High temperature resistant and anti-aging exhaust pipe lug and preparation method thereof

An exhaust pipe and anti-aging technology, which is applied in the field of automotive rubber products, can solve problems such as vibration and noise in the exhaust pipe hanger, affecting user satisfaction with automobile products, and reducing overall performance, so as to enhance thermal stability Performance and vibration isolation performance, good high temperature resistance and chemical corrosion resistance, reduce the effect of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

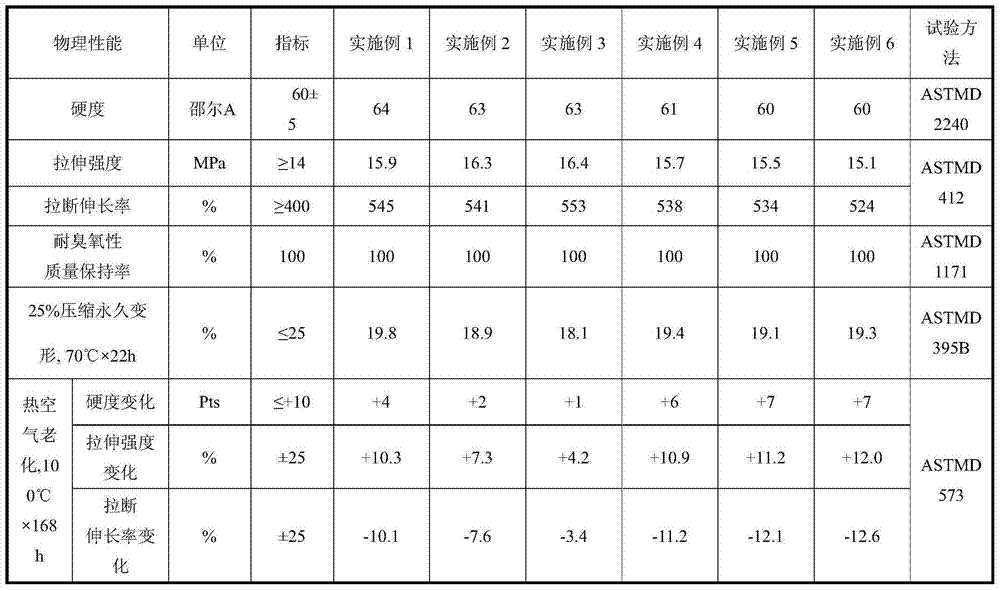

Examples

Embodiment 1

[0023] First, prepare the following raw materials in parts by mass: 80 parts of EPDM rubber, 20 parts of hydrogenated nitrile rubber, 4 parts of EPDM-g-PAN compatibilizer, 0.4 parts of insoluble sulfur IS-60, 1.2 parts of DCP, 2 parts of anti-aging Agent IPPST, 1 part of anti-aging agent RD, 0.5 part of anti-aging agent MB, 5 parts of indirect zinc oxide, 0.6 part of accelerator M, 0.5 part of accelerator TRA, 0.5 part of accelerator TMTD, 4 parts of naphthenic oil 4010, 3 parts of ancient Malone resin, 1 part of stearic acid, 1.5 parts of lubricant WB42, 35 parts of carbon black N-330, 25 parts of carbon black N-550.

[0024] Next, after fully mixing the raw materials, place them in an internal mixer for internal mixing for 4 to 6 minutes, and remove the glue at 110°C to obtain synthetic rubber. The synthetic rubber is placed in an open mill for open kneading and molding at 60-70°C to obtain long strips of molding rubber. Then, put the molding rubber into the barrel of the i...

Embodiment 2

[0026] Except that preparation raw material is different, other is the same as embodiment 1. In this example, the following raw materials were prepared in parts by mass: 80 parts of EPDM rubber, 20 parts of hydrogenated nitrile rubber, 6 parts of EPDM-g-PAN compatibilizer, 0.3 parts of insoluble sulfur IS-60, 1.4 parts of DCP, 2 parts Antiaging agent IPPST, 1 part of antiaging agent RD, 0.4 part of antiaging agent MB, 4 parts of indirect zinc oxide, 0.7 part of accelerator M, 0.4 part of accelerator TRA, 0.4 part of accelerator TMTD, 5 parts of naphthenic oil 4010, 3 parts Coumarone resin, 1 part of stearic acid, 1.3 parts of lubricant WB42, 40 parts of carbon black N-330, 20 parts of carbon black N-550.

Embodiment 3

[0028]Except that preparation raw material is different, other is the same as embodiment 1. In this example, the following raw materials are prepared in parts by mass: 80 parts of EPDM rubber, 20 parts of hydrogenated nitrile rubber, 5 parts of EPDM-g-PAN compatibilizer, 0.5 parts of insoluble sulfur IS-60, 1 part of DCP, 1.5 parts Anti-aging agent IPPST, 1 part of anti-aging agent RD, 0.5 part of anti-aging agent MB, 4 parts of indirect zinc oxide, 0.8 part of accelerator M, 0.5 part of accelerator TRA, 0.4 part of accelerator TMTD, 6 parts of naphthenic oil 4010, 4 parts Coumarone resin, 1 part of stearic acid, 1.6 parts of lubricant WB42, 40 parts of carbon black N-330, 25 parts of carbon black N-550.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com