Preparation method and application of nitrogen-doped MXene loaded cobalt phthalocyanine composite material

A composite material and nitrogen-doped technology, which is applied in the field of preparation of nitrogen-doped MXene functionalized composite materials and nitrogen-doped MXene-loaded cobalt phthalocyanine composite materials, can solve the problem of difficult determination of carbonization degree, easy generation of harmful gases, and influence on catalysis Activity and other issues, to achieve the effect of increasing catalytic active sites, good oxygen reduction catalytic activity, and reducing charge transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

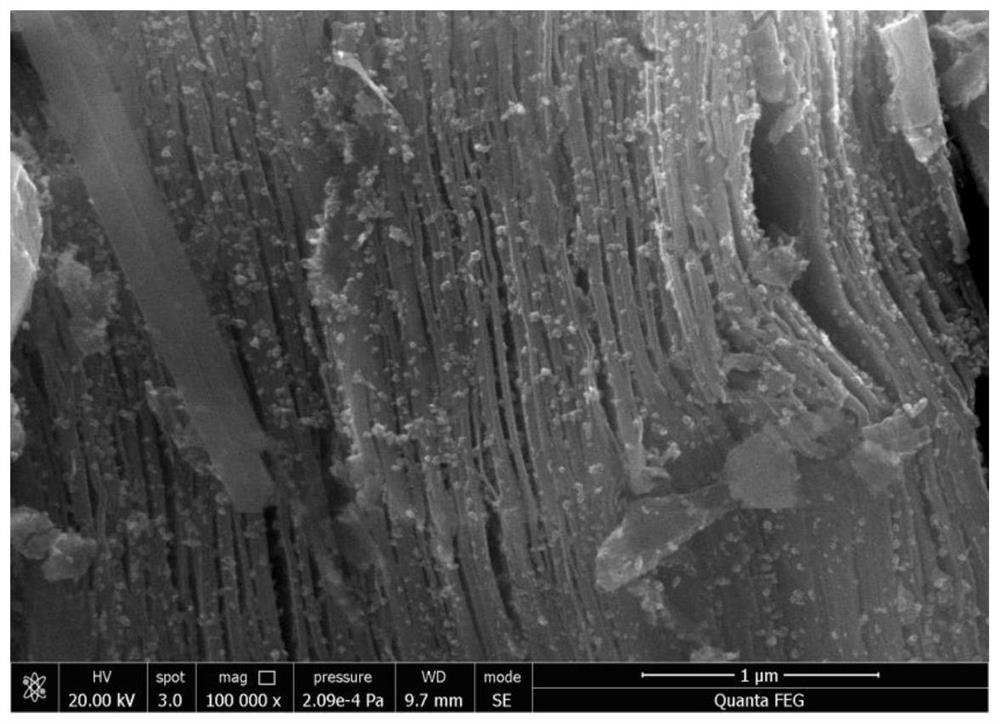

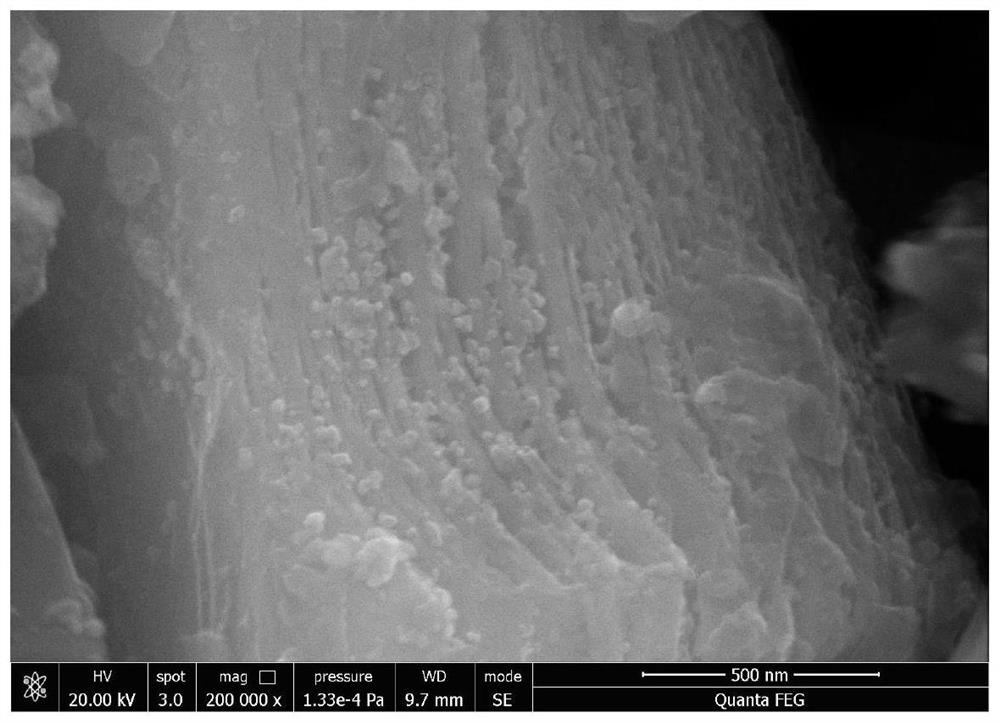

Image

Examples

Embodiment 1

[0033] 1. Synthesis of MXenes with F-terminal groups

[0034] Pour 10ml of 40% HF solution into the beaker and add 1g of Ti 3 AlC 2 The powder (200 mesh) was stirred at 25°C for 24 hours, washed by centrifugation with deionized water, filtered and dried for 12 hours to obtain MXene.

[0035]2. Preparation of nitrogen-doped MXene

[0036] Dissolve 20g of urea in 50ml of deionized water, add 0.05g of MXene, stir to form a homogeneous solution, pour it into a closed polytetrafluoroethylene autoclave, and move it into a dry box, and keep it at 150°C for 24 hours. After the reaction, it was centrifuged and washed with deionized water and ethanol, and filtered and dried to obtain nitrogen-doped MXene.

[0037] 3. Preparation of nitrogen-doped MXene-supported cobalt phthalocyanine composites

[0038] Pour 0.02 g of cobalt phthalocyanine into 10 ml of DMF solvent and sonicate for 0.5 h; pour 0.02 g of nitrogen-doped MXene into 10 ml of DMF solvent and sonicate for 0.5 h. Then the...

Embodiment 2

[0040] 1. Synthesis of MXenes with F-terminal groups

[0041] Pour 20ml of 49% HF solution into the beaker and add 2g of Ti 3 AlC 2 The powder was stirred at 35°C for 24 hours, washed by centrifugation with deionized water, and filtered and dried for 24 hours to obtain MXene.

[0042] 2. Preparation of nitrogen-doped MXene

[0043] Dissolve 30g of urea in 50ml of deionized water, add 0.1g of MXene, stir to form a homogeneous solution, pour it into a polytetrafluoroethylene autoclave, and move it into a dry box, and keep it at 180°C for 12 hours. After the reaction, it was centrifuged and washed with deionized water and ethanol, and filtered and dried to obtain nitrogen-doped MXene.

[0044] 3. Preparation of nitrogen-doped MXene-supported cobalt phthalocyanine composites

[0045] Pour 0.005 g cobalt phthalocyanine into 10 ml DMF solvent and sonicate for 1 hour; pour 0.02 g nitrogen-doped MXene into 10 ml DMF solvent and sonicate for 1 hour. Then the cobalt phthalocyanine ...

Embodiment 3

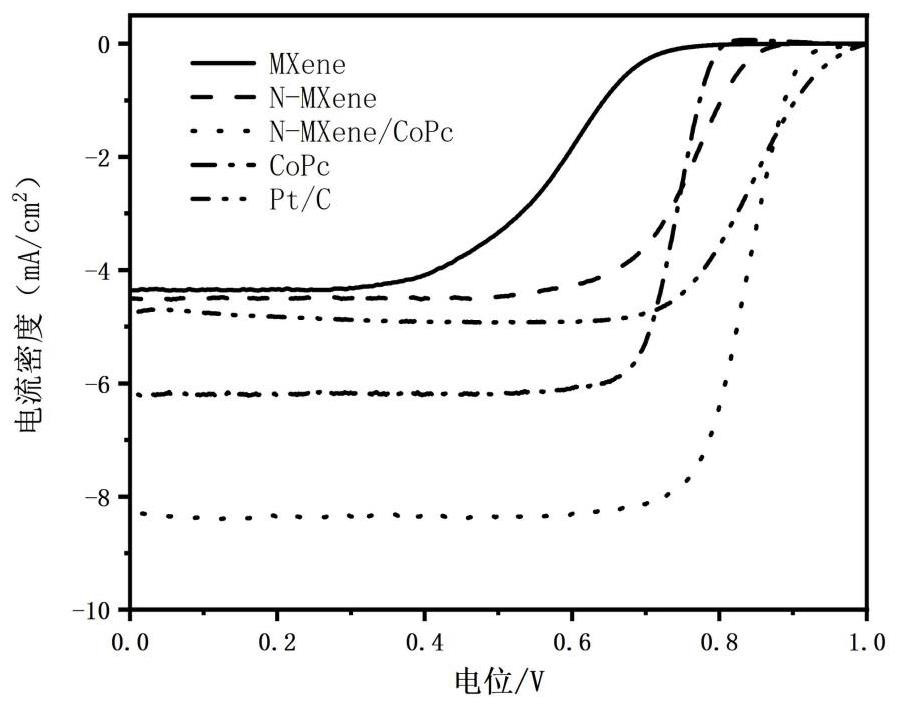

[0047] The as-synthesized nitrogen-doped MXene-supported cobalt phthalocyanine composite was tested as an oxygen reduction catalyst for ORR.

[0048] Use electrochemical workstation and RDE rotating disk electrode to carry out electrocatalytic performance test, adopt three-electrode system (auxiliary electrode is platinum electrode; Reference electrode is calomel electrode, the composite material obtained in embodiment 1 is as working electrode) in oxygen saturated In the case of 0.1mol / L KOH solution, carry out LSV test with the rotating speed of 1600rpm (as a catalyst, the reaction of catalysis is O 2 +2H 2 O+4e - →4OH - (i.e. oxygen reduction reaction)). In practical applications, it is loaded on the cathode of a fuel cell as a catalyst. In this paper, the potential is converted to a standard hydrogen electrode. Before the test, oxygen is passed for 20 minutes to saturate the electrolyte. At 1600rpm and a scan rate of 50mv / s, the electrode material is activated by volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com