Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Increase the effective luminous area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

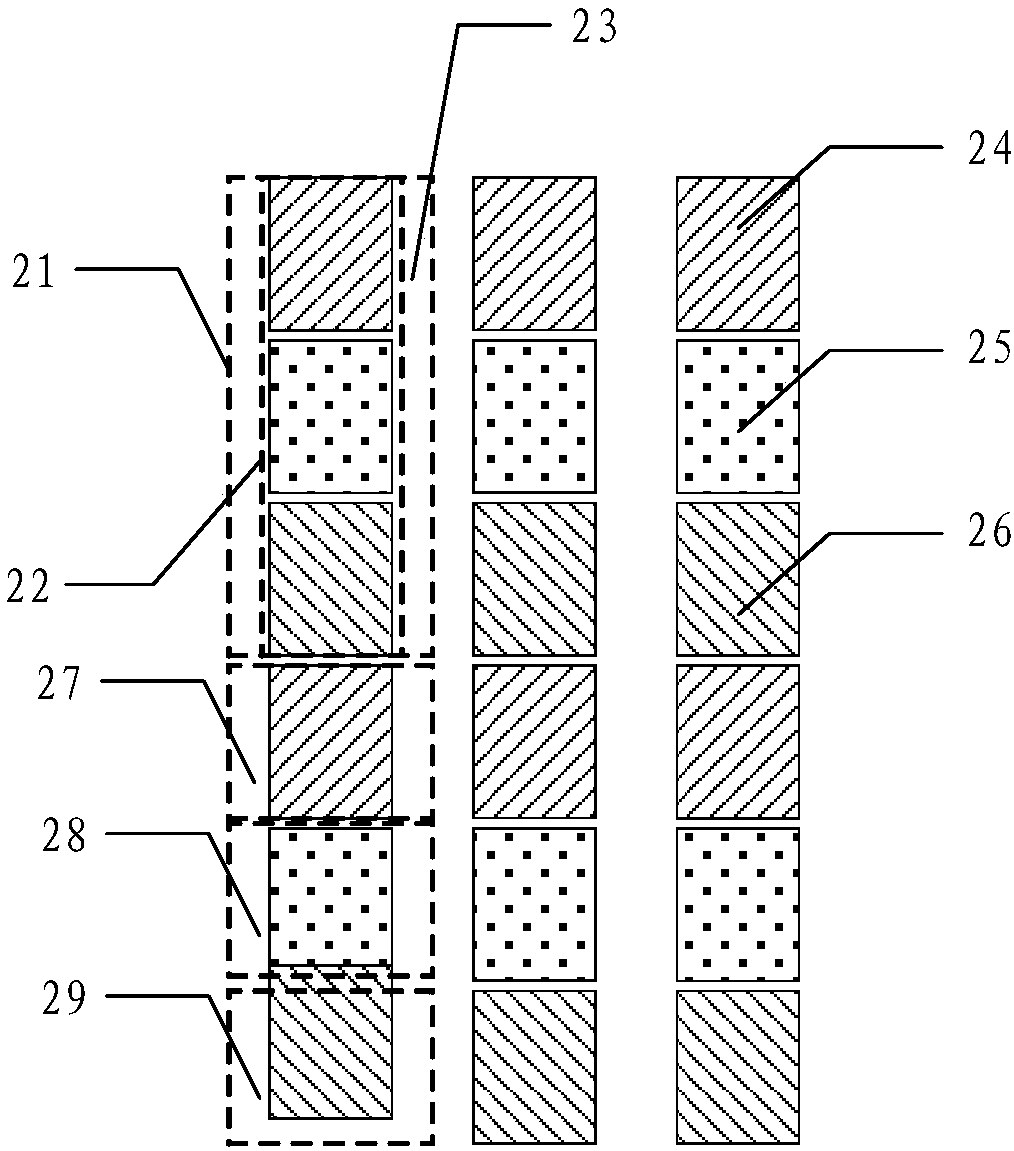

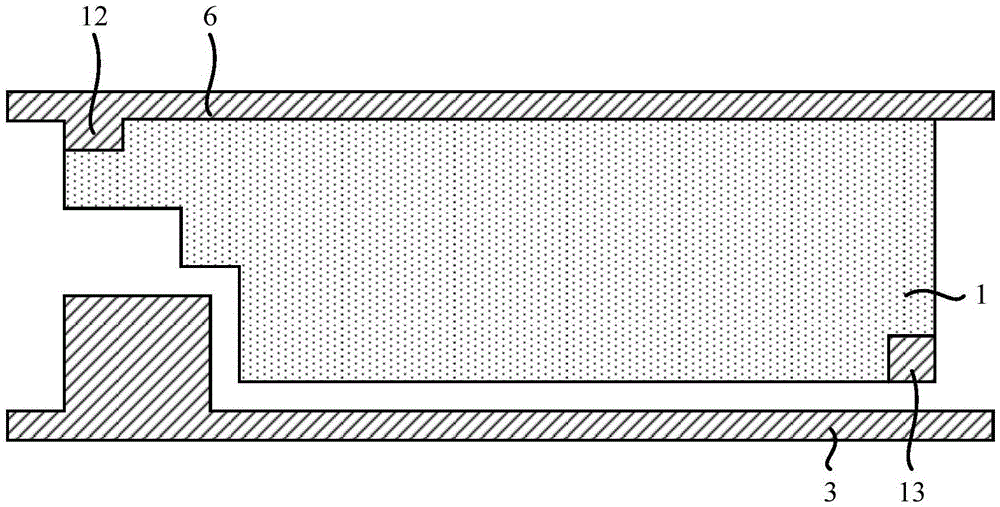

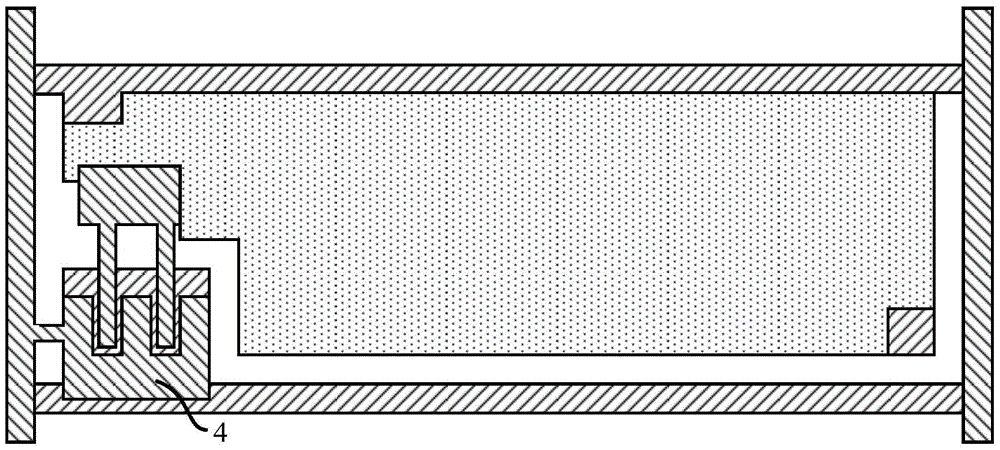

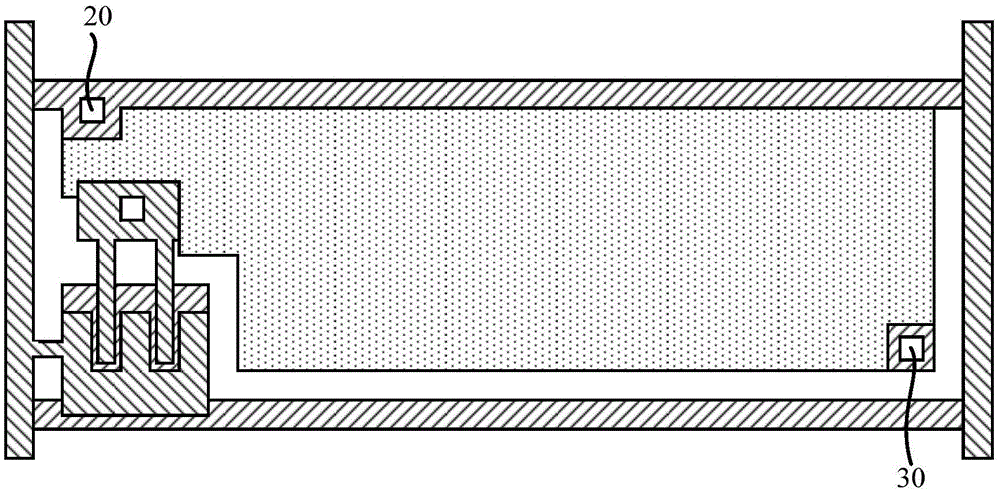

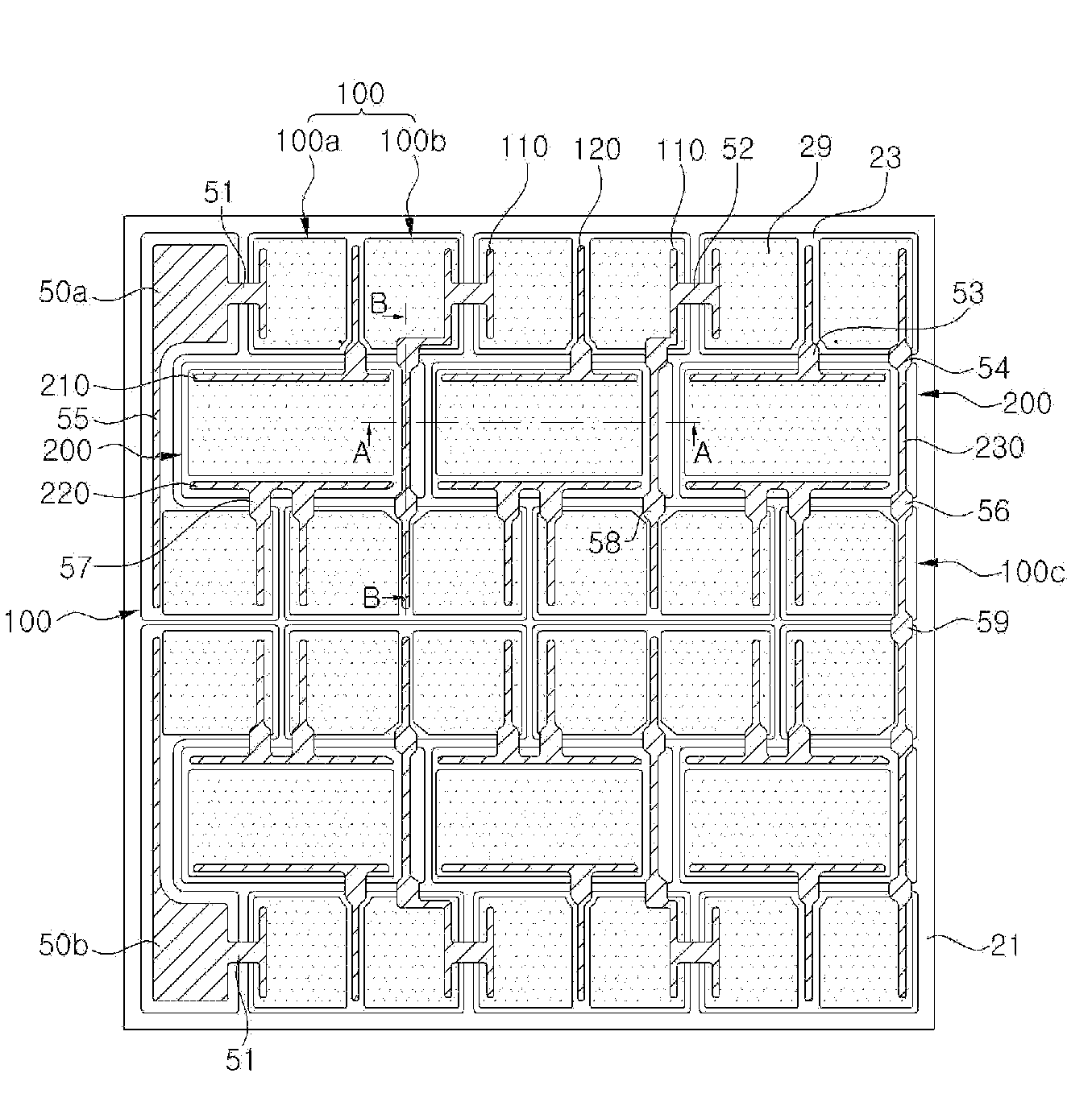

Display panel and display device

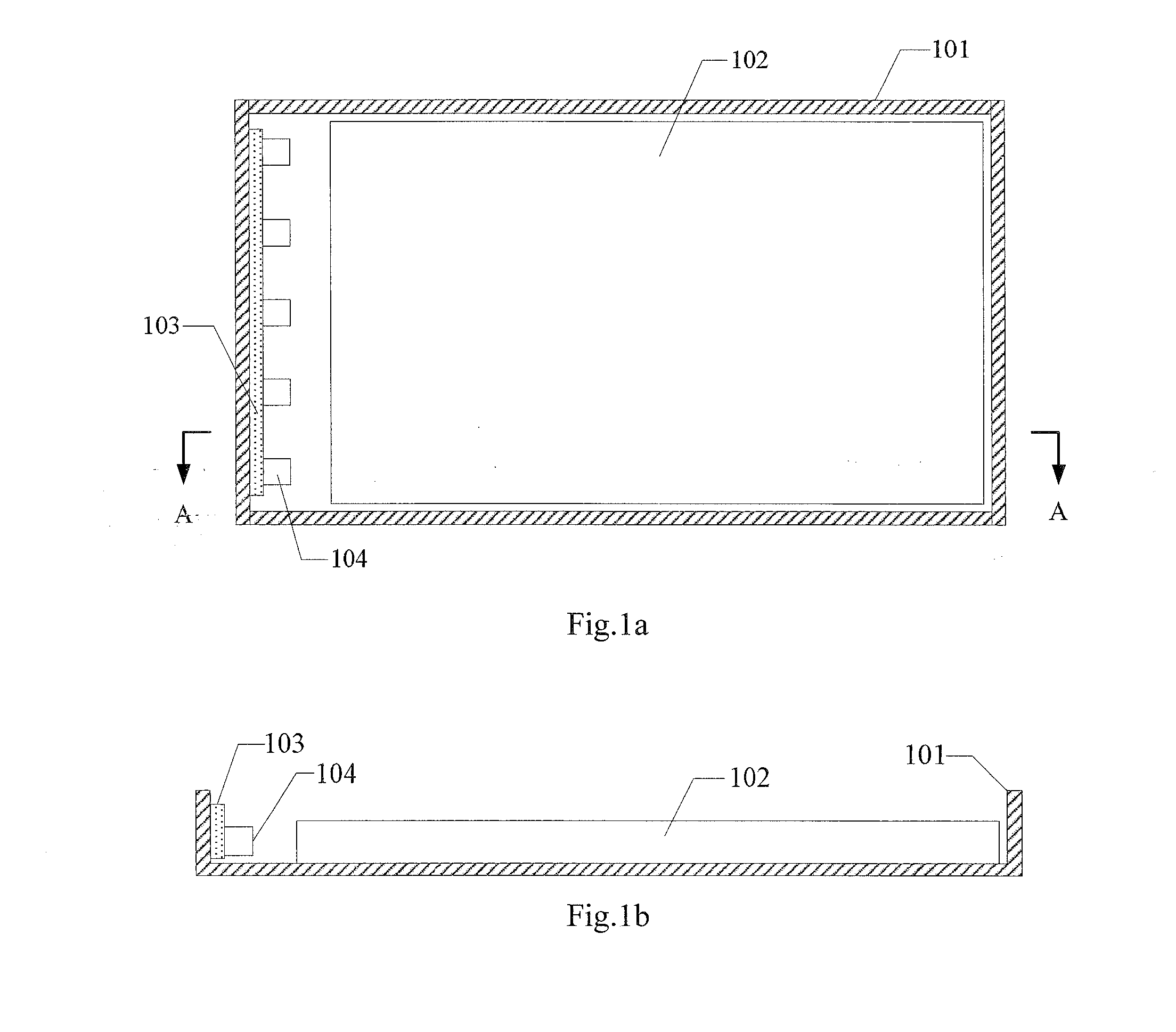

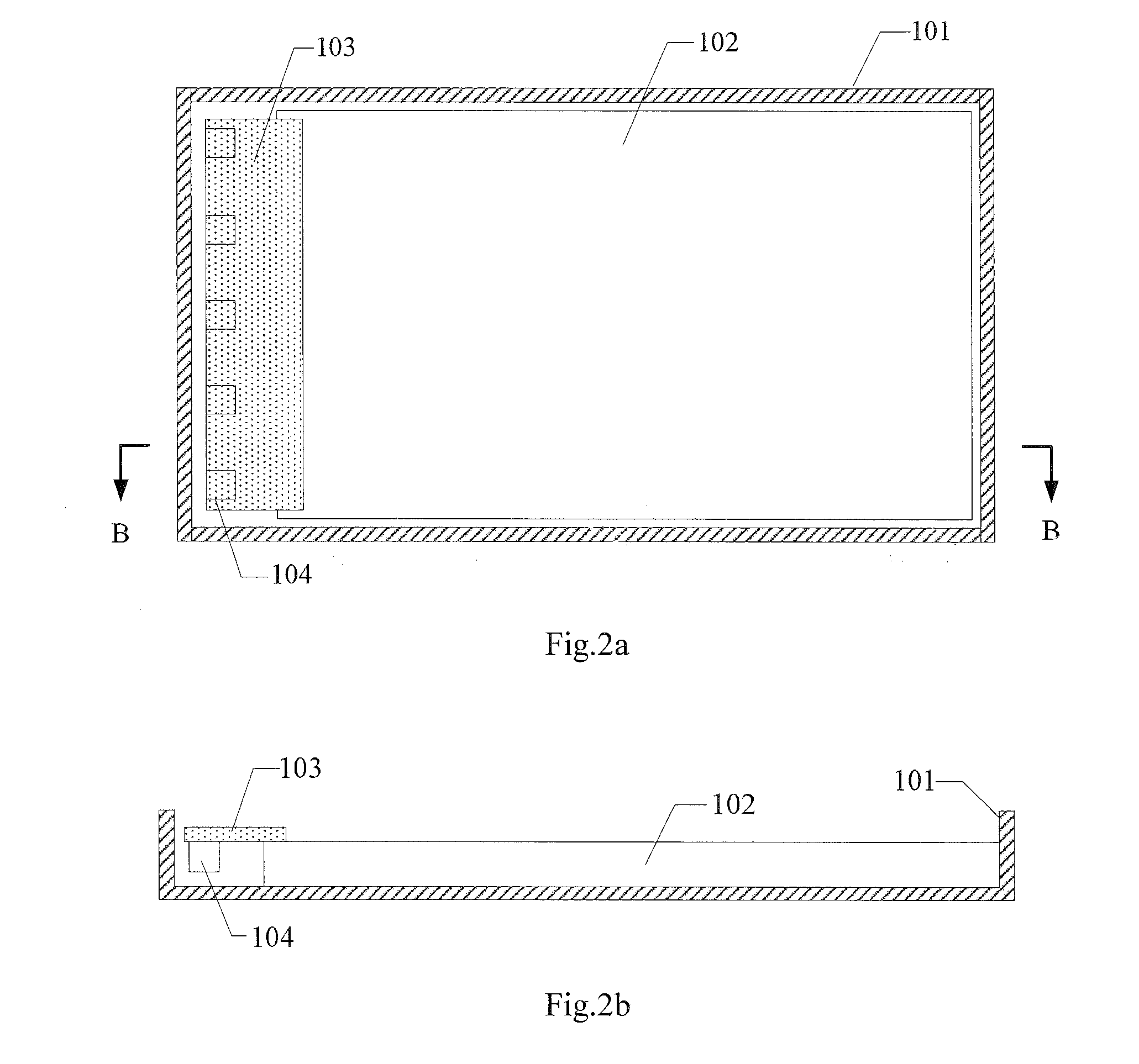

PendingCN108269502AIncrease the effective luminous areaIncrease brightnessIdentification meansDisplay deviceComputer science

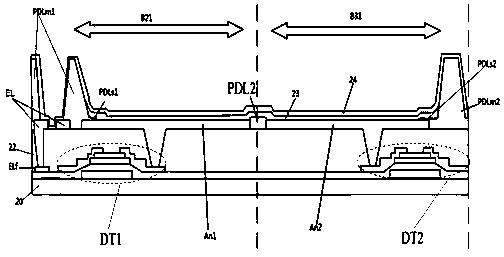

The invention provides a display panel and a display device. The display panel comprises a first display area and a second display area, wherein the first display area comprises display units distributed in arrays; each display unit comprises a first pixel unit and a light transmitting unit; the second display area comprises second pixel units distributed in arrays; the light emitting area of eachfirst pixel unit is larger than that of each second pixel unit. Overall luminance of the first display area or a transparent display area is improved by increasing an effective light emitting area ofthe first display area, so that luminance difference between the transparent area and the normal display area is reduced.

Owner:BOE TECH GRP CO LTD

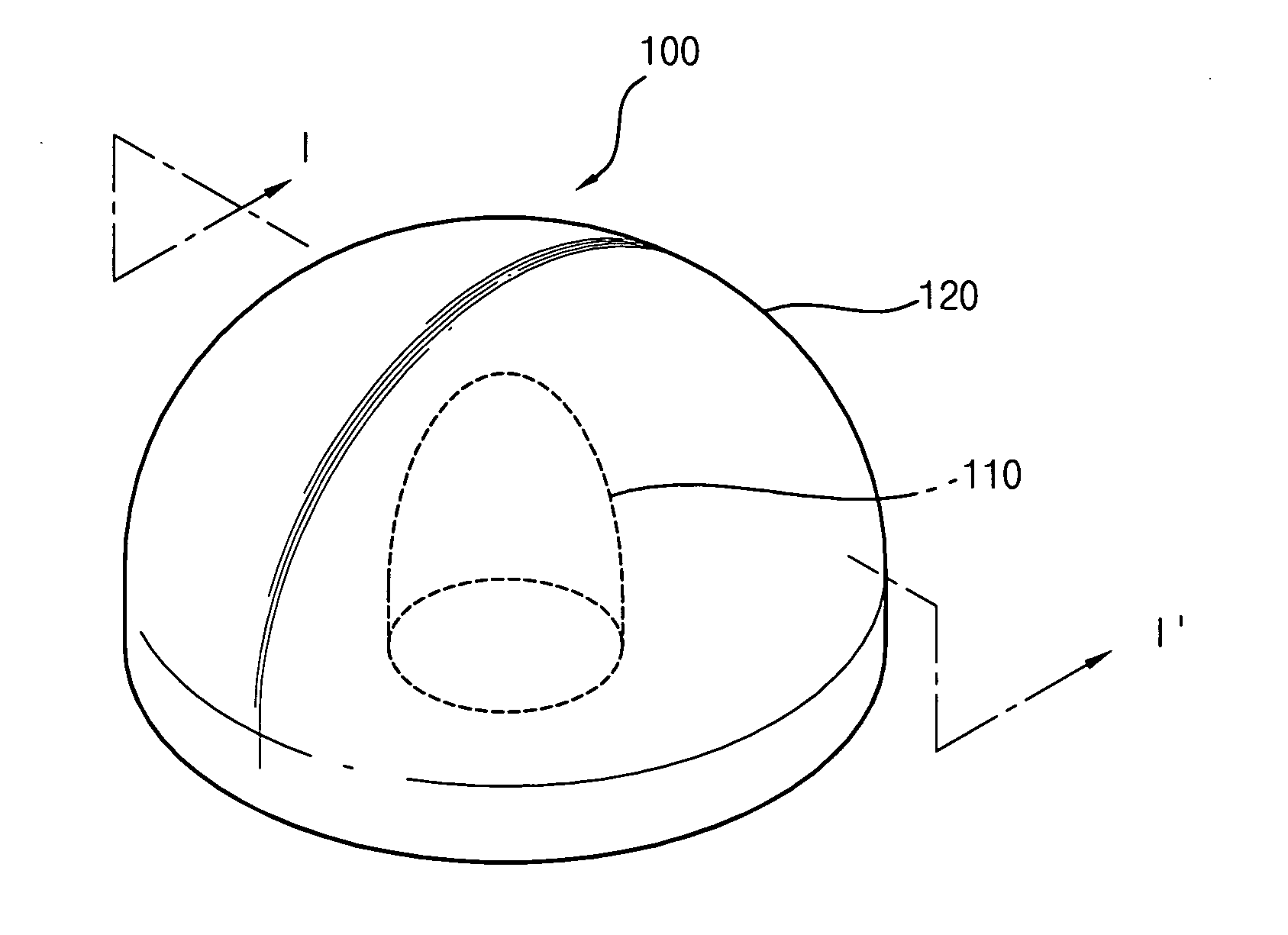

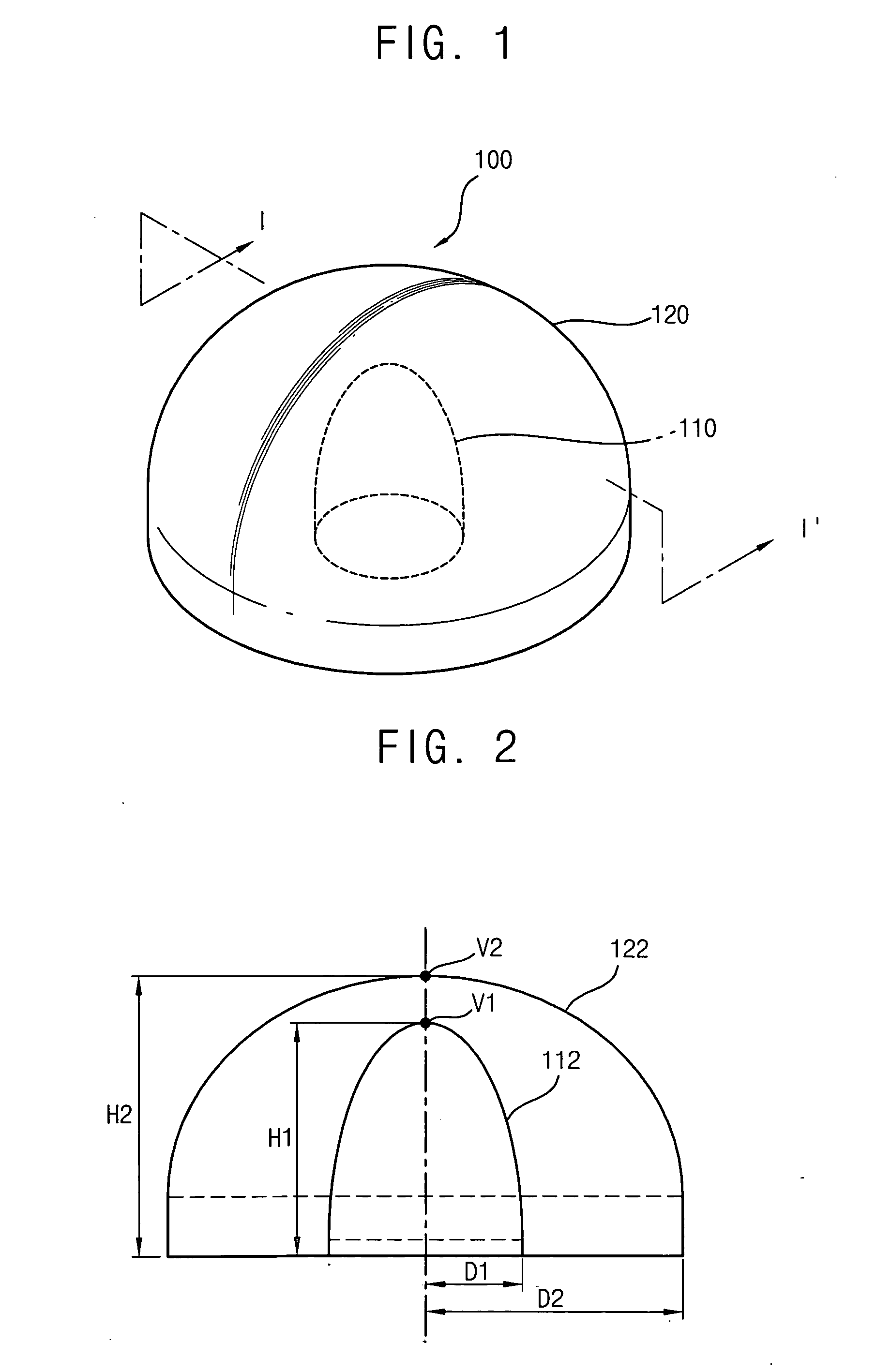

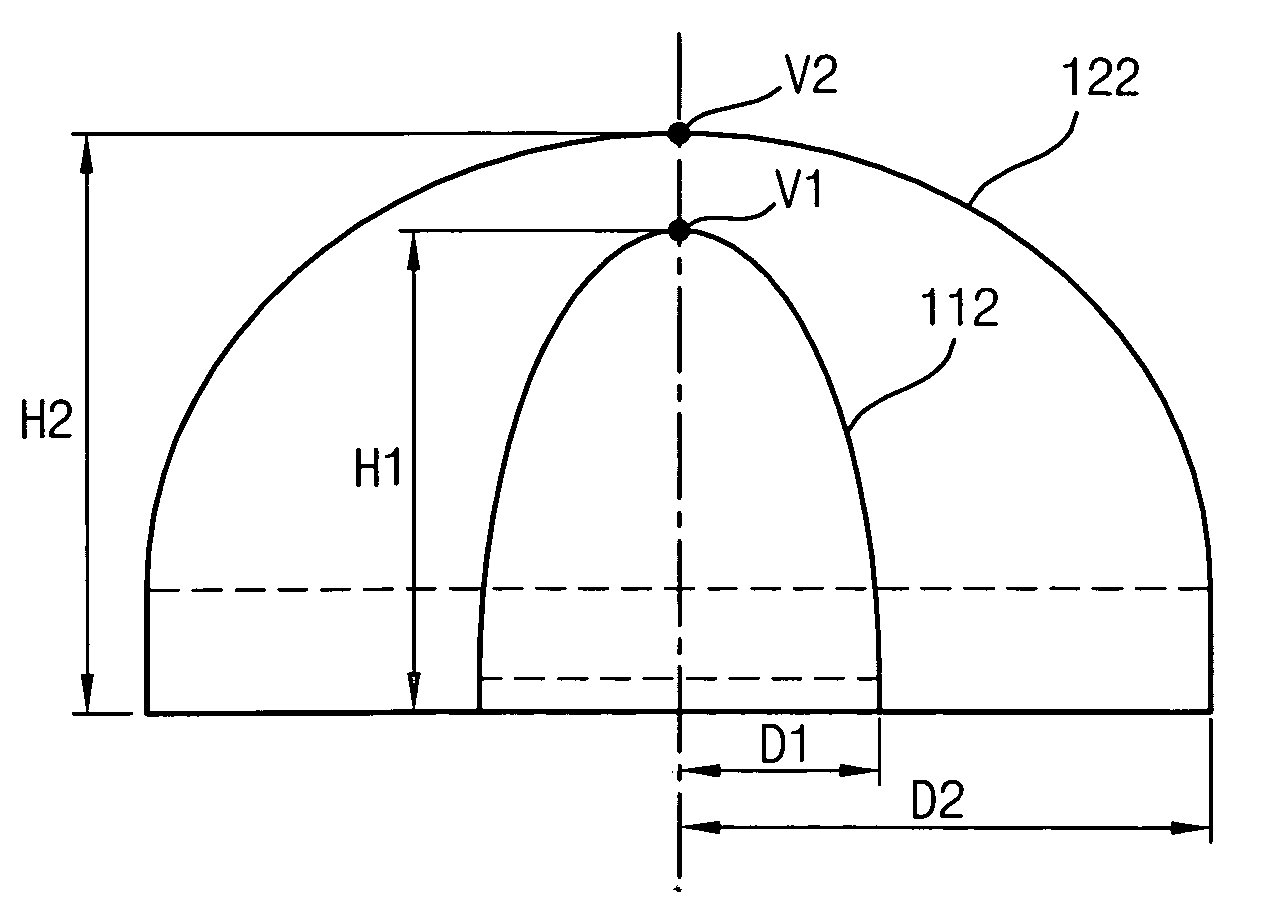

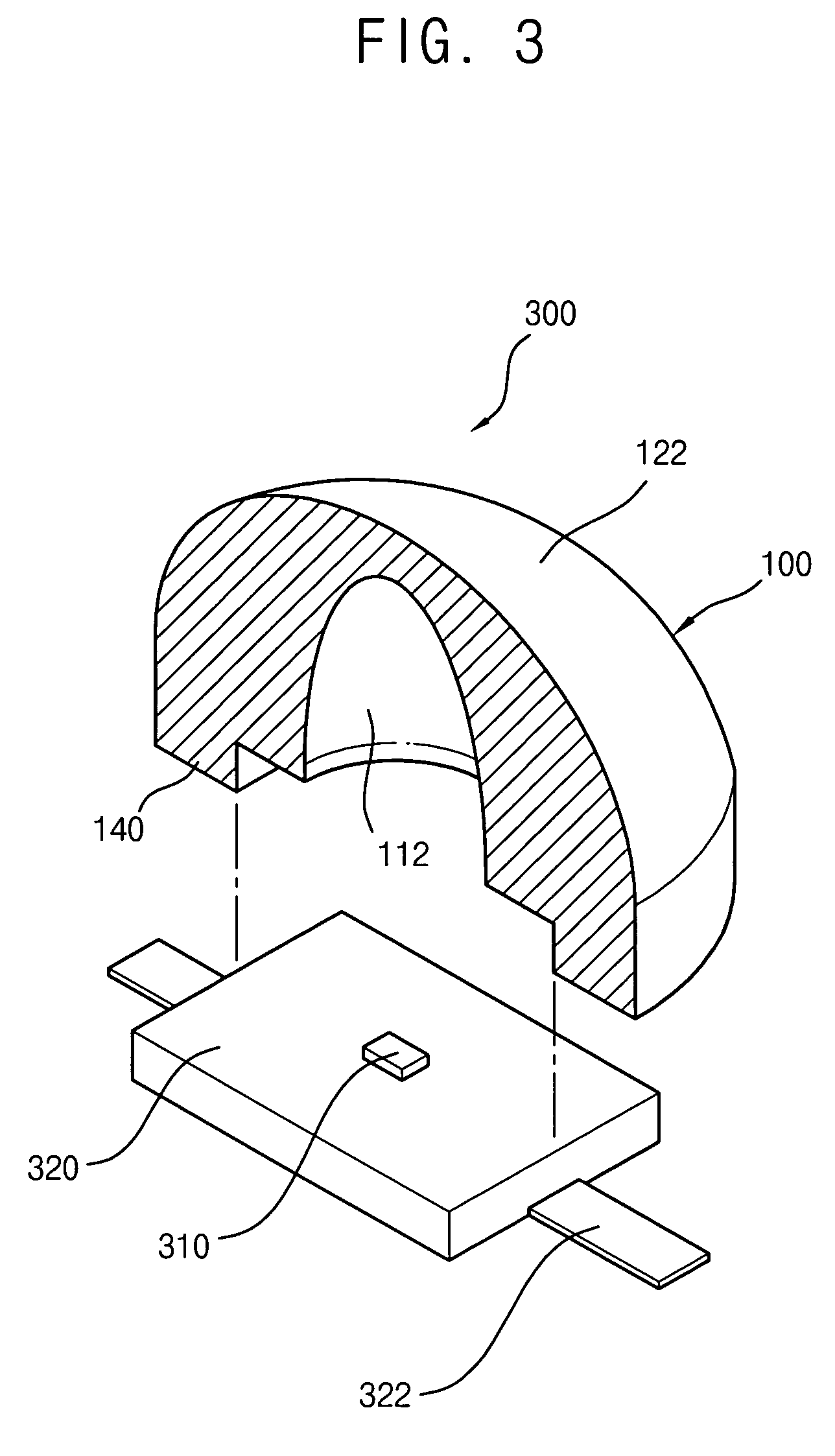

Optical lens, optical module having the same, and backlight assembly having the same

ActiveUS20060227431A1Increased effective light emitting radiusReduce manufacturing costKitchen equipmentLensOptical ModuleDisplay device

An optical module includes a point light source device and an optical lens. The point light source device generates light. The optical lens includes an inner curved surface and an outer curved surface. The inner curved surface has a first roughly ellipsoidal shape having a first major axis and a first minor axis that is substantially perpendicular to the first major axis. The outer curved surface has a second roughly ellipsoidal shape having a second major axis that is substantially perpendicular to the first axis and the second minor axis that is substantially perpendicular to the second major axis. The light generated by the point light source device enters the optical lens through the inner curved surface and exits from the optical lens through the outer curved surface. Therefore, the number of optical modules used in a display device may be reduced to lower manufacturing cost thereof.

Owner:SAMSUNG DISPLAY CO LTD

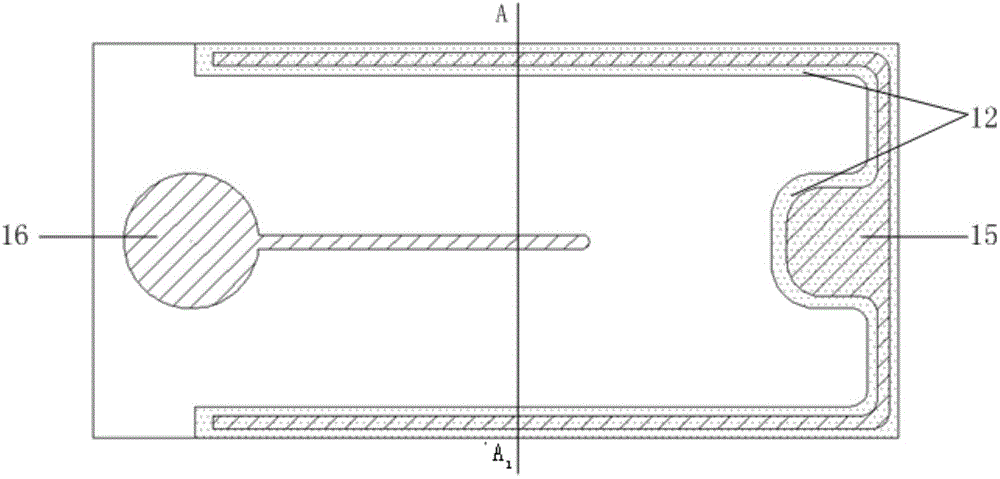

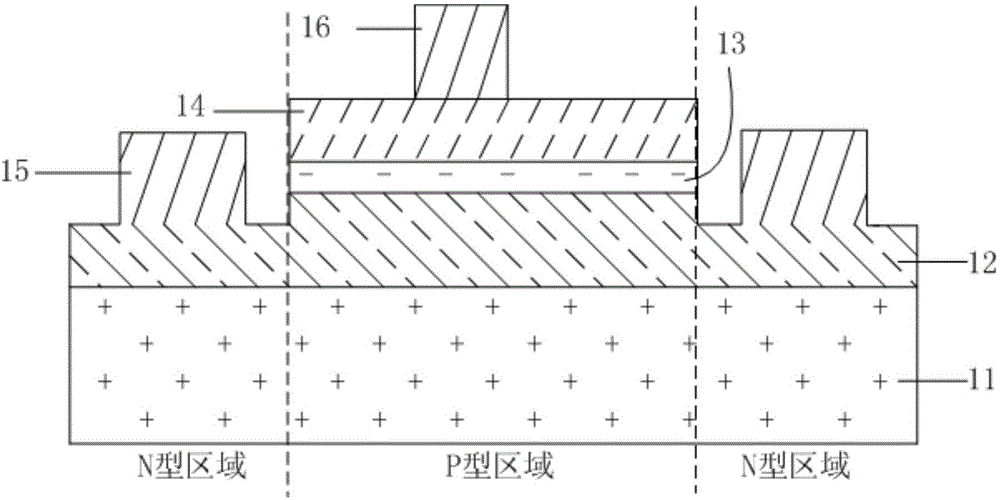

LED chip and processing technology thereof

InactiveCN103515504AIncrease the effective luminous areaIncrease brightnessSemiconductor devicesPower flowQuantum well

The invention relates to an LED chip and a processing technology thereof, and belongs to the technical field of manufacturing of photoelectron devices. The technology comprises the following steps: a P-type nitride layer on an epitaxial wafer substrate is etched to expose an N-type nitride layer; a current blocking layer is manufactured under a P-type electrode bonding pad area, an insulating substance under the P-type electrode bonding pad area, an insulating substance in direct contact with an N-type electrode bonding pad, and an expanding electrode and the P-type nitride layer, and an insulating substance on the side walls of a quantum well and P-type nitride are reserved through etching; an ITO film deposits on the surface of the substrate, a current expanding layer and alloy are manufactured through photoetching, a metal layer is formed on the surface of the substrate through vapor deposition, and after a part of the metal layer is stripped, a P-type electrode bonding pad, an N-type electrode bonding pad and an N metal expanding electrode are formed. Both the P-type electrode bonding pad and the N-type electrode bonding pad of the product are positioned on a P-type light-emitting surface and are the same in height; a part or all of the N metal expanding electrode is in direct contact with the N-type nitride layer. The invention has the advantages that the routing is convenient, the light-emitting efficiency and the brightness of the LED chip on the nitride substrate can be improved.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

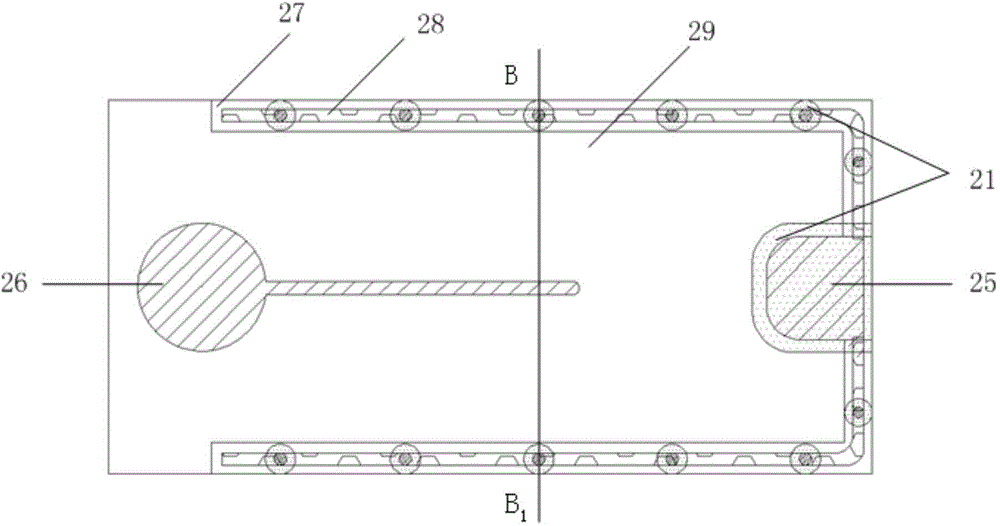

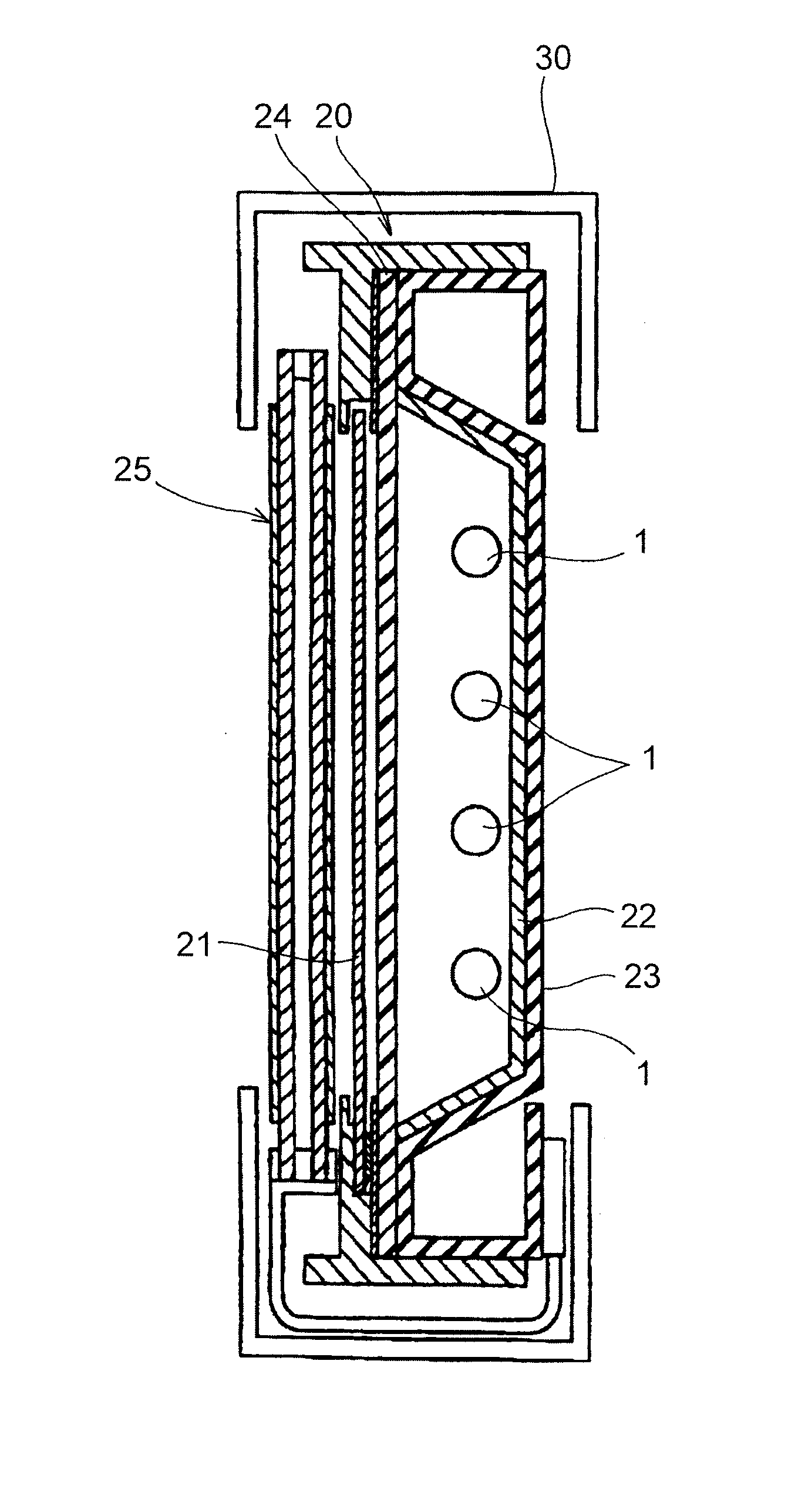

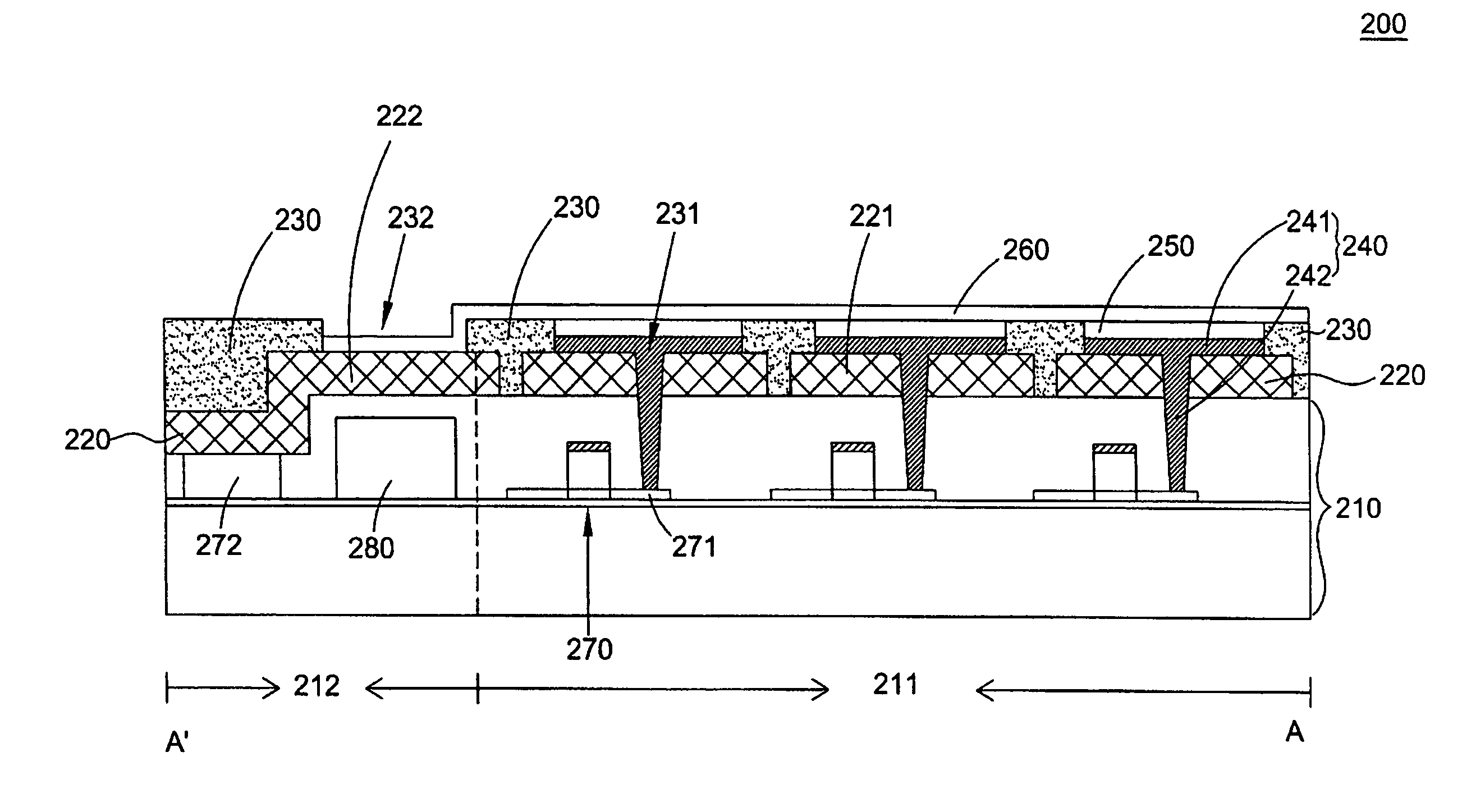

Transparent array substrate, transparent display panel, display panel and display terminal

ActiveCN110767714AIncrease spacingIncrease the effective luminous areaSolid-state devicesSemiconductor devicesScan lineHemt circuits

The invention discloses a transparent array substrate, a transparent display panel, a display panel and a display terminal. The transparent array substrate comprises a substrate, a pixel circuit, a first electrode, scanning lines and data lines, wherein the pixel circuit is arranged on the substrate, the first electrode is arranged on the pixel circuit and comprises a plurality of first electrodes, the scanning lines and the data lines are connected with the pixel circuit, the data lines and / or the scanning lines are arranged below the first pixel layer, the projection of the data lines on thesubstrate is first projection, the projection of the scanning lines is second projection, the projection of the plurality of first electrodes on the substrate is third projection, the first projection and the third projection are partially coincided and / or the second projection and the third projection are partially coincided, and the first electrodes, the scanning lines and the data lines are all transparent conductive materials. The data lines, the scanning lines and the first electrodes are arranged at different layers, the projection are arranged at edges of the first electrodes, thus, diffraction is reduced, meanwhile, the effective light-emitting areas of the first electrodes are expanded, and the aperture can be improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Optical lens, optical module having the same, and backlight assembly having the same

ActiveUS7443609B2Increase the effective luminous areaReduce in quantityKitchen equipmentLensOptical ModuleDisplay device

An optical module includes a point light source device and an optical lens. The point light source device generates light. The optical lens includes an inner curved surface and an outer curved surface. The inner curved surface has a first roughly ellipsoidal shape having a first major axis and a first minor axis that is substantially perpendicular to the first major axis. The outer curved surface has a second roughly ellipsoidal shape having a second major axis that is substantially perpendicular to the first axis and the second minor axis that is substantially perpendicular to the second major axis. The light generated by the point light source device enters the optical lens through the inner curved surface and exits from the optical lens through the outer curved surface. Therefore, the number of optical modules used in a display device may be reduced to lower manufacturing cost thereof.

Owner:SAMSUNG DISPLAY CO LTD

Production of gallium nitride light emitting diode chip with small volume and hight brightness

InactiveCN1780003AImprove light outputIncrease output light intensitySemiconductor devicesGallium nitrideLight-emitting diode

Owner:DAUAN LUMEI OPTOELECTRONICS

Electroluminescent device with high light emitting efficiency

InactiveCN103531720AImprove extraction efficiencyReduce short circuit problemsSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveRefractive index

The invention provides an electroluminescent device with high light emitting efficiency, which comprises a transparent substrate, a light scattering layer positioned on the transparent substrate, a surface smooth layer positioned on the light scattering layer and an electroluminescent layer positioned on the surface smooth layer. The electroluminescent device has the following technical effects: 1, light scattering particles are exposed out of an adhesive, each of the light scattering layer and the surface smooth layer is provided with a waved surface, light emitted from the light emitting layer is directly scattered by the waved light scattering particles after passing through the waved surface smooth layer with a high refractive index, parts of light rays which are less than a critical angle are directly emitted out, the light rays which are greater than or equal to the critical angle are reflected back, are reflected again by a reflection electrode layer, passes through the surface smooth layer and are scattered again, another part of light is extracted, and extraction is repeatedly carried out, so that the light extraction efficiency is greatly improved, and the waved surface of the light scattering layer increases an effective light emitting area; 2, the electroluminescent device adopts is simple in preparation process and facilitates scale mass production.

Owner:FIRST O LITE

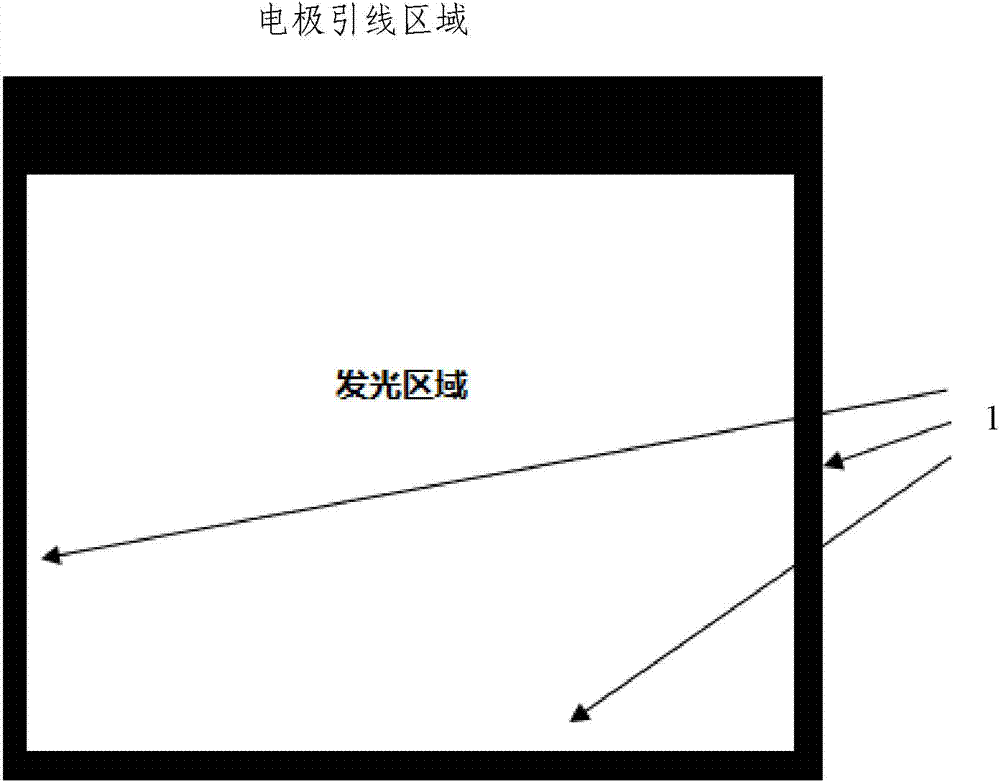

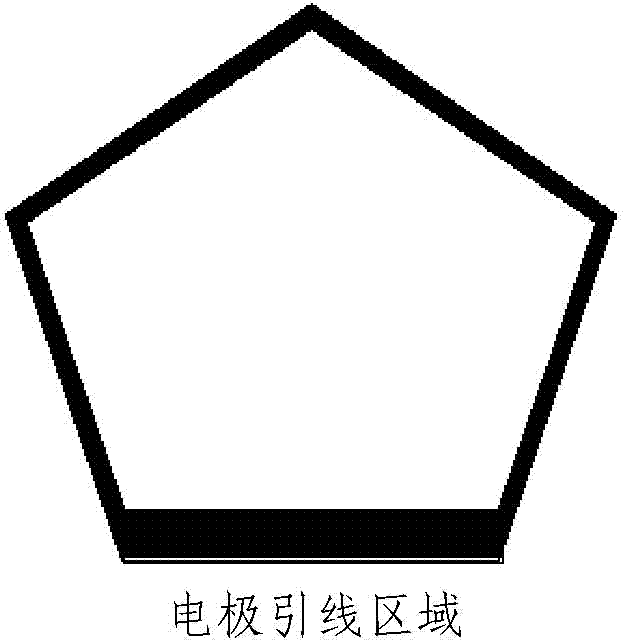

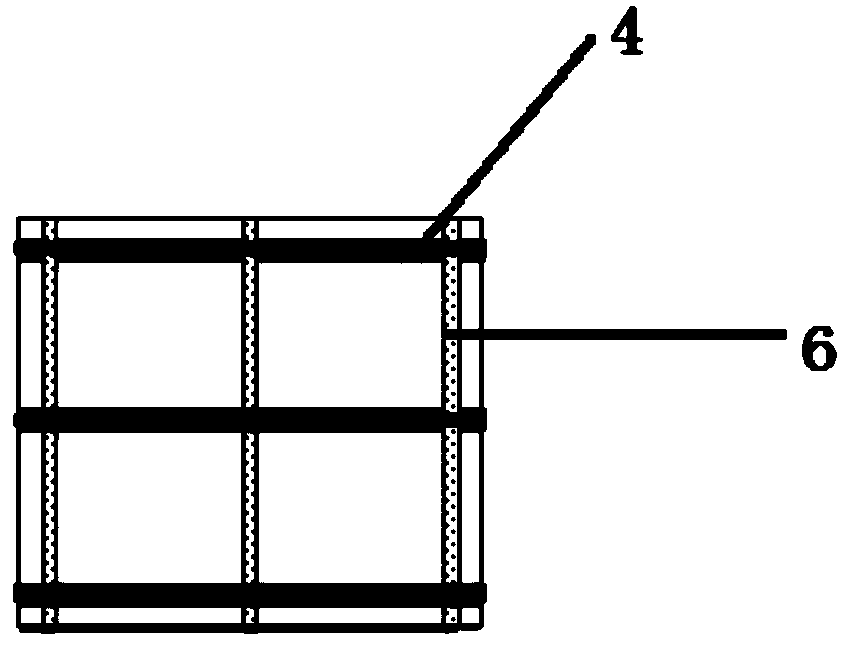

OLED (Organic Light Emitting Diode) lighting source

ActiveCN103702467AIncrease the effective luminous areaImprove luminous efficiencyElectroluminescent light sourcesSolid-state devicesAuxiliary electrodeLight source

The invention discloses an OLED (Organic Light Emitting Diode) lighting source, which is of a polygon structure, and comprises a base plate, and an electrode lead area and a lighting area located on the base plate. The lighting area comprises a first electrode, an organic function layer and a second electrode; one side of the lighting area is adjacent to the electrode lead area; auxiliary electrodes are respectively arranged on edges of other sides, are mutually connected, and are communicated with the electrode lead area. According to the OLED lighting source, only the auxiliary electrodes connected with the electrode lead area are arranged on the edges of the lighting area, and under the condition of equivalent uniformity of luminance, the effective lighting area can be increased, and the lighting efficiency is improved.

Owner:GUAN YEOLIGHT TECH CO LTD

LED chip structure and preparation method thereof

InactiveCN104600166AReduce areaIncrease the effective luminous areaSemiconductor devicesEtchingQuantum well

The invention discloses an LED chip structure and a preparation method thereof. The LED chip structure comprises a substrate, and an epitaxial layer positioned on the substrate; the epitaxial layer comprises a first area layer, a quantum well active layer and a second area layer. The LED chip structure further comprises a slot which extends from the second area layer to the second area layer or extending into the first area layer, a first electrode which is formed in the slot and in contact with the first area layer, and a second electrode which is formed on the second area layer. According to the LED chip structure, the area of an etching are of an LED chip can be reduced, the effective lighting area of the LED chip can be increased, and as a result, the lighting efficiency is increased.

Owner:WUXI CHINA RESOURCES HUAJING MICROELECTRONICS

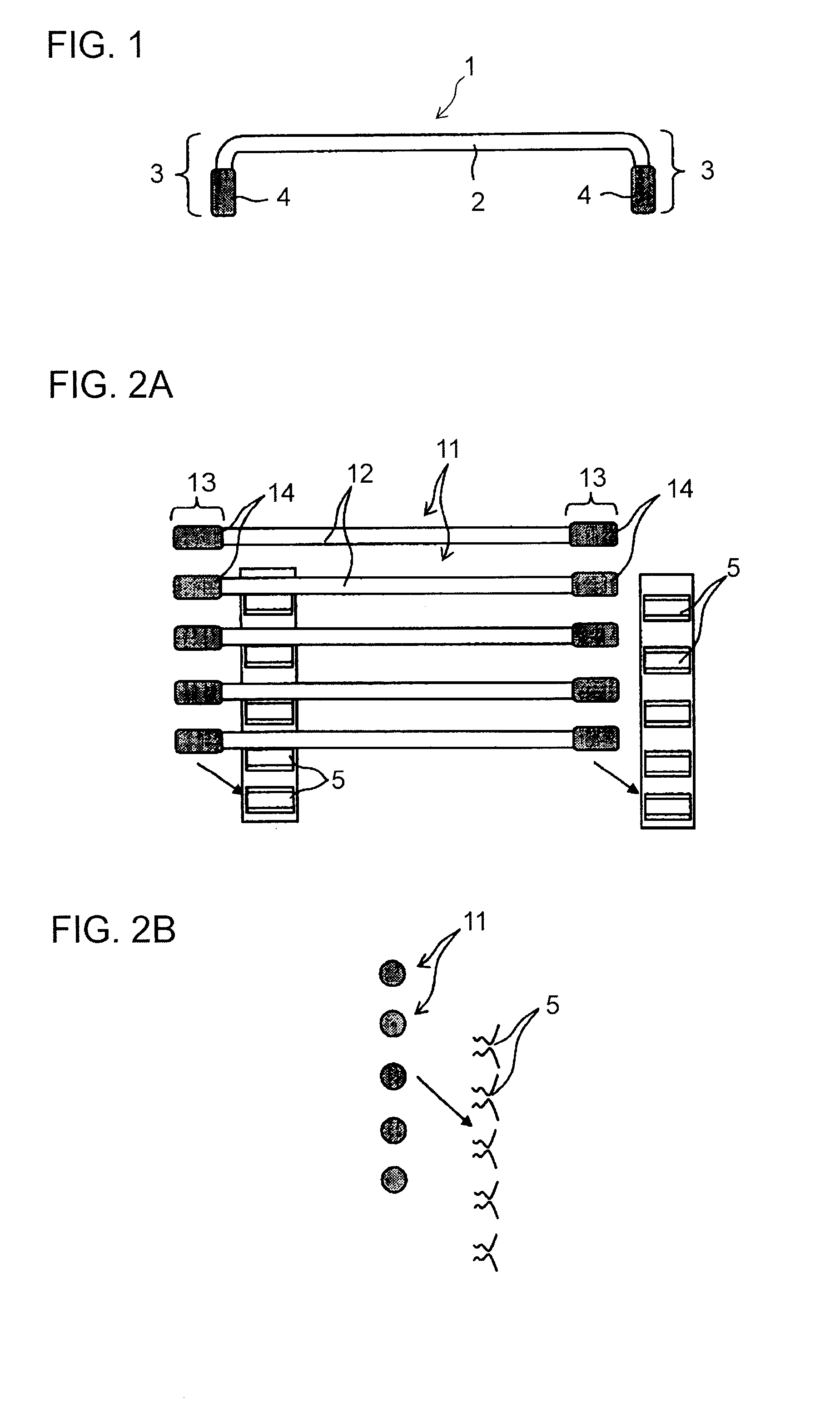

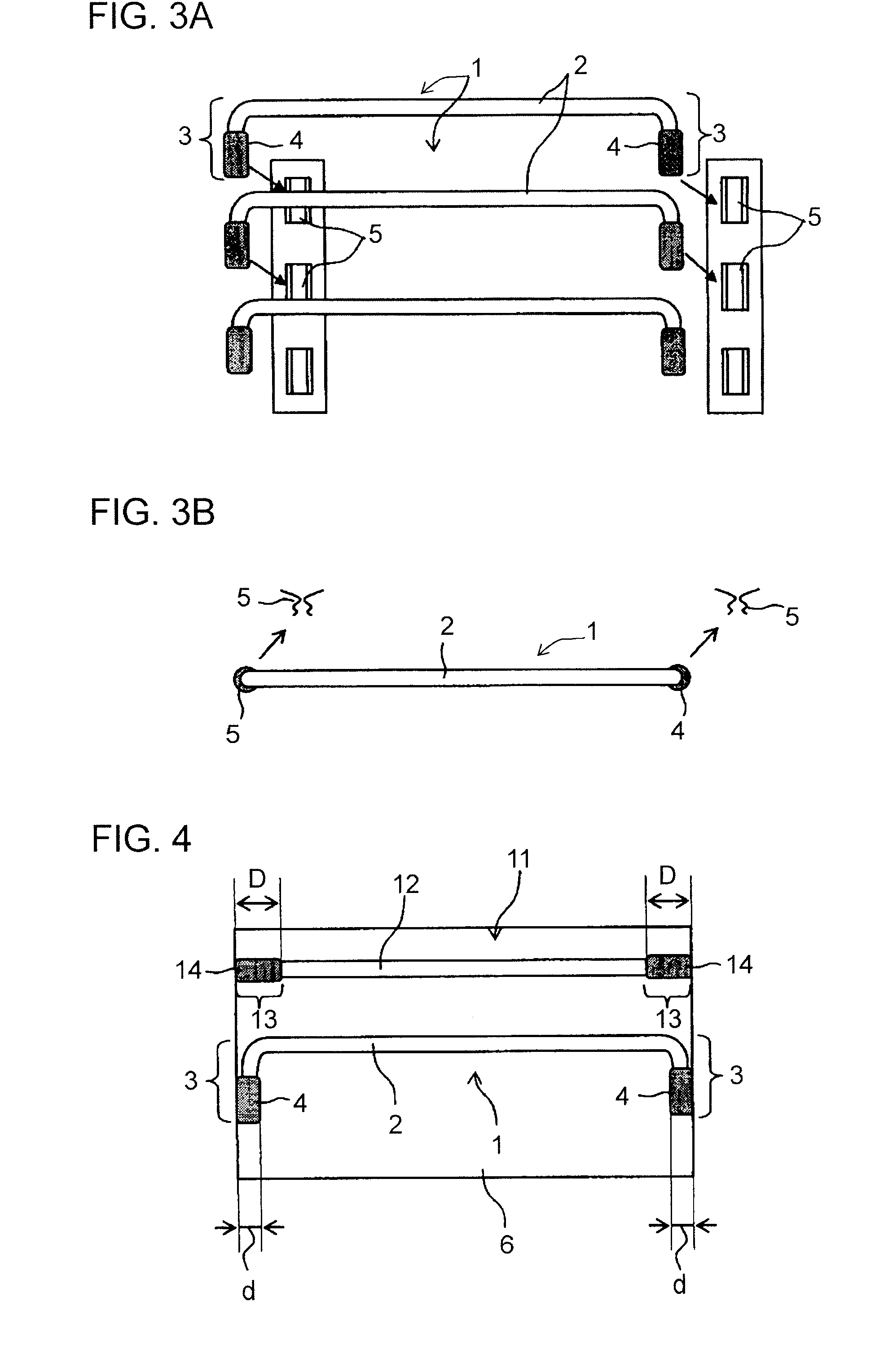

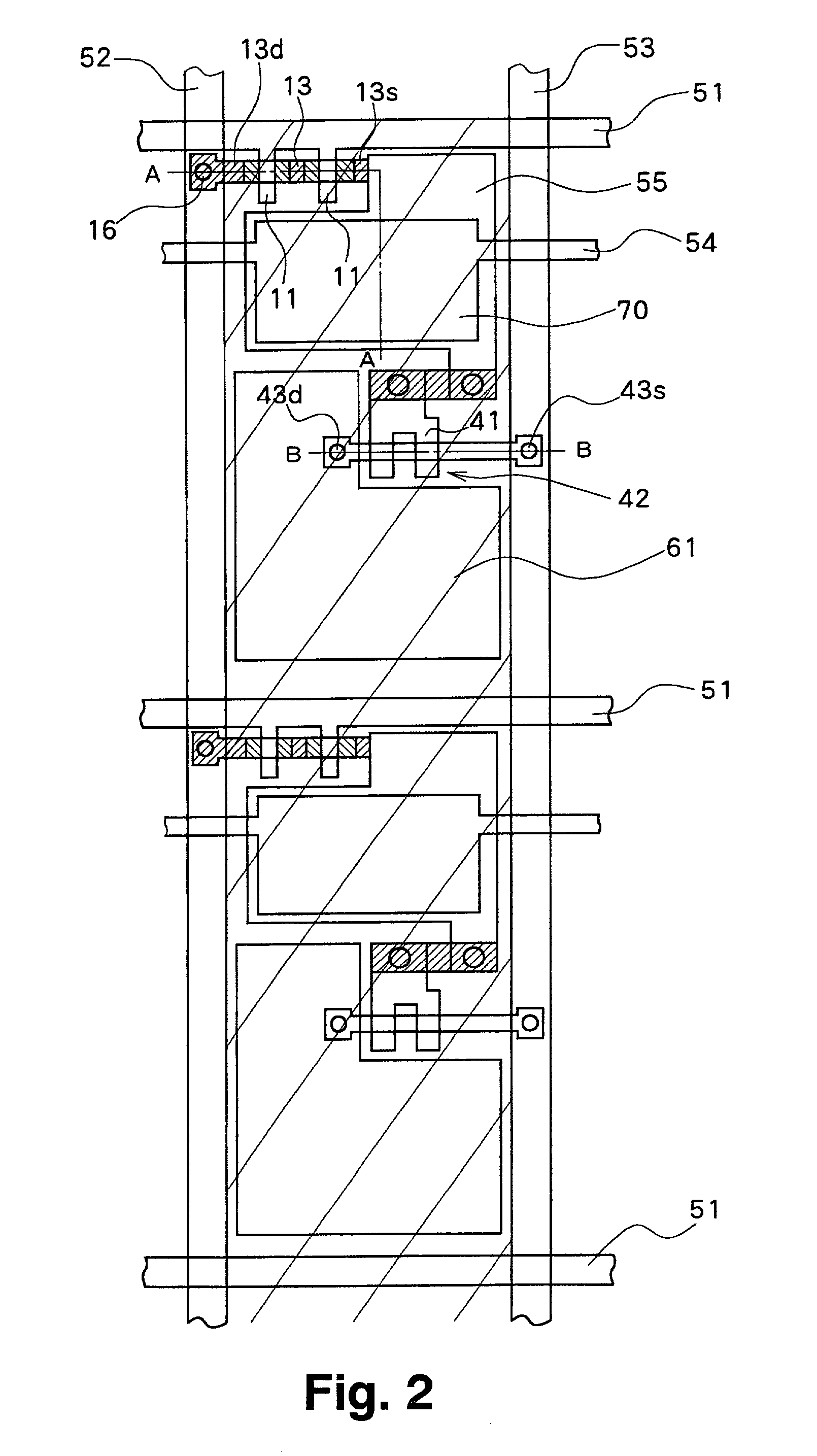

External Electrode Flourescent Lamp, Lighting Device, And Display Device

InactiveUS20080012498A1Save componentEasy to assembleSolid cathode detailsGas discharge lamp detailsDisplay deviceEngineering

An external electrode fluorescent lamp has external electrodes at opposite ends. The portions provided with the external electrodes are bent so that their axes are orthogonal to the axis of a light emitting sections. A conventional external electrode fluorescent lamp is not bent in its portions provided with external electrodes. Since the external electrodes of the external electrodes fluorescent lamps serve concurrently as holding sections for the fluorescent lamps the axial length is made greater than the outer diameter so as to provide sufficient strength. The width of the frame section of the fluorescent lamp of the invention when mounted on a backlight unit is smaller than the width of the frame section of conventional fluorescent lamp. Therefore, the effective light emitting area of the backlight unit can be enlarged.

Owner:SHARP KK

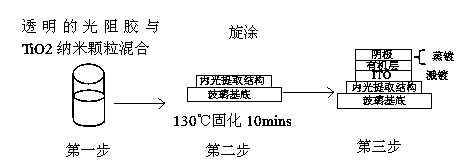

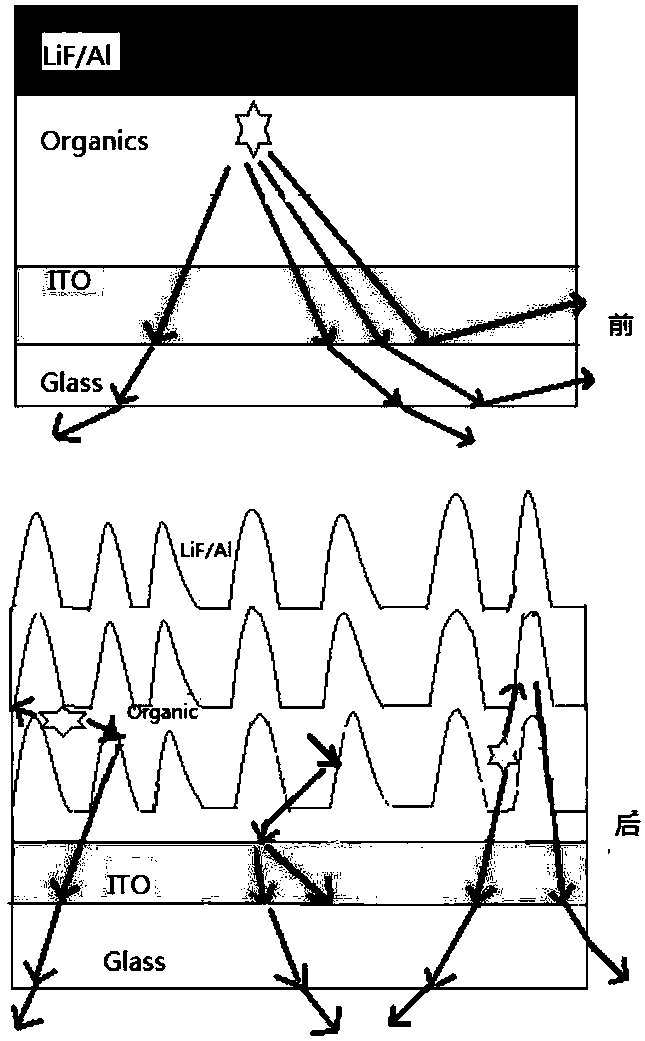

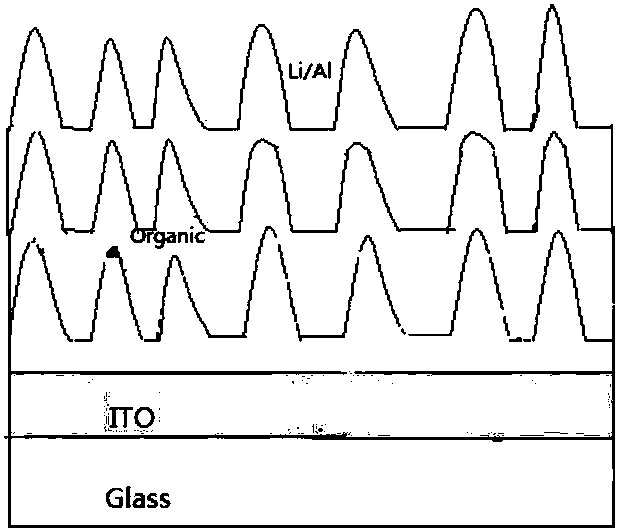

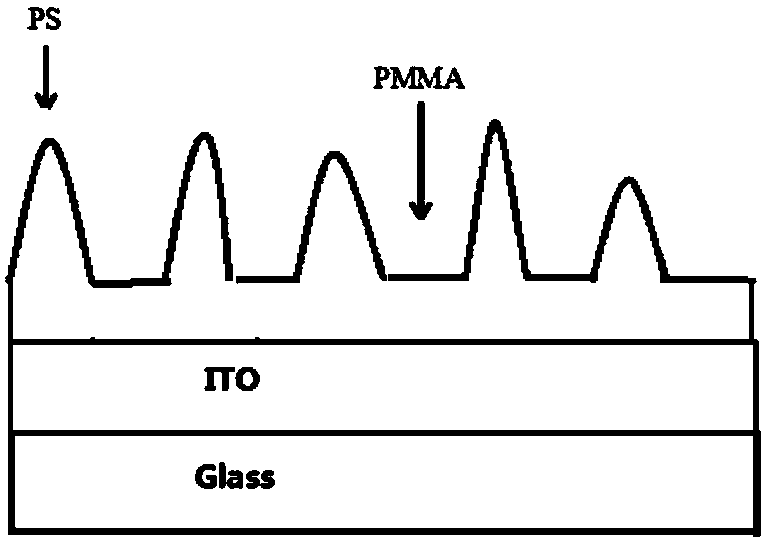

Production method of free nanometer columnar array for improving luminescence of OLED device

ActiveCN107689428AIncrease the effective luminous areaImprove light extraction rateSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyReflection loss

The invention discloses a production method of a free nanometer columnar array for improving luminescence of an OLED device. The method comprises the steps that firstly, an ITO substrate is cleaned byusing a laboratory ITO conductive glass cleaning agent with a certain concentration and an ultraviolet light cleaning machine in sequence; then even PMMA / PS thin film is prepared by using a common technology, the ITO substrate with the PMMA / PS thin film is annealed, and a free nanometer columnar array is obtained; finally, an organic layer and an electrode layer of the OLED device are subjected to vapor deposition in sequence, and the OLED device is obtained after being packaged. According to the production method, the phase separation process of the PMMA / PS thin film is regulated and controlled, and a free nanometer columnar array structure is prepared and obtained on the ITO substrate and is applied to the OLED device; the manufacturing technology is simple, the cost is low, meanwhile,the surface area of the thin film is effectively improved, and the effective luminescence area of the device is increased; meanwhile, the light emergence angle is changed, the total reflection loss isreduced, the light emergence rate is improved, and luminescence of the OLED device is improved.

Owner:HEFEI UNIV OF TECH

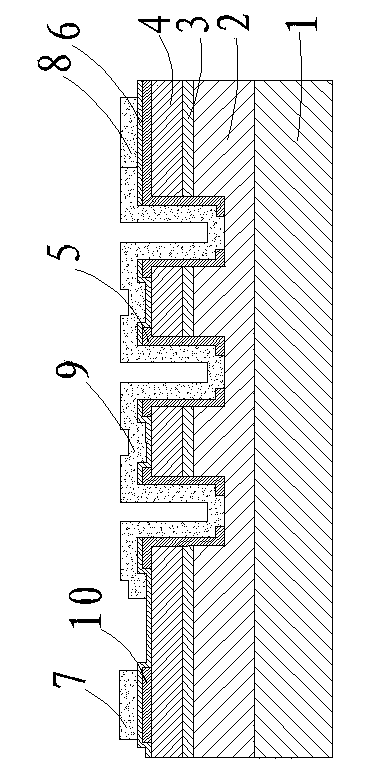

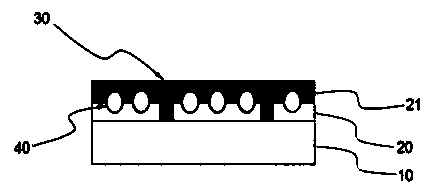

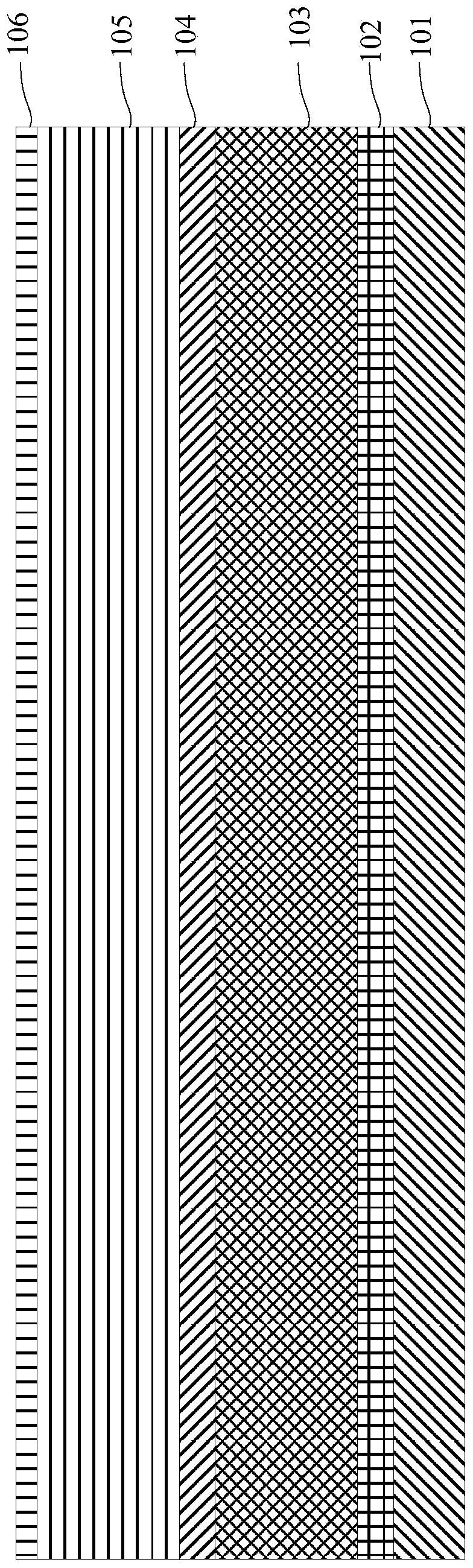

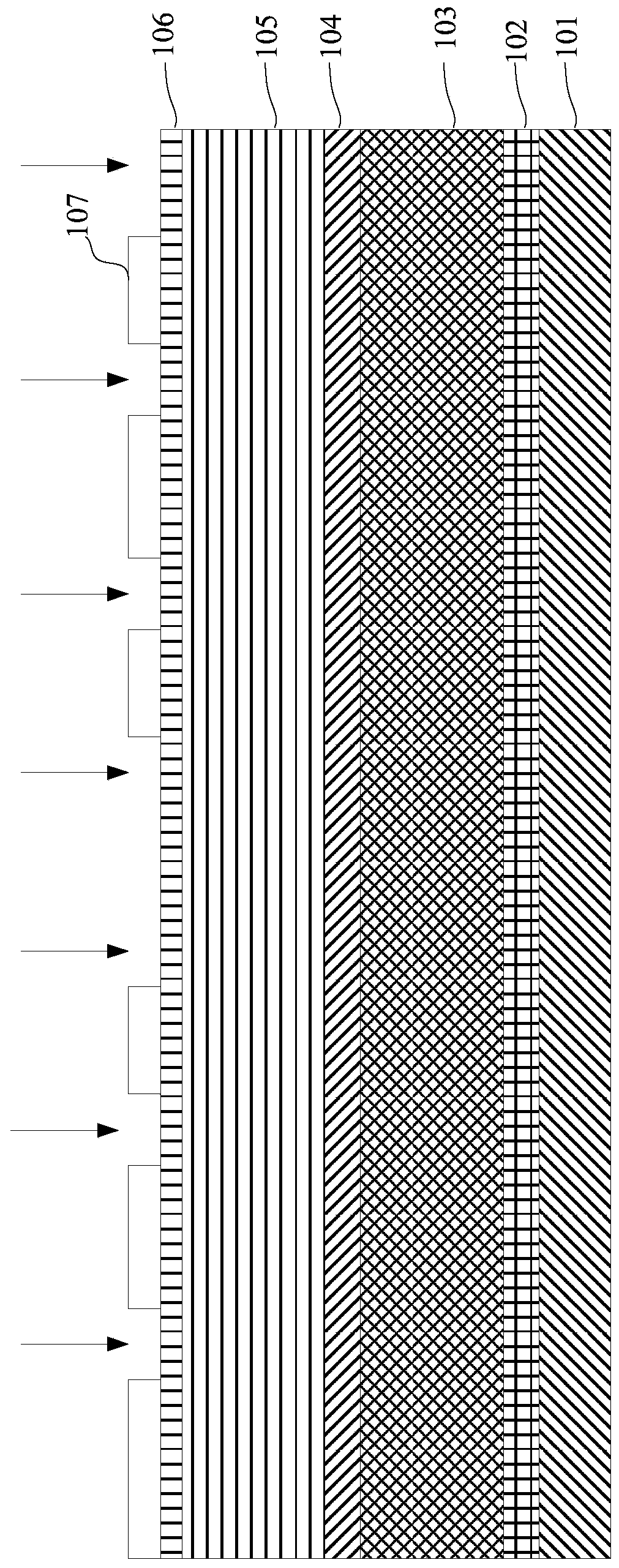

Display substrate, manufacturing method thereof and display device comprising display substrate

ActiveCN105489616AIncrease the effective luminous areaIncrease opening ratioSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to a display substrate, a manufacturing method thereof and a displaying device comprising the display substrate. A pixel unit in the display substrate comprises a first electrode and a first connecting part which is connected with the first electrode. The first connecting part is connected with a first connecting wire through a first via hole. The first connecting line of the pixel unit is connected with the first connecting line of another pixel unit above the pixel unit and the first connecting line of another pixel unit below the pixel unit. According to the technical solution of the display substrate, the first connecting line is connected with the first connecting part through the first via hole and furthermore is connected with a common electrode. Because the first connecting line is also used for connecting with the first connecting lines of another pixel unit above the pixel unit and another pixel unit below the pixel unit, thereby connecting with the common electrode in the longitudinal pixel unit. Compared with a manner of connecting with the common electrode in the longitudinal pixel unit through two via holes and two connecting lines in prior art, the manner of the display substrate is advantageous in that only one via hole is required; and relatively small reserved area for the via hole on the pixel electrode is realized, thereby enlarging an effective light emitting area and furthermore increasing an aperture ratio.

Owner:CHONGQING BOE OPTOELECTRONICS +1

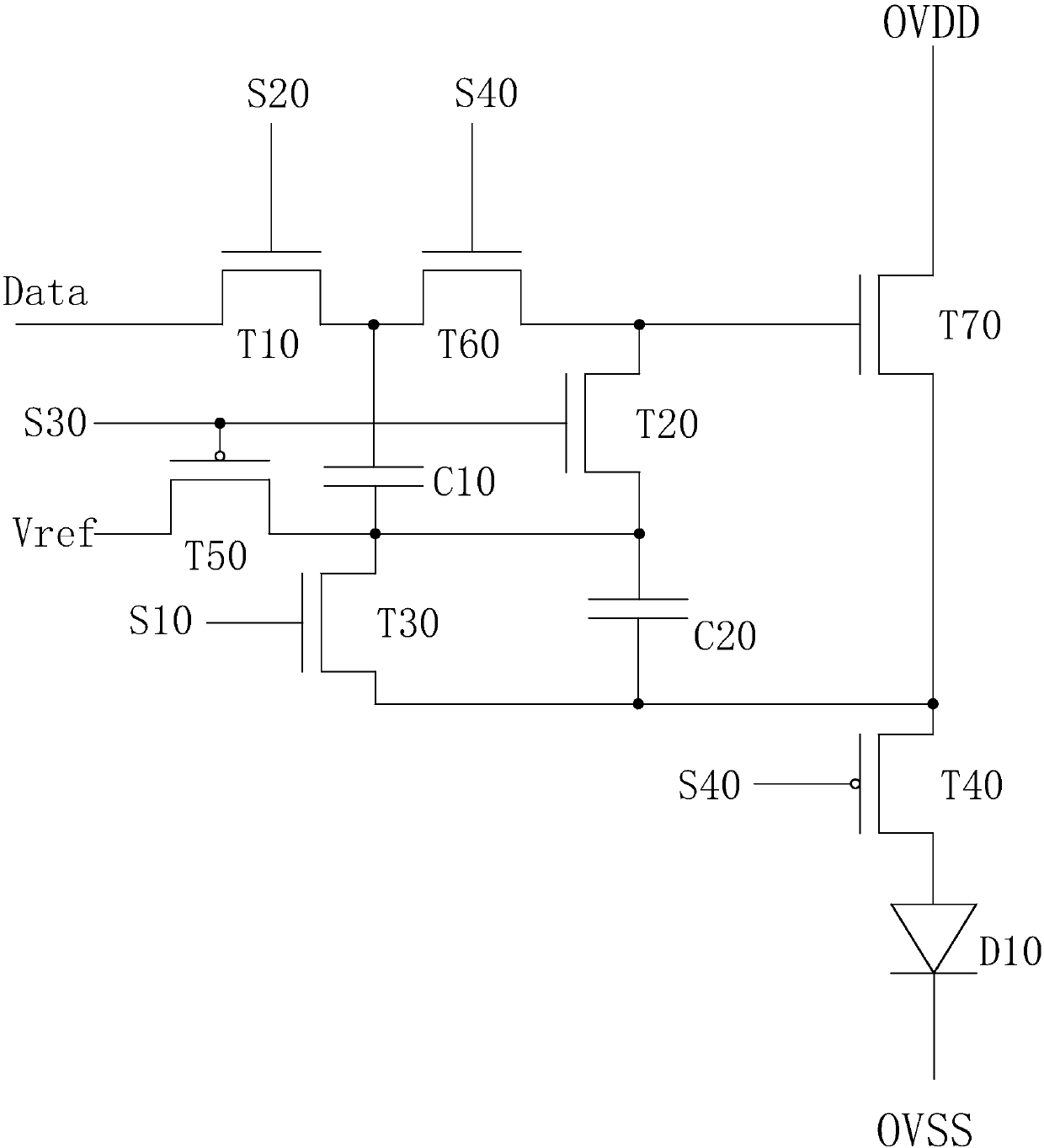

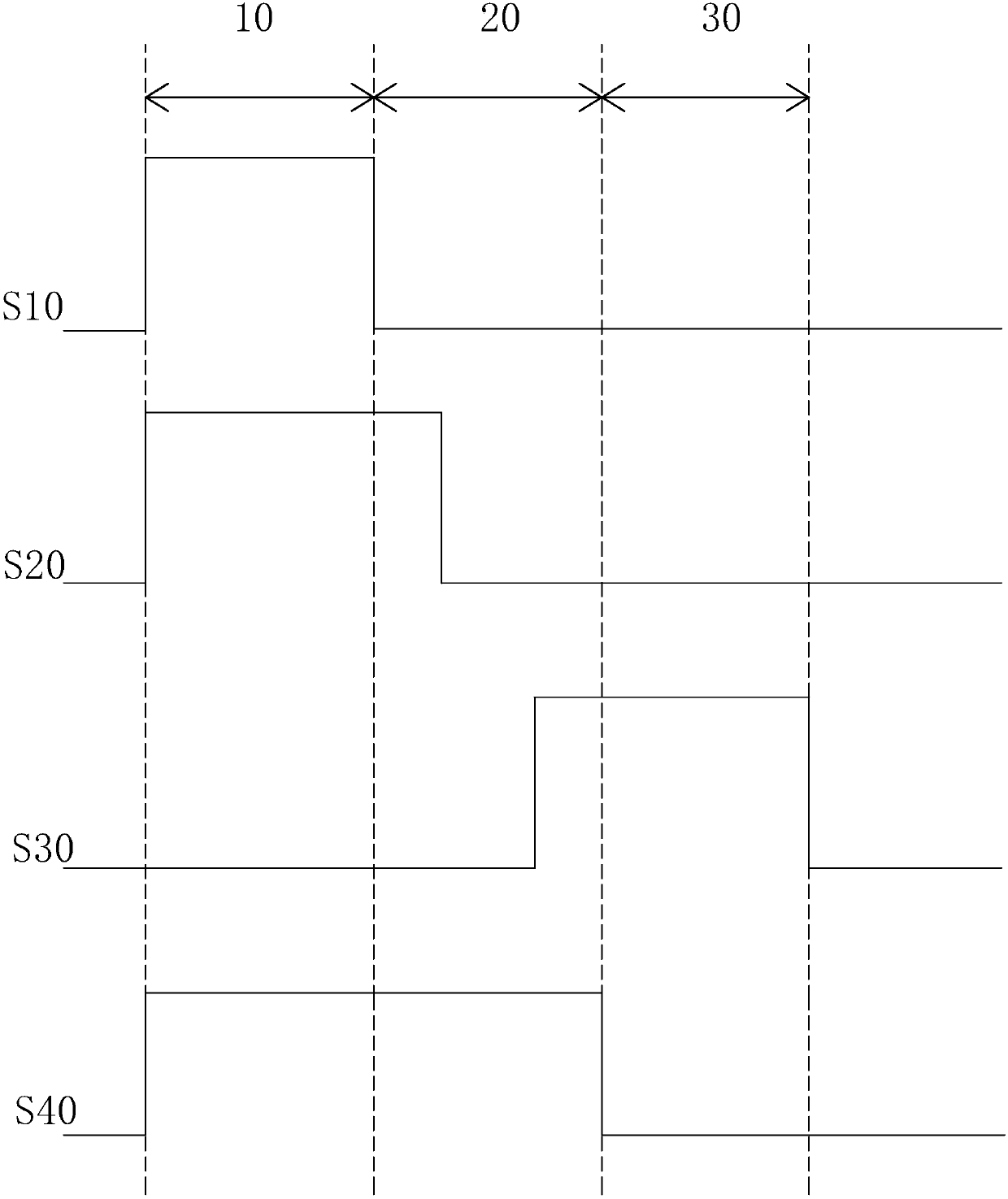

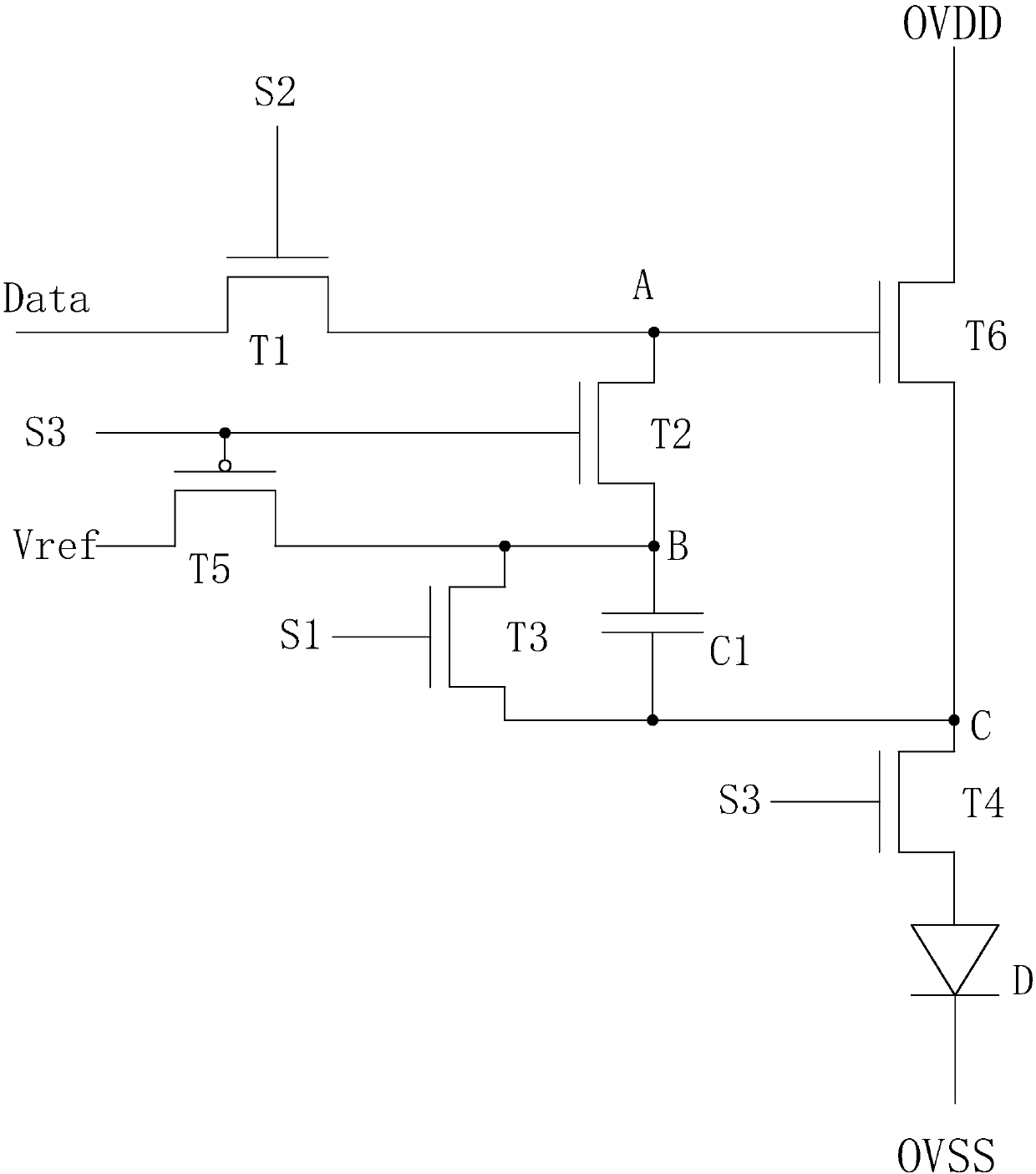

An AMOLED pixel drive circuit and a driving method thereof

ActiveCN107657921ASimple structureLuminous brightness is stableStatic indicating devicesControl signalEngineering

The invention provides an AMOLED pixel drive circuit and a driving method thereof. The pixel drive circuit with a 6T1C structure is employed with a specific drive time sequence, so that threshold voltages for driving thin film transistors can be effectively compensated for and currents flowing through organic light emitting diodes are stable, the light emitting brightness of the organic light emitting diodes is uniform and an image display effect is improved; through the cooperation of N-type thin film transistors and P-type thin film transistors, the numbers of thin film transistors and scanning control signals are reduced, the structure of the pixel drive circuit is simplified and an effective light emitting area is increased.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Vertical high voltage light emitting diode chip and manufacturing method thereof

ActiveCN110085619AIncrease the effective luminous areaImproved current spreadSolid-state devicesSemiconductor devicesElectricityHigh pressure

The invention discloses a vertical high voltage light emitting diode chip and a manufacturing method thereof. With the design of the vertical high voltage light emitting diode chip, the back surface electrode in a first chip region is electrically connected with a conductive substrate through a hole and a bonding layer and the back surface electrode is exposed without etching in the first chip region, thereby ensuring that the effective light emitting area of the vertical high voltage light emitting diode chip is large; besides, the back surface electrode of the first chip region does not needto be wired, thereby saving cost and improving reliability; in addition, the current spreading of each chip region is vertical, and the back surface electrode of the first chip region and the front surface electrode of the Nth chip region form a vertical structure so that the current spreading of the vertical high voltage light emitting diode chip is good, and the current resistance ability can be improved by avoiding current congestion; furthermore, the vertical high voltage light emitting diode chip has a better light type and meets the Lambert distribution and is easier to distribute light.

Owner:XIAMEN CHANGELIGHT CO LTD

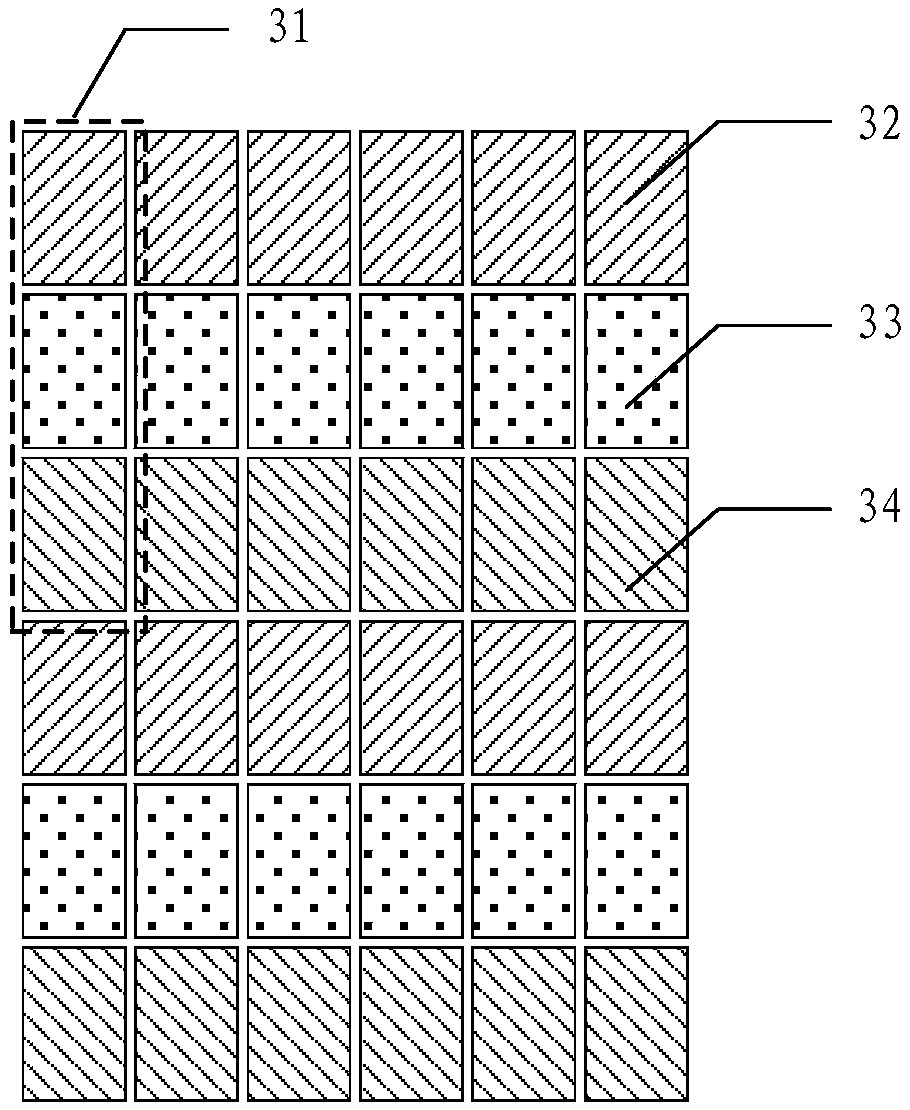

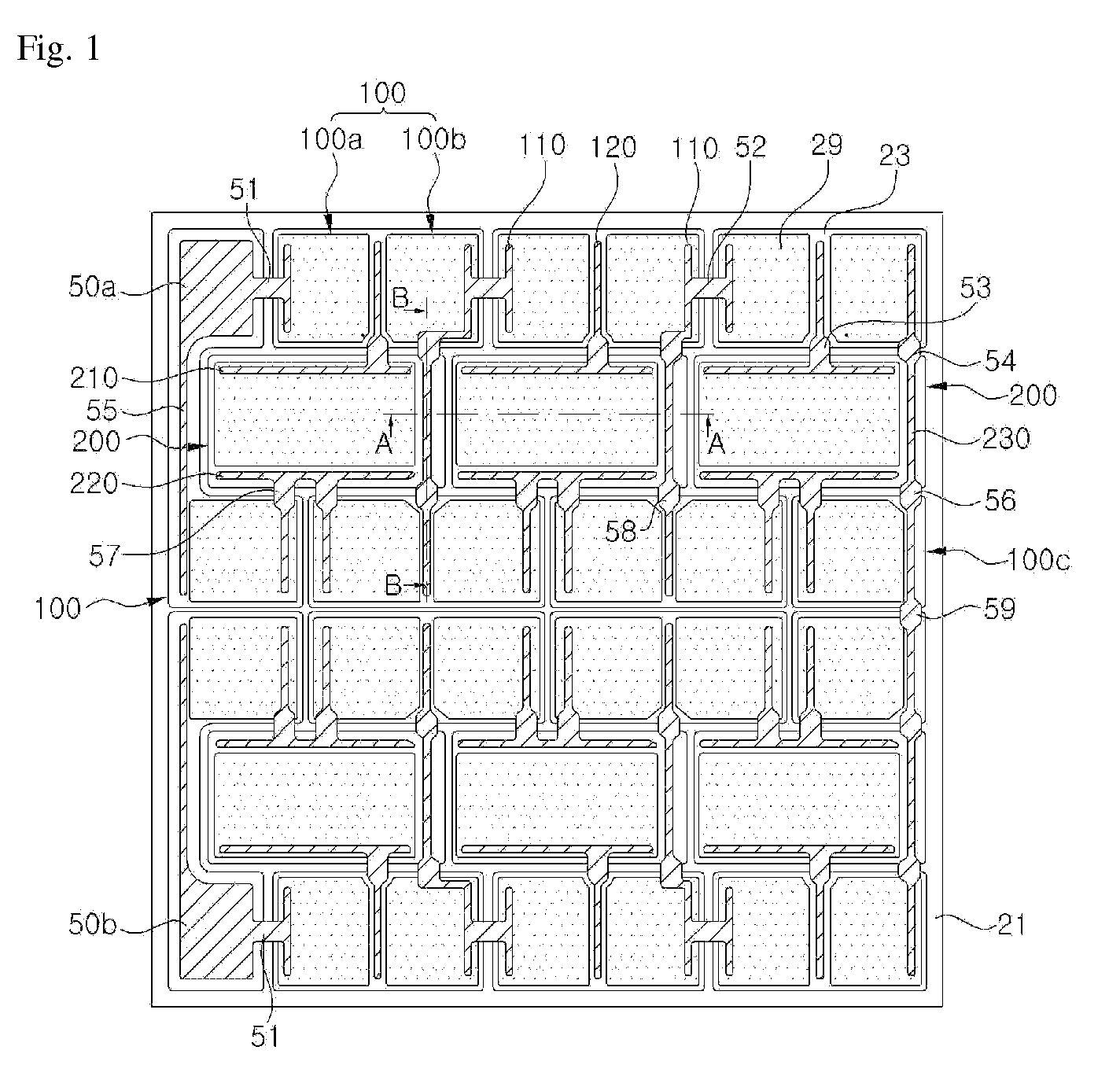

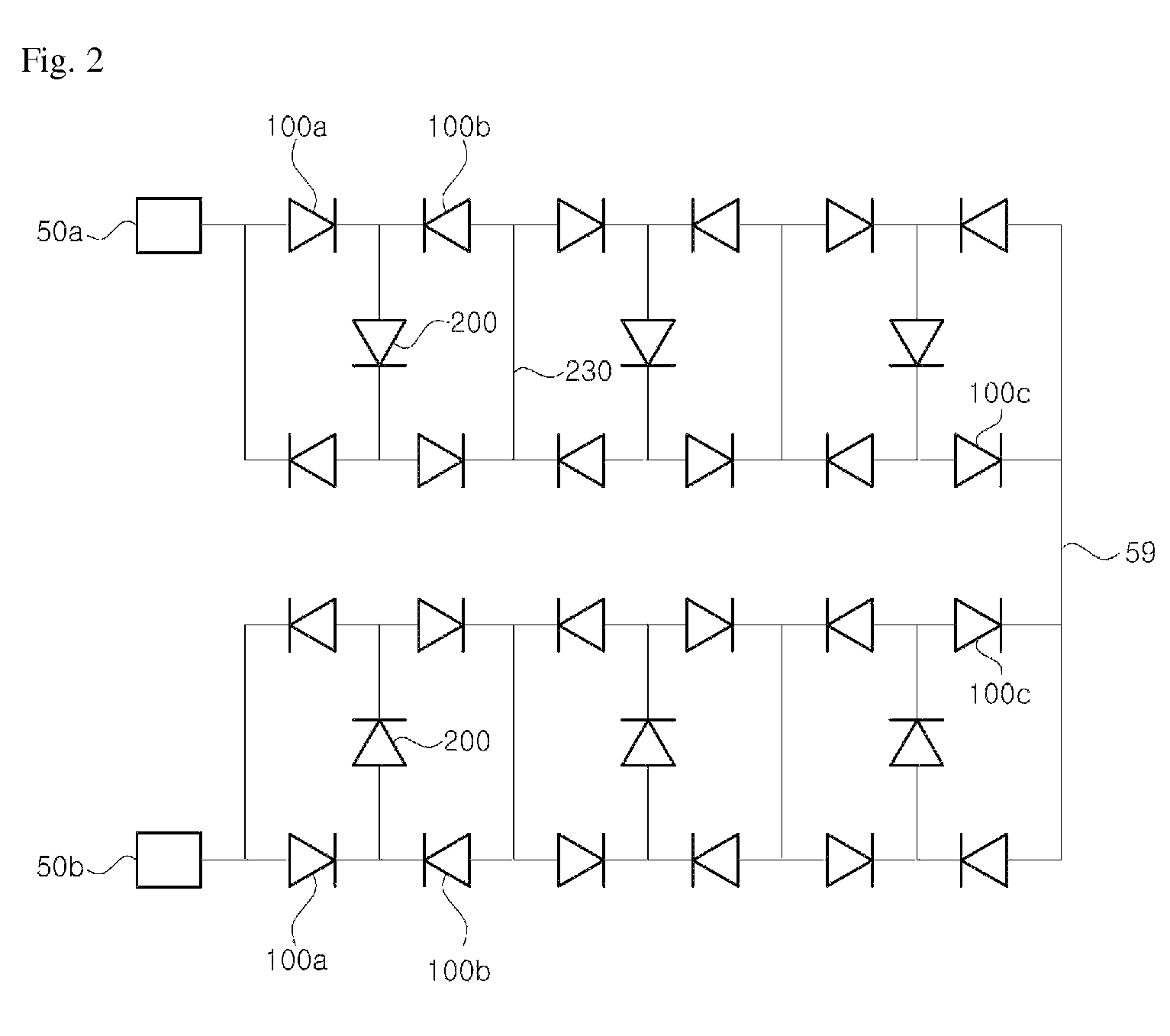

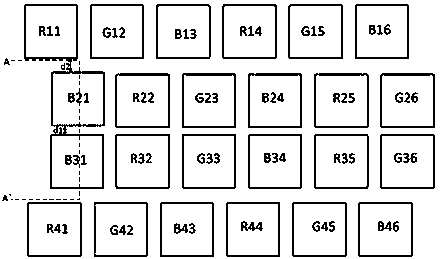

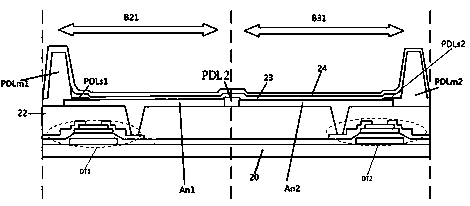

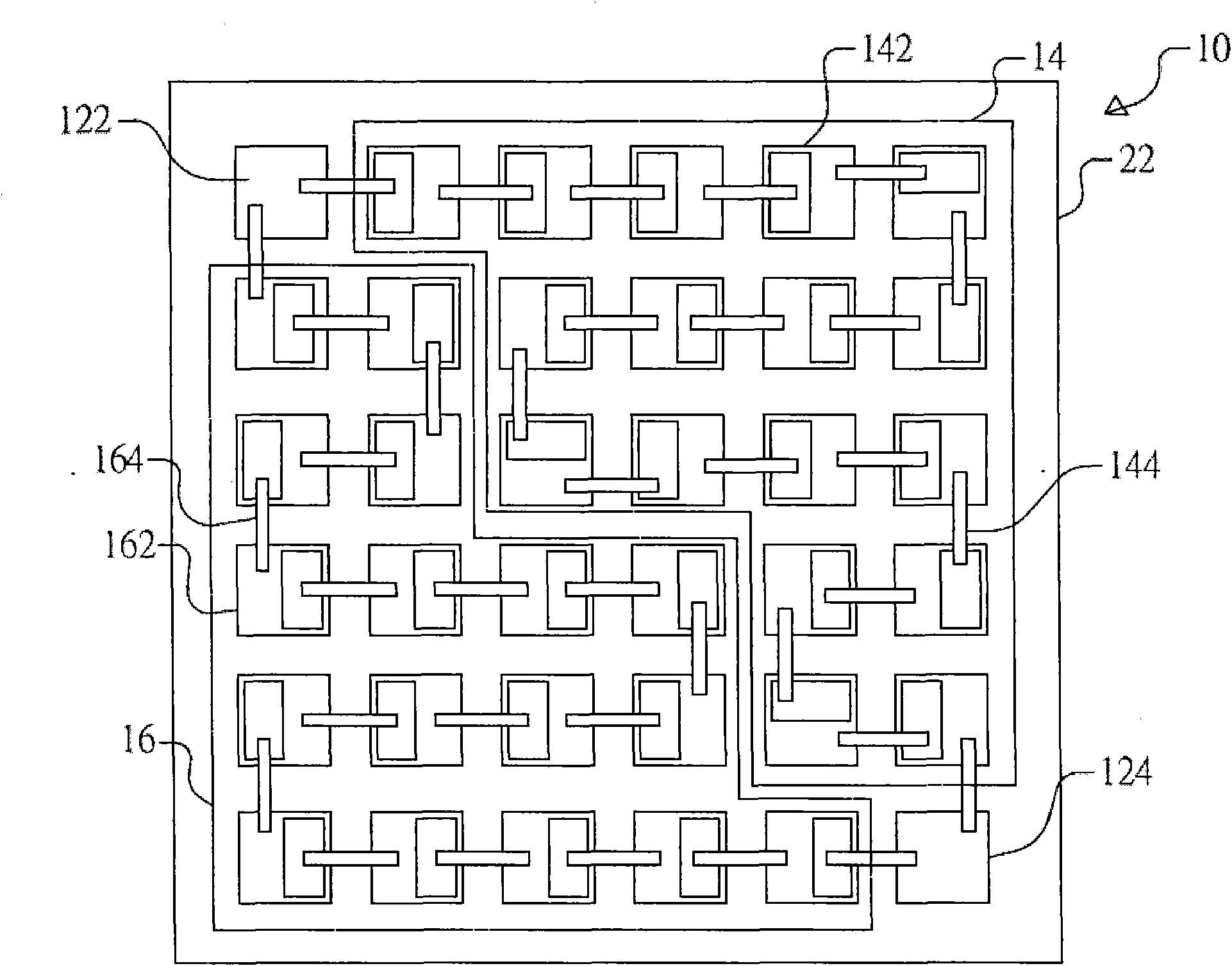

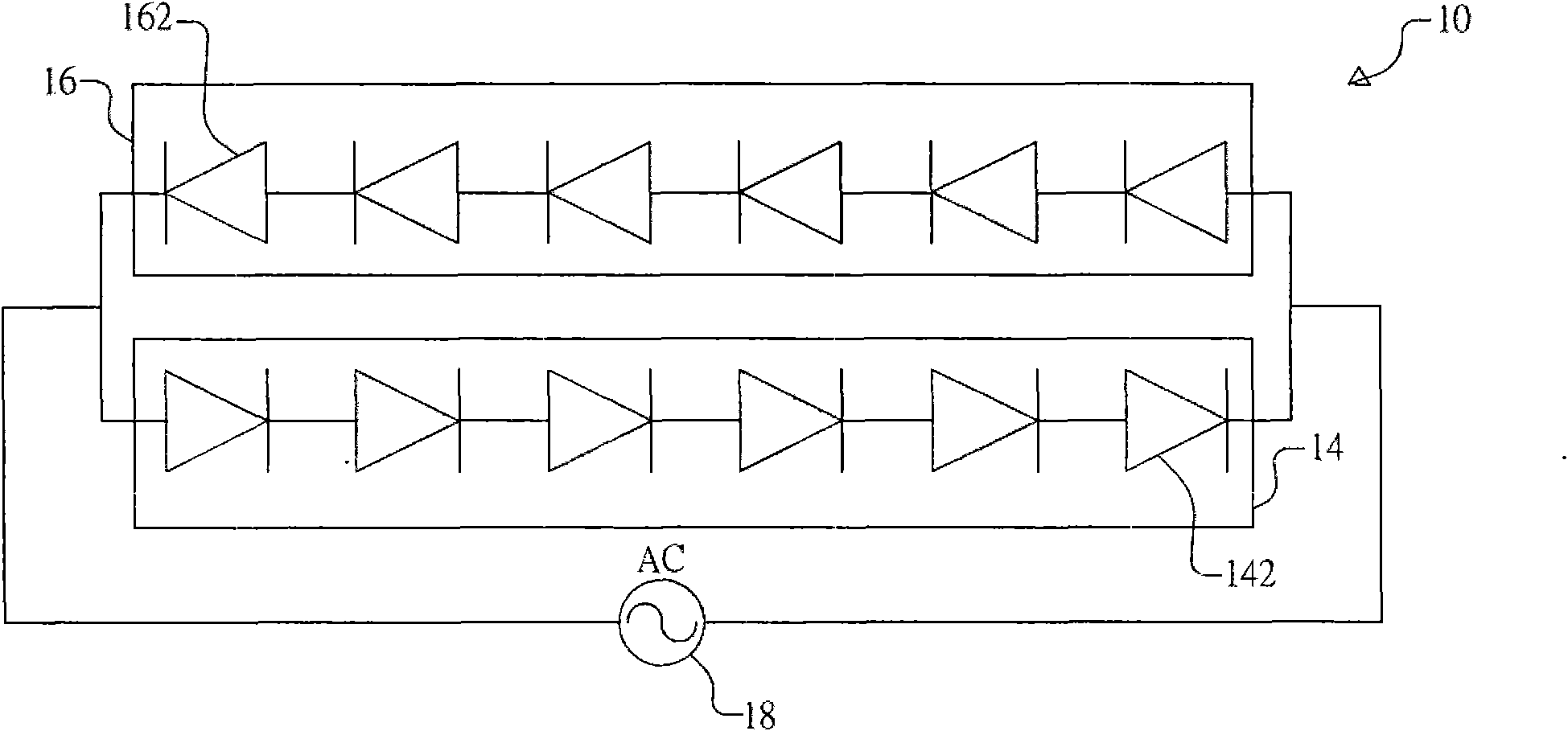

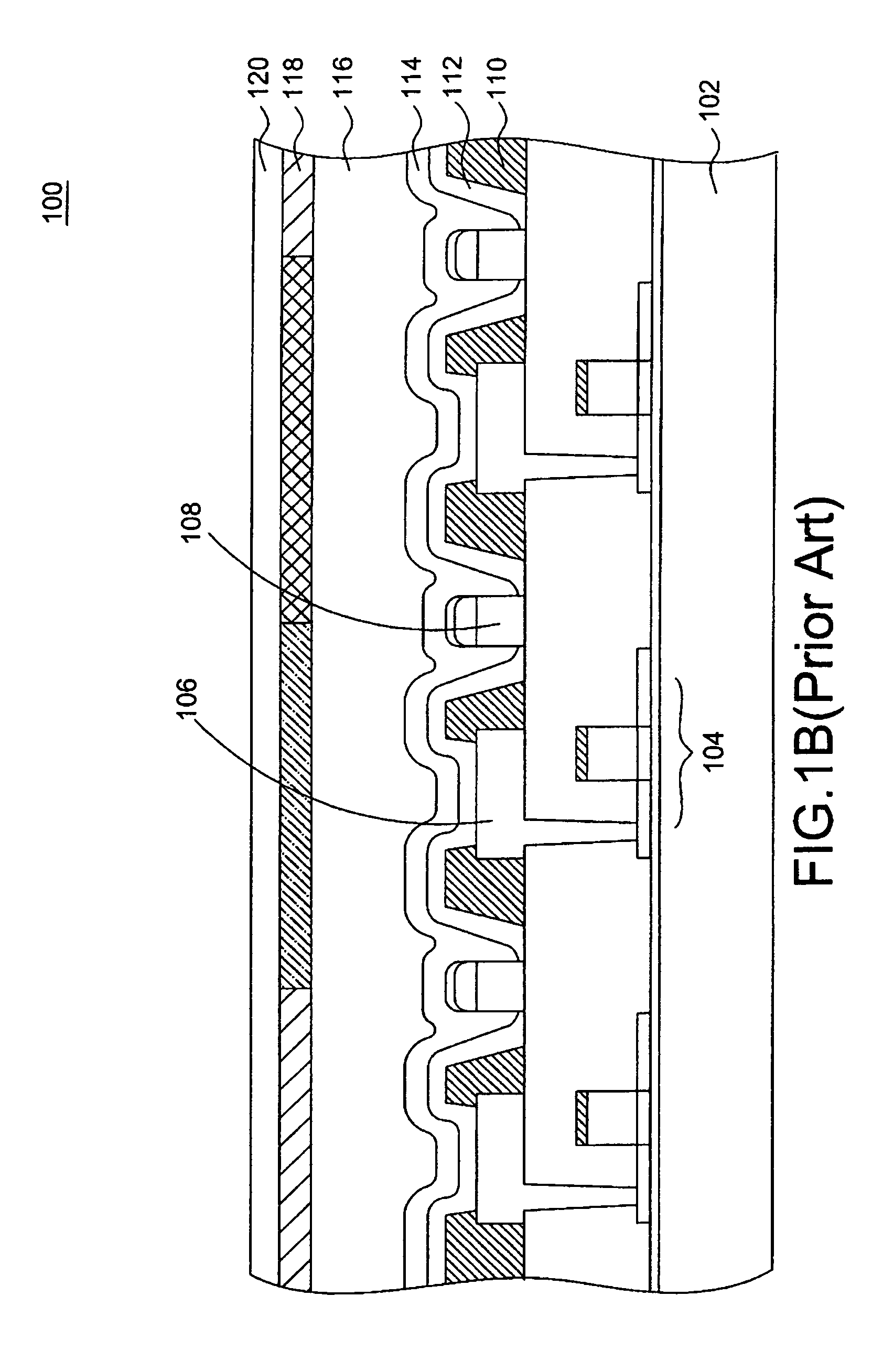

AC light emitting diode having full-wave light emitting cell and half-wave light emitting cell

InactiveUS8354680B2Minimizing reverse voltageIncrease the effective luminous areaDischarge tube luminescnet screensLamp detailsElectrical conductorFull wave

The present invention discloses an alternating current (AC) light emitting diode (LED) having half-wave light emitting cells and full-wave light emitting cells. The AC LED has a plurality of light emitting cells electrically connected between bonding pads on a single substrate. The AC LED includes a first row of half-wave light emitting cells each having an anode terminal and a cathode terminal, a second row of full-wave light emitting cells each having an anode terminal and a cathode terminal, and a third row of half-wave light emitting cells each having an anode terminal and a cathode terminal. In the AC LED, the second row is arranged between the first row and the third row, and the third row includes a pair of light emitting cells that share a cathode terminal with each other. The cathode terminal shared by the pair of light emitting cells in the third row is electrically connected to the anode terminal of a corresponding light emitting cell of the half-wave light emitting cells in the first row through a conductor that is electrically insulated from the full-wave light emitting cells in the second row.

Owner:SEOUL VIOSYS CO LTD

Display panel and display device

ActiveCN110600532AImprove film thickness uniformityImprove brightness uniformitySolid-state devicesSemiconductor devicesTransistor arrayDisplay device

The invention provides a display panel and a display device. The display panel includes a film transistor array layer, a first organic insulating layer, a plurality of first electrodes, a second organic insulating layer, an organic light emitting layer and a second electrode, wherein the first electrode, the organic light emitting layer and the second electrode form an organic electroluminescent device, a first interval is formed between first electrodes included in adjacent sub-pixels with the same color, the second organic insulating layer corresponding to the first interval has a first height, a second interval is formed between the first electrodes included in the adjacent sub-pixels with different colors, the second organic insulating layer corresponding to the second interval has a second height, and the second height is greater than the first height. The display panel is advantaged in that manufacturing difficulty can be reduced, printing precision and the printing speed are improved, and film thickness uniformity of the organic light emitting layer is improved.

Owner:BOE TECH GRP CO LTD +1

Dielectric material of plasma display screen,manufacturing method of lower base plate of plasma display screen and plasma display screen

The invention discloses a dielectric material of a plasma display screen. The dielectric material includes a low-melting glass powder of PbO-B2O3-SiO2-RO glass series, wherein R represents the alkali metal. The dielectric material also includes an inorganic filling powder which is one or more selected from a group consisting of zirconia, yttrium oxide, and alumina. Based on the total weight of the low-melting glass powder and the inorganic filling powder, the dielectric material comprises, by weight, 20-40% of PbO, 10-20% of B2O3, 15-30% of SiO2, 10-20% of RO, and 5-30% of the inorganic filling powder. The invention also discloses a manufacturing method of a lower base plate of the plasma display screen, and the dielectric material is used in the manufacturing method. The invention also discloses the plasma display screen including the lower base plate of the plasma display screen. The plasma display screen manufactured from the dielectric material of the invention can obtain good screen characteristics.

Owner:SICHUAN COC DISPLAY DEVICES

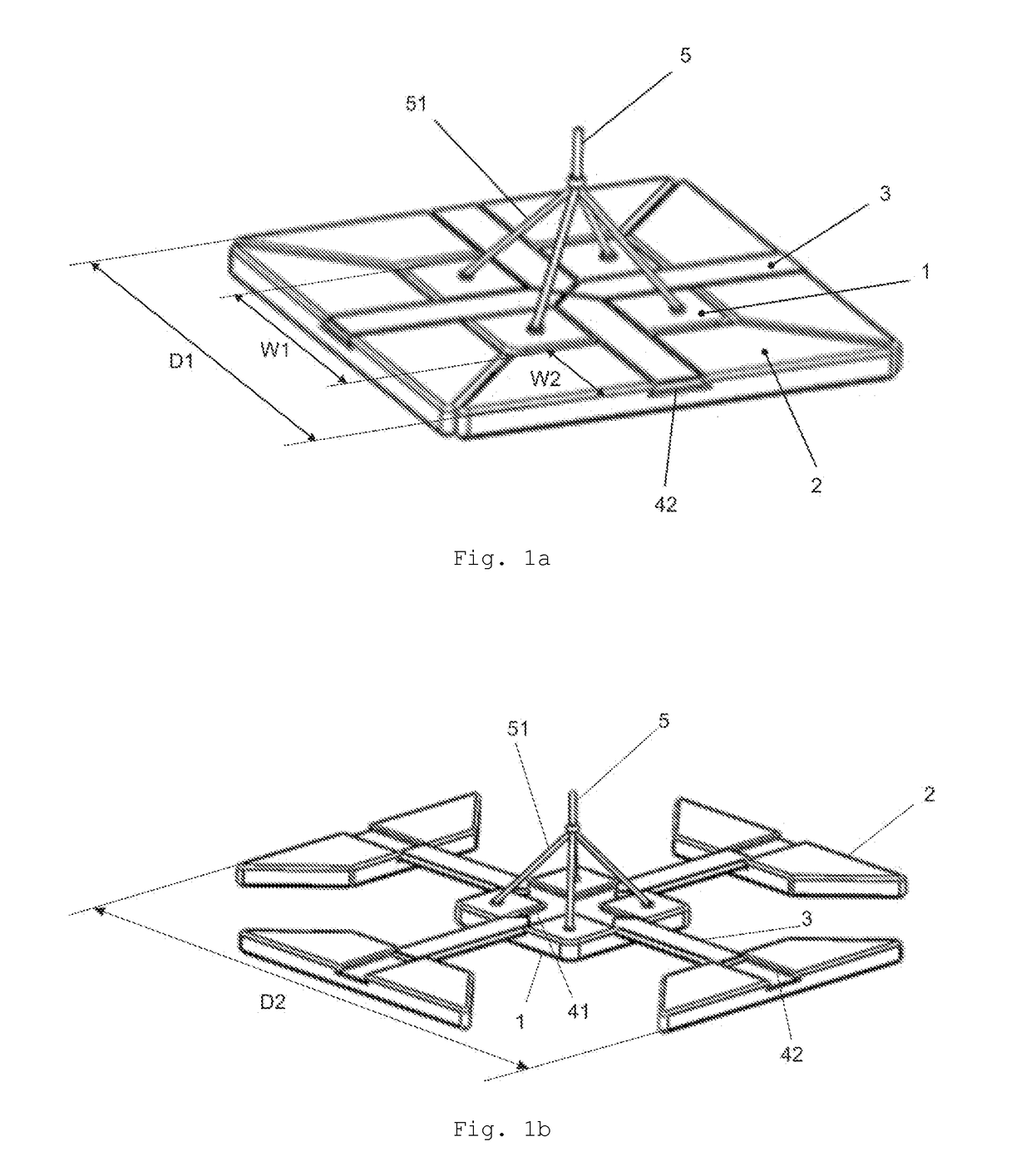

Alternating current light-emitting device

InactiveCN101860998ALarge luminous areaAvoid disconnectionElectrical apparatusElectroluminescent light sourcesEngineeringElectrical conductor

The invention discloses an alternating current (AC) light-emitting device. The device comprises a substrate and a plurality of light-emitting units, wherein the light-emitting units are arranged on the substrate, each light-emitting unit contains a first semiconductor layer, a luminous layer and a second semiconductor layer from bottom to top, at least one first electrode and second electrode are separately arranged on the first semiconductor layer and the second semiconductor layer, and each light-emitting unit is coupled with at least one adjacent light-emitting unit through a wire. As the light-emitting device has a plurality of light-emitting units and each light-emitting unit is coupled with at least one adjacent light-emitting unit through a wire, the problem that as one wire is broken, the AC light-emitting device is open can be avoided.

Owner:宁波璨圆光电有限公司

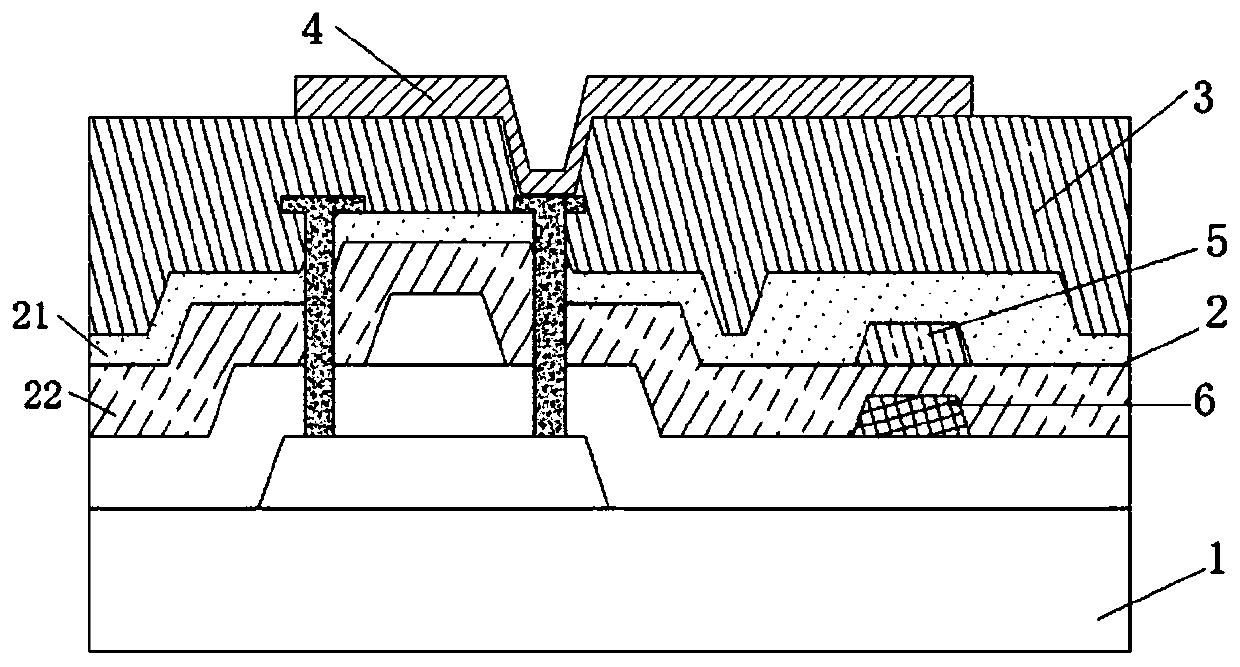

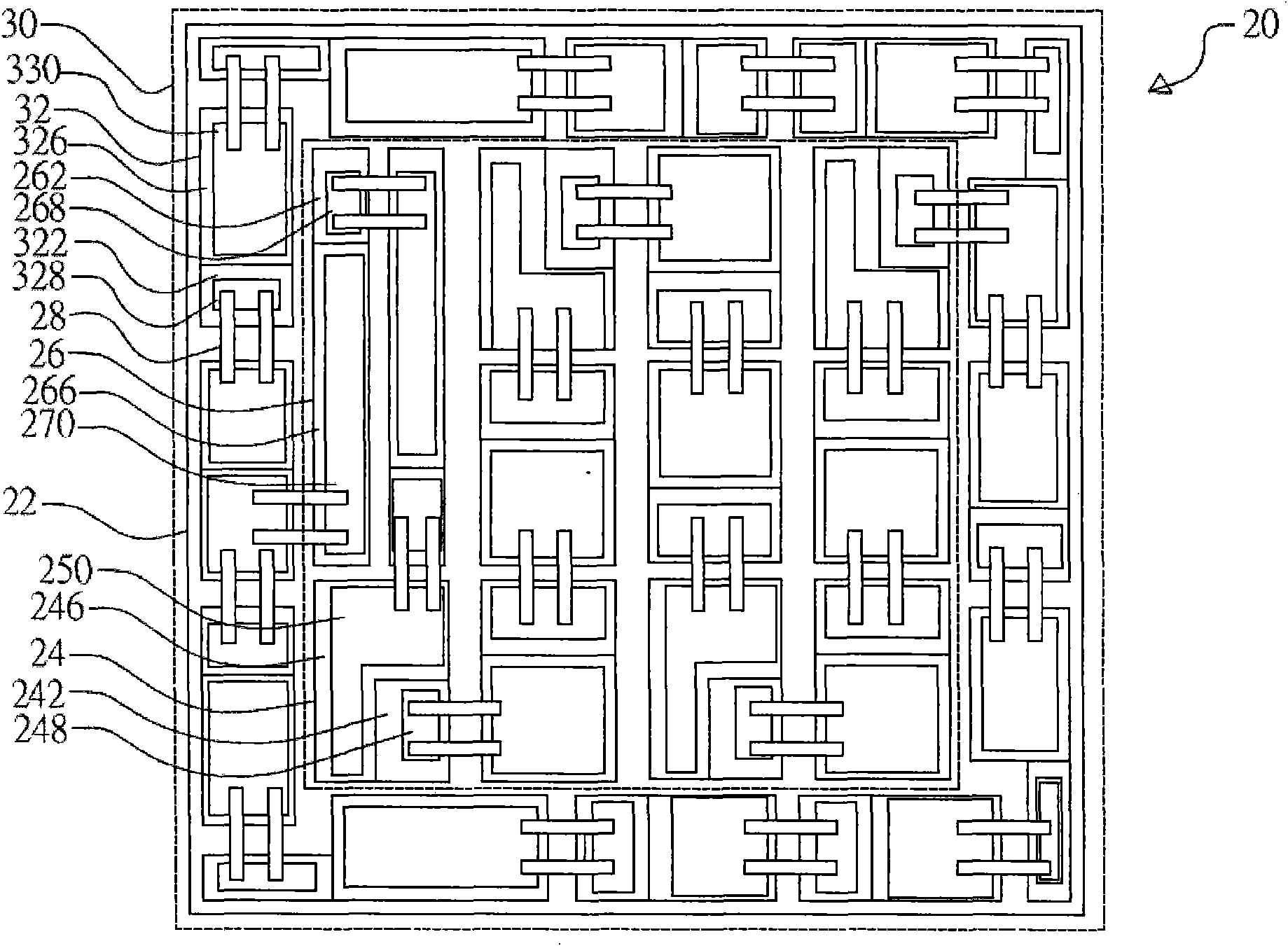

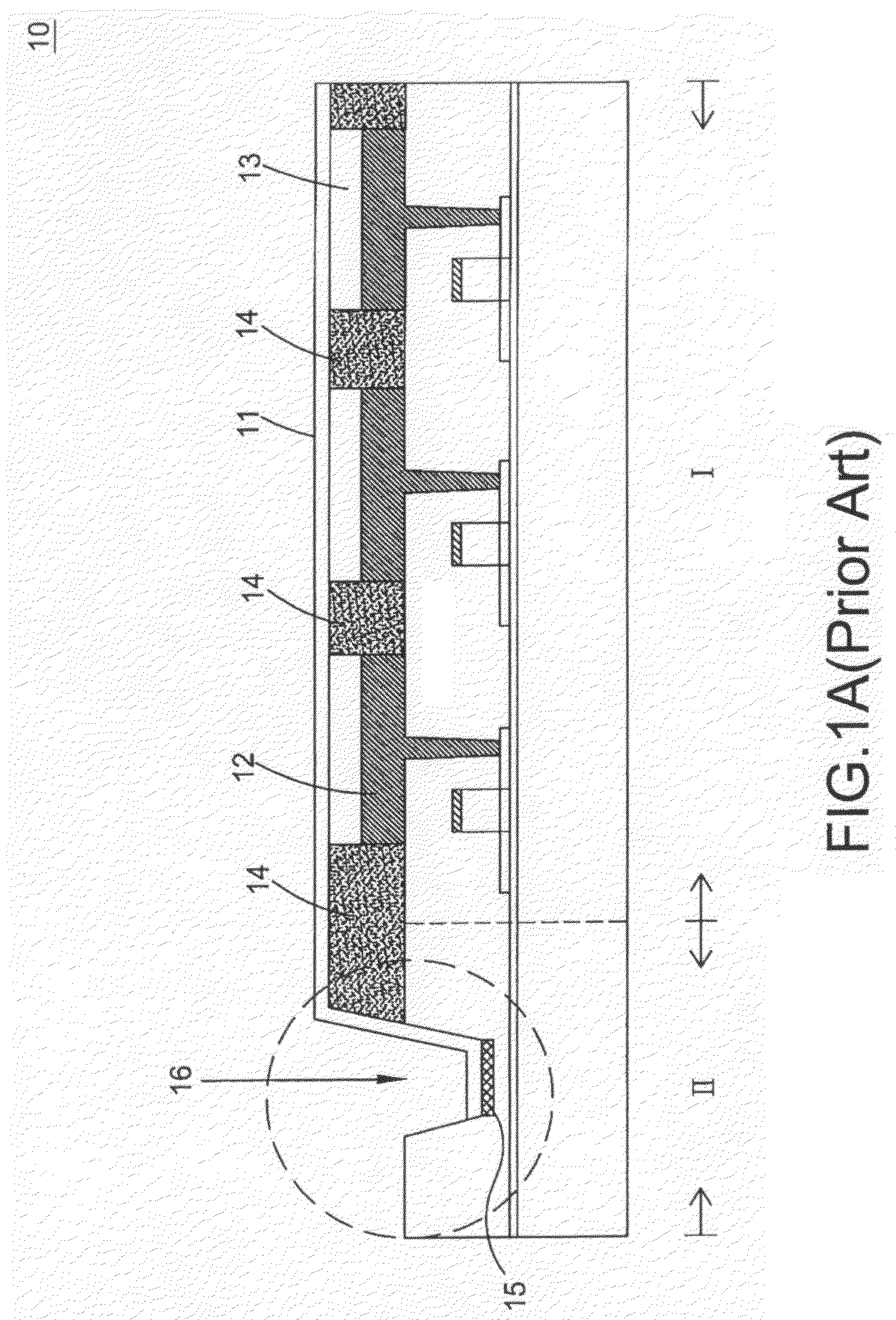

Organic light-emitting device, and methods of forming the same and electronic devices having the same

ActiveUS8053981B2Easy to shrinkIncrease the effective luminous areaDischarge tube luminescnet screensElectroluminescent light sourcesOrganic light emitting deviceElectrode Contact

An organic light-emitting device and methods of forming the same are provided. The organic light-emitting device includes: a substrate having a pixel area and a peripheral circuit area; a reflective layer on the substrate, the reflective layer having a first reflective part in the pixel area and a second reflective part in the peripheral circuit area; a first electrode layer having a first part on the first reflective part; a pixel definition layer on the substrate, the pixel definition layer forming a plurality of pixel openings to expose a portion of the first part of the first electrode layer and at least one electrode contact hole to expose the second reflective part; an organic light-emitting layer on the first electrode layer; and a second electrode layer on the organic light-emitting layer, the second electrode layer extending to the peripheral circuit area to electrically couple with the exposed area of the second reflective part.

Owner:INNOLUX CORP

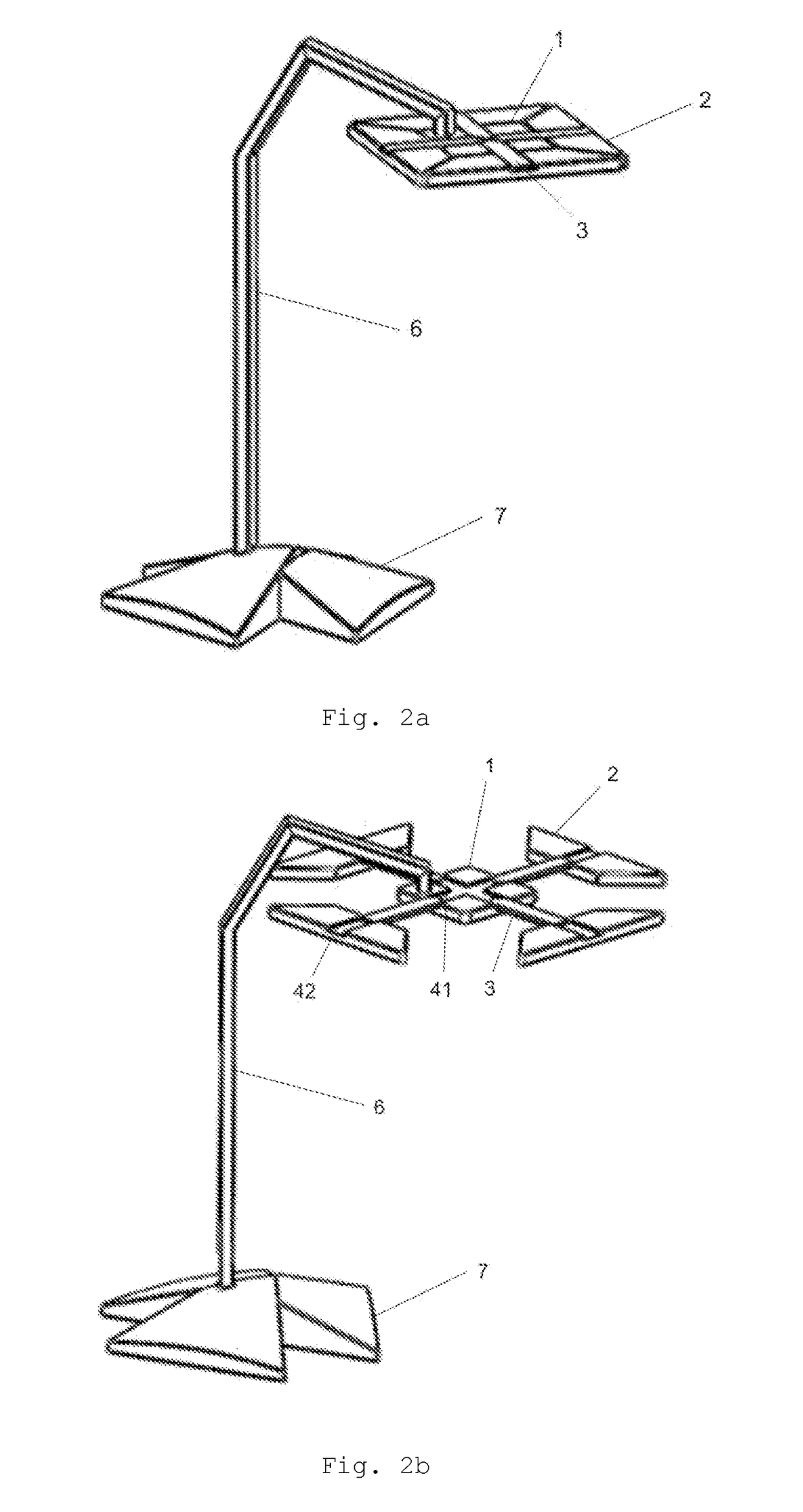

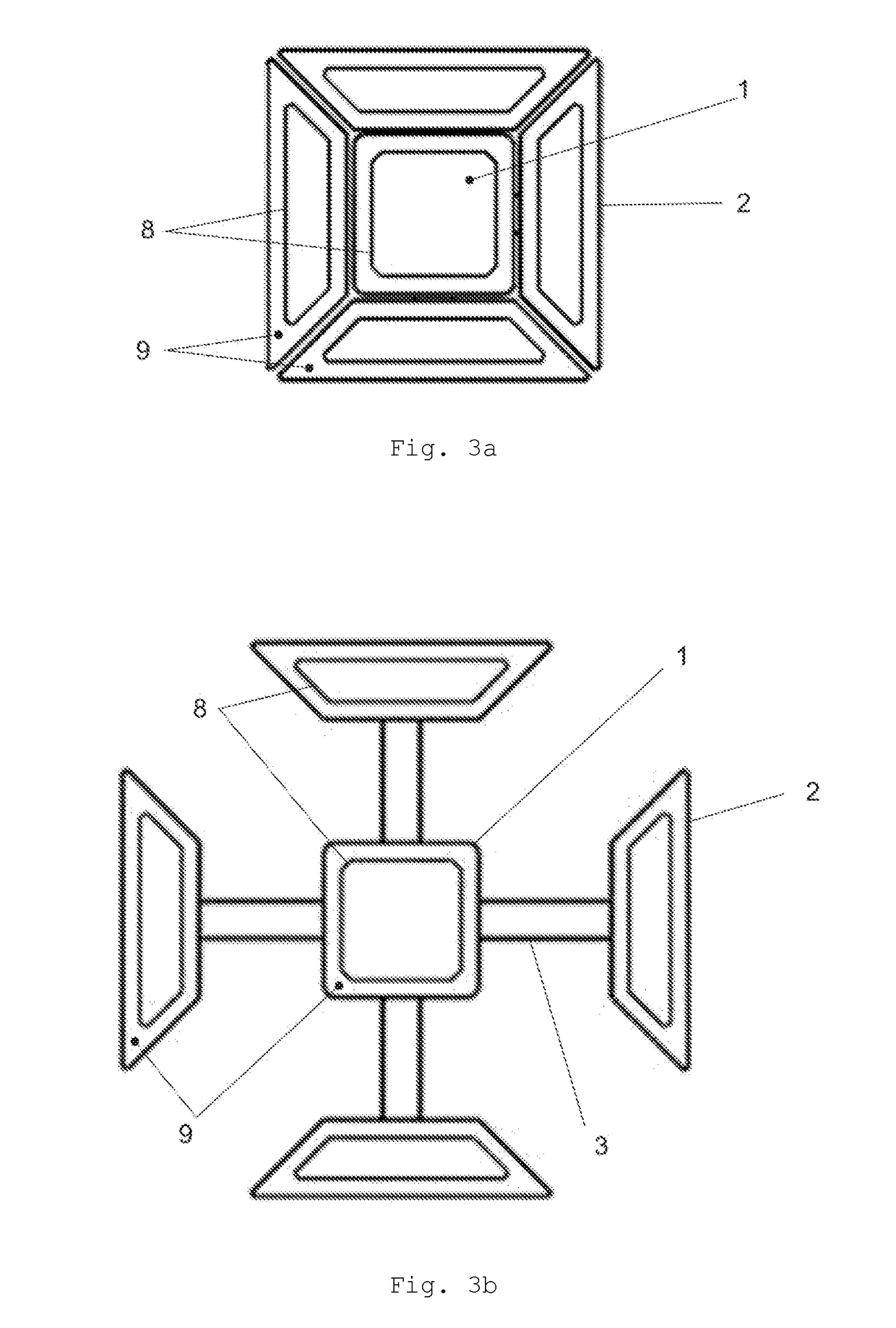

Extensible lamp to reduce shadow

ActiveUS20190032892A1Reduce shadowsCompact designLighting support devicesElectric circuit arrangementsEngineeringLight source

Owner:LEDVANCE GMBH

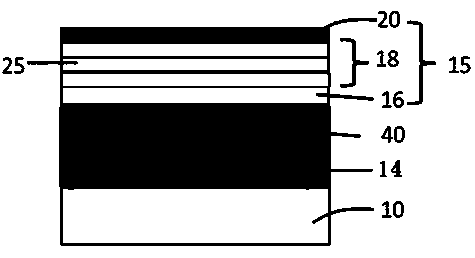

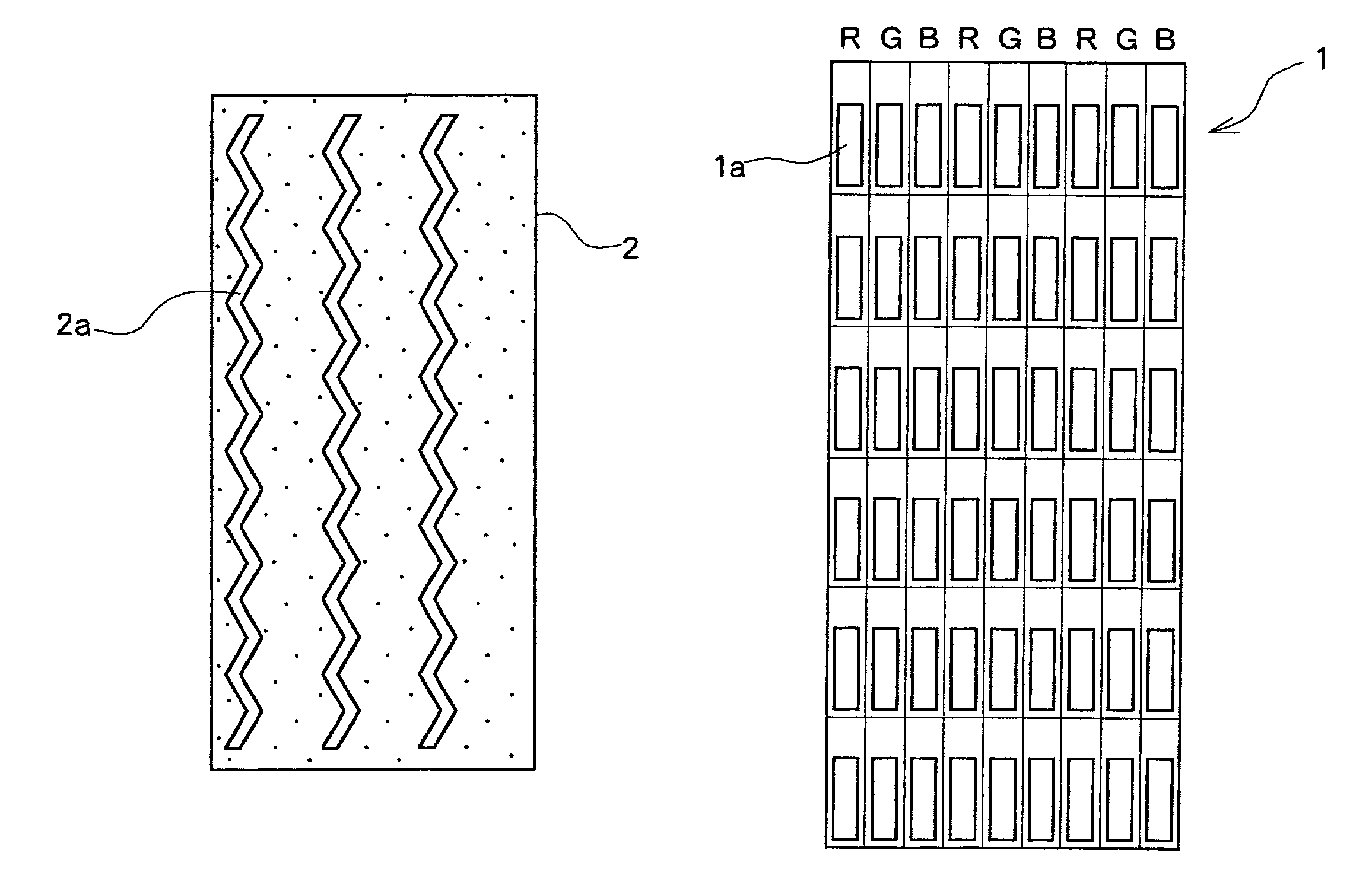

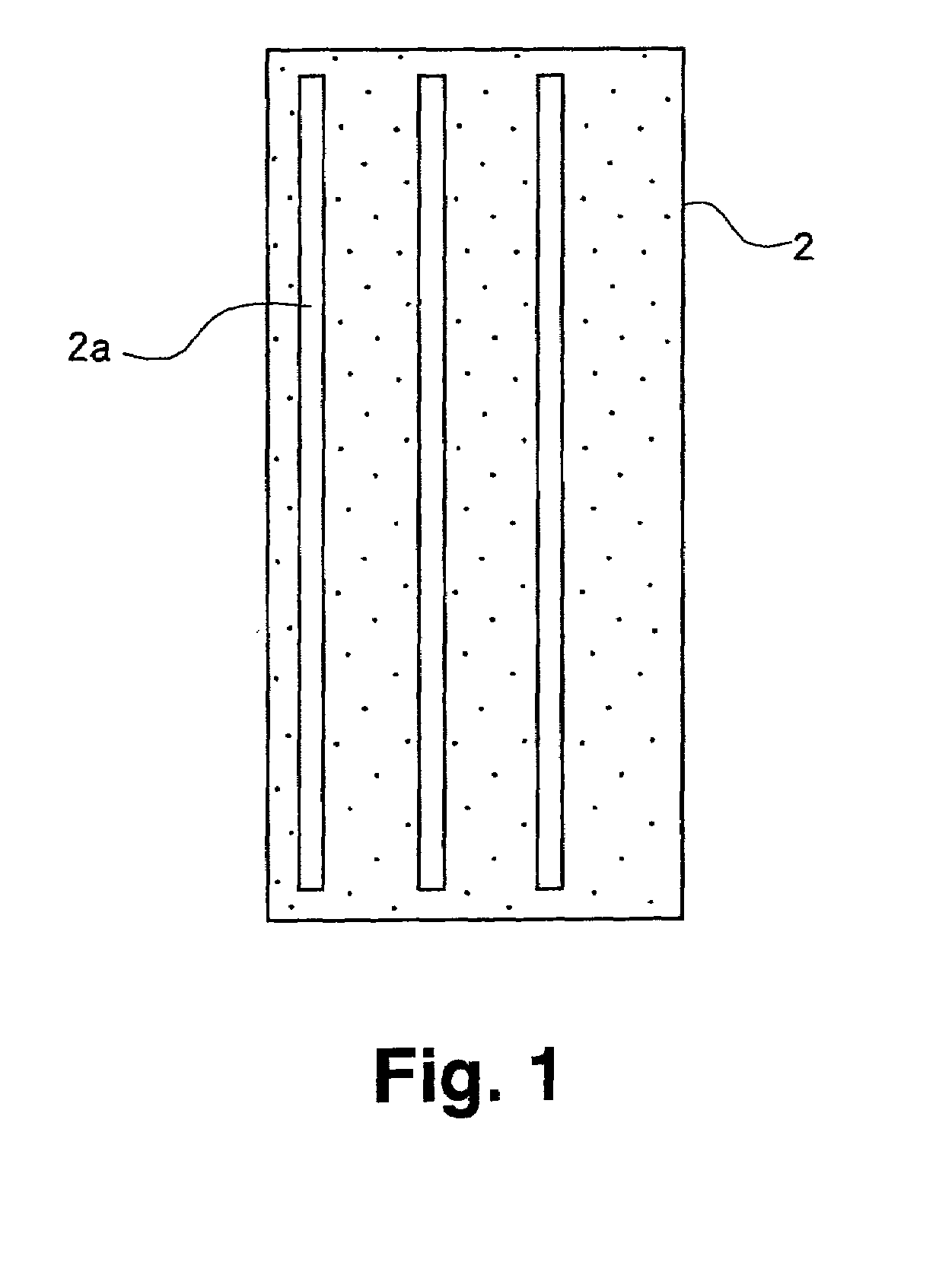

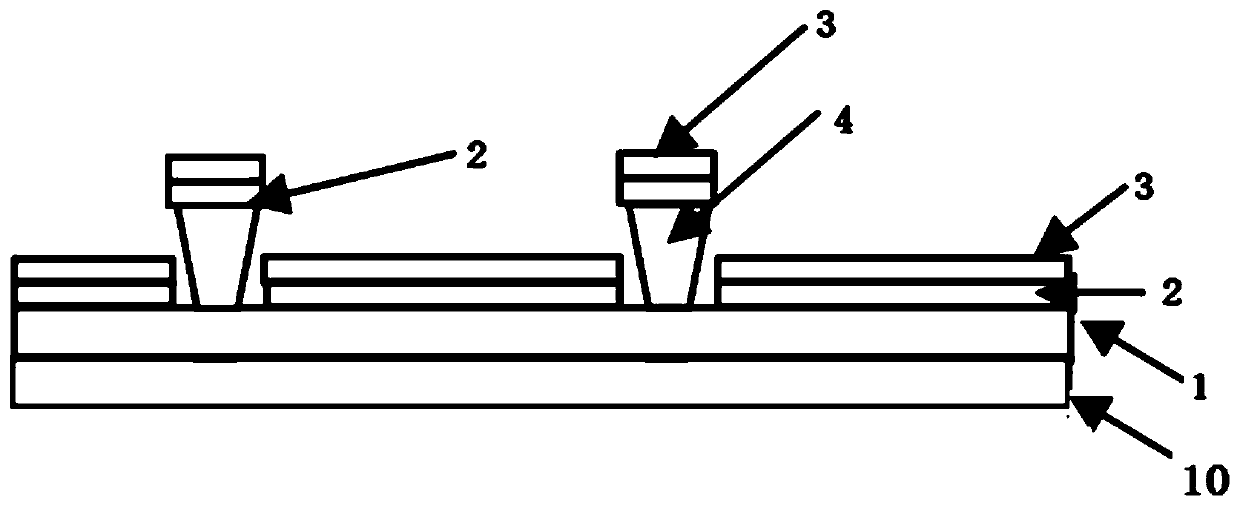

Light-emitting device and light-emitting device manufacturing method

InactiveUS6975065B2Suppress uneven light emissionIncrease the effective luminous areaDischarge tube luminescnet screensElectroluminescent light sourcesPhysicsElectron transport layer

An organic EL display in which the film thickness of an organic emissive layer is made uniform so as to increase the effective light emission area. An anode and a common cathode are formed for each pixel on the organic EL display. Switching by thin-film transistors causes current to flow between the anode and the cathode so that the organic EL element emits light. The organic EL element comprises a hole transport layer, the organic emissive layer, and an electron transport layer. Among a plurality of pixels disposed in a matrix configuration, the organic emissive layer is formed in common with adjacent pixels of the same color. Forming the organic emissive layer in common can prevent a decrease in the film thickness of the organic emissive layer at the edges of the shadow mask during vapor deposition and result in a uniform film thickness of the organic emissive layer.

Owner:SANYO ELECTRIC CO LTD

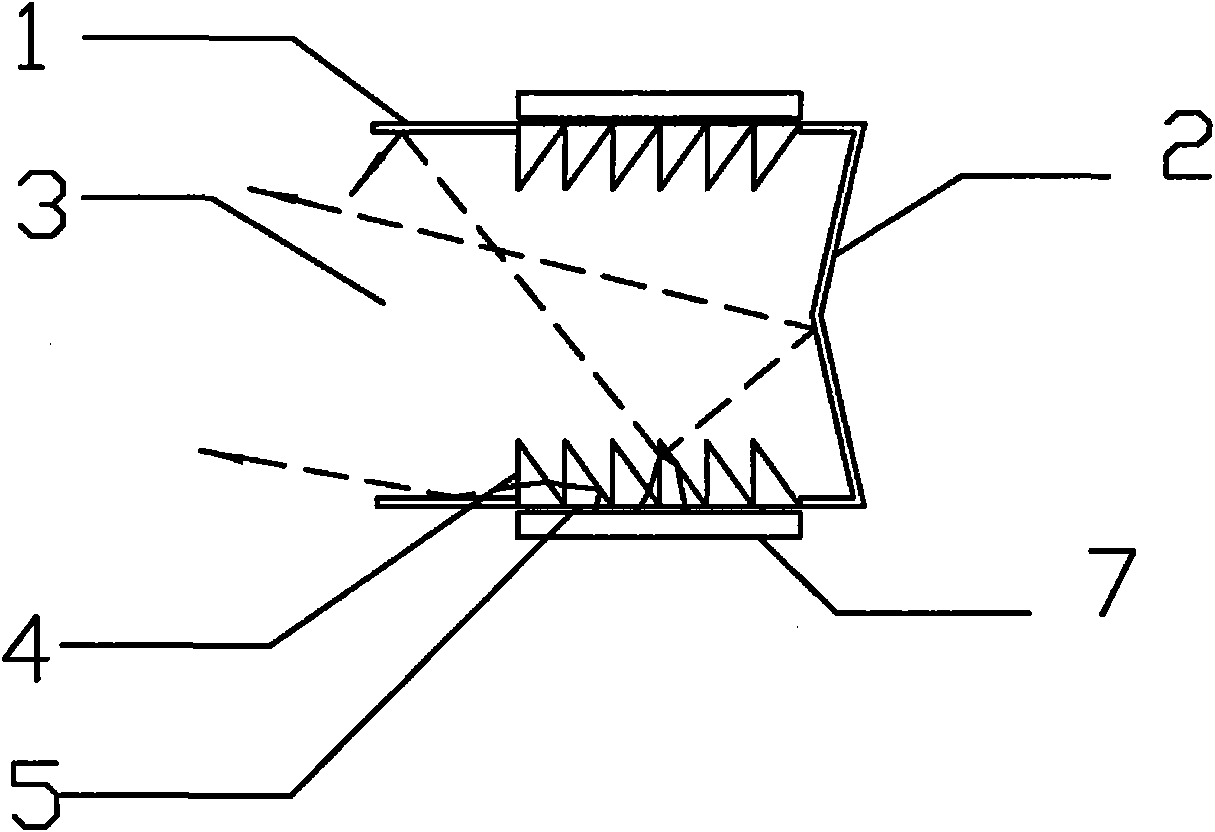

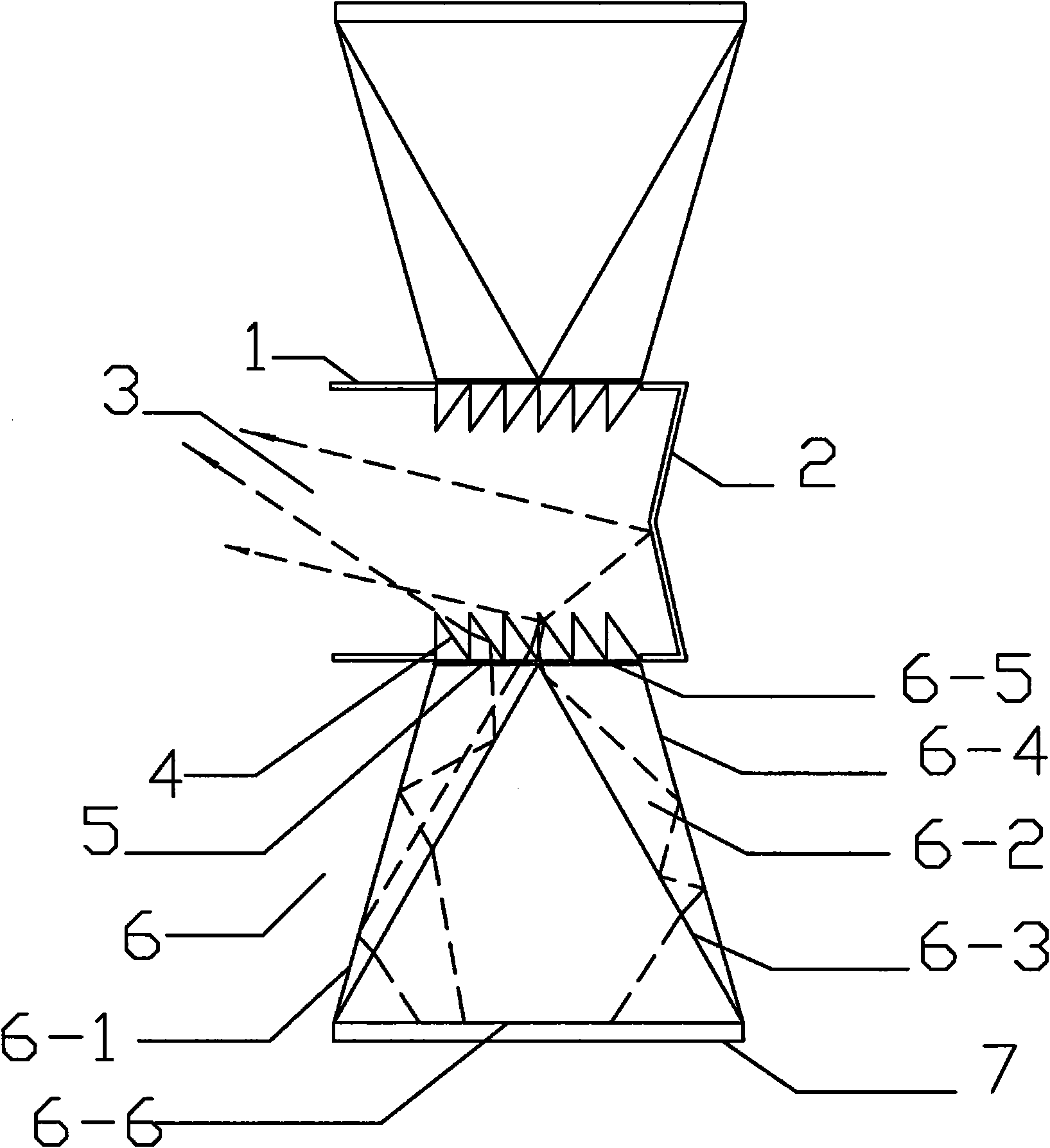

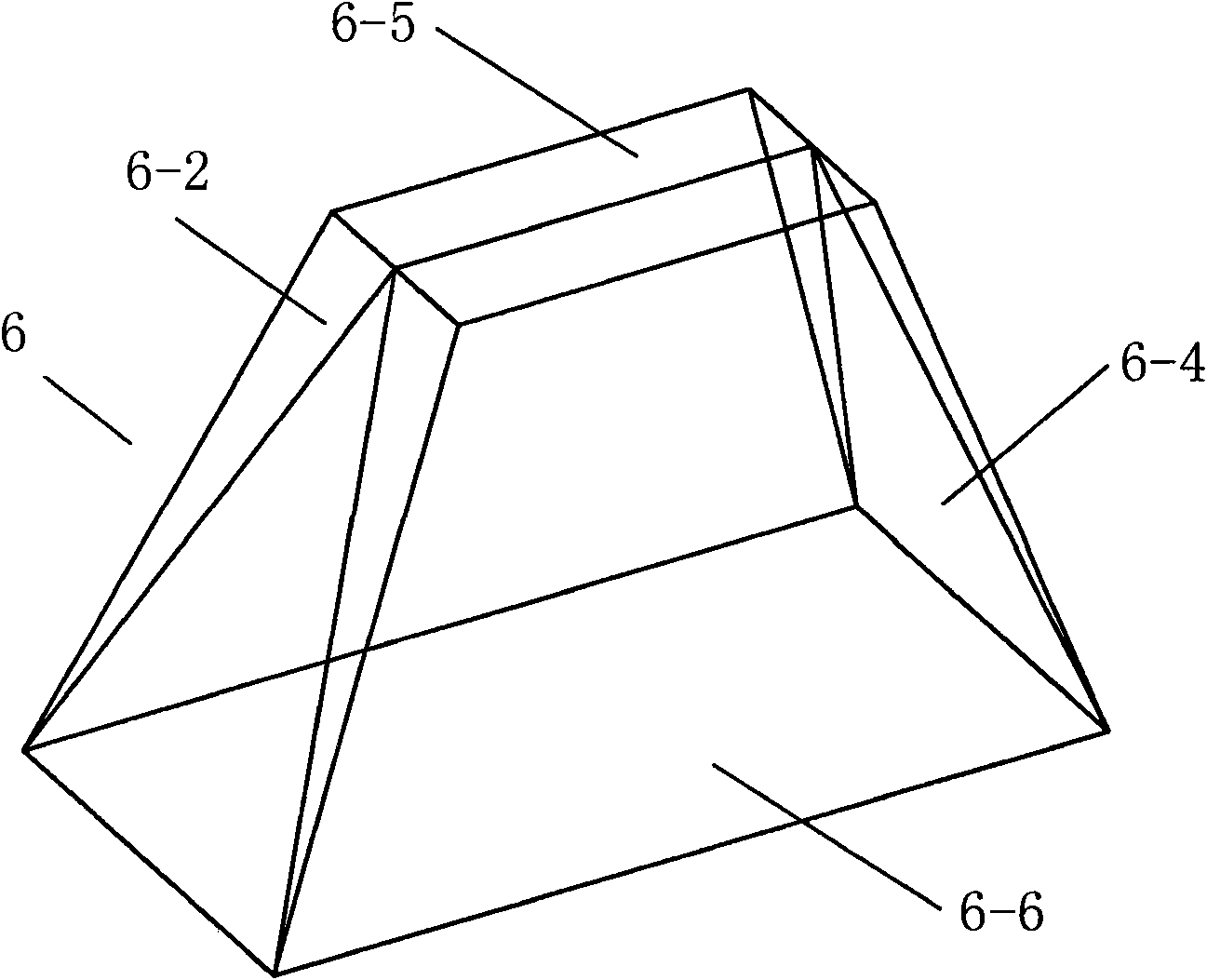

Solid state light source device

InactiveCN101539271AIncrease the effective luminous areaPlay a cooling roleMechanical apparatusPoint-like light sourceLight guidePrism

The invention relates to a solid state light source device, which comprises a hollow optical component which has a cavity containing air, vacuum or other light-transmitting mediums. The optical component provided with a light outlet is polyhedron-shaped and is provided with at least one light inlet, at least one light guide prism corresponding to the light inlet, and a surface illuminator corresponding to the bottom surface of the light guide prism. Reflection parts are arranged inside the optical component or inside and outside the optical component. A frustum-shaped light guide part of which the light incident area is larger than the light emergent area is arranged between the light inlet of the optical component and the surface illuminator; and after passing through the frustum-shaped light guide part, the light emitted by the surface illuminator is refracted or completely reflected by the light guide prism, and then is reflected by the reflection parts or directly emitted via the light outlet. As the frustum-shaped light guide part of which the light incident area is larger than the light emergent area is arranged between the light inlet of the optical component and the surface illuminator, the solid state light source device can enlarge the effective light-emitting area of the surface illuminator without changing the sizes of the optical component and the light inlet.

Owner:曹嘉灿

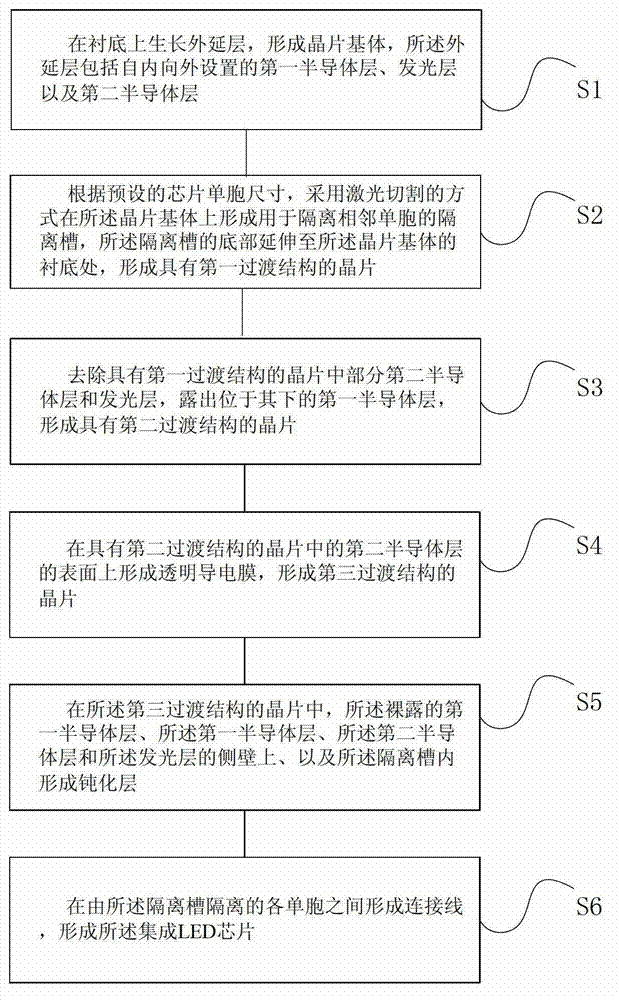

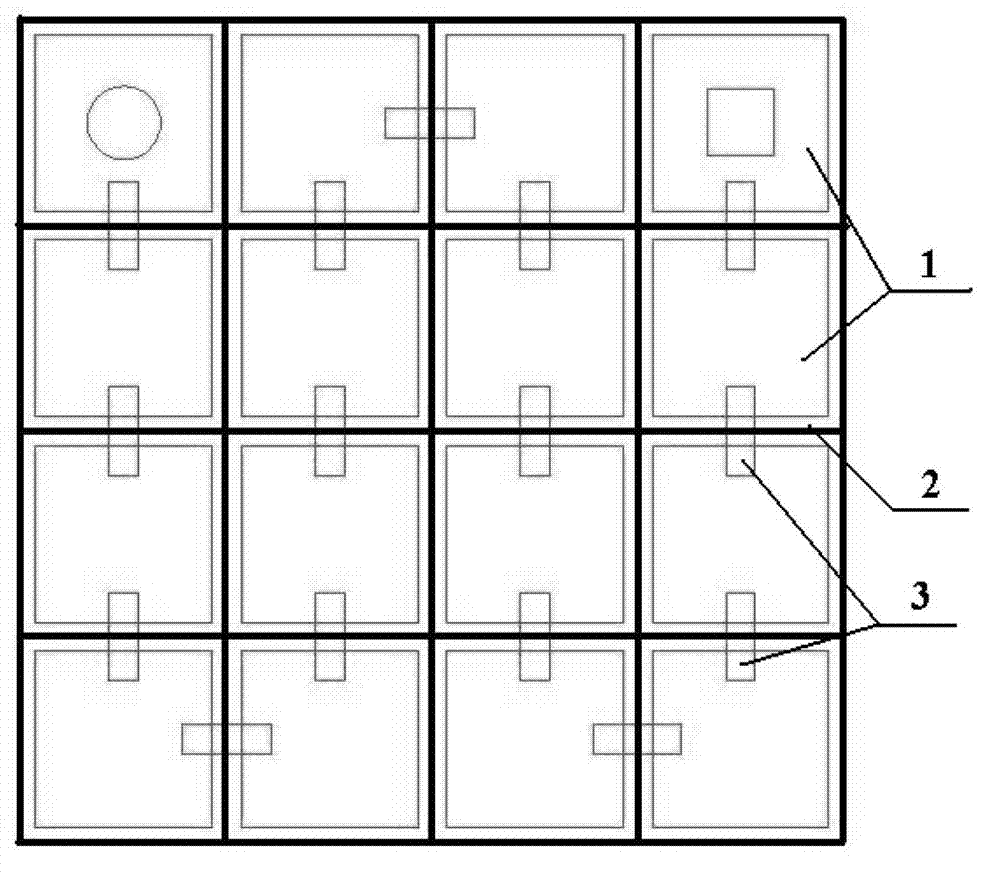

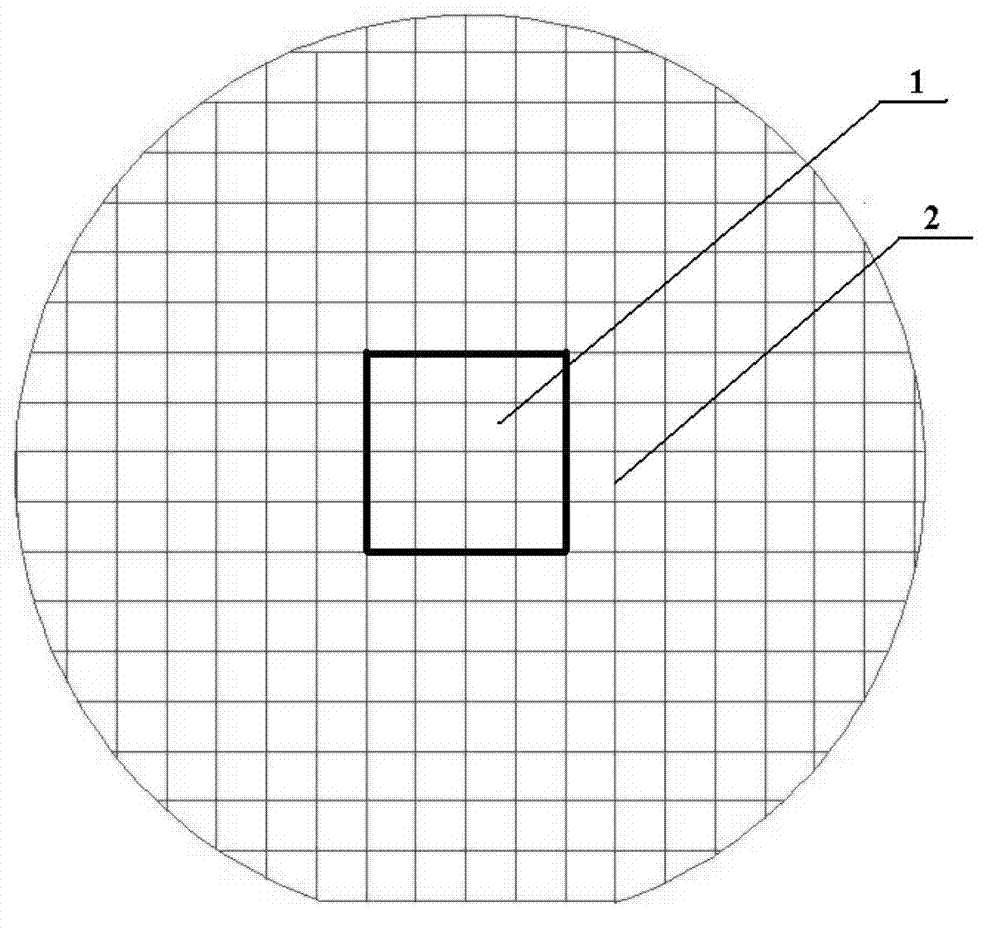

Integrated LED (Light Emitted Diode) chip and manufacturing method thereof

ActiveCN102969412AAchieve electrical isolationReduce spacingSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorEngineering

The invention discloses an Integrated LED (Light Emitted Diode) chip and a manufacturing method thereof. The method comprises the following steps of: S1, growing an epitaxial layer on a substrate to form a wafer matrix; S2, on the wafer matrix, forming an isolation groove for isolating adjacent mono-cells by laser cutting, wherein the bottom of the isolation groove stretches to the substrate of the wafer matrix; S3, removing a part of a second semiconductor layer and a emitting layer to enable a first semiconductor layer under the second semiconductor layer and the emitting layer to be exposed; S4, forming a transparent conductive film on the surface of the second semiconductor layer; S5, forming a passivation layer on a side wall and in the isolation groove, wherein the side wall formed by the superposition of the first semiconductor layer, the second semiconductor layer and the emitting layer; and S6, forming metal connecting wires among the mono-cells isolated by the isolation groove, so as to form the integrated LED chip. According to the Integrated LED (Light Emitted Diode) chip and the manufacturing method thereof disclosed by the invention, by forming the isolation groove by means of laser cutting, the manufacturing process is simplified, the production efficiency is improved, and the effective light-emitting area of the chip is increased.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

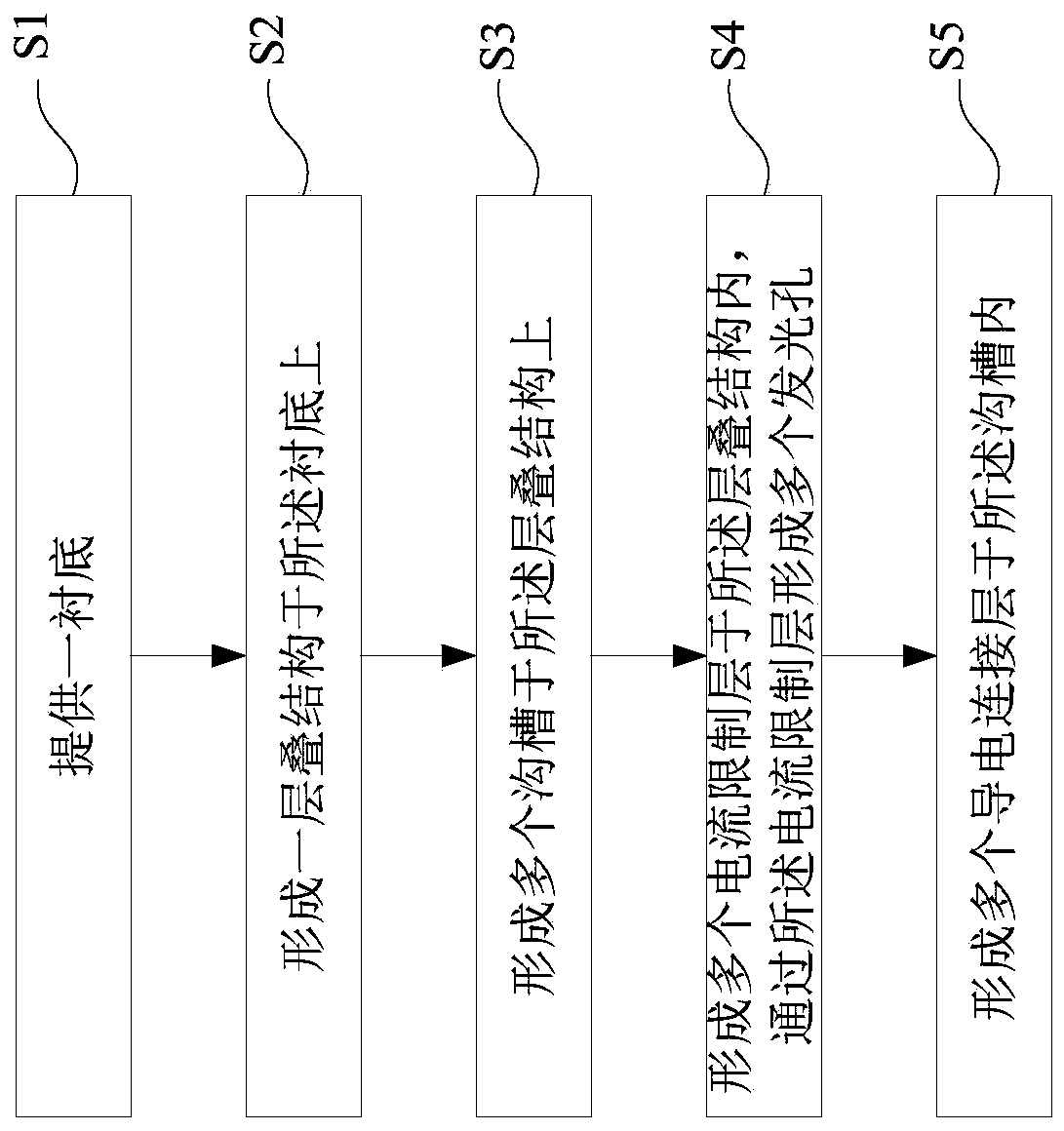

Vertical cavity surface emitting laser array and manufacturing method and application thereof

ActiveCN111313234AIncrease energy densityIncrease the effective luminous areaLaser detailsLaser optical resonator constructionVertical-cavity surface-emitting laserErbium lasers

The invention provides a vertical cavity surface emitting laser array and a manufacturing method and application thereof. The vertical cavity surface emitting laser array comprises at least two emitters, wherein each emitter comprises at least two emitting units, and a first conductive connection layer is arranged between the emitting units; and at least two insulating regions which are arranged between at least two emitters, wherein at least two emitters are connected in series. The vertical cavity surface emitting laser array can improve the light emitting area.

Owner:VERTILITE CO LTD

OLED device with high stability and preparation method thereof

ActiveCN109887959APermeation barrierSmall shrinkageSolid-state devicesSemiconductor/solid-state device manufacturingBiomedical engineeringElectrode material

The invention provides an OLED device with high stability and a preparation method thereof, the device includes a substrate, a first electrode material layer disposed on the substrate, and isolation posts. The first electrode material layer is patterned to form a plurality of first electrode cells, a first patterned region is arranged between adjacent first electrode cells, the isolation posts areparallel to and spaced from one another, and are perpendicular to the direction of the first electrode cell. The device is characterized in that at least a portion of the isolation columns are in direct contact with the first electrode cells and / or the substrate. By not providing an insulating material layer under the isolation column, the stability of the screen body is improved, and the pixel opening rate is effectively increased.

Owner:GUAN YEOLIGHT TECH CO LTD

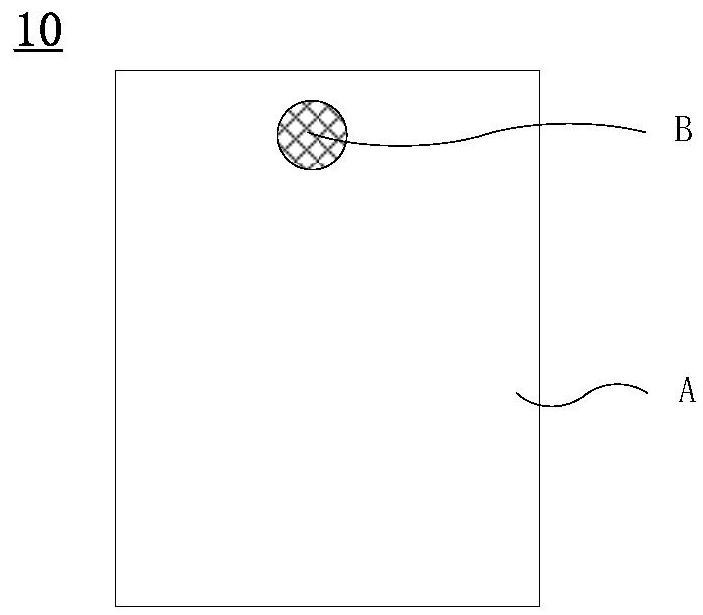

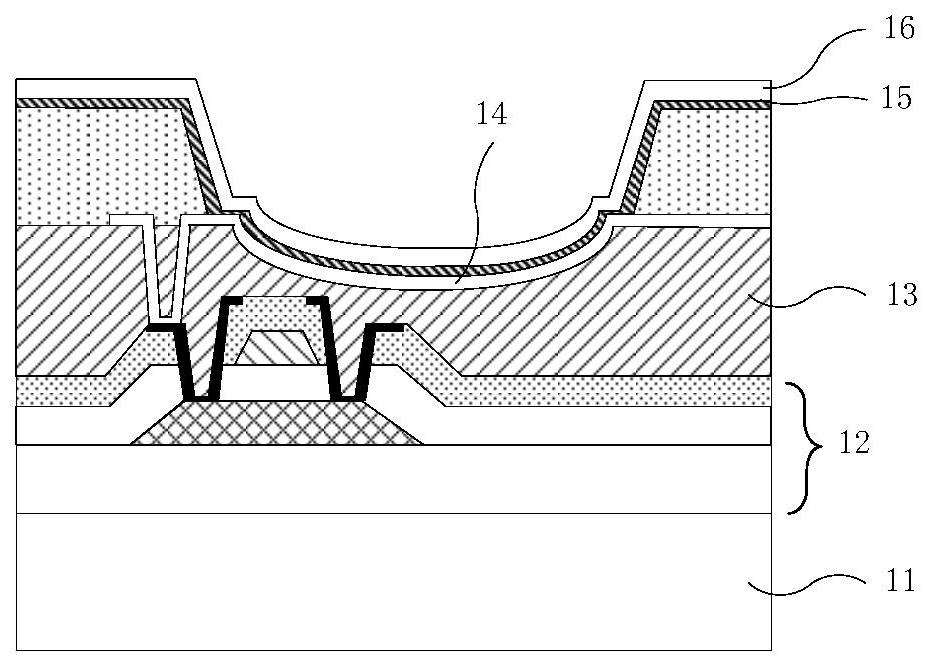

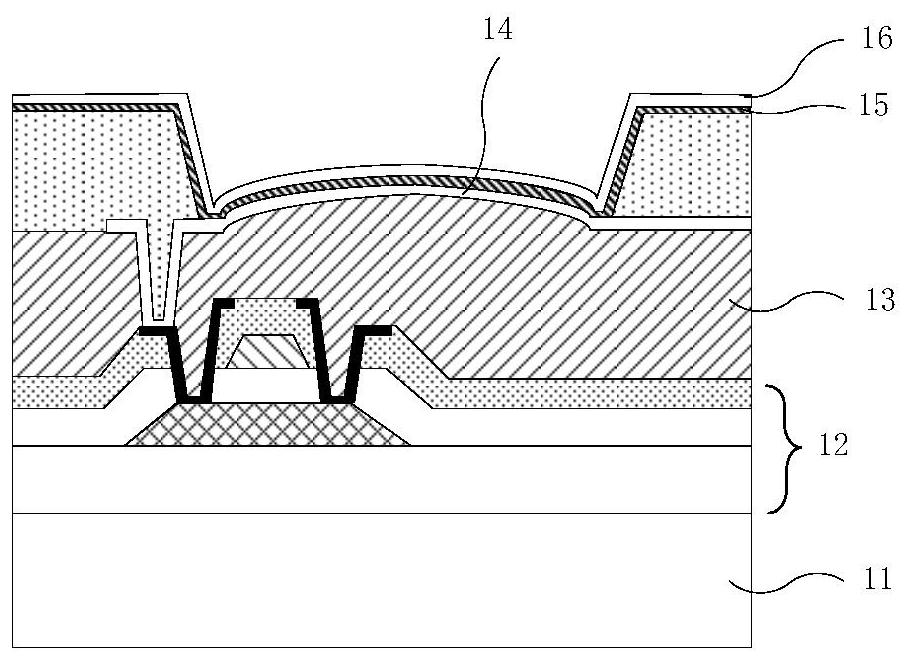

Organic light emitting display panel, method of manufacturing same, and organic light emitting display device

PendingCN114823784AImprove photoelectric performanceIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingWave structureDisplay device

The invention provides an organic light-emitting display panel, a manufacturing method thereof and an organic light-emitting display device, and the organic light-emitting display panel comprises a display region and a camera region. Each of the camera shooting area and the display area comprises a substrate and a plurality of pixel units formed on the substrate, and an organic light emitting diode of each pixel unit comprises a stacked structure formed by an anode, an organic light emitting layer and a cathode; in the camera shooting area, the stacked structure of at least one organic light-emitting diode is a curved surface structure or a wave structure, and the curved surface structure faces the substrate or is opposite to the substrate. According to the organic light-emitting display panel, the manufacturing method thereof and the organic light-emitting display device, the OLED device in the camera shooting area is designed to be of the curved surface structure or the wave structure, so that the effective light-emitting area is increased, the photoelectric performance and the brightness of the OLED device in the camera shooting area are improved, the parallax problem is solved, and the user experience is improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

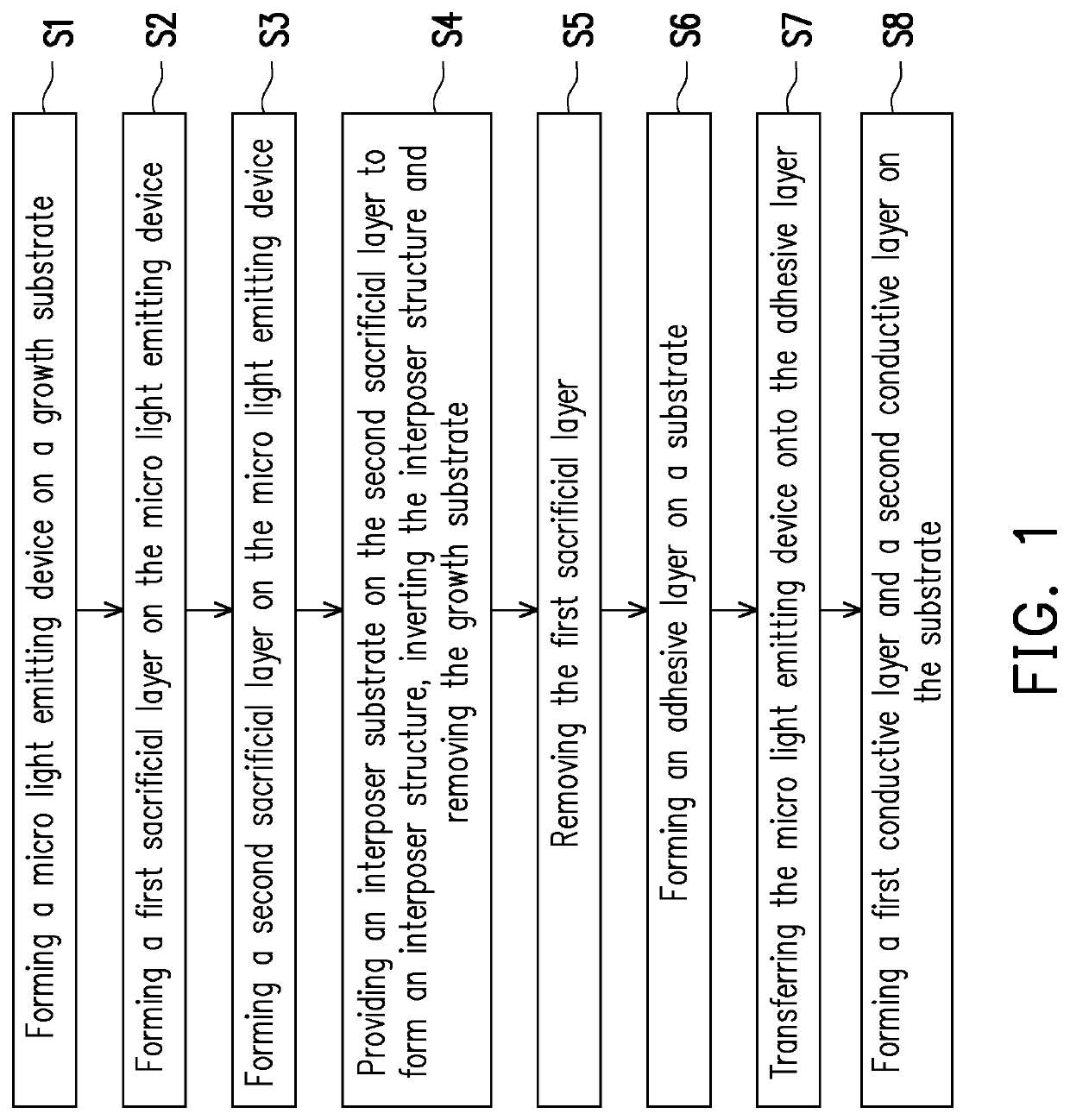

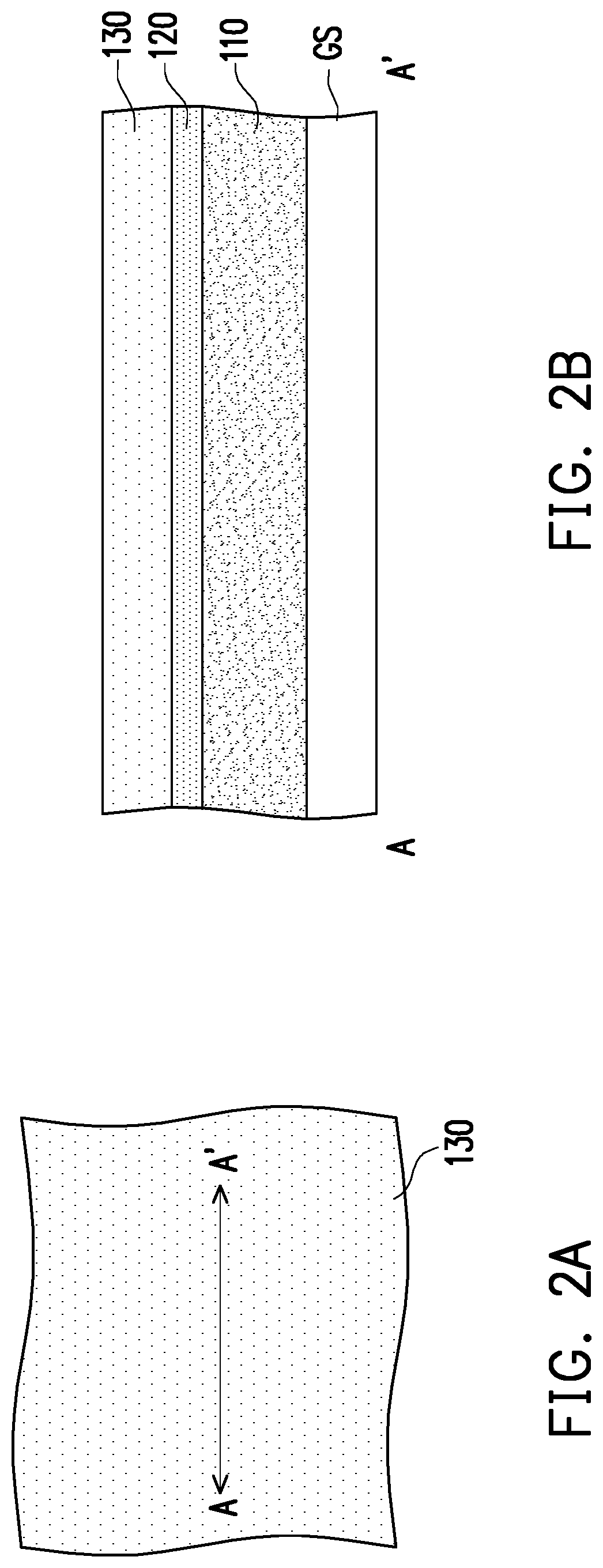

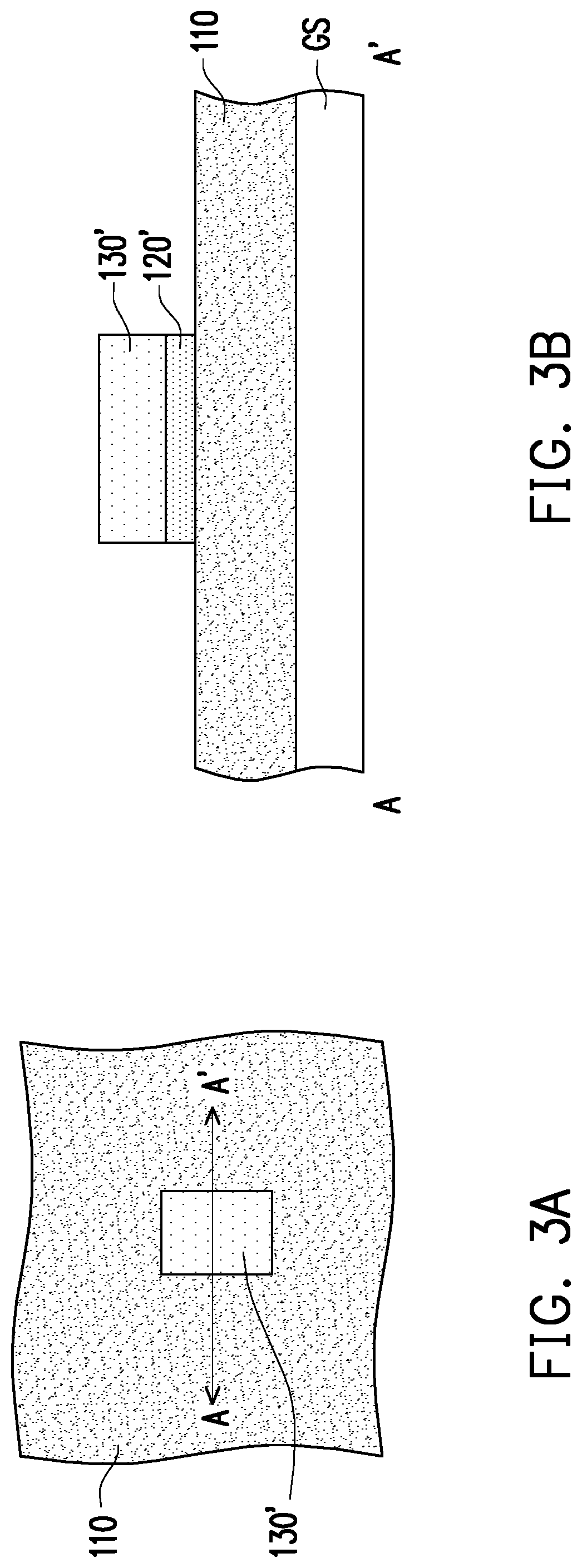

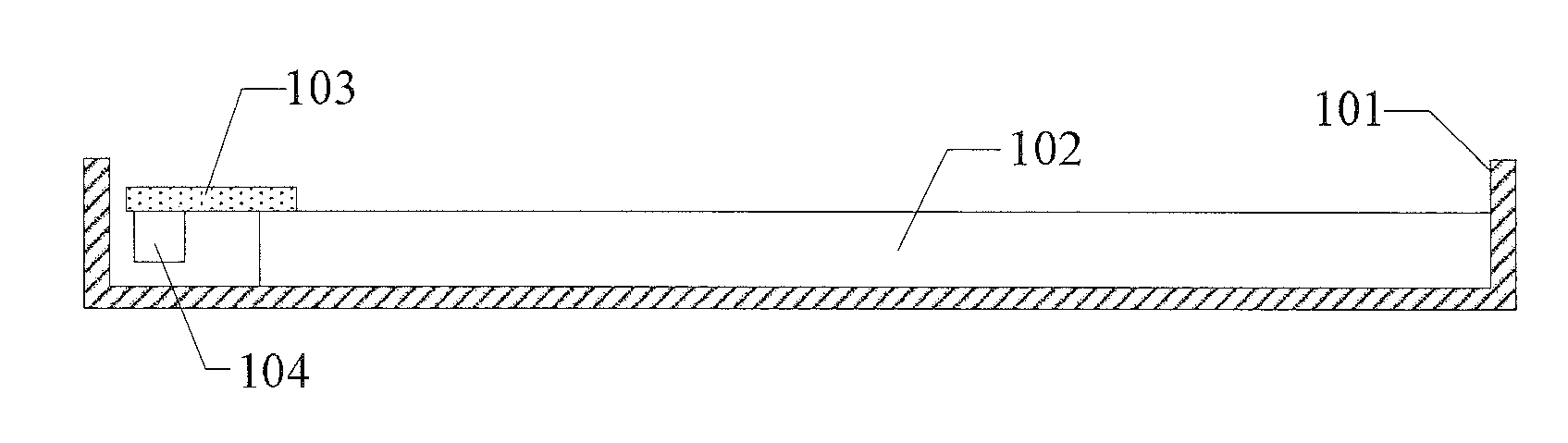

Light emitting device and manufacturing method thereof

ActiveUS20200028030A1Increase the effective luminous areaSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceSemiconductor

A light emitting device includes a substrate, an adhesion layer, a micro light emitting device (μLED), a first conductive layer, and a second conductive layer. A light emitting surface of the μLED is away from the substrate. The μLED includes a first semiconductive layer, a second semiconductive layer, a tether layer, a first electrode, and a second electrode. The tether layer covers a portion of sidewalls of the first semi-conductive layer, a portion of a bottom surface of the first semi-conductive layer, sidewalls of the second semiconductive layer, and a portion of a bottom surface of the second semiconductive layer. The first electrode and the second electrode are respectively electrically connected to the first semiconductive layer and the second semiconductive layer. The first conductive layer and the second conductive layer are respectively electrically connected to the first electrode and the second electrode.

Owner:AU OPTRONICS CORP

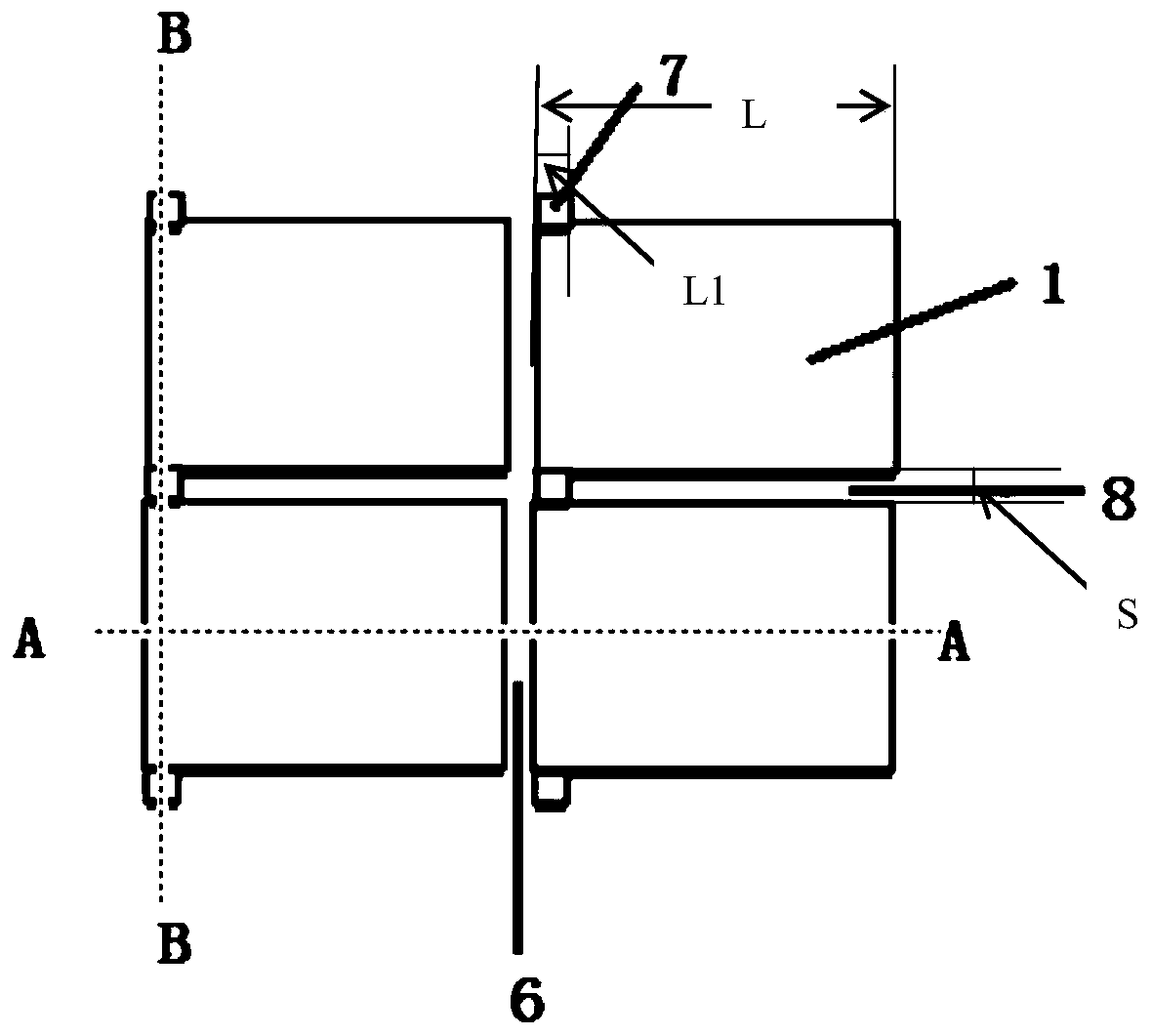

Backlight module and display apparatus

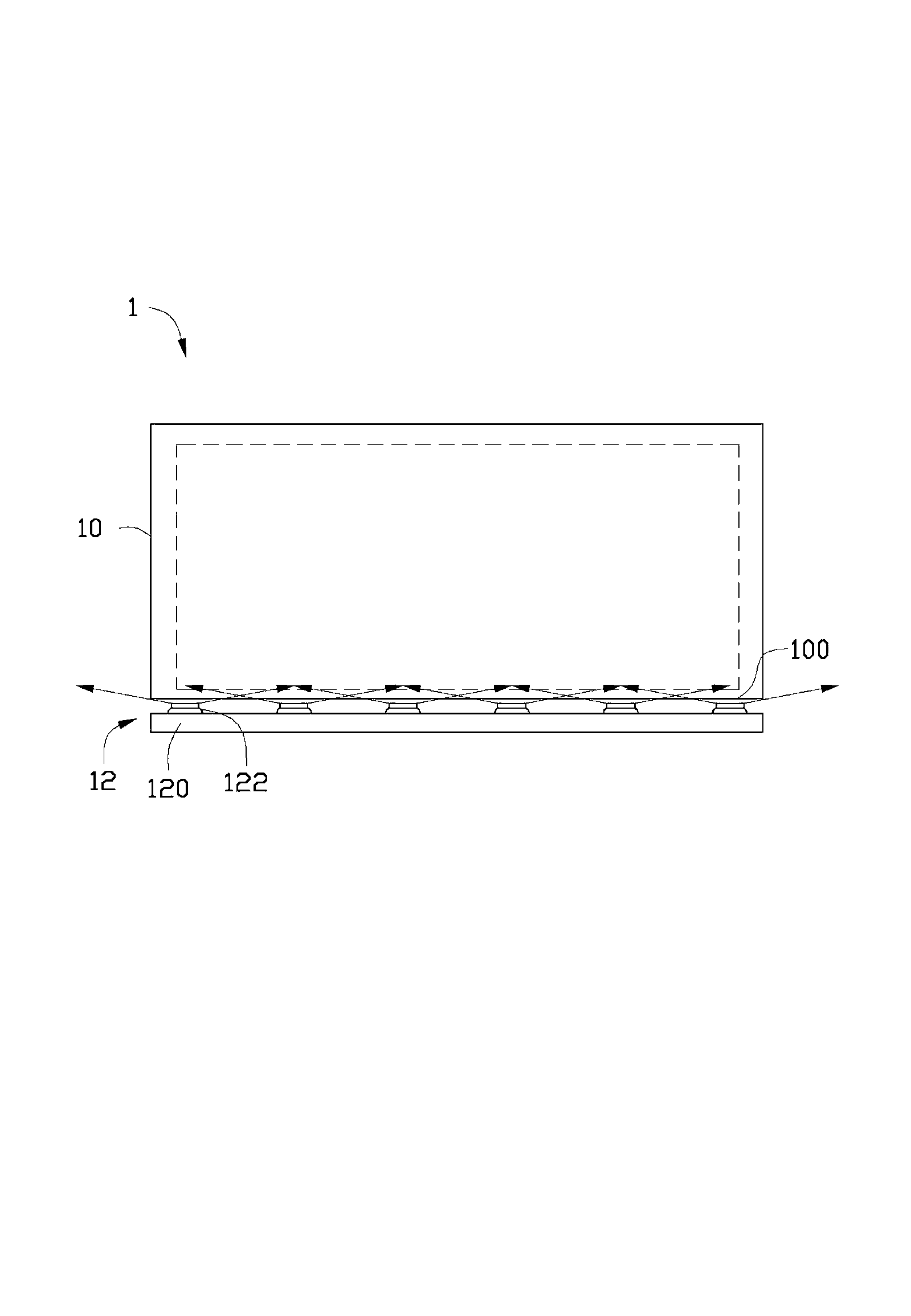

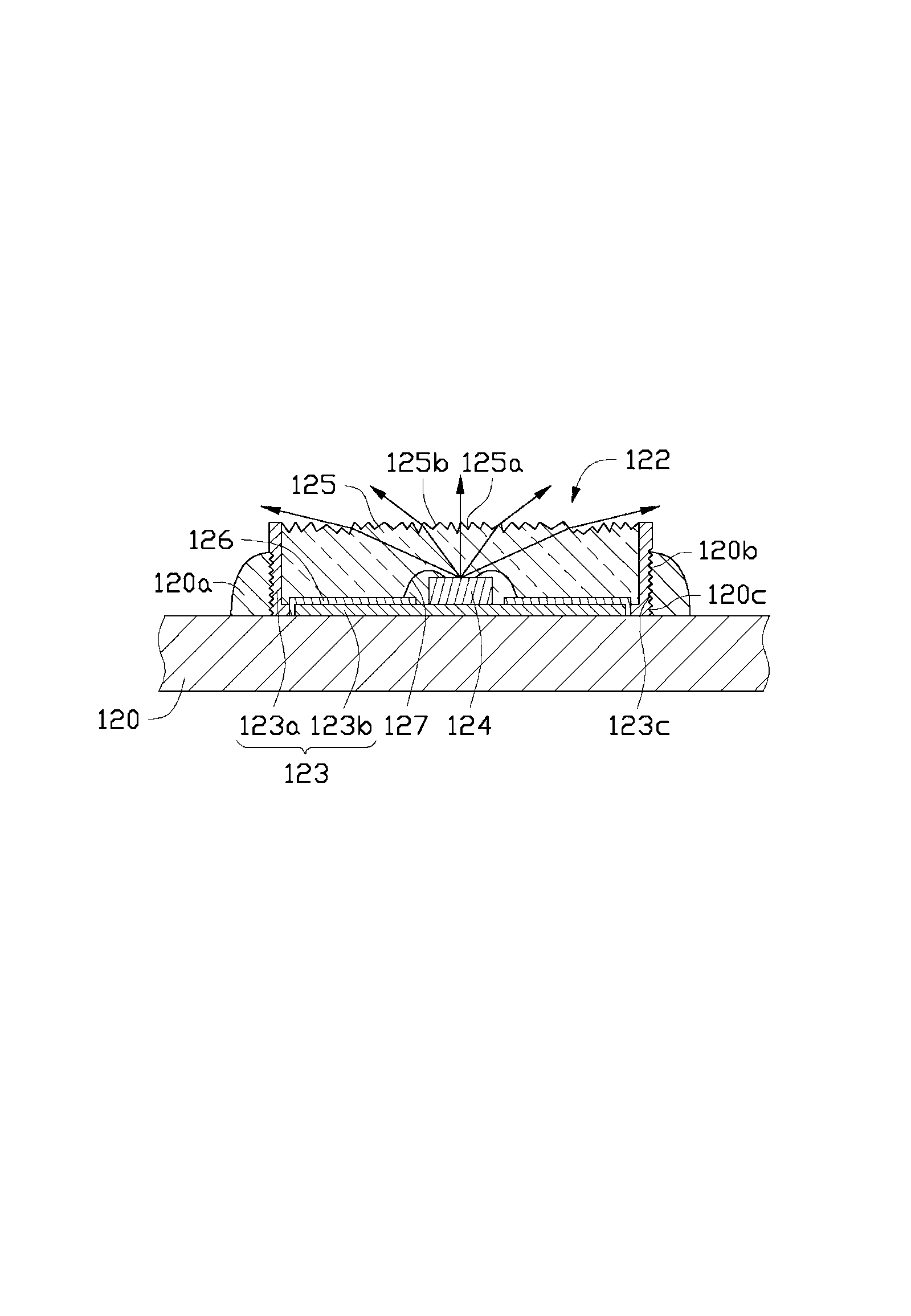

InactiveUS20160103277A1Reduce widthIncrease the effective luminous areaMechanical apparatusPlanar/plate-like light guidesElectricityLight guide

The present disclosure provides a backlight module and a display apparatus. The backlight module includes: a substrate configured to fix a plurality of light sources; the plurality of light sources fixed on the substrate and connected electrically to each other; and a light guide plate having at least one side on which a recess portion for receiving the plurality of light sources or receiving the plurality of light sources and at least part of the substrate is provided. At least the plurality of light sources are embedded into the recess portion, thus, the light emitted from the plurality of light sources may enter the light guide plate completely for utilization. Not only the brightness of the backlight module may be improved, but also the energy waste due to the part of the light of the plurality of light sources failing to enter the light guide plate may be avoided. And, at least the plurality of light sources being embedded into the recess portion may also reduce the width of non-light emitting region on a light incidence side of the backlight module, so as to reduce the width of the frame of the backlight module and to increase an effective light emitting area of the backlight module.

Owner:BOE TECH GRP CO LTD +1

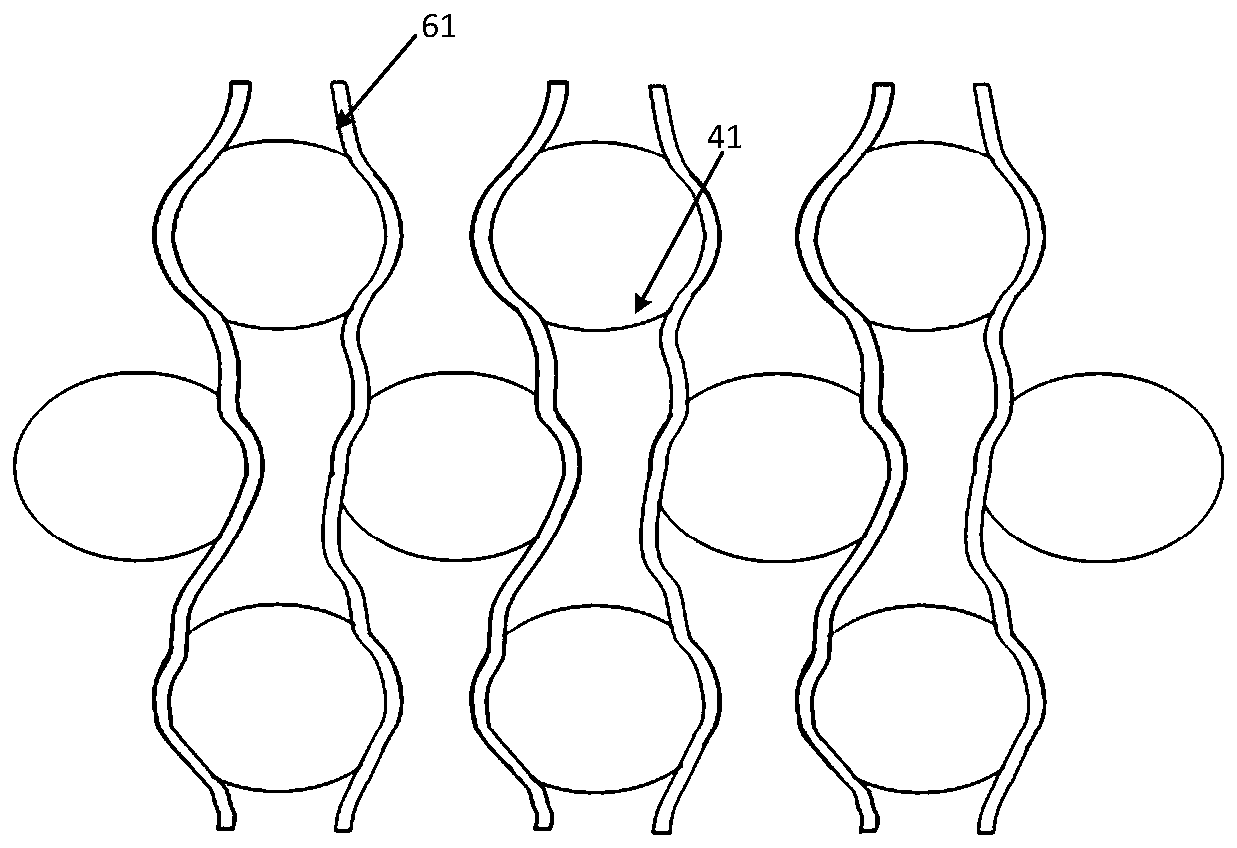

Light-emitting diode and backlight module with light-emitting diode

InactiveCN103137841AIncrease the effective luminous areaReduce firefly phenomenonPoint-like light sourceElongate light sourcesLight-emitting diodeMicrostructure

The invention provides a light-emitting diode which comprises a baseplate, a light-emitting diode chip and an encapsulation body. The light-emitting diode is arranged on the baseplate and connected with the outside through the baseplate. The encapsulation body covers the light-emitting diode chip. A microstructure with the function of photodiffusion is arranged on a surface, facing towards a light outlet direction of the light-emitting diode chip, of the encapsulation body, and light emitted by the light-emitting diode chip is emitted out of the encapsulation body through the microstructure. The invention further provides a backlight module with the light-emitting diode.

Owner:XINCHENG TECH CHENGDU +1

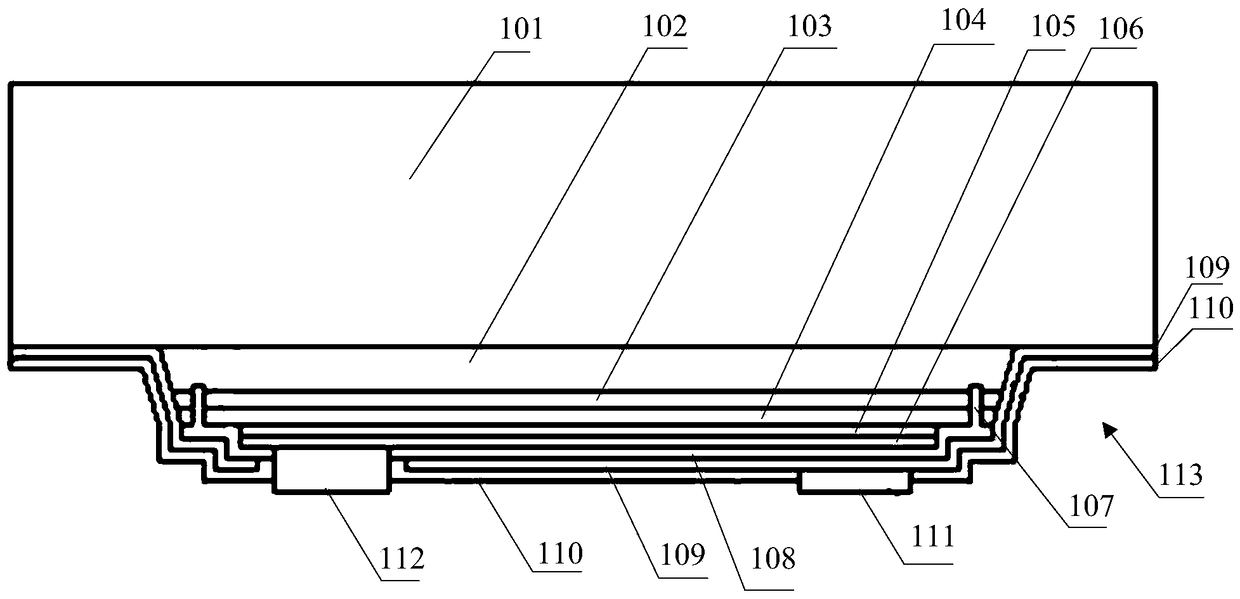

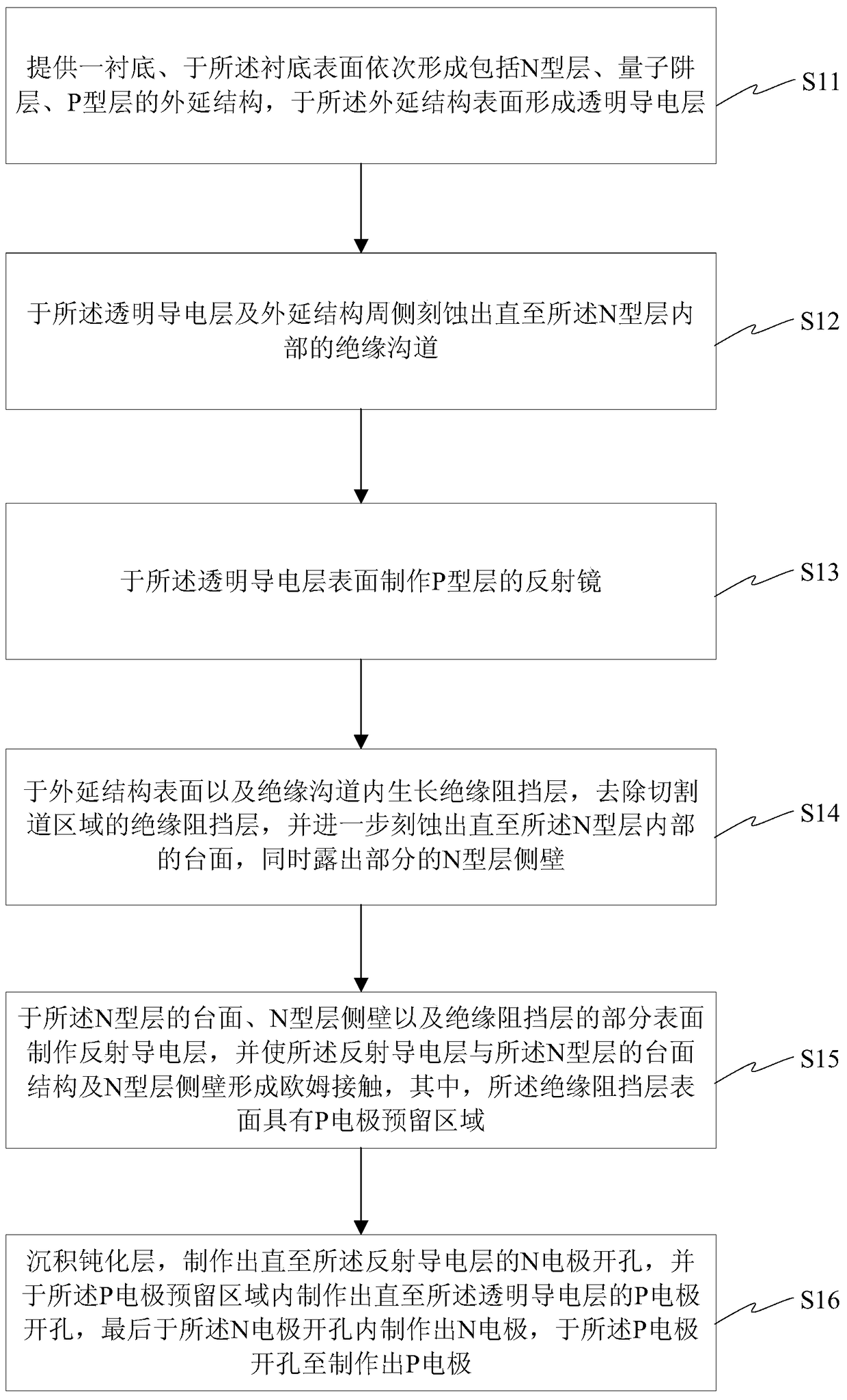

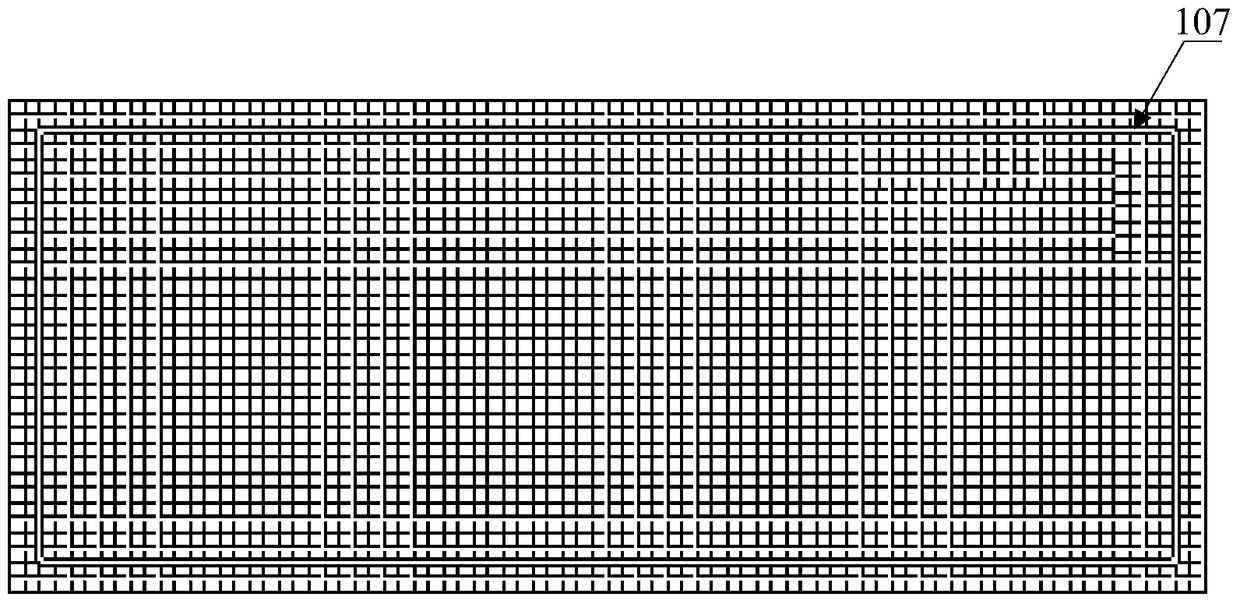

A flip-chip light-emitting diode chip and its manufacturing method

ActiveCN106711302BReduce leakage currentIncrease brightnessSemiconductor devicesLight-emitting diodeBrightness perception

The invention provides an inverted light emitting diode chip and a manufacturing method thereof. The inverted light emitting diode chip comprises a substrate, an epitaxy structure, a transparent conducting layer, a reflecting mirror, an insulation groove, an insulation barrier layer, a mesa structure, a reflective conducting layer, a passivation layer, an N electrode and a P electrode. According to the inverted light emitting diode chip and the manufacturing method thereof provided by the invention, a channel for insulation is formed on the periphery of the inverted light emitting diode chip, so that a leakage current of the chip can be reduced; the reflecting mirror is additionally arranged at a scribe line area, so that the product brightness is improved favorably; in addition, the derivation of N-GaN is manufactured on the side wall of the N-GaN and the scribe line area, so that the effective light emitting area of a light emitting diode can be greatly increased, and the brightness is improved; by means of an N reflective conducting layer and a P electrode reserving area, the N electrode and the P electrode can be directly manufactured after the passivation layer is tapped, so that the process step is reduced, and the production cost is reduced.

Owner:山东影响力智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com