Rubber composition with low zinc oxide content and preparation method thereof

A technology of rubber composition and zinc oxide, which is applied in the field of rubber materials, can solve the problems of non-compliance with the green and low-carbon sustainable development strategy, the environmental hazards of nano-scale zinc oxide, and the complicated production process of zinc compounds, so as to improve the activation efficiency , easy industrial production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0026] The preparation method of the rubber composition of embodiment 1-6 low zinc oxide

[0027] Embodiments 1-6 are respectively a preparation method of a zinc oxide-low rubber composition (styrene-butadiene rubber containing carbon nano-dots 1), which are all carried out according to the following steps:

[0028] (1) Preparation of carbon nanodots 1

[0029] According to the equimolar ratio of carboxylic acid groups to amino groups, take acrylic acid and butylenediamine, prepare an aqueous solution (the concentration of acrylic acid is 200 mg / mL), and heat it under 600 W microwave power for 5 min to obtain carbon nanodot1;

[0030] (2) Preparation of styrene-butadiene rubber containing carbon nanodots 1

[0031] According to the dosage in Table 1, styrene-butadiene rubber, carbon nano-dots 1, zinc oxide, stearic acid, rubber accelerator CZ (N-cyclohexyl-2-benzothiazole sulfenamide), rubber accelerator DM ( 2, 2'-dithiodibenzothiazole) and sulfur, and added to an internal...

Embodiment 7

[0036] The performance test of the rubber composition of embodiment 7 low zinc oxide

[0037] In this example, the properties of the products obtained in Examples 1-6 (i.e. low zinc oxide rubber composition) were comprehensively tested according to the Chinese national standard GB / T 528-2009, and their typical performance changes are shown in Table 2 below:

[0038] Table 2

[0039] .

[0040] The above test results show that, compared with the product obtained in Example 6 (comparative example), as the content of zinc oxide replaced by carbon nano-dots increases, the scorch and normal vulcanization times of the products obtained in Examples 1 to 5 are significantly shortened, and the lowest The torque ML and the maximum torque MH remained basically unchanged, indicating that the crosslinking density of the vulcanizate did not change significantly. In addition, the 100% modulus and tensile strength of the vulcanizate remained basically unchanged.

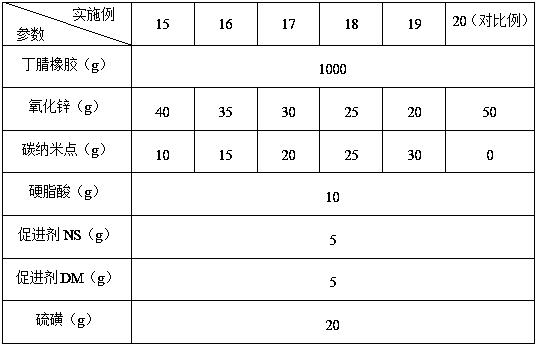

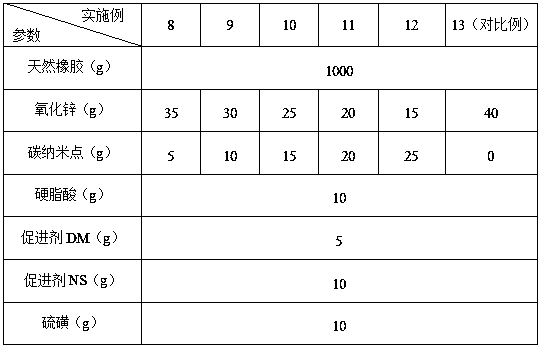

Embodiment 8-13

[0041] The preparation method of the rubber composition of embodiment 8-13 low zinc oxide

[0042] Examples 8-13 are respectively a preparation method of a zinc oxide-low rubber composition (natural rubber containing carbon nano-dots 2), which are all carried out in the following order:

[0043] (1) Preparation of carbon nanodots 2

[0044] According to the ratio of 3:1 molar ratio of carboxylic acid groups to amino groups, citric acid and ethylenediamine were prepared into an aqueous solution (the concentration of citric acid was 100 mg / mL), and under the microwave power of 750 W Heating for 3 min to obtain carbon nanodots 2;

[0045] (2) Preparation of natural rubber containing carbon nanodots 2

[0046] According to the dosage in Table 3, natural rubber, carbon nano-dots 2, zinc oxide, stearic acid, rubber accelerator DM, rubber accelerator NS (N-tert-butyl-2-benzothiazole sulfenamide) and Sulfur was added to the open mill, and blended at room temperature for 10 min to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com