Fin beating device

A technology for cleaning rollers and main bodies, applied in heat exchange equipment and other directions, can solve problems such as low production efficiency and inability to guarantee production quality, save intermediate labor and time costs, improve film production efficiency, and have broad market prospects and applications. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

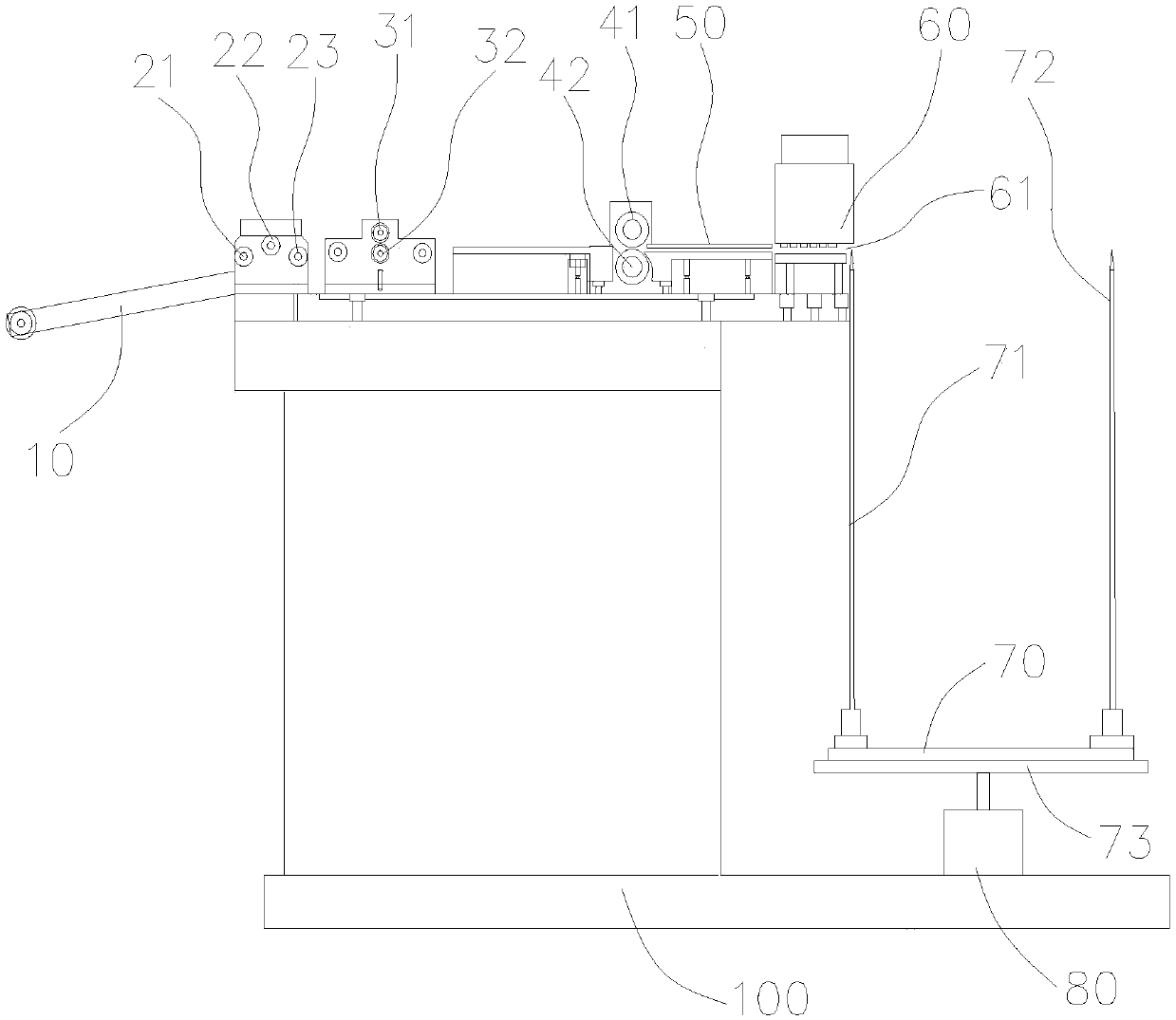

[0014] Such as figure 1 As shown, it is the chipping device of the present invention. The chipping device includes a main body 100, on which a conveyor belt 10, a first lower conveying roller 21, a first upper conveying roller 22, a second lower conveying roller 23, and an upper cleaning roller are sequentially installed. Roller 31, lower cleaning roller 32, upper pressure roller 41, lower pressure roller 42, flat pressing plate 50, slicer 60 and slicer 70, slicer 60 is located at sheet outlet 61, slicer 70 is equipped with Some first splicing rods 71 and some second splicing rods 72 that are arranged symmetrically, a base 73 is installed at the lower end of the splicing machine 70, a rotating motor 80 is installed under the base 73, and the output shaft of the rotating motor 80 is fixedly connected with the base 73, The rotary motor 80 drives the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com