High-temperature adhesive for adhesion of engineer boots and preparation method and application thereof

An adhesive and engineering technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc., can solve the problem of difficult to meet the needs of long-term use of shoes, poor compatibility of matrix resin, It is difficult to achieve high filling amount and other problems, to achieve the effect of improving heat resistance, heat resistance and adhesion performance, and improving overall heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

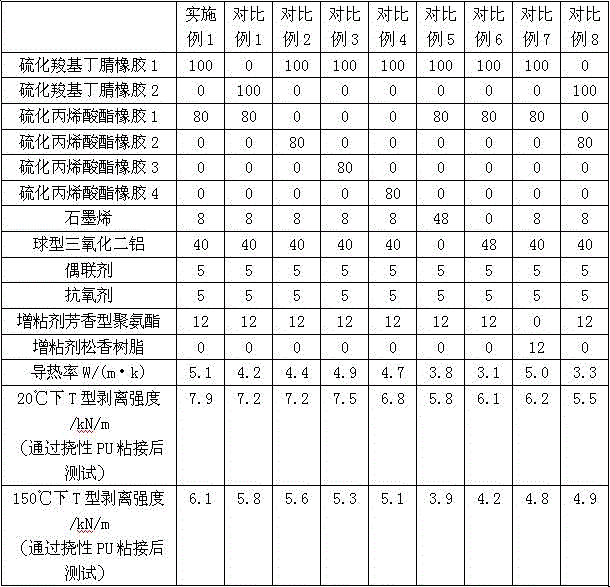

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention and are not intended to limit the scope of the present invention.

[0022] Vulcanized carboxylated nitrile rubber 1: First, 10 parts by weight of multi-walled carbon nanotubes, 5 parts by weight of thiophosphoric acid disulfide, and 2 parts by weight of N-oxydiethylene-2-benzothiazole sulfenamide are fully mixed , further added to 83 parts by weight of vulcanized nitrile rubber, heated and vulcanized, and granulated.

[0023] Vulcanized carboxylated nitrile rubber 2: first 5 parts by weight of thiophosphoric acid disulfide, 2 parts by weight of N-oxydiethylene-2-benzothiazole sulfenamide are fully mixed, and further added to 83 parts by weight of carboxylated nitrile rubber part, heat vulcanization, further add 10 parts by weight of multi-walled carbon nanotubes, mix uniformly and then granulate.

[0024] Acrylic rubber 1: Copo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com