Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Improve film production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

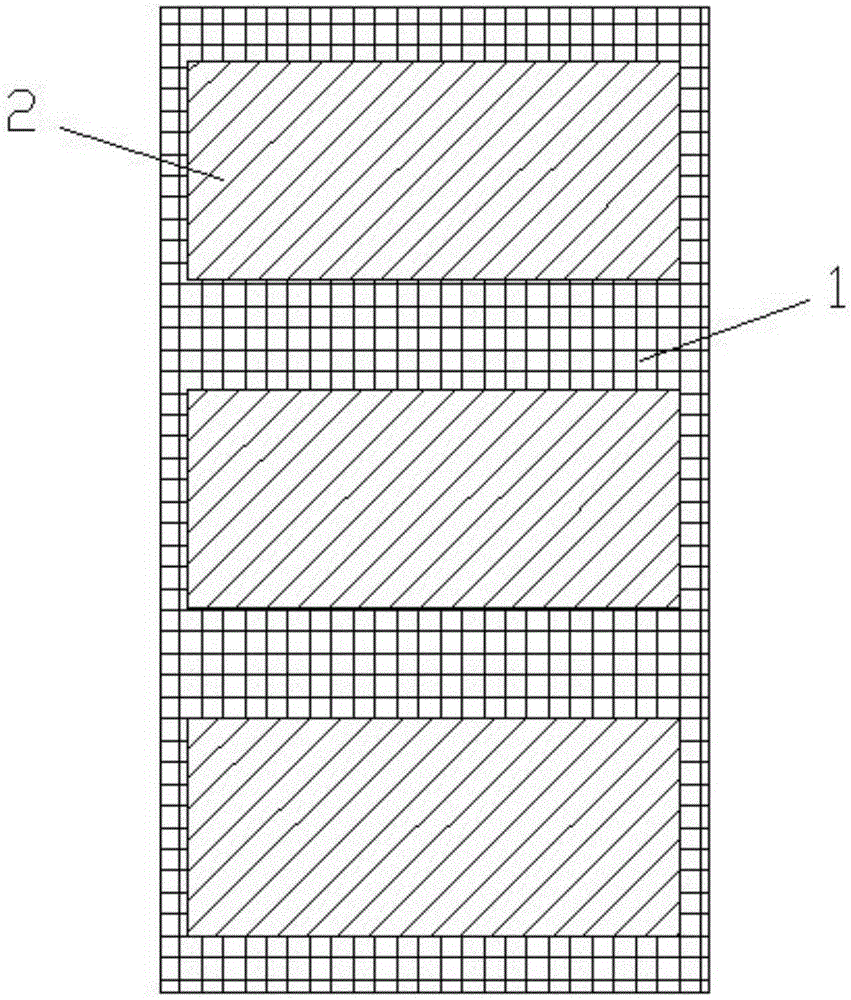

A kind of positive electrode of lithium ion battery and preparation method thereof

ActiveCN103715394BImprove bindingLight in massCell electrodesCell component detailsCarbon nanotubePole piece

The invention discloses a lithium ion battery anode and a preparation method thereof. The anode utilizes a carbon nano pipe film formed by a carbon nano pipe macroscopic pipe as a current collector, and an anode material layer is formed on the carbon nano pipe film. Compared with the traditional aluminum foil current collector anode, the lithium ion battery anode has the advantages that the weight of the lithium ion battery anode prepared by the method is light, and the anode material layer and the current collector are firmly combined. The preparation method comprises the following steps of preparing a high strength carbon nano pipe on a glass substrate by utilizing a carbon nano pipe macroscopic pipe continuum generated by a reactor port, generating the anode material layer on the carbon nano pipe film layer, separating the carbon nano pipe film layer with the anode material layer from and the glass substrate, and mounting a pole ear on a pole piece. Under the same size, the carbon nano pipe film is far lighter than the aluminum foil, the weight of the saved part can be replaced by the anode material, and the capacity of the battery is 15%-50% higher than that of a battery which takes the aluminum foil as an anode current collector. The lithium ion battery anode is low in cost, high in generation efficiency, simple in equipment, capable of realizing semicontinuous operation and suitable for mass production.

Owner:北京旭江科技有限公司

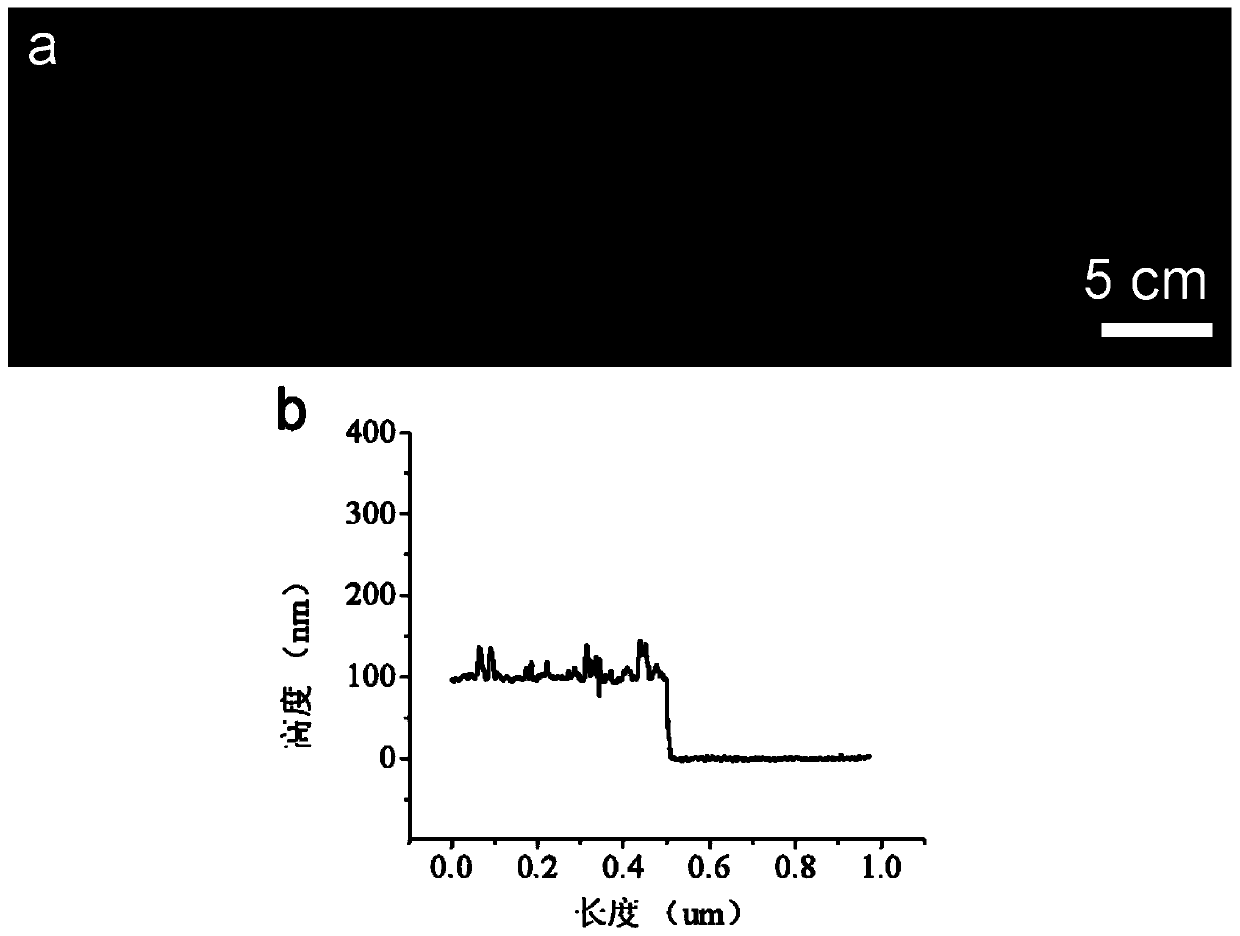

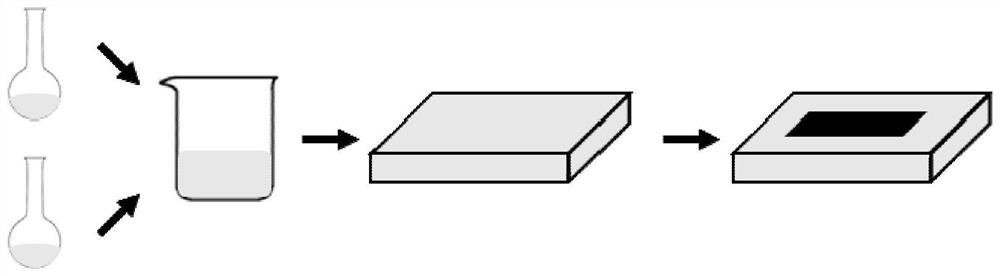

Film making method capable of precisely controlling film thickness and area of nanometer-thickness film

PendingCN110274803AEfficient and precise control of preparationControllable shapeMaterial nanotechnologyMaterial analysis using wave/particle radiationSpray nozzleEngineering

The invention relates to the field of preparation and application of a film material, in particular to a film making method capable of precisely controlling the film thickness and area of a nanometer-thickness film, thereby realizing high-efficiency control preparation of a nanometer-thickness film material with the uniform and consistent thickness. On the basis of the basic principle of a rotary centrifugal type film forming method, a printing spraying nozzle or pin head with a small aperture is used based on a base rotating device; under the conditions of the constant film forming liquid pressure and the controllable motion track, a certain amount of film forming liquid is sprayed on the surface of a film forming base at a certain rate in a micro liquid column manner, so that a uniform liquid film with the controllable thickness, shape, and area is formed; and thus a solid film material is obtained by controlling curing conditions. With the provided method, the high-efficiency and precise control preparation of the nanometer-thickness film material with the uniform thickness is realized. The film making method can be applied to technical fields of photoelectric devices, energy storage devices, protective functional coatings, catalytic materials, composite materials and the like widely.

Owner:深圳烯材科技有限公司

Polyvinyl chloride hollow fiber porous membrane preparation method

PendingCN108554204AImprove melt fluidityLower glass transition temperatureSemi-permeable membranesHollow filament manufactureWater bathsPolymer science

The invention discloses a polyvinyl chloride hollow fiber porous membrane preparation method. The method particularly comprises the following steps that 1, a formula is prepared, wherein 20-35% by mass of polyvinyl chloride, 8-25% by mass of water soluble ester solvent, 35-60% by mass of composite pore-foaming agent and 2-5% by mass of auxiliary additives are mixed uniformly to obtain the formula,wherein the sum of all ingredients is equal to 100%; 2, the formula is mixed to be uniform, then melt spinning is conducted by adopting a twin-screw extruder at 150-170 DEG C, after extrusion is conducted through a hollow spinning pack, winding is conducted through air bath and normal temperature coagulating bath in sequence, 1.5-4-time online stretching is conducted in a stretching water tank of60-80 DEG C, fixed-length heat setting is conducted for 40-90 min in water bath of 40-60 DEG C, and finally extraction washing is conducted with water to obtain a polyvinyl chloride hollow fiber porous membrane. The prepared polyvinyl chloride hollow fiber porous membrane has the uniform three-dimensional grid hole structure, and has good pressure resistance and mechanical property.

Owner:TIANJIN POLYTECHNIC UNIV

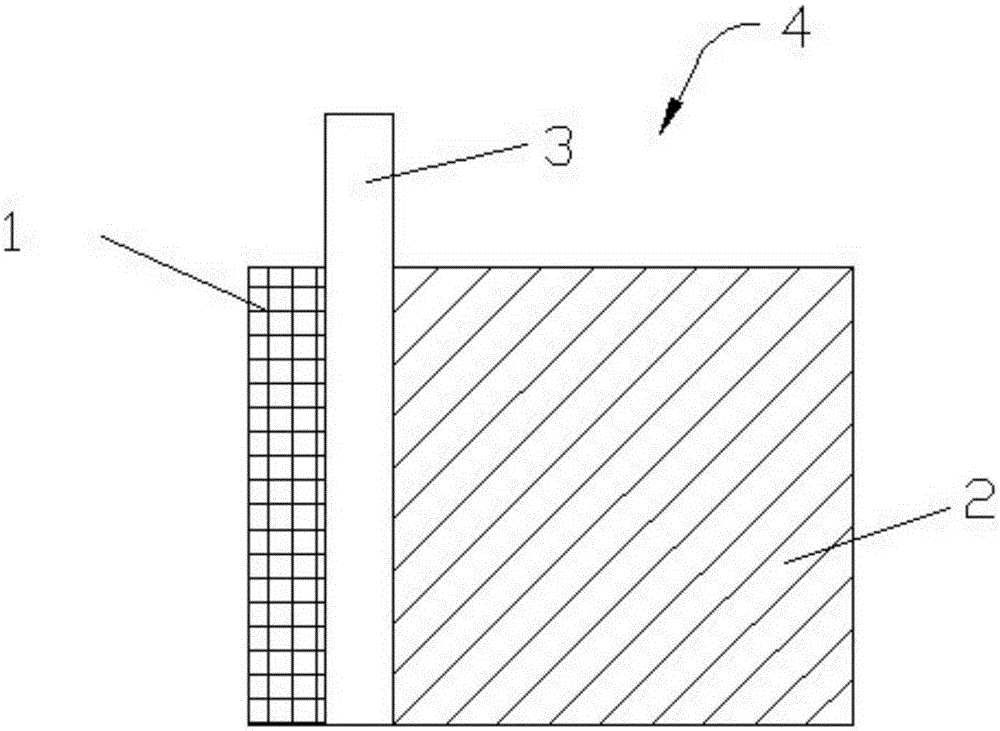

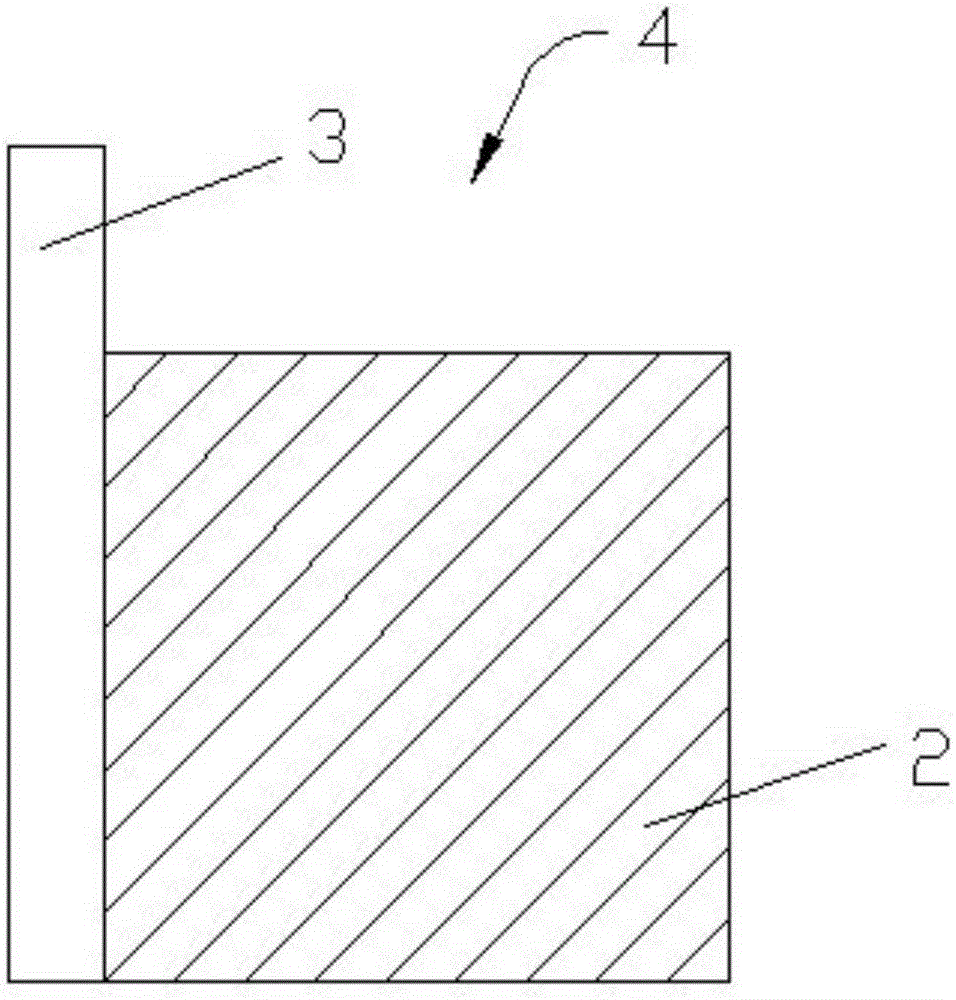

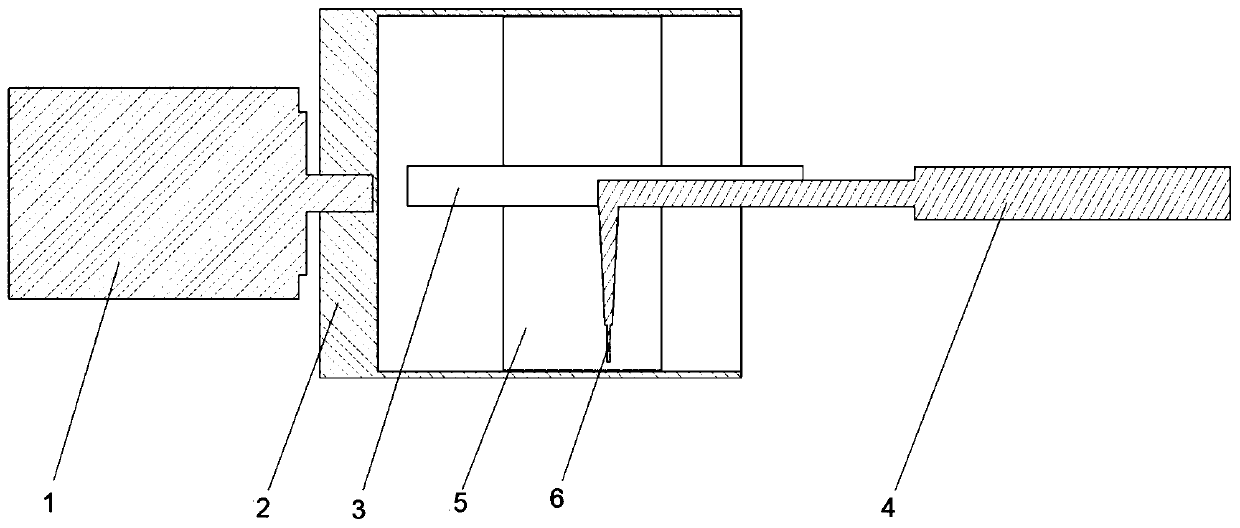

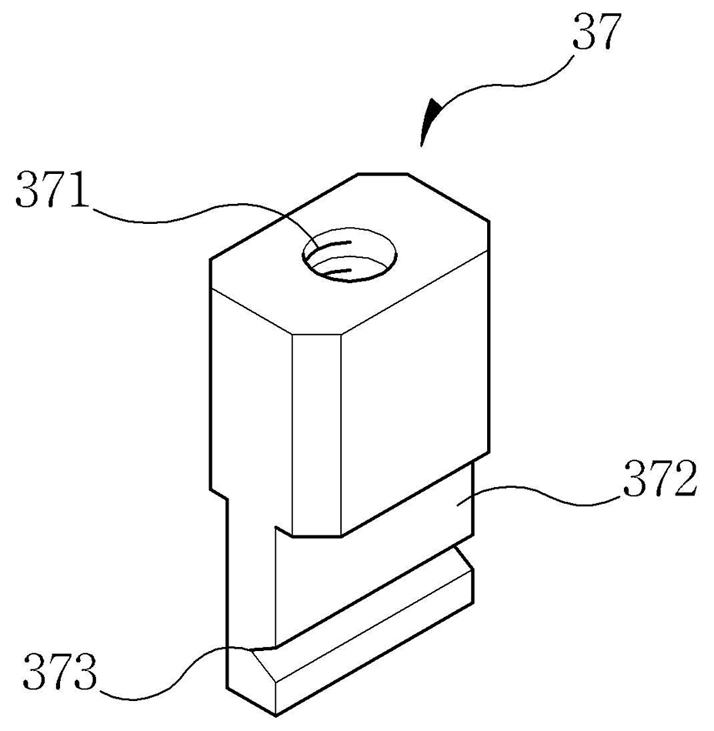

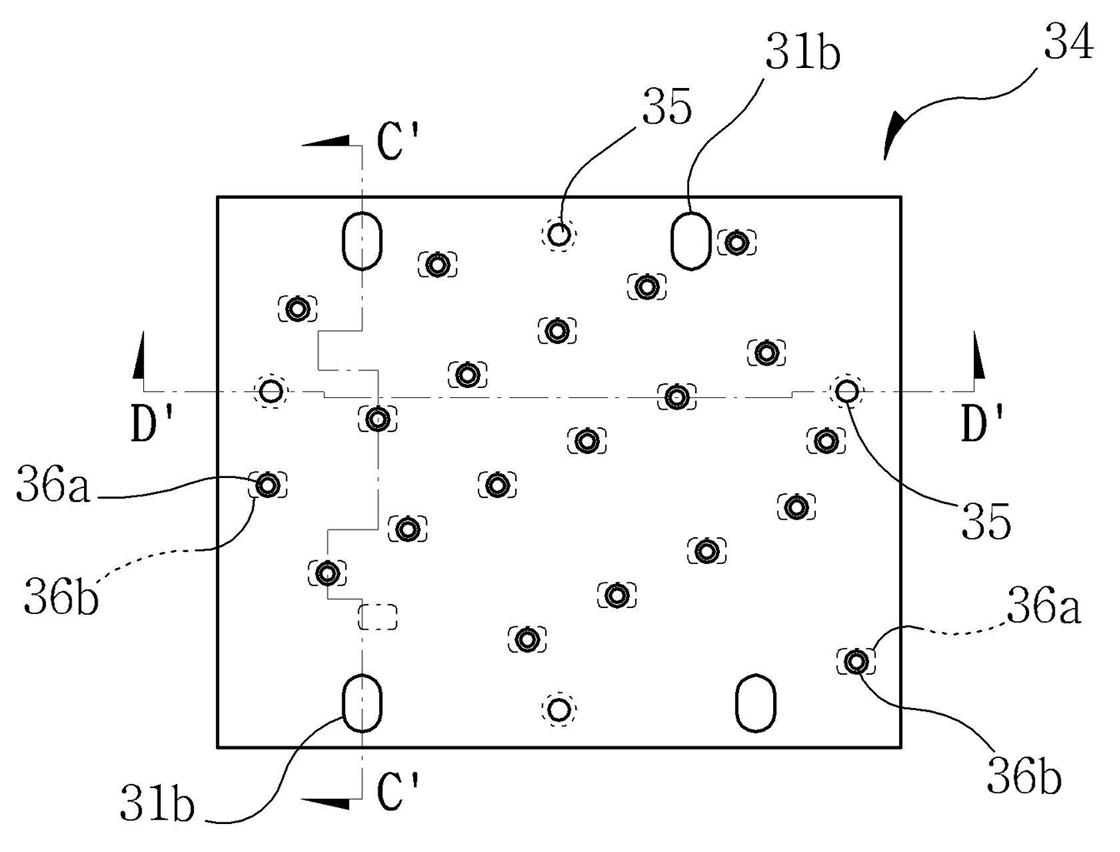

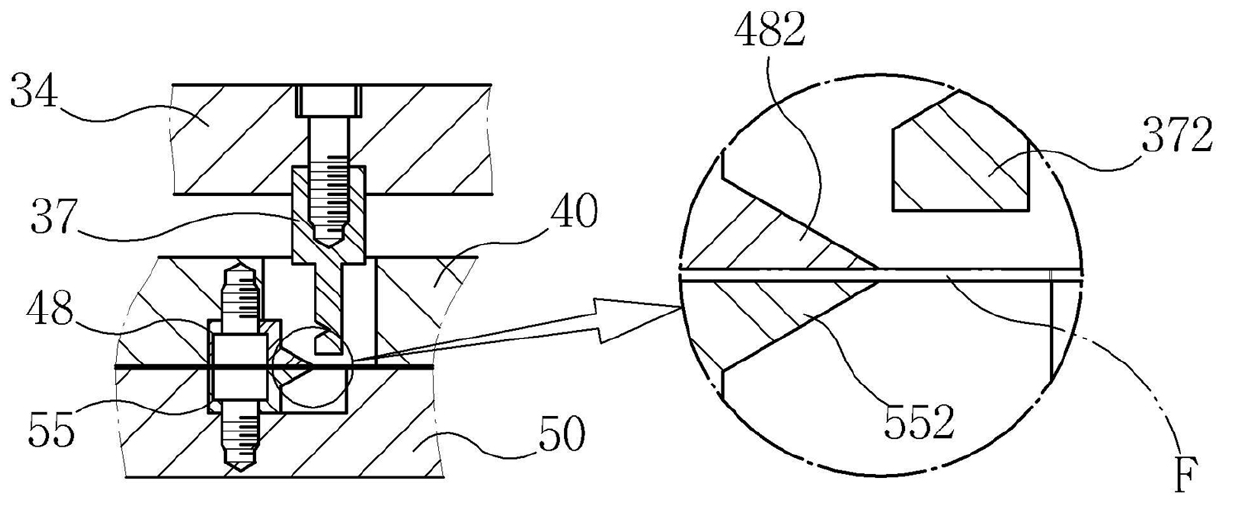

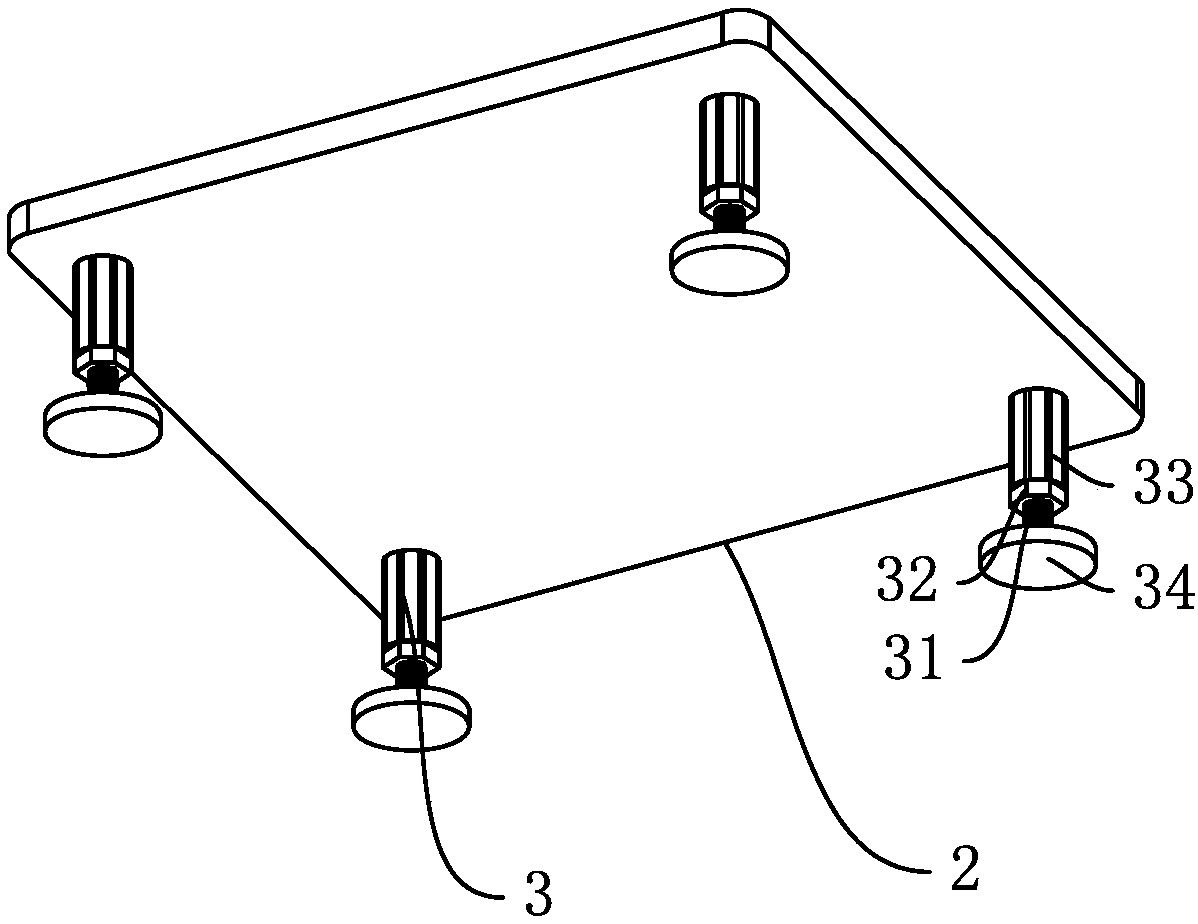

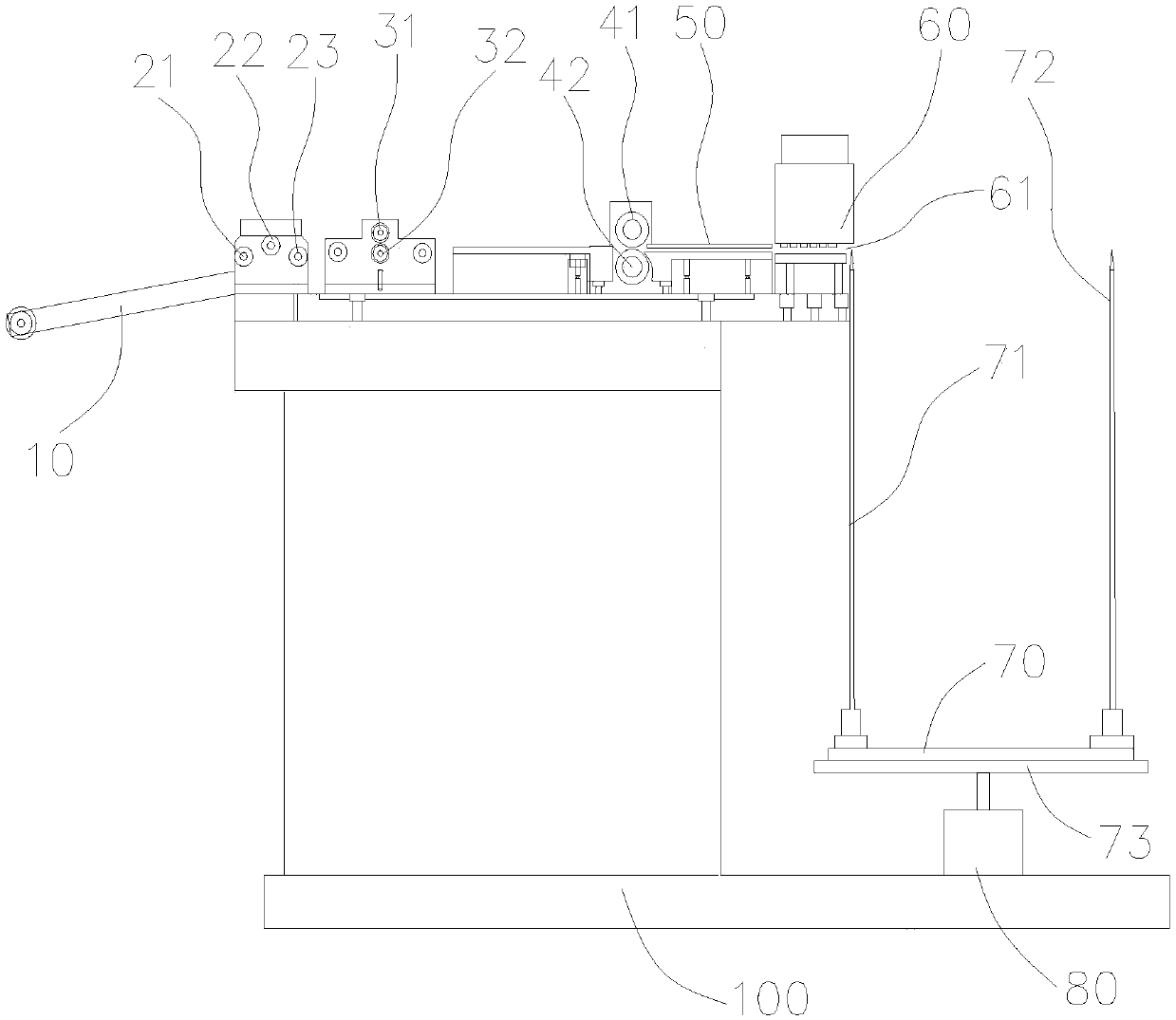

Film paraptera bending device

ActiveCN101947854AImprove film production efficiencySave human effortFlat articlesMetal working apparatusEngineeringSlide plate

The invention relates to a film paraptera bending device, used for forming a vertical and bending paraptera on the film of a panel. The invention provides a paraptera bending device. When a film forming an incision part is input, a paraptera is formed by automatically bending the inner side of the incision part. The paraptera bending device comprises a rack, a plurality of lifting rods disposed between a lifting stand and a bending platform, a lifting cylinder disposed on the lifting stand, a lifting plate which is combined with the lifting rod and is capable of lifting through the lifting cylinder, a sliding plate sliding back and forth on the lifting plate, a punch fixing plate combined with the sliding plate, a pressure plate which is capable of combining with the sliding plate through the lifting plate, and a bending plate disposed on top of a bending stand. The invention has advantages of conducting paraptera bending in a fast, correct and even way; improving the working efficiency of ink powder functioned film or various films for forming bending paraptera.

Owner:李昌永

Method for preparing a complex oxygen ion conductor electrolyte film by quick heat treatment of collosol and gel

InactiveCN1571203AAchieve preparationAccurate control of stoichiometric ratioFinal product manufactureSolid electrolyte fuel cellsElectrical conductorFilm material

The invention relates to a method for preparing multilayer compound nano oxygen ion conductor electrolyte film material, adopting rapid heat treatment sol-gel methd to prepare a multilayer film A / (B / A)n (A and B stand for YSZ or RCO, n>=1), where the preparing process for each film layer: sole precursor preparing, spin-spreading coating, rapid heat treatment, and film forming, in which, YSZ film preparation adopts ZrOCl2. 8H2O and Y(NO3)3.6H2O, uses ammonia as precipitator, uses thin hydrochloric acid to regulate pH value of solution, and uses glycol as metal chelating agent and the YSZ film is 10-400 nm thick; RCO film preparation adopts Ce(NO3)3.6H2O and R2O3, uses oxalic acid as precipitator and citric acid as metal chelating agent, and the RCO film is 10-400 nm thick. Circulating the above steps can prepare uniformly thick, compact, high-quality multilayer compound nano electrolyte film, shortening film making cycle, raising the efficiency, and reducing the cost.

Owner:DALIAN UNIV OF TECH

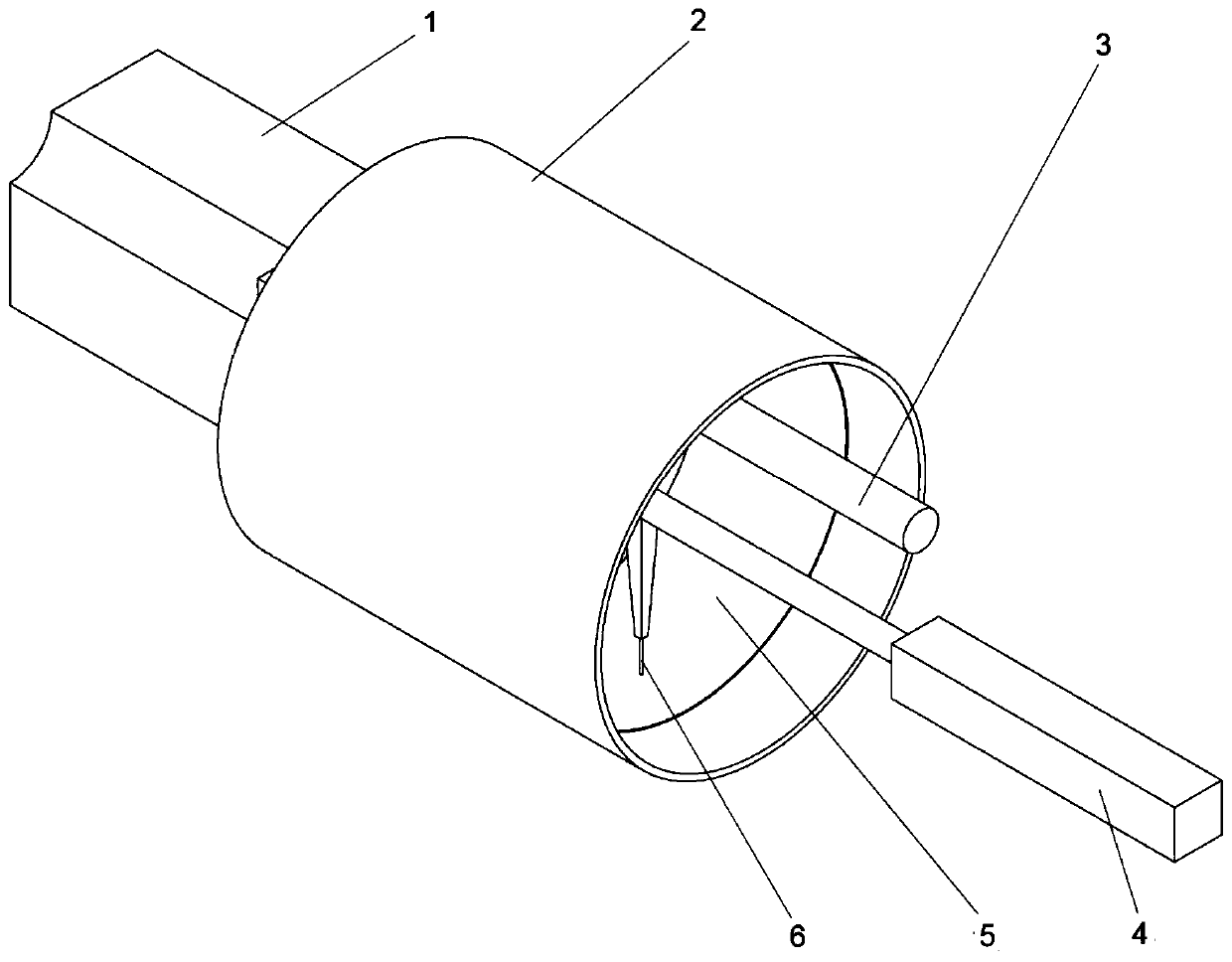

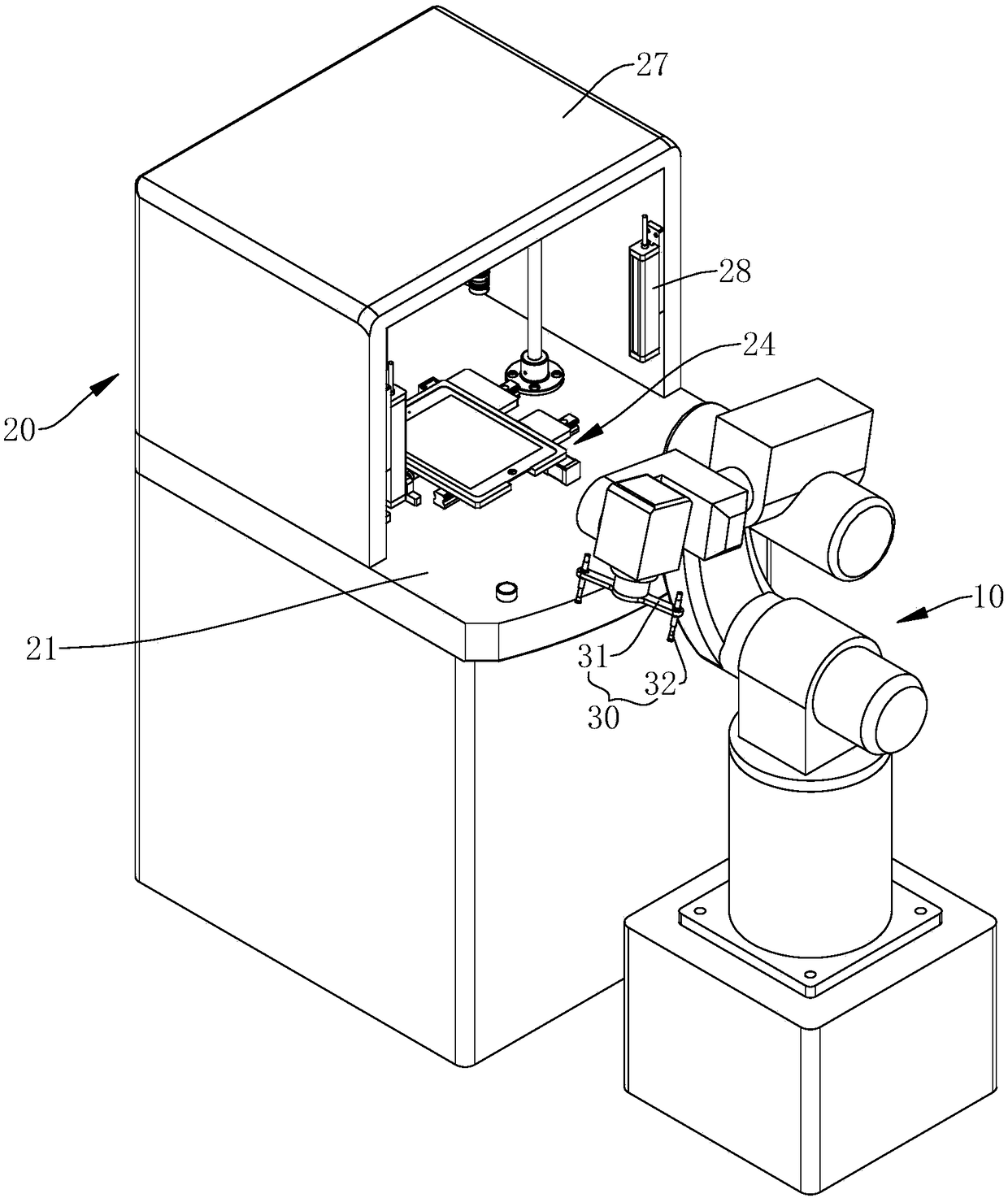

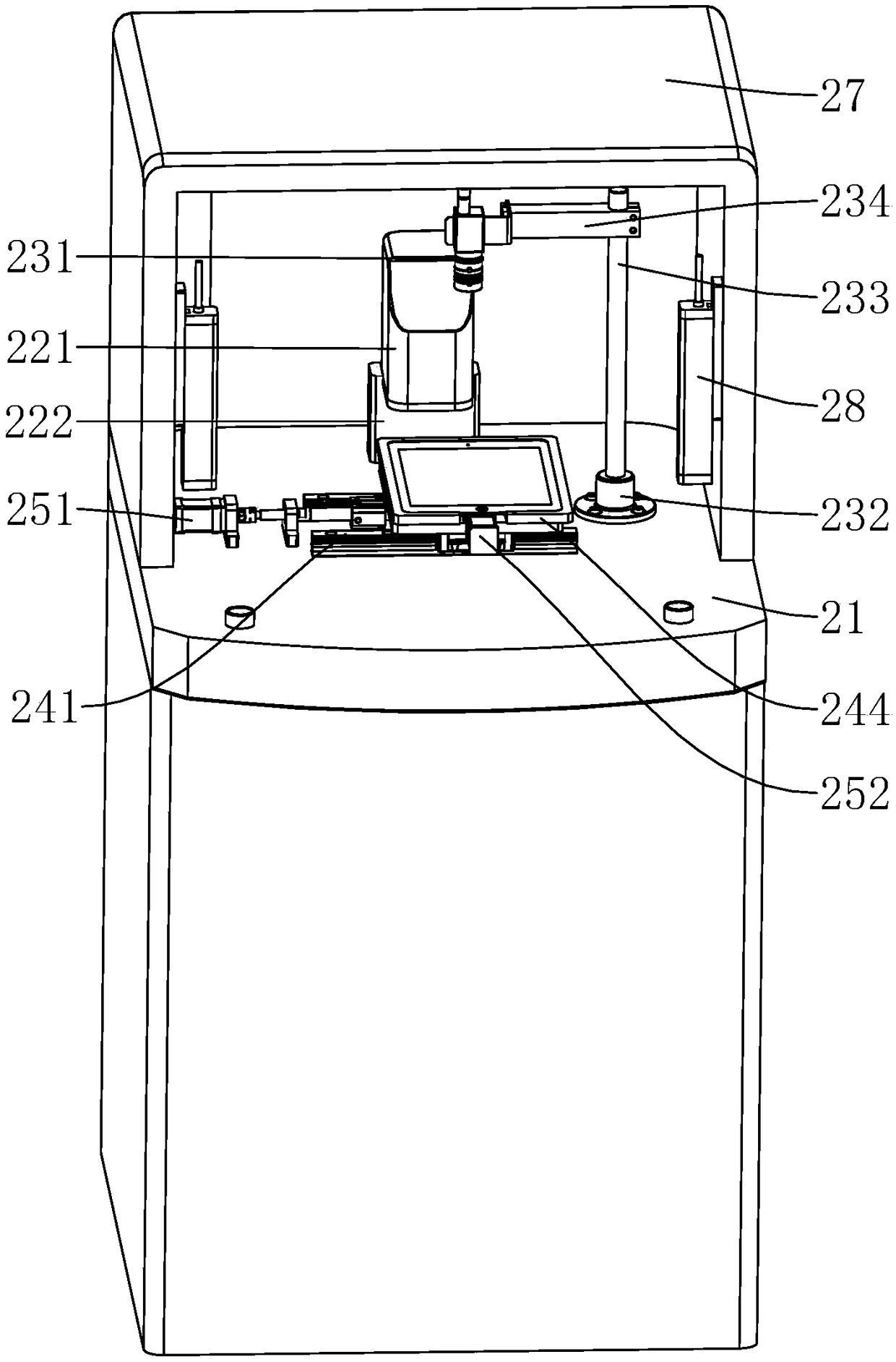

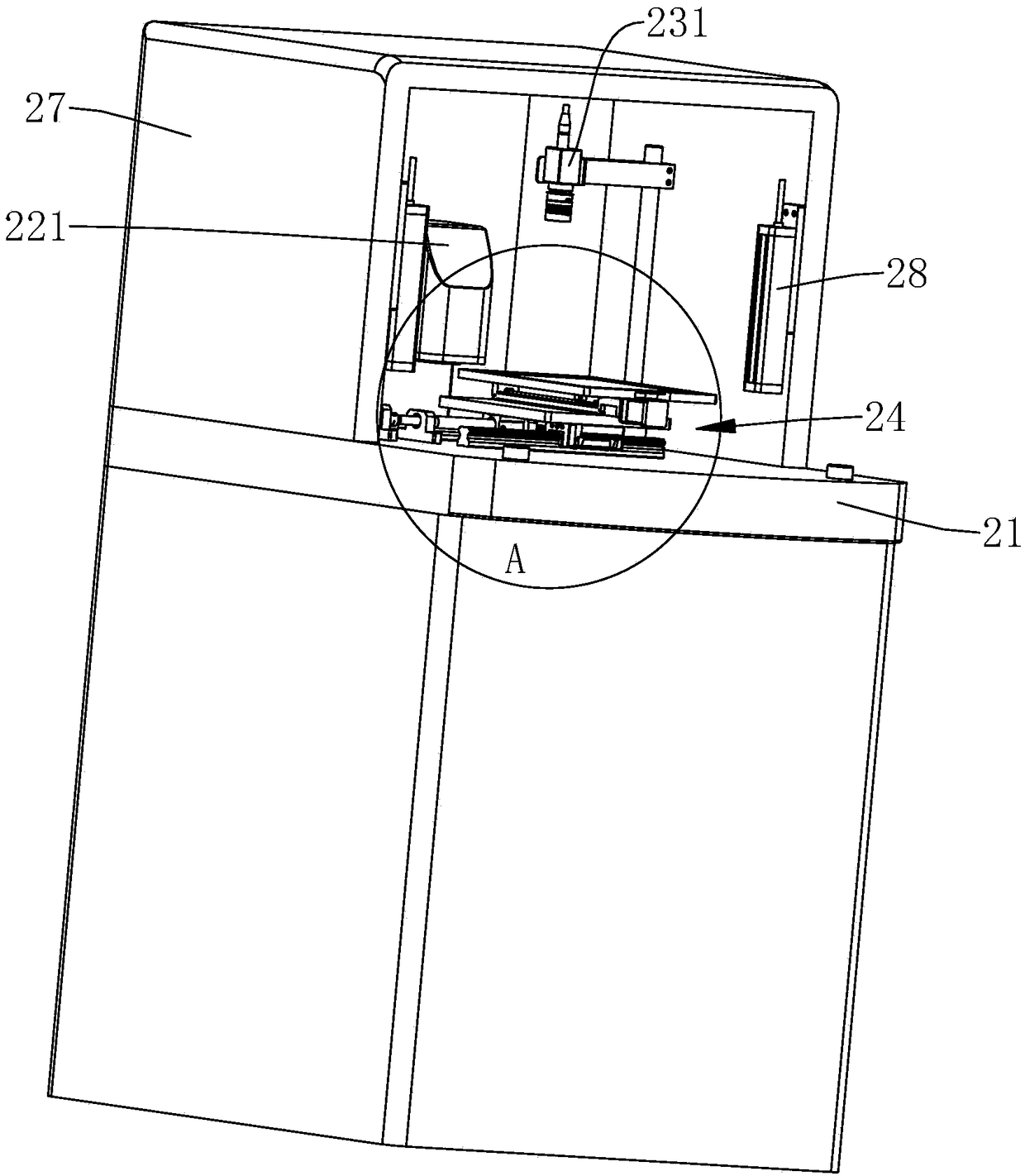

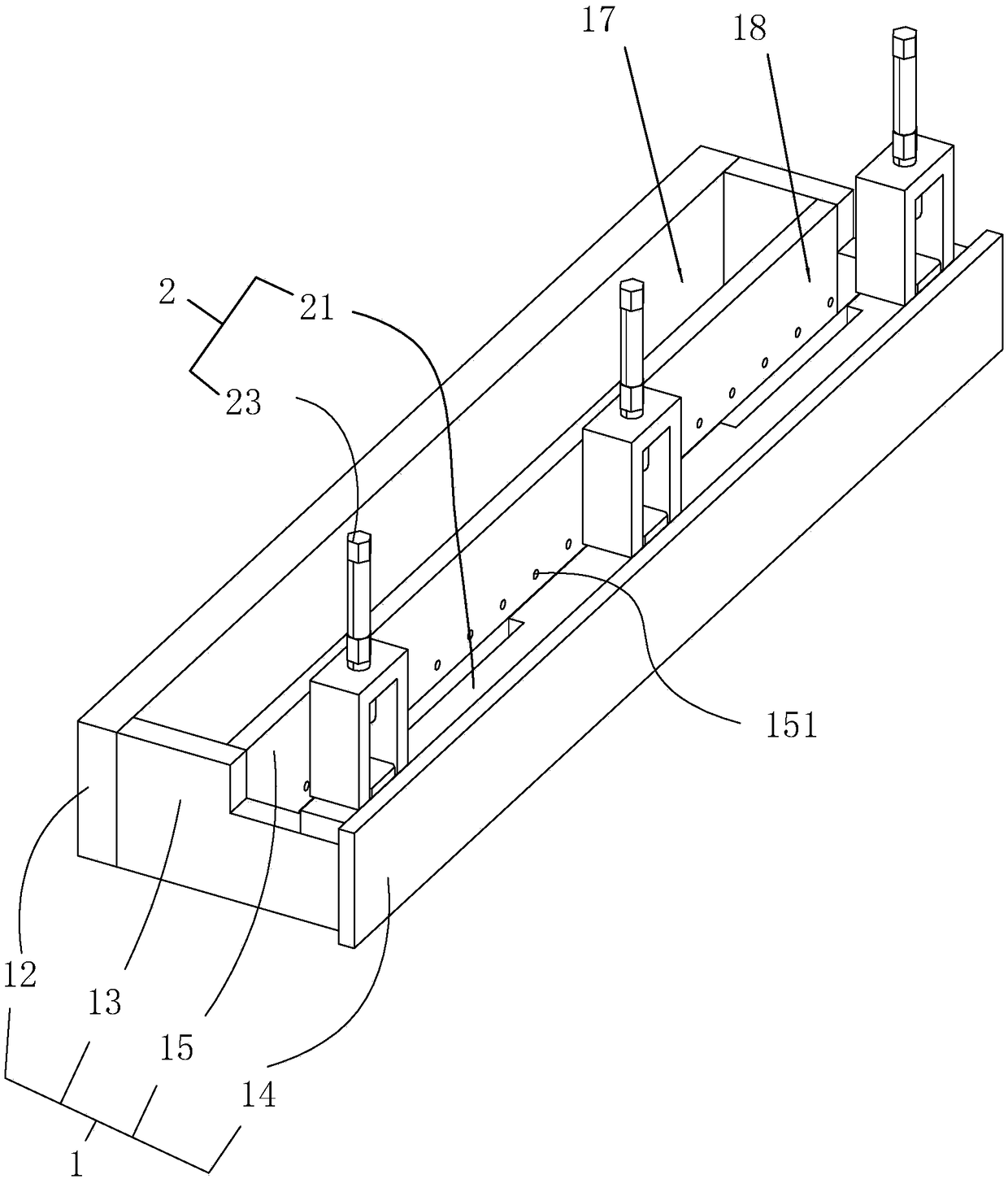

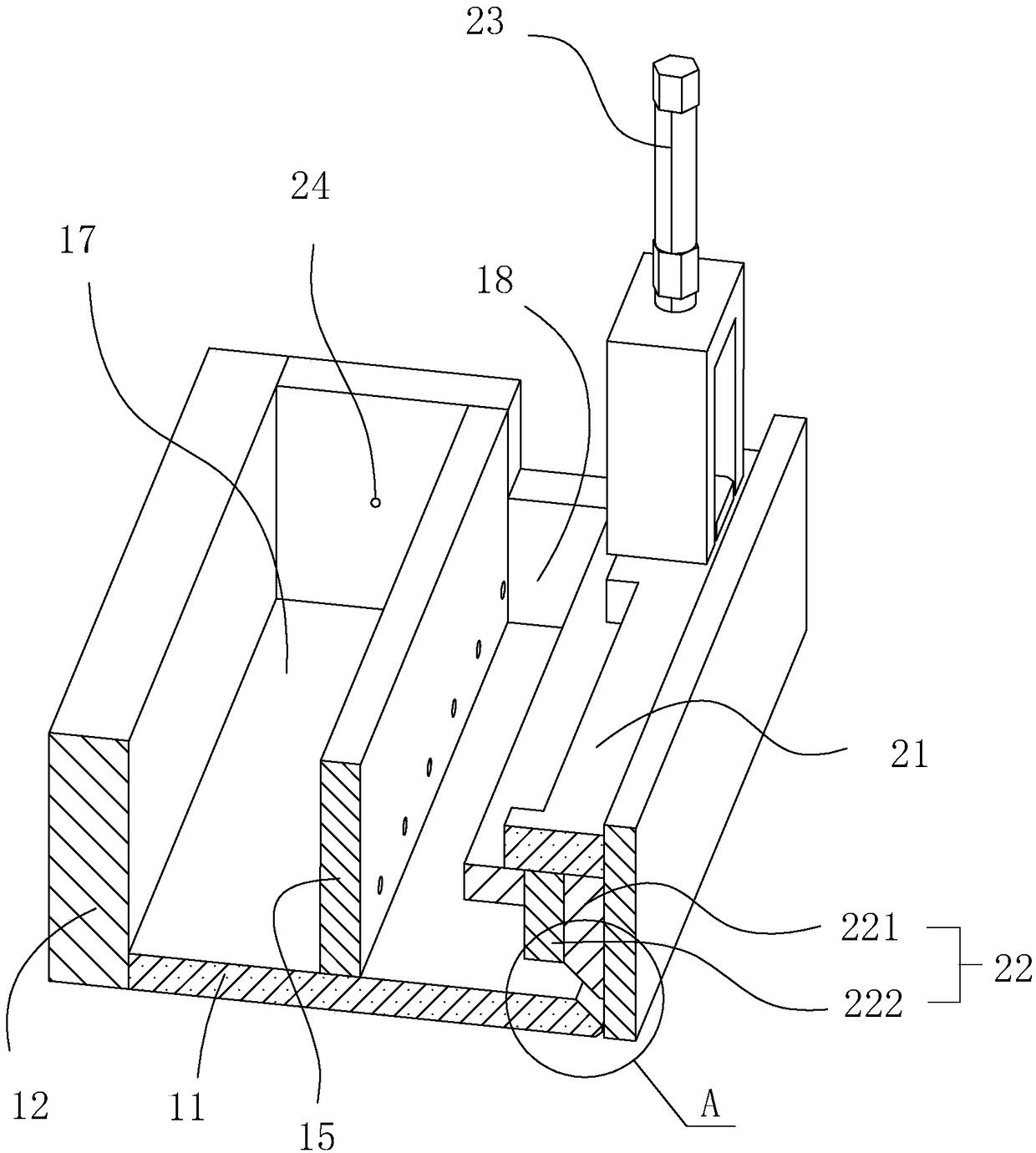

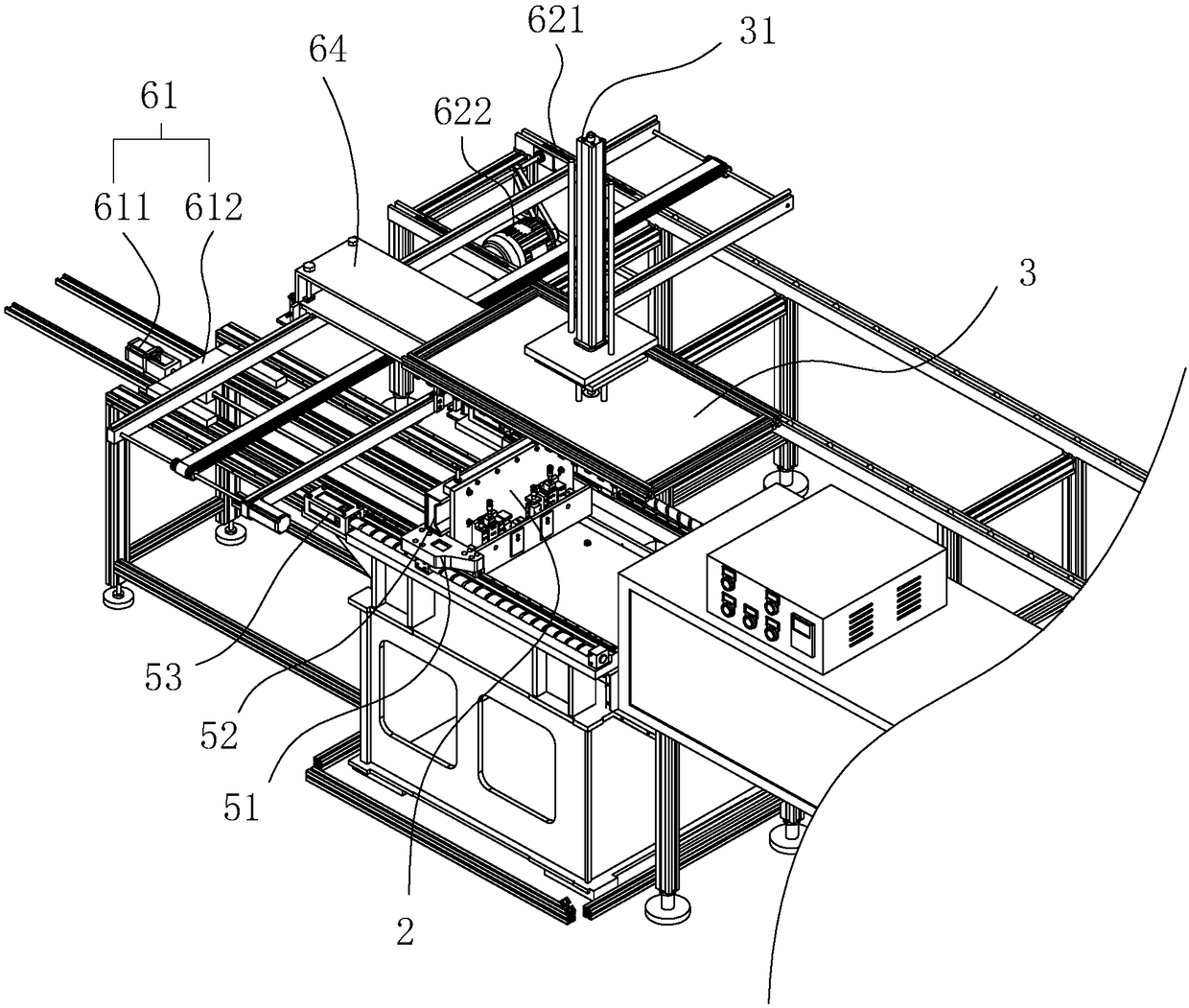

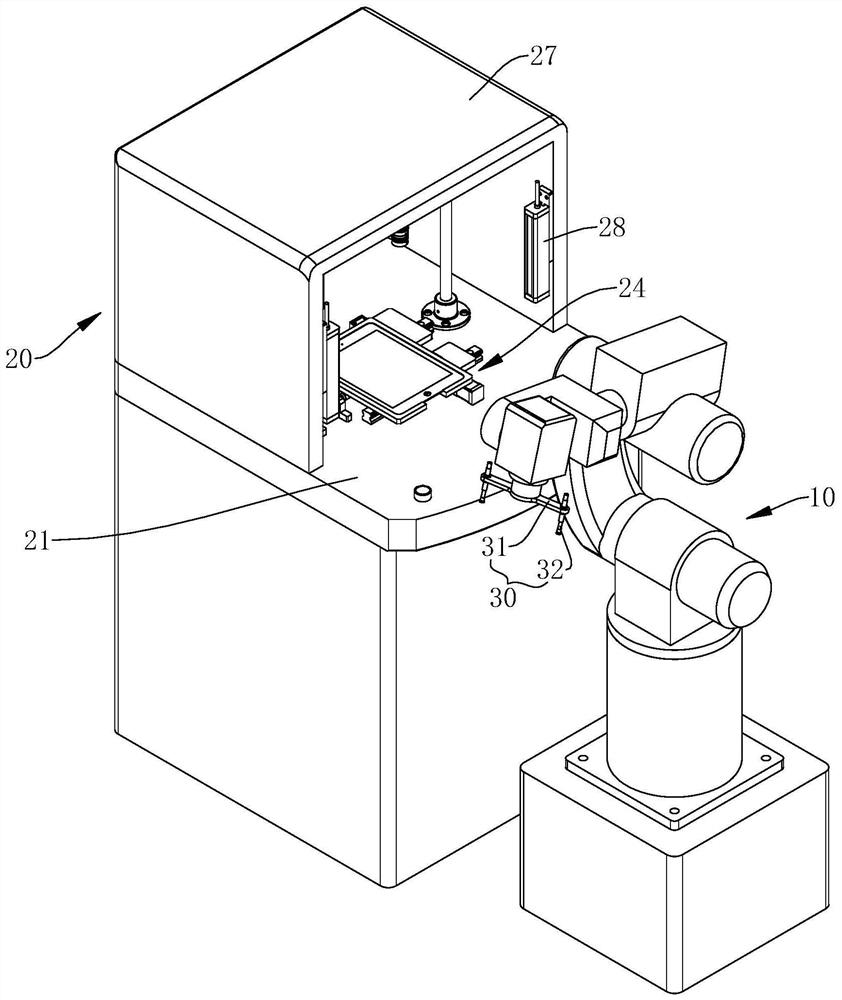

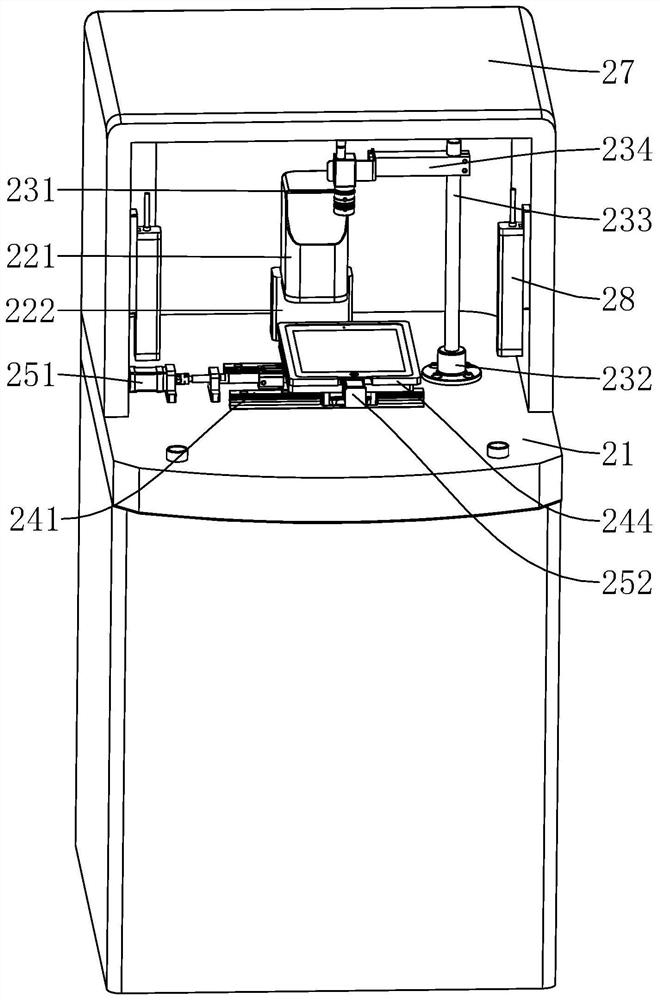

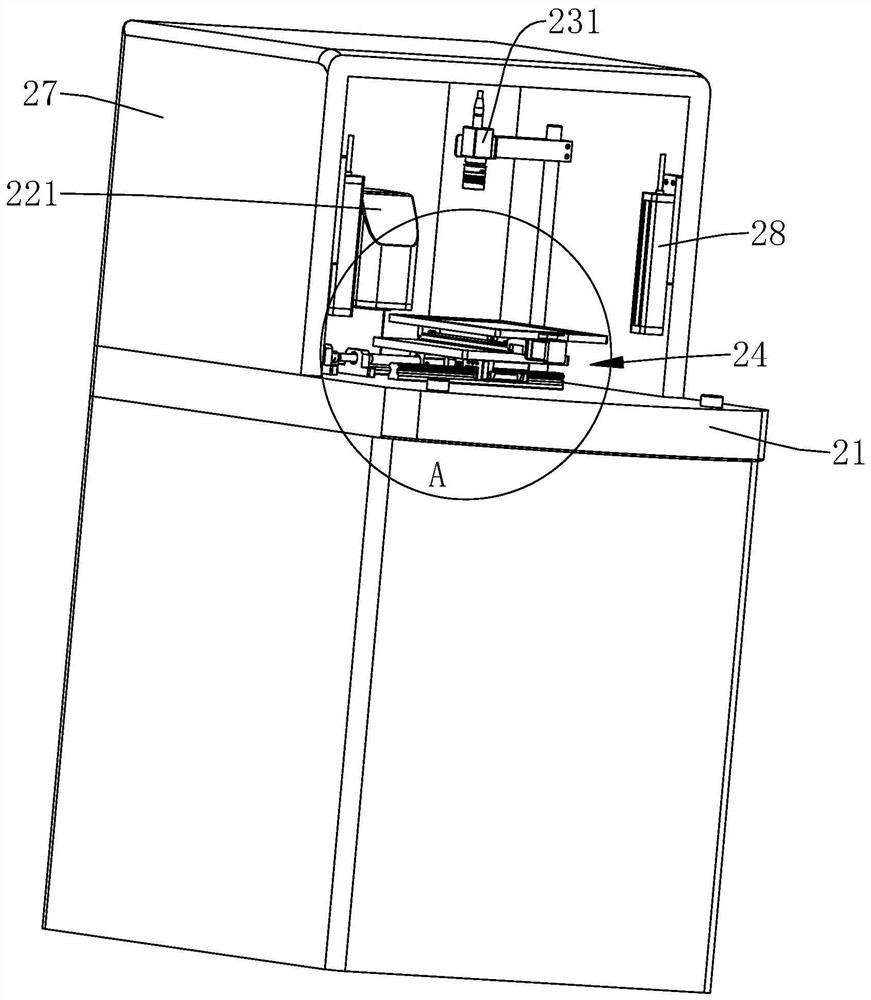

Film making unit, film making system, and film making method

ActiveCN108889519AHigh degree of intelligenceImprove film production efficiencyLiquid surface applicatorsSpraying apparatusEngineeringManipulator

The invention relates to the technical field of film-making equipment, disclosing a film-making unit, a film-making system and a film-making method formed by connecting a plurality of film-making units. The film-making unit comprises a manipulator and a film-making equipment. The free end of the manipulator is provided with a clamping portion for clamping and lowering the substrate, the driving mechanism can drive the sliding assembly to slide along the work plane of the worktable, the sliding assembly is provided with a tray for clamping the substrate, the coating mechanism and the spraying mechanism are both installed on the worktable, and the brush head of the coating mechanism and the spraying head of the spraying mechanism are aligned with the upper surface of the tray; A manipulator,a coating mechanism, a spraying mechanism, and a driving mechanism are electrically connecte to that control panel. The invention has the advantages that the coating or spraying film preparation method can be selected according to requirements, and full automation can be realized.

Owner:GUANGZHOU GV IND

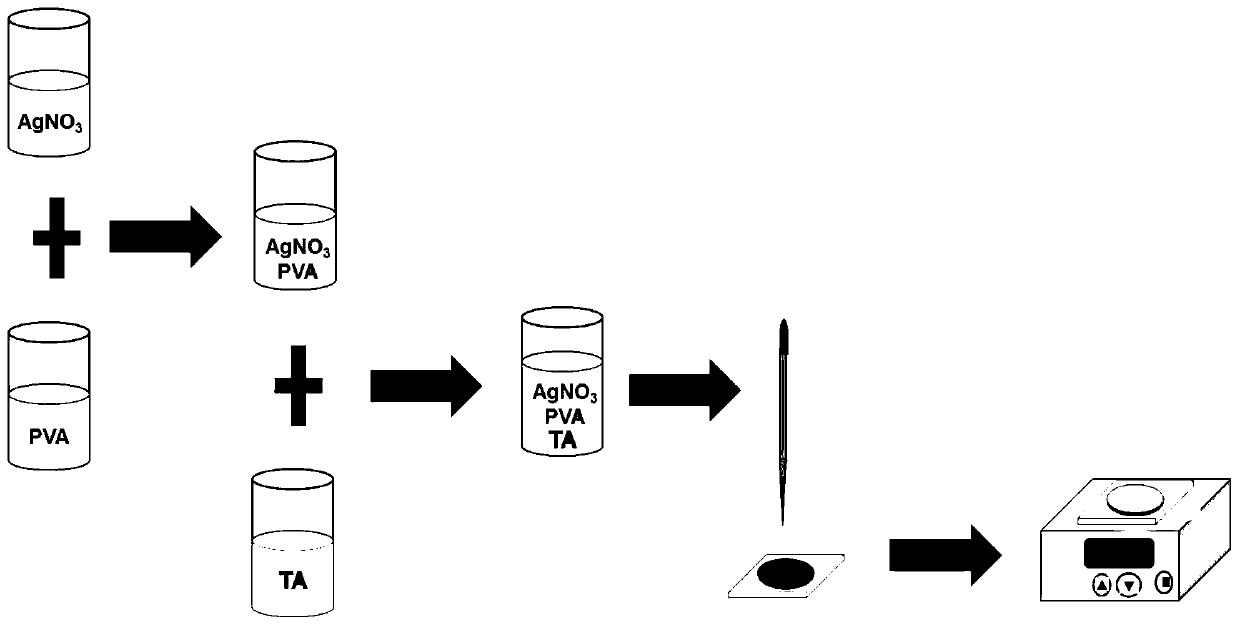

Flexible nano-composite holographic storage film, and preparation method and application thereof

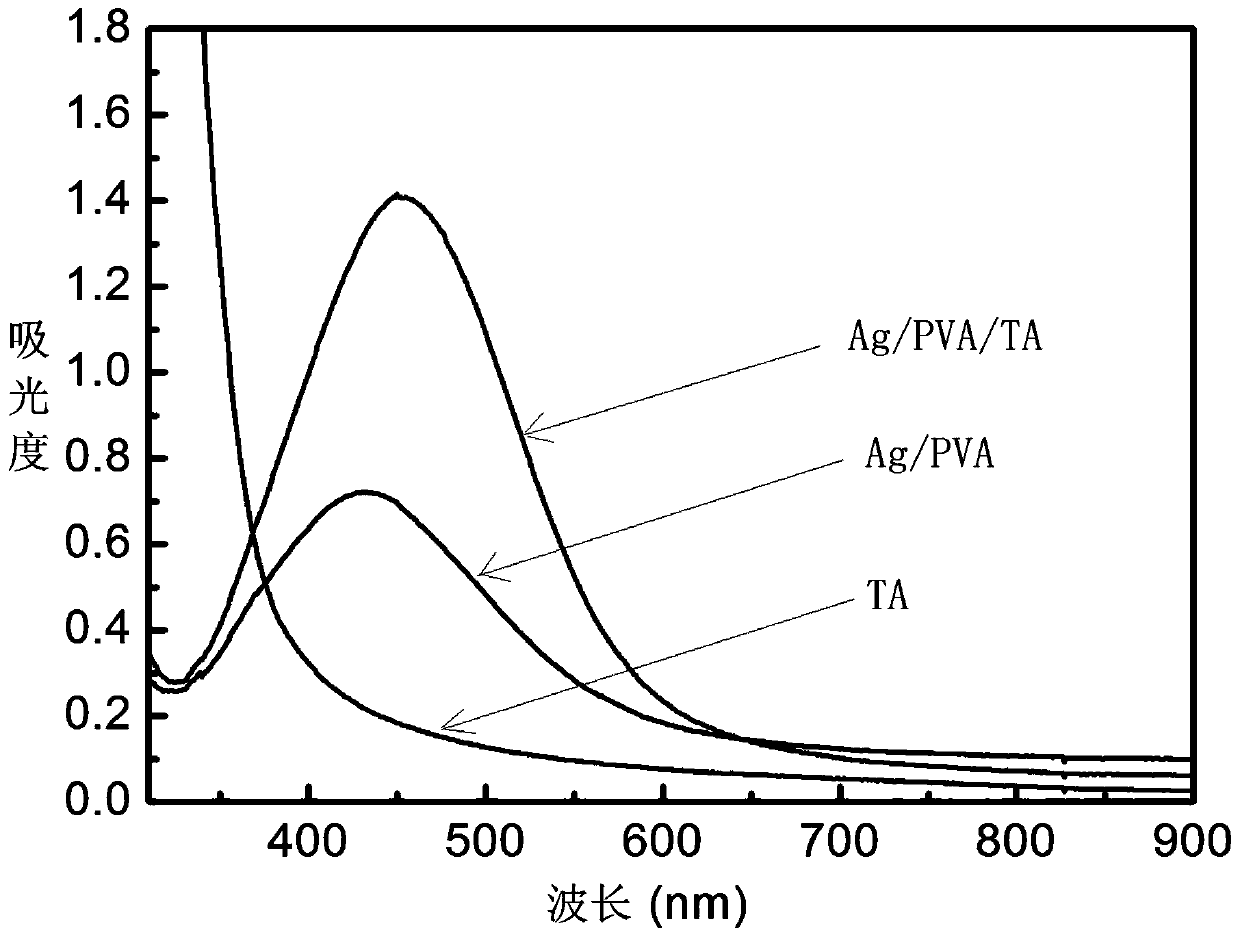

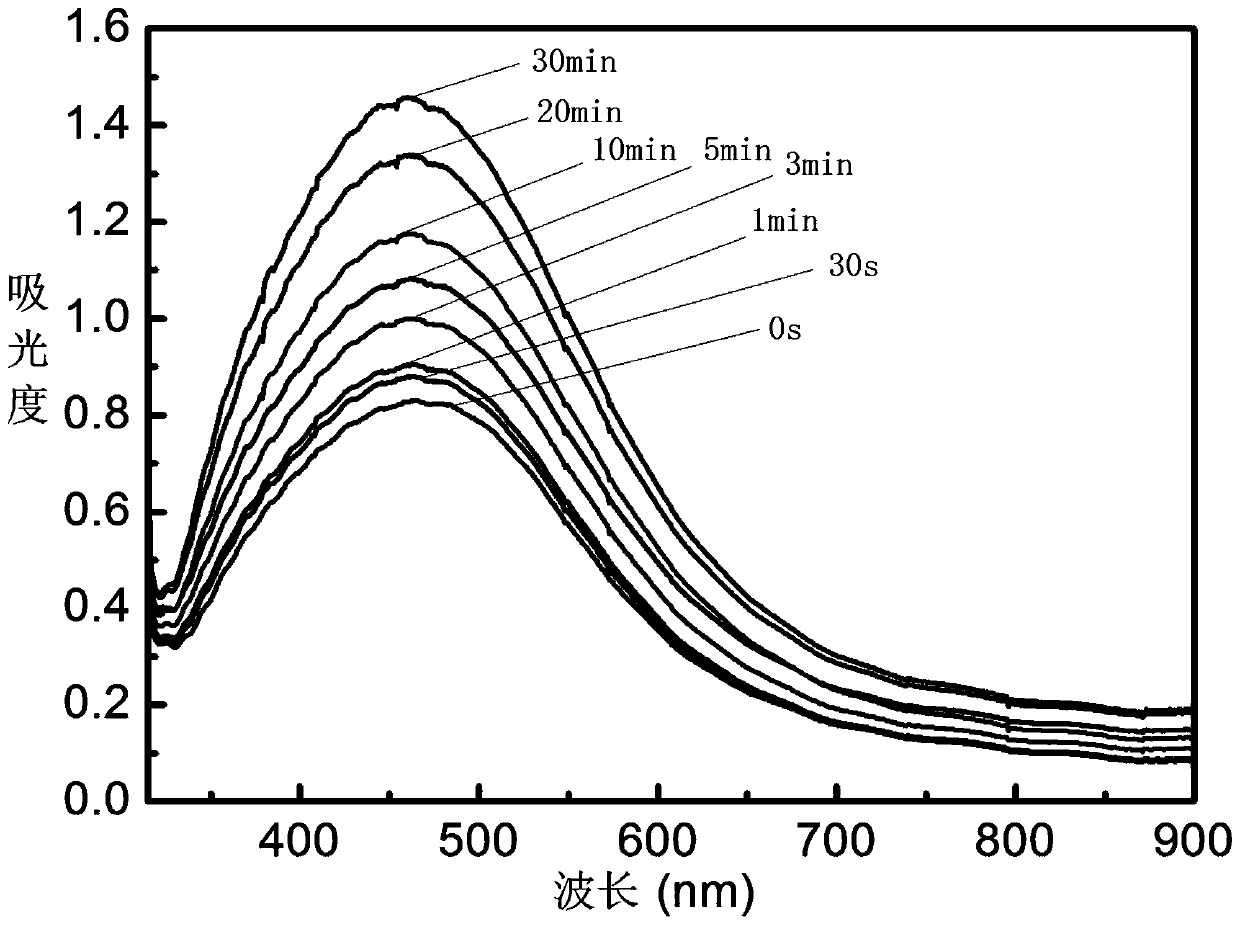

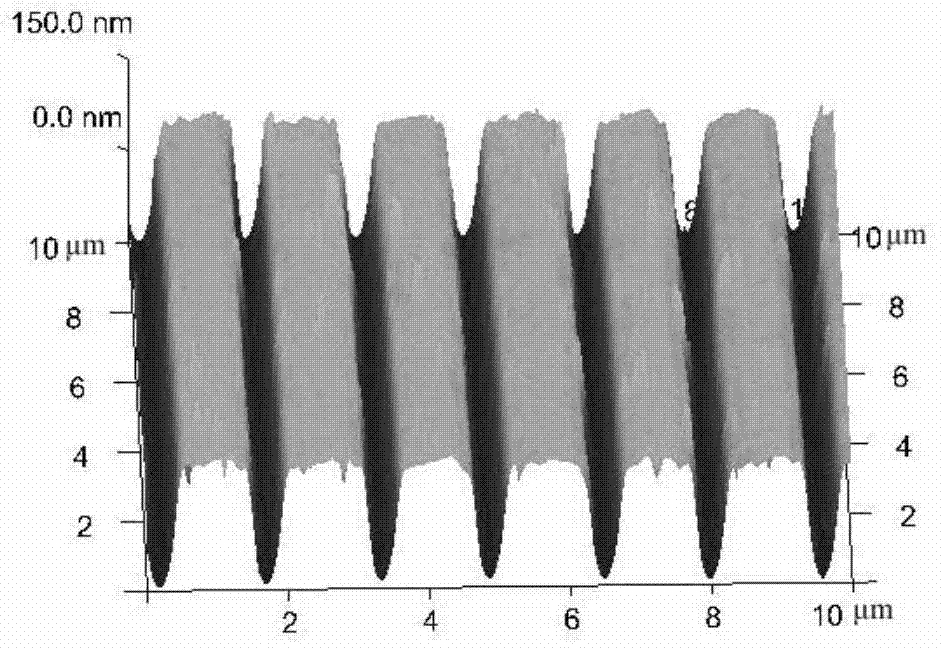

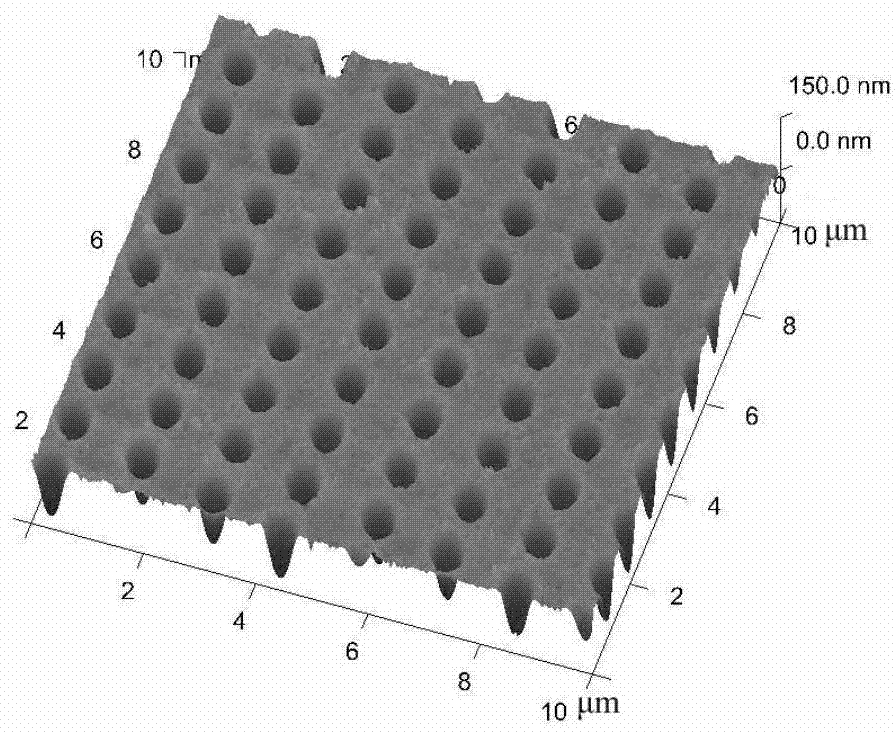

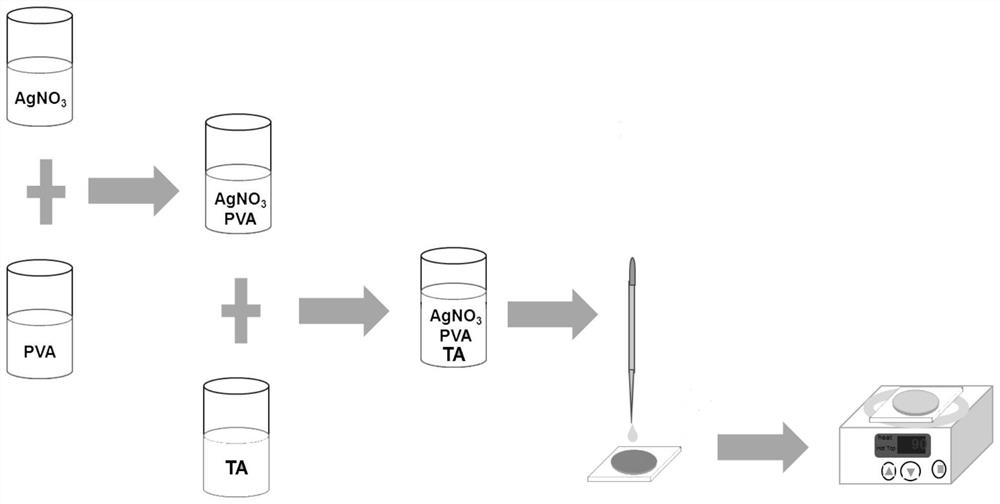

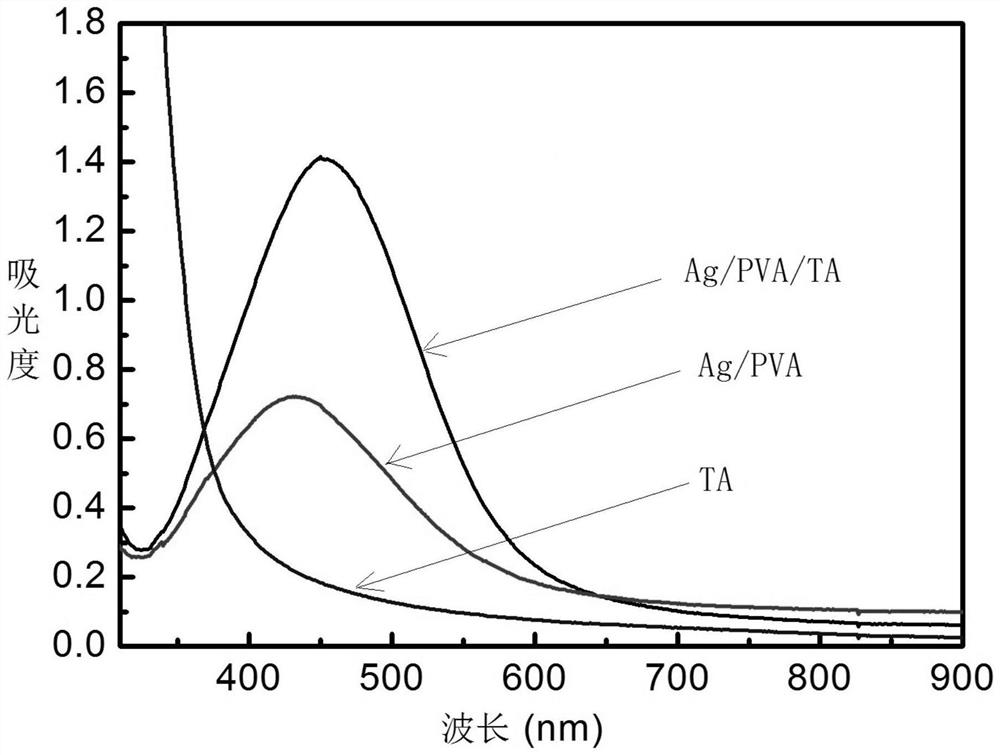

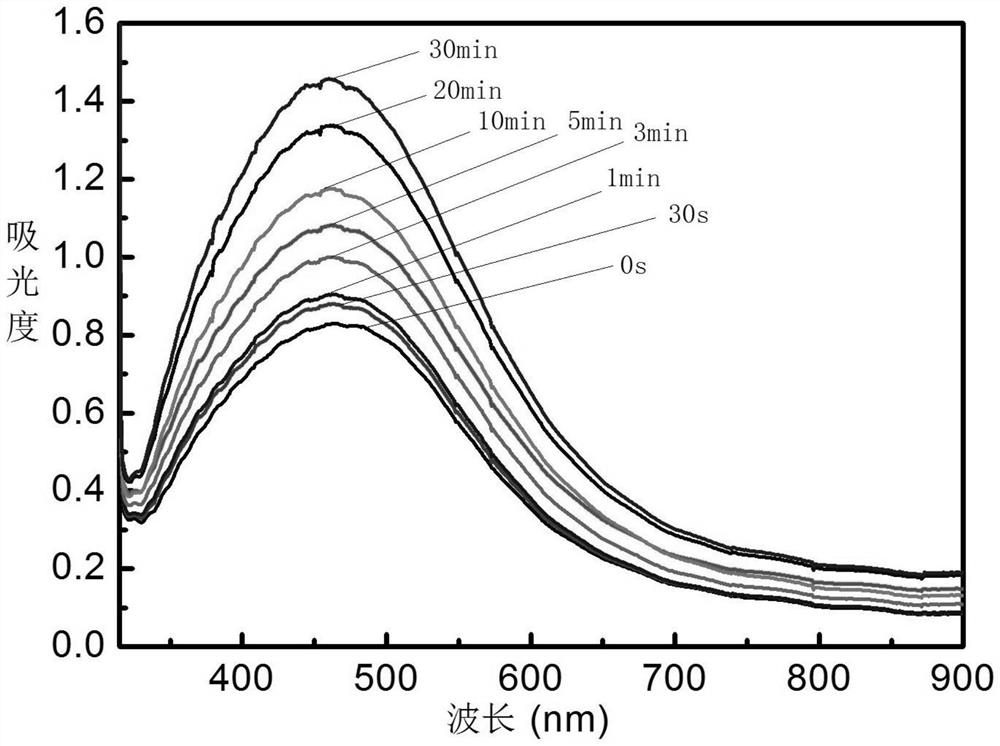

ActiveCN110452403AHigh diffraction efficiencyEnhanced resonance absorption phenomenonRecord information storageOptical record carrier manufactureHolographic storageComposite film

The invention discloses a flexible nano-composite holographic storage film, and a preparation method and an application thereof, and relates to the technical field of holographic storage. The purposeof the invention is to solve the problems of preparation methods of flexible devices being unable to store information. The preparation method comprises the following steps: preparing a AgNO3 solutionand a PVA solution, and mixing the AgNO3 solution with the PVA solution according to a volume ratio of 1:(1.1-1.4) to obtain a AgNO3 / PVA mixed solution; preparing a tannic acid solution having a PH value of 8.9, and mixing the tannic acid solution with the AgNO3 / PVA mixed solution to obtain a AgNO3 / PVA / TA mixed solution; and dispensing the AgNO3 / PVA / TA mixed solution on a bendable colorless plastic substrate, and heating the plastic substrate to form a film and realize the conversion of Ag<+> into Ag NPs in order to obtain the flexible Ag / PVA / TA nano-composite film. The preparation method ofthe invention has the advantages of simplicity, low in cost, and obtaining of the flexible film with a high diffraction efficiency and a high absorbance and suitable for holographic storage.

Owner:NORTHEAST NORMAL UNIVERSITY

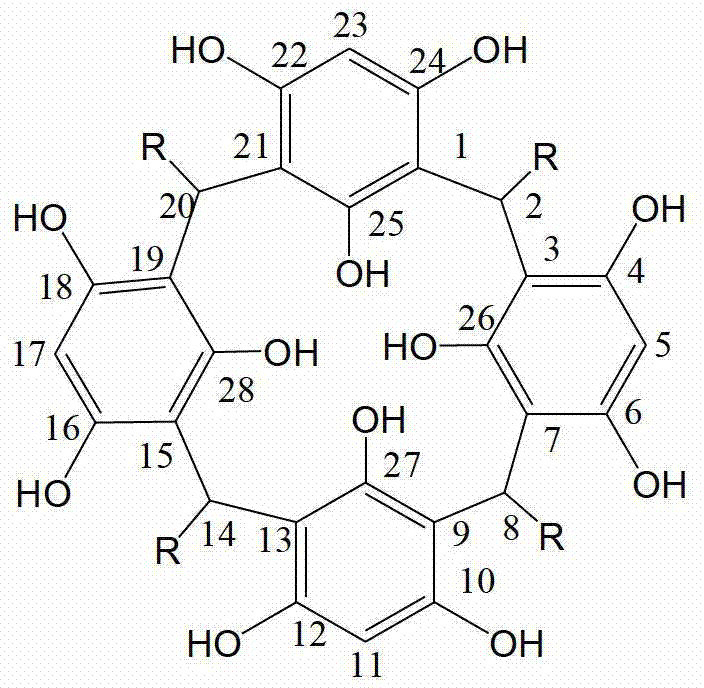

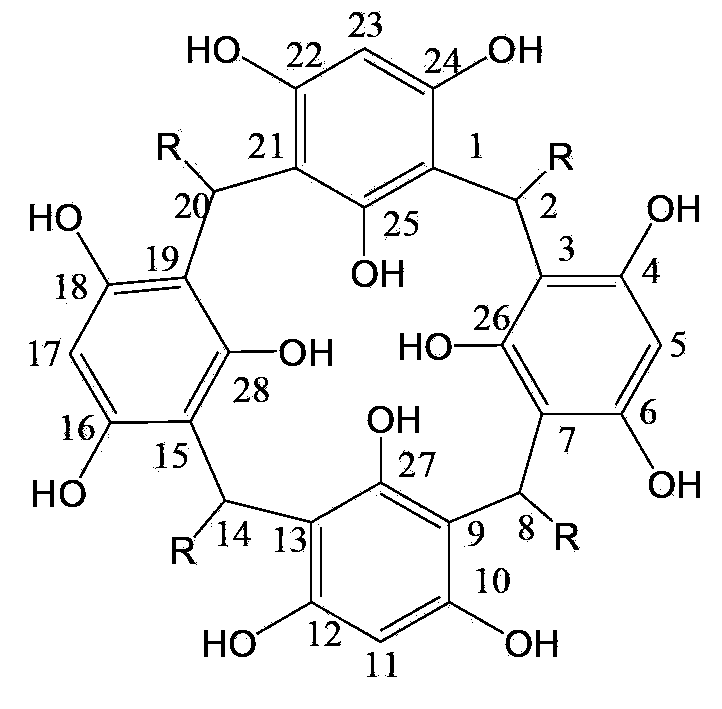

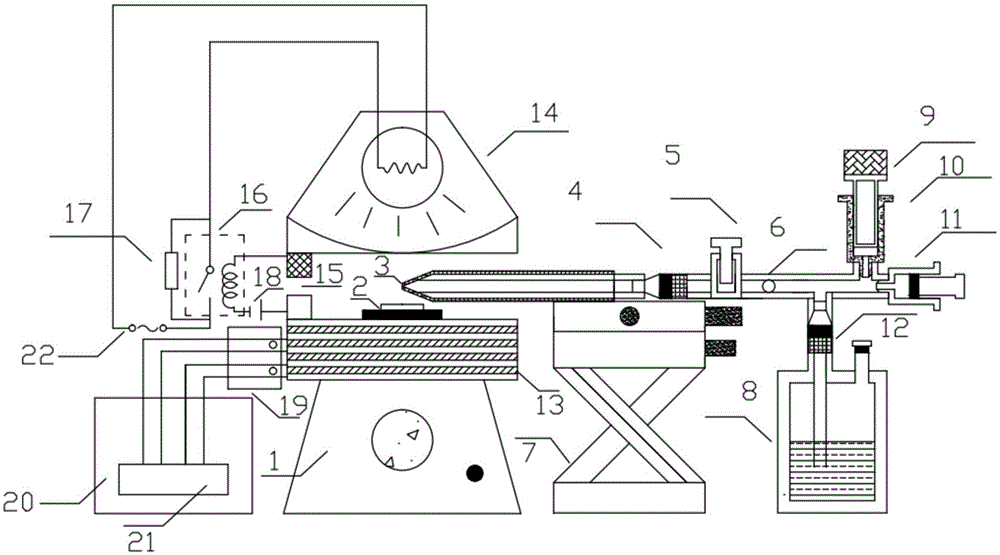

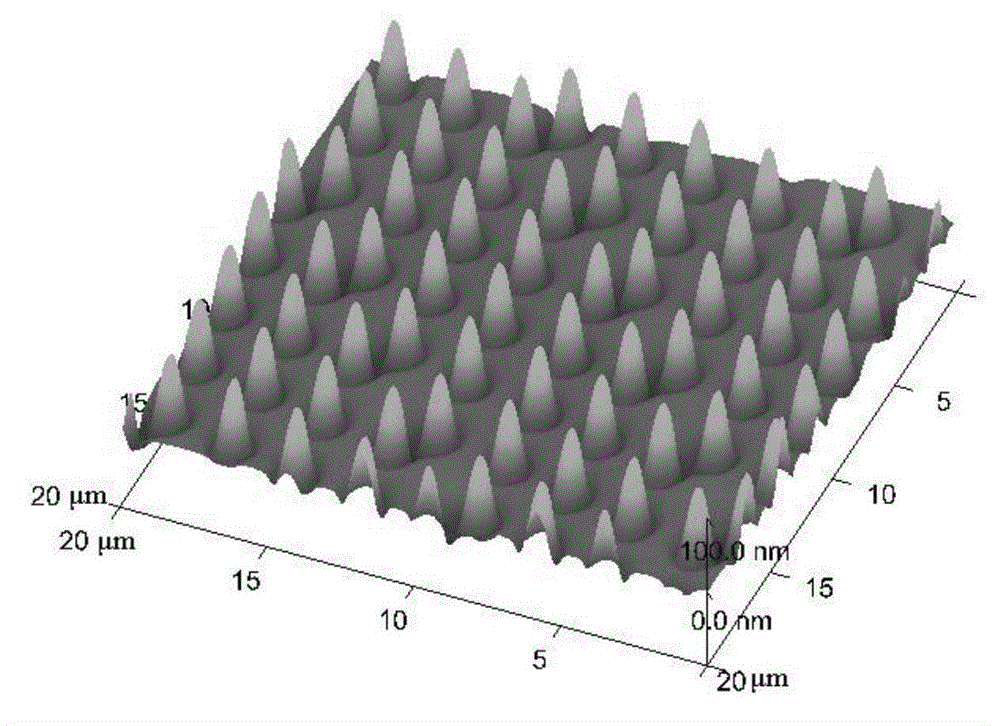

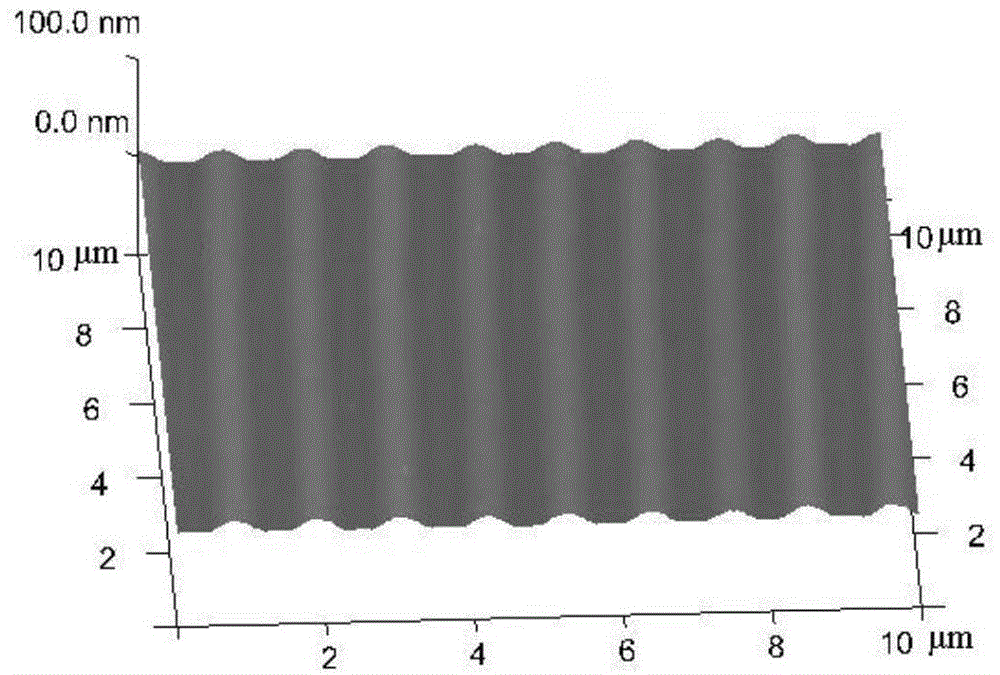

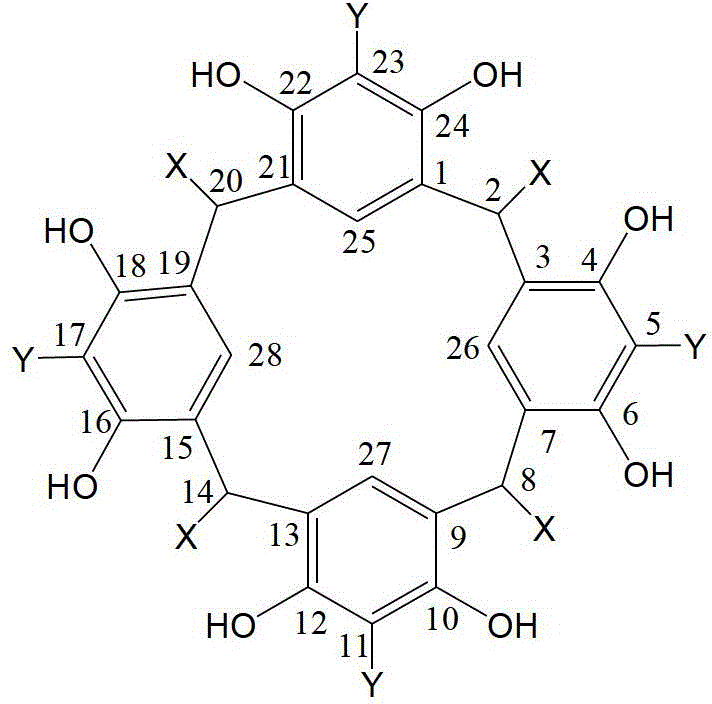

Laser thermal lithography organic photoresist and preparation method of photoresist

ActiveCN102880001AImprove film production efficiencyLow costOrganic chemistryOrganic compound preparationLithographic artistOrganic solvent

The invention discloses a laser thermal lithography organic photoresist, as well as a preparation method of the laser thermal lithography organic photoresist, wherein the photoresist is composed of 4, 6, 10, 12, 16, 18, 22, 24, 25, 26, 27 and 28-dodecanohydroxycalix [4]arene derivatives. The laser thermal lithography organic photoresist is prepared by phloroglucinol and aldehydes subjected to condensation reaction under the catalytic function of an acid. The photoresist can be dissolved in an organic solvent and can prepare a film in a simple spinning way. The photoresist is directly heated and gasified by laser to directly produce smooth pit-shaped micron and nano-pattern structures, and a following developing process is avoided, which further reduces the film making cost and improves the film making efficiency.

Owner:HANGZHOU INSTITUTE OF OPTICS AND FINE MECHANICS

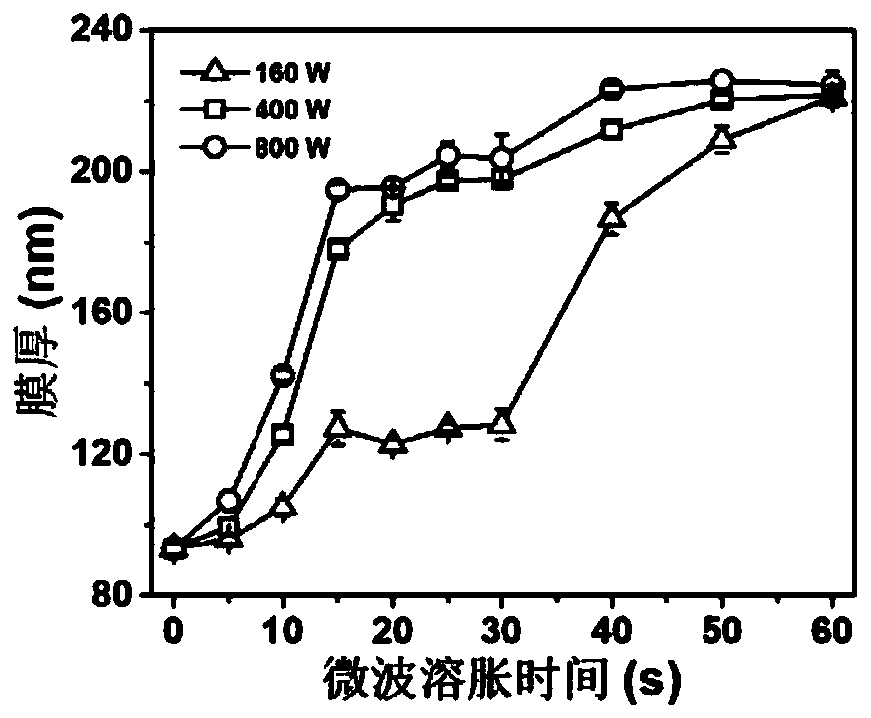

Microwave-enhanced selective swelling pore-forming method for separation membrane

ActiveCN110124539AImprove film production efficiencyEasy to prepareSemi-permeable membranesMembranesSolventForming processes

The invention provides a microwave-enhanced selective swelling pore-forming method for a separation membrane, which comprises the following steps: preparing a compact film by using an amphiphilic block copolymer; immersing the obtained compact film in an alcohol or carboxylic acid solvent, and treating the compact film by using microwaves with the power of 160-800 W for 15-60 s; and immediately taking out and drying the film at room temperature to obtain an amphiphilic block copolymer separation membrane with a bicontinuous porous structure. According to the method, the time required by selective swelling pore-forming of the amphiphilic block copolymer is greatly shortened, and the film preparation efficiency is improved. The method has universality and can be widely applied to the pore-forming process of various amphiphilic block copolymers. And by adjusting the microwave power and time, the pore-forming degree is precisely controlled.

Owner:NANJING UNIV OF TECH

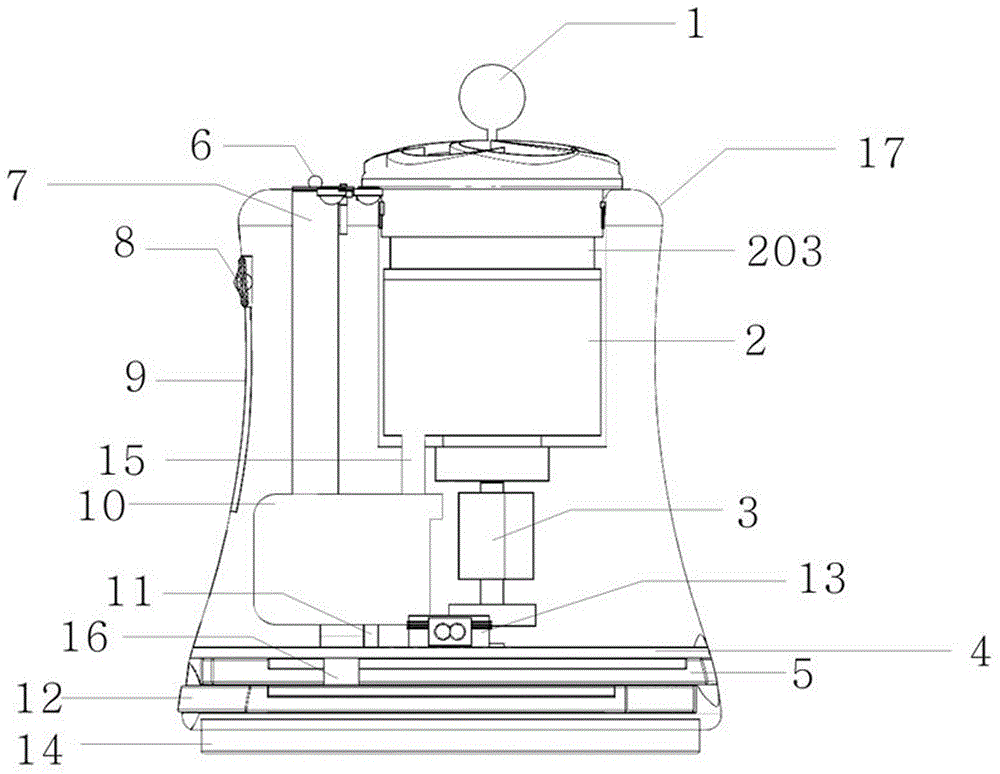

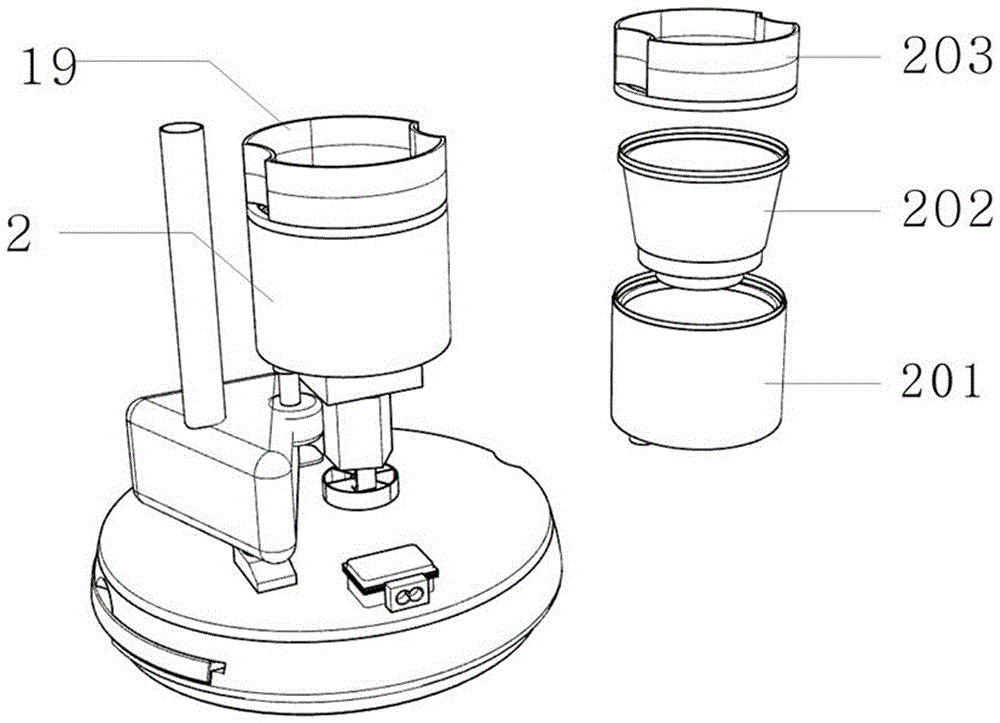

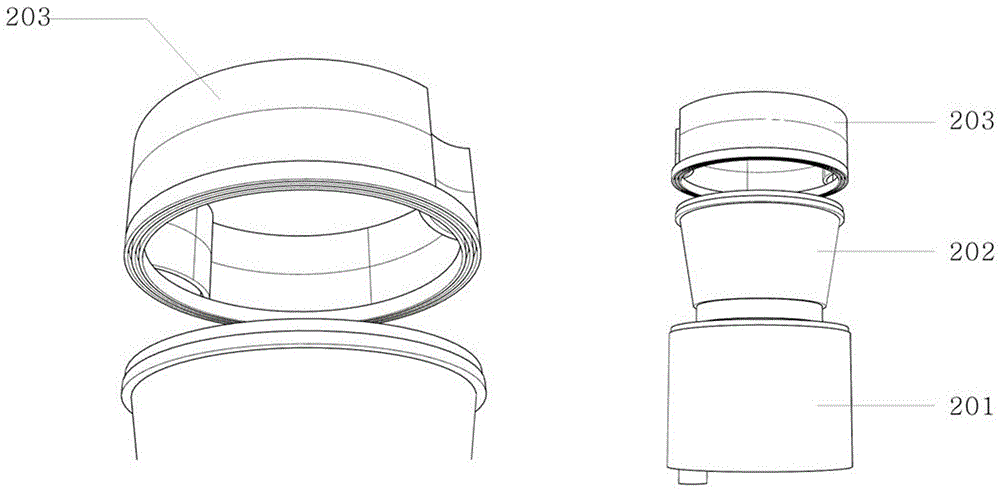

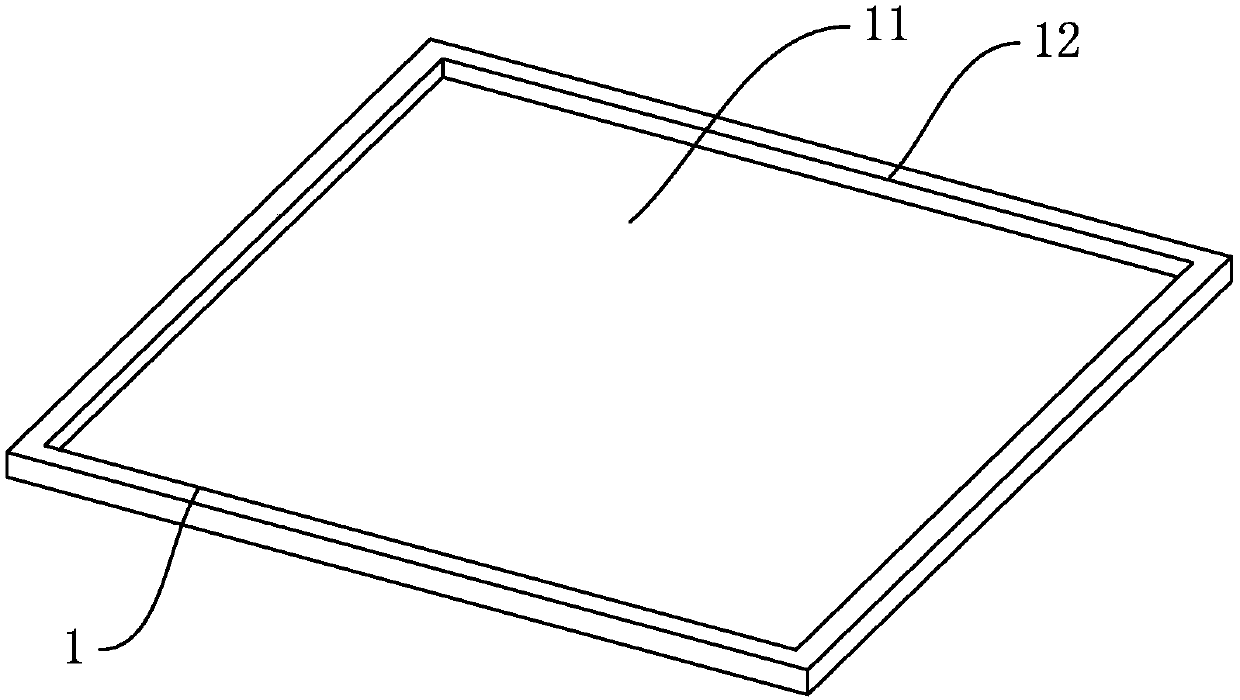

Fruit mask making machine

InactiveCN105963146AImprove film production efficiencyCosmetic preparationsToilet preparationsFruit juiceProcess engineering

The invention discloses a fruit mask making machine, relating to the technical field of beautifying. The fruit mask making machine comprises a top cover (1), a shell (17), a charging mechanism (2), a juicing mechanism (3), a stirring and heating mechanism (10), a mask tray (12), a neck mask tray (5) and a base (14). A mask molding mechanism comprises the mask tray (12) and the neck mask tray (5). In a mask making process, after the mixture of raw materials and fruit juice is fully stirred by the stirring and heating mechanism, the mixture is quantitatively injected onto the mask tray (12) and the neck mask tray (5) simultaneously, thereby making a mask and a neck mask in one step, so that the problem that a conventional mask making machine only can be used for molding one mask each time is solved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Preparation method and system of membrane material

ActiveCN112691558AAchieving controllable equipmentThickness is easy to adjustSemi-permeable membranesThin membraneEngineering

The invention discloses a preparation method and system of a membrane material. The preparation method of the membrane material comprises the steps of rotating a rotating body, enabling a selected area on the surface of the rotating body to be in contact with a film-forming solution when the selected area rotates to a first position, enabling the film-forming solution to be attached to the selected area to form a liquid membrane, and enabling the liquid membrane to form a membrane material as it continues to rotate with the selected area from the first position to the second position. The controllable preparation of various membrane materials can be realized, the thickness, the area, the components, the structure and the like of the membrane materials are easy to regulate and control, the membrane preparation efficiency is high, and the obtained membrane material is good in quality, low in cost and suitable for the requirement of large-scale production, and particularly has important application value in the field of preparation of high-quality, high-performance or special-performance membranes.

Owner:江西省纳米技术研究院

Device and method for solution casting large film

The invention discloses a device and method for solution casting a large film. The device comprises a heat-preservation top cover, a stainless steel water jacket, a film casting disc, a heating plateand a heat-preservation bottom plate; the heating plate is medially arranged on the heat-preservation bottom plate, the stainless steel water jacket is arranged at the portion, wound around a round upwards, along the edge of the heat-preservation bottom plate, and is higher than the film casting disc, a condensation-solvent collecting trough is arranged at the portion, wound around a round inwards, of the bottom edge of the stainless steel water jacket, and the heat-preservation top cover covers the upper end of the stainless steel water jacket for sealing; a plurality of adjusting supportinglegs are arranged below the heat-preservation bottom plate; a plate is arranged on the upper surface of the heating plate; the film casting disc is medially arranged on the upper surface of the heating plate; float glass is arranged at the disc bottom of the film casting disc, and a round of disc edge is arranged on the edge of the disc bottom upwards; the disc bottom of the float glass of the film casting disc is in directly contact with the plate on the upper surface of the heating plate; the film casting disc is located inside the outer contour of the heating plate, and the heating plate islocated inside the outer contour of the heat-preservation bottom plate. By means of the device and method, the large-area film can be prepared, the technology is simple, the film preparing efficiencyis high, the cost is low, the crystallinity degree of a finished product film is high, the isotropy is achieved, the thickness is even, and the finished-product rate is high.

Owner:郑重德

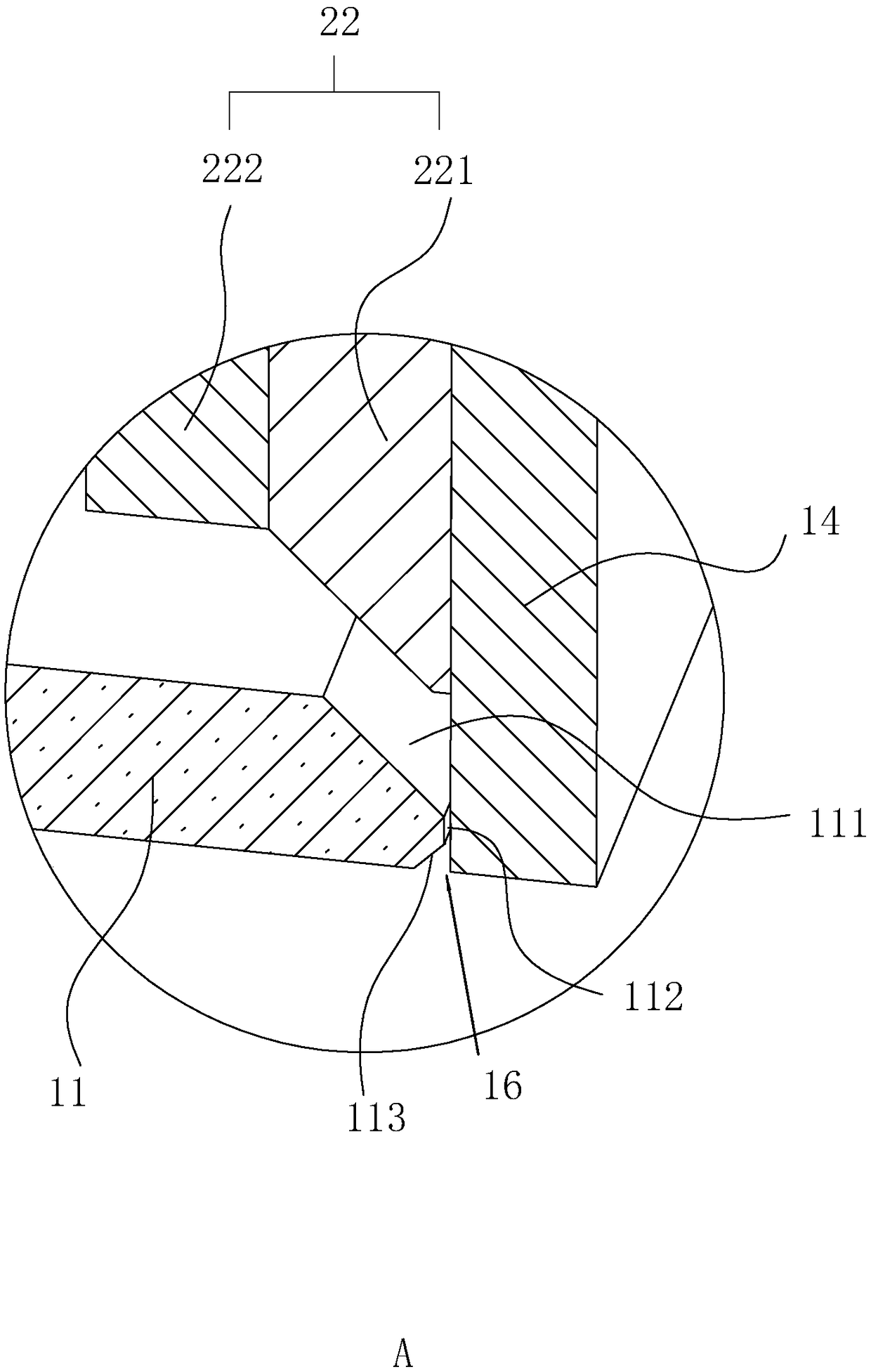

Casting valve and coating device with same

PendingCN108819063AReduce destabilizing effectsImprove film production efficiencyFlat articlesCoatingsLiquid storage tankMaterials science

The invention discloses a casting valve and a coating device with the same, and relates to the field of casting process firming. The casting valve comprises a base body and is characterized in that the base body is provided with a liquid storage tank and a casting tank which are adjacently arranged and separated by a partition plate, and a valve for controlling the liquid outlet of the casting tank to be opened and closed is also arranged on the base body; and a plurality of connecting holes communicating with the liquid storage tank and the casting tank are formed in the lower part of the partition plate in the horizontal direction, and the liquid inlet of the liquid storage tank is located at the upper part of the liquid storage tank. The casting valve and the coating device with the same has the advantages that the continuity is high, the firming efficiency is high, the coating uniformity is good, and the filming thickness is small.

Owner:温岭市聚氟科技有限公司

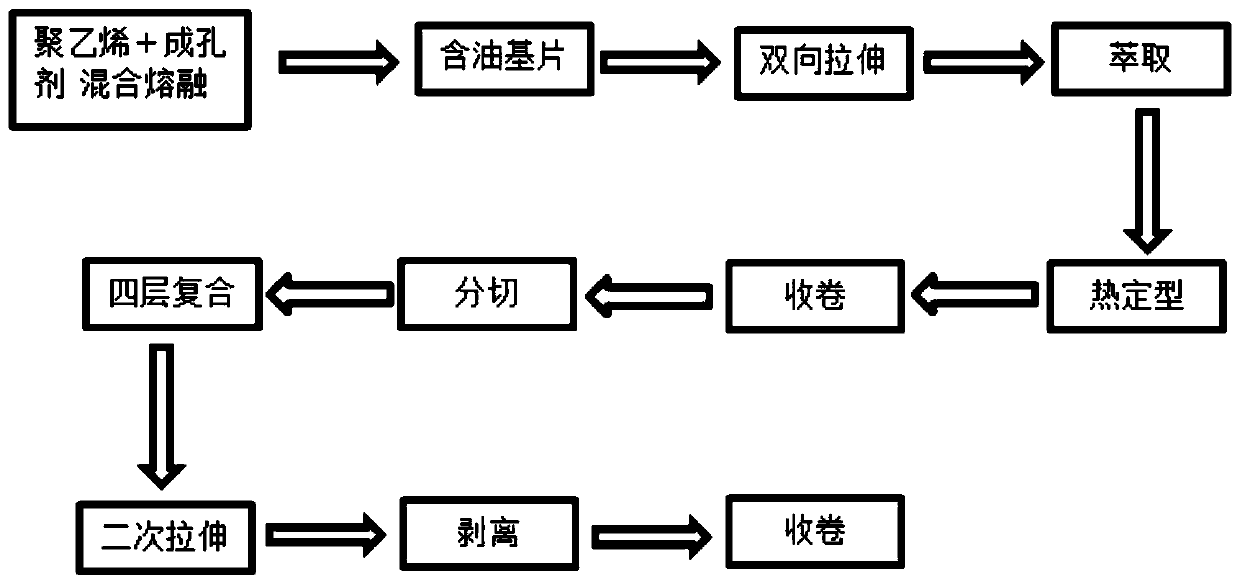

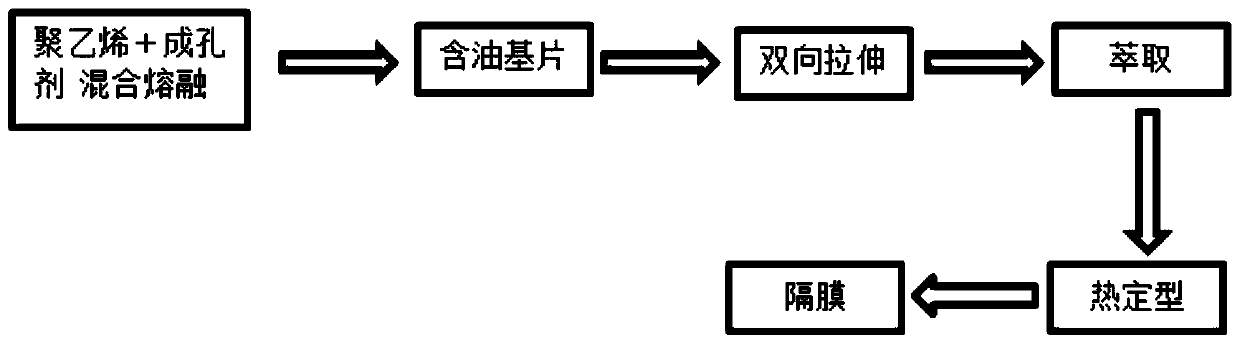

Method for producing lithium-ion secondary battery membrane

InactiveCN110247006AIncrease production capacityImprove film production efficiencyCell seperators/membranes/diaphragms/spacersSecondary cellsWork in processLithium-ion battery

The invention discloses a method for producing a lithium-ion secondary battery membrane. The method comprises the steps of preparing a microporous membrane by a lithium-ion battery membrane production process, cutting the microporous membrane to obtain a semi-finished microporous membranes, performing layer composition on at least two semi-finished microporous membranes to obtain a composite microporous membrane, stretching the composite microporous membrane, and peeling a corresponding layer of the stretched composite microporous membrane to obtain a finished microporous membrane. According to the method of the invention, the membrane forming efficiency can be improved, and the production capacity is expanded.

Owner:LIYANG YUEQUAN ELECTRIC ENERGY CO LTD

Flexible capacitive sensor and preparation method and application thereof

InactiveCN112890789AImprove the ability to withstand large deformationIncrease initial capacitanceEvaluation of blood vesselsSensorsElectromagnetic interferenceDielectric layer

The invention relates to the field of flexible sensors, in particular to a flexible capacitive sensor and a preparation method and application thereof. The flexible capacitive sensor comprises a dielectric layer and a flexible electrode, the flexible electrode is arranged on the surface of the dielectric layer, and the dielectric layer comprises a flexible dielectric elastomer substrate and inorganic high-dielectric particles. The flexible capacitive sensor has good stretchability and good dielectric response performance at the same time, the sensor is endowed with a high-baseline initial capacitance value by adding the inorganic high-dielectric particles, the capacity of the sensor for resisting pF-level electromagnetic interference in the external environment is improved, and the sensing range and the application field of the sensor are widened.

Owner:BEIJING UNIV OF POSTS & TELECOMM +2

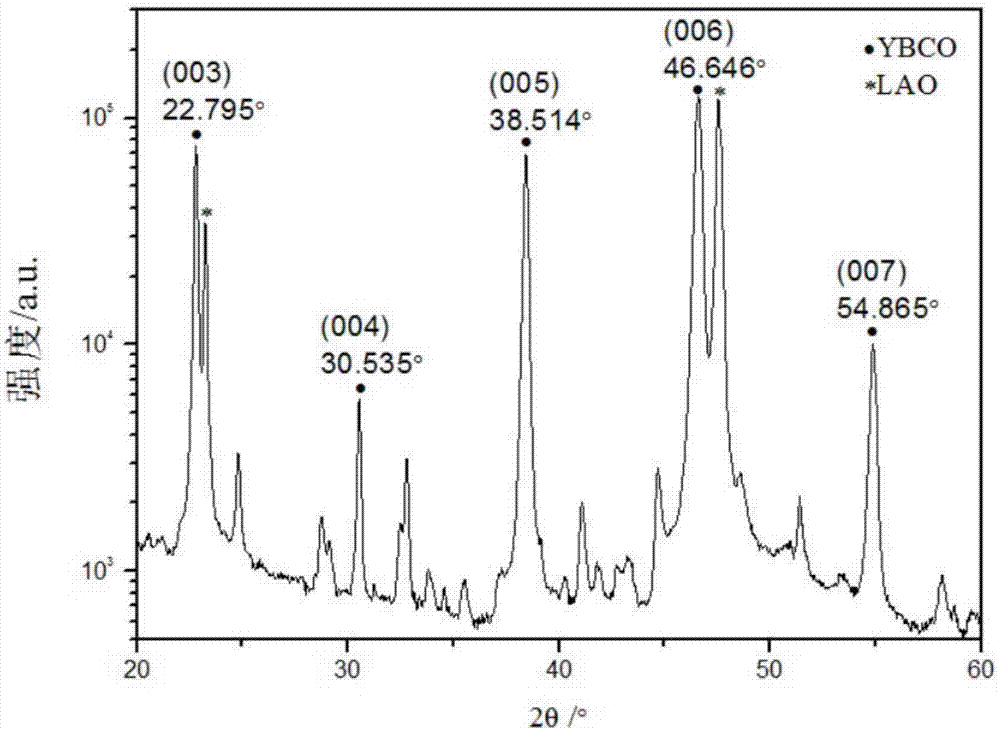

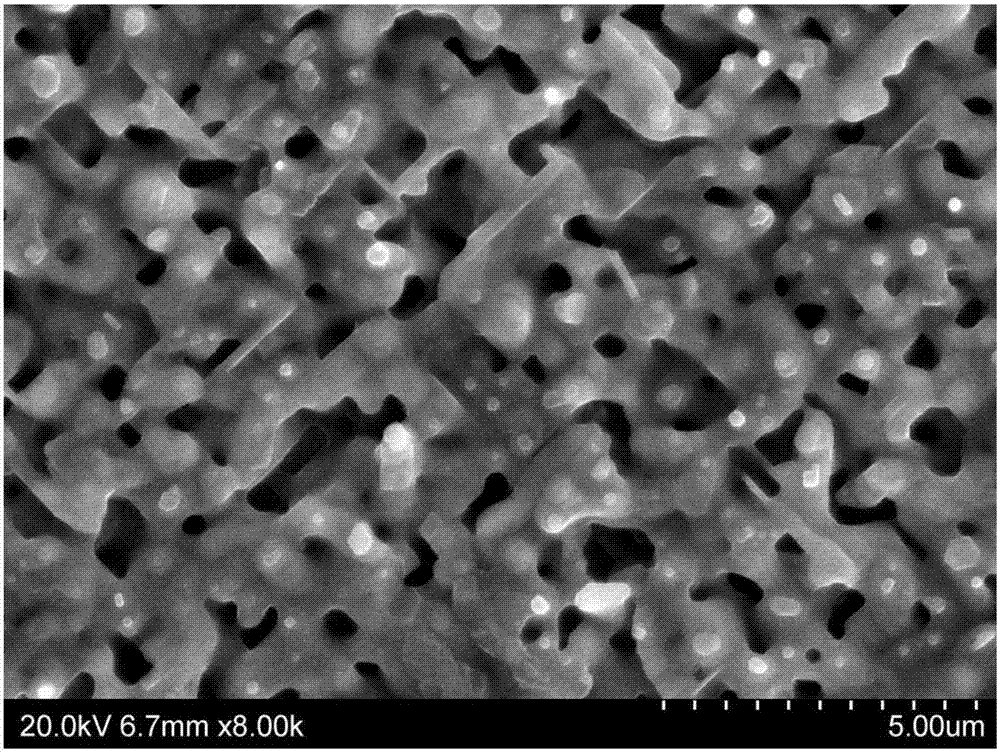

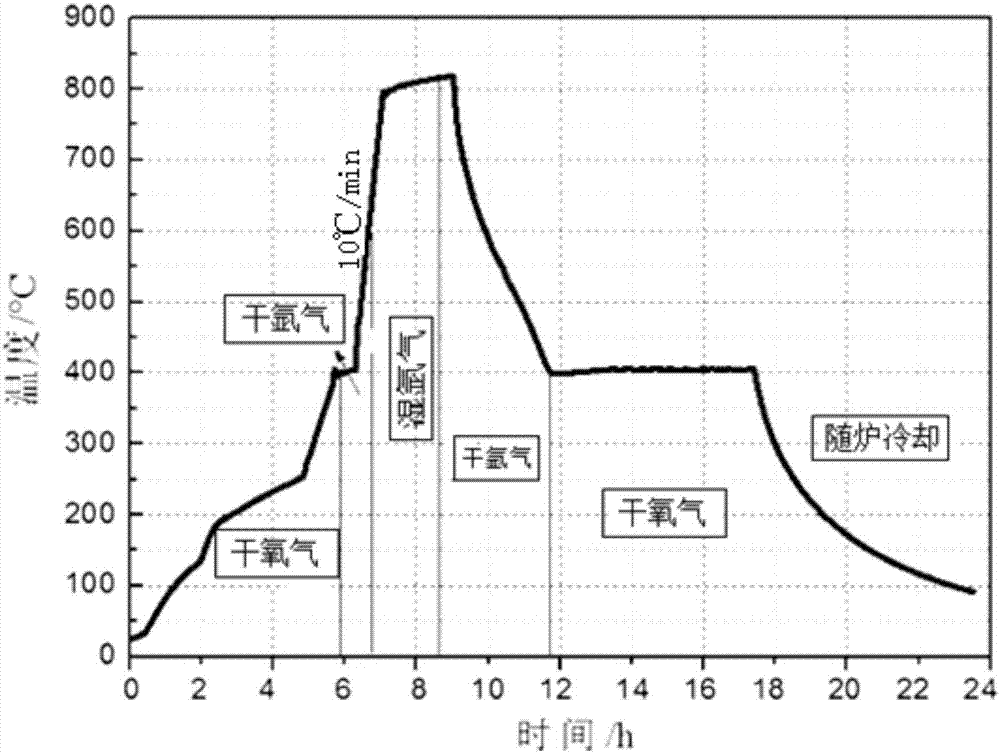

Method for preparing boron-doped YBCO (Yttrium Barium Copper Oxide) superconducting film by one-step heat treatment process

InactiveCN107311641ASolve the problems of continuous productionReduce consumptionBoron trioxideElectric properties

The invention discloses a method for preparing a boron-doped YBCO (Yttrium Barium Copper Oxide) superconducting film by a one-step heat treatment process, which belongs to the technical field of materials. With yttrium acetate, barium trifluoroacetate and copper isocaprylate as materials, ethanol as a medium and boric acid as a dopant, the boron-doped YBCO superconducting film is prepared by thermal crystallization. According to the method disclosed by the invention, a boron element is uniformly doped into the YBCO film, the viscosity of precursor solution is increased, the shrinkage of the film in the process of YBCO heat treatment is relieved, consequently, the preparation of the boron-doped YBCO superconducting film by the one-step heat treatment process becomes possible, and the quality of film formation is ensured. In addition, the boric acid is generated into diboron trioxide under the condition of high temperature, which is doped in the produced film to serve as a pinning center in the form of a second phase, and thereby the electric property of the film in a magnetic field is improved. The efficiency of production is high, and the method has a great application prospect.

Owner:NORTHEASTERN UNIV

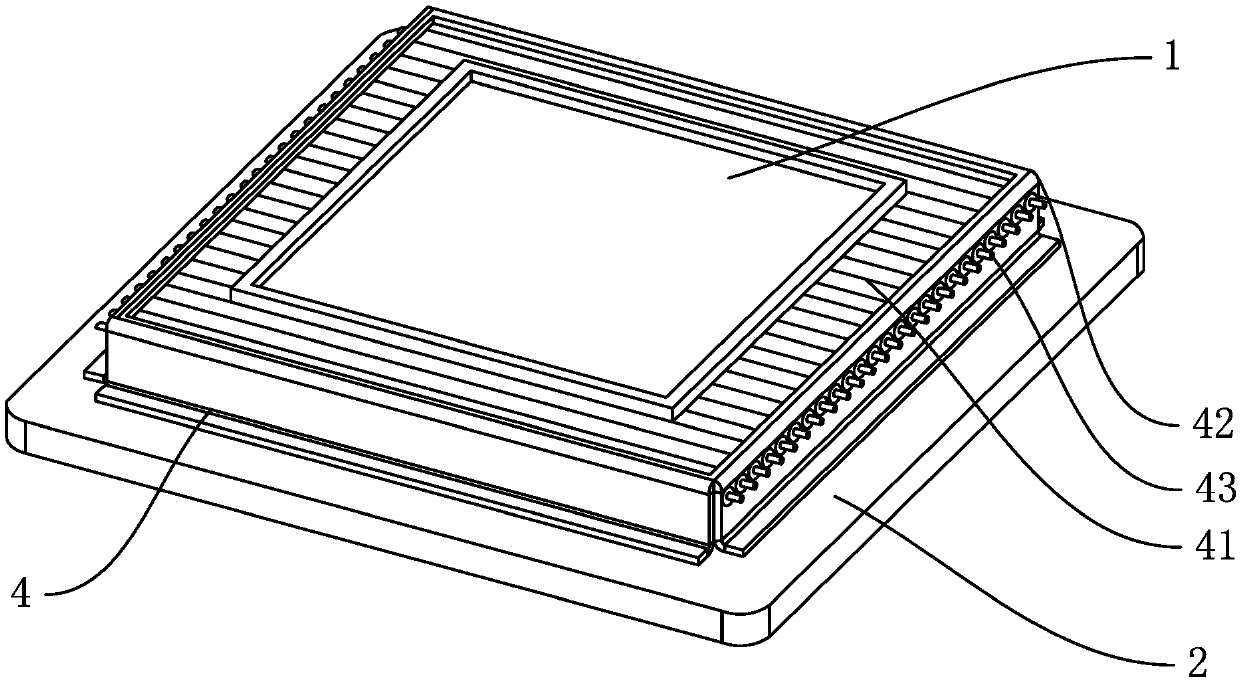

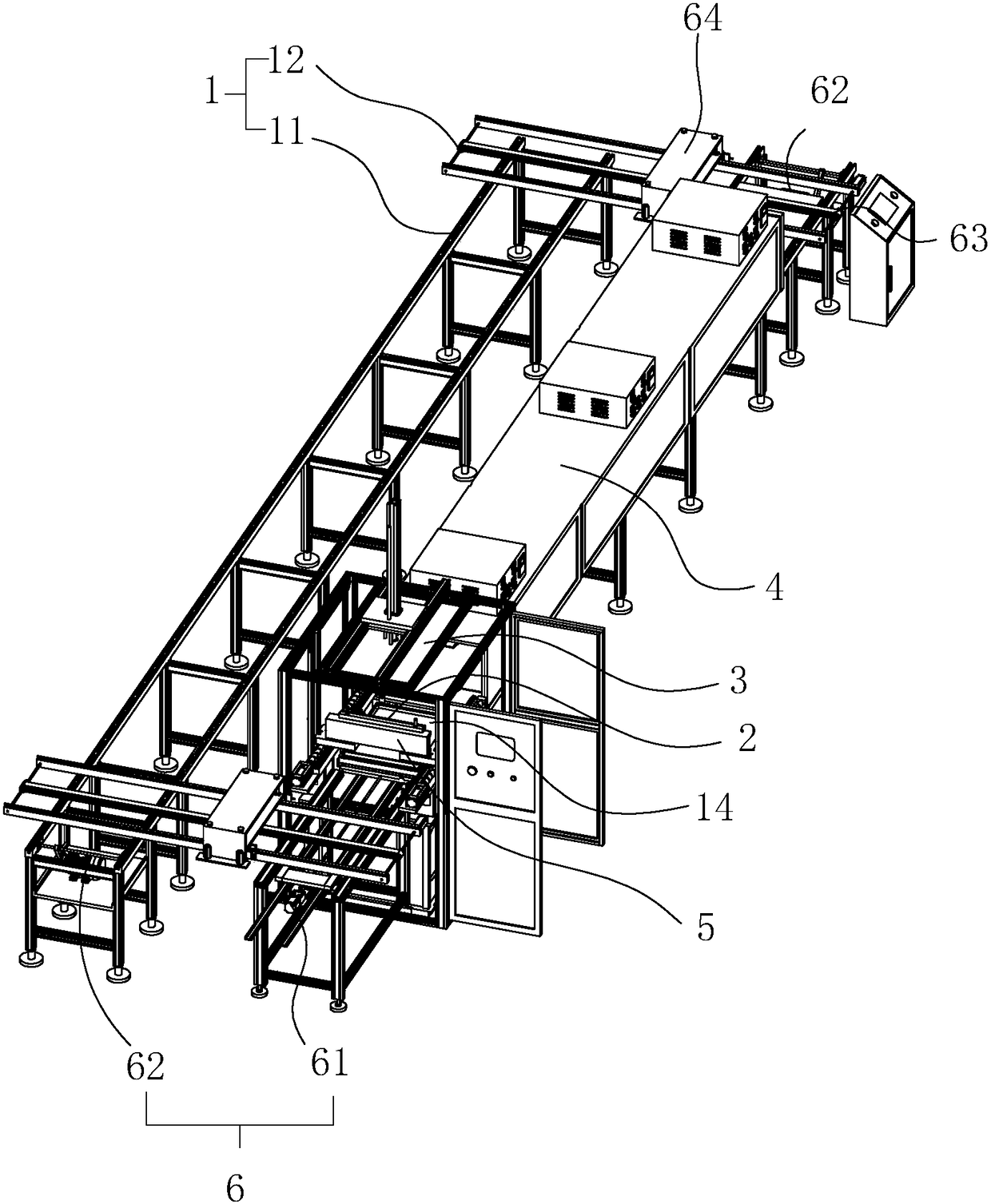

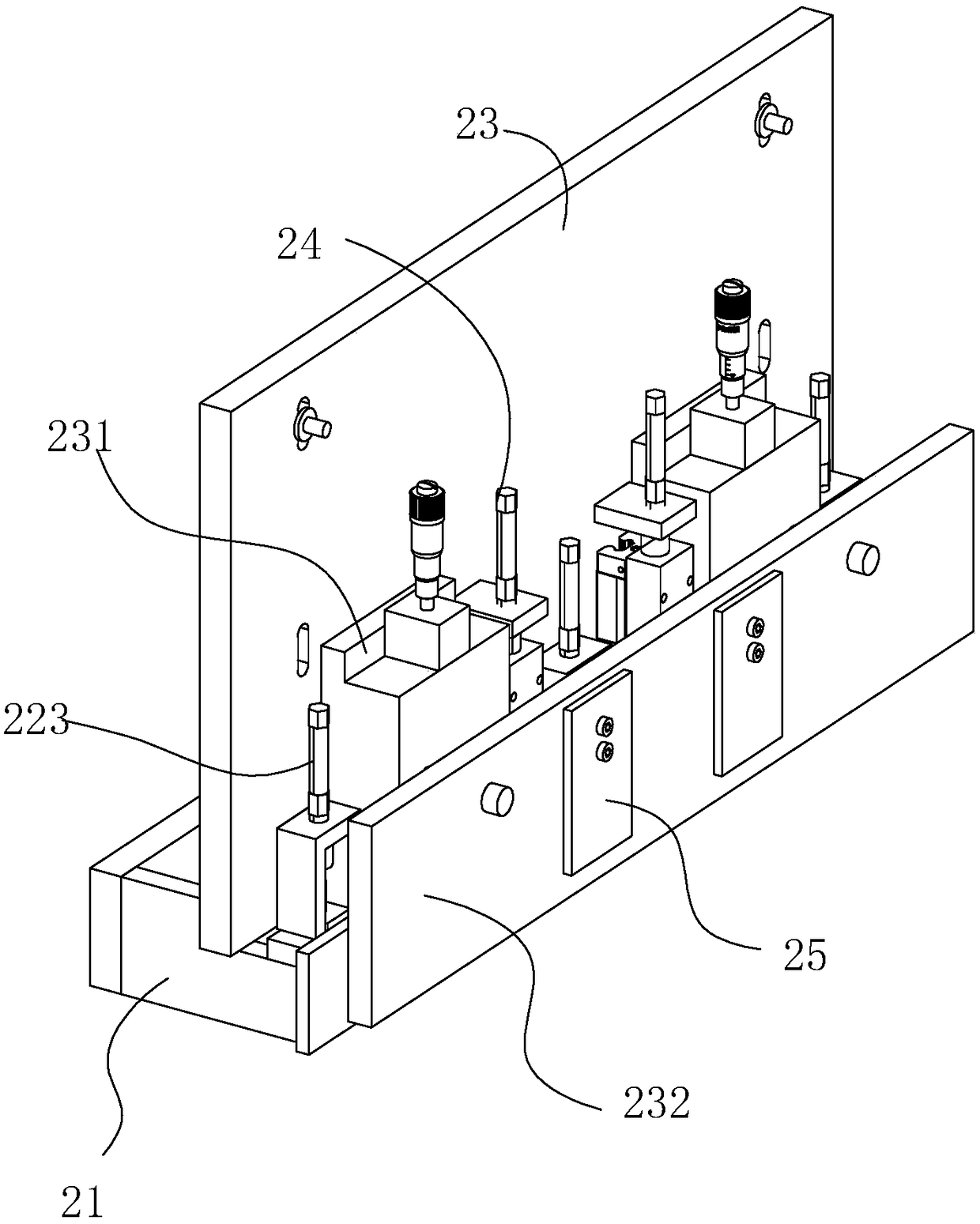

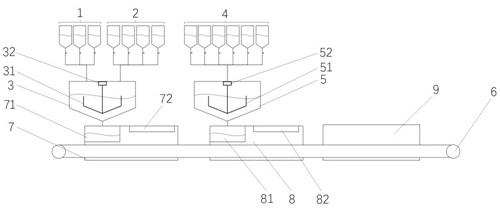

Tape casting membrane preparation production line

PendingCN108556235AContinuous film production conditionsStable Film Forming ConditionsPretreated surfacesFlat articlesProduction lineTape casting

The invention discloses a tape casting membrane preparation production line, and relates to the field of membrane preparation equipment. The tape casting membrane preparation production line comprisesa machine frame, wherein a hard membrane preparation plate, a bearing platform, a coating mechanism, a pre-drying mechanism, a drying oven and a conveying system are arranged on the machine frame; the bearing platform is used for bearing the membrane preparation plate; the coating mechanism is used for coating the membrane preparation plate with a membrane preparation solution; the pre-drying mechanism is positioned above the bearing platform; the drying oven is positioned at the downstream part of the bearing platform; the conveying system is used for conveying the membrane preparation plateto the drying oven from the bearing platform and then cyclically conveying to the bearing platform; the coating mechanism is arranged above the bearing platform. The continuous membrane preparation on a hard plate is realized; compared with a traditional flexible conveying belt membrane preparation mode, the device can effectively provide stable, flat and continuous membrane preparation conditions for the coating mechanism; the conditions are provided for preparing thinner and more uniform diaphragms.

Owner:温岭市聚氟科技有限公司

Mirror surface multicolor film preparation process based on raw material adjustment

InactiveCN112024332AMade preciselyImprove film production efficiencyCoatingsSpecial surfacesControl systemMaterials science

The invention relates to a mirror surface multicolor film preparation process based on raw material adjustment. The mirror surface multicolor film preparation process comprises a release layer preparation unit, a multicolor layer preparation unit, a coating unit and a central control unit. According to the mirror surface multicolor film preparation process, by arranging the central control unit ina system and connecting the central control unit with designated equipment in the system, the central control unit can calculate the area S for preparing a multicolor film according to the size of aselected to-be-prepared film, select the designated raw material consumption according to the area and adjust the operation parameters of the corresponding parts, and thus the materials for preparingare used to the greatest extent while the high-curing multicolor film is prepared; and the central control unit is provided with an S0 matrix, a T1 matrix, a T2 matrix, a T3 matrix, an A0 matrix groupand a D0 matrix group, the central control unit can establish an Ri matrix group according to the comparison result of the area S of the to-be-prepared multicolor film and each parameter in the S0 matrix so as to select a specified parameter to control the raw material consumption in the system and the operation parameters of each specified part, so that the multicolor film can be prepared more accurately, and the film preparation efficiency of the system can be further improved.

Owner:瑞年科技(广东)有限公司

High-breathability packaging material and preparation method thereof

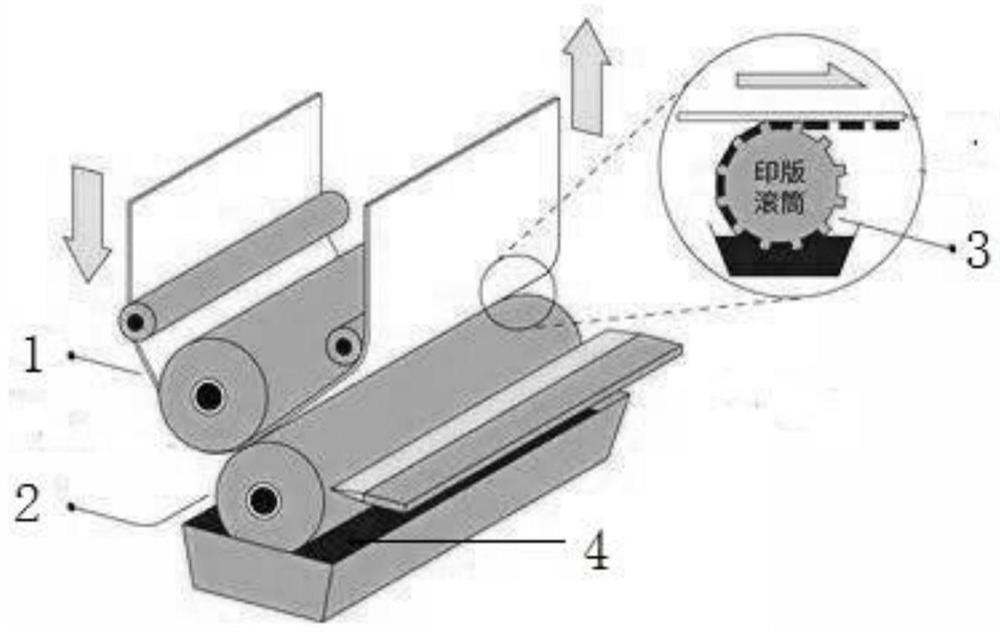

InactiveCN113369115AAdhesion improvement and dryingReduced printabilityFlexible coversLiquid surface applicatorsEthylene oxideMechanical engineering

The invention discloses a high-breathability packaging material for packaging medical apparatus and instruments. A film layer structure of the packaging material sequentially comprises a first heat-sealing layer, a base material layer and / or a second heat-sealing layer from inside to outside, and the first heat-sealing layer and / or the second heat-sealing layer are / is formed by taking a material containing heat-sealing resin as a raw material and coating one side of two sides of the base material layer with the raw material by adopting an intaglio printing method. The invention further discloses a preparation method of the high-breathability packaging material. Due to the fact that the heat-sealing resin is sprayed to one side or two sides of the base material layer in a fixed-point manner by adopting the intaglio printing method, the packaging material has good porosity, uniform pores and small holes, an excellent ventilation effect is achieved, the sterilization difficulty of ethylene oxide is reduced, the sterilization effect of ethylene oxide and the like is improved, and the medical apparatus and instruments packaged by the packaging material can keep a long-term sterile effect during transportation, storage and use.

Owner:JIANGYIN BAOBO PACKING

A flexible nanocomposite holographic storage film, film preparation method and application

ActiveCN110452403BHigh diffraction efficiencyEnhanced resonance absorption phenomenonRecord information storageOptical record carrier manufactureHolographic storagePolymer science

Owner:NORTHEAST NORMAL UNIVERSITY

Heterogeneous in-situ fiber-forming reinforced cellulose acetate hollow fiber membrane and preparation method thereof

ActiveCN105214517BImprove mechanical propertiesLow costSemi-permeable membranesPolymer scienceFiltration membrane

The invention discloses a heterogeneous in situ fiber forming reinforcing cellulose acetate hollow fibrous membrane. The hollow fibrous membrane is characterized by being prepared from, by mass, 14-30% of cellulose acetate, 2-10% of fiber forming polymers, 60-80% of diluent and 0.5-4% of pore-foaming agents, wherein the sum of all constituents is 100%. A preparation method of the reinforcing type hollow fibrous membrane comprises the steps of dissolving the cellulose acetate, the fiber forming polymers, the diluent and the pore-foaming agents, obtaining homogeneous membrane casting liquid, conducting vacuum deformation, further compacting the mixture through a double-screw extruder, jetting out the mixture through an annular spinning nozzle, then under the traction of a wire winding guide roller, immersing the mixture into a coagulation bath for conducting solidification and formation, obtaining a protogenous hollow fibrous membrane, then placing the protogenous hollow fibrous membrane into an extraction agent, extracting the diluent and the pore-foaming agents, conducting heat treatment, and obtaining the cellulose acetate hollow fibrous micro-filtration membrane. According to the heterogeneous in situ fiber forming reinforcing cellulose acetate hollow fibrous membrane and the preparation method thereof, no coating operation is needed in the preparation process, the process is simple, the membrane manufacturing efficiency is high, the cost is low, and the hollow fibrous membrane and the preparation method thereof are suitable for large-scale production.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

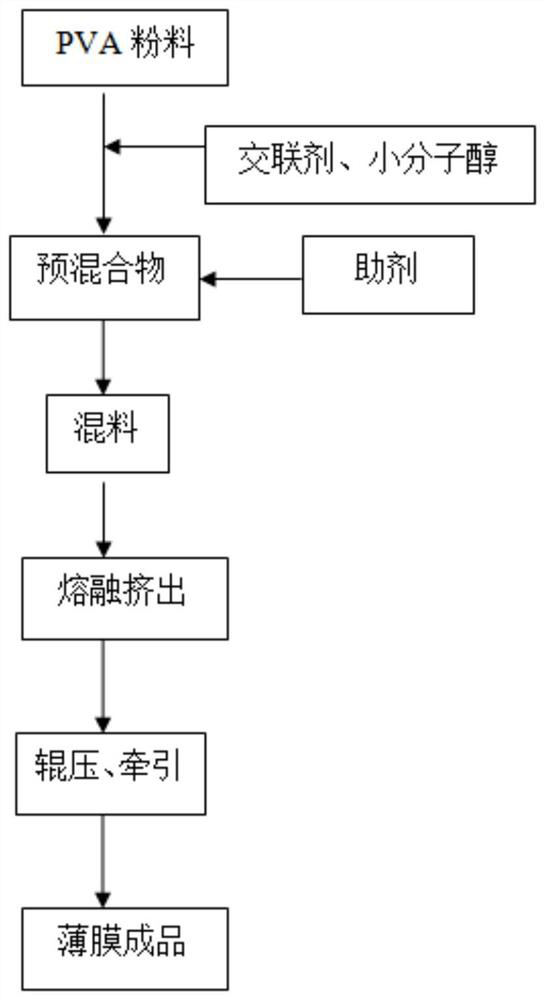

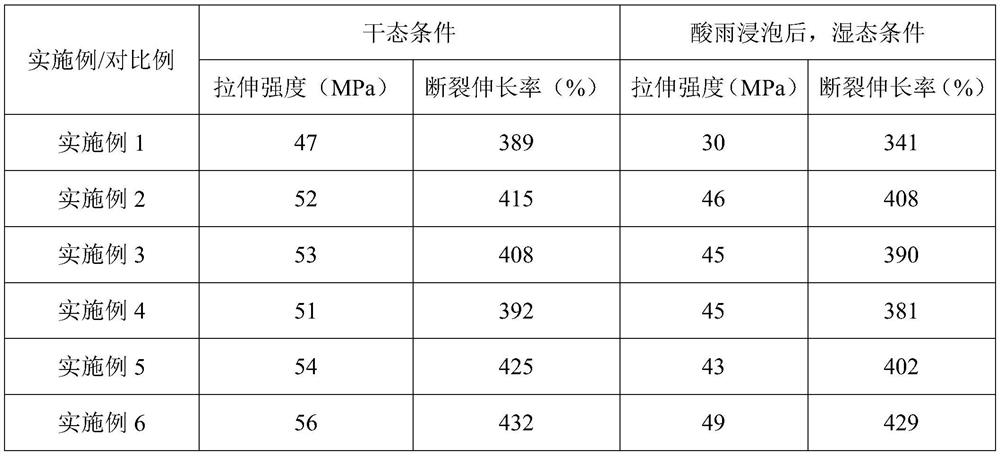

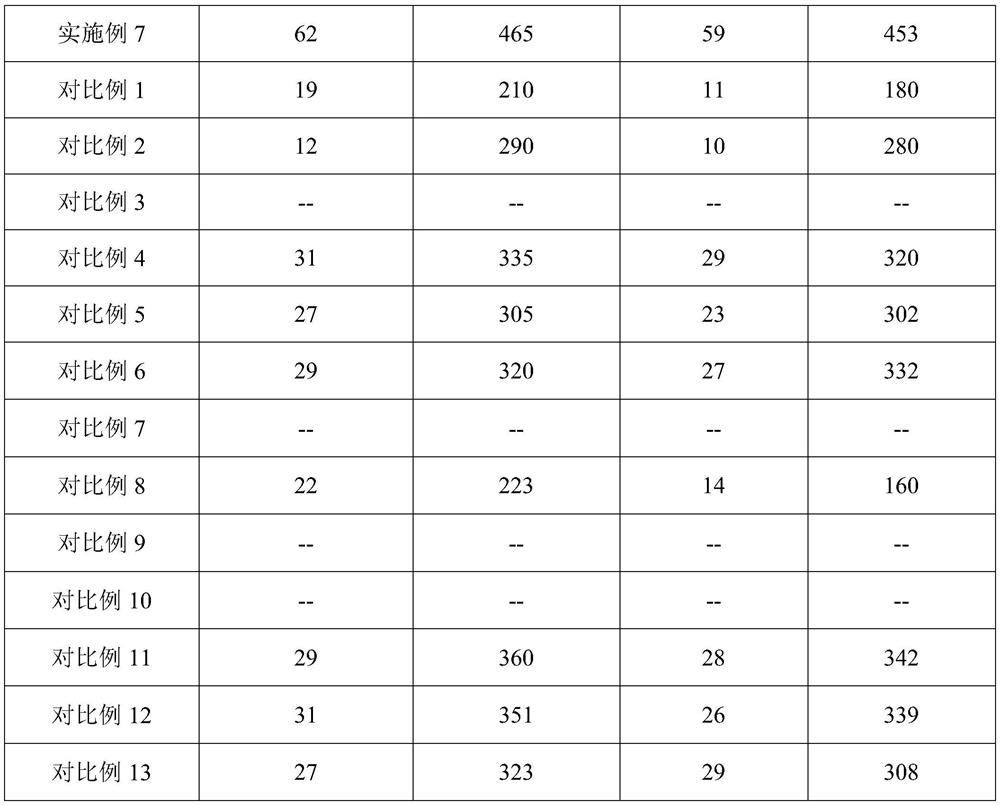

A kind of preparation method of water-resistant pva biodegradable film

ActiveCN109181183BPromote the development of industrialized productionGood moisturizing effectPolymer scienceCross linker

The invention discloses a method for preparing a water-resistant PVA biodegradable film. The steps include: a. preparing a PVA aqueous solution with raw materials containing small molecule alcohol, PVA, water and a crosslinking agent; b. extruding a PVA sheet using a screw extruder material.

Owner:NEW NAVIGATOR PLASTICS

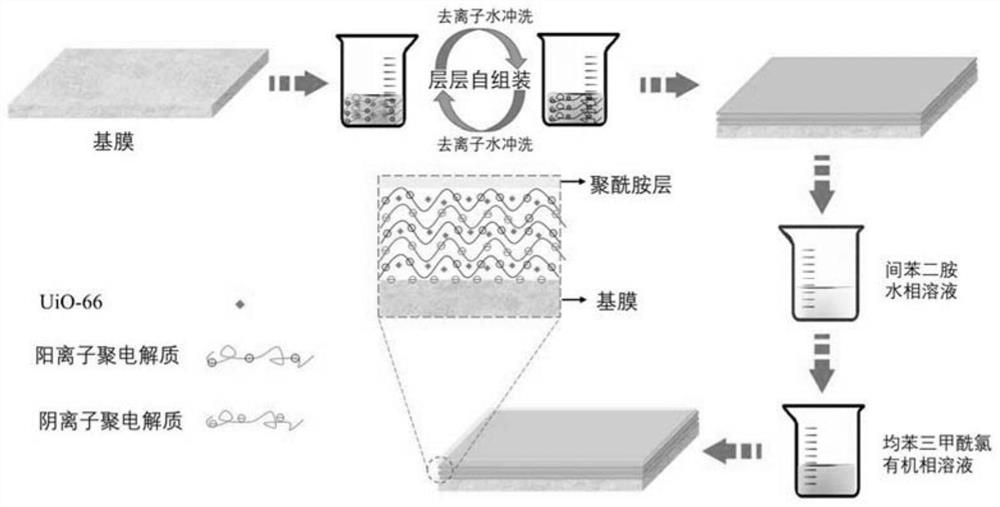

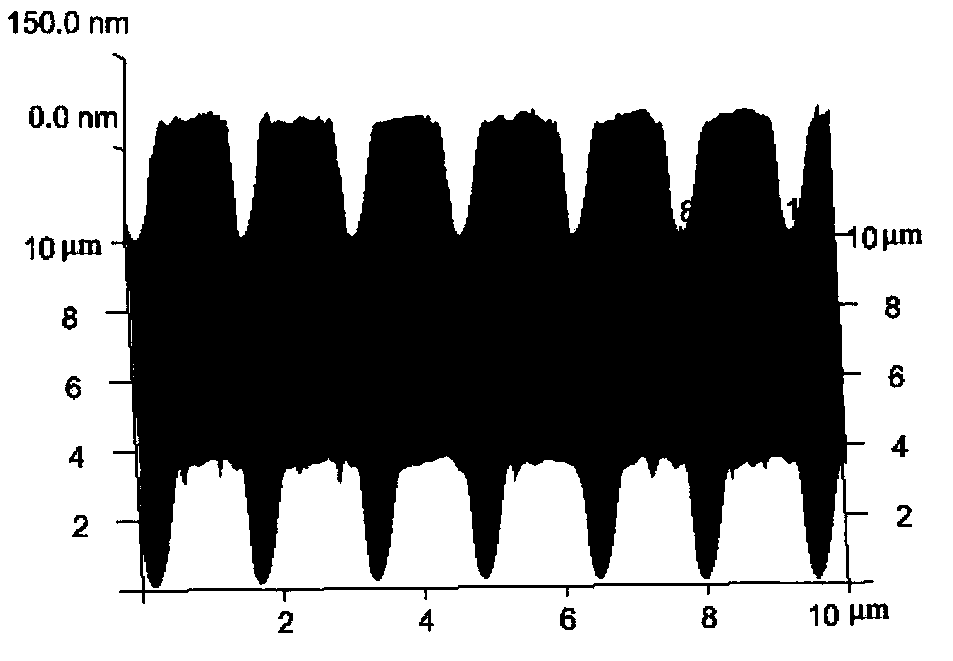

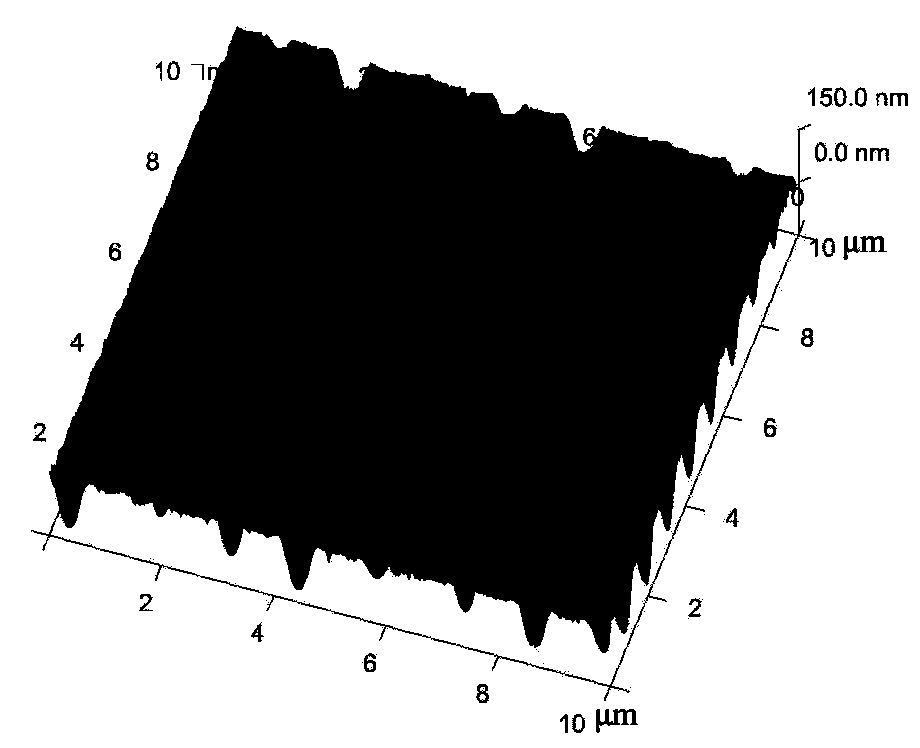

UiO-66 doped multifunctional layer composite nanofiltration membrane and method for preparing UiO-66 doped multifunctional layer composite nanofiltration membrane

ActiveCN114768547AImprove performanceImprove surface propertiesSemi-permeable membranesGeneral water supply conservationPolymer scienceCationic polyelectrolytes

The invention discloses a method for preparing a UiO-66 doped multifunctional layer composite nanofiltration membrane, and the method comprises the following steps: respectively contacting the surface of a base membrane with a cationic polyelectrolyte solution and an anionic polyelectrolyte solution which are mixed with UiO-66, and repeating the steps for a plurality of times until a multi-layer UiO-66 + polyelectrolyte composite membrane is obtained. And respectively contacting the surface of the multi-layer UiO-66 + polyelectrolyte composite membrane with a m-phenylenediamine aqueous phase solution and a trimesoyl chloride organic phase solution to obtain the multi-layer UiO-66 + polyelectrolyte-polyamide composite membrane. And carrying out heat treatment to obtain the UiO-66 doped multifunctional layer composite nanofiltration membrane. The composite nanofiltration membrane provided by the invention improves the membrane preparation efficiency and the membrane stability, and has the comprehensive properties of high flux, high retention rate, good pollution resistance, good organic compatibility, adjustable pore size and height, and easy realization of functional group modification.

Owner:XIAN UNIV OF SCI & TECH

Laser thermal lithography organic photoresist and preparation method of photoresist

ActiveCN102880001BImprove film production efficiencyLow costOrganic chemistryOrganic compound preparationLithographic artistOrganic solvent

The invention discloses a laser thermal lithography organic photoresist, as well as a preparation method of the laser thermal lithography organic photoresist, wherein the photoresist is composed of 4, 6, 10, 12, 16, 18, 22, 24, 25, 26, 27 and 28-dodecanohydroxycalix [4]arene derivatives. The laser thermal lithography organic photoresist is prepared by phloroglucinol and aldehydes subjected to condensation reaction under the catalytic function of an acid. The photoresist can be dissolved in an organic solvent and can prepare a film in a simple spinning way. The photoresist is directly heated and gasified by laser to directly produce smooth pit-shaped micron and nano-pattern structures, and a following developing process is avoided, which further reduces the film making cost and improves the film making efficiency.

Owner:HANGZHOU INSTITUTE OF OPTICS AND FINE MECHANICS

Fin beating device

InactiveCN110640043AImprove film production efficiencyHeat exchange apparatusControl systemEngineering

The invention discloses a fin beating device which comprises a main body. A conveying belt, a conveying roller set, a cleaning roller set, a pressing roller set, a fin beating machine and a fin receiving machine are sequentially installed on the main body, a control system is installed inside the main body, the conveying belt, the conveying roller set, the cleaning roller group, the pressing roller set, the fin beating machine and the fin receiving machine are all connected with the control system, a plurality of fin receiving rods are installed on the fin receiving machine, the fin beating machine is provided with fin outlets, and the fin receiving rods are arranged on the fin outlets. Compared with the prior art, the fin beating device adopts the full mechanical design, control over allflow of the fin beating production can be achieved, the fin beating production efficiency is improved, the intermediate labor and time cost is saved, and the market prospect and the application prospect are wide.

Owner:徐建

A kind of high throughput and high rejection rate dual-excellent PVDF flat membrane preparation method

ActiveCN108854593BReduce film production costImprove film production efficiencySemi-permeable membranesMembranesActive agentNonwoven fabric

The invention belongs to the technical field of membrane separation and specifically relates to a preparation method of a high-throughput and high-rejection rate double-excellence fluorocarbon specific surfactant blending modified PVDF membrane. The preparation method of a high-throughput and high-rejection rate double-excellence type PVDF flat membrane comprises the following steps: mixing a poreforming agent, a nonionic fluorocarbon specific surfactant, a main membrane material and an organic solvent; heating in water bath and stirring for 6-10h, wherein the pore forming agent, the nonionicfluorocarbon specific surfactant, the main membrane material and the organic solvent account for 1-3%, 1-7%, 12-20% and 70-86% of total mass; pouring a membrane casting solution after ultrasonic-vacuum-standing defoaming onto a glass plate or non-woven fabric in a Z-shaped manner, and scraping to obtain a film with 30-200mum thickness; standing for 15-30s in air; performing coagulating bath by taking emulsified oil / water mixed liquid as a non-solvent phase to obtain a membrane, wherein the membrane is the high-throughput and high-rejection rate double-excellence type PVDF flat membrane.

Owner:SHANXI UNIV

A homogenizer with pre-annealing function

ActiveCN103495529BSimple preparation processImprove glue dispensing efficiencyLiquid surface applicatorsCoatingsEngineeringOrganic matter

The invention discloses a glue mixing machine with a pre-annealing function. The glue mixing machine comprises a glue filling device, a heating device, a heat abstractor and a glue mixer, wherein the glue filling device is used for simplifying a manual glue dropping process into a control process of simple switch motion of a normal close type water valve, so that the glue dropping efficiency is improved, and the problem caused by experience-based glue dropping is avoided; the heating device is used for heating a sample and achieving a low-temperature pre-annealing function of a film; the heat abstractor is used for cooling an inner container of the glue mixer, promoting the exchange of heat and gas inside and outside the heating device, and discharging escaping organic substances after heating; the glue mixer is used for realizing glue throwing operation when the film is prepared. The glue mixing machine provided by the invention has the advantages that a film preparing experiment process of glue dropping, glue throwing and low-temperature pre-annealing in a sol-gel method is simplified into a film preparing experiment process of repeating glue dropping, glue throwing, low-temperature pre-annealing and then concentrated high-heat treatment with a rapid annealing furnace, so that the film preparing time is shortened, and the film preparing efficiency is greatly improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Laser write-through organic thermal etching material and preparation method thereof

ActiveCN102880003BImprove film production efficiencyLow costOrganic chemistryOrganic compound preparationEtchingEvaporation

The invention discloses a laser write-through organic thermal etching material and a preparation method thereof. The material is prepared by adopting 2-methyl resorcinol or 1,2,3-trisphenol and aldehydes having condensation reaction under the catalysis of acid. The material is used for laser write-through to prepare convex micrometer or nano-scale pattern structures, no femtosecond laser pulse or multi-layer film structures are needed, and only microsecond pulse or continuous laser and single layer film structures are needed, so that the requirements on laser equipment are reduced, the process is simplified, the cost is reduced, and the efficiency is increased; and in addition, compared with a laser thermal etching inorganic material which is used for producing films by using a magnetron sputtering or evaporation plating method under a high vacuum condition, the organic thermal etching material can be dissolved in organic solvents and can be used for producing films by adopting a simple spinning coating method, so that the cost in making films is further reduced, and the film making efficiency is increased.

Owner:HANGZHOU INSTITUTE OF OPTICS AND FINE MECHANICS

Membrane production unit, membrane production system and membrane production method

ActiveCN108889519BHigh degree of intelligenceImprove film production efficiencyLiquid surface applicatorsSpraying apparatusProcess engineeringManipulator

Owner:GUANGZHOU GV IND

Naphtha-containing water-borne acrylic resin and preparation method thereof

The invention provides a method for preparing naphtha-containing water-borne acrylic resin and the water-borne acrylic resin prepared by the method. The method uses a naphtha-containing compound solvent, and comprises the following steps: firstly, dissolving a chain transfer agent in the naphtha-containing compound solvent, adding a mixture A containing an acrylate monomer mixture I, an initiator and a chain transfer agent to initiate polymerization at a relatively low temperature; and then, refilling the initiator and the chain transfer agent into the system to control the reacting speed, and adding a mixture B containing an acrylate monomer mixture II. Therefore, the prepared water-borne acrylic acid has a core-shell structure and is hydrophilic and lyophobic, and a paint film prepared by the water-borne acrylic acid is excellent in hardness, adhesion, impact resistance, water resistance and other performances. Furthermore, the weight ratio of naphtha to other organic solvents of the naphtha-containing compound solvent can be adjusted according to using temperatures, so that the surface drying time can be adjusted, and the film making efficiency can be improved on the premise that the performance of the paint film is not lost.

Owner:河南索顿新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com