Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improved current spread" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

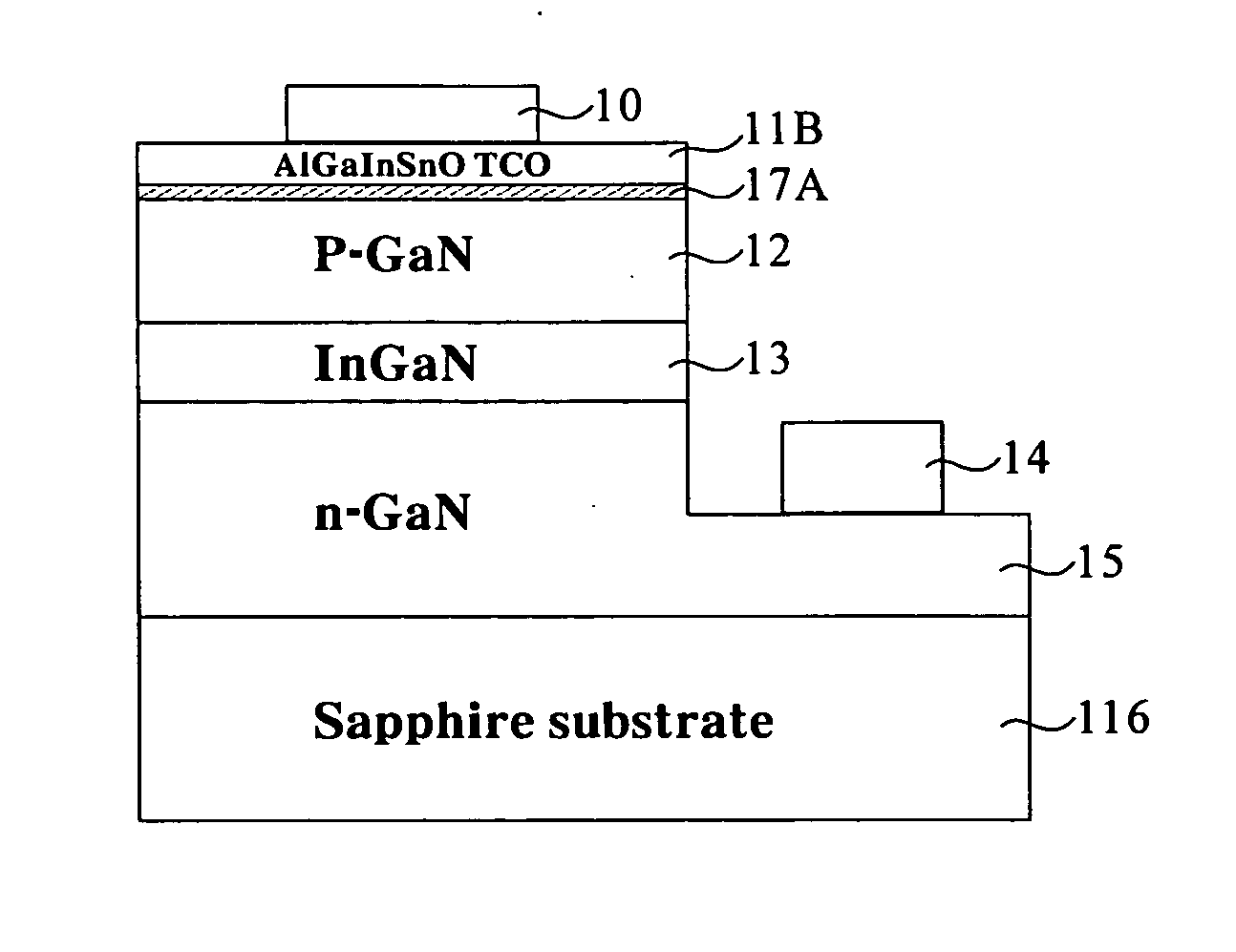

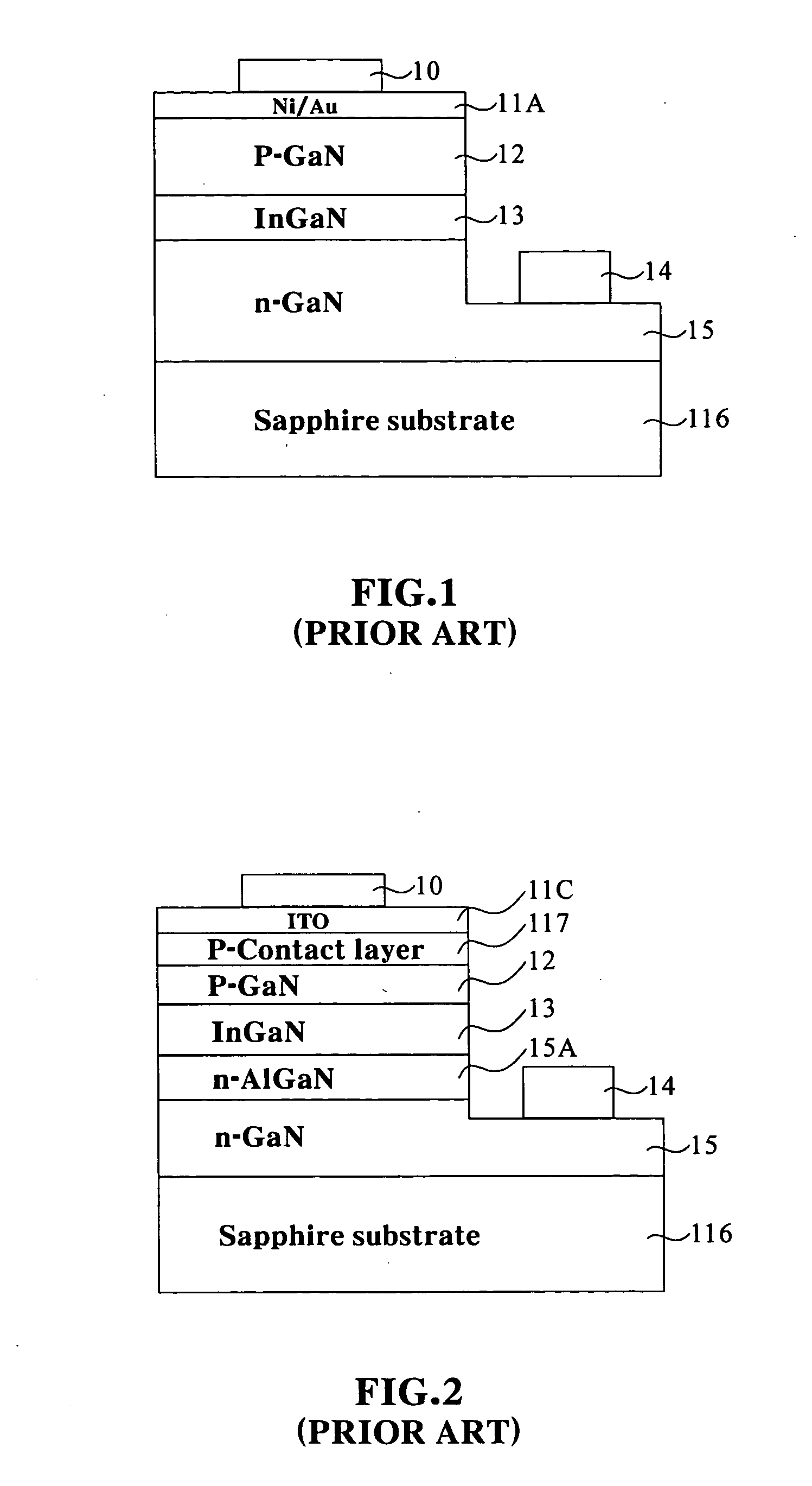

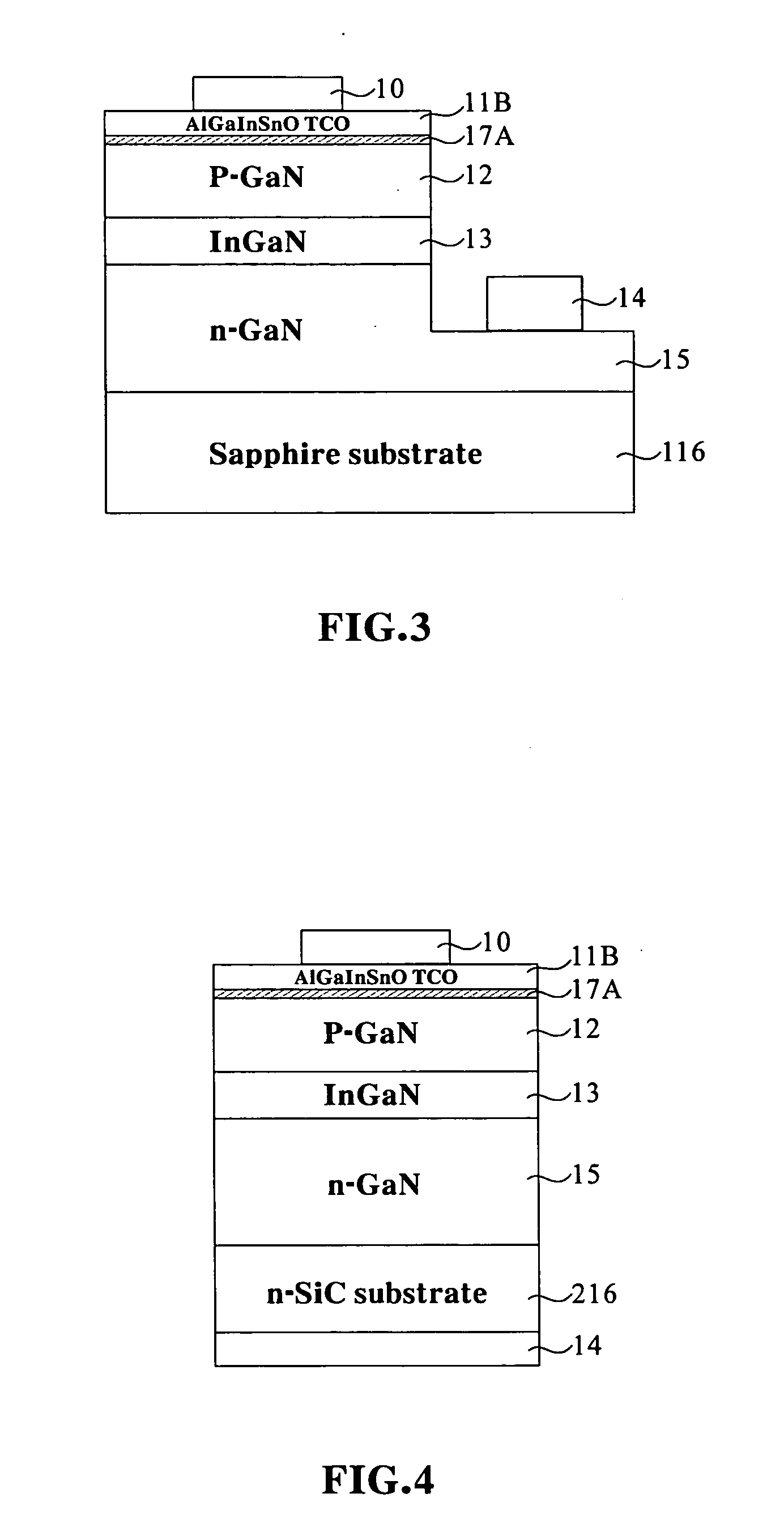

High brightness gallium nitride-based light emitting diode with transparent conducting oxide spreading layer

InactiveUS20050230701A1Reduce contact resistanceReduce the impactFibre treatmentSolid-state devicesOptical propertyGallium

A new transparent conducting oxide (TCO), which can be expressed as AlxGa3−x−yIn5+ySn2−zO16−2z; 0≦x<1, 0<y<3, 0≦z<2, has been used to improve the brightness and current spreading in GaN base LED process. The optical properties of this system are superior to regular Ni / Au transparent conducting layer in blue-green region, and the new Al2O3—Ga2O3—In2O3—SnO2 system is able to increase the brightness at 1.5˜2.5 time to compare to regular process. Furthermore, the new transparent conducting oxide thin film has the highest conductivity, which is better than the Ni / Au transparent conducting thin film.

Owner:ARIMA OPTOELECTRONICS

Micro-scale flip LED (Light Emitting Diode) chip and manufacturing method thereof

PendingCN107195747AWide coverageImprove reflectivitySemiconductor/solid-state device manufacturingSemiconductor devicesLithography processDistributed Bragg reflector

The invention discloses a micro-scale flip LED (Light Emitting Diode) chip and a manufacturing method thereof. A GaN epitaxial layer for manufacturing the LED is of a table structure, both the table base and the table surface of the table structure are in a round table shape, n- electrode rings are distributed on the table base, current spreading rings are distributed at the edge of the top of the table surface, the current spreading material does not diffuse ions at the temperature of 300 DEG C, a passivation layer is arranged on the edge of the top of the current spreading rings and the side wall of the table structure, a dielectric insulating layer and a distributed Bragg reflector layer having the periodic number not smaller than 1 are formed on the passivation layer by adopting chemical vapor deposition, and a p- reflecting electrode layer covers the top of the table surface and the side wall of the passivation layer. The method can improve the reflectivity of a reflector, simultaneously avoids the phenomenon of electric leakage caused by metal diffusion in the reflecting electrode layer, and has relatively large alignment tolerance in the photolithography technique.

Owner:SOUTH CHINA UNIV OF TECH

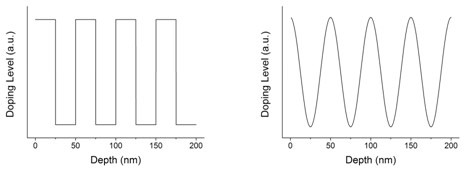

III-group nitride light-emitting diode (LED) and manufacturing method thereof

ActiveCN102185062AIncreased longitudinal resistivityImprove crystal qualitySemiconductor devicesNitrideLight-emitting diode

The invention discloses a III-group nitride light-emitting diode (LED) and a manufacturing method thereof. The LED comprises a substrate and a semiconductor epitaxial laminate which is laminated on the substrate, wherein the semiconductor epitaxial laminate sequentially comprises an N type layer, a luminescent layer and a P type layer from top to bottom. The LED is characterized in that: an N type layer table face is formed in the N type layer by etching a part of the semiconductor epitaxial laminate; an N type electrode is arranged on the N type layer table face; a P type electrode is arranged on the upper surface of the un-etched part of the P type layer; the N type layer also comprises a uniformly doped layer of which the doping concentration is consistent and a modulation doped layer of which the doping concentration is changeable; and the modulation doped layer is arranged between the uniformly doped layer and the luminescent layer. A doped mode of the modulation doped layer is gradual transition doping which connects uniformly doped layer and the luminescent layer of which the doping concentration is consistent. The concentration change trend is decrease progressively change from the uniformly doped layer to the luminescent layer. By the LED and the manufacturing method, the crystal quality and the luminance uniformity can be obviously improved, and the lighting effect is improved.

Owner:SUN YAT SEN UNIV

Copper substrate-based nitride LED vertical chip and preparation method thereof

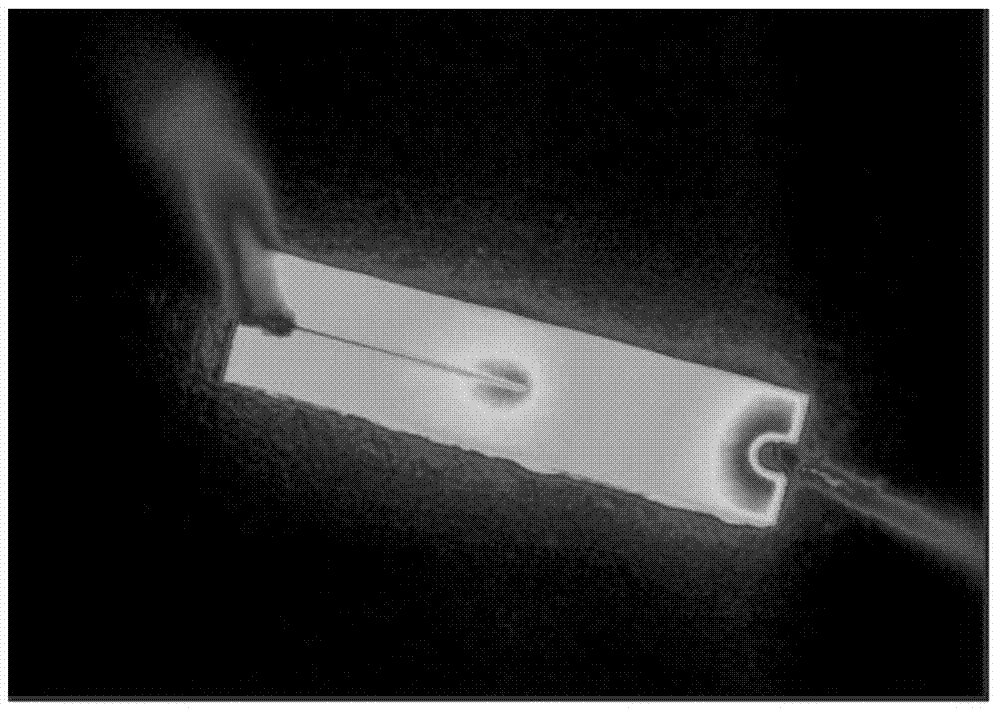

InactiveCN104576862AImproved current spreadReduce thermal resistanceSemiconductor devicesHigh current densityElectron

The invention relates to a copper substrate-based nitride LED vertical chip and a preparation method thereof. The copper substrate-based nitride LED vertical chip comprises an n-type electrode, a two-dimensional derived film, a nitride epitaxial layer and a p-type electrode, wherein the two-dimensional derived film is attached onto the n-type electrode; the nitride epitaxial layer is attached onto the two-dimensional derived film; the p-type electrode is attached onto the nitride epitaxial layer. The preparation method for the copper substrate-based nitride LED vertical chip comprises the following steps: after a copper substrate-based nitride LED epitaxial wafer is prepared, piercing a hole from the back surface of a copper substrate to a buffer layer or an n-type electron injection layer by using a hole piercing process; manufacturing a metal channel structure for realizing the contact with the n-type electron injection layer, and simultaneously realizing the conduction between the n-type electron injection layer and the copper substrate; manufacturing the p-type electrode on the top of a p-type cavity injection layer. The nitride LED vertical chip disclosed by the invention has the characteristics of better current expanding, lower thermal resistance, higher reliability and the like, and is very suitable for the application directions of high current density driving and high optical power density output.

Owner:江苏巨晶新材料科技有限公司

Electrode preparation method for improving current expansion and luminous efficiency of GaAs-based light-emitting diode

InactiveCN105449065AImprove current spreading efficiencyImprove scaling efficiencySemiconductor devicesPower flowEvaporation

The invention discloses an electrode preparation method for improving the current expansion and luminous efficiency of a GaAs-based light-emitting diode, and the method comprises the steps: preparing a patterned recessed region on a GaAs-based epitaxial wafer through photoresist coating and plasma etching, and removing photoresist; depositing an ITO film on the GaAs-based epitaxial wafer, and carrying out the thermal annealing of the ITO film; carrying out sequential vapor plating of a plurality of metal film layers on the ITO film through photoresist coating and electron-beam evaporation, and forming a pattern electrode, wherein the pattern electrode comprises a pasting layer, a reflection layer, a blocking layer, and a welding layer; removing the metal films in a region outside the pattern electrode through employing a peeling method, and completing the preparation of a P electrode of the GaAs-based light-emitting diode; removing the residual photoresist; thinning a GaAs-based substrate of the GaAs-based epitaxial wafer, carrying out the vapor plating of one metal film layer on the surface of the GaAs-based substrate, and completing the preparation of the N electrode of the GaAs-based light-emitting diode. The method improves the current expansion of the GaAs-based light-emitting diode through employing the ITO film.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

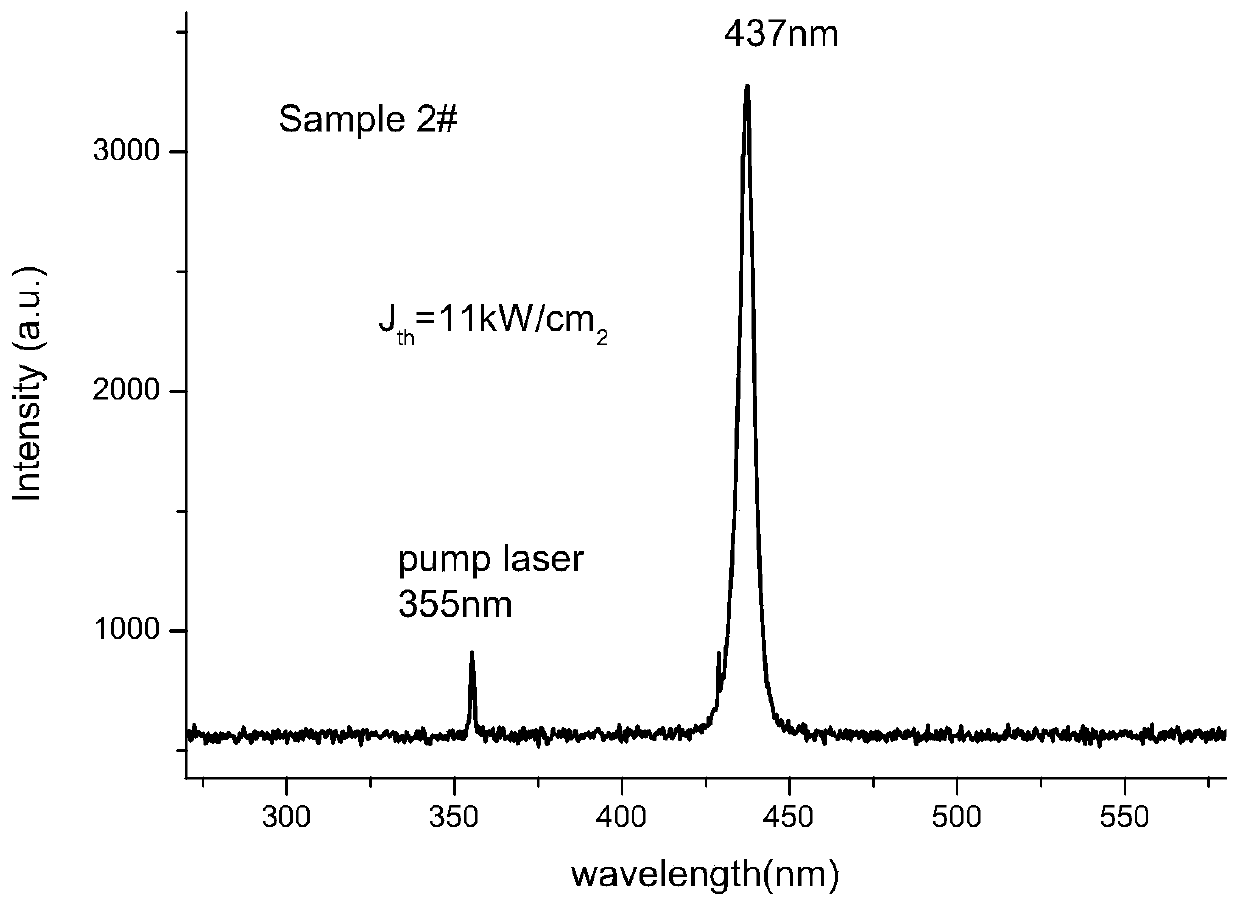

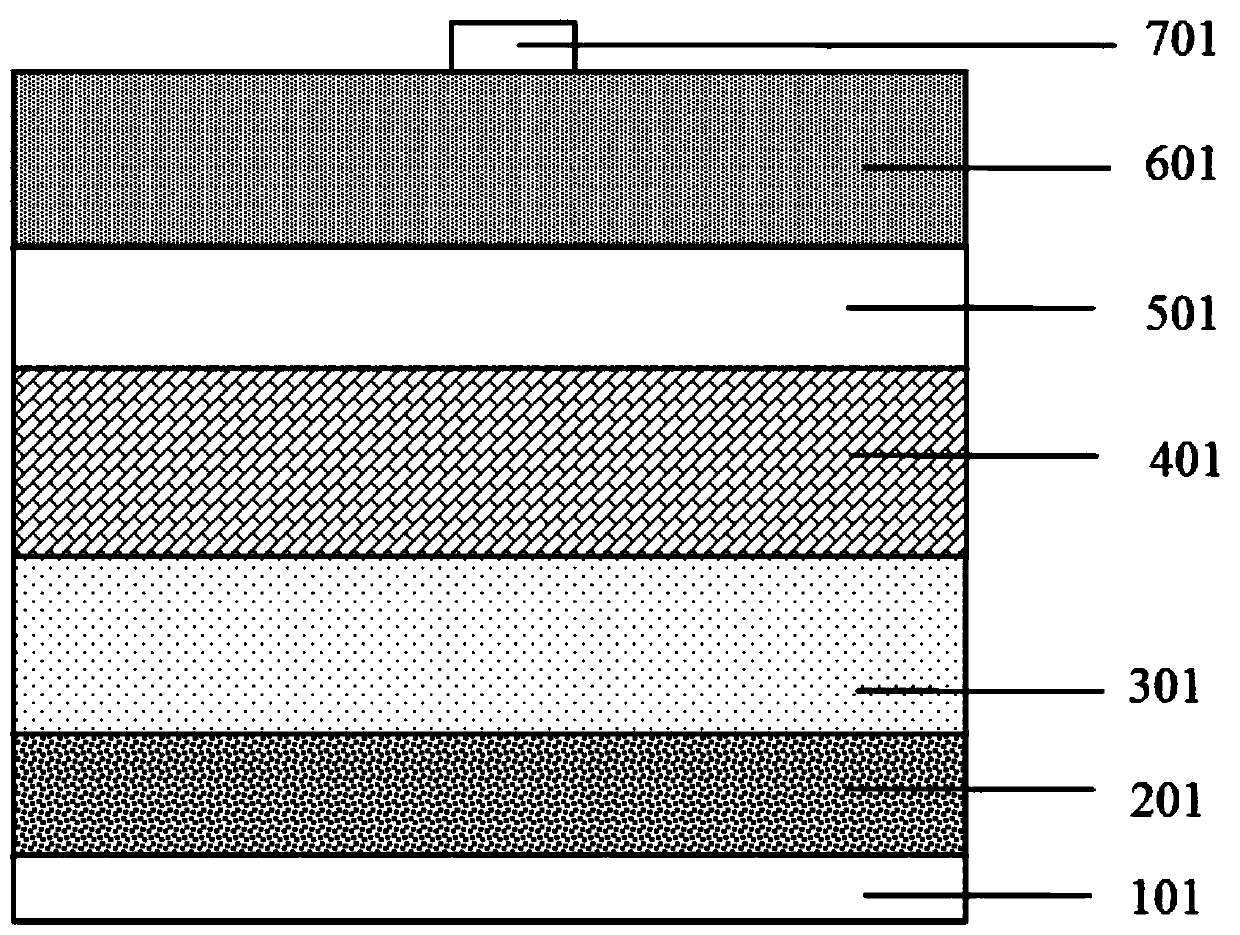

Laser diode based on gallium nitride single-crystal substrate and preparation method of laser diode

ActiveCN110729631AImproved current spreadPlay the effect of saving electronsOptical wave guidanceLaser detailsQuantum efficiencyQuantum well

The invention discloses a laser diode based on a gallium nitride single crystal substrate and a preparation method of the laser diode. The laser diode comprises the GaN single-crystal substrate, an n-type GaN layer, an n-type limiting layer, a lower waveguide layer, a composite quantum well active region, an electron blocking layer, an upper waveguide layer, a p-type limiting layer and a p-type GaN layer which are sequentially stacked from bottom to top. According to the invention, the high-quantum efficiency stress regulation and control active region structure, the novel optical waveguide layer structure and the novel limiting layer structure of the gallium nitride-based laser diode are designed and optimized; the laser diode is prepared on the low-dislocation-density GaN single-crystalsubstrate; the technical difficulty of epitaxial preparation of a GaN-based laser is eliminated; and a GaN-based laser with high reliability and high quantum efficiency can be obtained.

Owner:DONGGUAN UNIV OF TECH

Light emitting diode (LED) chip structure

InactiveCN102637799AImprove injection efficiencyImproved current spreadSemiconductor devicesOhmBlock structure

The invention discloses a light emitting diode (LED) chip structure. A P type ohm contact electrode layer is arranged on a P type semiconductor layer of the structure, an insulation blocking structure is arranged on the P type ohm contact electrode layer, a P type transparent conducting layer is arranged on the insulation blocking structure, the insulation blocking structure is covered by the P type transparent conducting layer, and the P electrode is in contact with the P type transparent conducting layer, wherein the insulation blocking structure comprises a plurality of cylindrical insulation structure or is a insulation layer provided with a plurality of through holes. The LED chip structure provided by the invention has the advantages that the current injection efficiency is improved through improving the current expansion, so the LED brightness is improved.

Owner:EPILIGHT TECH

Vertical chip structure for nitride LED (light-emitting diode) and preparation method of vertical chip structure

InactiveCN104637794AImproved current spreadReduce thermal resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesHigh current densityPower flow

The invention relates to a vertical chip structure for a nitride LED (light-emitting diode) and a preparation method of the vertical chip structure. The vertical chip structure for the nitride LED comprises an n-type electrode, a nitride LED epitaxial wafer structure and a p-type electrode, wherein the n-type electrode is located below the nitride LED epitaxial wafer structure and is attached to the nitride LED epitaxial wafer structure; the p-type electrode is located above the nitride LED epitaxial wafer structure and is attached to the nitride LED epitaxial wafer structure. The method comprises the following steps: after fabricating a two-dimensional derived membrane and a nitride epitaxial layer on a composite substrate, firstly, fabricating the n-type electrode on the back surface of the composite substrate; then fabricating the p-type electrode on the nitride epitaxial layer; finally, segmenting an LED apparatus wafer to obtain a discrete device. A vertical chip for the nitride LED, prepared by the method, has the advantage of being suitable for high-current density (greater than or equal to 100A / cm<2>) drive and high-optical power density output.

Owner:江苏巨晶新材料科技有限公司

Light emitting diode using ITO regional sheet resistance change to improve current spreading and manufacturing method

InactiveCN104617198AImproved current spreadImprove uniformitySemiconductor devicesMetal electrodesLight-emitting diode

The invention relates to a light emitting diode using ITO regional sheet resistance change to improve current spreading and a manufacturing method. The light emitting diode comprises an epitaxial wafer grown on a substrate, an ITO film located on the epitaxial wafer, a metal electrode and a passivation layer; three ITO regions with different sheet resistances are located on the ITO film, a high-sheet resistance ITO region III is located below the metal electrode, a low-sheet resistance ITO region I is formed through a mask pattern, and the low-sheet resistance ITO region I extends to the edge through using the metal electrode as the center and has a branch shape. According to the light emitting diode using the ITO regional sheet resistance change to improve the current spreading and the manufacturing method, through improving or lowering the sheet resistance on the selective region of the ITO layer, the current spreading route guidance is realized, without increasing a current blocking layer, the current spreading uniformity of the light emitting diode can be improved through the regional treatment of the current spreading layer ITO, the light emitting efficiency is improved, and the high voltage of the chip is avoided.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

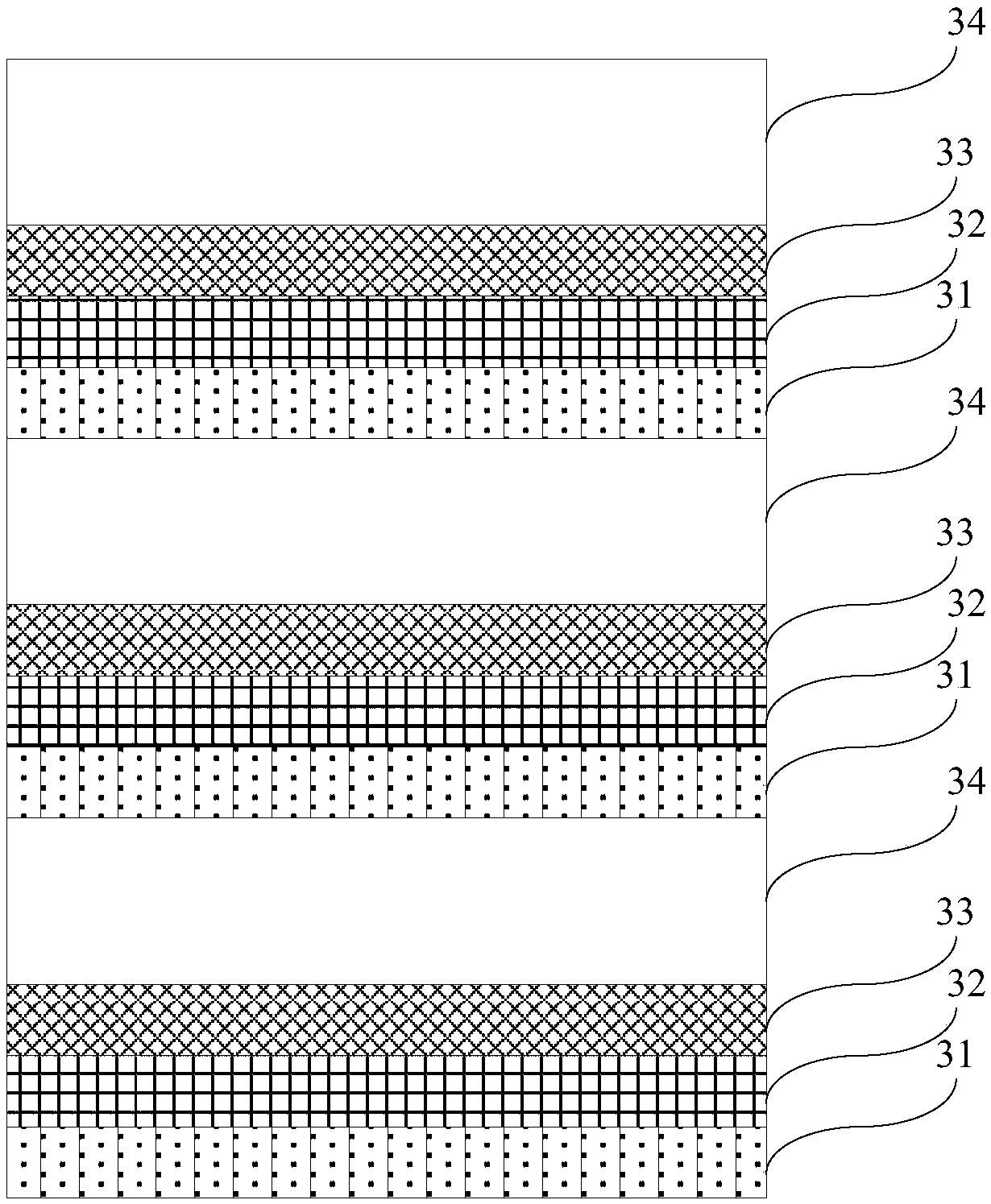

Light emitting diode epitaxial wafer and preparation method thereof,

ActiveCN109346568AImproved current spreadLow growth temperatureSemiconductor devicesGallium nitrideActive layer

The invention discloses a light emitting diode epitaxial wafer and a preparation method thereof, and belongs to the technical field of semiconductors. The light-emitting diode epitaxial wafer comprises a substrate, an N-type semiconductor layer, a stress release layer, an active layer and a P-type semiconductor layer, wherein the N-type semiconductor layer, the stress release layer, the active layer and the P-type semiconductor layer are sequentially stacked on the substrate; the stress release layer comprises a plurality of composite structures which are stacked in sequence, wherein each composite structure comprises a first sub-layer, a second sub-layer, a third sub-layer and a fourth sub-layer which are stacked in sequence; the first sub-layer is made of non-doped indium gallium nitride, the second sub-layer is made of non-doped aluminum nitride, the third sub-layer is made of silicon nitride, and the fourth sub-layer is made of non-doped gallium nitride. According to the light-emitting diode epitaxial wafer, the photoelectric property of the LED is finally improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

Chip structure for LED

InactiveCN101752479AReliable contactIncrease contactSemiconductor devicesLight-emitting diodePhysics

The invention relates to a chip structure for an LED. The chip comprises a substrate, an epitaxial layer, a current extension layer, an N electrode, a P pad and a passivation layer. The passivation layer is superposed on the current extension layer. At least one hole is formed on the current extension layer, and the passivation layer contacts the epitaxial layer together through the hole. By forming at least one hole on the current extension layer, the surface of the epitaxial layer is exposed and the epitaxial layer is more reliably contacted with the passivation layer which covers on the epitaxial layer. Therefore, good contact between the current extension layer and the epitaxial layer is protected. The technology for manufacturing the LED is convenient, and the current extension of the chip can be obviously improved and the packaging percent of pass and the reliability of the LED are improved.

Owner:SHENZHEN CENTURY EPITECH LEDS

Vertical high voltage light emitting diode chip and manufacturing method thereof

ActiveCN110085619AIncrease the effective luminous areaImproved current spreadSolid-state devicesSemiconductor devicesElectricityHigh pressure

The invention discloses a vertical high voltage light emitting diode chip and a manufacturing method thereof. With the design of the vertical high voltage light emitting diode chip, the back surface electrode in a first chip region is electrically connected with a conductive substrate through a hole and a bonding layer and the back surface electrode is exposed without etching in the first chip region, thereby ensuring that the effective light emitting area of the vertical high voltage light emitting diode chip is large; besides, the back surface electrode of the first chip region does not needto be wired, thereby saving cost and improving reliability; in addition, the current spreading of each chip region is vertical, and the back surface electrode of the first chip region and the front surface electrode of the Nth chip region form a vertical structure so that the current spreading of the vertical high voltage light emitting diode chip is good, and the current resistance ability can be improved by avoiding current congestion; furthermore, the vertical high voltage light emitting diode chip has a better light type and meets the Lambert distribution and is easier to distribute light.

Owner:XIAMEN CHANGELIGHT CO LTD

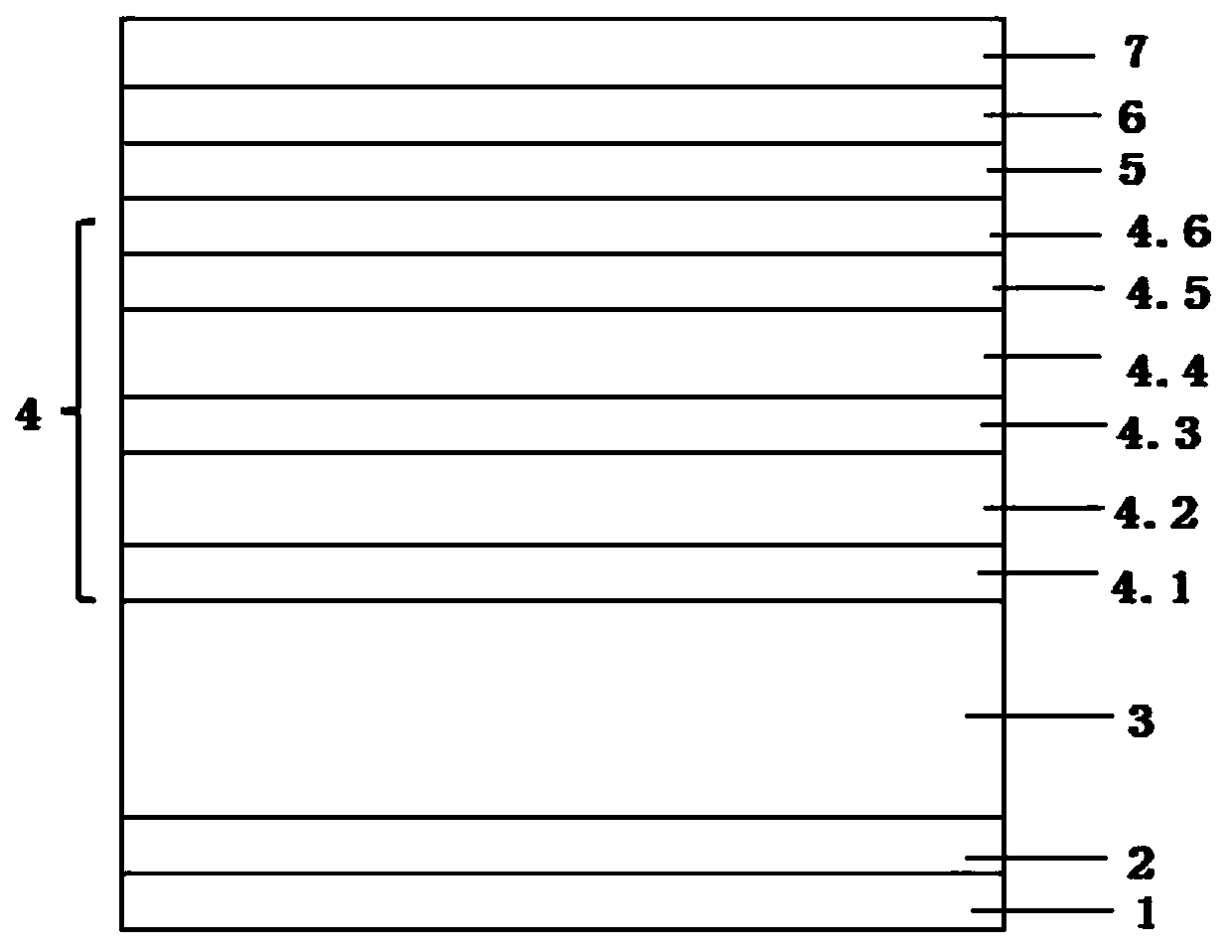

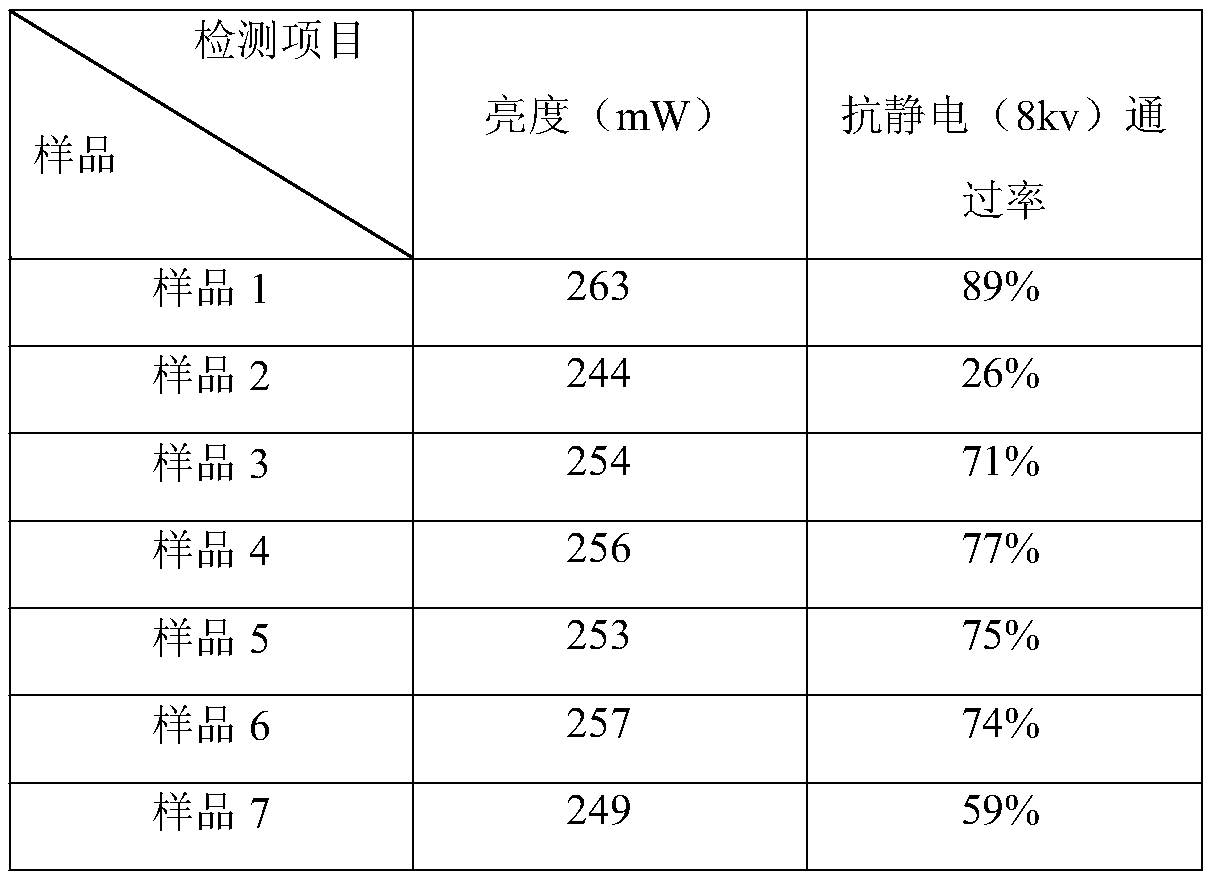

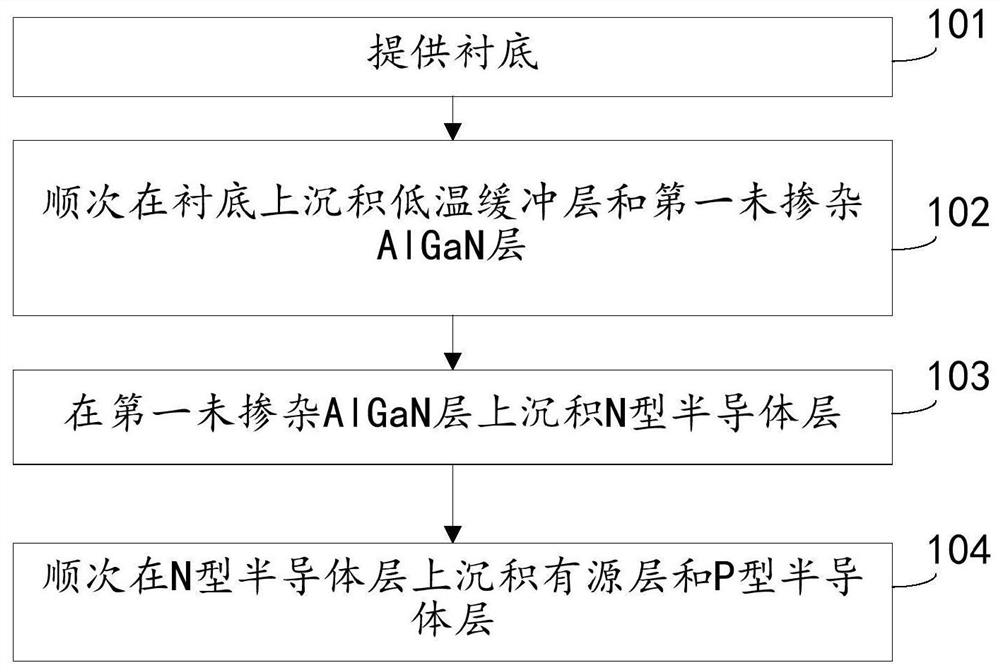

LED epitaxial growth method

ActiveCN111261755AImprove antistatic performanceReduce stressSemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideElectron blocking layer

The invention provides an LED epitaxial growth method for improving antistatic capability and luminous efficiency. The LED epitaxial growth method specifically comprises the steps of 1, processing a substrate; 2, growing a low-temperature buffer layer gallium nitride layer on the substrate; 3, growing an undoped gallium nitride layer; 4, growing a composite N-type layer; 5, growing a multi-quantumwell light-emitting layer; 6, growing an electron barrier layer doped with aluminum and magnesium; 7, growing a magnesium-doped high-temperature P-type gallium nitride layer; and 8, annealing in a furnace for 25-30 minutes under the conditions that the temperature is 750-800 DEG C and the pressure is 500-800mbar, closing a heating system and a gas supply system, and cooling along with the furnace. According to the epitaxial growth method, the bottom stress is greatly released, the bottom dislocation density is reduced, the gallium nitride crystal quality is improved, the current expansion isimproved, the antistatic performance of the LED is improved, and the light output power of the LED is also improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

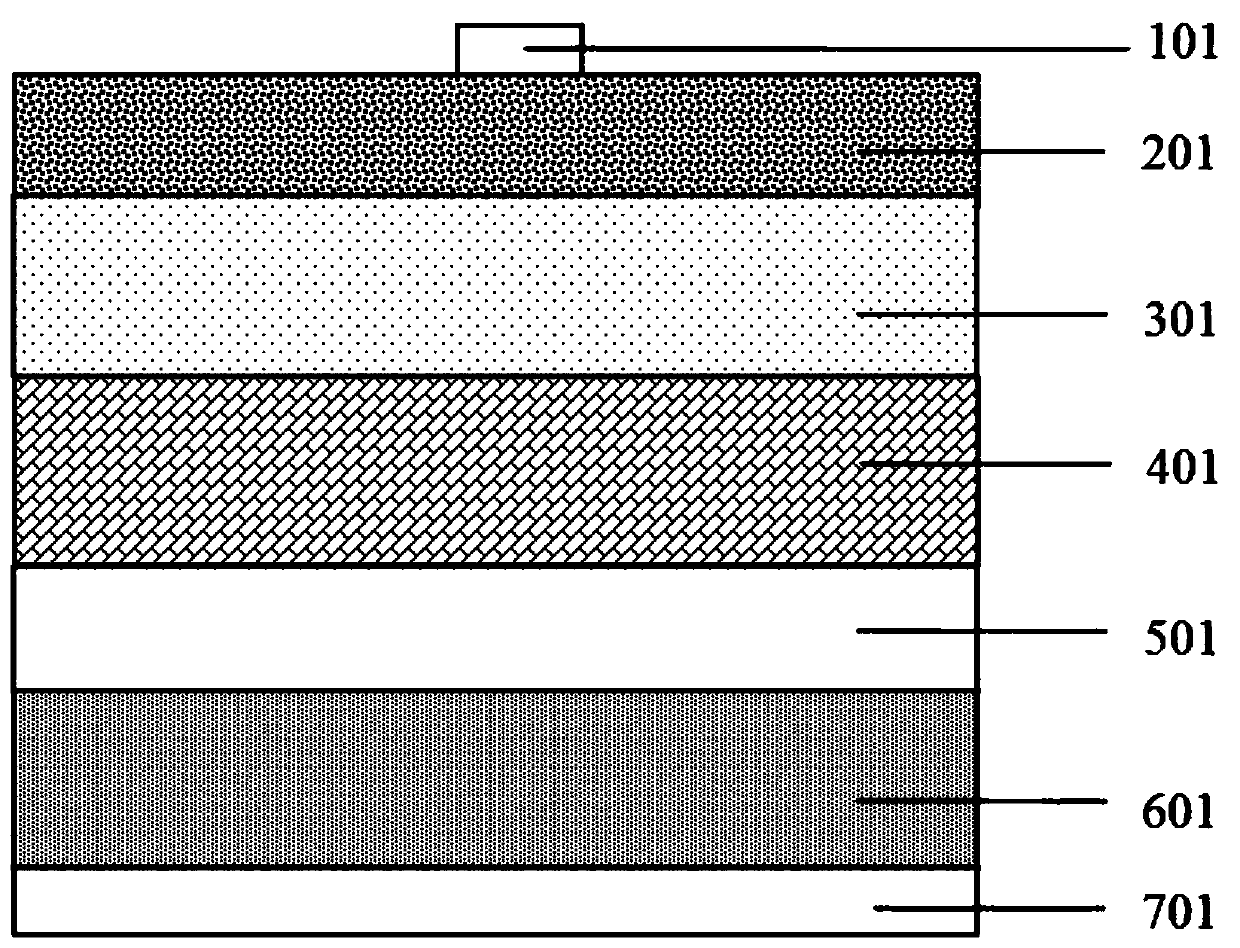

Epitaxial wafer of ultraviolet light emitting diode and preparation method thereof

ActiveCN112687773AImprove electrical performanceLower bulk resistanceSemiconductor devicesUltraviolet light emitting diodesActive layer

The invention provides an epitaxial wafer of an ultraviolet light emitting diode and a preparation method thereof, and belongs to the field of light emitting diodes. The epitaxial wafer comprises a substrate, and a low-temperature buffer layer, a first undoped AlGaN layer, an N-type semiconductor layer, an active layer and a P-type semiconductor layer which are sequentially stacked on the substrate, and the N-type semiconductor layer comprises a high-doped N-type layer and a low-doped N-type layer. Wherein the low-doped N-type layer comprises a first low-doped layer stacked on the high-doped N-type layer, the high-doped N-type layer and the first low-doped layer each comprise a plurality of AlGaN layers and a plurality of SiN layers which are distributed alternately, and the Si doping concentration in the high-doped N-type layer is higher than that in the low-doped N-type layer. The electrical property of the ultraviolet light emitting diode can be improved.

Owner:HC SEMITEK SUZHOU

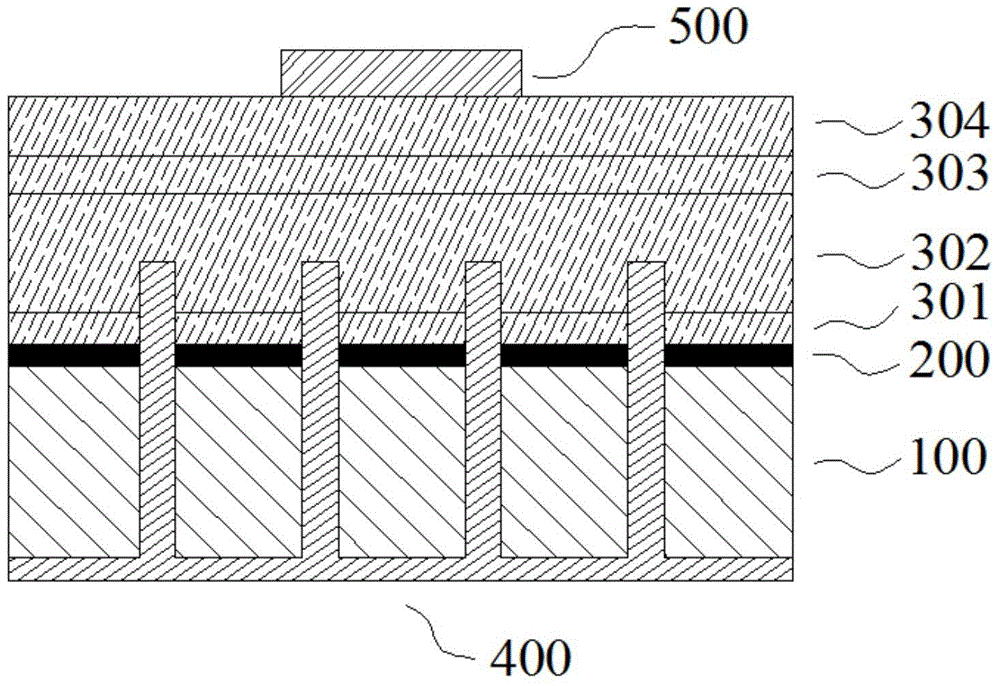

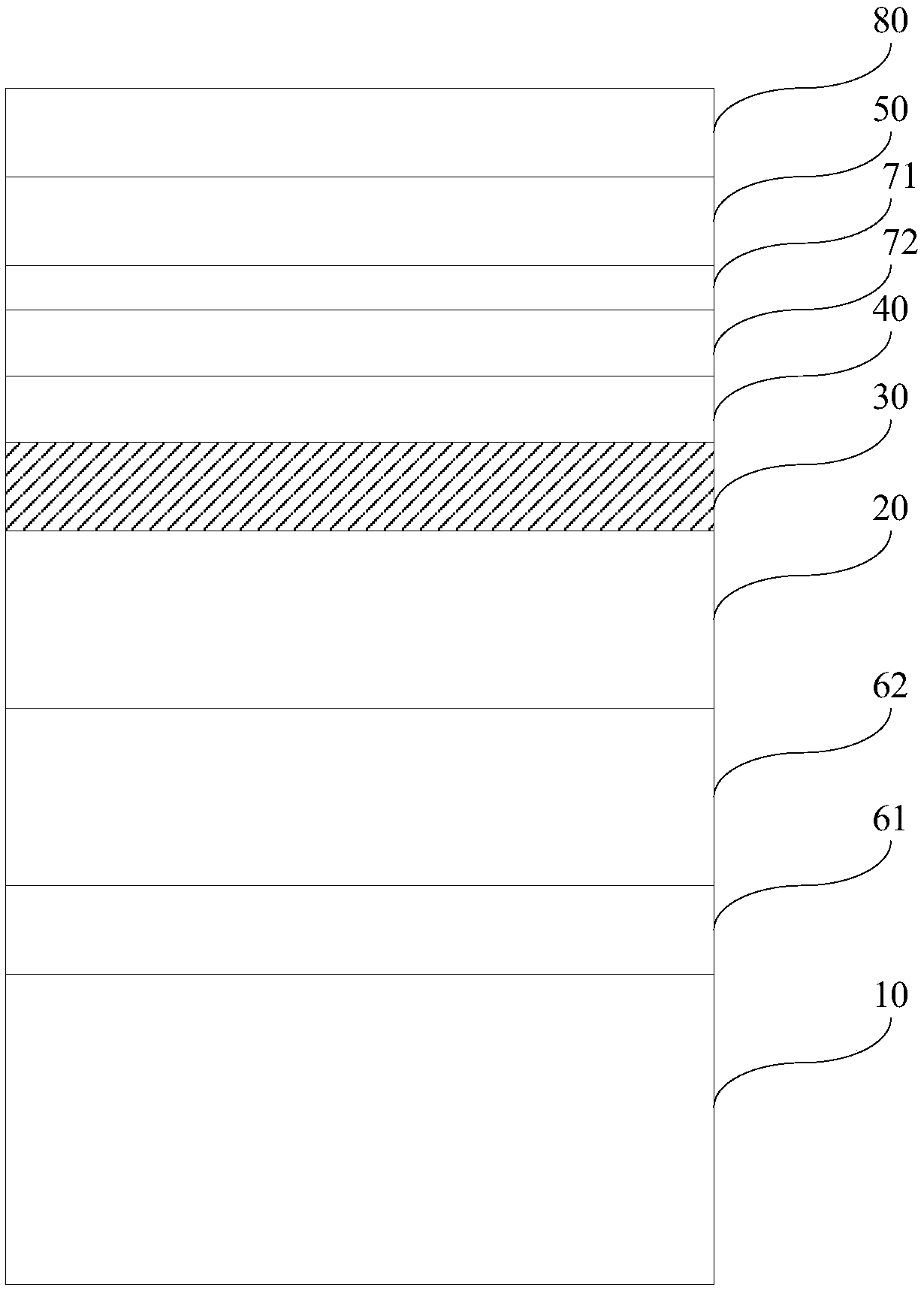

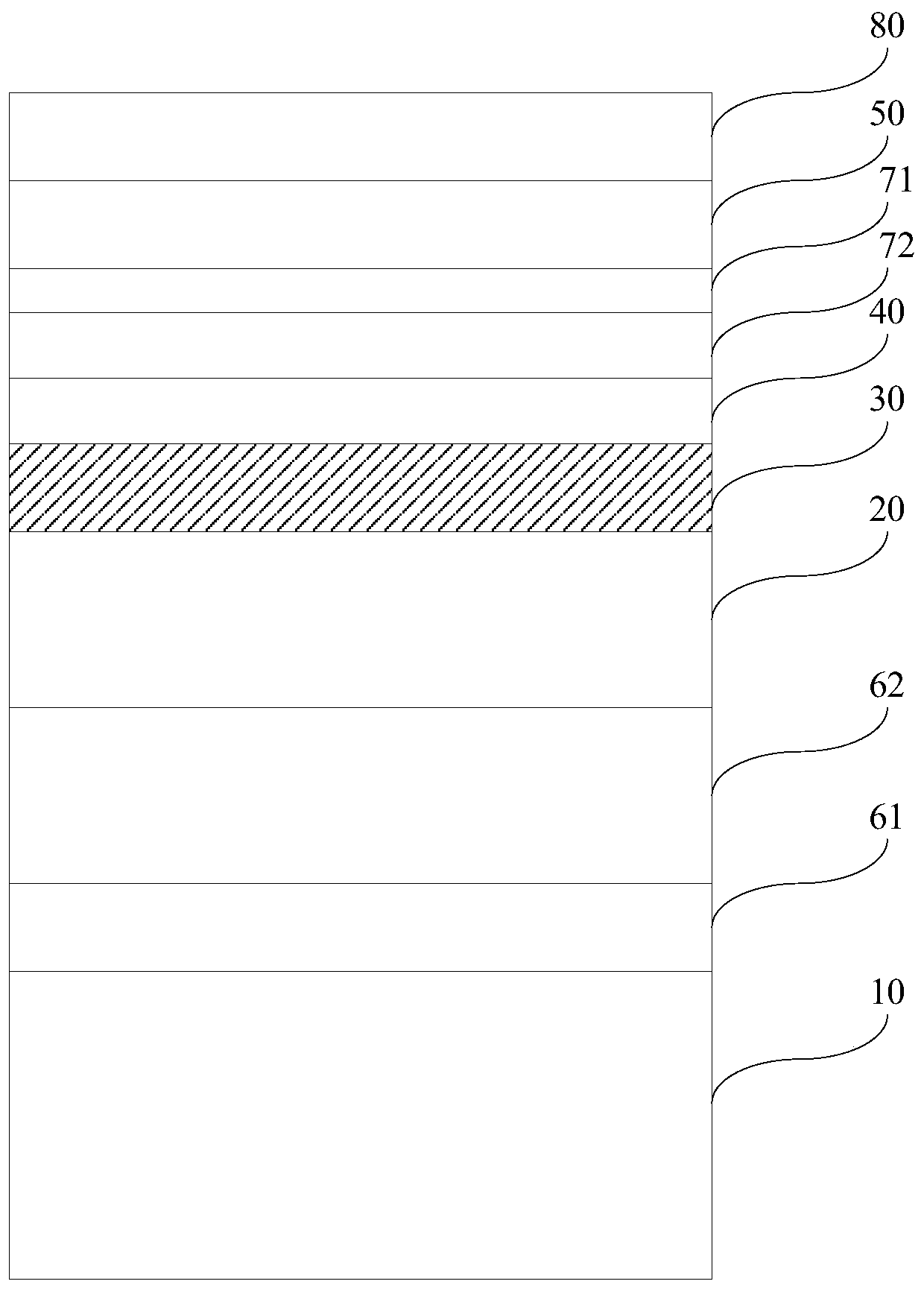

GaN-based vertical structure micro-cavity Micro-LED based on electroplating technology and preparation method thereof

The invention discloses a GaN-based vertical structure micro-cavity Micro-LED based on an electroplating technology and a preparation method thereof. The micro-cavity Micro-LED is narrow in light-emitting full width at half maximum and good in light-emitting directivity; thickness of a chip is reduced, and a metal reflector of the p-GaN layer (5) and a dielectric film reflector of the n-GaN layerare used as end faces of a resonant cavity to form a resonant micro-cavity structure in the vertical direction, so side wall light emission is inhibited, front light emission directivity is improved,and the crosstalk effect between adjacent pixels of Micro-LED display is reduced. Meanwhile, the resonant micro-cavity structure selects a specific wavelength, so the light-emitting spectrum is narrowed, the spectral purity is higher, the display threshold of the Micro-LED is improved, a Micro-LED active region of the vertical structure is large in area, and n-GaN light absorption is less, the current expansion is good, the voltage is low, the current density is small, and advantages in the aspects of lighting effect, saturation current and long-term reliability are achieved; and secondly, a Cu substrate has good electrical conductivity and thermal conductivity, and thermal resistance of the chip is small.

Owner:长沙安牧泉智能科技有限公司

Emergent circularly polarized light vertical structure Micro-LED for 3D display, and preparation method thereof

ActiveCN112018221AImprove light directionalityEliminate crosstalkSemiconductor devicesGratingNano structuring

The invention discloses an emergent circularly polarized light vertical structure micro-cavity Micro-LED for 3D display, and a preparation method thereof. According to the invention, the micro-cavityMicro-LED can emit circularly polarized light, and the circularly polarized light is adopted for 3D polarized display, so that the crosstalk problem of patterns caused by inclination of glasses can beeliminated only by setting the optical axis position of the circularly polarized glasses; the thickness of a chip is reduced, and a grating on a conductive layer and a dielectric film reflector on an-GaN layer are used as the end surface of a resonant cavity to form a resonant micro-cavity structure in the vertical direction, so that the light emission of the side wall is inhibited, and the light emission directivity of the front surface is improved; the resonant micro-cavity structure selects a specific wavelength, so that the luminescent spectrum is narrowed, the spectral purity is higher,and the threshold of Micro-LED display can be improved; the grating has polarization selection light emitting property, so that the emergent light passing through the structure is linearly polarizedlight; and a micro-nano structure is integrated at the top and is equivalent to a 1 / 4 wave plate, so that the linearly polarized light is converted into circularly polarized light.

Owner:诺视科技(苏州)有限公司

Six-side coarsened infrared LED chip and manufacturing method thereof

The invention provides a six-side coarsened infrared LED chip and a manufacturing method thereof. An ITO finger-shaped electrode, instead of the metal finger-shaped electrode, is adopted for current expansion, thereby effectively solving the problem of shading absorption of the metal finger-shaped electrode, and achieving the good current expansion. Moreover, compared with a front ITO current expansion layer, the ITO finger-shaped electrode has the advantages that the surface roughening treatment can be carried out on the area outside the ITO finger-shaped electrode, so that the light extraction efficiency is improved. A Schottky barrier region is arranged below the ITO finger-shaped electrode, so that the current can be preferentially expanded to the periphery of the chip along the ITO finger-shaped electrode, thereby reducing the current directly injected to the lower part of the electrode, and improving the effective injection of the current. Through the grid type N electrode structure, the LED chip can avoid the problem of non-uniform current distribution of the dot-matrix type back electrode, and also can avoid the problem of light absorption of the whole back electrode.

Owner:YANGZHOU CHANGELIGHT

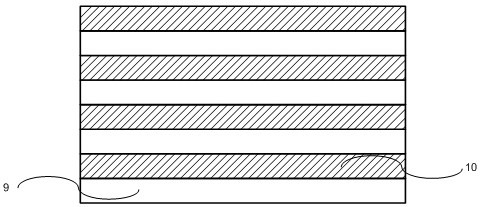

A kind of epitaxy device of semiconductor light-emitting diode

ActiveCN108470807BReduce voltageThe increase in voltage is smallSemiconductor devicesMetal electrodesLight-emitting diode

The invention provides the epitaxial device of a semiconductor light emitting diode. The device comprises an N electrode, an N-type semiconductor contact layer, an N-type semiconductor conducting layer, a luminescent layer, a P-type semiconductor conducting layer, a P-type semiconductor contact layer and a P electrode which are successively contacted with each other. An interface contact resistance between the N electrode and the N-type semiconductor contact layer is adjusted by the doping concentration of the N-type semiconductor contact layer. Or an interface contact resistance between the Pelectrode and the P-type semiconductor contact layer is adjusted by the doping concentration of the P-type semiconductor contact layer. In the invention, in an interface where the surface of a semiconductor is contacted with a metal electrode, current expansion is improved; because the contact of metal and the semiconductor is sensitive, the electric conductivity of the interface is easy to adjust and control, and only a thin layer is needed in an epitaxy so that the current expansion can be greatly improved; and the ascending range of a device voltage is small.

Owner:NANCHANG UNIV +1

Epitaxial wafer of ultraviolet light emitting diode and its preparation method

ActiveCN112687773BImprove electrical performanceLower bulk resistanceSemiconductor devicesUltraviolet light emitting diodesActive layer

The disclosure provides an epitaxial wafer of an ultraviolet light-emitting diode and a preparation method thereof, belonging to the field of light-emitting diodes. The epitaxial wafer includes: a substrate and a low-temperature buffer layer sequentially stacked on the substrate, a first undoped AlGaN layer, an N-type semiconductor layer, an active layer, and a P-type semiconductor layer, and the N-type semiconductor layer including a highly doped N-type layer and a low-doped N-type layer sequentially stacked on the first undoped AlGaN layer, and the low-doped N-type layer includes stacking on the highly doped N-type layer The first low-doped layer, the highly-doped N-type layer and the first low-doped layer both include a plurality of AlGaN layers and a plurality of SiN layers alternately distributed, and Si in the highly-doped N-type layer The doping concentration is higher than the Si doping concentration in the low-doped N-type layer. The present disclosure can improve the electrical performance of the ultraviolet light emitting diode.

Owner:HC SEMITEK SUZHOU

Semiconductor light emitting device and manufacturing method for the same

ActiveCN100388515CAvoid crowdingImproved current spreadSemiconductor devicesEngineeringLight emitting device

This invention discloses one semiconductor light element and its process method, which The device has upper and down electrode structure through device light layer both sides two ohm electrodes relative space upper shape compensation or etching block light down part of semiconductor to reduce upper and down light parts current crowding situations.

Owner:LATTICE POWER (JIANGXI) CORP

Vertical GaN-based LED chip and manufacture method thereof

ActiveCN101604717BEasy to achieve evaporationImprove light extraction efficiencySemiconductor devicesQuantum wellOptoelectronics

The invention provides a vertical GaN-based LED chip and a manufacture method thereof. The chip comprises a substrate, N type GaN, a quantum well active layer, P type GaN, a current expansion layer, a metal mirror and a conductive substrate; a P electrode is manufactured on the conductive substrate; a window directly toward a N type GaN layer is arranged on the substrate; a layer of metal is evaporated at each side in the window; a N electrode is led out from the metal layer. The manufacture method comprises the following steps: epitaxially growing the N type GaN, the quantum well active layer, the P type GaN and the current expansion layer on a sapphire or 6H-SiC transparent substrate from bottom to top in sequence according to the conventional method; the metal mirror is manufactured onthe current expansion layer; the conductive substrate is welded on the metal mirror; the window directly toward the N type GaN layer is processed; the metal layer is evaporated at each side in the window and the N electrode is led out from the metal layer. The invention reduces the influence of instable factors in the technological process. The GaN-based LED chip is high in utilization ratio of effective light-emitting area, good in current expansion and good in heat dissipation of tube cores.

Owner:山东鲁南大数据产业发展有限公司

III-group nitride light-emitting diode (LED) and manufacturing method thereof

ActiveCN102185062BIncreased longitudinal resistivityImprove crystal qualitySemiconductor devicesEffect lightNitride

The invention discloses a III-group nitride light-emitting diode (LED) and a manufacturing method thereof. The LED comprises a substrate and a semiconductor epitaxial laminate which is laminated on the substrate, wherein the semiconductor epitaxial laminate sequentially comprises an N type layer, a luminescent layer and a P type layer from top to bottom. The LED is characterized in that: an N type layer table face is formed in the N type layer by etching a part of the semiconductor epitaxial laminate; an N type electrode is arranged on the N type layer table face; a P type electrode is arranged on the upper surface of the un-etched part of the P type layer; the N type layer also comprises a uniformly doped layer of which the doping concentration is consistent and a modulation doped layer of which the doping concentration is changeable; and the modulation doped layer is arranged between the uniformly doped layer and the luminescent layer. A doped mode of the modulation doped layer is gradual transition doping which connects uniformly doped layer and the luminescent layer of which the doping concentration is consistent. The concentration change trend is decrease progressively change from the uniformly doped layer to the luminescent layer. By the LED and the manufacturing method, the crystal quality and the luminance uniformity can be obviously improved, and the lighting effect is improved.

Owner:SUN YAT SEN UNIV

A kind of high-brightness light-emitting diode based on Aln/PSS composite substrate and preparation method thereof

ActiveCN110729383BReduce dislocation densityDislocation maskingSemiconductor devicesPhysical chemistryComposite substrate

The invention discloses a high-brightness light-emitting diode based on an AIN / PSS composite substrate and a preparation method of the high-brightness light-emitting diode. The high-brightness light-emitting diode comprises the AlN / PSS composite substrate, a u-type GaN merging layer, an n-type GaN layer, a low-temperature GaN V-pits layer, an active region, an electron blocking layer, a high-temperature p-type GaN layer and a contact layer which are sequentially stacked from bottom to top. The high-brightness light-emitting diode provided by the invention comprises the u-GaN merging layer of anovel structure, the V-pits layer and the active region; and therefore, the crystal quality of an epitaxial layer can be effectively improved, the stress of the active region can be effectively relieved, current expansion in a horizontal direction can be improved, the light-emitting efficiency of the light-emitting diode can be improved, and the brightness of the prepared light-emitting diode ishigh.

Owner:DONGGUAN UNIV OF TECH

Reverse polarity vertical light emitting diode and its preparation method

ActiveCN110808319BImproved current spreadReduce thermal resistanceSemiconductor devicesQuantum efficiencyQuantum well

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

A kind of transparent electrode of light-emitting diode and preparation method thereof

ActiveCN109638136BImprove light extraction efficiencyLow resistivitySemiconductor devicesIndiumChemical cleaning

The invention provides a transparent electrode of a light-emitting diode. A preparation method of the transparent electrode comprises the following steps: S1, carrying out chemical cleaning on the surface of an epitaxial wafer, then putting the epitaxial wafer into an MOCVD reaction chamber with temperature of 300-900 DEG C and pressure of 3-100 Torr, and treating for 1-60 minutes; S2, under the protective atmosphere, adjusting the growth temperature to 450-650 DEG C, adjusting the pressure of the reaction chamber to 3-80 Torr, then, introducing an indium source, a tin source and an oxygen source, controlling the growth speed to 0.1-3 nm / min, and growing an ITO main body layer with the thickness of 40-500 nm on the surface of the pretreated epitaxial wafer; and S3, under the protective atmosphere, adjusting the growth temperature to 300-450 DEG C, adjusting the pressure of the reaction chamber to 3-80 Torr, then, introducing an indium source, a tin source and an oxygen source, controlling the growth speed to 1-10 nm / min, and growing an ITO coarsening layer with the thickness of 20-200 nm on the ITO main body layer. The method for in-situ growth of the coarsening layer is very matched with the preparation method of a main body layer of the ITO transparent electrode, subsequent complex process treatment is avoided, and the light extraction efficiency of the LED can be effectivelyimproved.

Owner:SUN YAT SEN UNIV +1

A light-emitting diode epitaxial wafer and its preparation method

ActiveCN109346568BImproved current spreadLow growth temperatureSemiconductor devicesIndiumGallium nitride

The invention discloses a light emitting diode epitaxial wafer and a preparation method thereof, and belongs to the technical field of semiconductors. The light-emitting diode epitaxial wafer comprises a substrate, an N-type semiconductor layer, a stress release layer, an active layer and a P-type semiconductor layer, wherein the N-type semiconductor layer, the stress release layer, the active layer and the P-type semiconductor layer are sequentially stacked on the substrate; the stress release layer comprises a plurality of composite structures which are stacked in sequence, wherein each composite structure comprises a first sub-layer, a second sub-layer, a third sub-layer and a fourth sub-layer which are stacked in sequence; the first sub-layer is made of non-doped indium gallium nitride, the second sub-layer is made of non-doped aluminum nitride, the third sub-layer is made of silicon nitride, and the fourth sub-layer is made of non-doped gallium nitride. According to the light-emitting diode epitaxial wafer, the photoelectric property of the LED is finally improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

A 3D display-oriented micro-led with a vertical structure for emitting circularly polarized light and its preparation method

ActiveCN112018221BImprove light directionalityEliminate crosstalkSemiconductor devicesGratingNano structuring

The invention discloses a microcavity Micro-LED with a vertical structure for emitting circularly polarized light facing 3D display and a preparation method thereof. The microcavity Micro-LED of the present invention can emit circularly polarized light and use circularly polarized light for 3D polarized light display , as long as the optical axis position of the circularly polarized glasses is set properly, the crosstalk problem of the pattern caused by the tilt of the glasses can be eliminated. The present invention reduces the thickness of the chip, and uses the grating on the conductive layer and the dielectric film mirror on the n-GaN layer as the end face of the resonant cavity to form a resonant microcavity structure in the vertical direction, which will suppress the light from the side wall and improve the direction of light from the front sex. At the same time, the resonant microcavity structure will select a specific wavelength to narrow the emission spectrum and have higher spectral purity, which will help increase the threshold value of Micro-LED display. Moreover, the grating has polarization selective light output, and the output light through this structure is linearly polarized light. The top integrated micro-nano structure is equivalent to a 1 / 4 wave plate, which converts linearly polarized light into circularly polarized light.

Owner:NUOSHI TECH (SUZHOU) CO LTD

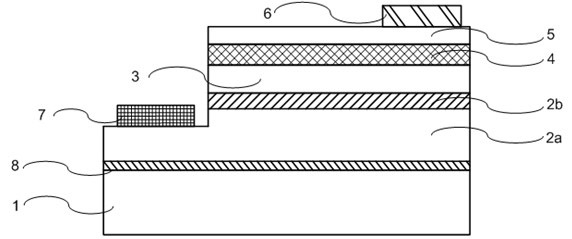

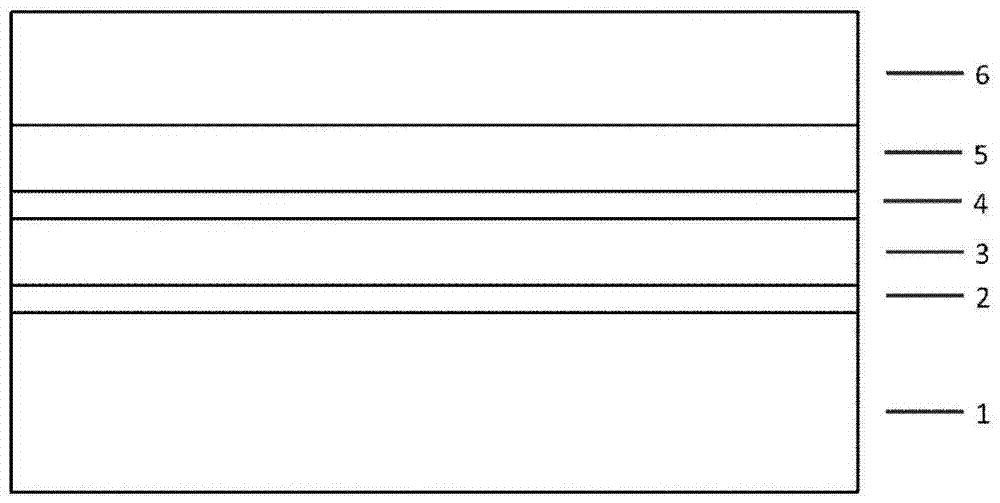

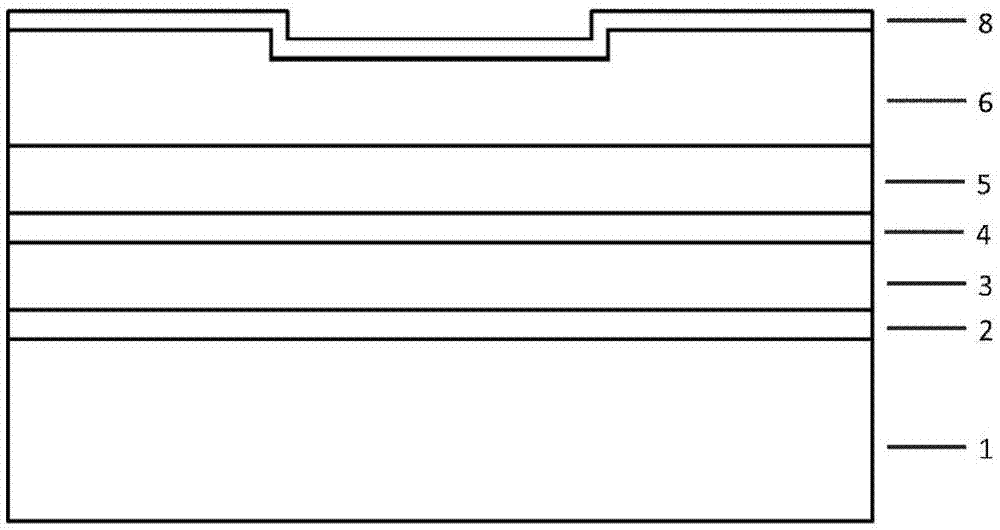

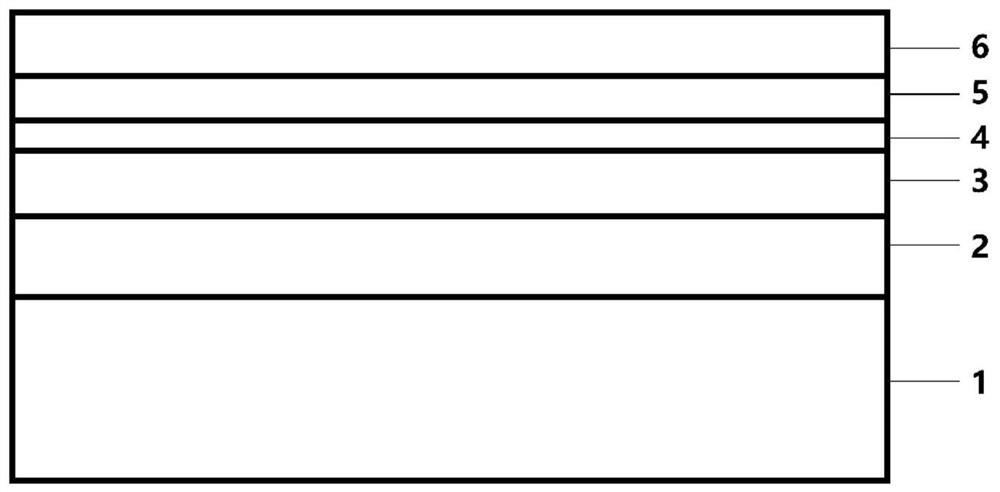

GaN high-efficiency light-emitting diode based on physical polishing roughening ITO layer and manufacturing method

InactiveCN109545929AImproved current spreadImprove light extraction efficiencySemiconductor devicesSurface roughnessIndium tin oxide

The invention discloses a GaN high-efficiency light-emitting diode based on a physical polishing roughening ITO layer and a manufacturing method, and mainly solves problems of complicated process andlow luminous efficiency of an existing ITO roughening process. The GaN high-efficiency light-emitting diode includes, from bottom to top: a sapphire substrate layer (1), a high-temperature AlN nucleation layer (2), a n-type GaN layer (3), an InxGa1-xN / GaN multiple quantum well layer (4), an AlzGa1-zN electron blocking layer (5), a p-type GaN layer (6), a polished roughened indium tin oxide ITO layer (7), and an electrode (8). The polishing roughening method uses diamond sandpaper to polish, and surface roughness after polishing and roughening is 10-100nm. An ITO layer roughening process is simplified, efficiency of a light-emitting diode is improved, and the light-emitting diode can be used for illumination, biology, medical treatment, anti-counterfeiting identification, purification and data storage.

Owner:XIDIAN UNIV

An epitaxy method to improve current spreading of gan-based LED chips

ActiveCN104576853BImproved current spreadLower local junction temperatureSemiconductor devicesPower flowQuantum well

The invention provides an epitaxial method for improving GaN based LED chip current spreading. An epitaxial structure comprises a sapphire substrate, a low-temperature GaN nucleating layer, a high-temperature GaN buffer layer, a high-temperature u-type GaN layer, a composite n-type GaN layer, a composite current spreading layer, a multi-quantum well light-emitting layer, a p-type AlGaN electron blocking layer, a high-temperature p-type GaN layer and a p-type GaN contact layer from bottom to top in sequence. After the composite n-type GaN layer finishes growing, the composite current spreading layer grows; the composite current spreading layer is composed of 15-20 groups of u-GaN / n-GaN superlattices and 5-10 groups of n-GaN / n-AlGaN superlattices. Current spreading of a prolate chip can be improved remarkably, local junction temperature of the chip is lowered, uniformity of light-emitting brightness distribution of the chip is improved, and the whole chip is uniform in light emission without brightness gathering.

Owner:宁波安芯美半导体有限公司

A vertical high-voltage light-emitting diode chip and its manufacturing method

ActiveCN110085619BIncrease the effective luminous areaImproved current spreadSolid-state devicesSemiconductor devicesElectrical connectionEngineering

The invention discloses a vertical high-voltage light-emitting diode chip and a manufacturing method thereof, wherein. Through the design of the vertical high voltage light emitting diode chip, the back electrode at the first chip area is electrically connected to the conductive substrate through the opening and the bonding layer, so that the back electrode is exposed without etching in the first chip area, so as to ensure the vertical high voltage light emitting diode. The effective light-emitting area of the chip is large; and, the back electrode of the first chip area does not need to be wired, which saves costs and improves reliability; in addition, the current expansion of each chip area is in the vertical direction, and the first chip area The back electrode and the front electrode of the Nth chip area form a vertical structure, so that the current of the vertical high-voltage light-emitting diode chip expands better, thereby avoiding current congestion and improving the current tolerance; in addition, the vertical high-voltage light-emitting diode chip has a better light type , which conforms to the Lambertian distribution and is easier to light distribution.

Owner:XIAMEN CHANGELIGHT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com