Modified rare earth sulfide assistant, preparation method thereof, and rubber production method

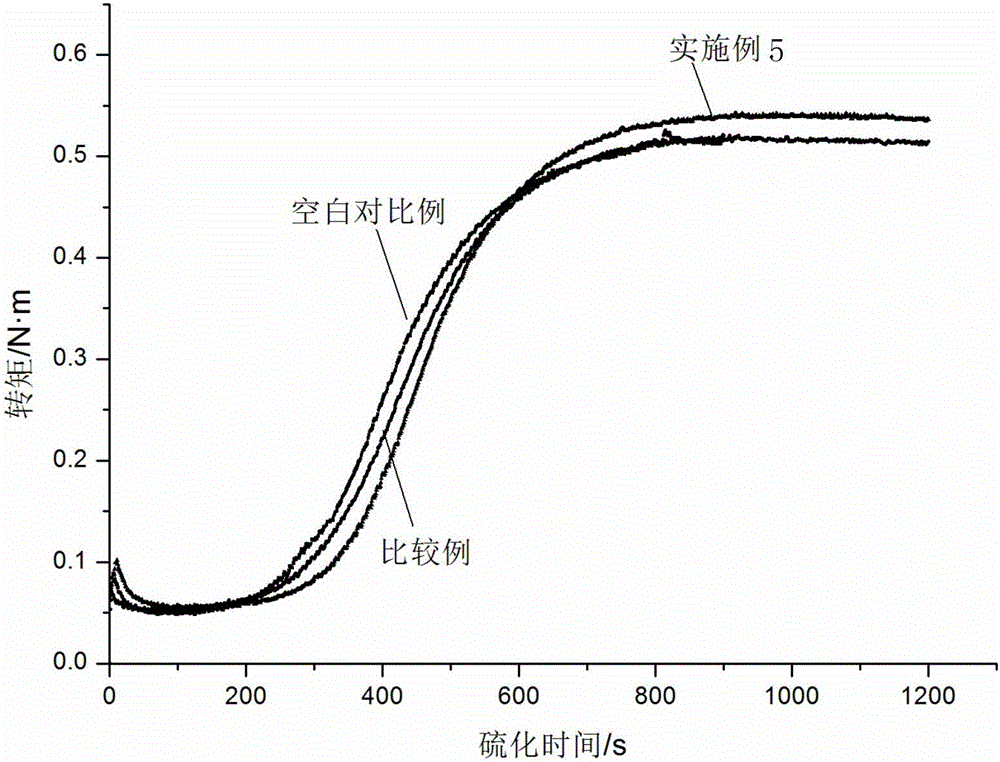

A rare earth sulfide and organic modifier technology, applied in the field of modified rare earth sulfide additives and their preparation, can solve the problems of fast vulcanization speed, reduced production efficiency, and poor hardness of vulcanizate, and achieves low cost, coke Prolonged burning time and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] At first, the present invention provides a kind of preparation method of modified rare earth sulfide auxiliary agent, and it comprises the steps:

[0022] Step 1, adding an organic modifier to an organic solvent to obtain an organic modification solution; the organic modifier is a coupling agent or an organic carboxylic acid;

[0023] Step 2. Disperse the rare earth sulfide powder in the organic modification solution, heat, stir, filter and vacuum dry in a closed container to obtain the modified rare earth sulfide additive; the heating temperature is 50-80°C, The time is 1 to 4 hours.

[0024] In the above step 1, the organic solvent can be ethanol, methanol, ethyl acetate, dichloromethane, acetone, etc. Ethanol is preferably used in the present invention.

[0025] The coupling agent is preferably a silane coupling agent, titanate coupling agent or aluminate coupling agent. The organic carboxylic acid is preferably a saturated carboxylic acid or an unsaturated carbox...

Embodiment 1

[0037] Weigh 0.060g silane coupling agent and dissolve in 20mL ethanol, 2g D 50 Put 2.78 μm samarium sulfide into ethanol solution of silane coupling agent, seal the container, stir at 50°C for 2 hours, then filter and dry for 10 hours to obtain organic surface-modified samarium sulfide. On the basis of keeping the original formula and technological process of natural rubber unchanged, organically modified samarium sulfide was added to 200g of natural rubber, and mastication, mixing and vulcanization tests were carried out.

Embodiment 2

[0039] Weigh 0.200g aluminate coupling agent and dissolve in 20mL ethanol, 4g D 50 Put 0.96 μm cerium samarium mixed sulfide into ethanol solution of aluminate coupling agent, seal the container, stir at 60°C for 2 hours, then filter and dry for 12 hours to obtain organic surface modified cerium samarium sulfide. On the basis of keeping the original formula and technological process of natural rubber unchanged, organically modified cerium samarium sulfide was added to 200 g of natural rubber, and mastication, mixing and vulcanization tests were carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com