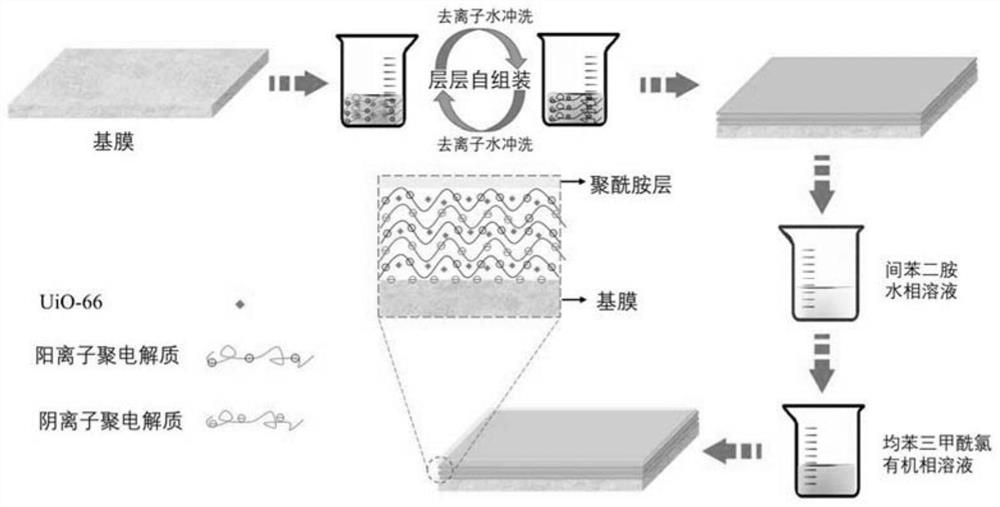

UiO-66 doped multifunctional layer composite nanofiltration membrane and method for preparing UiO-66 doped multifunctional layer composite nanofiltration membrane

A uio-66, multi-functional technology, applied in the field of membrane separation, can solve the problems of reduced composite membrane retention rate, long time-consuming composite membrane, low production efficiency, etc., to improve flux and retention rate, improve membrane flux, phase Good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of UiO-66 is:

[0040] Add 30-60mL N,N-dimethylformamide (DMF), 8-12mL concentrated hydrochloric acid and 1-1.5g zirconium chloride to the flask, and ultrasonically treat for 20-30min to obtain solution A; Phthalic acid and 80-120 00mL DMF were mixed into solution A for sonication for 20-30min, then heated in a water bath at 70-100°C for 6-12h, filtered and dried to obtain UiO-66 solid powder.

[0041] Step 2, mix the surface of the membrane covered with a cationic polyelectrolyte monolayer with a concentration of 0.5-2.5 g / L and an anionic polyelectrolyte (polyacrylic acid, sodium poly-4-styrene sulfonate or sodium alginate with a concentration of 0.5-2.5 g / L); ) solution was contacted for 10-30 min, then rinsed with deionized water for 2 min, and then drained the membrane surface liquid to obtain a membrane covered with an anionic-cationic polyelectrolyte double layer.

[0042] Step 3: Repeat steps 1 and 1 to 3 times on the membrane covered wit...

Embodiment 1

[0047] (1) A polyvinylamine (PVAm, concentration 0.5g / L) solution containing 5wt% UiO-66 was prepared.

[0048] First, 50 mL of N,N-dimethylformamide (DMF), 10 mL of concentrated hydrochloric acid and 1.25 g of zirconium chloride were added to the flask, and ultrasonically treated for 20 min to obtain solution A; then 1 mL of terephthalic acid and 100 mL of DMF were mixed into the solution Ultrasonic treatment in A for 20 min, then heated in a water bath at 80 °C for 8 h, filtered and dried to obtain UiO-66 solid powder.

[0049] Then, the UiO-66 solid powder was mixed with 5wt% polyvinylamine solution, and then the mixed solution was ultrasonically treated for 1 h to obtain a PVAm solution mixed with UiO-66, which was denoted as UiO-66 / non-space PVAm solution.

[0050] Using the polysulfone ultrafiltration membrane as the base membrane, the surface of the base membrane was contacted with the UiO-66 / PVAm solution for 30 minutes, and then the membrane surface was rinsed with de...

Embodiment 2

[0056] (1) A polyethyleneimine (PEI, concentration 1.5g / L) solution containing 8wt% UiO-66 was prepared.

[0057] First, 60 mL of N,N-dimethylformamide (DMF), 8 mL of concentrated hydrochloric acid and 1 g of zirconium chloride were added to the flask, and ultrasonically treated for 30 min to obtain solution A; then 2 mL of terephthalic acid and 80 mL of DMF were mixed into solution A Ultrasonic treatment was carried out for 25 min, then heated in a water bath at 70 °C for 12 h, filtered and dried to obtain UiO-66 solid powder.

[0058] Then, the UiO-66 solid powder was mixed with 8wt% polyethyleneimine solution, and then the mixed solution was ultrasonically treated for 1 h to obtain a PEI solution mixed with UiO-66, which was denoted as UiO-66 / PEI solution.

[0059] The ultrafiltration membrane obtained after the hydrolysis modification of the polyacrylonitrile membrane was used as the base membrane, and the surface of the base membrane was contacted with the UiO-66 / PEI solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com