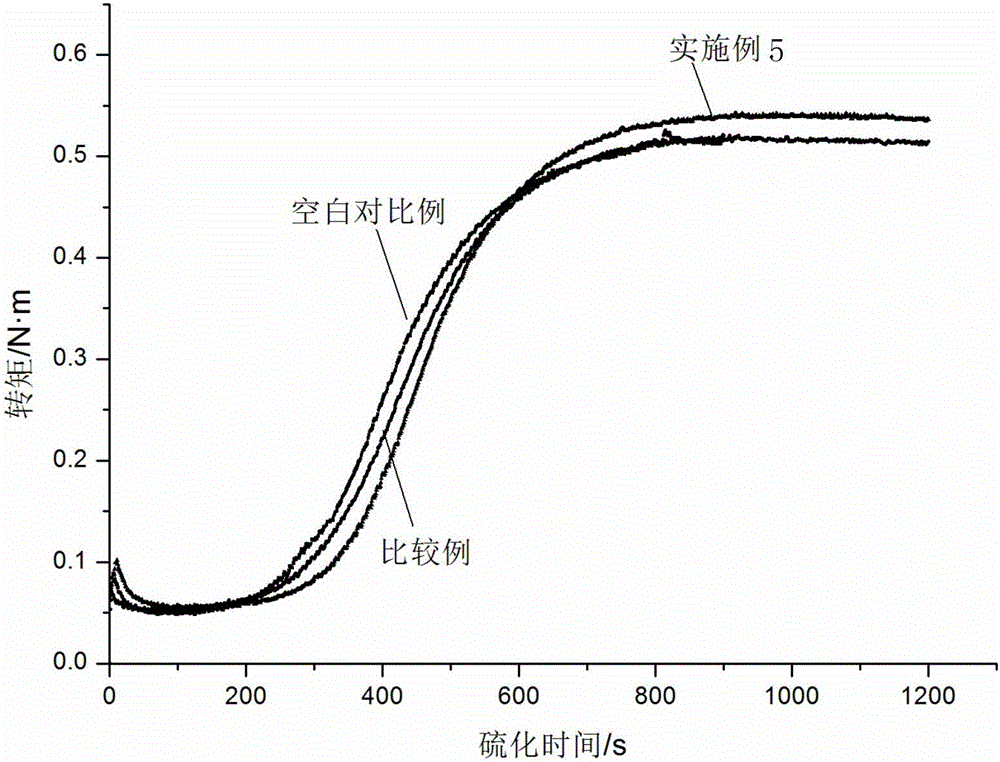

Ethylene-propylene-diene monomer and chloroprene rubber co-vulcanization material and preparation method therefor

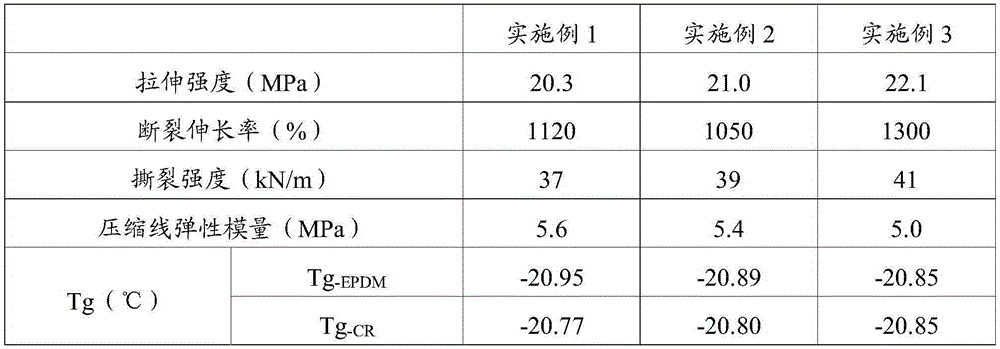

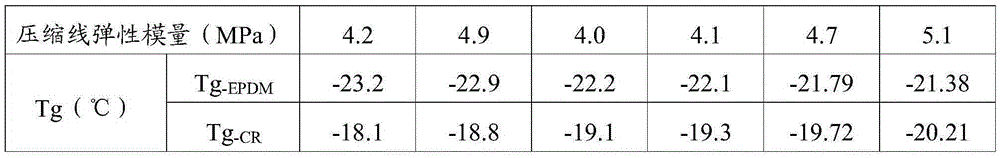

The invention provides an ethylene-propylene-diene monomer and chloroprene rubber co-vulcanization material and a preparation method therefor. The co-vulcanization material is prepared from a mixture through mixing and vulcanization in order. The mixture comprises, by weight, 65-100 parts of ethylene-propylene-diene monomer EPDM, x parts of chloroprene rubber, x being more than 0 and less than 40, 5-10 parts of zinc oxide, 3-4 parts of magnesium oxide, 4-6 parts of stearic acid, 10-30 parts of carbon black, 1-5 parts of silane coupling agent Si69, 1-10 parts of maleic anhydride, 1-5 parts of glycidyl methacrylate, 1-2 parts of sulphur and 4-8 parts of vulcanization accelerator. The silane coupling agent Si69, maleic anhydride and glycidyl methacrylate are employed to process EPDM, the combining capability of EPDM and sulphur is raised, the EPDM phase vulcanization rate is raised, therefore EPDM and chloroprene rubber co-vulcanization effects are improved, and thus EPDM / CR co-vulcanization rubber has excellent mechanical properties.

Owner:ZHONGBEI UNIV +1

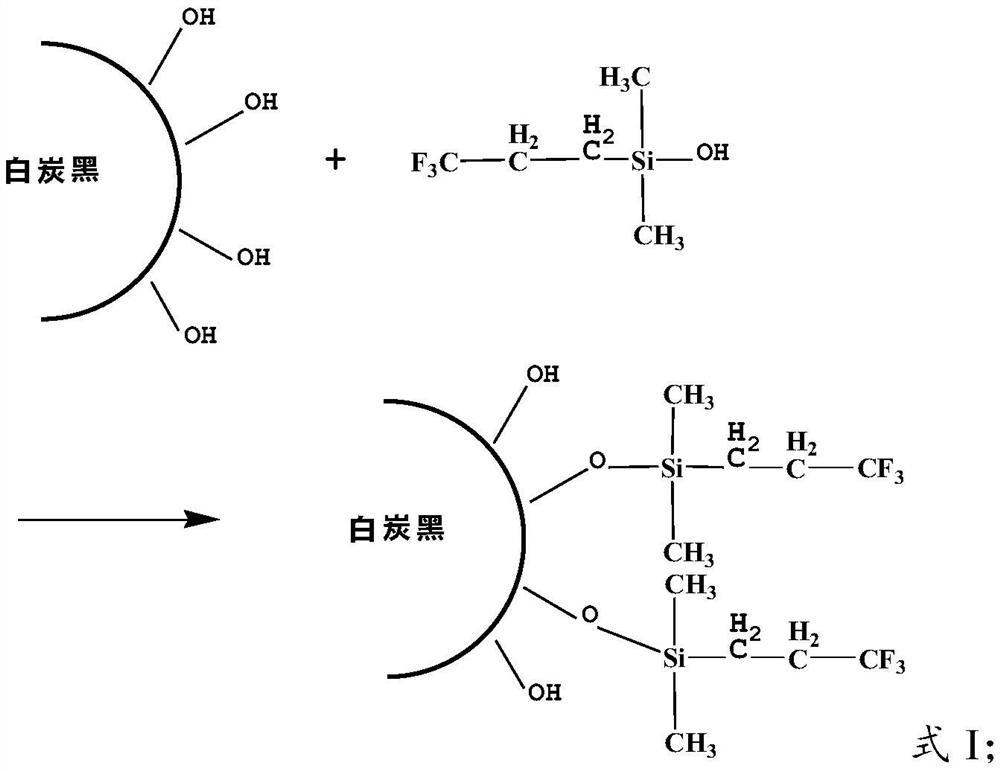

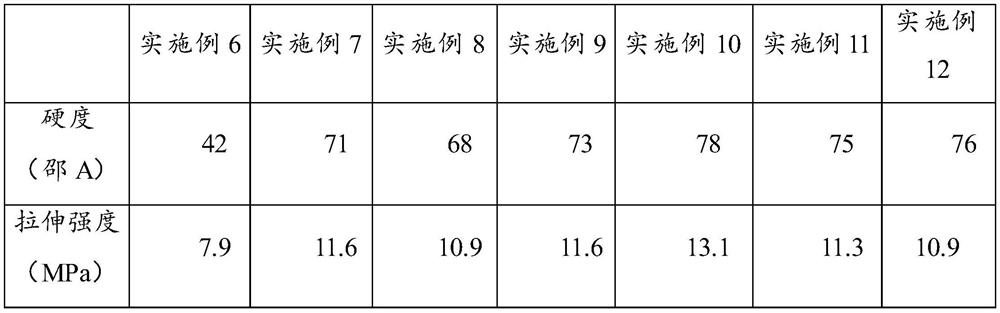

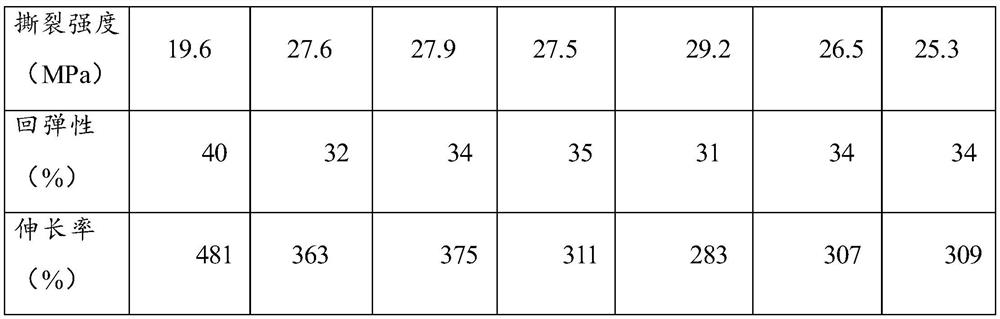

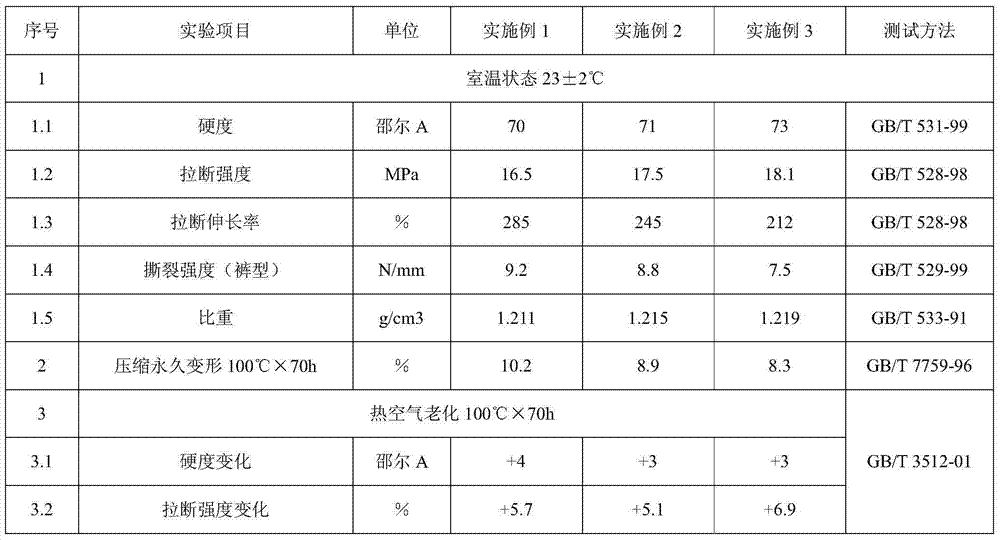

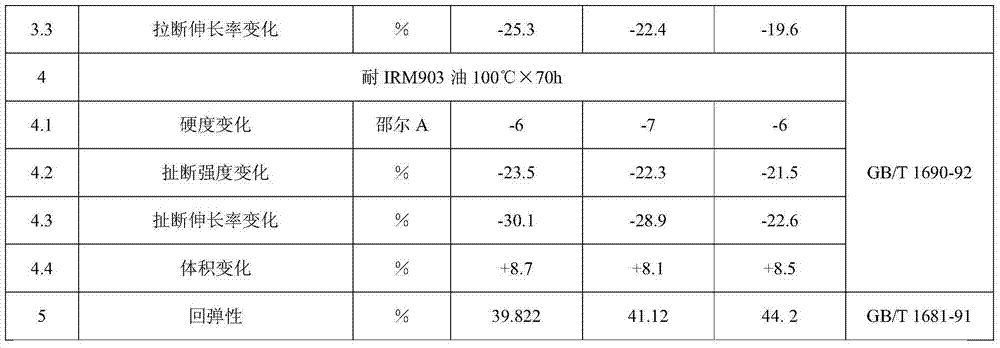

Fluorosilicone rubber compound and preparation method thereof

InactiveCN111808430AImprove mechanical propertiesStable physical propertiesPolymer scienceTrisilazane

The invention provides a fluorosilicone rubber compound. The fluorosilicone rubber compound is prepared from the following raw materials by weight: 100 parts of fluorosilicone raw rubber, 3-20 parts of hydroxyl fluorosilicone oil, 0.1-10 parts of polyvinyl fluorosilicone oil, 15-60 parts of fluorine-containing structured control agent modified white carbon black and 1-2 parts of a vulcanizing agent, wherein the fluorine-containing structured control agent is trimethyl-tri(trifluoropropyl)cyclotrisilazane or fluorine-containing silanol. According to the invention, the white carbon black modified by the fluorine-containing structured control agent has 3, 3, 3, -trifluoropropyl, so that the white carbon black in the treatment process has stable physical properties, and good durability and chemical resistance; meanwhile, the fluorine-containing structured control agent modified white carbon black has better compatibility with the fluorine silica gel, so that the white carbon black can be effectively combined with the fluorosilicone rubber, the vulcanization rate is increased, the cross-linking reaction with the fluorosilicone rubber is carried out, the interaction with the fluorosilicone rubber is enhanced, the tearing strength and hardness of the fluorosilicone rubber can be effectively improved, the treatment efficiency of the white carbon black can be obviously improved, and themechanical properties of the fluorosilicone rubber can be obviously improved.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

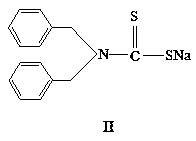

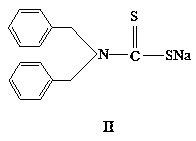

A kind of tetrabenzylthiuram monosulfide and its preparation method and application

The invention discloses sulfide tetrabenzyl thiuram and a preparation method and application thereof. The preparation method comprises the following steps: enabling dibenzylamine, sodium hydroxide and carbon disulfide to react in a solvent to generate an intermediate sodium dibenzyldithiocarbamape, then oxidizing the sodium dibenzyldithiocarbamape into the disulfide tetrabenzyl thiuram by use of hydrogen peroxide, and then desulfurizing the disulfide tetrabenzyl thiuram by use of hydrogen to obtain the sulfide tetrabenzyl thiuram. The sulfide tetrabenzyl thiuram disclosed by the invention is high in purity, high in melting point, and white in appearance, the vulcanization rate can be obviously accelerated, the sulfide tetrabenzyl thiuram can express good scorching security and fast vulcanization performance whether to increase the vulcanization temperature and change the sulfur dosage or to add the white carbon black, and the use of the sulfide tetrabenzyl thiuram has no bad influence to the physical performance of the sulfide rubber.

Owner:SHANDONG YANGGU HUATAI CHEM

High temperature resistant and anti-aging exhaust pipe lug and preparation method thereof

The invention discloses a high temperature resistant and anti-aging exhaust pipe lug and a preparation method thereof. The exhaust pipe lug comprise the following raw materials: 70-90 parts of EPDM, 10-30 parts of hydrogenated nitrile rubber, 3-8 parts of an EPDM-g- PAN compatibilizer, 0.2-0.5 part of sulphur, 1-2 parts of a peroxide crosslinking agent and the balance of a fertilizer composition. Complex main ethylene propylene terpolymer and hydrogenated nitrile rubber are used as raw rubbers, the EPDM-g-PAN compatibilizer can effectively improve the compatibility of the two raw rubbers; sulfur and peroxide vulcanization system are employed for compound to improve vulcanization rate of the raw rubber, so that the rubber material has good high temperature resistance and chemical corrosion resistance. In addition, a reactive antiager in the form of chemical bond can be combined on the main chain of rubber polymer to effectively improve the aging resistance performance and durability performance; and the compound naphthenic oil and coumarone resin as plasticizers can effectively reduce the smell of rubber products, and enhance the thermal stability and vibration isolation performance.

Owner:ANHUI ZHONGDING SEALING PARTS

Method for improving zinc oxide sulfuration activity

The invention relates to a method for improving zinc oxide sulfuration activity and belongs to the technical field of natural rubber processing. The method comprises adding 0.5-10 parts of rare earth oxide into 100 parts of common zinc oxide and carrying out ball milling and high temperature sintering rare earth doping. According to inherent characteristics of rare earth, zinc oxide particle conformation structure and ion surface chemical properties are changed, sulfuration activity is improved, a use ratio of zinc oxide in the rubber formula is reduced from 5: 100 to 2: 100, sulfuration time is shortened, natural vulcanized rubber crosslinking density and mechanical properties are improved and reasonable utilization and saving of a zinc ore resource are realized.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

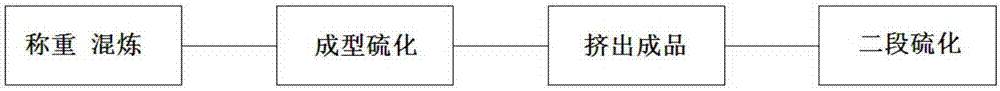

Transparent bloomless silicone rubber mixed compound and preparation method

The invention discloses a transparent bloomless silicone rubber mixed compound and a preparation method. The transparent bloomless silicone rubber mixed compound is prepared from the following components: 100 parts of methyl vinyl silicone rubber mixed compound, 0.5 to 1.0 part of DCBP and 0.3 to 1.0 part of alkyl peroxide. The preparation method comprises the following steps: measuring various components according to a ratio, uniformly dispersing the components into 100 parts of silicone rubber mixed compound, extruding molding by virtue of a rubber extruder, shaping and vulcanizing at a temperature of 500 to 600 DEG C for 5 to 30 s, wherein a temperature of a horizontal drying passage is 200 to 300 DEG C, and the time is 1 to 10 min; and preparing an extruded product corresponding to themold. Compared with the product in the prior art, the product disclosed by the invention has the advantages that on the premise of hardly changing the physical mechanical performance, and in the production, 1 to 2 months with blooming are prolonged to 2 years or more without blooming, so that the extruded product can be stored for a long time, the appearance is not changed, the secondary treatment of the product is reduced, and the product security is improved. In addition, the secondary vulcanizing time can also be reduced, the energy consumption can be saved, and the production cost can bedecreased.

Owner:JINAN CHENSHENG MEDICAL SILICONE RUBBER PROD

Method for preparing natural clove extract-containing medical rubber plug used for sterilization and disinfection

The invention provides a natural clove extract-containing medical rubber plug used for sterilization and disinfection, relating to a preparation method of a medical rubber plug. The raw material used by the preparation method of the medical rubber plug contains clove extract powder. In the invention, the clove extract powder is added, so that the prepared rubber plug can realize sterilization and disinfection. Besides, the invention is simple in process and is easy to operate, the raw material cost is low, the vulcanization rate is improved, the raw material usage is reduced, and the performances of products meet the requirements of the national standard.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

Modified rare earth sulfide assistant, preparation method thereof, and rubber production method

The invention relates to the field of rubber production, and especially relates to a modified rare earth sulfide assistant, a preparation method thereof, and a rubber production method. The preparation method of the modified rare earth sulfide assistant comprises the following steps: 1, adding an organic modifier to an organic solvent to obtain an organic modification solution, wherein the organic modifier is a coupling agent or an organic carboxylic acid; and 2, dispersing rare earth sulfide powder in the organic modification solution, heating and stirring the obtained solution in a closed container at 50-80DEG C for 1-4h, filtering the obtained material, and carrying out vacuum drying to obtain the modified rare earth sulfide assistant. The modified rare earth sulfide assistant is organically modified rare earth sulfide, and has the advantages of good dispersion effect, low cost, good combination with rubber polymers, facilitation of displaying of the performances of rare earth materials, and rubber scorching period prolongation and vulcanization rate acceleration effects.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

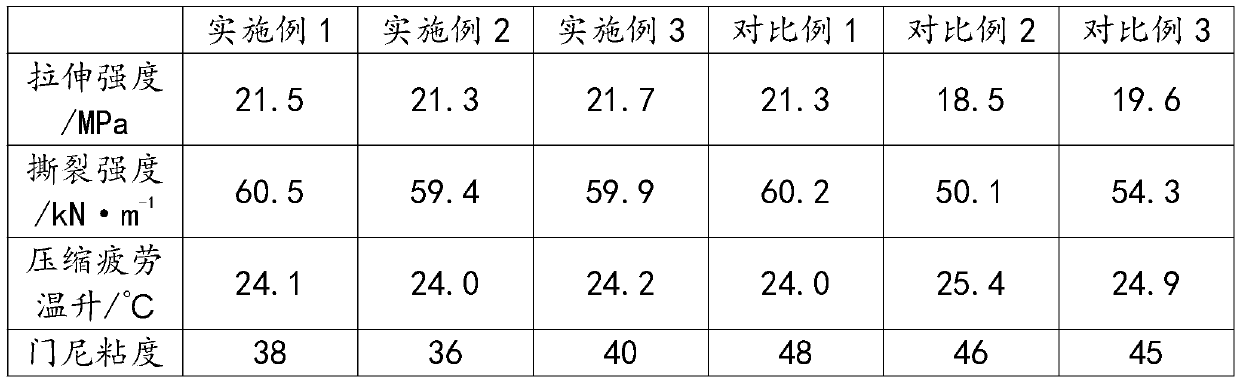

Low-mooney rubber material applicable to injection vulcanization and preparation method of low-Mooney rubber material

InactiveCN110157106ALower Mooney ViscosityAccelerated vulcanizationRubber materialMicrocrystalline wax

The invention discloses a low-Mooney rubber material applicable to injection vulcanization. The low-Mooney rubber material is prepared from the following raw materials in parts by weight: 80-100 partsof an ethylene-propylene-diene monomer, 60-80 parts of white carbon black, 4-5 parts of zinc oxide, 1-2 parts of stearic acid, 0.5-1 part of a flowing agent, 1-2 parts of an anti-aging agent, 0.8-1 part of a microcrystalline wax, 20-25 parts of paroline, 2-3 parts of an accelerant and 1-2 parts of aids. The invention furthermore discloses a preparation method of the rubber material. Due to adoption of a softening agent, namely the paroline, in rubber materials, and due to process adjustment the preparation process, the property that a rubber material is rapidly vulcanized can be met; meanwhile, the dispersibility of the white carbon black can be improved, and the tension and wearing resistance of the rubber material can be improved; and the rubber material which is low in mooney viscosityand high in vulcanization efficiency and is applicable to an injection process can be prepared.

Owner:NINGGUO ZHENGDAO RUBBER & PLASTIC PARTS

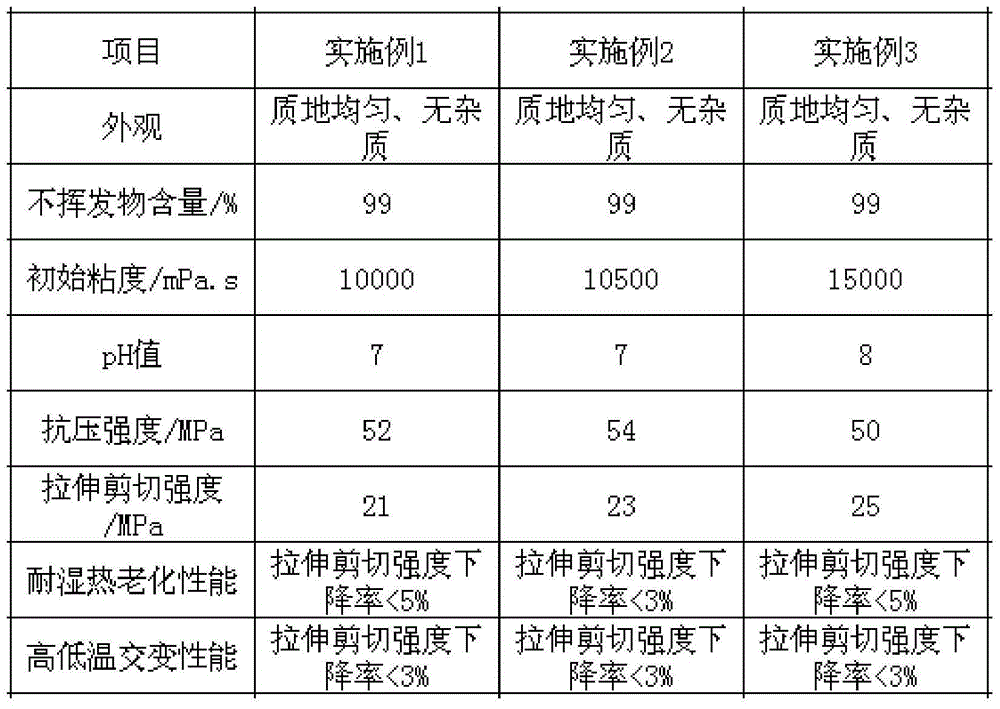

High-elastic adhesive for coir mattress and preparation method thereof

InactiveCN105778823AIncrease vulcanization rateIncreased degree of vulcanizationNatural rubber adhesivesNon-macromolecular adhesive additivesMethacrylateSodium stearate

The invention relates to a high-elastic adhesive for coir mattress. The adhesive comprises the following ingredients (by weight): 200-300 parts of natural latex, 100-50 parts of sericin, 10-25 parts of magnesium methacrylate, 20-30 parts of 20% sodium stearate aqueous solution, 20-30 parts of dicumyl peroxide, 1-2 parts of a vulcanization accelerator, 2-3 parts of an anti-aging agent, 1-2 parts of a mildew inhibitor, 0.5-1 part of a flexibilizer and 80-100 parts of a dispersant. By the addition of magnesium methacrylate, vulcanization rate of natural latex can be accelerated, and degree of vulcanization is raised. Under the action of dicumyl peroxide, magnesium methacrylate can remarkably improve mechanical properties and thermal aging resistance of natural latex.

Owner:TIANJIN SHENGLONG RUBBERISED MATTRESS

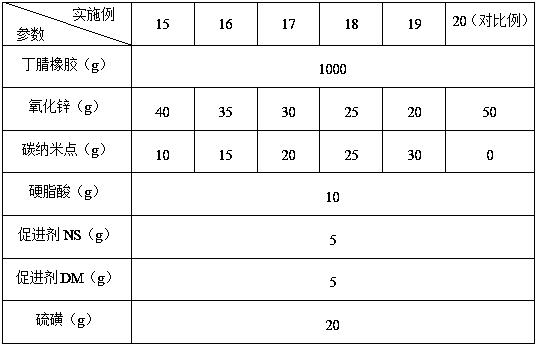

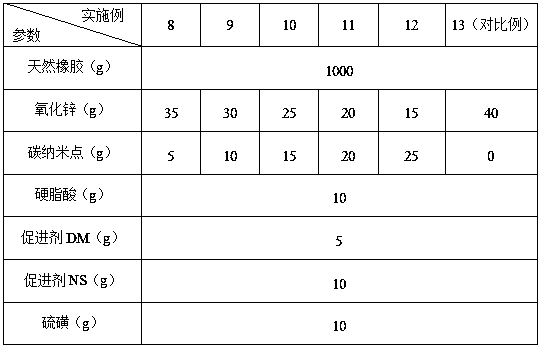

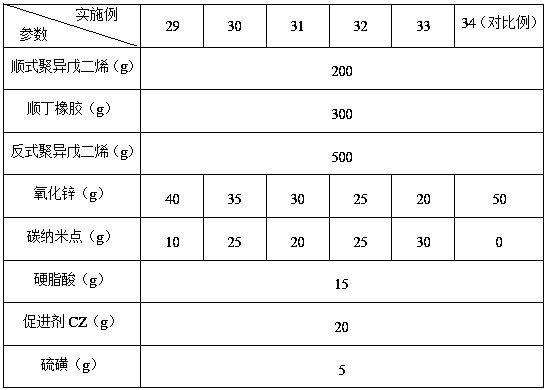

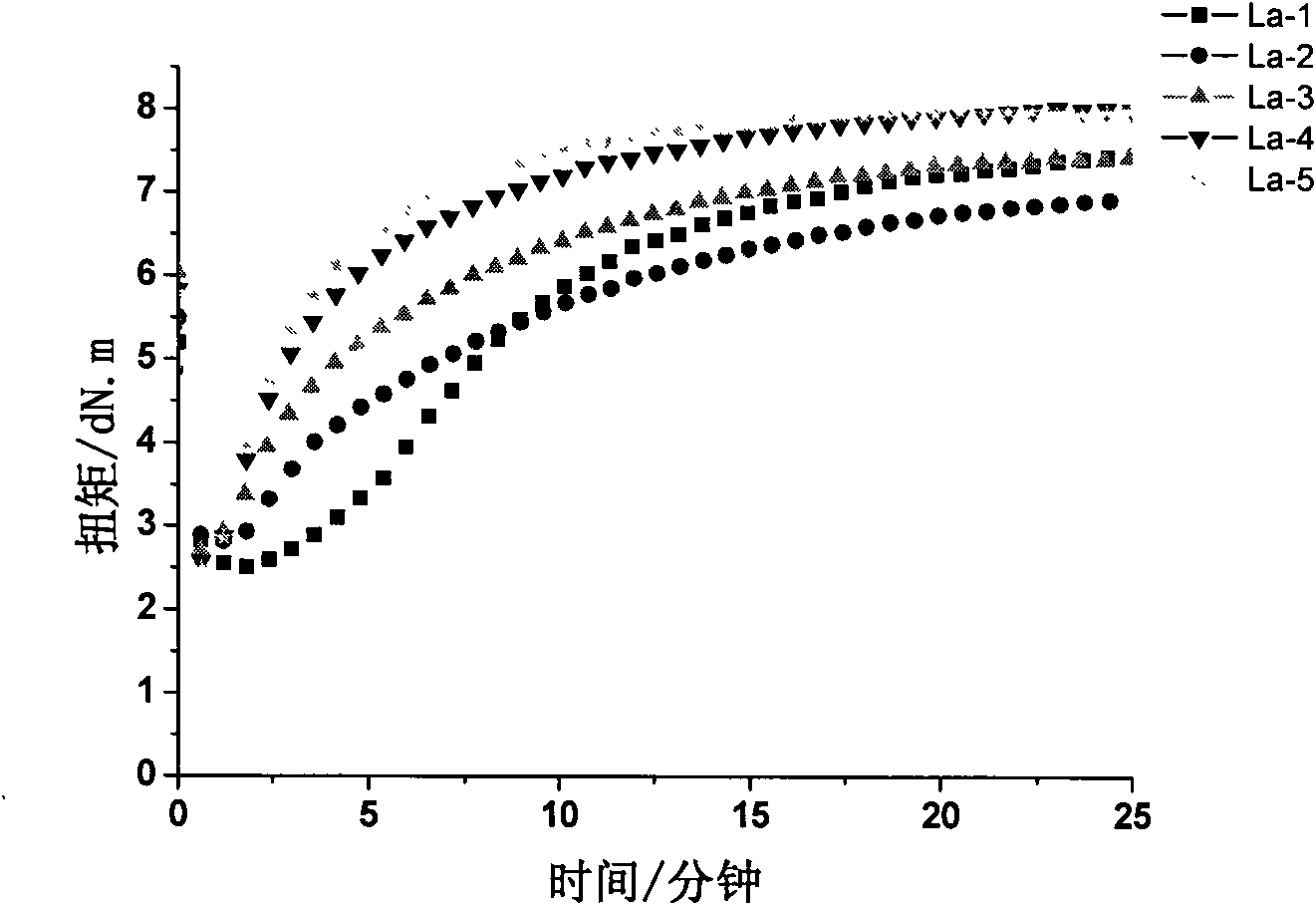

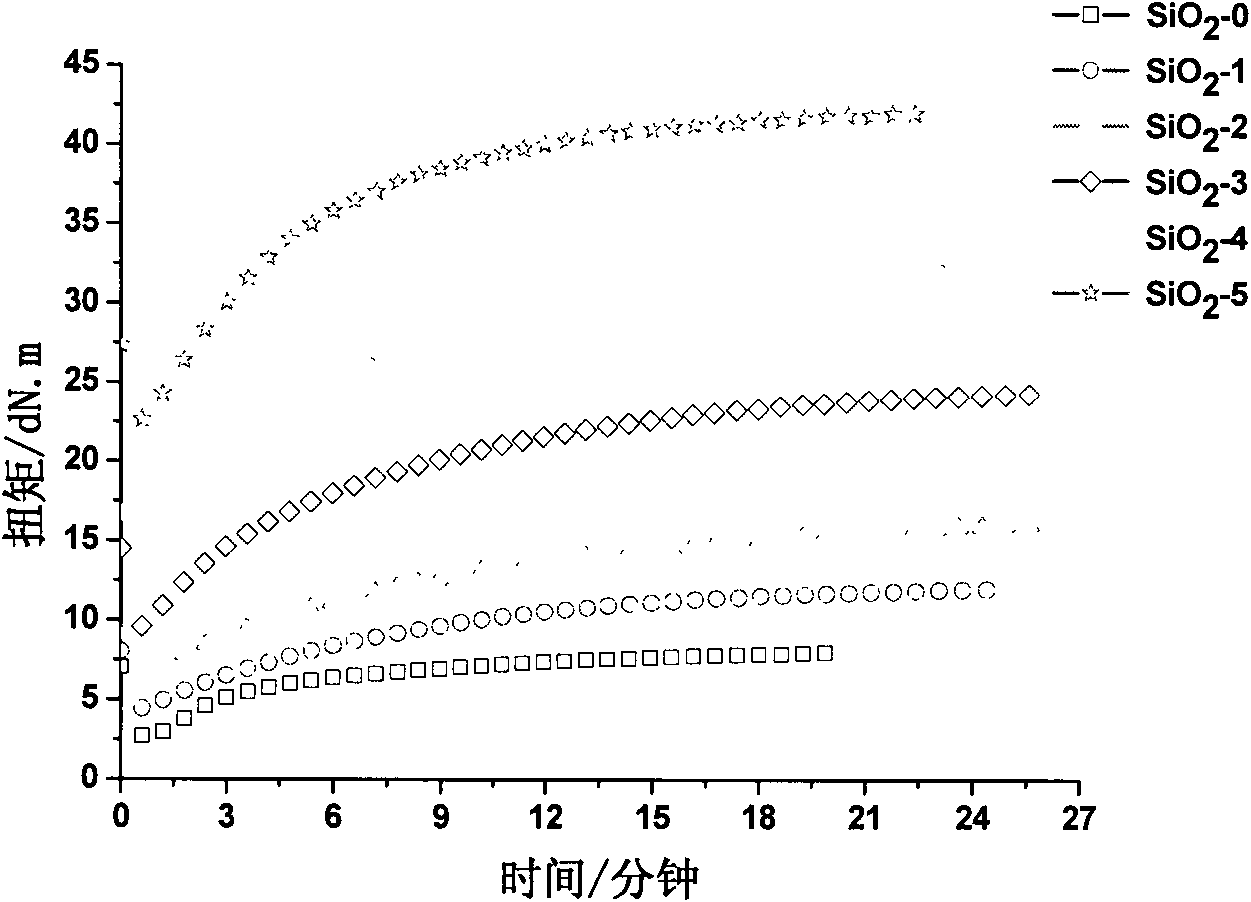

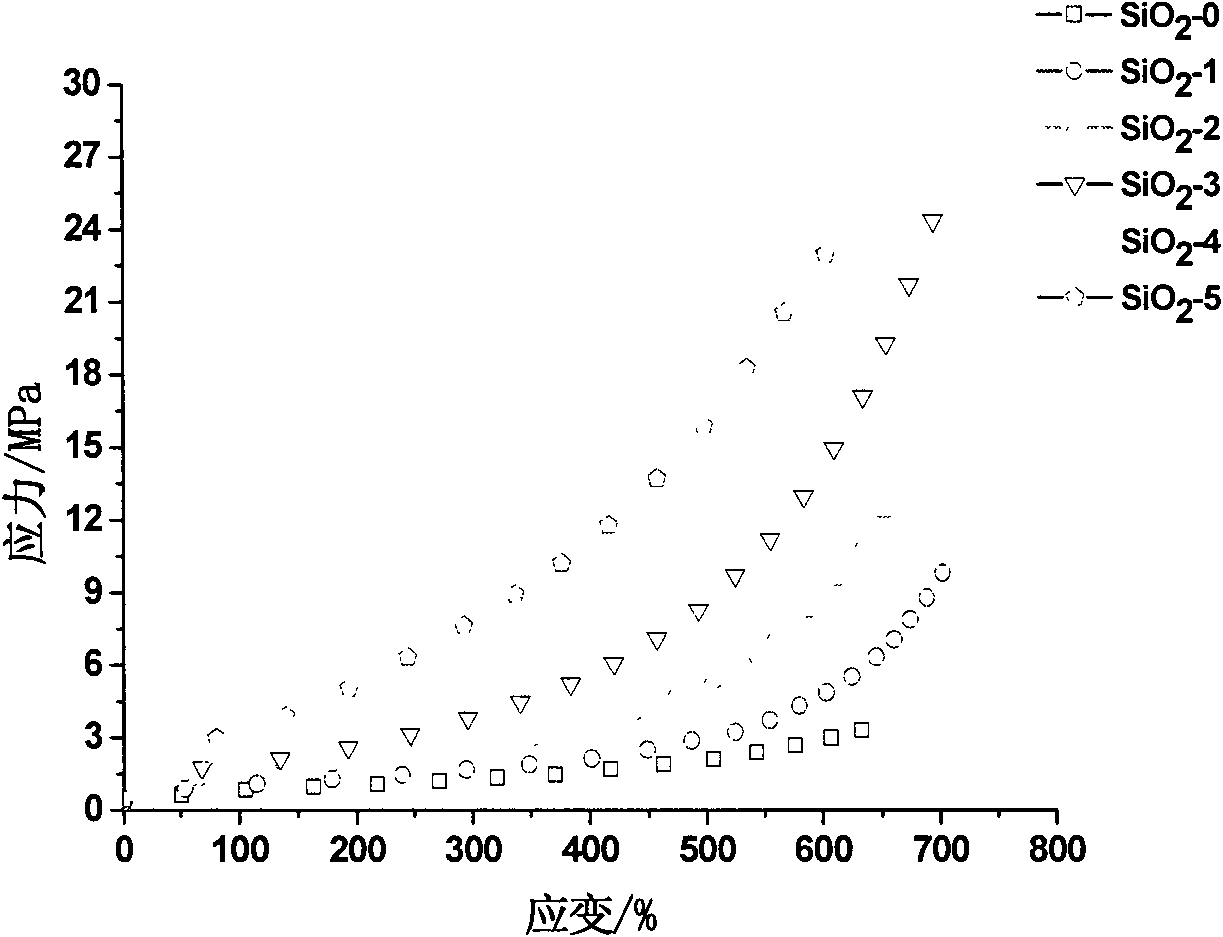

Rubber composition with low zinc oxide content and preparation method thereof

The invention discloses a rubber composition with low zinc oxide content. Raw materials for preparing the rubber composition comprise olefin rubber, carbon nanodots, zinc oxide, stearic acid, a rubberaccelerator and sulfur. The invention further discloses a preparation method of the rubber composition with low zinc oxide content. The preparation method comprises the steps of raw material blending, rubber compound vulcanization and the like. Reduction of zinc oxide in rubber is achieved by adding the carbon nanodots, emission of zinc oxide serving as an environment harmful substance is effectively reduced, the preparation process is simple, the cost is low, industrial production is easy, and the preparation method has great development prospects in the aspect of preparation of green rubbervulcanization activators and is suitable for production and preparation of all rubber compositions.

Owner:SOUTH CHINA UNIV OF TECH

Rare earth rubber vulcanization accelerator, and preparation method and application thereof

ActiveCN101962452BGood effect of promoting vulcanizationIncrease vulcanization rateOrganic chemistryEnvironmental resistanceRare-earth element

Owner:SOUTH CHINA UNIV OF TECH

Rubber composition and pneumatic tire using the same

ActiveCN101098922AIncrease vulcanization rateHigh vulcanization productivitySpecial tyresWheelsPolymer scienceVulcanization

A rubber composition which comprises a rubber component comprising at least one of a natural rubber and a diene-based synthetic rubber, a filler comprising an inorganic filler, a specific compound being excellent in the compatibility with the rubber component and also the affinity with the inorganic filler, and sodium borate. The above rubber composition can improve the driving stability of a tire and also is excellent in vulcanization productivity and extrusion workability.

Owner:BRIDGESTONE CORP

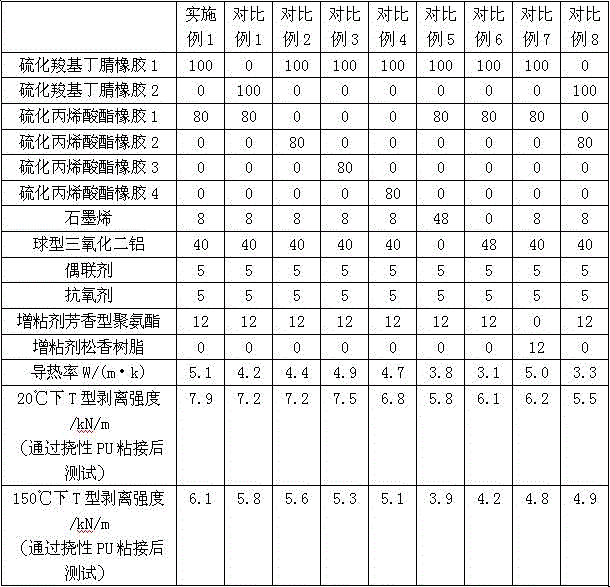

High-temperature adhesive for adhesion of engineer boots and preparation method and application thereof

InactiveCN106118546AIncrease vulcanization rateIncreased degree of vulcanizationNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a high-temperature adhesive for adhesion of engineer boots with excellent high temperature resistance and high adhesive strength and provides a preparation method and application thereof. The adhesive comprises 100 weight parts of vulcanized carboxyl butadiene acrylonitrile rubber, 50-80 weight parts of vulcanized acrylic rubber, 30-50 weight parts of thermal conducting filler, 3-8 weight parts of a coupling agent, 2-10 weight parts of an antioxidant and 18-30 weight parts of a tackifier. By selecting the carboxyl butadiene acrylonitrile rubber and acrylic rubber with excellent high thermal property, compounding graphene, carbon nano tubes and spherical aluminum oxide and selecting the tackifier, the high temperature resistance and adhesive strength are balanced, and the high-temperature adhesive for adhesion of engineer boots with excellent high temperature resistance is obtained.

Owner:东莞爱的合成材料科技有限公司

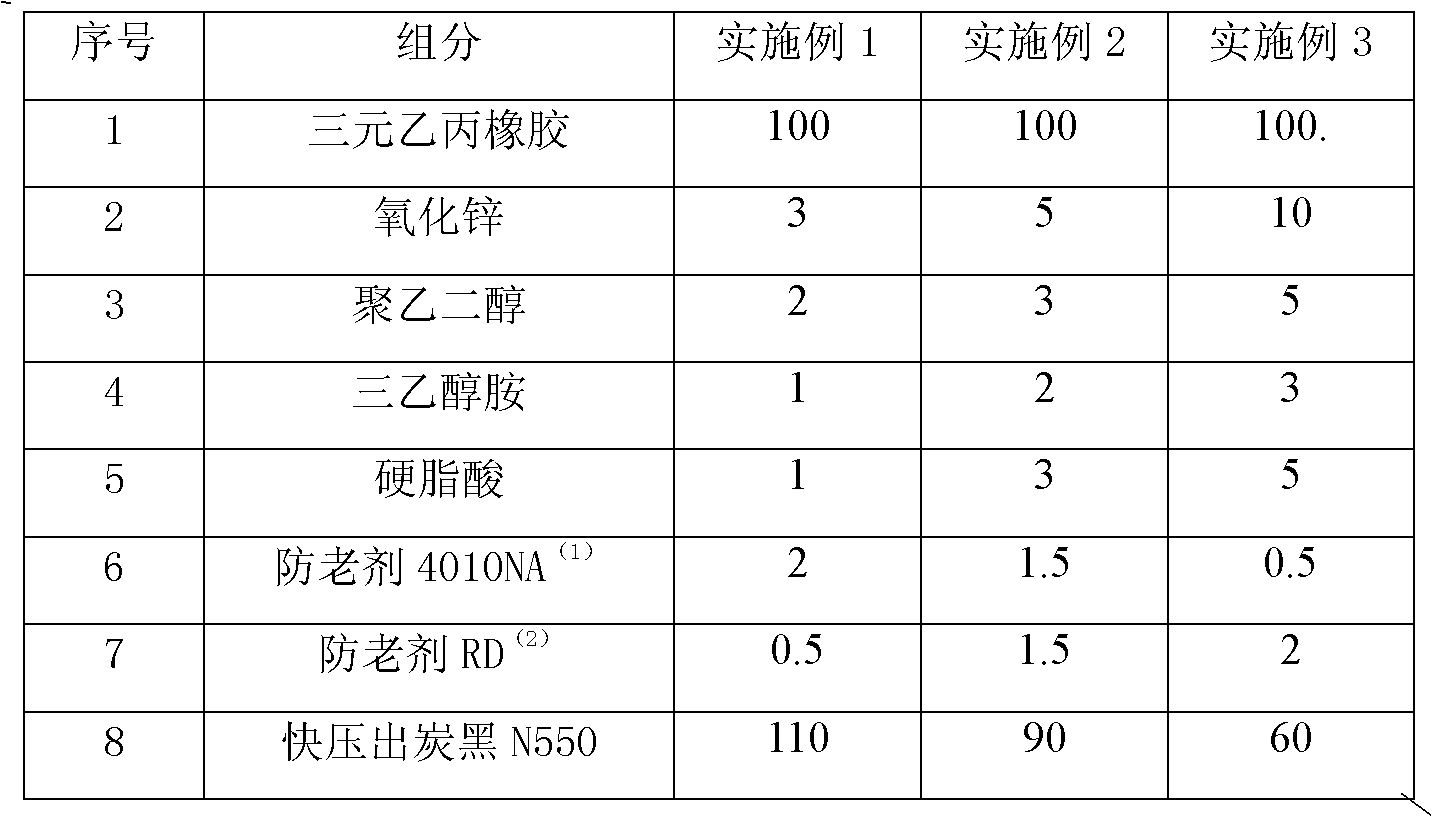

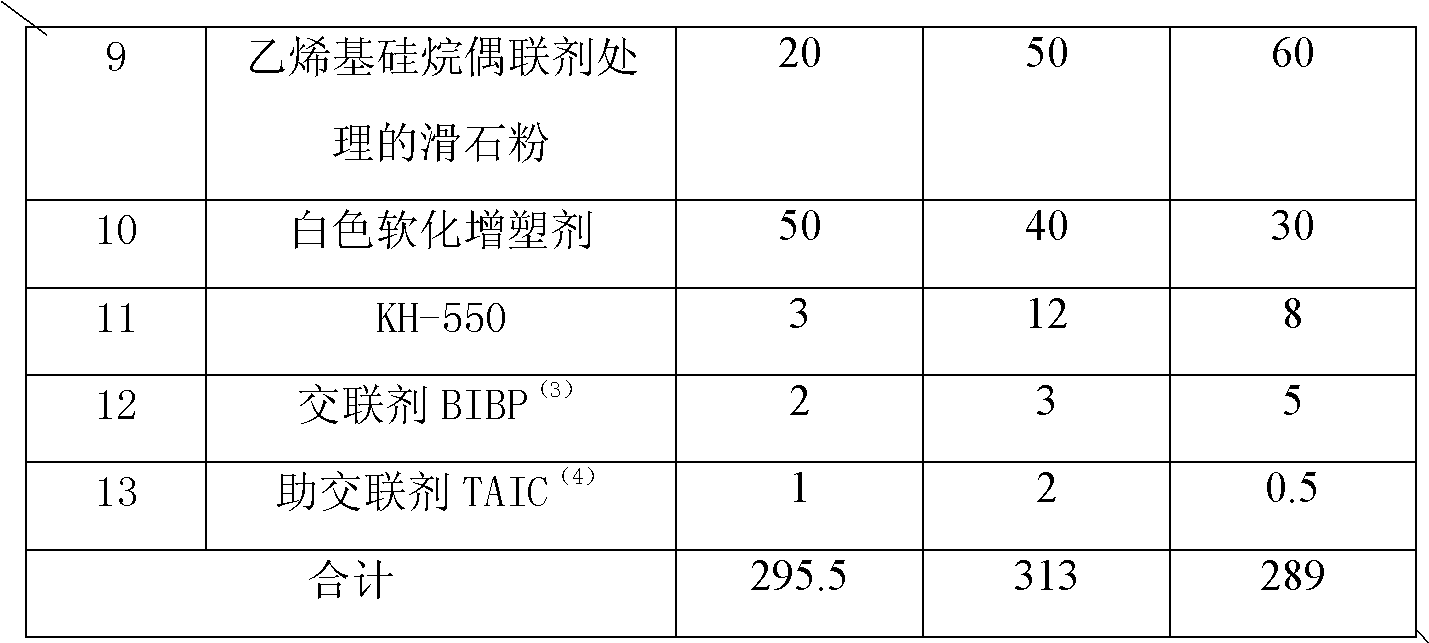

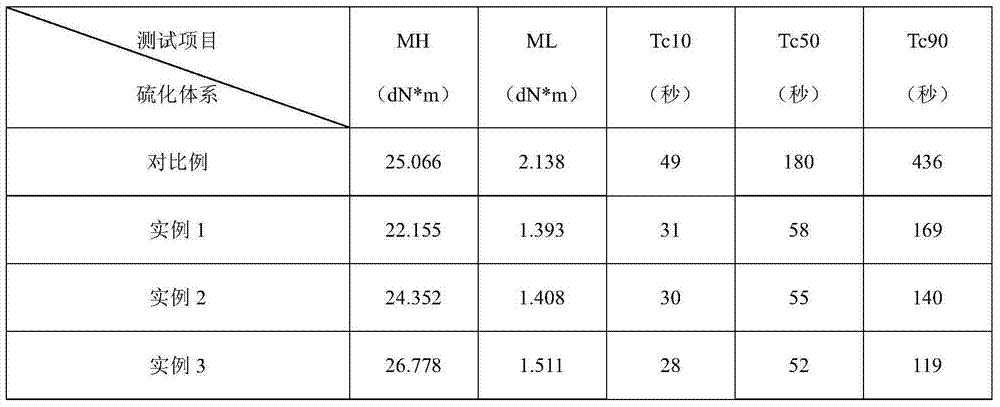

Rubber for non-stub-bar mandril rubber hoop and preparation method of rubber hoop

The invention relates to rubber for a non-stub-bar mandril rubber hoop and a preparation method of the rubber hoop. The non-stub-bar mandril rubber hoop is prepared from raw materials through banburying, open milling, compression molding and installation, wherein the raw materials comprise ethylene propylene diene rubber, zinc oxide, polyethylene glycol, triethanolamine, stearic acid, an anti-aging agent 4010NA, an anti-aging agent RD, fast extruding carbon black N550, talcpowder treated by a vinyl silane coupling agent, a white softening plasticizer, a coupling agent KH-550, a cross-linking agent BIBP and an auxiliary cross-linking agent TAIC. Compared with a stainless steel hoop, the rubber hoop mandril is convenient to assemble and disassemble. The rubber hoop has low cost which is one tenth that of the stainless steel hoop so as to contribute to reducing production cost of enterprises. The rubber hoop and a rubber pipe are rubber products, so compatibility is high, a metal catalytic oxidation phenomenon does not occur in the processes of metal corrosion and vulcanization, the vulcanization process of the rubber pipe is contributed, and waste caused by cutting stub bars is reduced.

Owner:TIANJIN PENGYI GRP CO LTD

Applications of proline in aspects of vulcanization, reinforcement and aging resistance of rubber

InactiveCN102850588AIncrease vulcanization rateHigh tensile strengthComposite materialPolymer chemistry

The invention discloses applications of proline in aspects of vulcanization, reinforcement and aging resistance of rubber. A first usage method of the proline includes adding the proline during primary processing of the rubber, wherein the added quantity of the proline is 0.01%-1% of the total weight of the rubber; and a second usage method of the proline includes adding the proline during the production of rubber products, wherein the added quantity of the proline is 0.01%-1% of the total weight of the rubber. According to the applications of the proline in the aspects of vulcanization, reinforcement and aging resistance of the rubber, vulcanization rates of rubber vulcanization processes can be increased, and simultaneously, tensile strength and aging resistant performances of the rubber products are improved.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Application of alanine in vulcanization and aging prevention of rubber

The invention discloses an application of alanine in vulcanization and aging prevention of rubber. A first use method of alanine comprises the step of adding alanine in the primary machining process of rubber, wherein the addition amount of alanine is 0.01-1% of the total weight of rubber; and a second use method of alanine comprises the step of adding alanine in the process of producing rubber products, wherein the addition amount of alanine is 0.01-1% of the total weight of rubber. According to the application, the vulcanization rate and the aging coefficient of the rubber can be increased, and the performance of the rubber can be improved.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

Preparation method of a kind of antibacterial and anti-inflammatory lubricating condom containing natural cinnamaldehyde

Owner:SOUTH SUBTROPICAL CROPS RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

Nitrile rubber of peroxide fast curing system and preparation method thereof

The invention discloses a nitrile rubber of a peroxide fast curing system and a preparation method thereof. The nitrile rubber contains by weight 100-200 parts of nitrile rubber, 4-9 parts of a peroxide vulcanizing agent, 1.2-2.7 parts of an auxiliary crosslinking agent and an adjuvant composition. On the one hand, the curing agent is compounded with an auxiliary crosslinking agent, and the ratio of vulcanization agent and cross-linking agent is optimized; on the other hand, the addition of antioxidant avoids delay in vulcanization time, so as to improve the cure rate and reduce curing time. In addition, the tensile strength, stretching strength, thermal aging resistance and compression permanent deformation of the nitrile rubber are also improved.

Owner:ANHUI ZHONGDING SEALING PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com