Flexible capacitive sensor and preparation method and application thereof

A flexible capacitor and sensor technology, applied in the field of flexible sensors, can solve problems such as nonlinearity, limited application range of capacitive sensors, external environmental interference, etc., achieve high linearity and signal-to-noise ratio, broaden the sensing range and application fields, and prevent effect of disease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

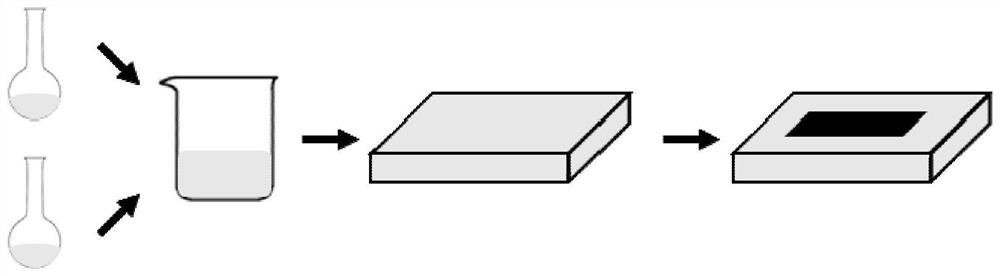

[0061] According to another aspect of the present invention, the present invention also relates to the preparation method of described flexible capacitive sensor, comprises the following steps:

[0062] adhering the flexible electrode to the surface of the dielectric layer;

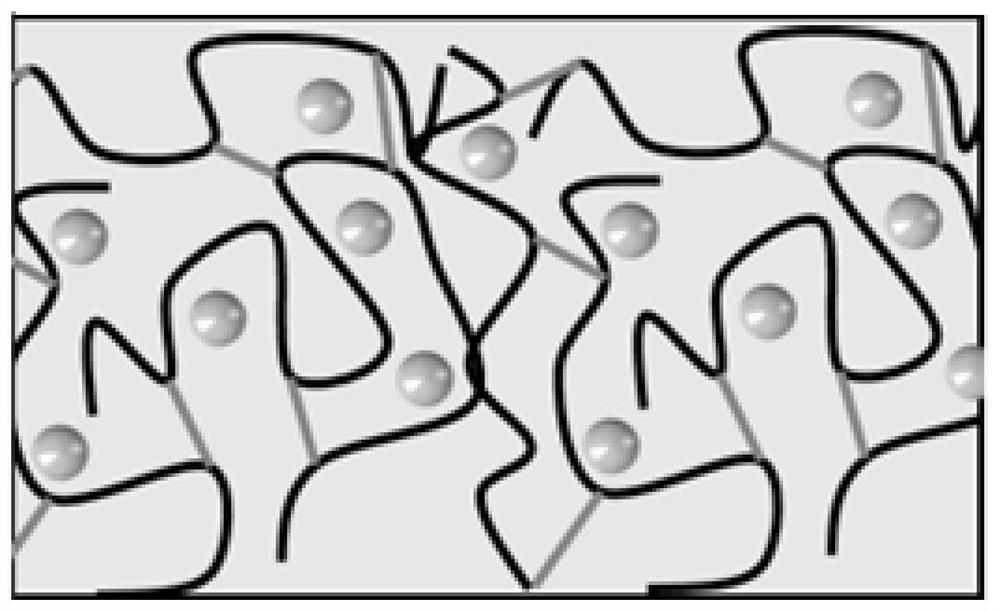

[0063] The dielectric layer is mainly obtained by compounding the inorganic high dielectric particles and the flexible dielectric elastomer substrate.

[0064] The preparation method of the flexible capacitive sensor provided by the invention has the advantages of easy control of the experimental process, suitable for large-scale production and the like.

[0065] Preferably, the preparation method of the dielectric layer includes: drying the mixture of the solution of the flexible dielectric elastomer substrate and the inorganic high dielectric particles.

[0066] The drying of the present invention adopts constant temperature drying, which can quickly solidify the coated mixed solution and shorten the p...

Embodiment 1

[0101] A preparation method for a flexible capacitive sensor, comprising the following steps:

[0102] (a) preparing butyl acrylate by atom transfer radical polymerization, the heating temperature of the atom transfer radical polymerization is 60°C, and the heating time is 12h;

[0103] (b) preparing barium titanate particles by a sol-precipitation method, the heating temperature of the sol-precipitation method is 160°C, and the heating time is 4h;

[0104] (c) Add barium titanate to the butyl acrylate solution in proportion, after ultrasonic stirring for 3 hours, pour it on a glass plate, and dry at a constant temperature of 70°C for 12 hours to obtain a cured composite film; the thickness of the composite film is 100 μm , the volume ratio of barium titanate particles and composite film is 1:8;

[0105] (d) Ultrasonicating the single-walled carbon nanotubes in an aqueous solution of alkyl sodium dodecahydrate for 3 hours, and suction filtering onto filter paper to prepare si...

Embodiment 2

[0109] A preparation method for a flexible capacitive sensor, comprising the following steps:

[0110](a) preparing butyl acrylate by atom transfer radical polymerization, the heating temperature of the atom transfer radical polymerization is 50°C, and the heating time is 15h;

[0111] (b) preparing barium titanate particles by a sol-precipitation method, the heating temperature of the sol-precipitation method is 150°C, and the heating time is 5h;

[0112] (c) Add barium titanate in proportion to the butyl acrylate solution, stir ultrasonically for 2-3 hours, pour it on a glass plate, and dry it at a constant temperature of 80°C for 10 hours to obtain a cured composite film; the thickness of the composite film 80μm, the volume ratio of barium titanate particles and composite film is 1:12;

[0113] (d) Ultrasonicating the single-walled carbon nanotubes in an aqueous solution of alkyl sodium dodecahydrate for 2 hours, and suction filtering onto filter paper to prepare single-wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com