High-elastic adhesive for coir mattress and preparation method thereof

A technology of springing coconut palm beds and adhesives, which is applied in the field of mattresses, can solve problems such as mattress vulcanization difficulties, and achieve the effects of excellent heat-air aging resistance, high tearing performance, and accelerated vulcanization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

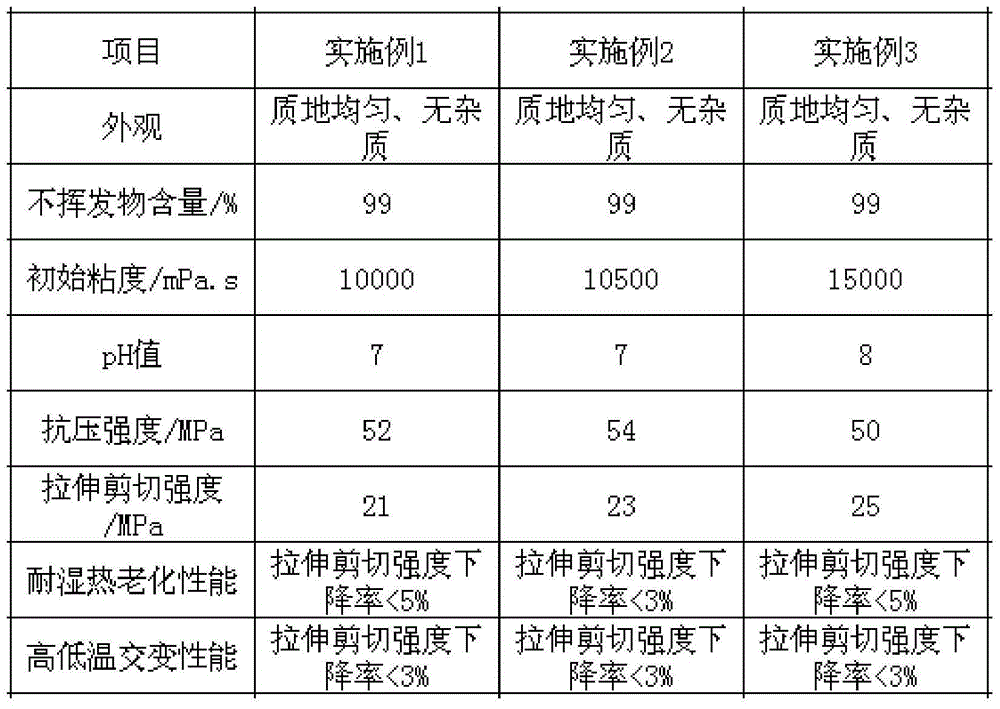

Examples

Embodiment 1

[0030] A high-elastic coir mattress adhesive, its components and parts by weight are as follows:

[0031] Natural latex: 200 parts;

[0032] Sericin: 150 parts;

[0033] Magnesium methacrylate: 10 parts;

[0034] 20% sodium stearate aqueous solution: 20 parts;

[0035] Dicumyl peroxide: 30 parts;

[0036] DBZ: 1 copy;

[0037] Plant polymer RPP and N-isopropyl-N'-phenyl-p-phenylenediamine are mixed in a mass ratio of 1:2: 2 parts;

[0038] Ag / TiO2-SiO2: 2 parts;

[0039] Nitrile rubber: 0.5 parts;

[0040] Nano calcium carbonate: 80 parts.

[0041] A preparation method of an adhesive for a high-elastic coconut palm mattress, the steps are as follows:

[0042] Put the natural latex and sericin from the storage tank into the matching tank, press the compressed air into the metering tank, exhaust the ammonia, and then put it into the vulcanization tank. When the ammonia content of the latex is about 2%, add magnesium methacrylate And 20% sodium stearate aqueous solution,...

Embodiment 2

[0044] A high-elastic coir mattress adhesive, its components and parts by weight are as follows:

[0045] Natural latex: 300 parts;

[0046] Sericin: 100 parts;

[0047] Magnesium methacrylate: 25 parts;

[0048] 20% sodium stearate aqueous solution: 30 parts;

[0049] Dicumyl peroxide: 20 parts;

[0050] Xanthate: 2 parts;

[0051] Aryl phosphite: 3 parts;

[0052] Ultrafine AgO powder: 2 parts;

[0053] Nitrile rubber: 1 part;

[0054] Nano calcium carbonate: 100 parts.

[0055] A preparation method of an adhesive for a high-elastic coconut palm mattress, the steps are as follows:

[0056] Put the natural latex and sericin from the storage tank into the matching tank, press the compressed air into the metering tank, exhaust the ammonia, and then put it into the vulcanization tank. When the ammonia content of the latex is about 2%, add magnesium methacrylate and 20% sodium stearate aqueous solution, slowly heated to 20-30 ° C, added dicumyl peroxide, cooled to below ...

Embodiment 3

[0058] A high-elastic coir mattress adhesive, its components and parts by weight are as follows:

[0059] Natural latex:: 250 parts;

[0060] Sericin: 125 parts;

[0061] Magnesium methacrylate: 20 parts;

[0062] 20% sodium stearate aqueous solution: 25 parts;

[0063] Dicumyl peroxide: 25 parts;

[0064] Dithiocarbamate: 1.5 parts;

[0065] Thiourea derivative CTU: 2.5 parts;

[0066] Chitosan-silver: 1.5 parts;

[0067] Nitrile rubber: 0.8 parts;

[0068] Quartz powder: 90 parts;

[0069] A preparation method of an adhesive for a high-elastic coconut palm mattress, the steps are as follows:

[0070] Put the natural latex and sericin from the storage tank into the matching tank, press the compressed air into the metering tank, exhaust the ammonia, and then put it into the vulcanization tank. When the ammonia content of the latex is about 2%, add magnesium methacrylate and 20% sodium stearate aqueous solution, slowly heated to 20-30°C, added dicumyl peroxide, cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com