Preparation method and application of ionic liquid modified nitrogen-sulfur co-doped graphene oxide composite material

A nitrogen-sulfur co-doping and graphene composite technology is applied in chemical instruments and methods, catalyst activation/preparation, organic compound/hydride/coordination complex catalysts, etc. and other problems, to achieve the effects of mild synthesis conditions, good oxygen reduction catalytic activity, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

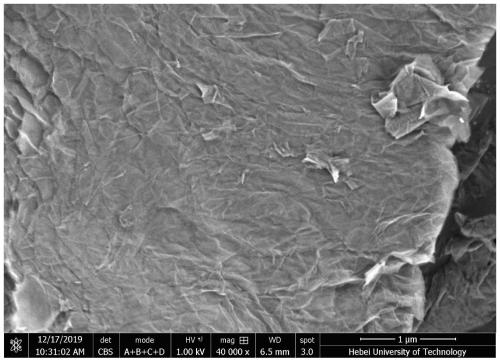

Image

Examples

Embodiment 1

[0030] 1. Synthesis of Ionic Liquids

[0031] Get N-methylimidazole 0.05mol (4.1g) and 3-bromopropylamine hydrobromide 0.04mol (8.76g) and mix in reactor, add 100ml dehydrated alcohol solvent and it is dissolved, in N 2 Under protection, place in an oil bath and heat to 78°C, stir and reflux for 24 hours to obtain a light yellow solution. Purify the obtained crude product by a rotary evaporator to obtain a viscous liquid, then add water to dissolve all the rotary evaporated material, and adjust the pH to 11 with KOH to restore the protected amino group, distill under reduced pressure, and wash The finished product was placed in a vacuum drying oven, heated to 80°C, dried for 4 hours, and vacuum-dried to constant weight. After drying, it was taken out into a light yellow viscous paste, and 50 mL of a mixture of ethanol and tetrahydrofuran was added (ethanol: tetrahydrofuran = 4:1 ), after stirring and dissolving, the product was extracted by distillation under reduced pressure...

Embodiment 2

[0038] 1. Synthesis of Ionic Liquids

[0039] Get 0.05mol (4.1g) of 1-vinylimidazole and 0.04mol (8.76g) of 3-bromopropylamine hydrobromide and mix in the reactor, add 100ml dehydrated alcohol solvent and it is dissolved, in N 2Under protection, place in an oil bath and heat to 78°C, stir and reflux for 24 hours to obtain a light yellow solution. Purify the obtained crude product by a rotary evaporator to obtain a viscous liquid, then add water to dissolve all the rotary evaporated material, and adjust the pH to 11 with KOH to restore the protected amino group, distill under reduced pressure, and wash The finished product was placed in a vacuum drying oven, heated to 80°C, dried for 4 hours, and vacuum-dried to constant weight. After drying, it was taken out into a light yellow viscous paste, and 50 mL of a mixture of ethanol and tetrahydrofuran was added (ethanol: tetrahydrofuran = 4:1 ), after stirring and dissolving, the product was extracted by distillation under reduced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com