Laser thermal lithography organic photoresist and preparation method of photoresist

A technology of laser thermal etching and photoresist, which is applied in the field of photoresist, can solve the problems of developer environmental pollution, etc., and achieve the effect of high film production efficiency and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

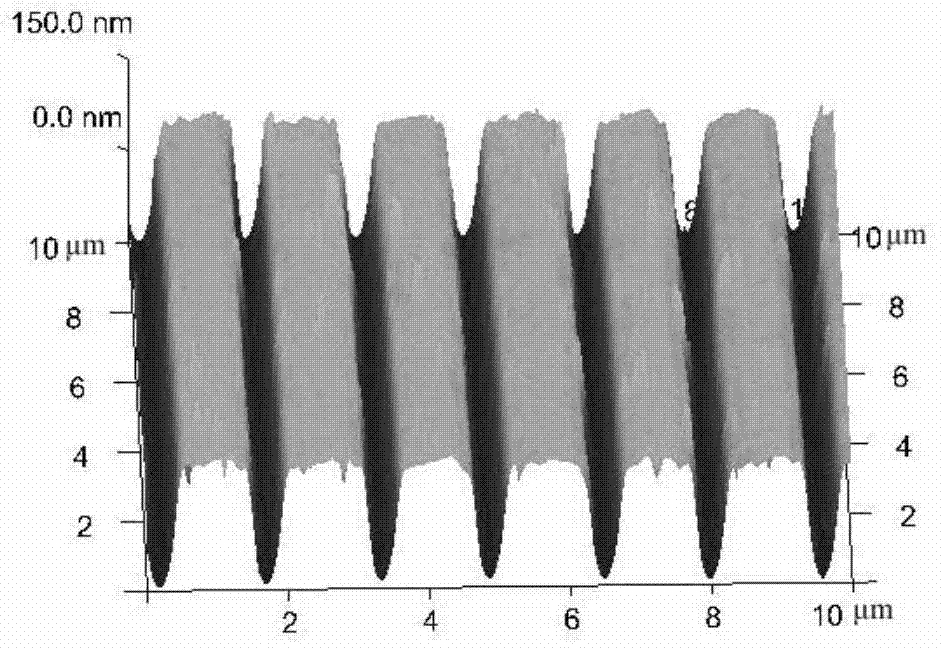

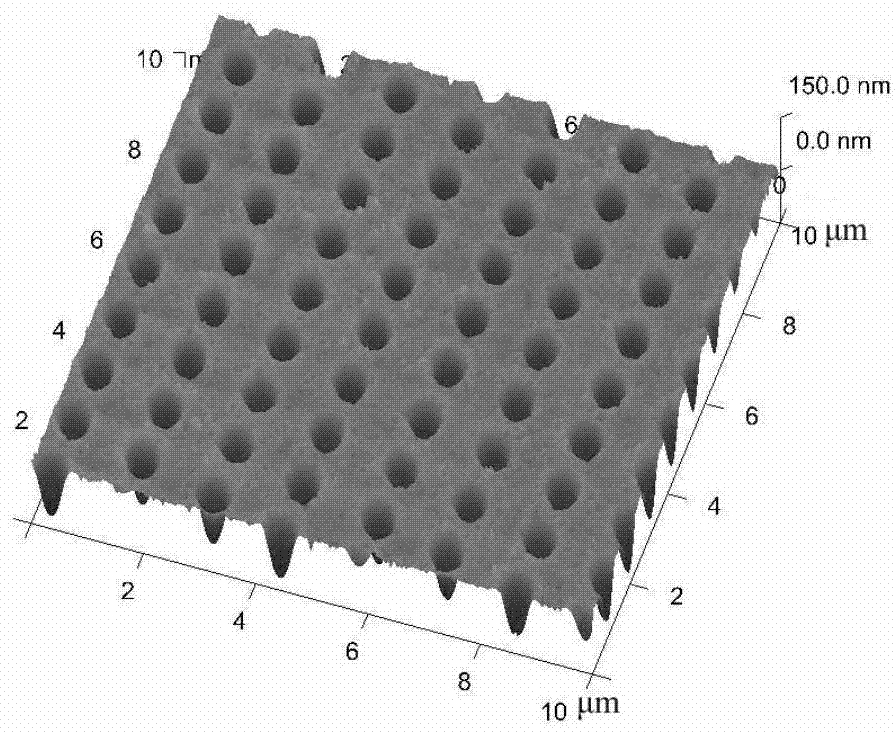

Image

Examples

preparation example Construction

[0029] The preparation method of the described laser thermal etching organic photoresist, the specific preparation steps of the method are as follows:

[0030] ① The range of synthetic raw materials and their weight percentages are: phloroglucinol 3.1wt%~6.3wt%; concentrated hydrochloric acid 15wt%~20wt%; aldehyde compounds 1.5wt%~6.6wt%; ethanol 33.55wt%~52.8 wt%; deionized water 24wt% ~ 39.5wt%; select the weight percentage of synthetic raw materials and weigh the raw materials;

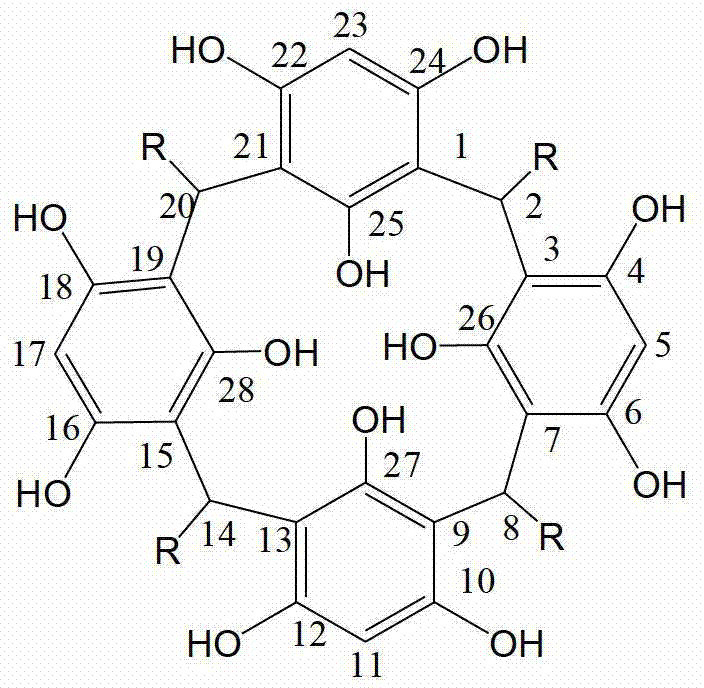

[0031] ②Dissolve the phloroglucinol in the mixed solution of ethanol and deionized water, pass it under the protection of nitrogen, stir and slowly add the concentrated hydrochloric acid dropwise, and then slowly add the Aldehyde compounds are added dropwise, stirred and reacted at a temperature of 25°C to 78°C for 12 to 48 hours, the reaction formula is as follows:

[0032]

[0033] ③ After the reaction, stand and cool for 1 to 2 hours, filter and dry under reduced pressure to obtain the targe...

Embodiment 1

[0036] The preparation method of this embodiment:

[0037] Weigh the synthetic raw materials in the following percentages by weight:

[0038] Phloroglucinol: 6.3wt%; concentrated hydrochloric acid: 20wt%; n-heptanal: 5.7wt%; ethanol: 34wt%; deionized water: 34wt%.

[0039] Stir and react at 25°C for 12 hours, the reaction formula is as above;

[0040] After the reaction is over, let it stand for cooling for 1 hour, the product precipitates out from the reaction solution, and the obtained product is filtered off, and vacuum-dried at 50°C to obtain 2, 8, 14, 20-tetra-n-hexyl-4, 6, 10, 12, 16, 18, 22, 24, 25, 26, 27, 28-Dodecahydroxycalix[4]arene.

[0041] The characteristic absorption peak of the infrared spectrum is: 3312cm -1 ,2955cm -1 ,2926cm -1 ,2856cm -1 ,1612cm -1 ,1456cm -1 ,1130cm -1 .

Embodiment 2

[0043] As above-mentioned specific synthetic steps:

[0044] Weigh the synthetic raw materials in the following percentages by weight:

[0045] Phloroglucinol: 3.1wt%; concentrated hydrochloric acid: 15wt%; n-heptanal: 2.7wt%; ethanol: 52.8wt%; deionized water: 26.4wt%.

[0046] Stir and react at 25°C for 18 hours, the reaction formula is as above;

[0047] After the reaction, let stand and cool for 2 hours, the product precipitated from the reaction solution, filtered out the obtained product, and dried in vacuum at 50°C to obtain 2, 8, 14, 20-tetra-n-hexyl-4, 6, 10, 12, 16, 18, 22, 24, 25, 26, 27, 28-Dodecahydroxycalix[4]arene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com