Light-emitting diode and backlight module with light-emitting diode

A technology of light emitting diodes and light guide plates, applied in the field of backlight modules and light emitting diodes, can solve the problems of increasing the number of light emitting diodes, small light emitting angles of light emitting diodes, and increasing product cost, so as to increase the effective light emitting area and reduce the phenomenon of fireflies. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

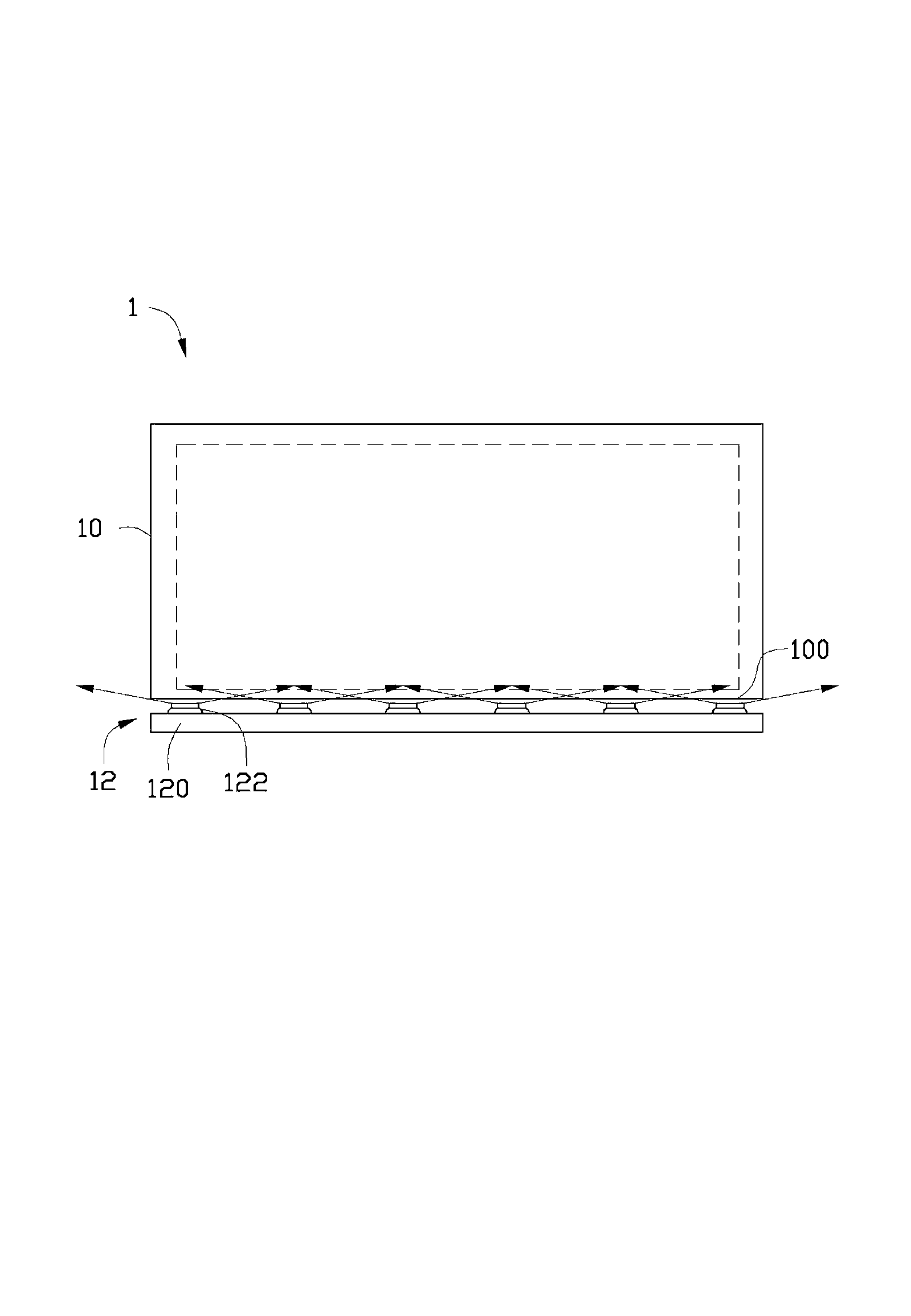

[0012] Such as figure 1 and figure 2 As shown, the backlight module 1 provided by the embodiment of the present invention includes a light guide plate 10 and an LED light source 12 . One of the side surfaces of the light guide plate 10 is the light incident surface 100 . The LED light source 12 is disposed towards the light incident surface 100 of the light guide plate 10 . The light emitted by the LED light source 12 is evenly mixed by the light guide plate 10 to provide backlight for the liquid crystal panel.

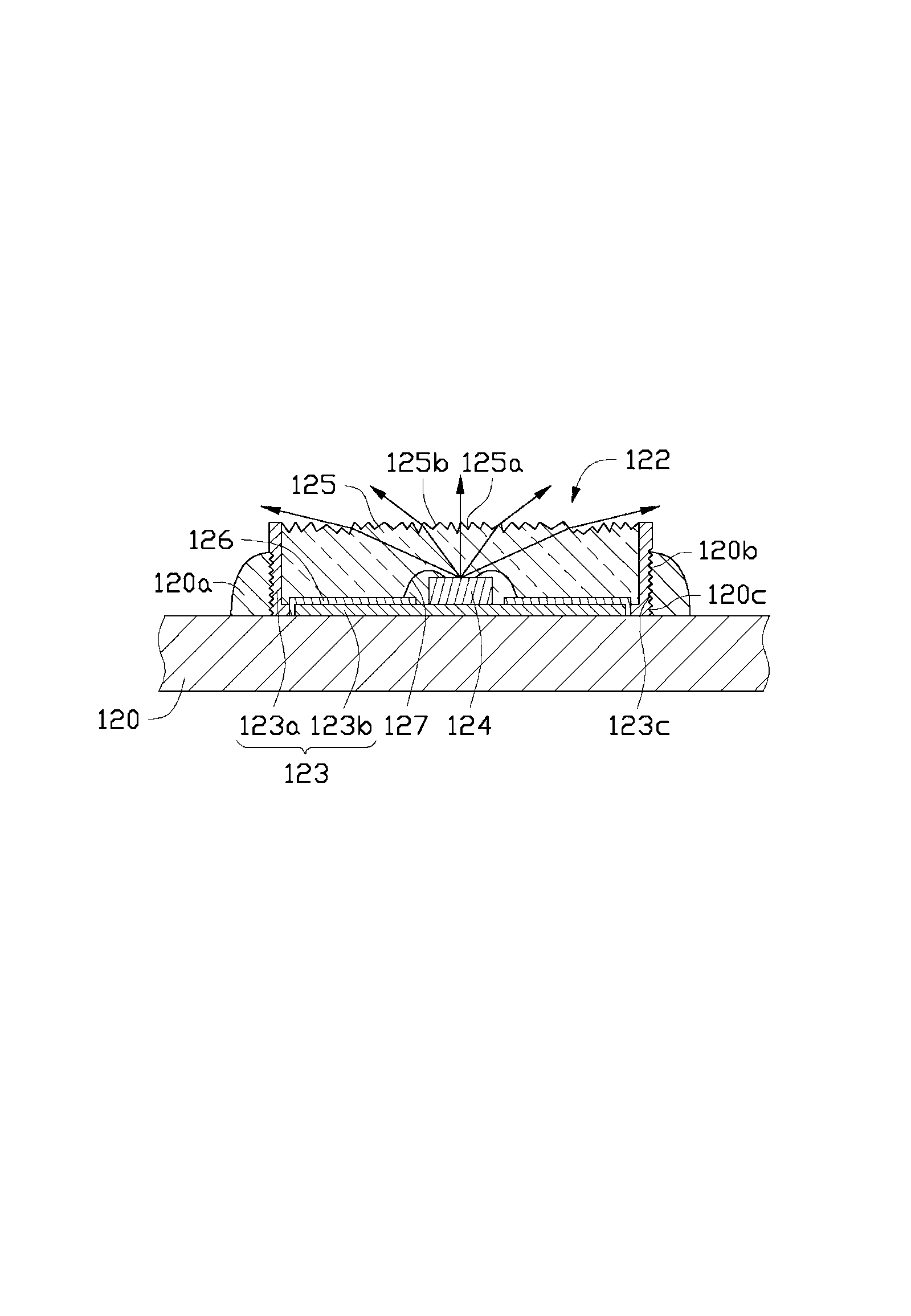

[0013] The LED light source 12 includes a light bar 120 and a plurality of LEDs 122 disposed on the light bar 120 . The light bar 120 is an elongated strip. One side of the light bar 120 is provided with a plurality of positioning structures 120a at equal intervals, and the light emitting diodes 122 are disposed on the positioning structures 120a. In this embodiment, the positioning structure 120a is a plurality of positioning blocks with fixing through holes 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com