Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Increase the limiting current density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of electroplating diamond fret saw

The invention relates to a preparation method of an electroplating diamond fret saw, comprising the following technological processes: 1. roughening processing is carried out to micrometer diamond particles in advance, nanometer diamond powder is added in cationic surface active agents according to the proportion of 1 : 3 by mass ratio, so as to prepare uniform and stable nanometer diamond powder suspending liquid, plating solution is arranged in an electroplating tank, after the weighted nanometer diamond powder suspending liquid is mixed with the micrometer diamond particles according to the proportion of 1 : 3 by mass ratio, and then the mixture is added in the plating solution, the plating solution is circulated continuously, and nickel aminosulfonate is main material in the plating liquid, and boracic acid and nickel chloride are additionally added, and a magnetic stirring device is arranged in the electroplating tank; 2. a steel wire continuously and uniformly passes through the electroplating tank, under the action of electrical current, nickel ions move to cathode from anode, so as to drive the nanometer diamond powder and the micrometer diamond particles to move to the steel wire, so as to lead the steel wire to be plated with the nanometer diamond powder and the micrometer diamond particles, meanwhile, chemical nickel-plating is carried out to the steel wire; 3. after the steel wire is separated from the electroplating tank, wires are wound up after being cleaned and dried. The method can continuously and quickly produce electroplating diamond fret saw, and the production efficiency is high.

Owner:JIANGSU FUNLIN SUPER HARD TOOLS

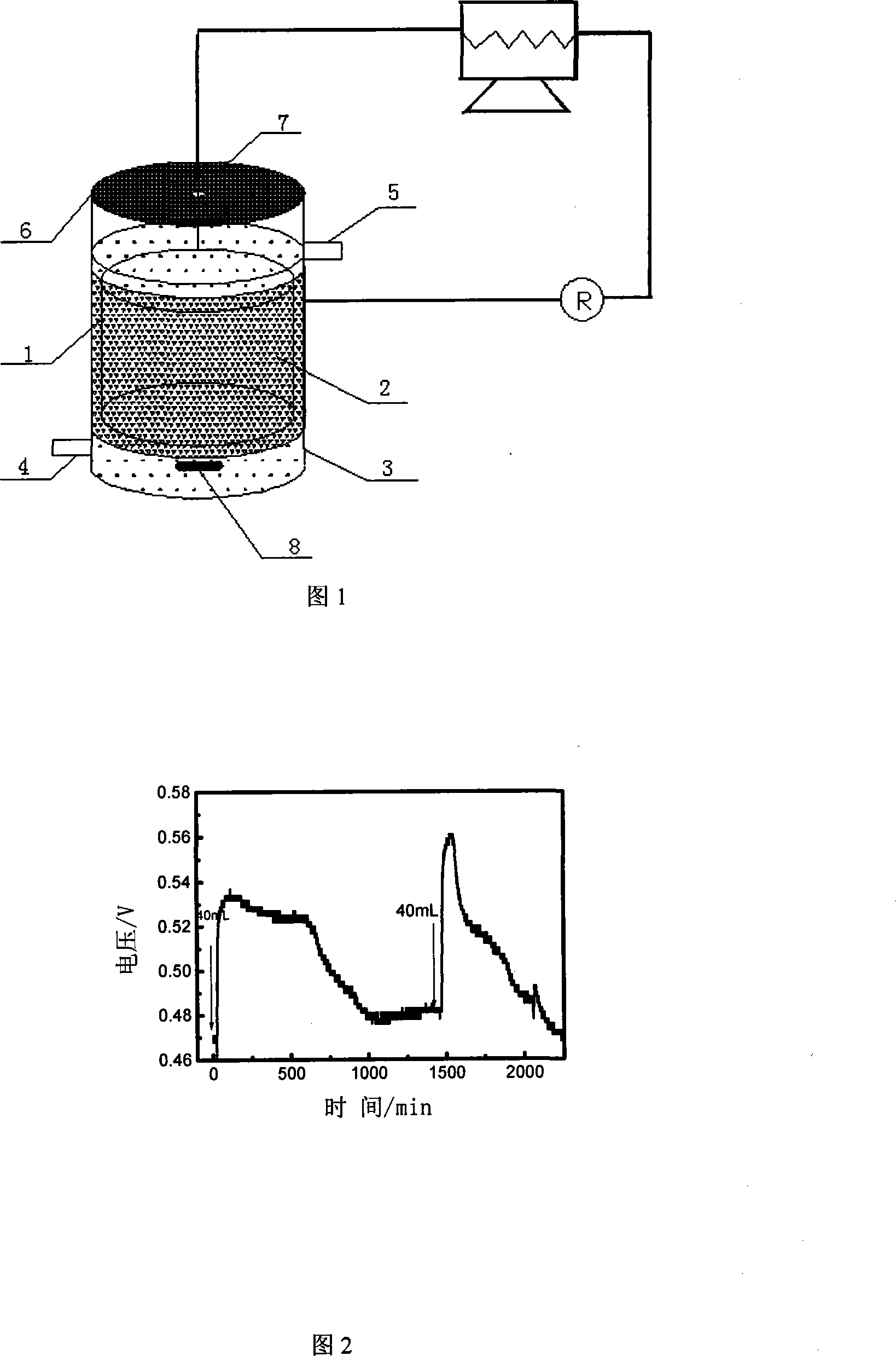

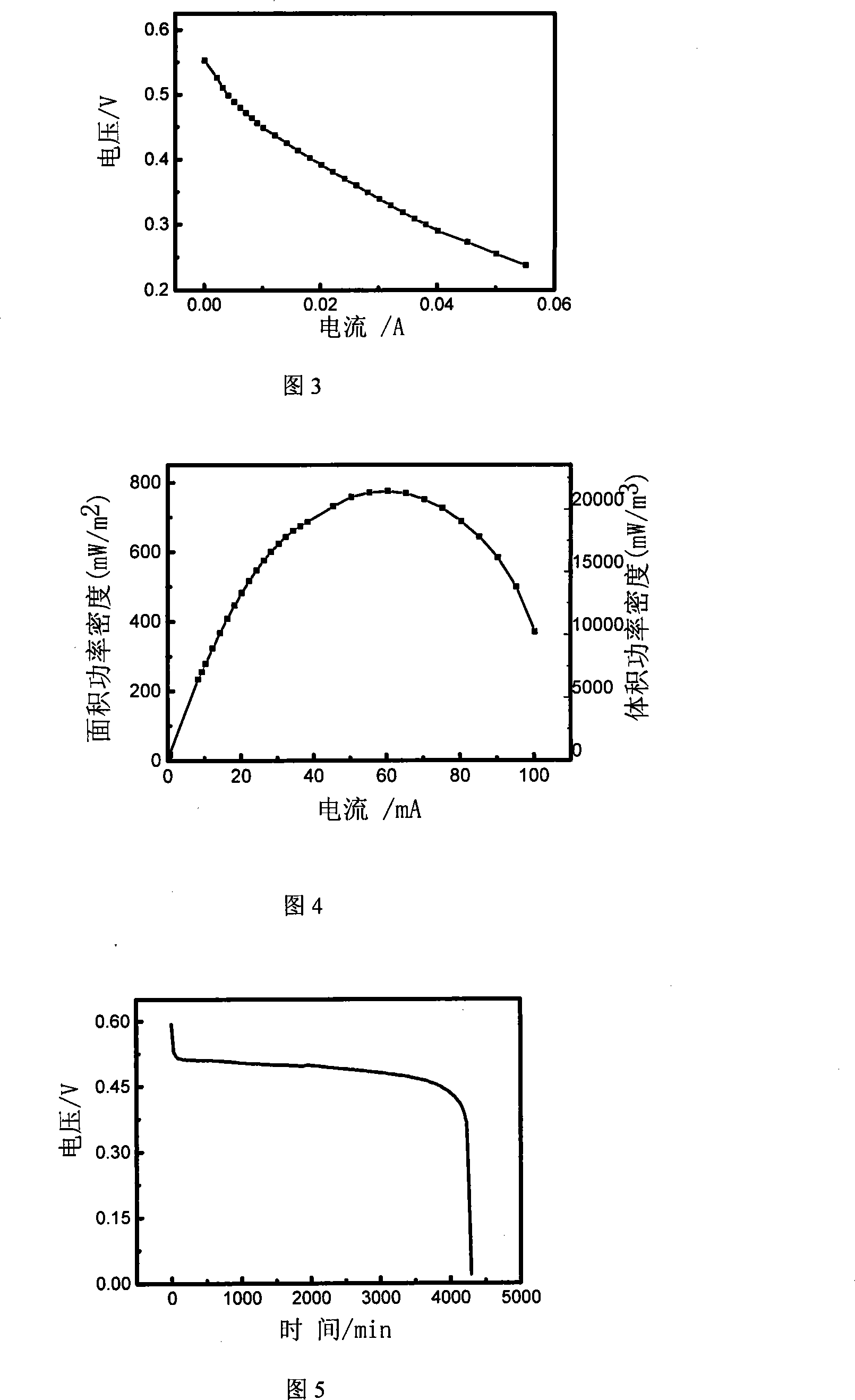

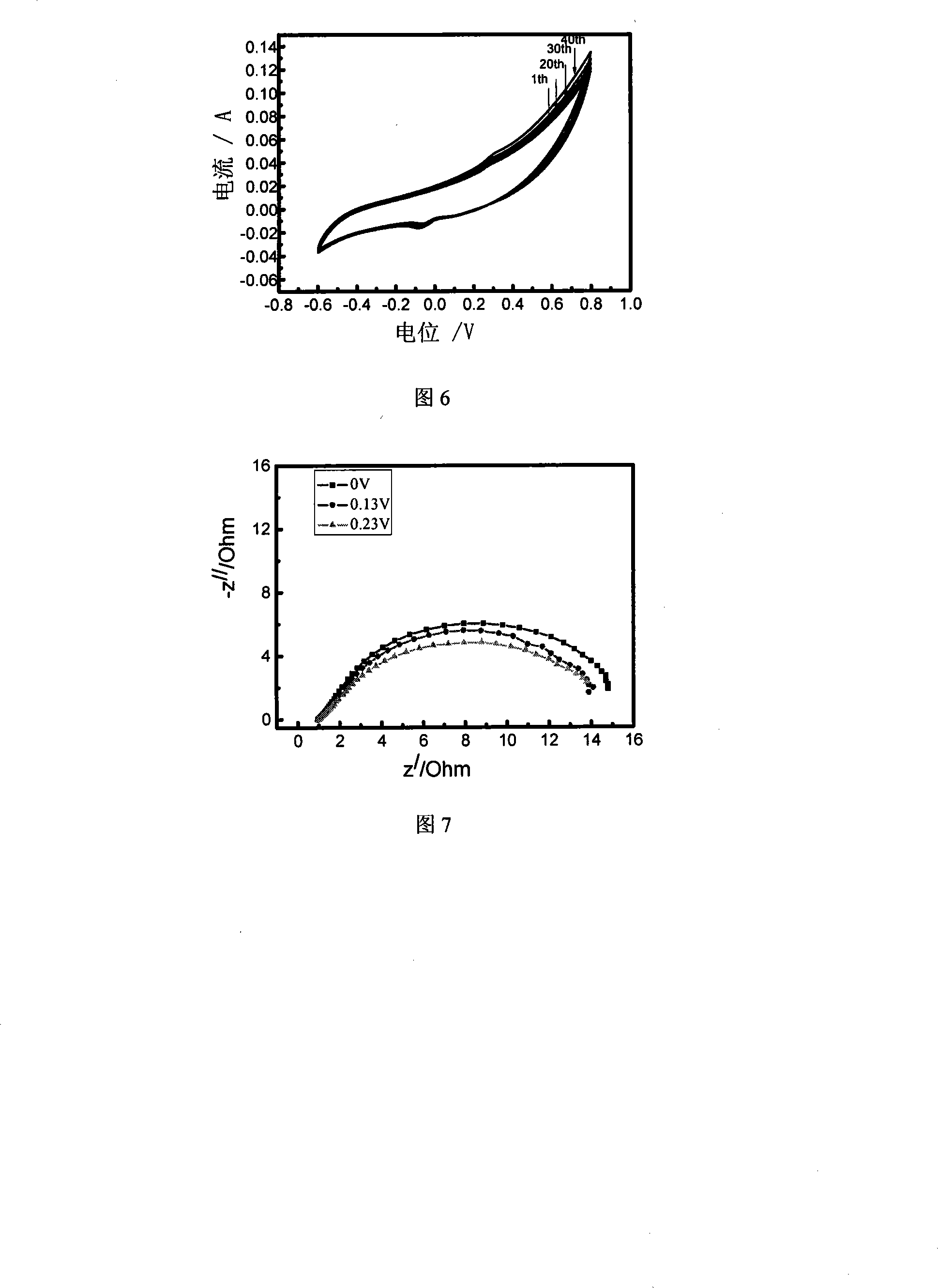

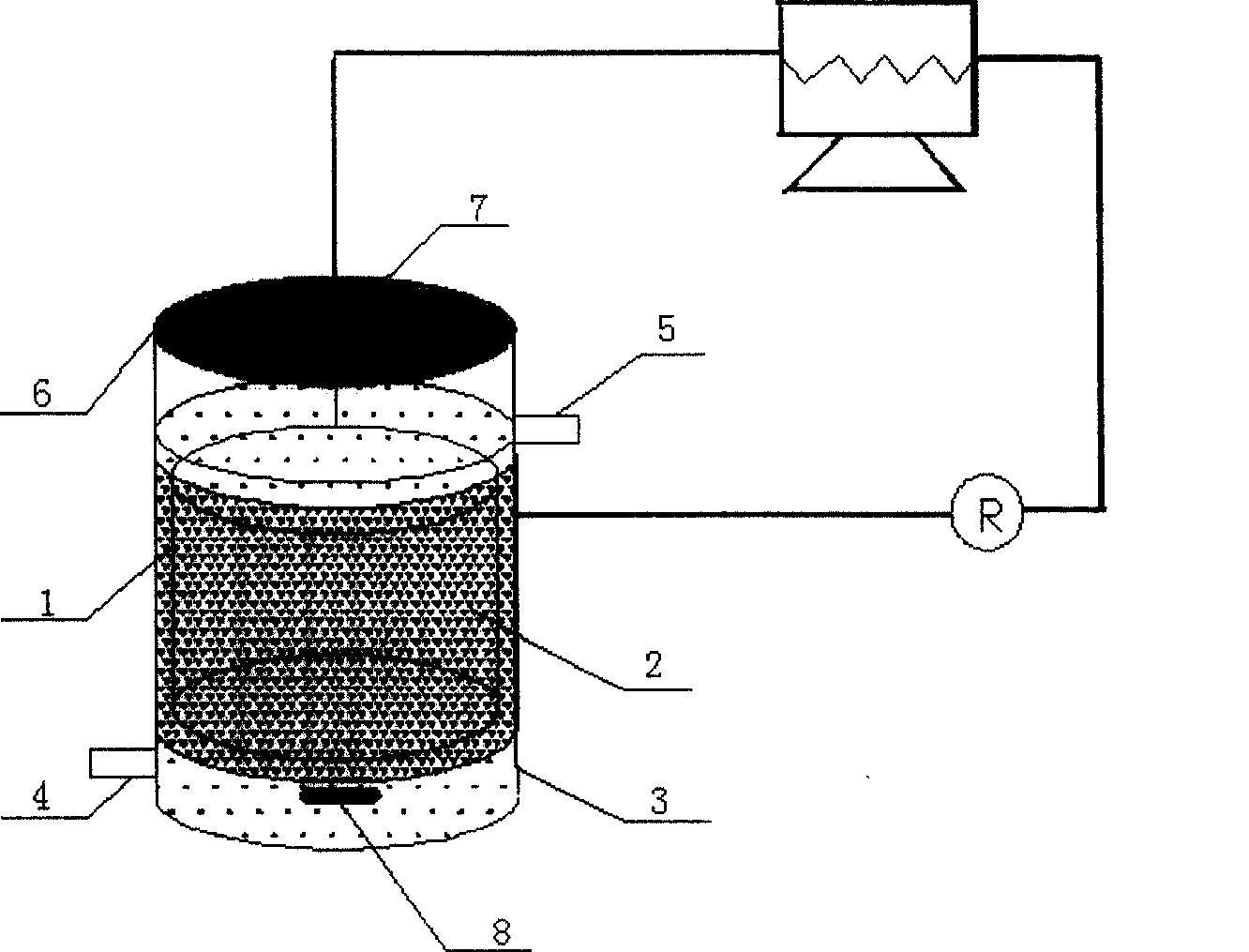

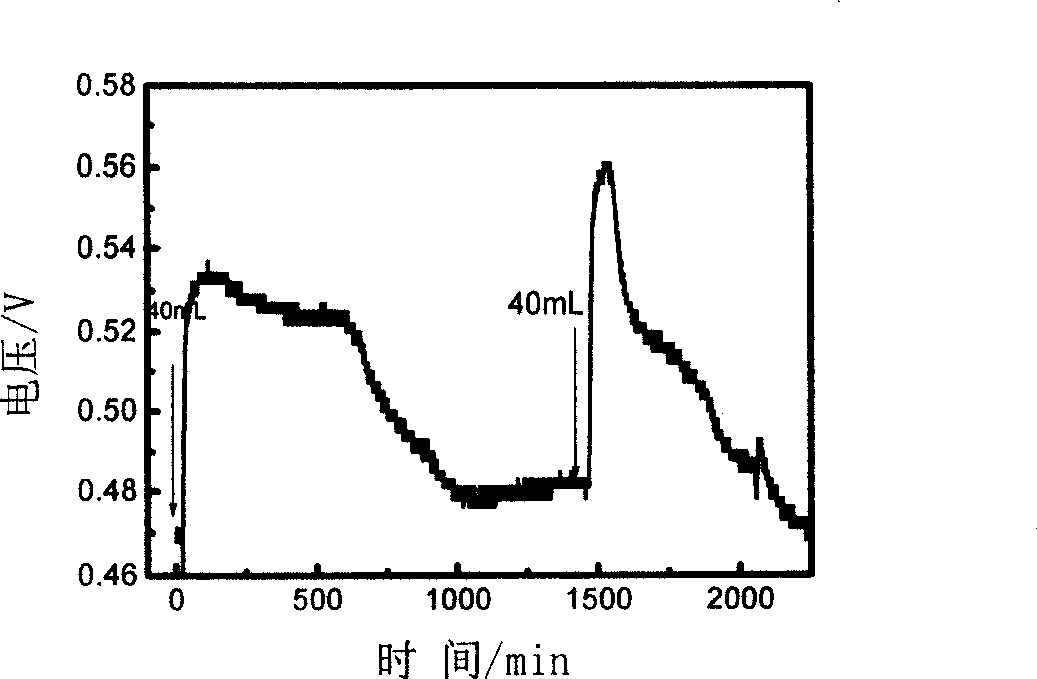

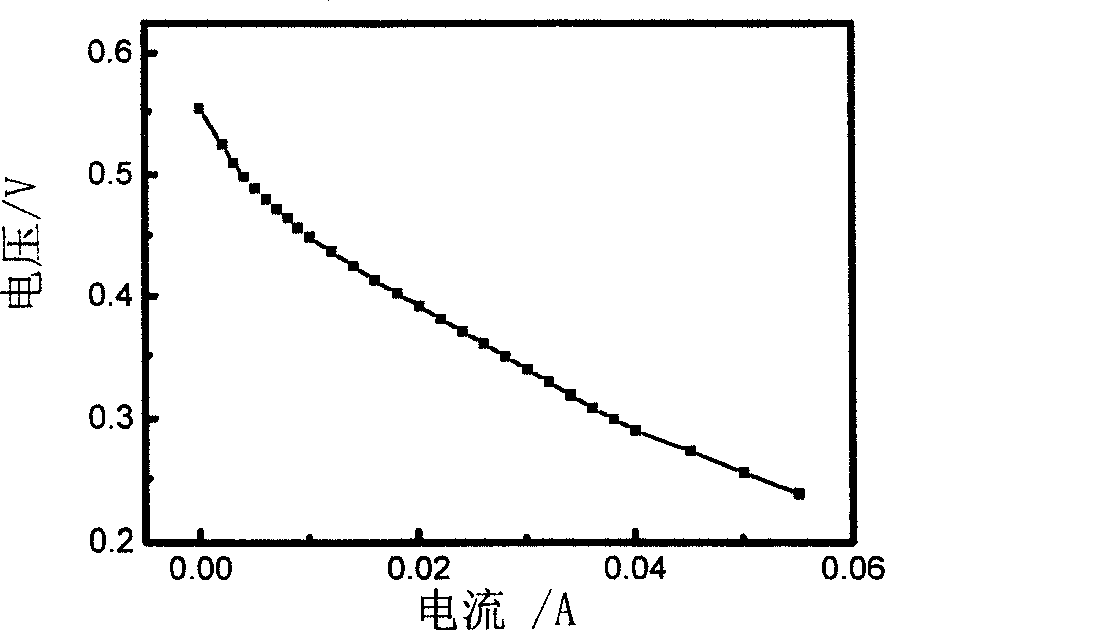

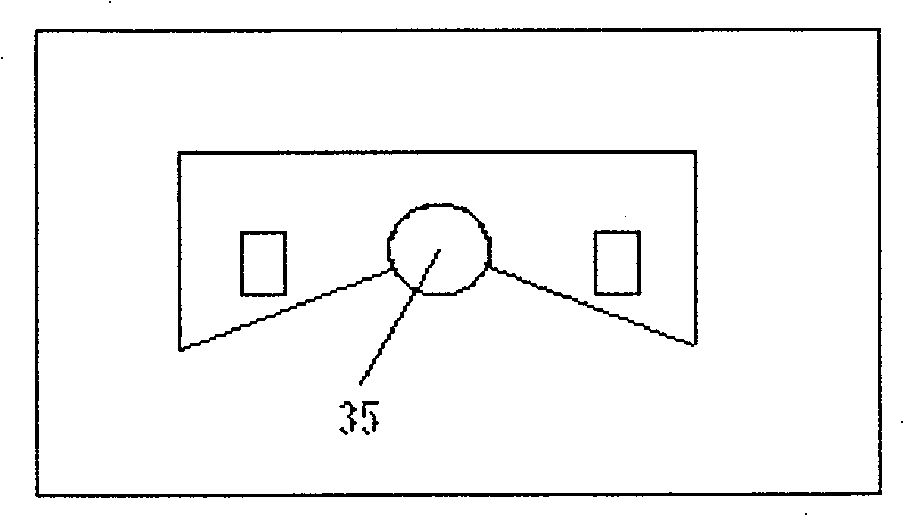

Single microbiological fuel cell with gaseous diffusion electrode as cathode

InactiveCN101207219ALow running costEasy to handleCell electrodesBiochemical fuel cellsCopper conductorClosed loop

The invention provides a single-chamber microbial fuel cell, which takes a gas diffusion electrode as the negative electrode. The invention comprises a container, a positive electrode and a negative electrode; wherein, the positive electrode adopts a foamed metal electrode, the negative electrode adopts a gas diffusion electrode containing metallic catalyst, such as Ag, the container adopts a cylindric glass container, a water inlet opening is arranged at the lower end of the container, a water outlet opening is arranged at the upper end, a sealing cover is arranged at the upper part of the container, a sampling opening is arranged at the middle part of the sealing cover, the positive electrode is positioned at the inner side of the container, the negative electrode is positioned at the outer side of the container, the positive electrode and the negative electrode are arranged along the circumference of the container, copper conductors are connected between the both electrodes, and the both electrodes are connected with a load to form a closed loop. The gas diffusion electrode adopted by the invention exposes in the air, the oxygen gas in the air can be directly utilized as electron acceptors, an extra aerating device is not required; therefore the running cost is reduced. Organism, such as dextrose and discharge water can be used as the fuel of the cell, chemical energy can be effectively converted into electric energy; simultaneously, better discharge water processing effect can be achieved.

Owner:HARBIN ENG UNIV

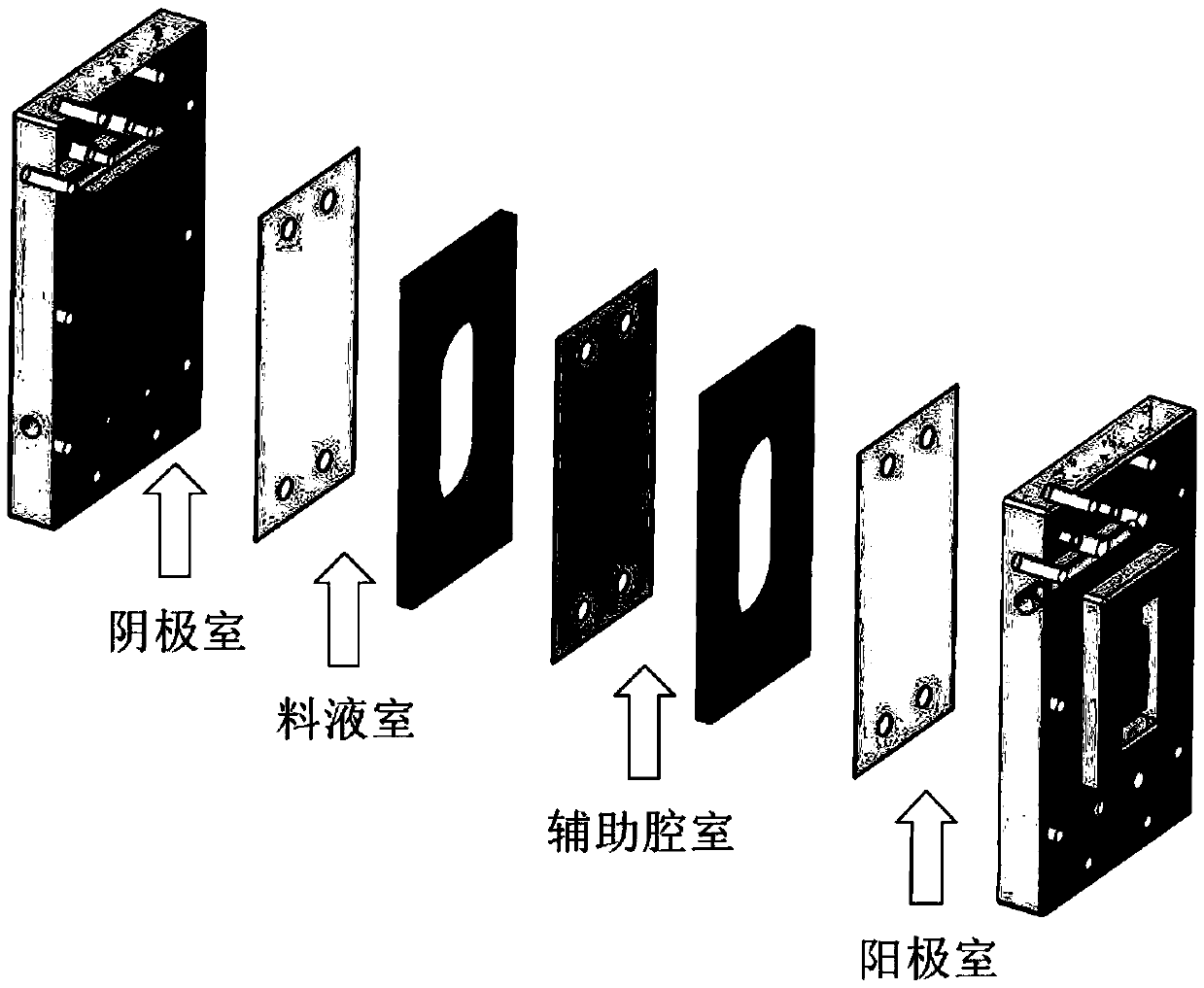

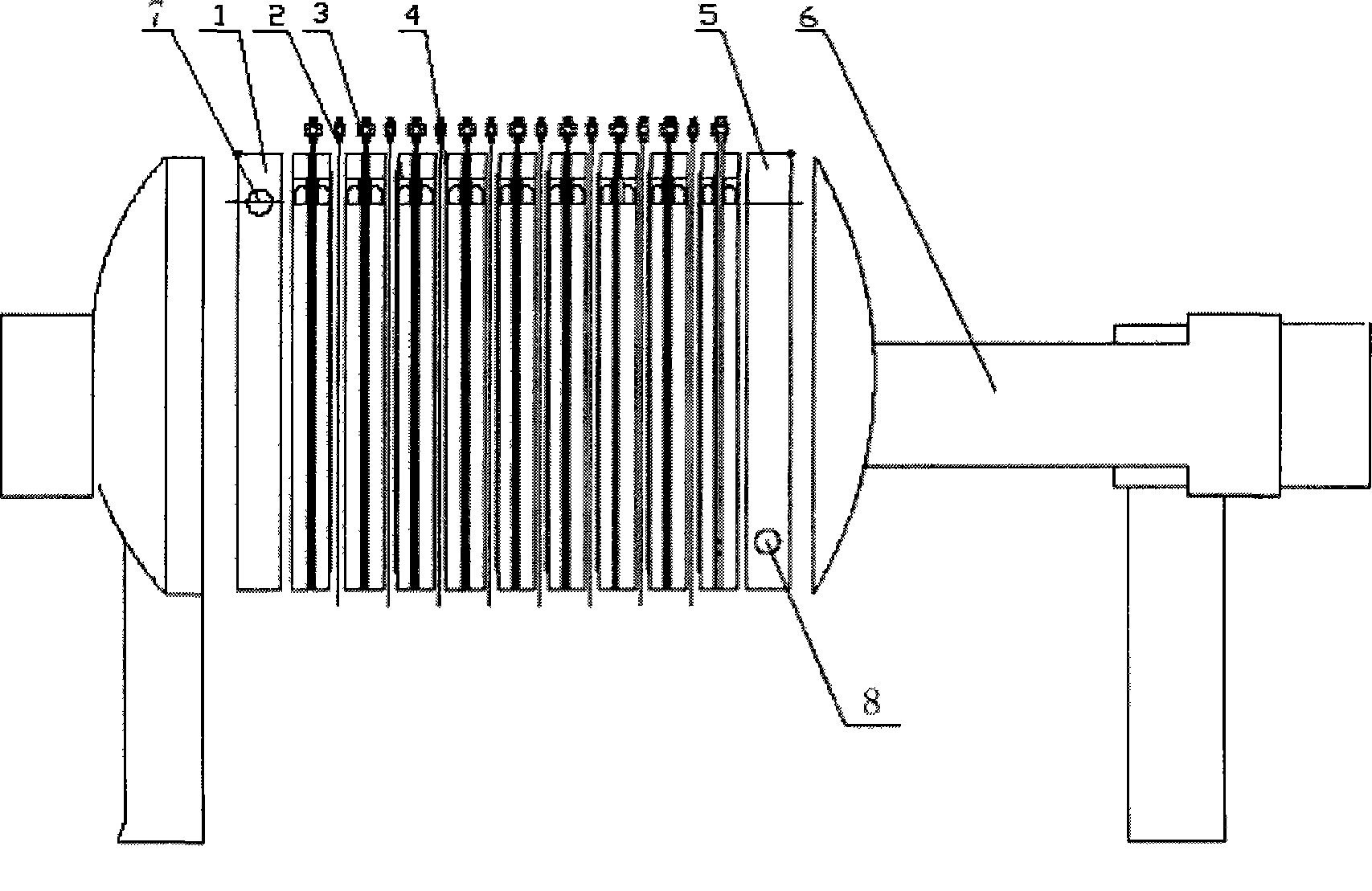

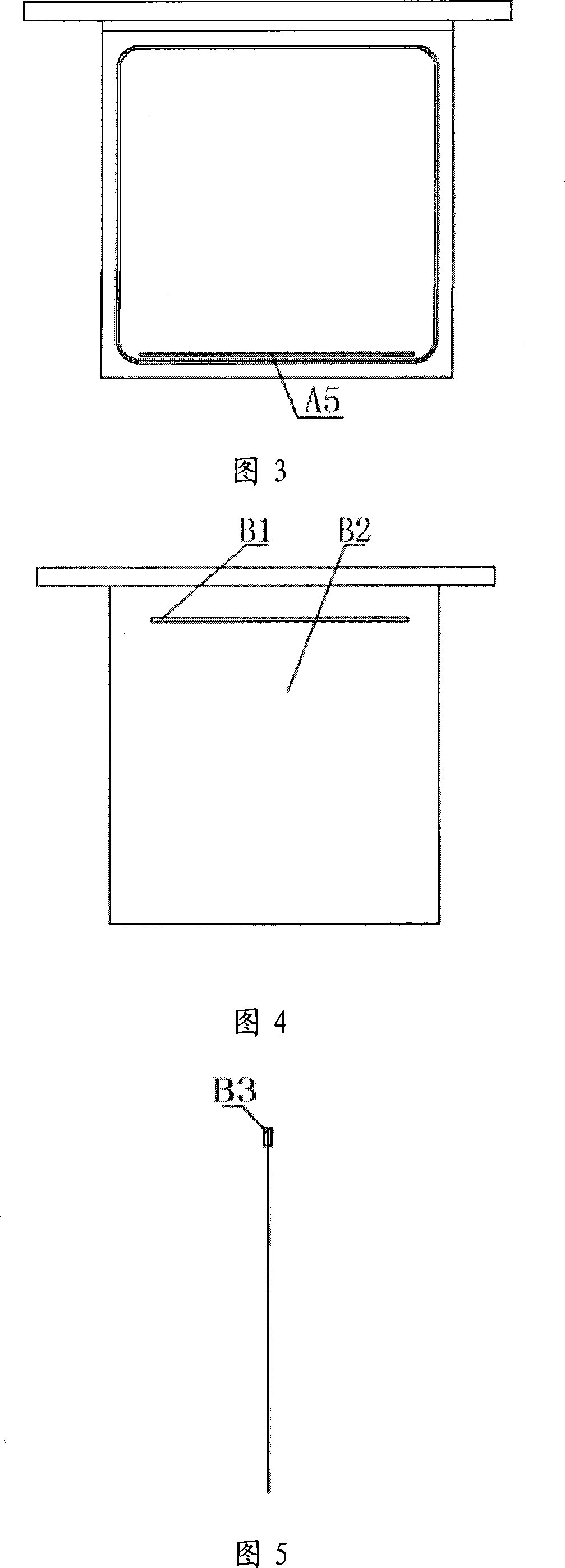

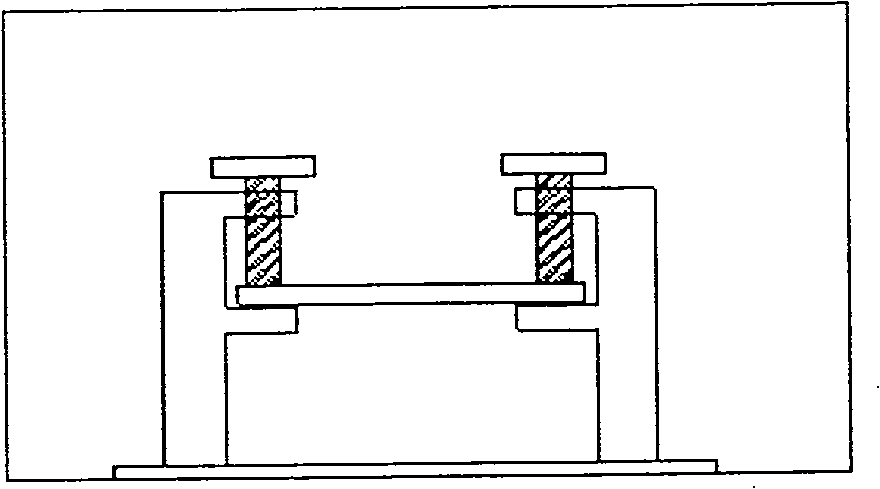

Enclosed type electrolytic tank and electrolytic system

The invention discloses a sealed electrolysis bath and an electrolytic system, the electrolysis bath comprises two end plates, an anode component, a cathode component, sealing components and a compacting device, wherein liquid flowing ports are evenly arranged on the two end plates, liquid flowing through-holes are correspondingly arranged on the anode component and the cathode component, the anode component and the cathode component are separately arranged between the two end plates, a polar chamber is formed between the anode component and the cathode component, the sealing components are evenly arranged on the contact position of the anode component, the cathode component and the end plates, and the anode component, the cathode component and the end plates form a sealed structure after being compacted through the compacting device. The electrolysis bath has simple structure and can increase the circulation speed of electrolyte, the overpotential is effectively lowered, the current density of an anode and a cathode is increased when in electrolysis, the productivity of unit electrolysis bath is increased, and the electrolysis bath can be widely applied in electrowinning various metal and in electrowinning metallic solution with low concentration. The sealed structure avoids the influence of gas which is discharged in the electrolysis process to environment in a workshop.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

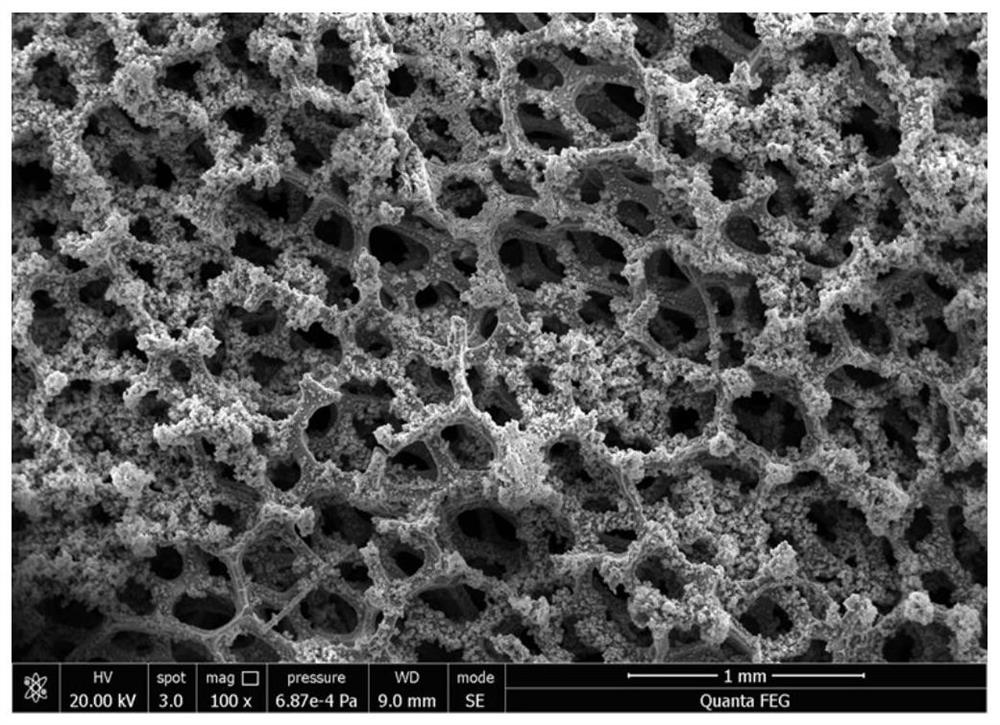

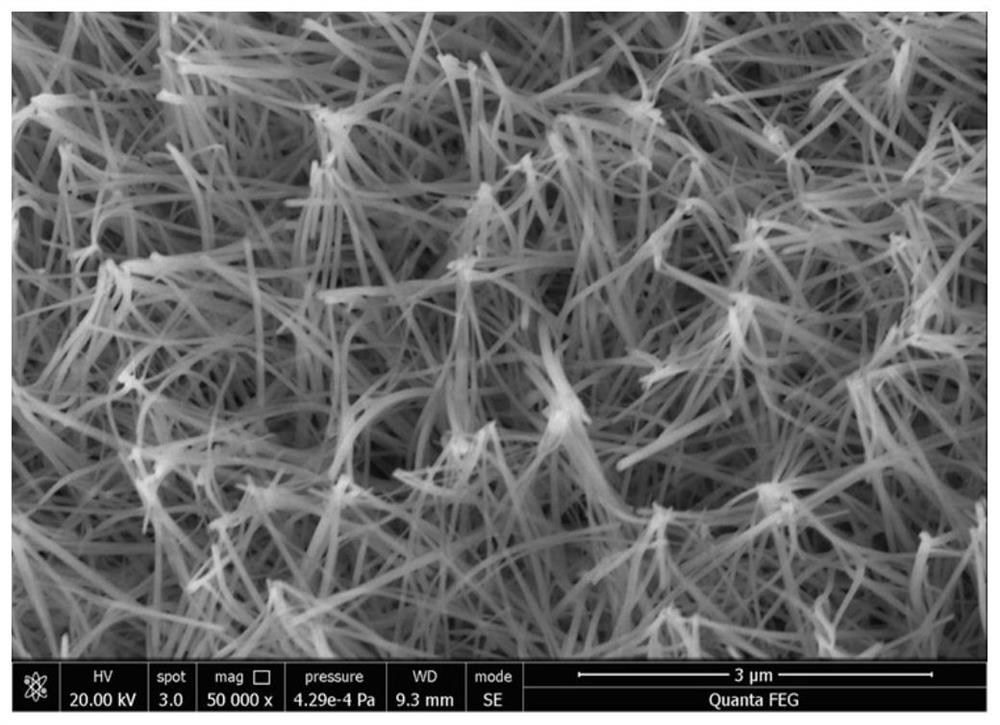

Jet electroform method and equipment for manufacturing foamed metal

InactiveCN101092719AChange the mass transfer processUniform thicknessElectroforming processesSpray nozzleMetallic materials

This invention discloses method and apparatus for producing electroplated foam metal by spraying. The method comprises: placing surface-treated cathode plate into an electroforming tank, controlling the temperature of the electroforming solution at 20-65 deg.C, spraying via the spray nozzle connected with the central chamber of the anode bar to the cathode plate at a rate of 1.5-7.5 m / s to obtain a branch-like or sponge-like metal deposition layer, controlling the current density at 200-750 A / dm2, controlling the movement of the spray nozzle along the vertical direction, the horizontal lateral direction and horizontal longitudinal direction to form a porous foam metal deposition layer with required thickness and shape, and drying the foam metal deposition layer. The method has such advantages as no need for auxiliary medium, simple process and convenient production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

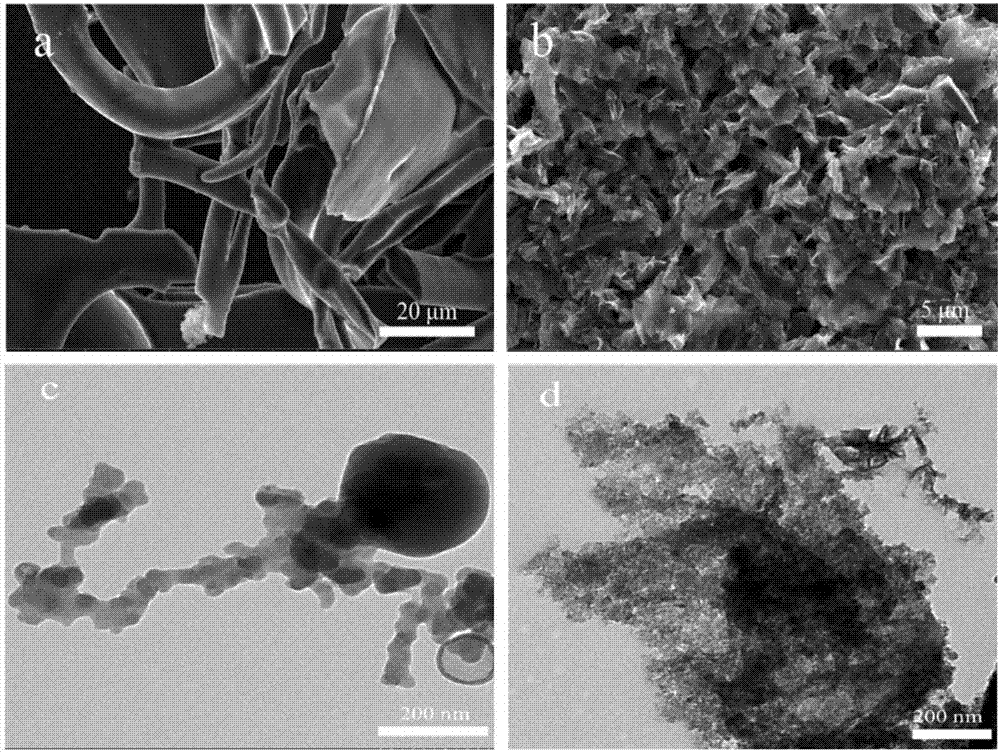

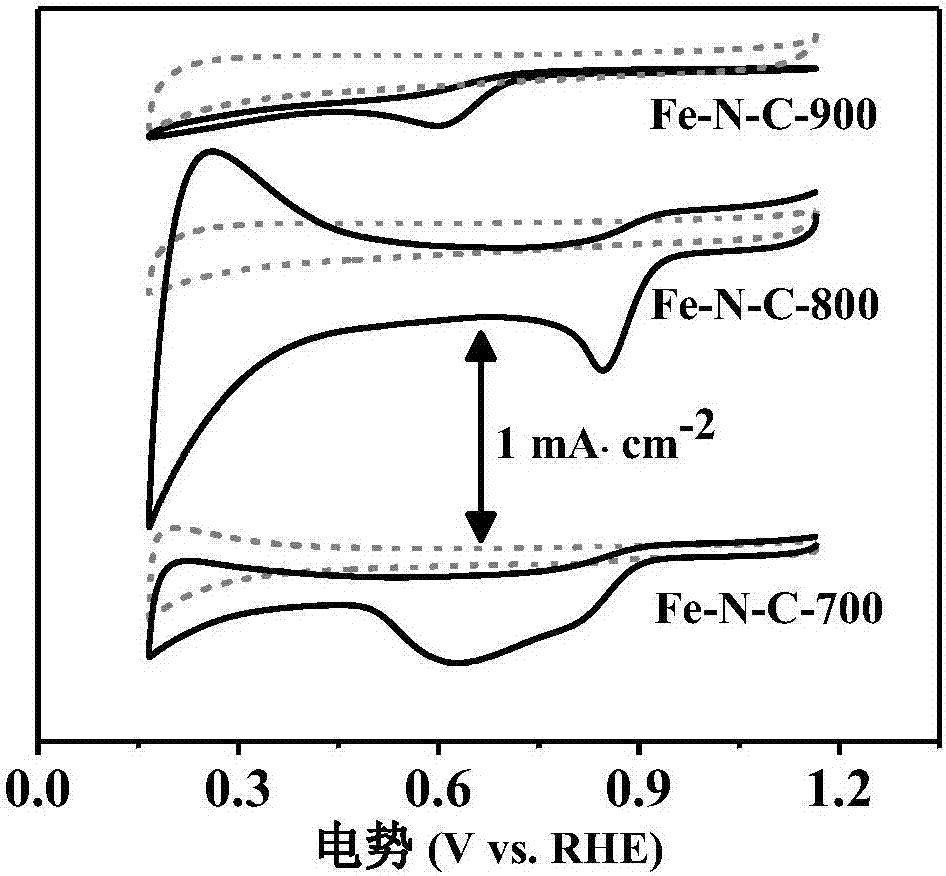

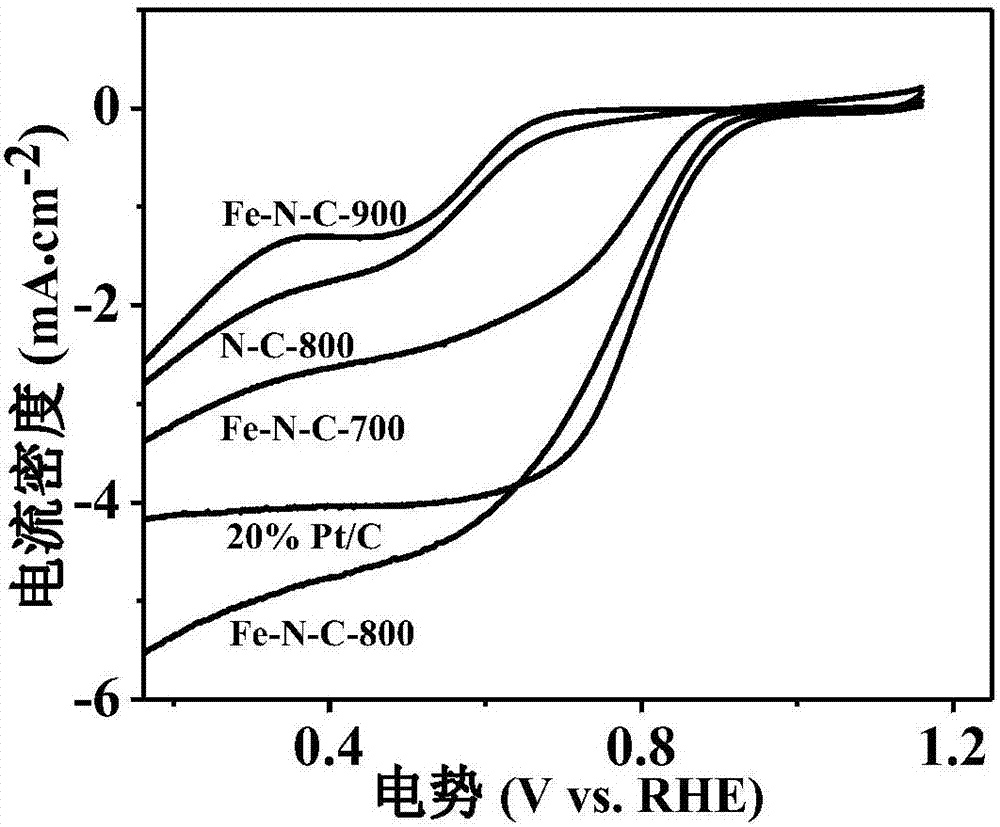

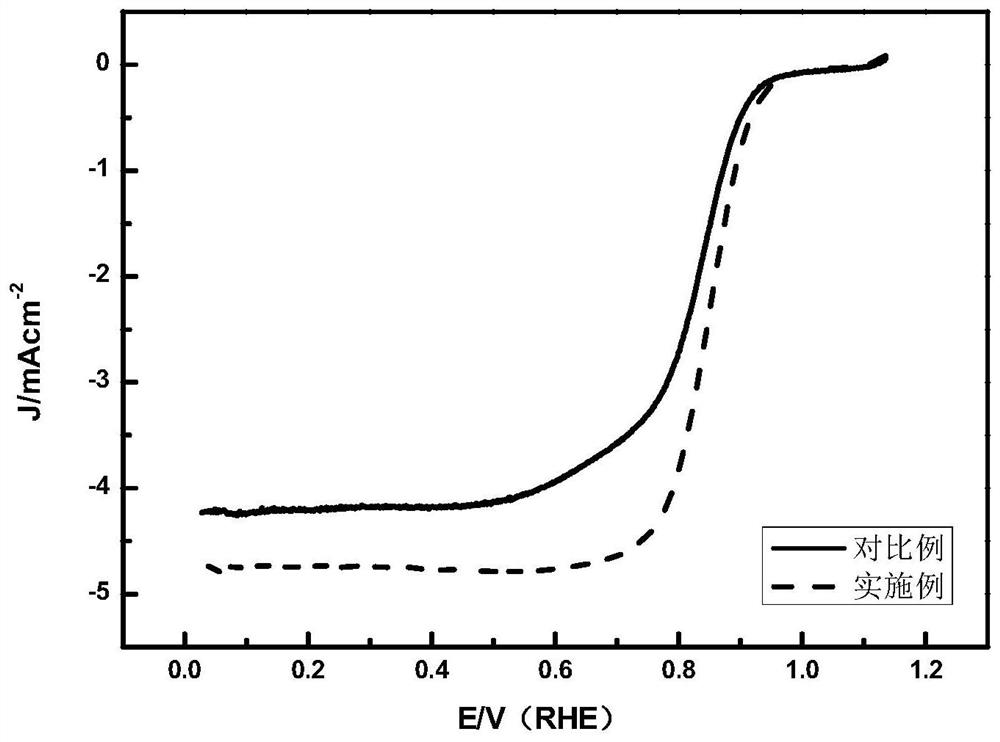

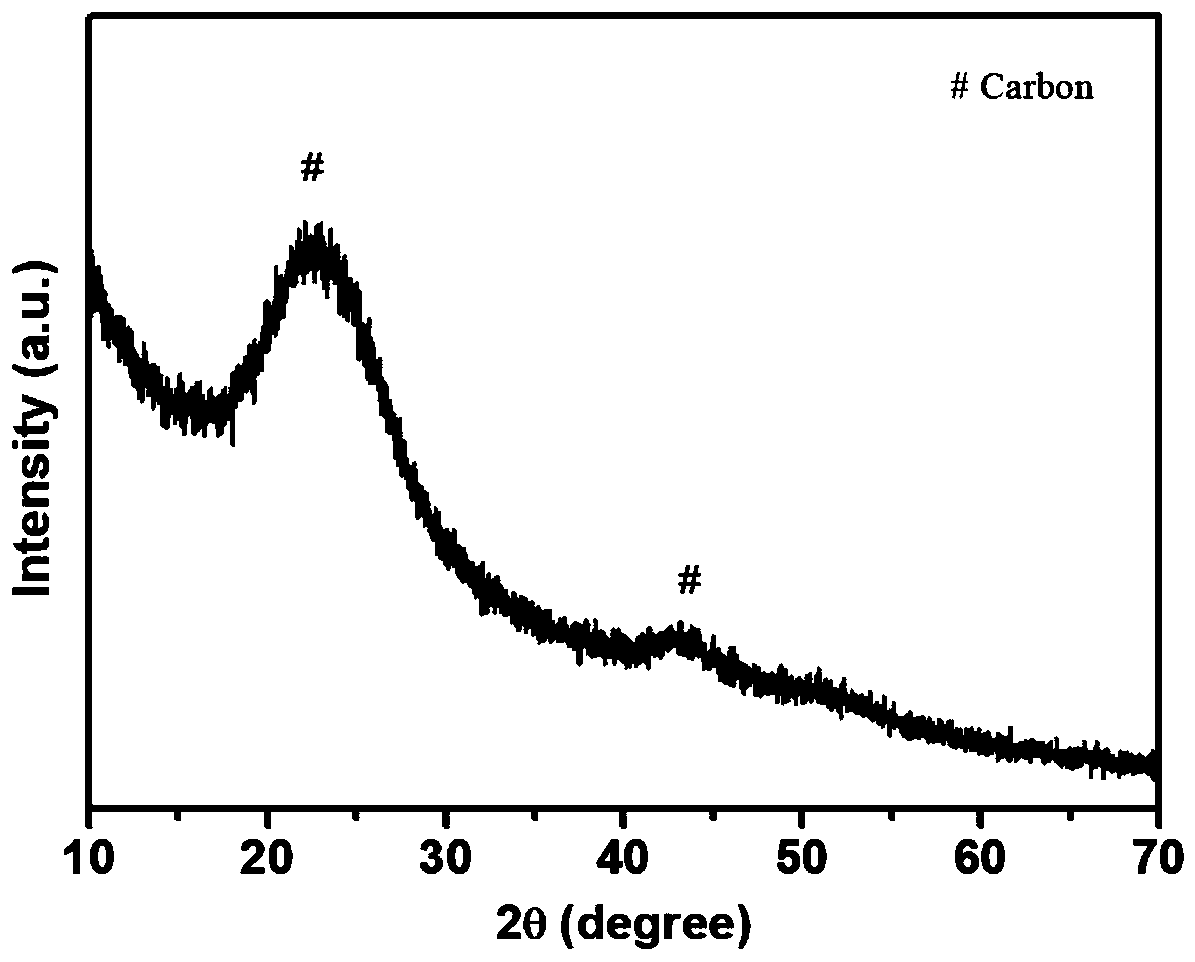

Fe-N doping porous carbon oxygen reduction catalyst

The invention relates to a Fe-N doping porous carbon oxygen reduction catalyst. The Fe-N doping porous carbon oxygen reduction catalyst is prepared by the following steps: after uniformly mixing iron ions and silk fibroin solution, freeze-drying, and performing the high-temperature carbonization treatment to a freeze-dried product. The green and environmental silkworm cocoon in the natural world with the cheap price which is easily and extensively obtained is used as a precursor for successfully synthesizing the high-efficient Fe-N doping porous carbon catalyst for oxygen reduction. Through the optimization of a preparation technology, the suitable reaction conditions can be determined. The prepared catalyst has many advantages, such as the larger electric current density, the higher electron transfer number, the lower hydrogen peroxide yield, the good stability and methyl alcohol poison resistance.

Owner:CAPITAL NORMAL UNIVERSITY

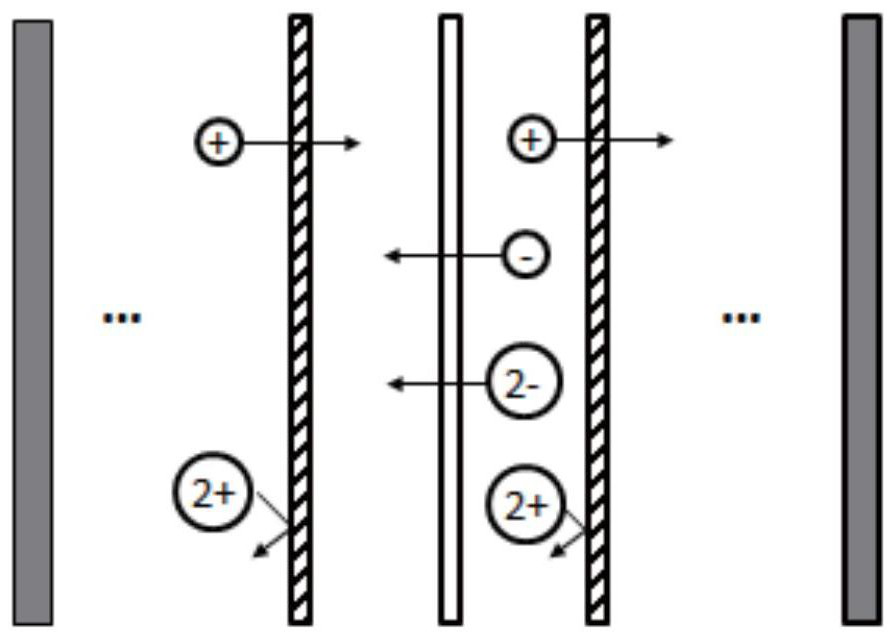

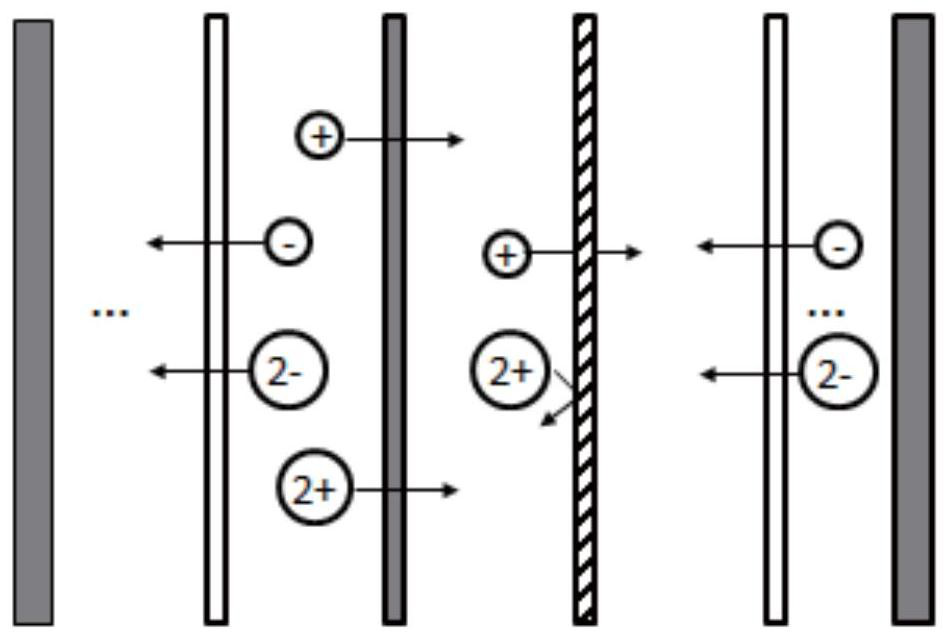

Method for preparing mono-/multi-valent ion exchange membrane by membrane fouling and electrodialysis deposition

ActiveCN108905658APrecise thickness controlTight bondSemi-permeable membranesMembranesVolumetric Mass DensityElectrodialysis

The invention discloses a method for preparing a mono- / multi-valent ion exchange membrane by membrane fouling and electrodialysis deposition. The method utilizes a phenomenon that an electrolyte in asolution performs fouling on an ion exchange membrane, and employs an electrodialysis process to foul the surface or interior of a to-be-modified ion exchange membrane by a target pollutant so as to enable the ion exchange membrane to have a mono- / multi-valent ion selective permeability, so that the mono- / multi-valent ion exchange membrane is obtained. According to the method of the invention, through chemical bond combination between the target pollutant and the ion exchange membrane main structure, the surface resistance is effectively reduced, the limiting current density under electrodialysis operating conditions is improved, and peeling of a modification compound from a membrane matrix is avoided during long-term operation. The method has a simple operation process, is easy to industrialize, has a wide range of raw materials, and has low cost in the membrane modification process.

Owner:UNIV OF SCI & TECH OF CHINA

Single cell microbiological fuel cell with gaseous diffusion electrode as cathode

InactiveCN100499240CUniform and efficient power generationLow running costCell electrodesBiochemical fuel cellsCopper conductorClosed loop

The invention provides a single-chamber microbial fuel cell, which takes a gas diffusion electrode as the negative electrode. The invention comprises a container, a positive electrode and a negative electrode; wherein, the positive electrode adopts a foamed metal electrode, the negative electrode adopts a gas diffusion electrode containing metallic catalyst, such as Ag, the container adopts a cylindric glass container, a water inlet opening is arranged at the lower end of the container, a water outlet opening is arranged at the upper end, a sealing cover is arranged at the upper part of the container, a sampling opening is arranged at the middle part of the sealing cover, the positive electrode is positioned at the inner side of the container, the negative electrode is positioned at the outer side of the container, the positive electrode and the negative electrode are arranged along the circumference of the container, copper conductors are connected between the both electrodes, and the both electrodes are connected with a load to form a closed loop. The gas diffusion electrode adopted by the invention exposes in the air, the oxygen gas in the air can be directly utilized as electron acceptors, an extra aerating device is not required; therefore the running cost is reduced. Organism, such as dextrose and discharge water can be used as the fuel of the cell, chemical energy can be effectively converted into electric energy; simultaneously, better discharge water processing effect can be achieved.

Owner:HARBIN ENG UNIV

Platinum alloy catalyst, preparation method thereof and application of platinum alloy catalyst in fuel cell cathode catalyst

InactiveCN110931805AIncrease the areaIncrease the limit currentCell electrodesPtru catalystMetallurgy

The invention discloses a platinum alloy catalyst, a preparation method of the platinum alloy catalyst and an application of the platinum alloy catalyst in a fuel cell cathode catalyst. The method comprises the following steps: 1) preparing a mixed solution of a first reducing agent glucose and a precursor of a first metal component platinum; 2) under the condition that the pH value of the mixed solution is 3-10, heating and adding a carbon carrier, and raising the temperature to 80-95 DEG C for reaction; 3) adding a second metal component precursor, and reacting; 4) cooling and separating a reaction product; 5) dissolving the reaction product in water, adding a second reducing agent, heating to 80-95 DEG C, and reacting; 6) cooling and separating a reaction product to obtain a catalyst precursor; and 7) calcining to obtain the platinum alloy catalyst. According to the preparation method, a large amount of organic solvents are not needed, the reaction conditions are mild, non-toxic andmild glucose is used as a main reducing agent in an aqueous solution, and the efficient hydrogen fuel cell catalyst is prepared by introducing a second mild reducing agent for further synergistic dispersion and reduction. Wide application prospects are realized in the field of fuel cell catalysts.

Owner:FAW JIEFANG AUTOMOTIVE CO

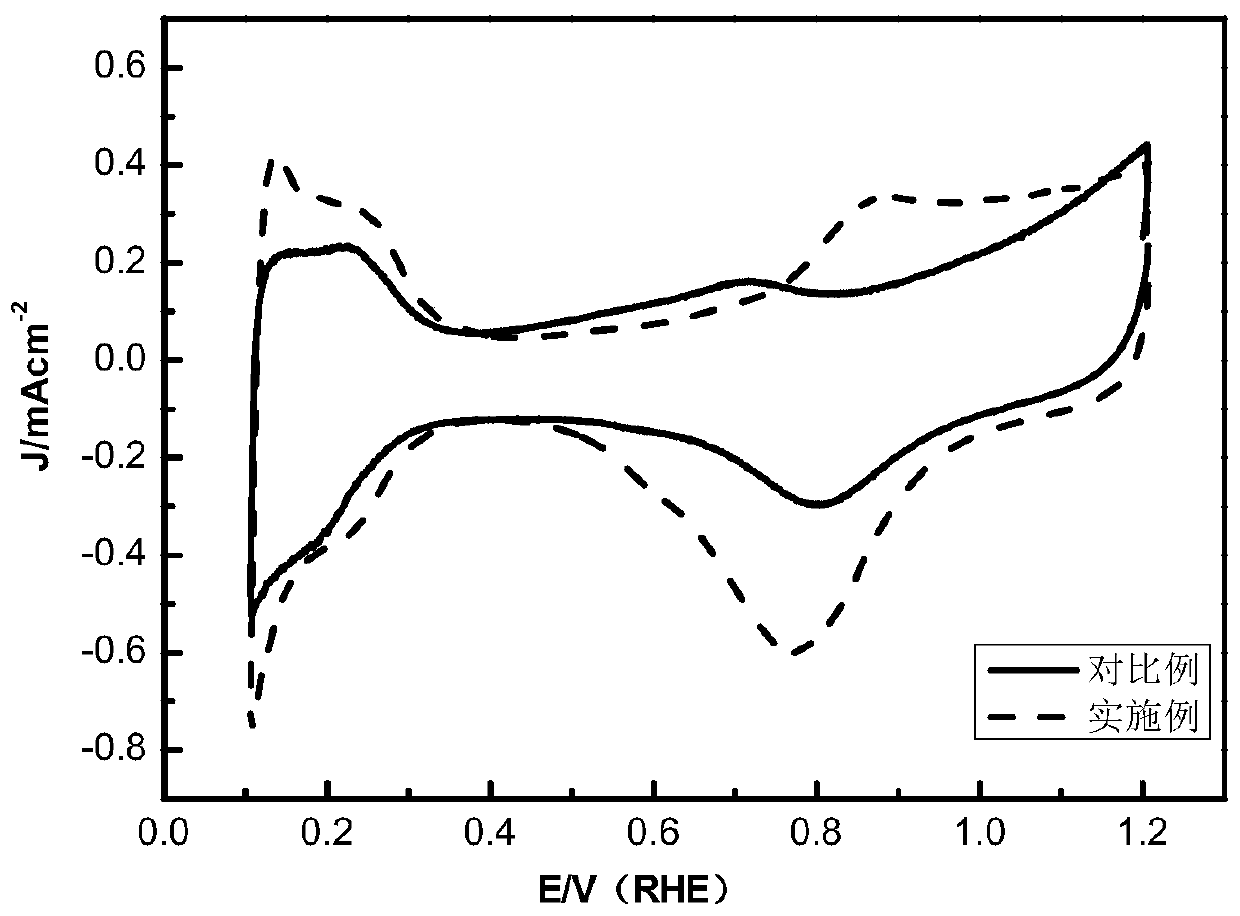

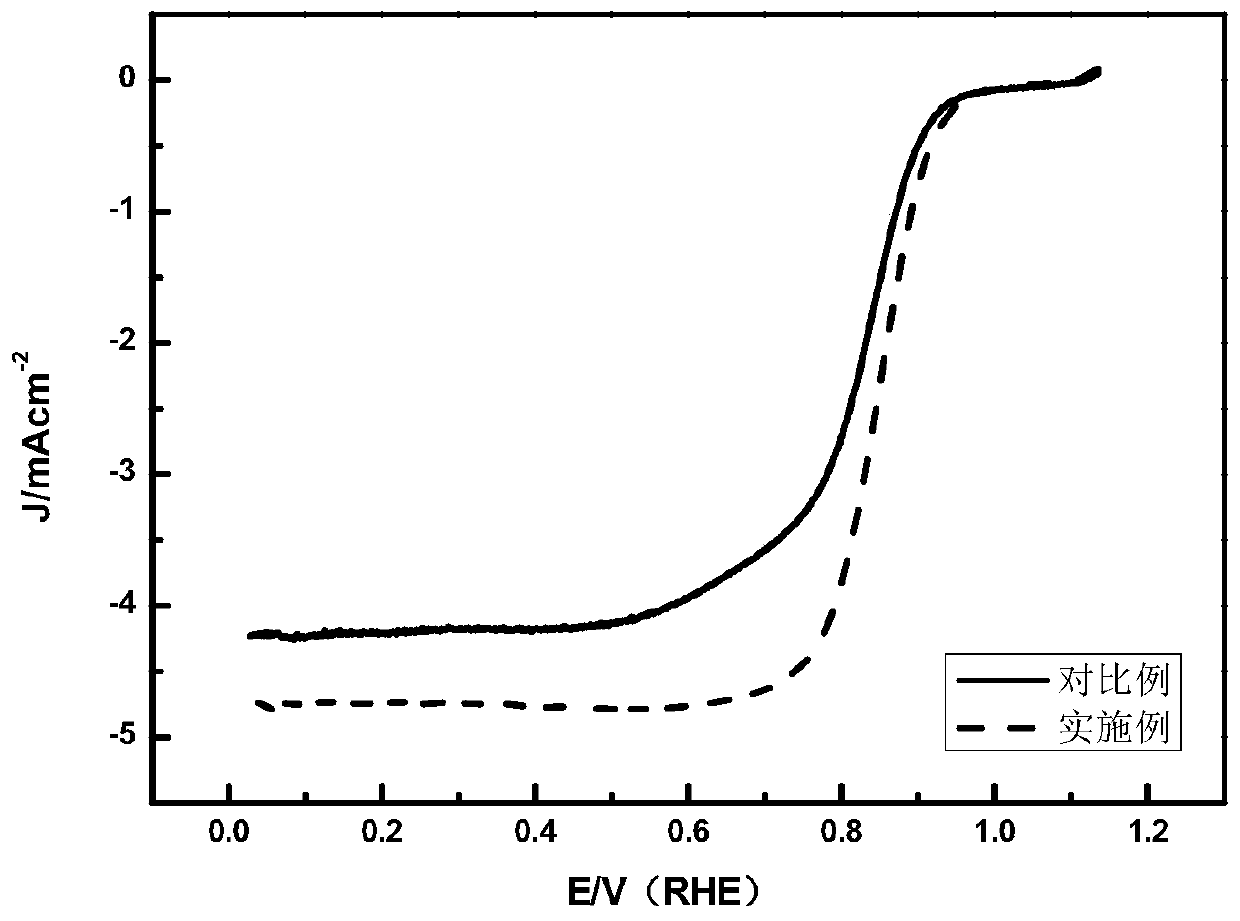

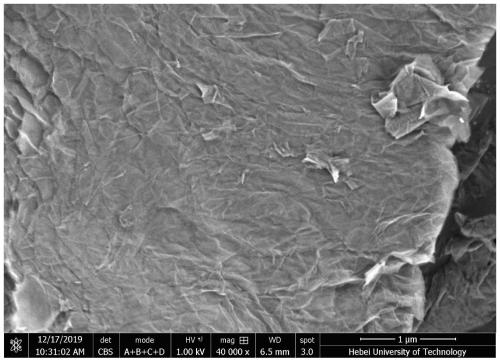

Preparation method and application of ionic liquid modified nitrogen-sulfur co-doped graphene oxide composite material

ActiveCN111229310AImprove electronic performanceHigh chemical activityOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesDoped graphenePtru catalyst

The invention relates to a preparation method of an ionic liquid modified nitrogen-sulfur co-doped graphene oxide composite material. The method comprises the following steps: preparing a dispersion liquid from graphene oxide and deionized water, then mixing 1-aminopropyl-3-alkyl imidazole bromide salt, potassium hydroxide and the graphene oxide dispersion liquid, carrying out a reaction process to obtain a 1-aminopropyl-3-alkyl imidazole bromide salt and graphene oxide composite product, then mixing the product with thiourea, adding a solvent to dissolve the mixture, and reacting at 160-200 DEG C to obtain the composite material. The composite material is loaded on a cathode electrode to serve as a catalyst. The material obtained by the invention has good oxygen reduction catalytic activity and a wide application prospect.

Owner:HEBEI UNIV OF TECH

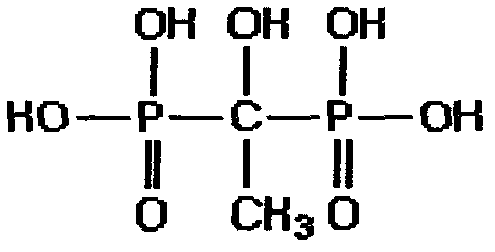

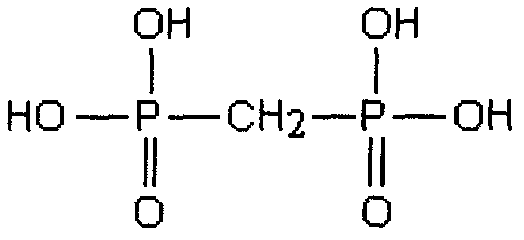

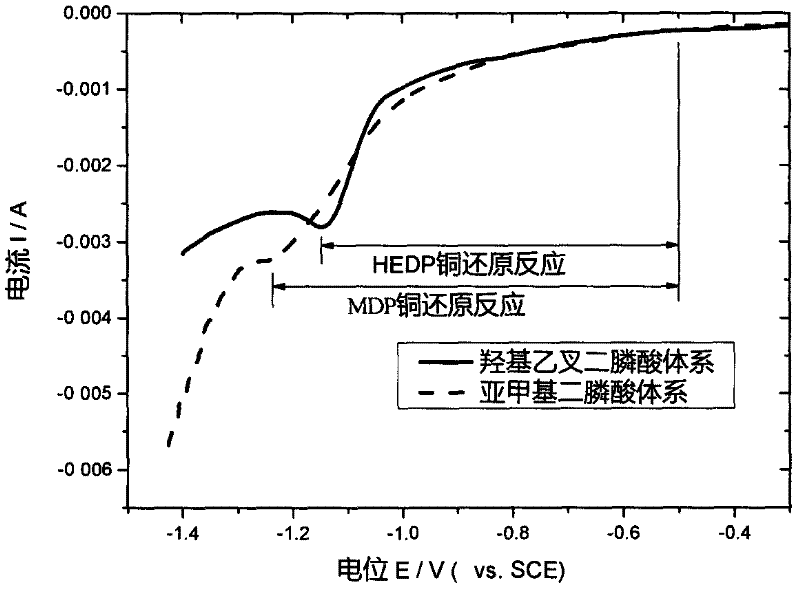

Alkaline non-cyanide copper plating solution with main coordination agent of methylenediphosphonate

The invention provides an alkaline copper plating solution with a main coordination agent of methylenediphosphonate, and relates to non-cyanide electroplating field. The plating solution comprises the following components: methylenediphosphonate (MDP) with concentration of 30-100 g / L, cupric ion with concentration of 3-25 g / L, and carbonate ion with concentration of 10-80 g / L. By using sodium hydroxide or potassium hydroxide, pH value of the solution is adjusted to 7.5-13.5. The plating solution in the invention has the characteristics of simple formula, no cyanide pollution, small concentration polarization generated in an electroplating process, good stability of the plating solution, and wide allowable current density range. By using the plating solution to plate copper on iron matrix, zinc matrix, zinc alloy matrix or aluminium zinc galvanizing directly, a copper plating layer with good bonding force with the matrix is obtained.

Owner:HANGZHOU AMAER TECH

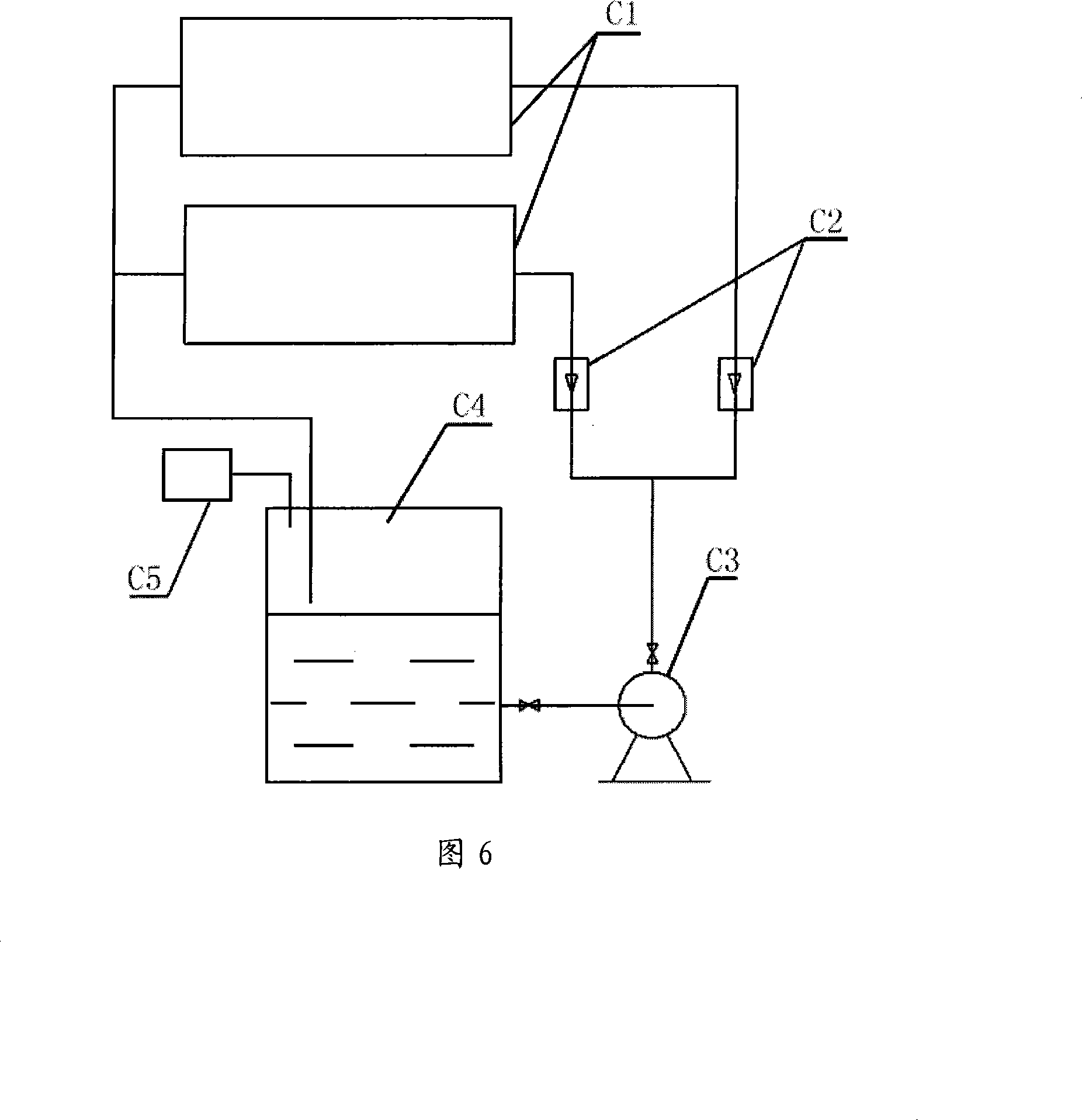

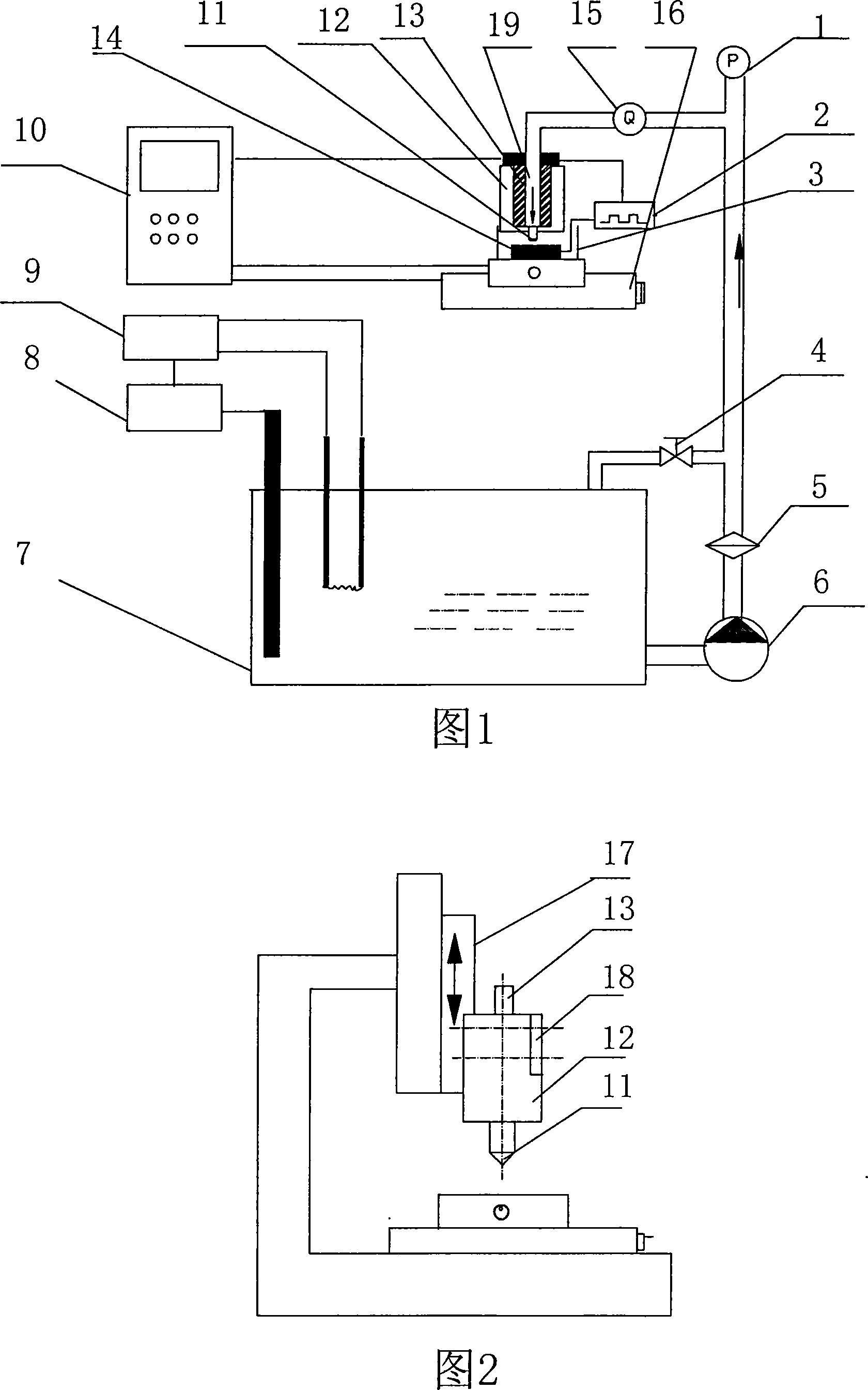

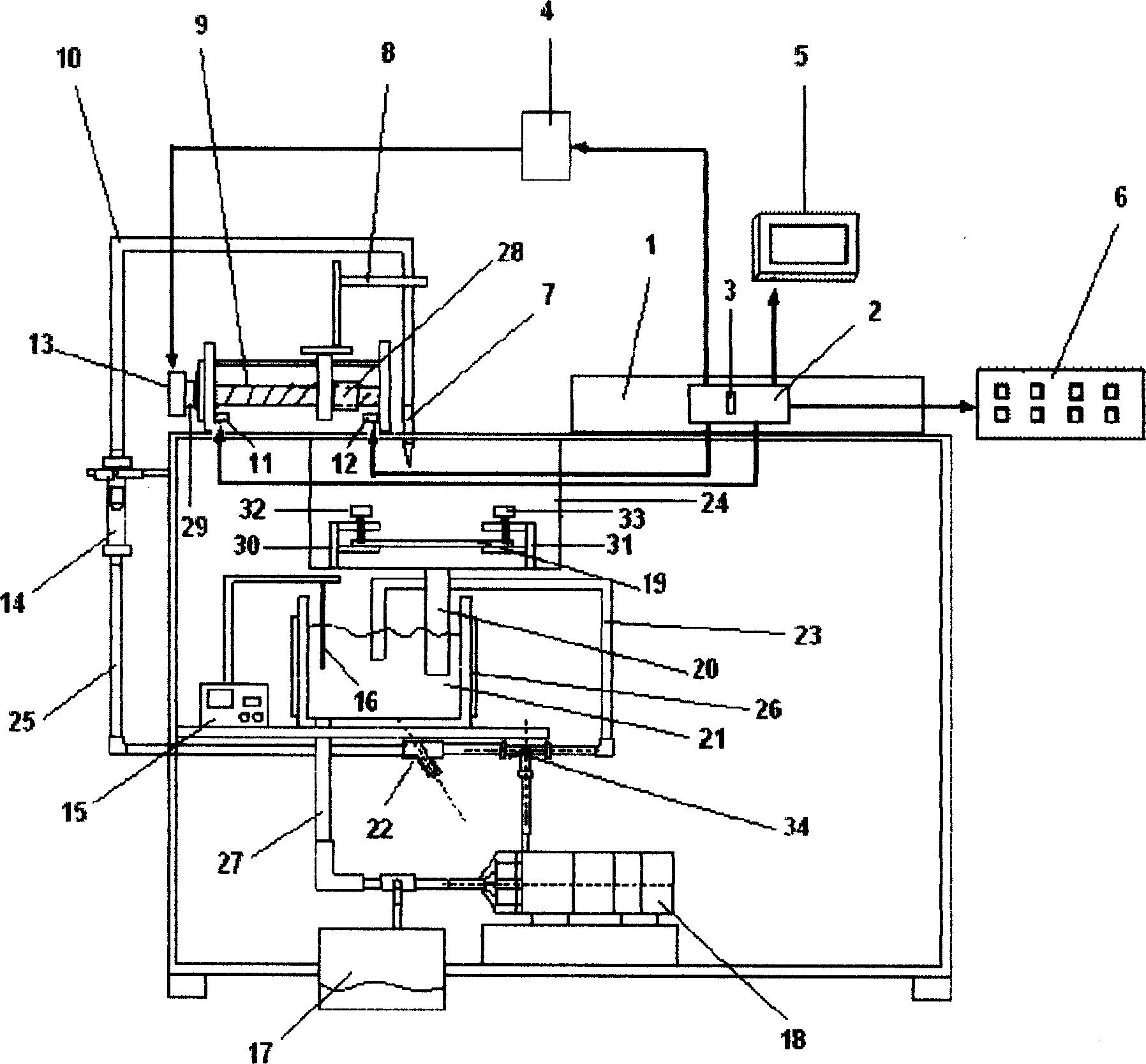

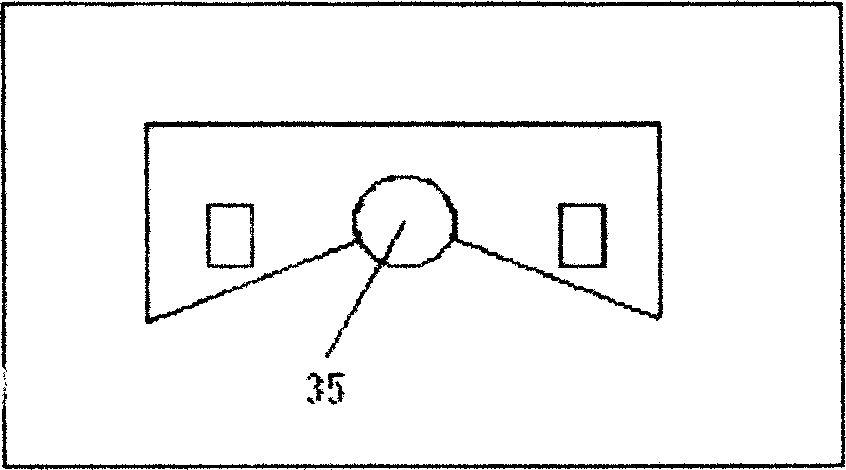

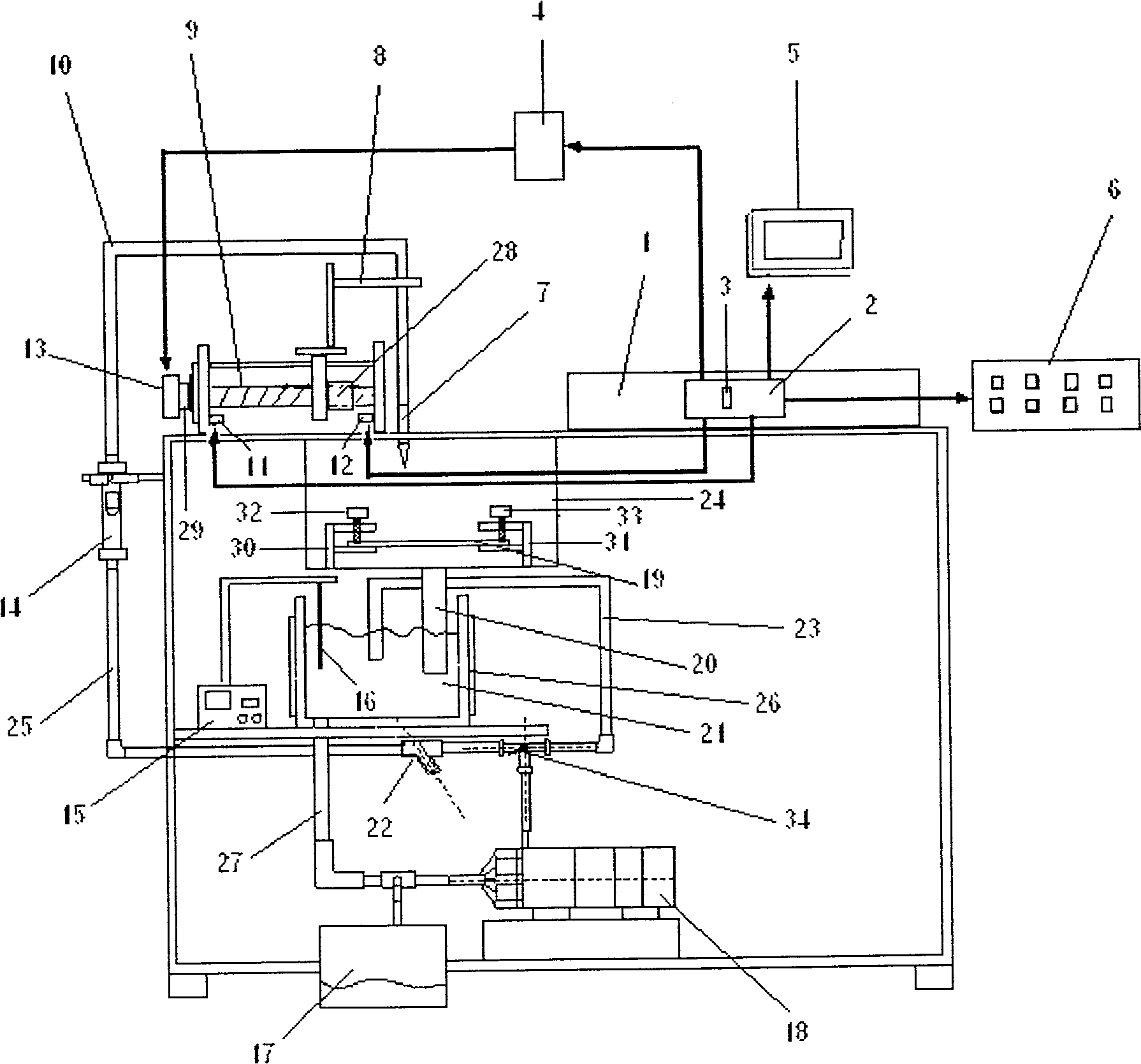

High-speed electrospraying device

The present invention relates to mechanical apparatus technology, and is especially one kind of high speed electric spray coating apparatus comprising coating solution circulation system, mechanical driving system, microcomputerized circuit control system and control console. Compared with available technology, the present invention has the advantages of novel structure, in which electrolyte is sprayed in certain flow rate and pressure from the nozzle as anode to the workpiece as the cathode to activate the coating mechanically, reduce the thickness of the boundary layer and diffusion layer, speed the stirring of solution, raise the limit current density and raise the deposition speed, high selectivity, quick speed, low cost and no need of mask, etc.

Owner:SHANGHAI UNIV OF ENG SCI

Enclosed type electrolytic tank and electrolytic system

The invention discloses a sealed electrolysis bath and an electrolytic system, the electrolysis bath comprises two end plates, an anode component, a cathode component, sealing components and a compacting device, wherein liquid flowing ports are evenly arranged on the two end plates, liquid flowing through-holes are correspondingly arranged on the anode component and the cathode component, the anode component and the cathode component are separately arranged between the two end plates, a polar chamber is formed between the anode component and the cathode component, the sealing components are evenly arranged on the contact position of the anode component, the cathode component and the end plates, and the anode component, the cathode component and the end plates form a sealed structure afterbeing compacted through the compacting device. The electrolysis bath has simple structure and can increase the circulation speed of electrolyte, the overpotential is effectively lowered, the current density of an anode and a cathode is increased when in electrolysis, the productivity of unit electrolysis bath is increased, and the electrolysis bath can be widely applied in electrowinning various metal and in electrowinning metallic solution with low concentration. The sealed structure avoids the influence of gas which is discharged in the electrolysis process to environment in a workshop.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Monovalent selective cation exchange membrane and preparation method thereof

InactiveCN112108019ALower resistanceHigh selectivityMembranesElectrodialysisPoly ether ether ketoneIndustrial waste water

The invention provides a monovalent selective cation exchange membrane and a preparation method thereof. The preparation method is characterized by comprising the following steps: (1), dissolving oneor more of sulfonated polysulfone, sulfonated polyvinylidene fluoride and sulfonated polyether-ether-ketone in an organic solvent to obtain a membrane casting solution to prepare a base membrane; (2),preparing a functionalized mesoporous polymer by using a self-assembly method, and dispersing the functionalized mesoporous polymer into an aqueous solution of an amine compound with carboxyl and sulfonic acid groups; and (3) carrying out interfacial polymerization to obtain the monovalent cation selective ion exchange membrane. The prepared membrane is low in resistance, high in limiting currentdensity, high in monovalent / multivalent ion selectivity and simple in preparation method, can be used for separation of monovalent cations and multivalent cations, and is typically applied to concentrated seawater recycling and industrial wastewater zero discharge such as separation of NaCl / MgCl2 and Na2SO4 / MgSO4.

Owner:宜兴喜瑞洲企业管理有限公司

Preparation method of cathode oxygen reduction reaction catalyst based on two-dimensional graphite phase carbon nitride cobalt doped porous carbon material

ActiveCN113394413AEasy to operateReaction conditions are easy to controlCell electrodesPtru catalystPorous carbon

The invention relates to a preparation method of a cathode oxygen reduction reaction catalyst based on a two-dimensional graphite phase carbon nitride cobalt doped porous carbon material. An active substance of a nano material is C3N4@Co-BDC-TA. The problems existing in an existing fuel cell catalyst are solved, the defects in the prior art are overcome, the problems of single precursor obstacle and low synthesis cost of the existing fuel cell catalyst are generally faced, and the defects of high cost, toxicity and the like of a platinum-based catalytic material are overcome; and on the basis of a two-dimensional layered g-C3N4 material, a porous carbon material formed by taking tannin as a connecting agent and fixing metal Co with terephthalic acid is developed, and the porous carbon material has the advantages of relatively high initial potential and half-slope potential, excellent limiting current, excellent stability, good methanol tolerance, relatively high methanol poisoning resistance and the like.

Owner:FUZHOU UNIV

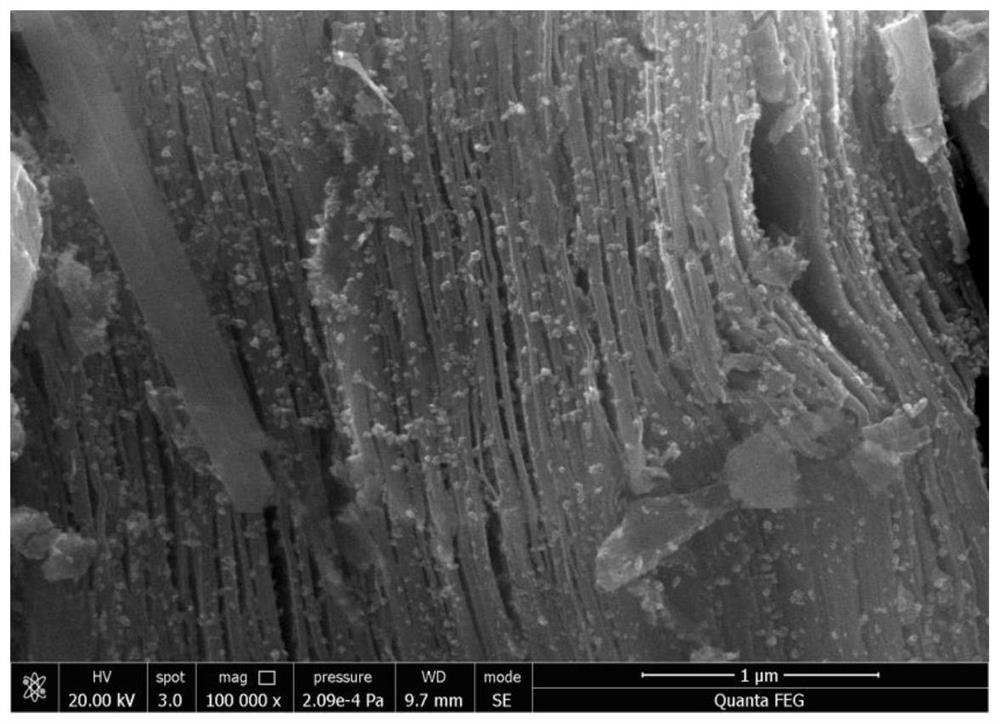

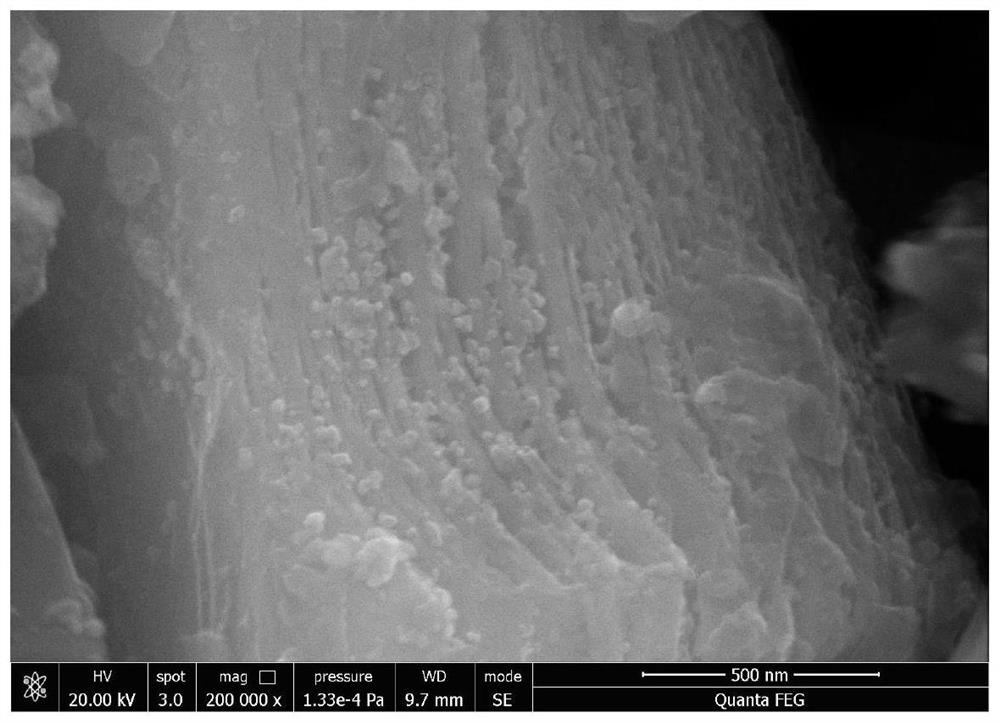

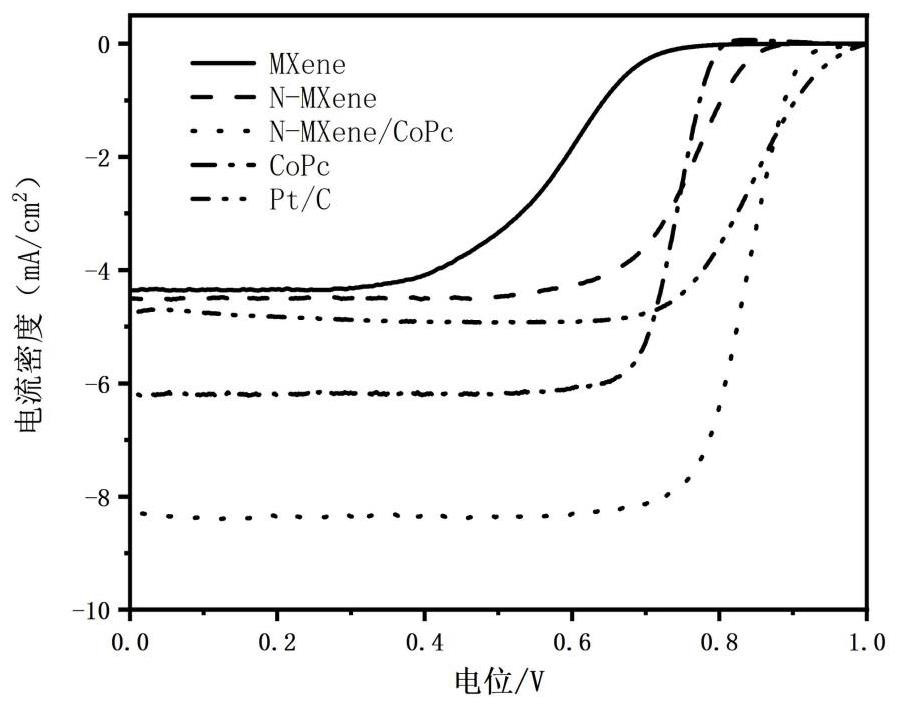

Preparation method and application of nitrogen-doped MXene loaded cobalt phthalocyanine composite material

ActiveCN114361470ALower transfer resistanceIncrease transfer rateCell electrodesPtru catalystPhysical chemistry

The invention relates to a preparation method and application of a nitrogen-doped MXene loaded cobalt phthalocyanine composite material. The method comprises the following steps: firstly, chemically etching Ti3AlC2 through a hydrofluoric acid solution to prepare MXene (namely Ti3C2F2) of which the surface adsorbs an F end group, then selecting urea as a nitrogen doping agent, loading a nitrogen element onto the MXene through a one-step hydrothermal method, and then combining cobalt phthalocyanine and the nitrogen-doped MXene to prepare the catalyst. The catalyst is applied to ORR, and the obtained catalytic material has good oxygen reduction catalytic activity and wide application prospects.

Owner:HEBEI UNIV OF TECH

High-speed electrospraying device

The present invention relates to mechanical apparatus technology, and is especially one kind of high speed electric spray coating apparatus comprising coating solution circulation system, mechanical driving system, microcomputerized circuit control system and control console. Compared with available technology, the present invention has the advantages of novel structure, in which electrolyte is sprayed in certain flow rate and pressure from the nozzle as anode to the workpiece as the cathode to activate the coating mechanically, reduce the thickness of the boundary layer and diffusion layer, speed the stirring of solution, raise the limit current density and raise the deposition speed, high selectivity, quick speed, low cost and no need of mask, etc.

Owner:SHANGHAI UNIV OF ENG SCI

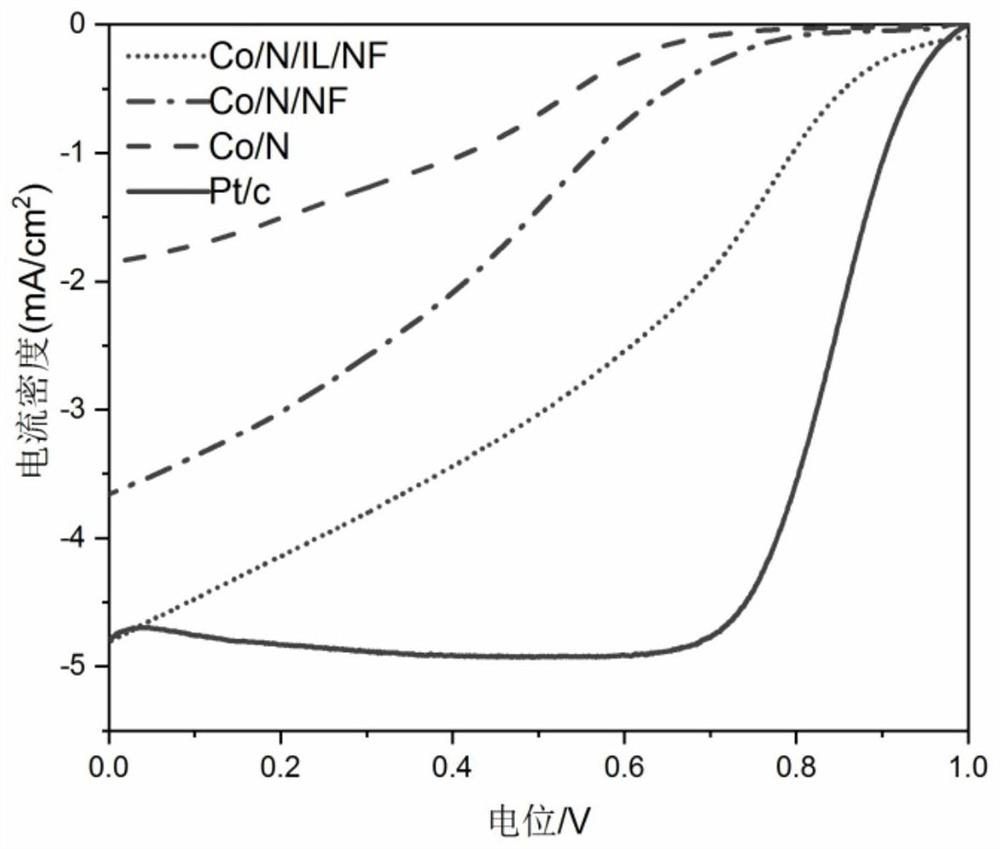

Preparation method and application of polyionic liquid functionalized cobalt-nitrogen loaded foamed nickel composite material

ActiveCN112259750ALower transfer resistanceIncrease transfer rateCell electrodesHydration reactionPlatinum

The invention relates to a preparation method and application of a polyionic liquid functionalized cobalt-nitrogen loaded foamed nickel composite material. The method comprises the following steps of:1, uniformly coating a treated polyionic liquid solution on foamed nickel, and then performing drying; 2, immersing the foamed nickel treated in the step 1 into a mixed solution containing urea, cobalt nitrate hexahydrate and CTAB (cetyltrimethyl ammonium bromide), transferring the product into a high-pressure reaction kettle, and keeping the state for 8h-12h at the temperature of 150DEG C-170DEGC to obtain a black blocky composite material; wherein the polyionic liquid is specifically poly[Dbz-mim]cl. The electro-catalytic composite material synthesized by the method provided by the invention has good oxygen reduction catalytic activity. The initial potential and the half-wave potential of the composite material are 0.85V and 0.71V respectively and are close to 0.95V and 0.81V of commercial platinum-carbon, and the composite material has high limiting current density.

Owner:HEBEI UNIV OF TECH

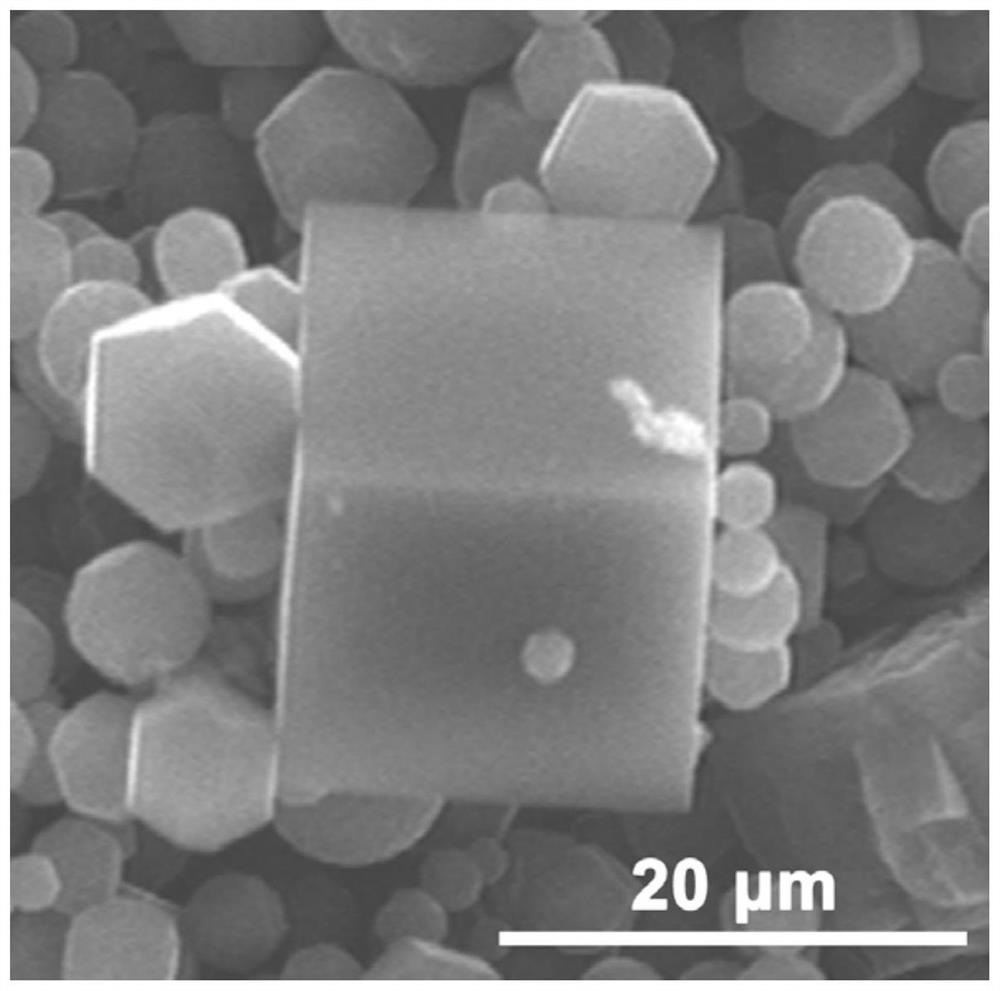

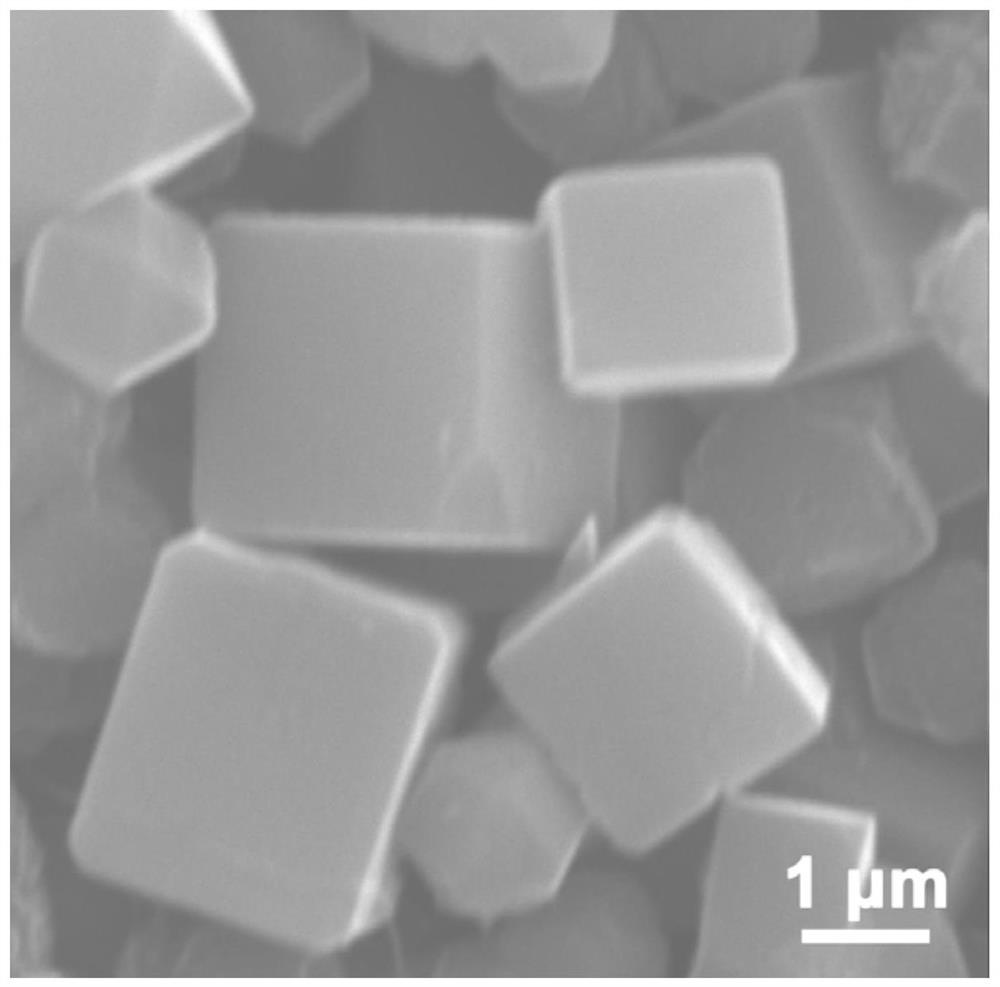

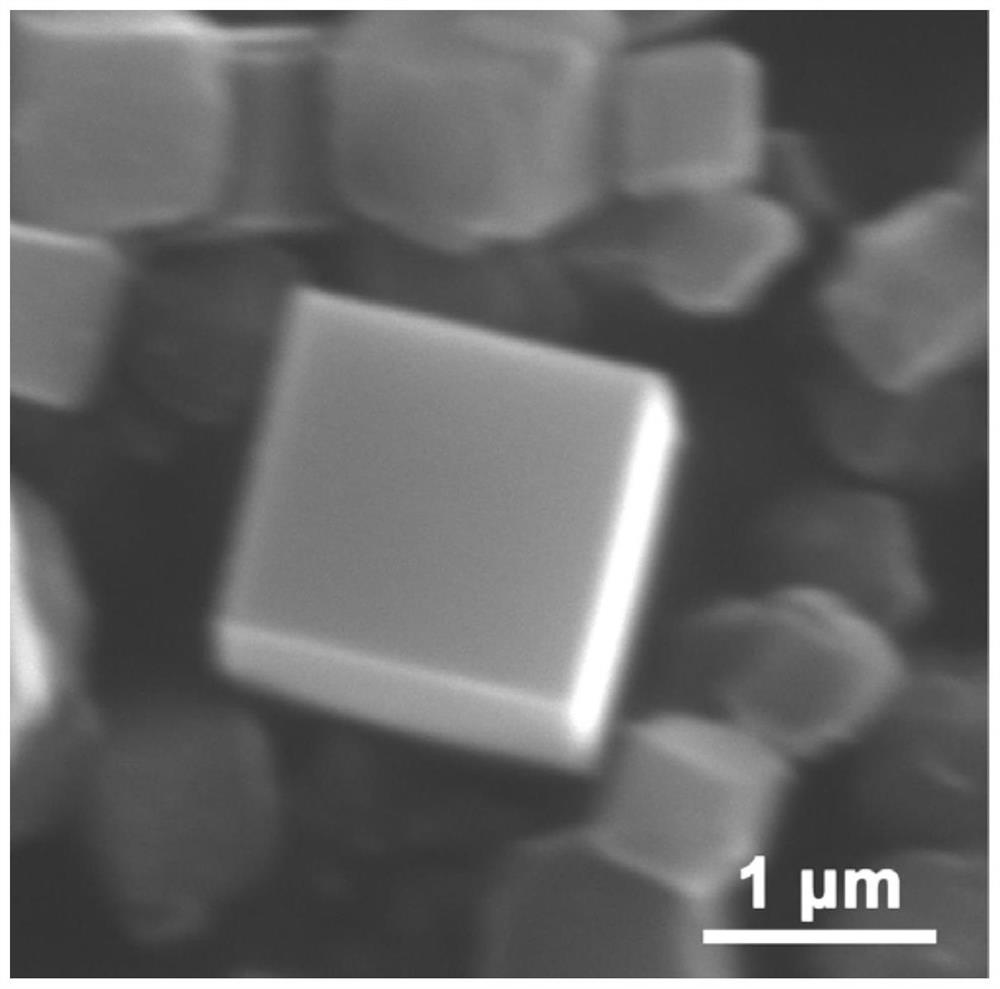

Nitrogen-doped carbon microcubes derived from metal organic framework as well as preparation method and application of nitrogen-doped carbon microcubes

PendingCN114156092AEasy to prepareSimple and fast operationPhysical/chemical process catalystsHybrid capacitor electrodesMetal-organic frameworkPyrrolidinones

The invention belongs to the field of inorganic non-metallic materials and electrochemistry, and discloses a metal organic framework-derived nitrogen-doped carbon microcube as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) adding a zinc salt, a ligand and polyvinylpyrrolidone into an organic solvent, stirring, putting into a reaction kettle, putting the reaction kettle into a drying oven at 165-200 DEG C, reacting for 1-22 hours, cooling, cleaning, and preserving heat at 60 DEG C for more than 24 hours to obtain metal organic framework particles; and (2) placing the dried metal organic framework particles in a hearth, heating to 900-1500 DEG C, preserving heat for 1-10 hours, and naturally cooling to room temperature to obtain the nitrogen-doped carbon microcubes. The method is simple in preparation, easy to operate and low in cost, and the obtained nitrogen-doped carbon microcubes have very high application value in the fields of electro-catalysis and energy storage.

Owner:UNIV OF JINAN

A kind of method for preparing tellurium powder

ActiveCN107190272BSpeed up the flowIncreased concentration of tellurium ionsElectrolysis componentsHigh current densityVolumetric Mass Density

Owner:CENT SOUTH UNIV

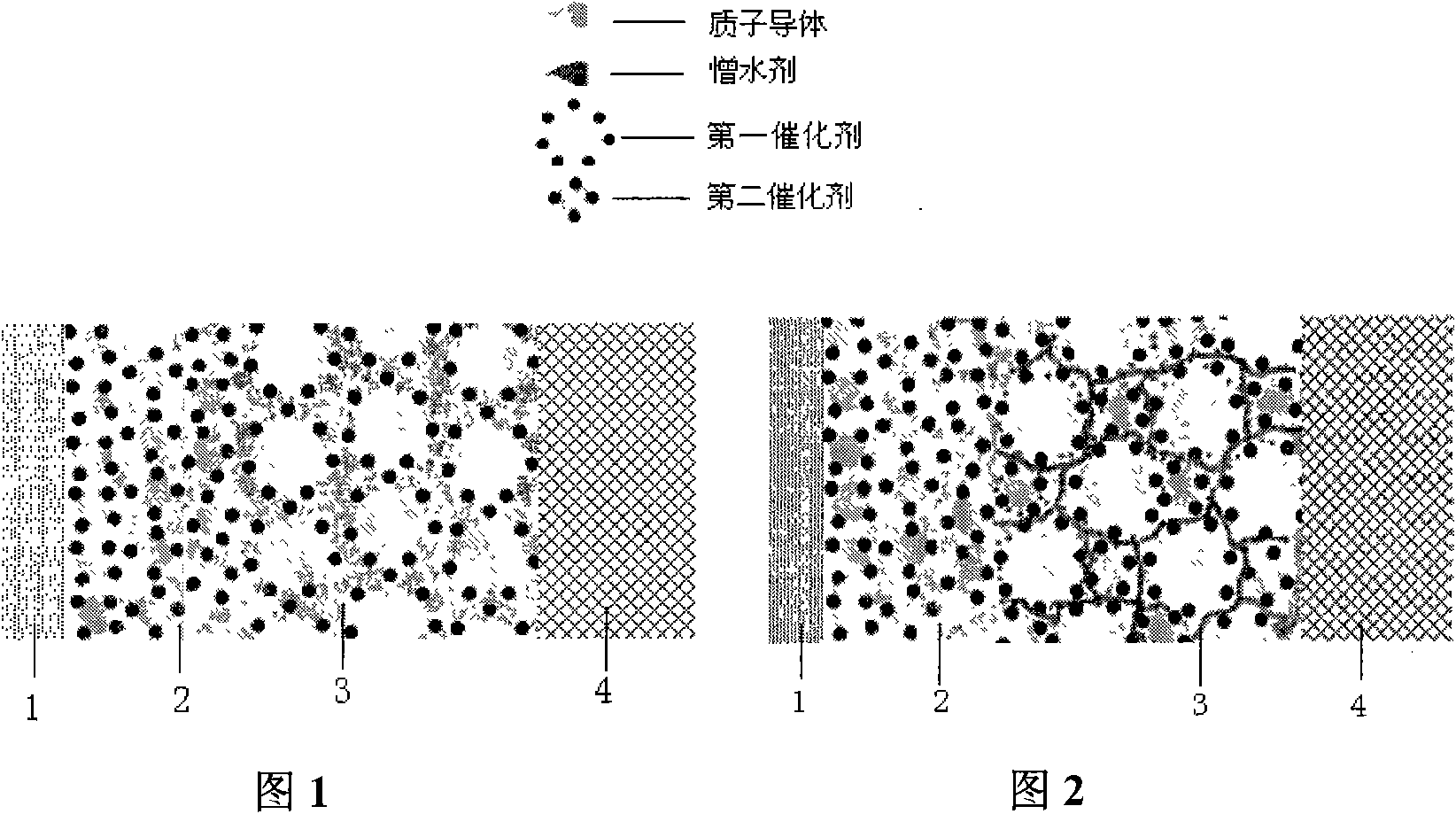

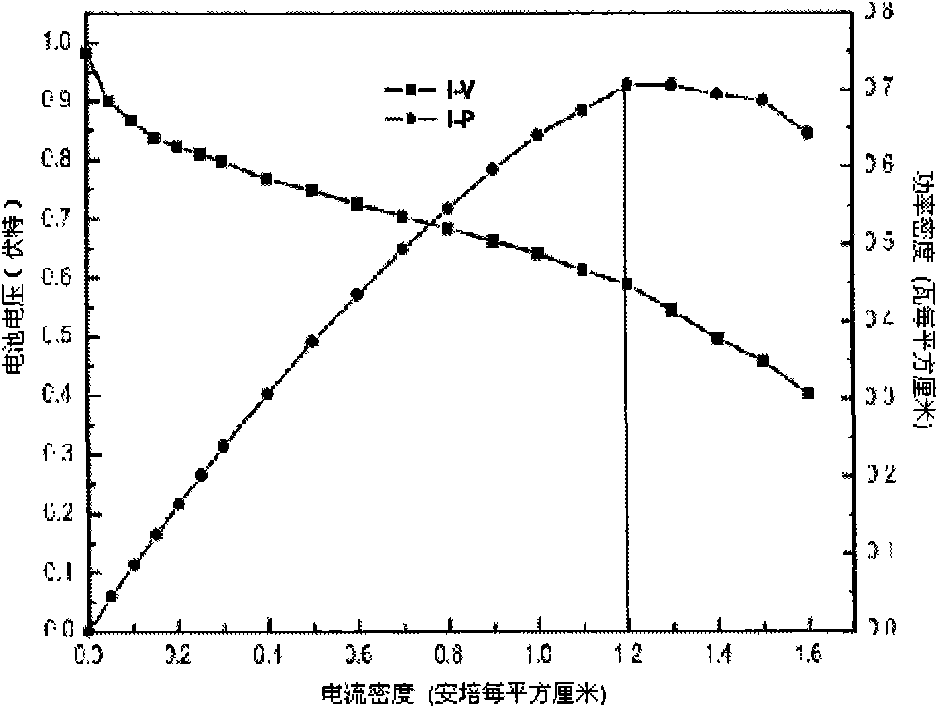

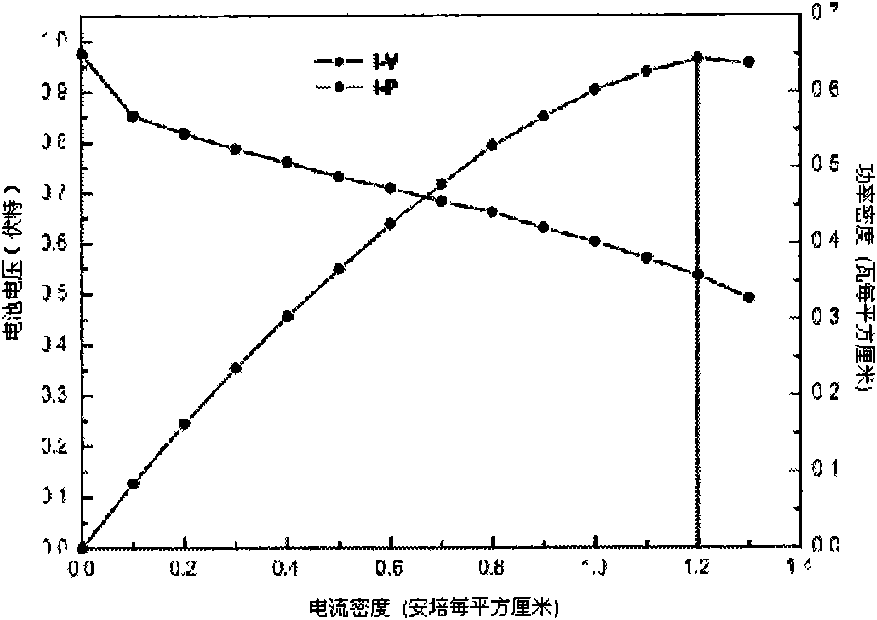

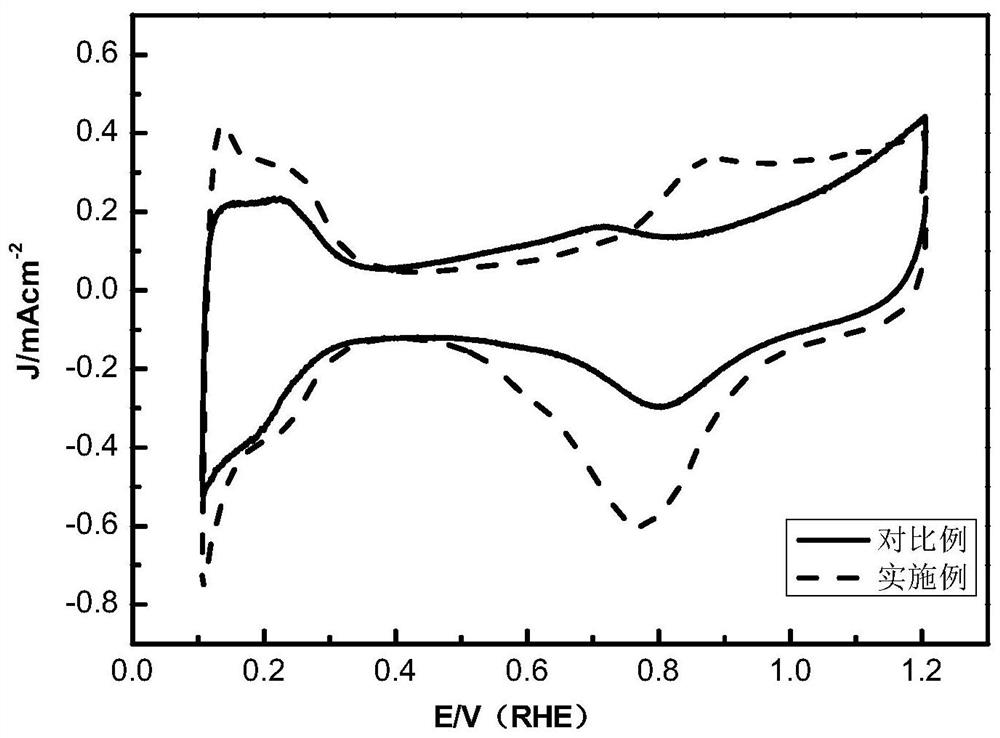

Low-platinum cathode catalyst layer used for fuel cell and application thereof

ActiveCN102104155BIncrease profitImprove output power densityCell electrodesSolid electrolyte fuel cellsElectrical conductorPolymer chemistry

The invention relates to a high-performance low-platinum cathode catalyst layer structure used for a fuel cell and application thereof. In the high-performance low-platinum cathode catalyst layer structure used for the fuel cell, Pt / C or PtMxOy / C serves as an electro-catalyst; a hydrophilic internal catalyst layer connected with a proton exchange membrane is formed by a Pt / C or PtMxOy / C catalyst (a second catalyst) prepared by a carbon carrier of which the specific area is 800 to 1,200 m<2> / g and a proton conductor serving as main components; and a hydrophobic external catalyst layer connected with a diffusion layer is formed by a Pt / C or PtMxOy / C catalyst (a first catalyst) prepared by a carbon carrier of which the specific area is 50 to 300 m<2> / g or a composite catalyst of the first catalyst and the second catalyst and a water repellent serving as the main components. The low-platinum cathode catalyst layer structure has the characteristics of less Pt dosage, thin thickness, high catalyst utilization rate and limiting current density, high stability and high durability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of platinum alloy catalyst, its preparation method and its application in fuel cell cathode catalyst

InactiveCN110931805BIncrease the areaIncrease the limit currentCell electrodesPtru catalystMetallurgy

The invention discloses a platinum alloy catalyst, its preparation method and its application in a fuel cell cathode catalyst. The method comprises: 1) preparing a mixed solution of the first reducing agent glucose and the precursor of the first metal component platinum; 2. ) under the condition that the pH value of the mixed solution is 3-10, heating and adding a carbon carrier, and raising the temperature to 80-95°C for reaction; 3) adding the precursor of the second metal component, and reacting; 4) cooling and separating the reaction product; 5) Dissolving the reaction product in water, adding a second reducing agent, heating to 80-95°C, and reacting; 6) cooling and separating the reaction product to obtain a catalyst precursor; 7) calcining to obtain a platinum alloy catalyst. The preparation method of the present invention does not require a large amount of organic solvents, and the reaction conditions are mild. In the aqueous solution, non-toxic and mild glucose is used as the main reducing agent, and a second mild reducing agent is introduced to further coordinate dispersion and reduction to prepare a high-efficiency hydrogen fuel cell. catalyst. It has broad application prospects in the field of fuel cell catalysts.

Owner:FAW JIEFANG AUTOMOTIVE CO

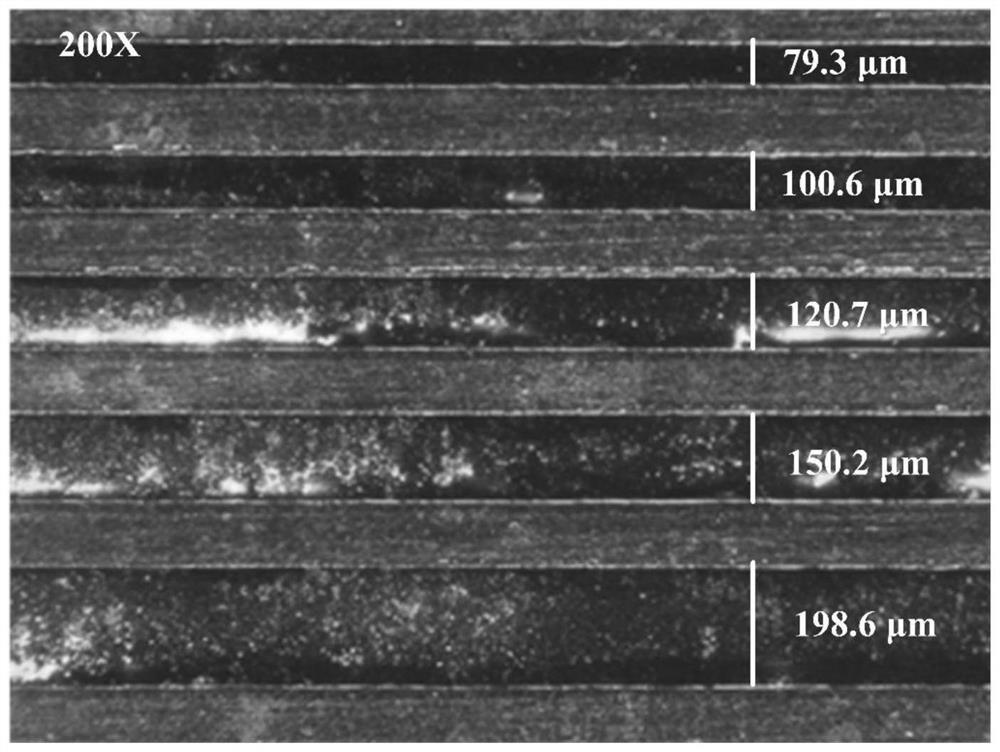

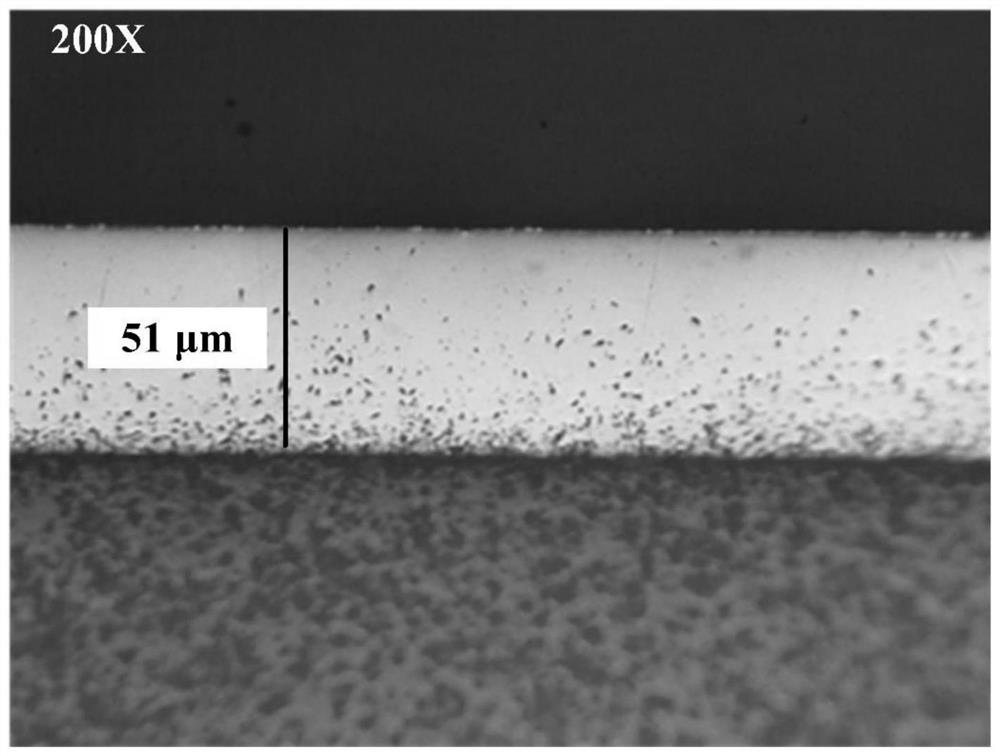

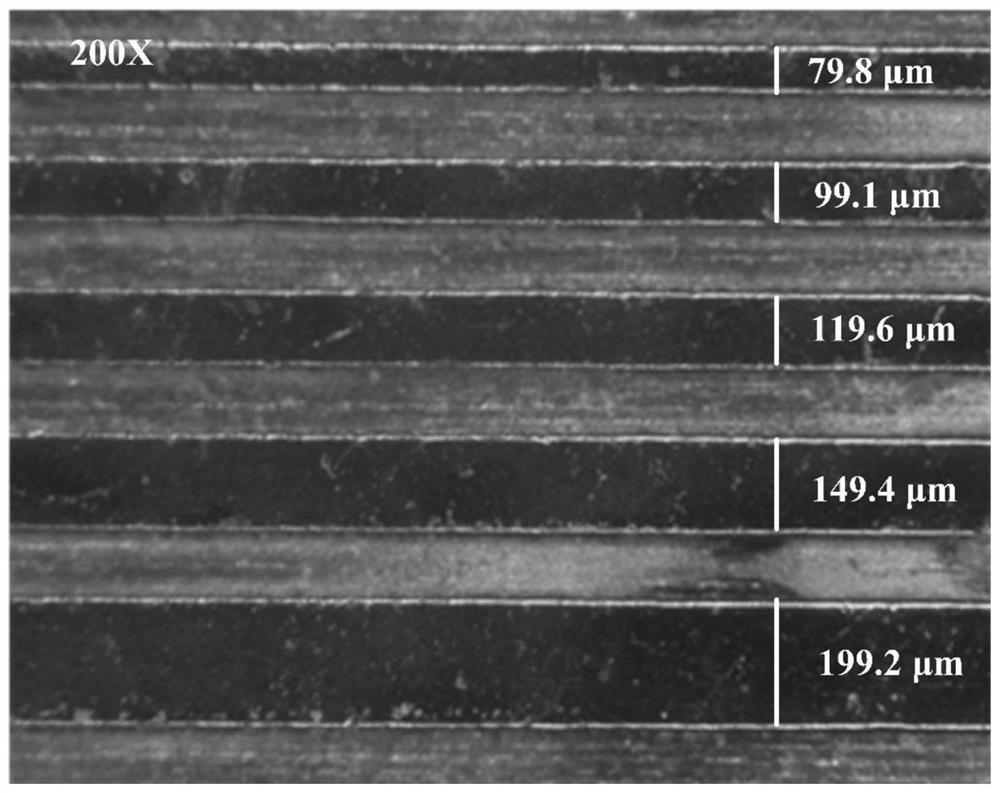

High-speed copper electroplating solution and ceramic substrate pattern electroplating method thereof

ActiveCN114150351ASimple componentsIncrease the limiting current densityVacuum evaporation coatingSputtering coatingCopper platingCopper sulfate

The invention discloses a high-speed copper electroplating solution and a ceramic substrate pattern electroplating method thereof. The solution is an acidic copper sulfate system, and comprises the following main salts according to concentration: 120-150g / L of copper sulfate and 60-80g / L of sulfuric acid; the additive comprises the following components: 6-10 mg / L of an accelerator, 0.3-0.4 g / L of an inhibitor and 50-70 mg / L of chloride ions. When the pattern of the ceramic substrate is electroplated, bubbling, ultrasound and other auxiliary processes for strengthening mass transfer are needed. The electrocoppering solution is simple in component, high in limiting current density, high in current efficiency, safe and environmentally friendly, high-speed copper plating of fine patterns with the line width / line distance of 50-500 micrometers can be achieved under the large current density, the growth rate is larger than 100 micrometers / h, a copper plating layer is bright in surface, uniform in thickness, compact in structure, low in impurity content and high in corrosion resistance, and the electrocoppering effect is good. The method is especially suitable for preparing a metal circuit layer on the surface of a ceramic substrate.

Owner:武汉利之达科技股份有限公司 +1

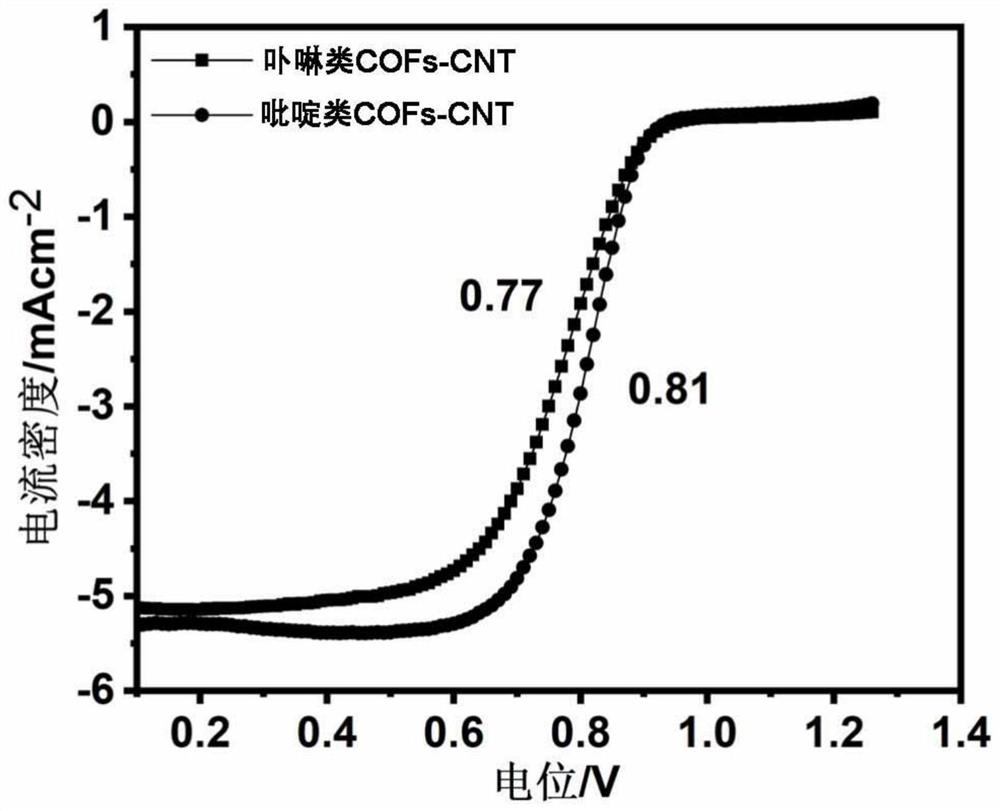

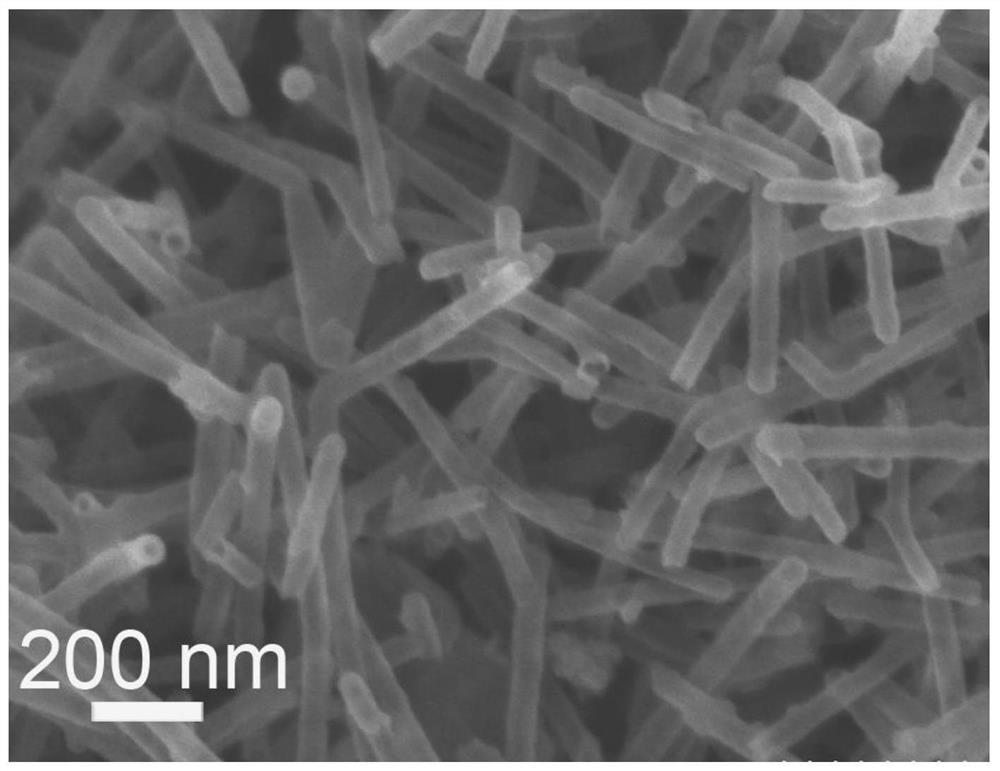

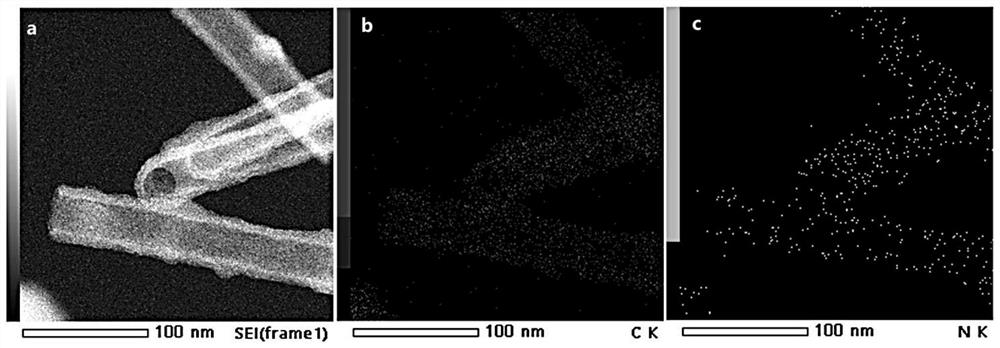

Method for catalyzing ORR reaction based on COFs derived carbon nanotubes

ActiveCN112038647AIncrease the limiting current densityCell electrodesNanotechnologyPtru catalystFuel cells

The invention discloses a method for catalyzing ORR reaction based on COFs derived carbon nanotubes, and belongs to the field of electrocatalytic oxygen reduction of cathode parts of fuel cells. Application of the carbon nanotubes derived from the covalent organic frameworks COFs in the catalytic cathode oxygen reduction reaction comprises the following steps that the carbon nanotubes derived fromthe covalent organic frameworks COFs are used as catalysts to be applied to the cathode oxygen reduction reaction, and the adopted carbon nanotubes are derived from the COFs. Regulation and control of ORR activity are facilitated through regular and controllable metal / heteroatom doped or carbon tube diameter and wall thickness, good application prospects are achieved, and the solvothermal preparation method is simple and safe.

Owner:JIANGNAN UNIV

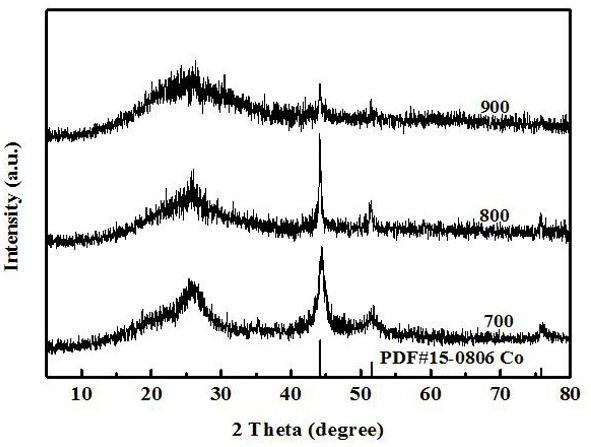

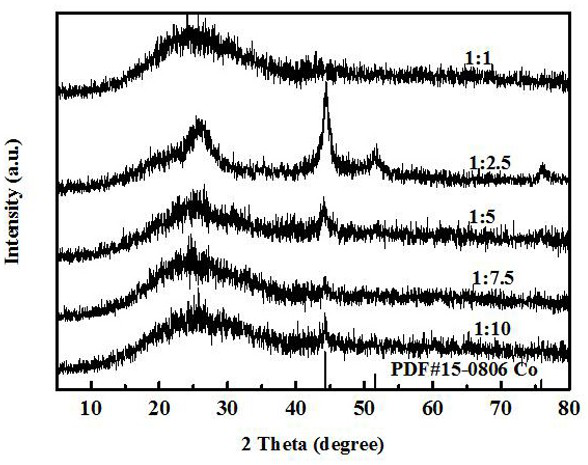

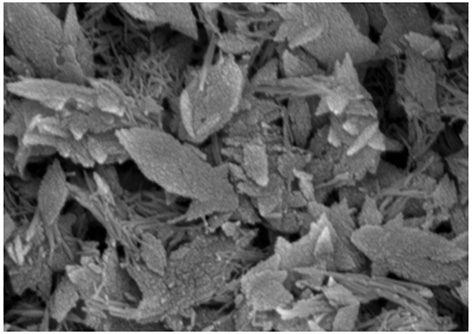

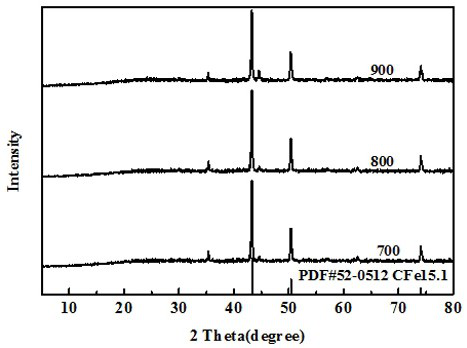

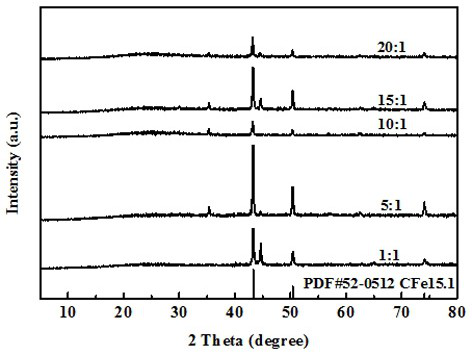

Heat treatment process for improving oxygen reduction catalytic activity of non-noble metal catalyst

InactiveCN113054205AHigh half-wave potentialIncrease the limiting current densityCell electrodesCathode catalystPtru catalyst

The invention discloses a heat treatment process for improving oxygen reduction catalytic activity of a non-noble metal catalyst, which comprises the following steps: step 1, stirring and dispersing an imidazole source at normal temperature, and dissolving in a methanol solvent; 2, stirring and dispersing a metal source at normal temperature, and dissolving the metal source in a methanol solvent; 3, mixing the solutions in the step 1 and the step 2, and carrying out a hydrothermal reaction; 4, carrying out centrifugal separation and centrifugal washing on the catalyst material prepared in the step 3; 5, drying the washed catalyst; and 6, fully grinding the dried catalyst material, and carrying out heat treatment in an inert gas atmosphere. The prepared Fe-N-C catalyst material subjected to low-temperature treatment is excellent in catalytic performance, and possibly has incomparable advantages when being used as a cathode catalyst material of a proton exchange membrane fuel cell. The low-temperature heat treatment mode can be used for reference in other types of Fe-N-C materials.

Owner:HARBIN INST OF TECH

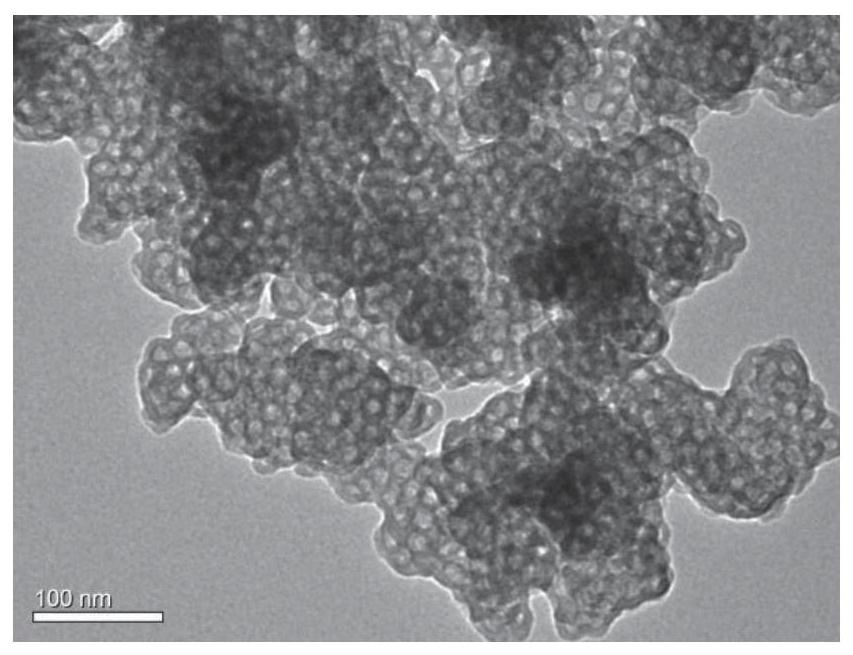

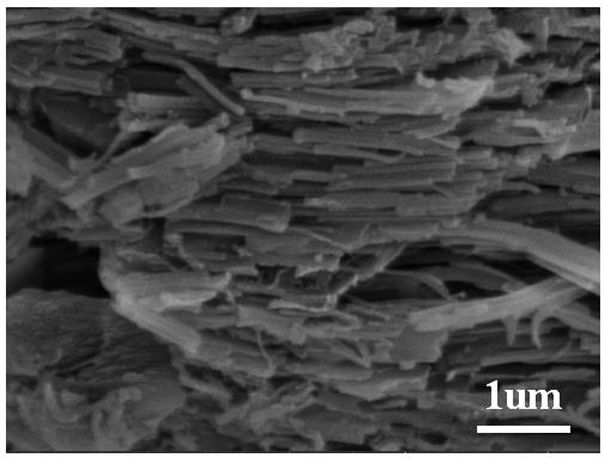

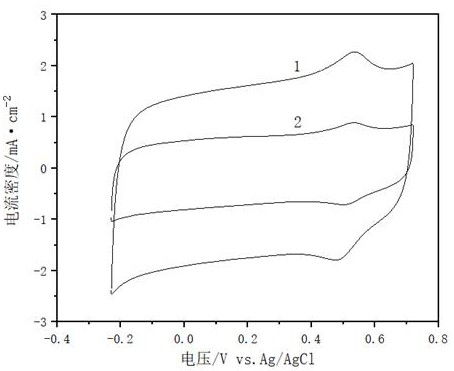

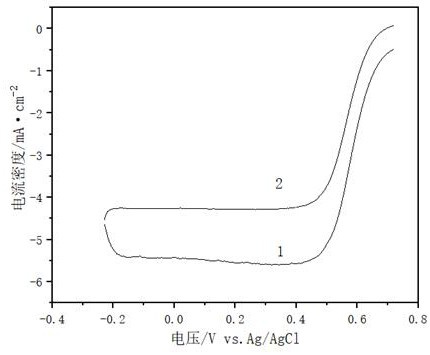

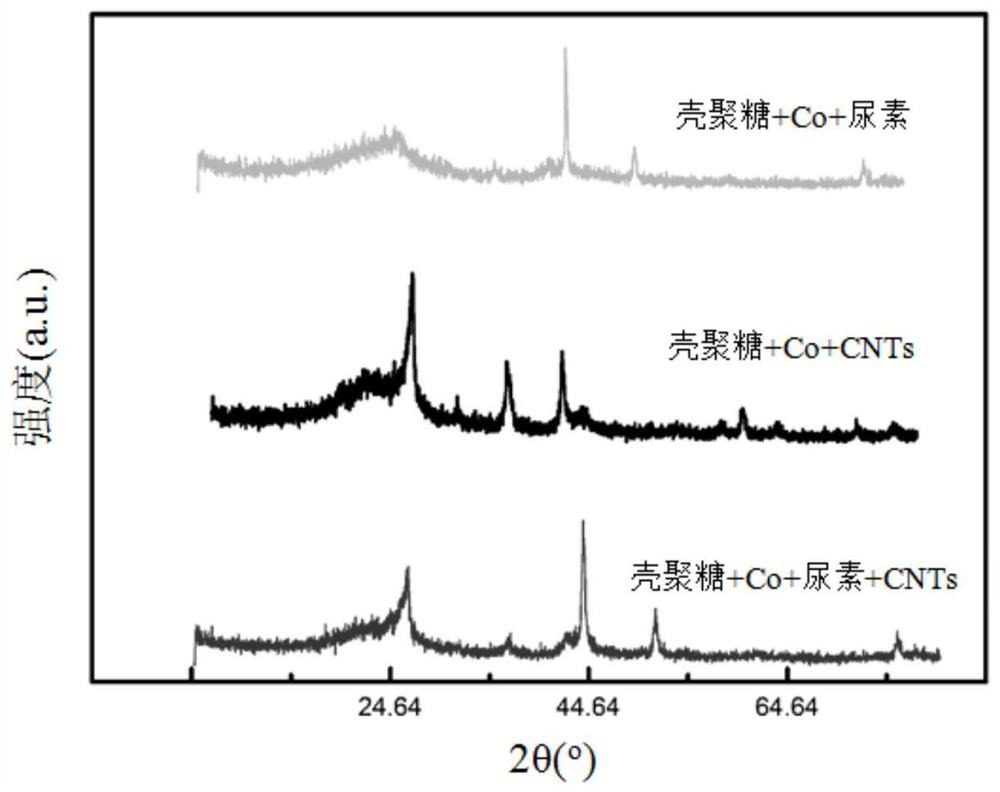

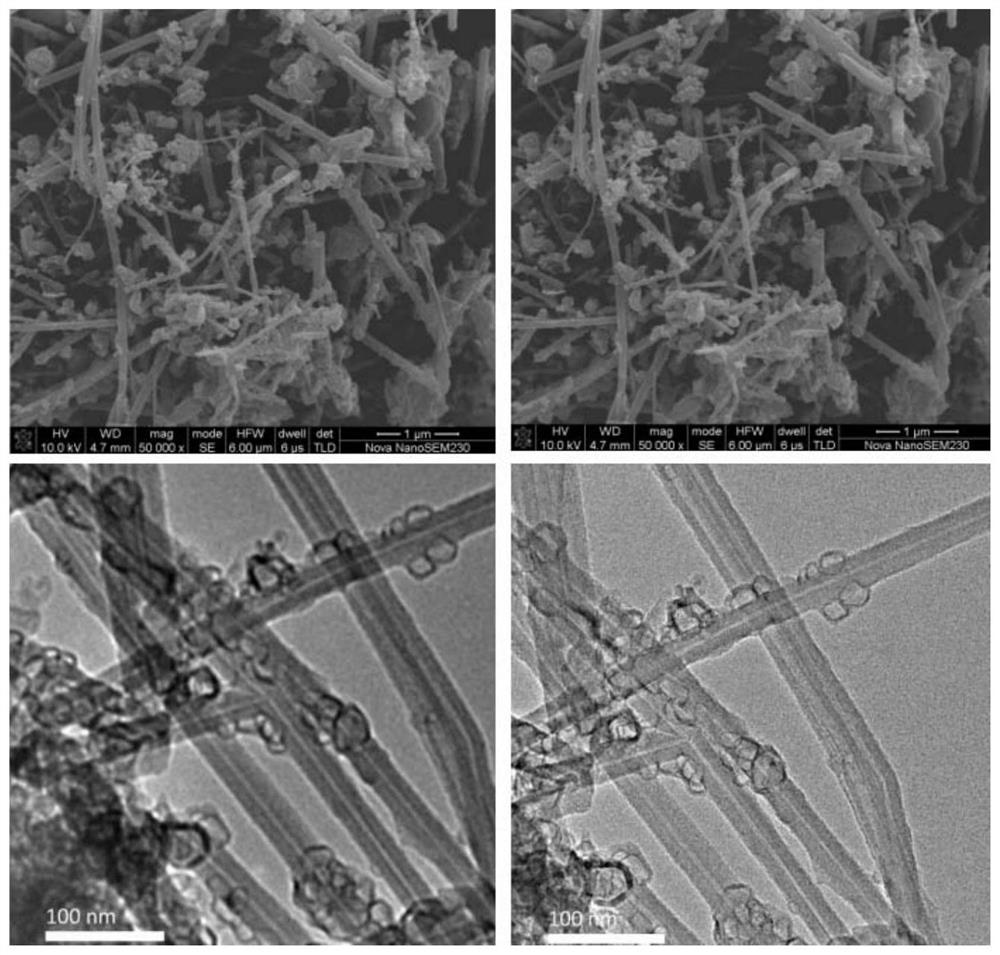

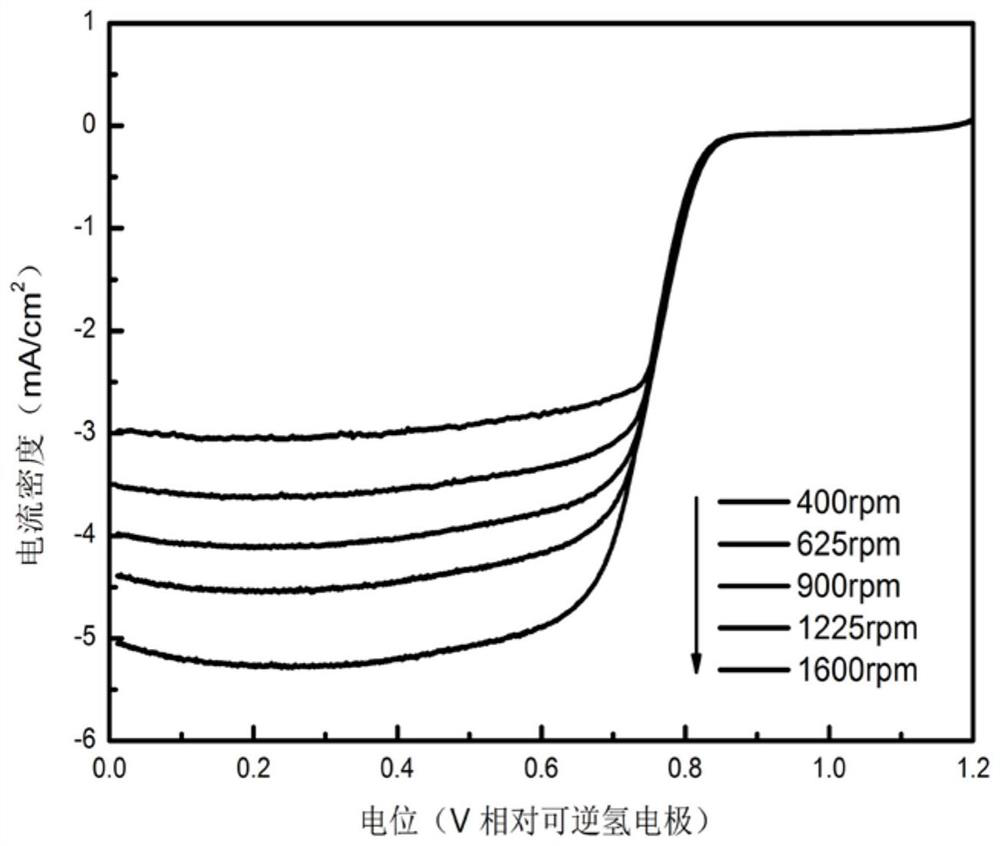

A kind of co-n-c composite catalyst and its preparation method and application

InactiveCN108258253BEnhanced ORR kineticsIncrease the limiting current densityFuel and primary cellsCell electrodesElectrochemical responsePtru catalyst

The invention discloses a Co-N-C composite catalyst. The Co-N-C composite catalyst comprises a Co and N codoped carbon nanoparticle and CNTs (Carbon Nanotube), and the Co and N codoped carbon nanoparticle grows on the surface of the CNTs to form a three-dimensional net structure. The Co-N-C composite catalyst takes chitosan as a carbon source and chitosan and urea as nitrogen sources, the CNTs areadded, the Co-N-C / CNTs composite catalyst is synthesized through an in-situ transformation method, the synergistic effect of the Co-N-C and the CNTs obviously strengthens the ORR dynamics of the Co-N-C, the composite catalyst is applied to an aluminum-air battery cathode material, the limiting current density is up to 5.3 mA cm<-2> and is equivalent to that of a commercial Pt / C electrode (5.2 mAcm<-2>); the Co-N-C nanoparticle grows on the surface of the CNTs to form the three-dimensional net structure, so that the composite catalyst is better in electric conduction and has a large specificsurface area, more electrochemical reaction active sites are achieved, the adsorption of molecular oxygen is promoted, the catalysis is further carried out to reduce the molecular oxygen, then the catalytic activity of the ORR (Oxygen Reduction Reaction) is obviously improved; the process method is simple, the cost is low, the requirement on equipment is not high, and the Co-N-C composite catalystis suitable for large-scale production.

Owner:CENT SOUTH UNIV

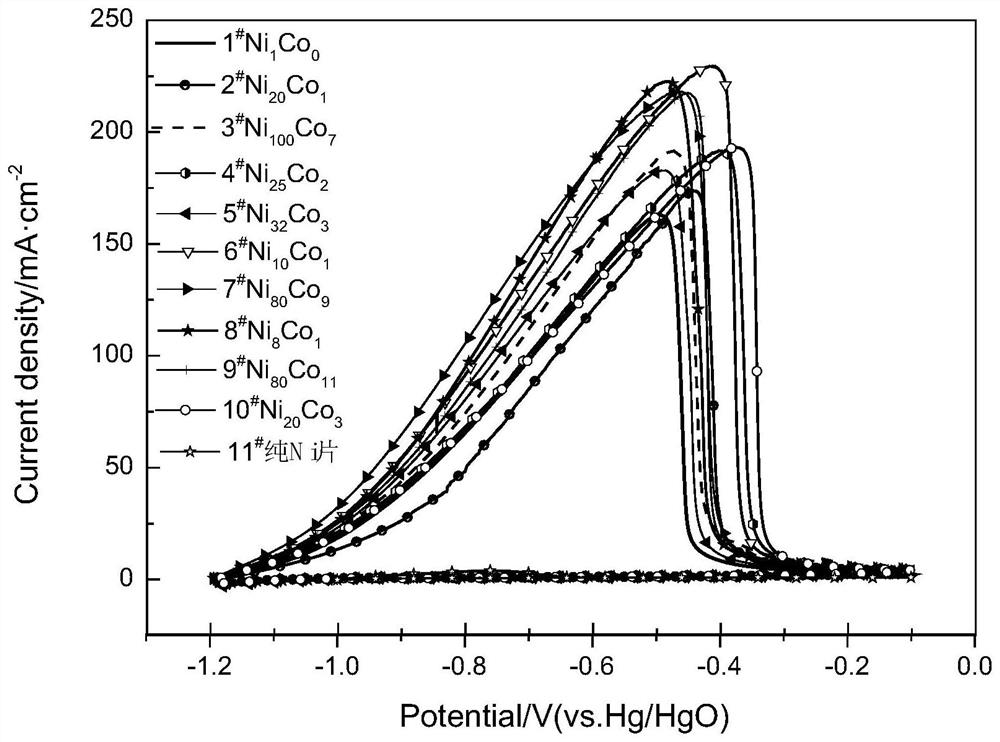

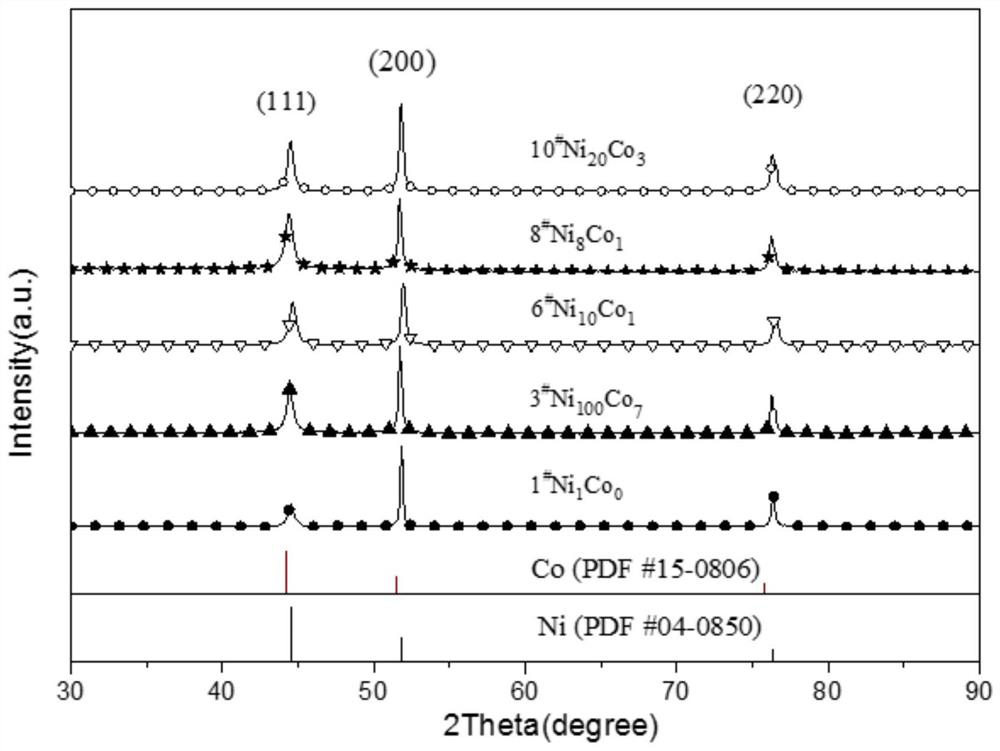

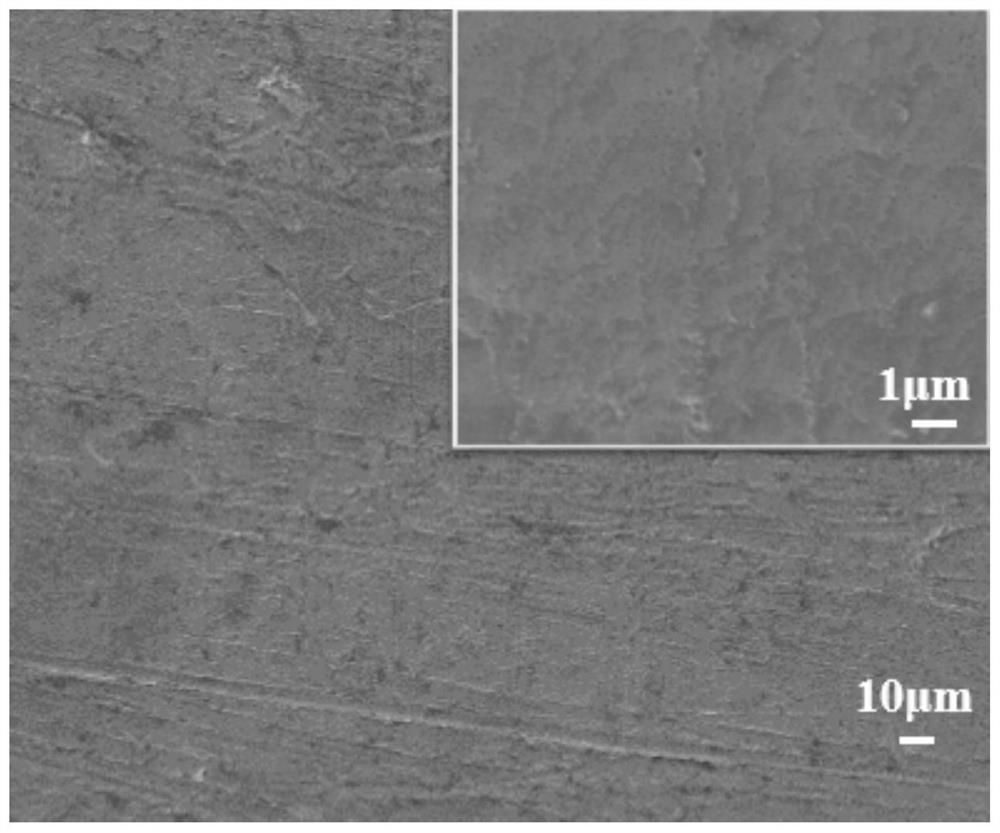

A nickel-cobalt binary catalyst promoting the direct oxidation of sodium borohydride

ActiveCN109994744BImprove performanceIncreased maximum power densityCell electrodesPtru catalystCobalt catalyst

A kind of nickel-cobalt binary catalyst that promotes the direct oxidation of sodium borohydride is characterized in that: (1) under normal temperature and pressure, prepare 0.2mol / dm 3 nickel chloride (NiCl 2 ·6H 2 O), 0.0000~0.0300mol / dm 3 Cobalt Chloride (CoCl 2 ·6H 2 O) and 4mol / dm 3 Ammonium chloride (NH 4 The mixed solution of Cl) is an electrodeposition solution; (2) Assembling a two-electrode system: a 1cm×2cm polished Ni sheet is placed in the above solution as a cathode, wherein the working area of the Ni sheet is 1cm×1cm, and a carbon rod (3) Using the constant current method, in a constant temperature water bath at 298.15K, with a deposition current of 2A, and a deposition time of 20s, deposit Ni and Co on the above smooth Ni sheet. The nickel-cobalt catalyst prepared by electrodeposition has a porous structure, and the addition of cobalt makes the catalyst have a larger average pore size and porosity, which significantly increases the specific surface area, increases the number of catalytic active sites, and reduces the resistance to be overcome in the direct oxidation reaction. The charge transfer of the electrode reaction is enhanced; at the same time, the discharge potential of the fuel is reduced, the discharge efficiency of the fuel is significantly improved, and the oxidation performance of the fuel is improved.

Owner:CHONGQING UNIV

Preparation method of electroplating diamond fret saw

Owner:JIANGSU FUNLIN SUPER HARD TOOLS

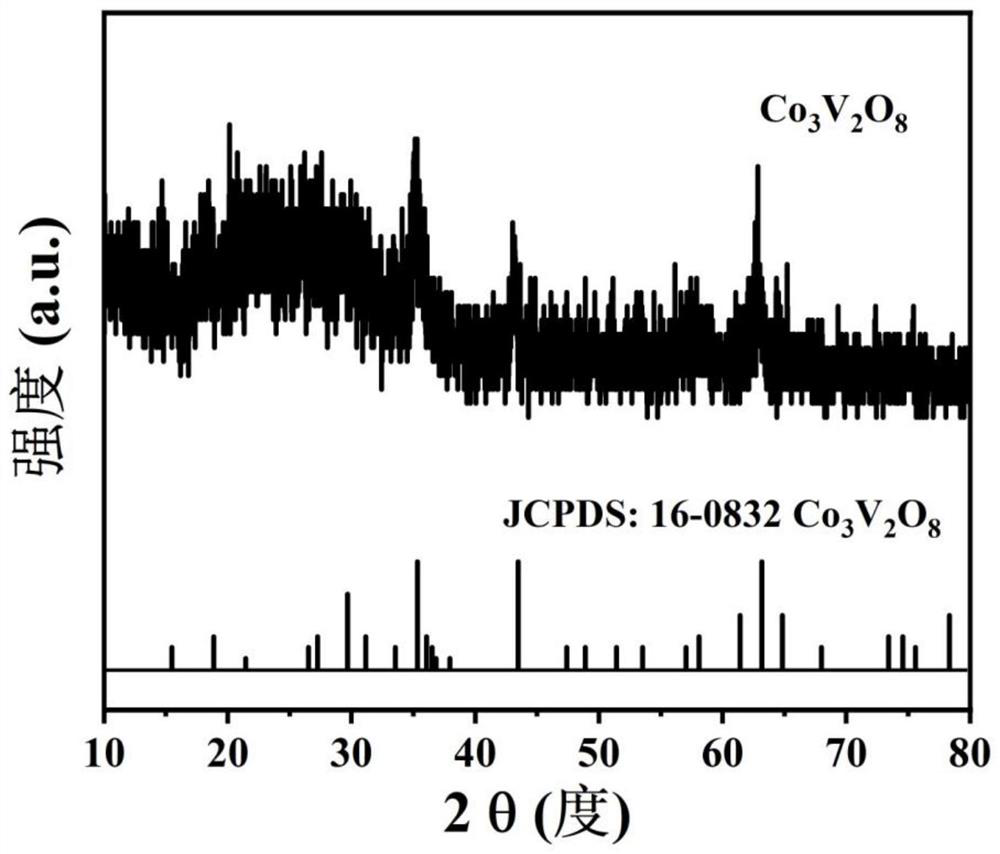

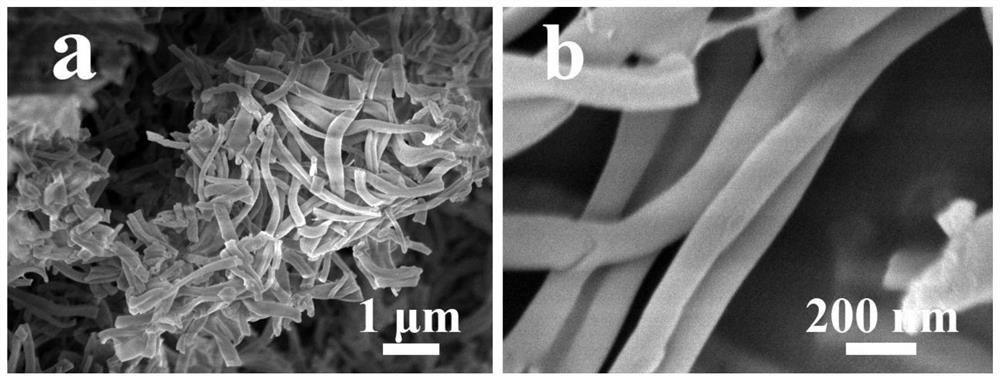

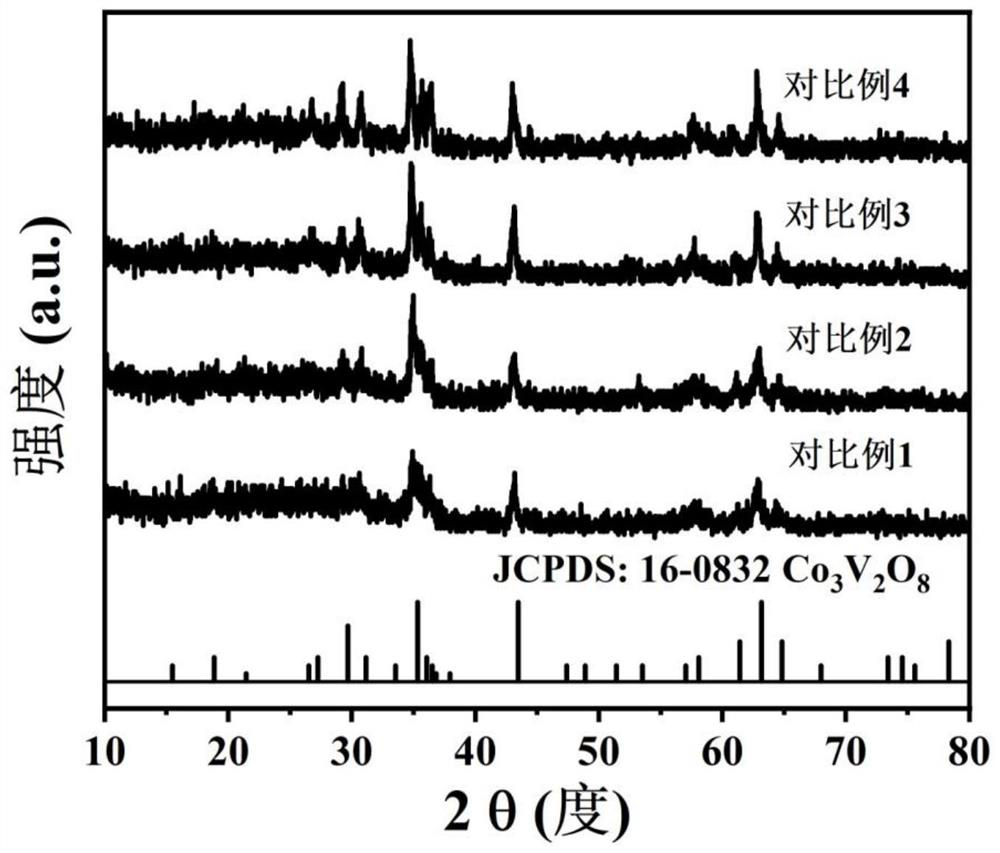

Co3V2O8 bifunctional electro-catalytic material as well as preparation method and application thereof

PendingCN113952987AImprove electrocatalytic performanceIncrease the limiting current densityCell electrodesCobalt compoundsSpinningNanofiber

The invention relates to a Co3V2O8 bifunctional electro-catalytic material as well as a preparation method and application thereof, which belongs to the technical field of electro-catalytic materials. The Co3V2O8 bifunctional electro-catalytic material is prepared by combining a sol-gel method with an electrostatic spinning technology; the micro-morphology of the electrocatalytic material is nanofiber, and the diameter of the nanofiber is 100-200 nm. The Co3V2O8 electro-catalytic material not only has excellent oxygen reduction (ORR) performance, but also has excellent hydrogen evolution (OER) performance, the preparation method is simple, and the Co3V2O8 electro-catalytic material has a good application prospect.

Owner:QILU UNIV OF TECH

Preparation method of copper hydroxide two-dimensional nanocomposite based on iron-based dopamine supramolecular modification

ActiveCN113422070BReaction conditions are easy to controlHigh onset potentialMaterial nanotechnologyCell electrodesPtru catalystNanocomposite

The invention discloses a method for preparing a copper hydroxide two-dimensional nanocomposite material based on iron-based dopamine supramolecular modification, which uses CuCl 2 , PEG, etc. as raw materials to prepare Cu(OH) 2 nanosheets, which were then dispersed in absolute ethanol to obtain Cu(OH) 2 solution, then add dopamine and Fe(NO) 3 9H 2 O, through hydrothermal reaction and heat treatment, a 2D material that can be used as a fuel cell anode material is finally prepared Cu(OH)2 @PDA‑Fe. The composite material obtained in the present invention has higher initial potential, half-slope potential, excellent limiting current, excellent stability and good methanol tolerance, has strong resistance to methanol poisoning, etc., and can solve the problem of existing fuel cells. The catalyst has problems such as single precursor, high cost and toxicity of Pt-based catalytic materials, and it is expected to be used to replace Pt / C catalysts.

Owner:FUZHOU UNIV

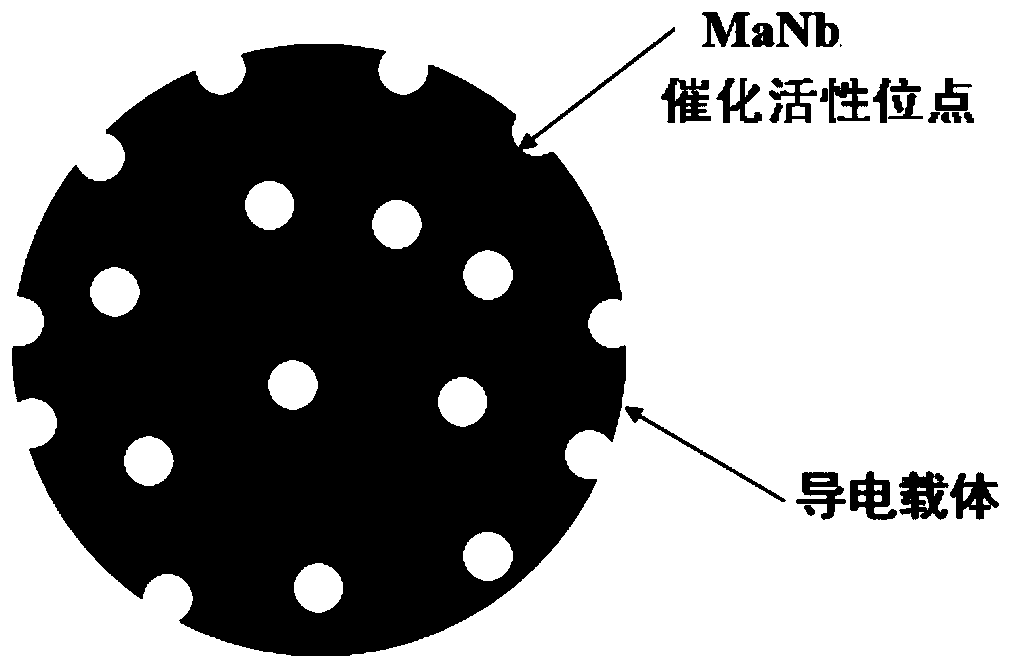

Fuel cell film electrode catalyst, and preparation method and application thereof

The invention provides a fuel cell film electrode catalyst, and a preparation method and an application thereof. The method comprises steps that S1, a transition metal cation source compound is dissolved in first solvent to obtain first solution; organic nitrogen-containing ligand is dissolved in second solvent to obtain second solution; a porous conductive carbon material is dispersed in third solvent to obtain suspension; S2, the first solution is mixed with the second solution, then mixed with the suspension, and is adsorbed and separated to obtain solid phase material; and S3, the solid phase material reacts through annealing treatment to obtain the fuel cell film electrode catalyst comprising a porous conductive carbon carrier, and transition metal and nitrogen supported in inner pores of the carrier. The method is advantaged in that the prepared catalyst activity is high, a quite excellent gas-solid liquid three-phase interface is achieved, the method is simple, cost is low, themethod is quite suitable for positive poles of high power metal air cells and fuel cells, and the method has good commercial prospect.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com