Monovalent selective cation exchange membrane and preparation method thereof

A cation exchange membrane and selective technology, applied in the field of membrane separation, can solve the problems of low selectivity and stability of monovalent ion selective membrane, and achieve the effects of good electrical conductivity, simple preparation method and high monovalent ion selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

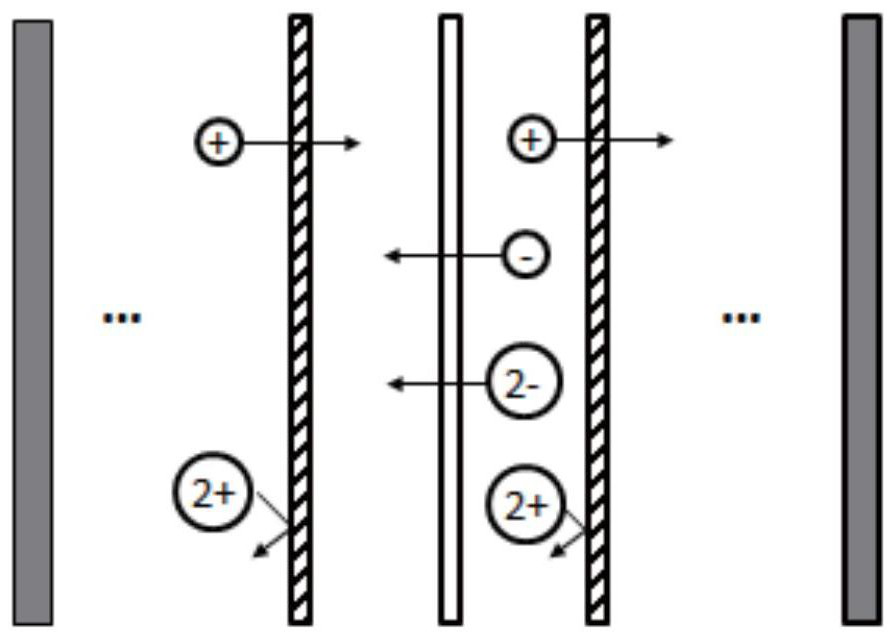

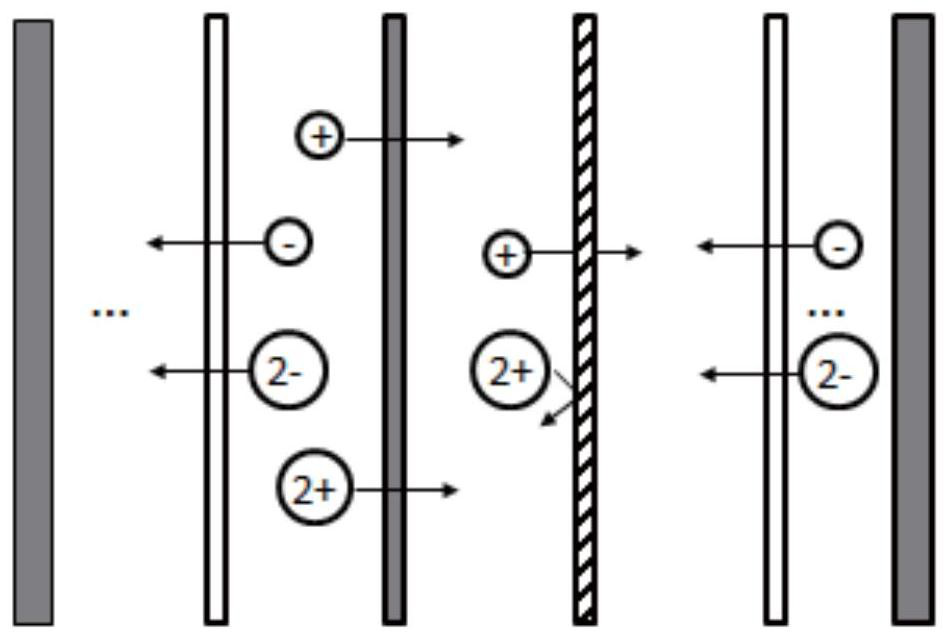

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of a monovalent selective cation exchange membrane, the specific steps are as follows:

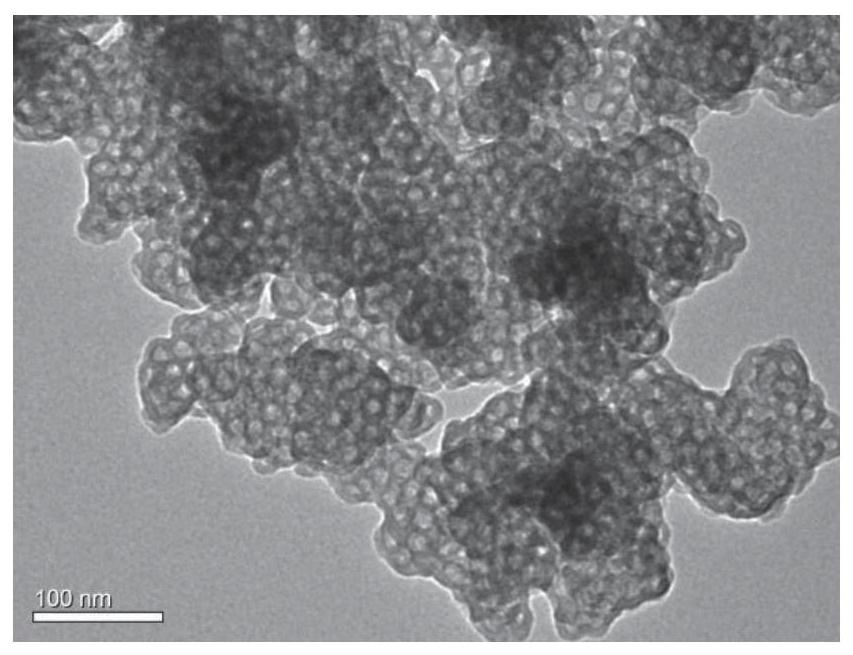

[0040]Step 1, preparation of carboxyl mesoporous polymer: carboxyl mesoporous polymer is an aqueous solution of polymer precursor hydroxybenzoic acid, hexamethylenetetramine, nonionic surfactant F127 and ethylenediamine, wherein hydroxybenzoic acid The concentration of F127 is 2-5wt.%, the concentration of hexamethylenetetramine is 0.5-1.5wt.%, the concentration of F127 is 3-5wt.%, the concentration of ethylenediamine is 0.5-1.5wt.%. Preparation method, reaction temperature is 100-150°C, reaction time is 3-10 hours, washed with ethanol and water and suction-filtered, dried overnight at 50-80°C in vacuum, and then calcined at 350°C for 5-8 hours in an Ar gas atmosphere. The heating and cooling rate of calcination is 1-2°C / min. Transmission electron micrographs of carboxyl mesoporous polymers as image 3 shown;

[0041] Step 2, preparation of the basement membr...

Embodiment 2

[0046] A preparation method of a monovalent selective cation exchange membrane, the specific steps are as follows:

[0047] Step 1, preparation of sulfonic acid-based mesoporous polymer: sulfonic acid-based mesoporous polymer is based on polymer precursor (aqueous solution of hydroxybenzenesulfonic acid) and nonionic surfactant (hexamethylenetetramine and F127) aqueous solution), wherein the concentration of hydroxybenzenesulfonic acid is 0.5-2wt.%, the concentration of hexamethylenetetramine is 0.5-1.5wt.%, and the concentration of F127 is 0.5-1.5wt.%. It is prepared by oil bath reaction, The reaction temperature is 60-120°C, the reaction time is 16-32 hours, washed with ethanol and water and suction-filtered, dried overnight at 50-80°C in vacuum, and then calcined at 300-350°C for 5-8 hours in an Ar gas atmosphere. The heating rate of the calcination is 1-3° C. / min. The transmission electron micrographs of sulfonic acid-based mesoporous polymers are as follows: Figure 4 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com