A homogenizer with pre-annealing function

A glue homogenizer and pre-annealing technology, which is applied in the field of glue homogenizers, can solve the problems of low film-making efficiency, achieve the effects of improving glue dispensing efficiency, streamlining the preparation process, and improving film-making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

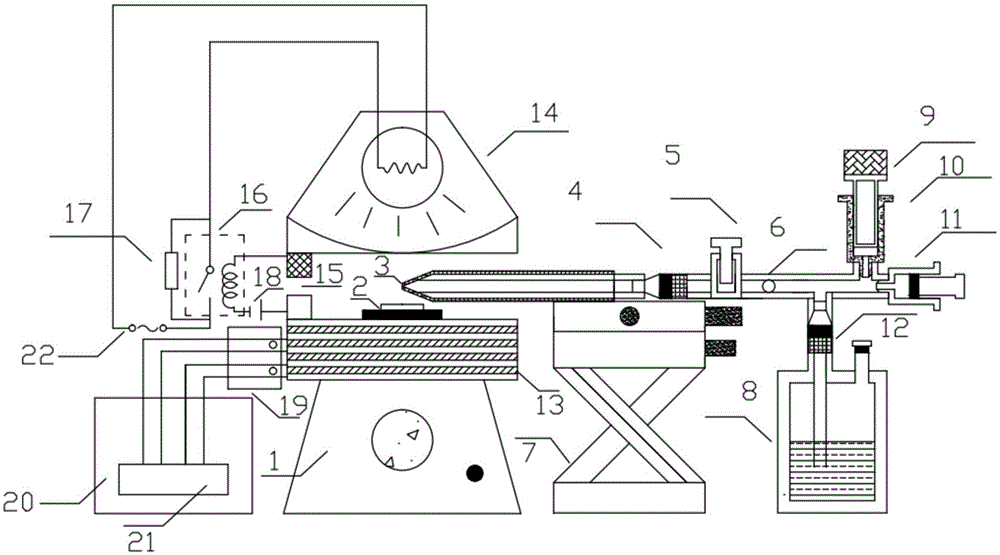

Image

Examples

Embodiment Construction

[0022] Implementation example

[0023] 1. Prepare the precursor solution. Mn for the target component 1.56 co 0.96 Ni 0.48 o 4 Manganese oxide, respectively weigh 91.76g of manganese acetate tetrahydrate, 57.39g of cobalt acetate tetrahydrate, 28.66g of nickel acetate tetrahydrate, dissolve the powder according to the ratio of 400ml of acetic acid and 100ml of water for every 100g of acetate, pour into In the solution holding dish of the negative pressure suction filter, select a filter membrane with a pore size of 0.45 μm to carry out negative pressure suction filtration, filter out the impurity precipitate in the solution, and obtain Mn 1.56 co 0.96 Ni 0.48 o 4 Precursor solution, and put the solution into a storage bottle for later use.

[0024] 2. Preparation of manganese-cobalt-nickel-oxygen film. Using the homogenizer device in alumina (Al 2 o 3 ) prepared Mn on the substrate 1.56 co 0.96 Ni 0.48 o 4 After each spin-coating of the film, use its self-heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com