Method for producing lithium-ion secondary battery membrane

A lithium-ion battery and production method technology, applied in the field of battery diaphragm production, can solve the problems of complex manufacturing process and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

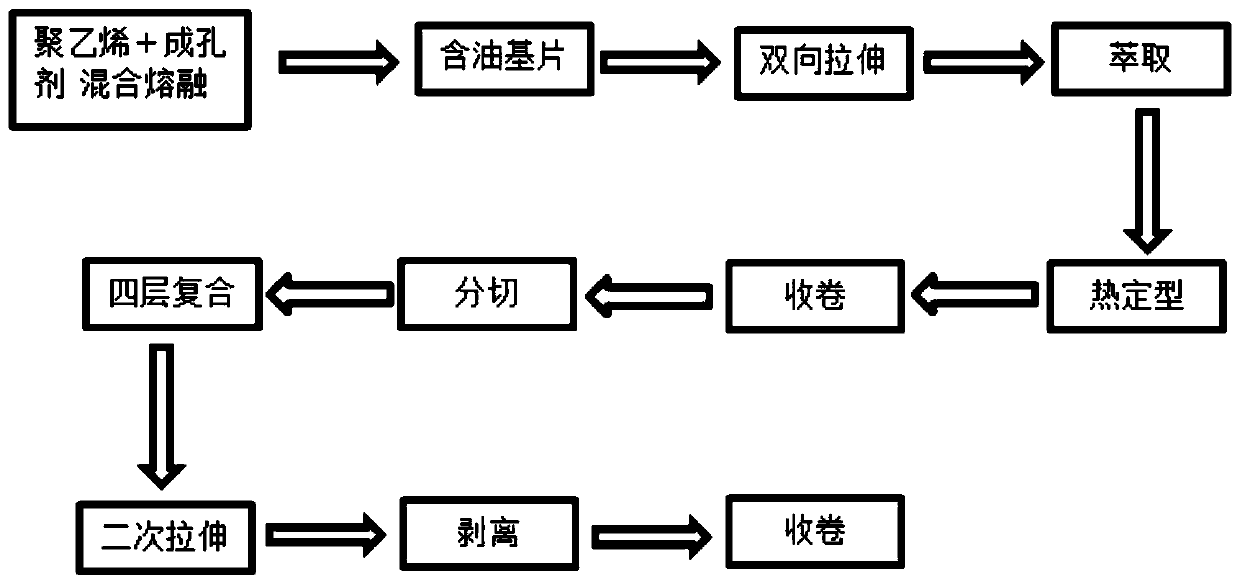

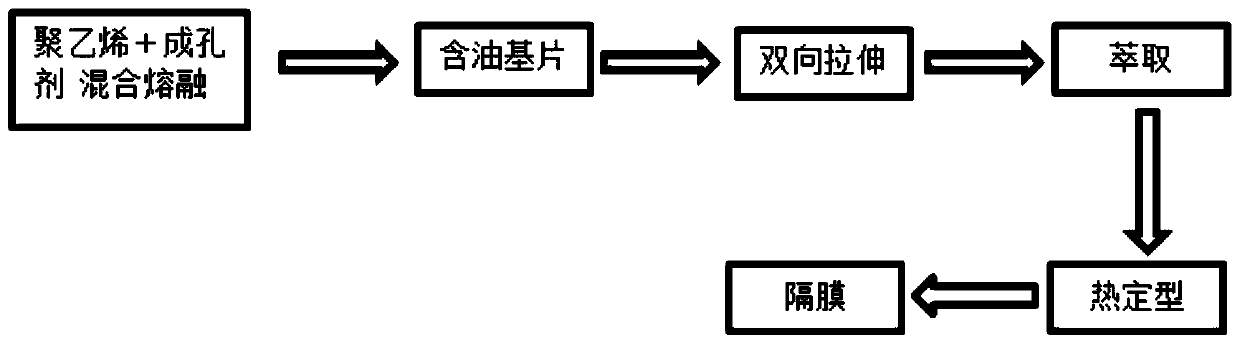

[0062] Such as figure 1 Shown, a kind of production method of lithium-ion secondary battery diaphragm, comprises in the step of method:

[0063] Preparation of microporous diaphragms by lithium-ion battery diaphragm production process;

[0064] Slitting the microporous membrane through a cutting system to obtain a semi-finished microporous membrane;

[0065] Four rolls of the semi-finished microporous diaphragm are compounded in four layers by a composite device to obtain a composite microporous diaphragm; wherein, the thickness of the film in the semi-finished microporous diaphragm is 36 μm; biaxial stretching, and the longitudinal ratio of biaxial stretching and horizontal draw ratio are both 2;

[0066] Stretching the composite microporous membrane;

[0067] The stretched composite microporous diaphragm is peeled off by a stripping device to obtain a finished microporous diaphragm; the thickness of the film in the finished microporous diaphragm is 9 μm.

[0068] In this...

Embodiment 2

[0085] The method of the present embodiment is basically the same as the embodiment one, the difference is: the viscosity-average molecular weight of the polyethylene is 3,000,000,

[0086] The mass percent of polyethylene is 25%,

[0087] The mass percentage of the pore forming agent is 75%.

[0088] The cooling temperature was 30°C.

[0089] The temperature of the heat treatment was 132°C.

Embodiment 3

[0091] The method of the present embodiment is basically the same as the embodiment one, the difference is: the viscosity-average molecular weight of the polyethylene is 2,000,000,

[0092] The mass percent of polyethylene is 30%,

[0093] The mass percentage of the pore forming agent is 70%.

[0094] The cooling temperature was 30°C.

[0095] The temperature of the heat treatment was 132°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com