LED chip and processing technology thereof

An LED chip and processing technology technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of affecting the thermal stability of the chip, the area cannot emit light, and the effective light-emitting area of the die is reduced, so as to improve the brightness and light extraction efficiency, The effect of improving brightness and luminous efficiency, and increasing the effective luminous area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

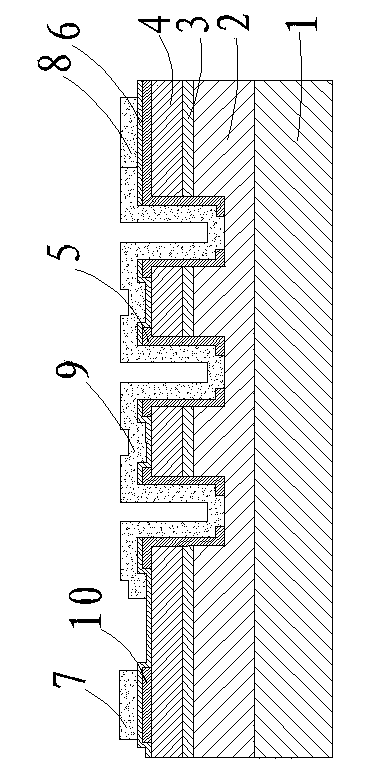

[0022] One, such as figure 1 As shown, the processing technology:

[0023] 1. Preparation of epitaxial substrate: N-type nitride layer 2, quantum well layer 3 and P-type nitride layer 4 are sequentially fabricated on substrate layer 1 such as sapphire (other materials used in the industry can also be used).

[0024] 2. Etching part of the P-type nitride layer 4 on the epitaxial wafer substrate, removing the P-type nitride layer 4 and the quantum well layer 3 in a part of the epitaxial wafer substrate, and exposing the N-type nitride layer 2 . The etching method can be inductively coupled plasma etching method, or electron cyclotron resonance etching method, or reactive ion etching method. The etching depth and process conditions are the same as the conventional LED manufacturing process.

[0025] 3. Make a current blocking layer under the designed P-type electrode pad area: use the PECVD growth method to grow an insulating material with a thickness of 2000? on the substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com