Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Improve explosion protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based environment-friendly porcelain glaze-like plastic coating and preparation method thereof

The invention discloses water-based environment-friendly porcelain glaze-like plastic coating and a preparation method thereof. The water-based environment-friendly porcelain glaze-like plastic coating adopts a formula comprising the following materials by mass: 20 to 40 percent of a water-based acrylic emulsion, 10 to 20 percent of water-based silica sol, 35 to 50 percent of water-based inorganic silicon dioxide nanodispersion, 0.1 to 0.3 percent of a wetting dispersant, 1 to 5 percent of silane, 0.1 to 0.5 percent of an amine neutralizing agent, 5 to 10 percent of lead-free pigment, 0.5 to 2.5 percent of a film-forming additive, and 5 to 25 percent of deionized water. The water-based environment-friendly porcelain glaze-like plastic coating can be coated on the surfaces of various materials in the form of porcelain glaze, and can be applied on the surfaces of the materials of various shapes through roller-applied coating, shower coating, spraying, blade coating, brush coating, dip coating and the like; moreover, the formed porcelain glaze coating is unique and free from hydrolysis, and cannot be melted at a certain temperature, so that a base material can be effectively protected from corrosion, abrasion, scraping, acid-alkali, impact, inflaming and fire.

Owner:吕标

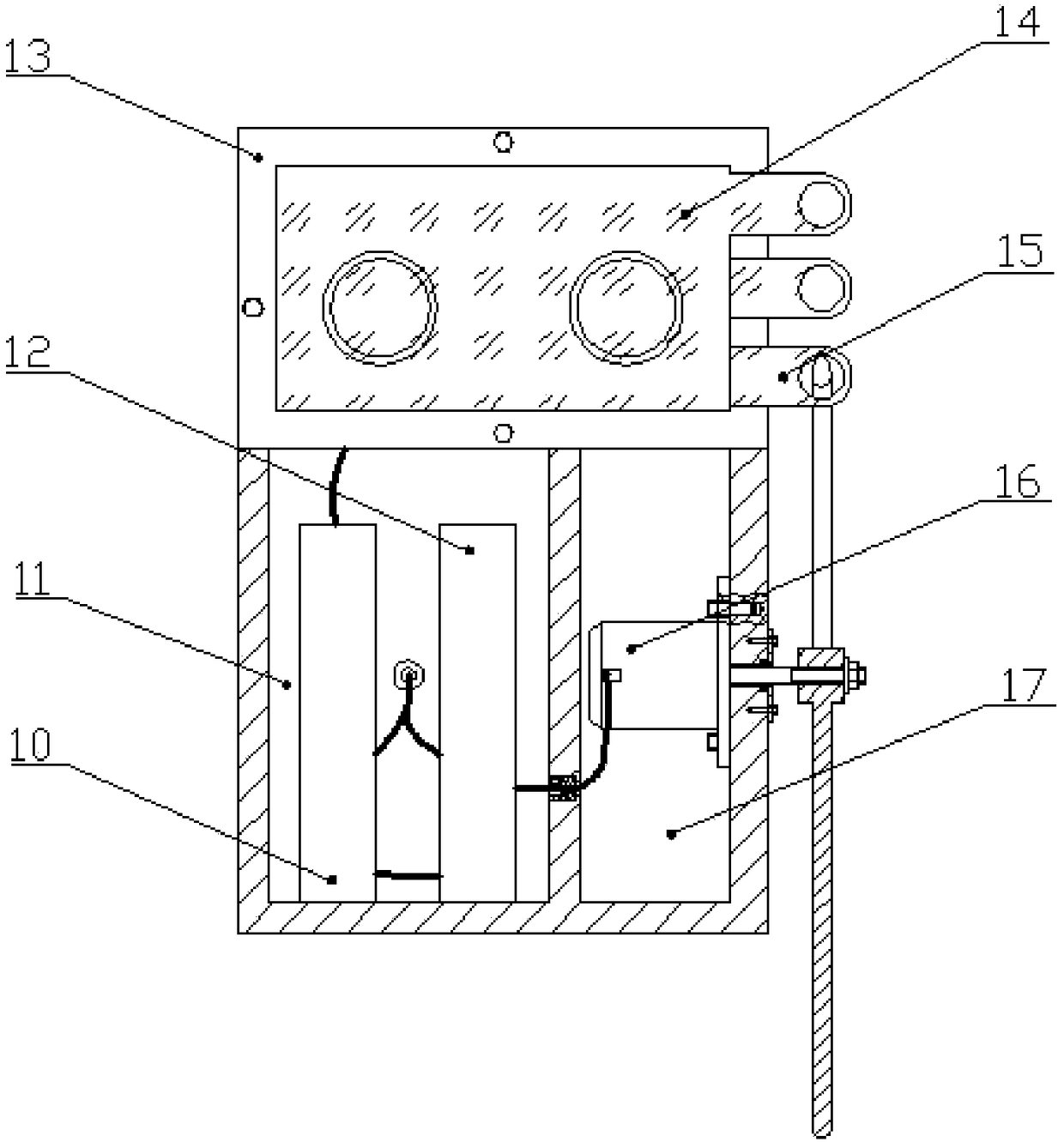

Marine fuel cell power generation module and safe working method thereof

ActiveCN112687923AImprove explosion protectionImprove securityPropulsion based emission reductionPropulsion power plantsFuel cellsProcess engineering

The invention discloses a marine fuel cell power generation module which comprises a cabinet body, a box body, an air unit, a cooling water unit and a controller unit, the box body is composed of a box shell of a closed cavity structure, a fuel cell stack, a hydrogen unit and a purging pipeline, a gas outlet and a gas collecting port of the purging pipeline are evenly distributed in the box shell, purging gas is positive pressure inert gas, the box shell is sequentially provided with an explosion venting valve, a purge gas inlet and a purge gas outlet, the purge gas outlet is provided with a hydrogen concentration sensor and an audible and visual alarm, a gas interlocking valve is arranged at an inlet of the hydrogen unit, and the hydrogen concentration sensor, the audible and visual alarm, the gas interlocking valve and the controller unit are in communication connection. The invention also discloses a safe working method of the marine fuel cell power generation module, by monitoring and alarming the risk degree in the hydrogen leakage process in the box body, the explosion-proof and safety performance of the fuel cell power generation module is improved.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

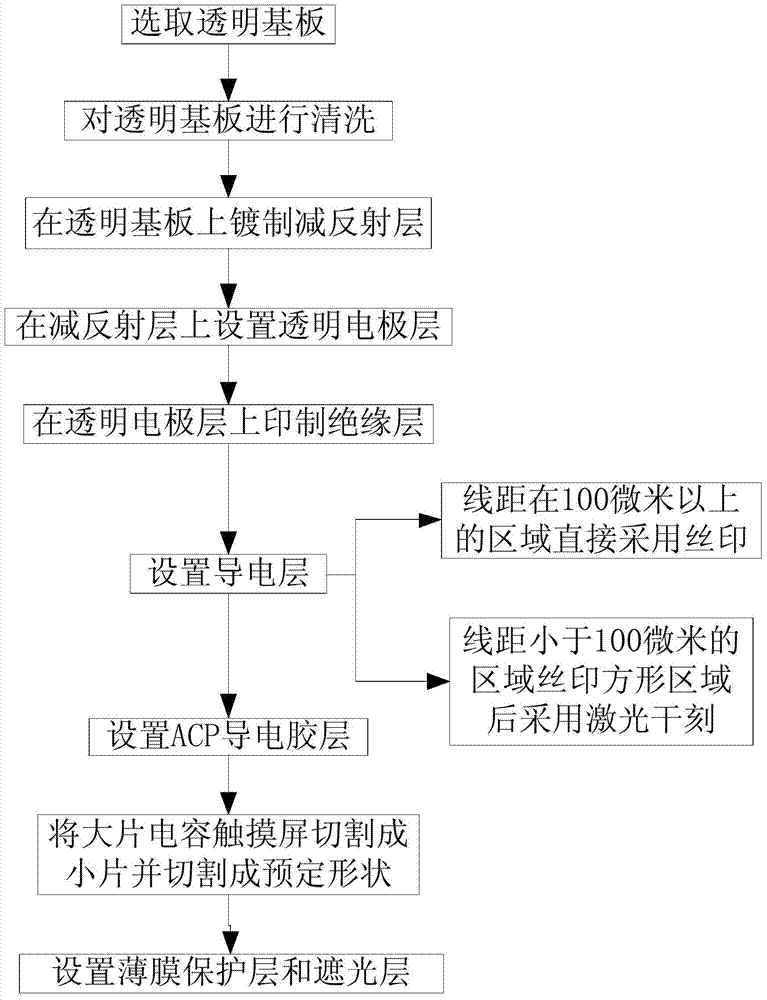

Capacitive touch screen and manufacturing method thereof

ActiveCN104750323ASave man hoursImprove molding efficiencyInput/output processes for data processingCapacitanceEngineering

The invention discloses a manufacturing method of a capacitive touch screen and the capacitive touch screen manufactured by the method. The method includes that a transparent substrate is selected, an antireflection layer that is made of silicon dioxide is plated on the transparent substrate, a transparent electrode layer is designed on the antireflection layer, an insulating layer that covers a part of the transparent electrode layer is printed on the transparent electrode layer, a conducting circuit layer is designed after the printing of the insulating layer is finished, finally, an ACP conductive adhesive layer is designed on the conducting circuit layer and then small piece formation is performed, a part of conductive electrodes in the conducting circuit layer is formed by means of silk screen printing, and the other part of conductive electrodes in the conducting circuit layer is formed by means of laser dry etching. According to the capacitive touch screen and the manufacturing method thereof, the length of a flexible circuit board on the capacitive touch screen is reduced, and the forming efficiency of the capacitive touch screen is increased.

Owner:深圳市合力泰光电有限公司

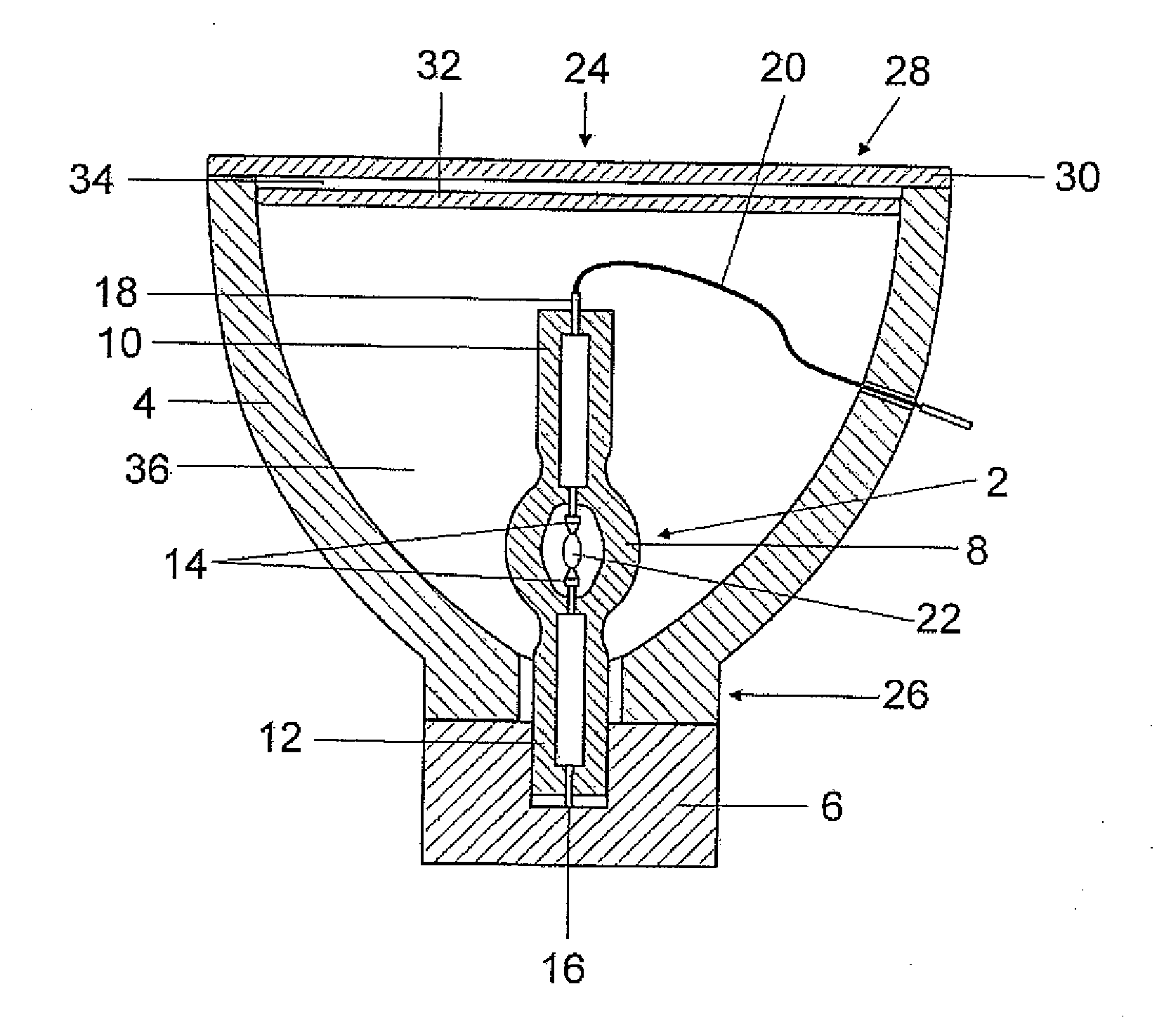

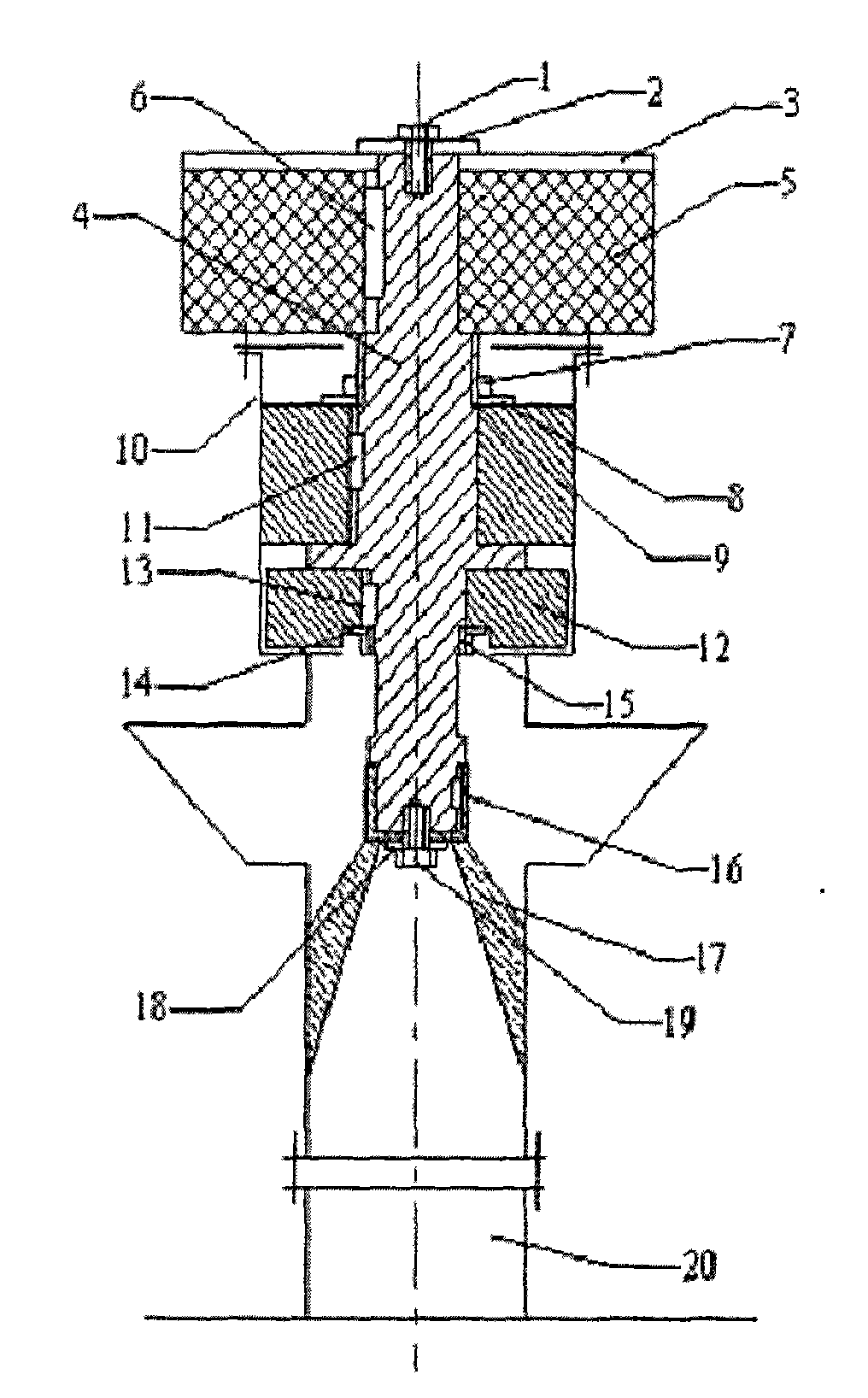

Explosion Protection System for a High Pressure Lamp

InactiveUS20110074273A1Improve explosion protectionEasy to catchIncadescent screens/filtersVacuum tube vessels/containers/shieldsExplosion protectionEngineering

A base for a high pressure lamp, such base having lateral walls enclosing the lamp bulb. Also disclosed are lateral walls for a base, and a lamp system comprising such base.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG

220 kV gas insulation transformer

ActiveCN104157434AFireproofImprove fire performanceTransformers/inductances coils/windings/connectionsVariable inductancesThermodynamicsTransformer

The invention relates to a 220 kV gas insulation transformer, and belongs to the technical field of transformers. According to the technical scheme, the 220 kV gas insulation transformer comprises a box, SF6 gas, an SF6 gas sleeve, a cable box, a transformer body, a transformer on-load voltage regulation switch, a gas density gauge, a pressure monitoring device, a sudden pressure relay, a gas temperature gauge, a winding temperature gauge, a plate radiator, a gas circulation pump, an airflow indicator, a blowing device and a cooling system intelligent control box, wherein the SF6 gas, the SF6 gas sleeve and the cable box are used for outgoing of a 220 kV high-voltage cable, the transformer body comprises an iron core, a coil and a lead, the gas density gauge, the pressure monitoring device, the sudden pressure relay, the gas temperature gauge and the winding temperature gauge are used for secondary protection, the plate radiator, the gas circulation pump, the airflow indicator, the blowing device and the cooling system intelligent control box are used for cooling the transformer, and an internal insulating and cooling medium of the transformer is the SF6 gas. Compared with a traditional oil-immersed transformer, the 220 kV gas insulation transformer has higher fire resistance, explosion resistance and safety and more complete monitoring and protection configuration, thereby being more suitable for being used in population concentration places such as city centers.

Owner:SHENZHEN POWER SUPPLY BUREAU +2

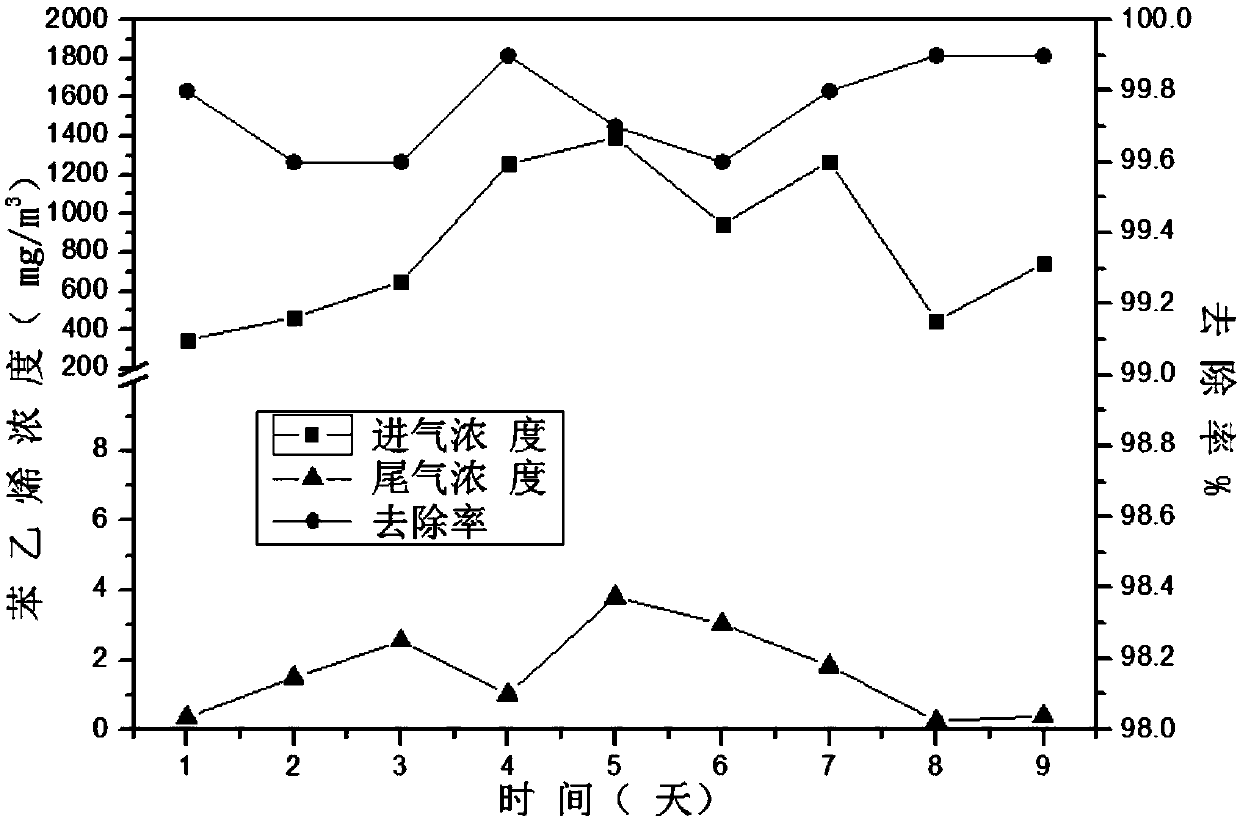

Styrene waste gas treatment device and method

InactiveCN111097256AImprove securityPrevent self-aggregationGas treatmentDispersed particle filtrationExhaust fumesOrganic matter

The present invention relates to a styrene waste gas treatment device which comprises: an absorption unit, which is configured to use an absorbent to perform absorption treatment on styrene in styrenewaste gas so as to obtain a styrene-rich absorption liquid and an absorbent volatile matter-rich waste gas; a demisting unit which is configured to perform demisting treatment on the absorbent volatile matter-rich waste gas to obtain demisted absorbent volatile matter-rich waste gas; a membrane separation unit which is configured to perform separation treatment on the demisted absorbent volatilematter-rich waste gas to obtain permeation side gas rich in organic matters and permeation residue side gas; a condensation separation unit which is configured to perform condensation separation treatment on the permeation side gas rich in organic matters to obtain a condensate and a gas phase; and an adsorption unit which is configured to perform adsorption treatment on the permeation residue side gas to obtain waste gas for up-to-stand discharge. The invention also relates to a method for treating styrene waste gas by adopting the device. The method provided by the invention can solve the problem of styrene self-polymerization, can efficiently treat styrene waste gas, and can realize comprehensive utilization of resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fireproof flame-resistant core board material and production method thereof

InactiveCN102152523ANo antihalogenationImprove fire resistanceLaminationLamination apparatusFiberSlag

The invention relates to a fireproof flame-resistant core board material and a production method thereof. The fireproof flame-resistant core board material provided by the invention comprises a component A comprising magnesium chloride and the mixed liquid of titanium white, an expanding agent and a thickening agent, a component B comprising magnesium oxide and a component C comprising plant straw, coal ash, slag and polystyrene foam particle mixture through the mixture and fiber cloth at the ratio of the component A to the component B to the component C of 1:(1-1.5):(1-2.0). The fireproof flame-resistant core board material provided by the invention has the advantages of good flame resistance and low cost, is environment-friendly protection and safe.

Owner:HUNAN SHENGHENG ENVIRONMENTAL PROTECTION FIREPROOF TECH

Blockage and air ventilation type explosion-proof and fireproof plate

InactiveCN109680725ASignificant cushioningDual action of significant fire insulationProtective foundationSurface layerDual action

The invention provides a blockage and air ventilation type explosion-proof and fireproof plate, and belongs to the field of disaster prevention of projects. The blockage and air ventilation type explosion-proof and fireproof plate is of a rectangular structure, and is characterized in that the inner surface layer and the outer surface layer are respectively a first pressure-relief vibration-proofand fireproof plate layer and a second pressure-relief vibration-proof and fireproof plate layer; vertical end reinforcing transverse ribs are arranged at both ends, and vertical middle reinforcing transverse ribs are uniformly distributed in the middle position; two rows of middle heat-blockage fireproof cavities are uniformly distributed in the middle position. The blockage and air ventilation type explosion-proof and fireproof plate has the beneficial effects that the fireproof property is good, the stress property is good, the installation is convenient, the replacement is easy, and the installation is quick, simple and convenient; the surface layer is provided with an obvious pressure-relief vibration-proof port, a fire blockage layer in the middle position has obvious buffer and fireblockage double functions, the explosion-proof and fireproof properties are obviously improved, and the personal casualty and the economic loss are effectively reduced when a fire accident occurs onan underground structure.

Owner:SHENYANG JIANZHU UNIVERSITY

Explosion-proof glass and preparation method thereof

The invention discloses explosion-proof glass and a preparation method thereof. The preparation method comprises the following steps: taking 50-100 parts of petroleum resin, 20-30 parts of boron oxide, 5-20 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 15-20 parts of dodecyl polyglucoside, 5-10 parts of aluminium oxide, 1-5 parts of silicon phosphate, and 1-5 parts of mica powder, mixing to obtain the mixture; adding the mixture in a crucible, keeping temperature for 2-3h at 850 DEG C, warming to 1300-1500 DEG C to keep temperature for 1-2h, thereby obtaining glass stock solution; adding 1-3 parts of dispersing agent, 1-3 parts of adhesive and 1-2 parts of thickening agent in the glass stock solution, stirring for 10-20min to obtain the glass solution; pouring the glass solution in a preheated copper plate die for molding; placing in a muffle furnace preheated to 600-800 DEG C to anneal for 2-4h, cooling to room temperature with the furnace so as to obtain the explosion-proof glass. Themanufacturing raw material of the explosion-proof glass is simple and easy to obtain, the manufacturing process is simple and easy to operate; the obtained finished product has extremely high explosion-proof and impact resistance.

Owner:句容耀皮节能玻璃科技发展有限公司

Special die for blockage and air ventilation type explosion-proof and fireproof plate

InactiveCN109680726AImprove fire performanceImprove mechanical performanceProtective foundationSurface layerDual action

The invention provides a special die for a blockage and air ventilation type explosion-proof and fireproof plate, and belongs to the field of disaster prevention of projects. An one-piece die cover isa rectangular cylinder, and two rows of cavity die covers are vertically arranged in the one-piece die cover; butting type blockage buffer port die covers are vertically and uniformly distributed atthe corresponding sides of the interior of each cavity die cover; anti-disengaging circular plates are arranged at the inner side of each cavity die cover and the crossing part of each cavity die cover and the corresponding butting type blockage buffer port die cover. The special die has the beneficial effect that the production technology is simple and quick. The produced blockage and air ventilation type explosion-proof and fireproof plate has the advantages that the fireproof property is good, the stress property is good, the installation is convenient, the replacement is easy, and the installation is quick, simple and convenient; the surface layer is provided with an obvious pressure-relief vibration-proof port, a fire blockage layer in the middle position has obvious buffer and fire blockage double functions, the explosion-proof and fireproof properties are obviously improved, and the personal casualty and the economic loss are effectively reduced when a fire accident occurs on anunderground structure.

Owner:SHENYANG JIANZHU UNIVERSITY

Method for manufacturing vibration isolator

ActiveCN103467784AImprove carrying capacityGood damping energy dissipation capacityCoatingsStearic acidNoise reduction

The invention discloses a method for manufacturing a vibration isolator. The method is as below: first dipcoating 5-10 rubber layers on a whisker surface of tetrpod-like zinc oxide; taking 100 parts by weight of plasticated natural rubber; adding 10-15 parts by weight of the tetrpod-like zinc oxide with rubber layers dip-coated on the whisker surface, 3-5 parts by weight of nano zinc oxide, 0.3-0.8 parts by weight of stearic acid, 15-20 parts by weight of spray carbon black, 1-3 parts by weight of an antioxidant N-phenyl-beta-naphthylamine, 2-3 parts by weight of sulfur and 0.3-0.8 part by weight of an accelerator disulfide benzothiazole; mixing evenly; injecting the mixture into a metal mold cavity of a molding machine injection isolator by an injection molding machine; and vulcanizing the mixture at 150-160 DEG C for 15-20 min to obtain the isolator product. The isolator manufactured by the manufacturing method provided by the invention has strong carrying capacity and high damping dissipation energy, good noise reduction and isolation performance and obvious effects.

Owner:ANHUI HUAJING MACHINERY

Glass film

InactiveCN105331156AImprove heat insulationImprove insulation effectAntifouling/underwater paintsPaints with biocidesCalcium biphosphateALUMINUM PHOSPHATE

The invention discloses a glass film which is prepared from, by weight, 14 parts of butyl acrylate, 1-2 parts of propylene glycol, 0.2 part of calcium phosphate, 1.4 parts of aluminum nitride powder, 1.3 parts of acrylic acid, 3.4 parts of silicon dioxide, 2.3 parts of aluminum phosphate and 4.5 parts of dodecyl polyglucoside. The glass film can improve the heat-isolation, heat-preservation, cold-resistant, anti-explosion, anti-corrosion, anti-bacterial and anti-static performance of glass.

Owner:CHANGSHU SEDY INLAY GLASS PROD

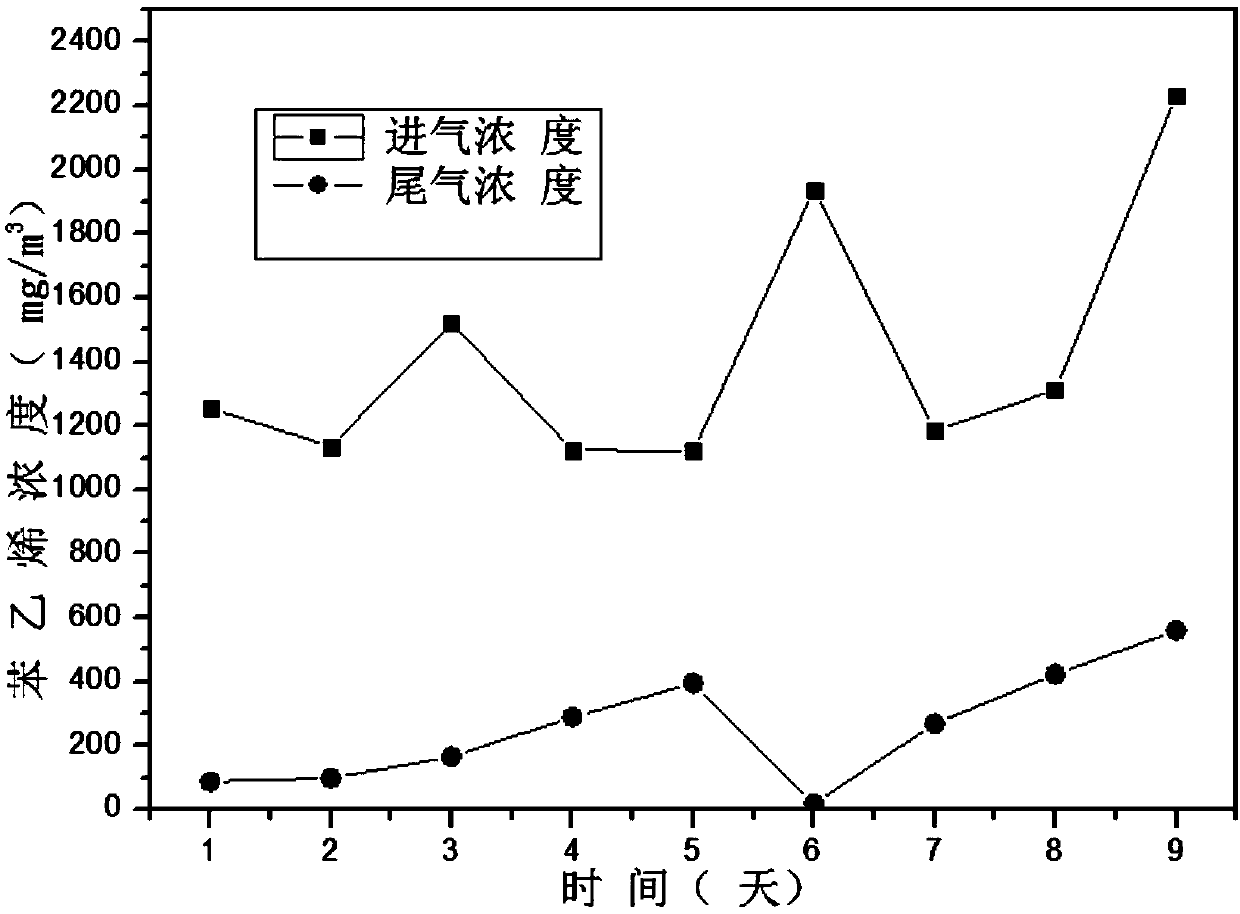

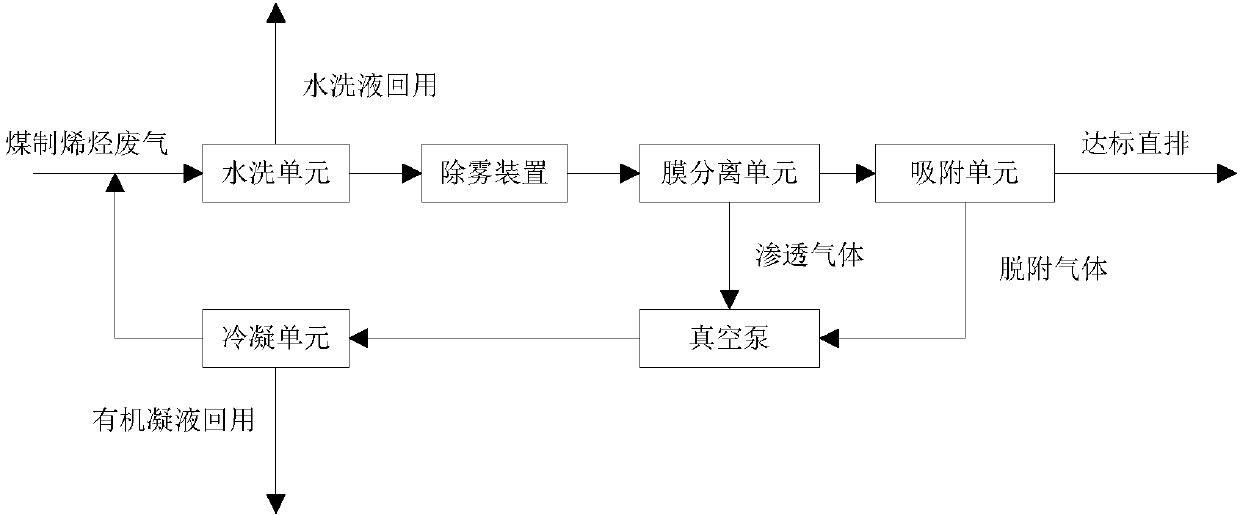

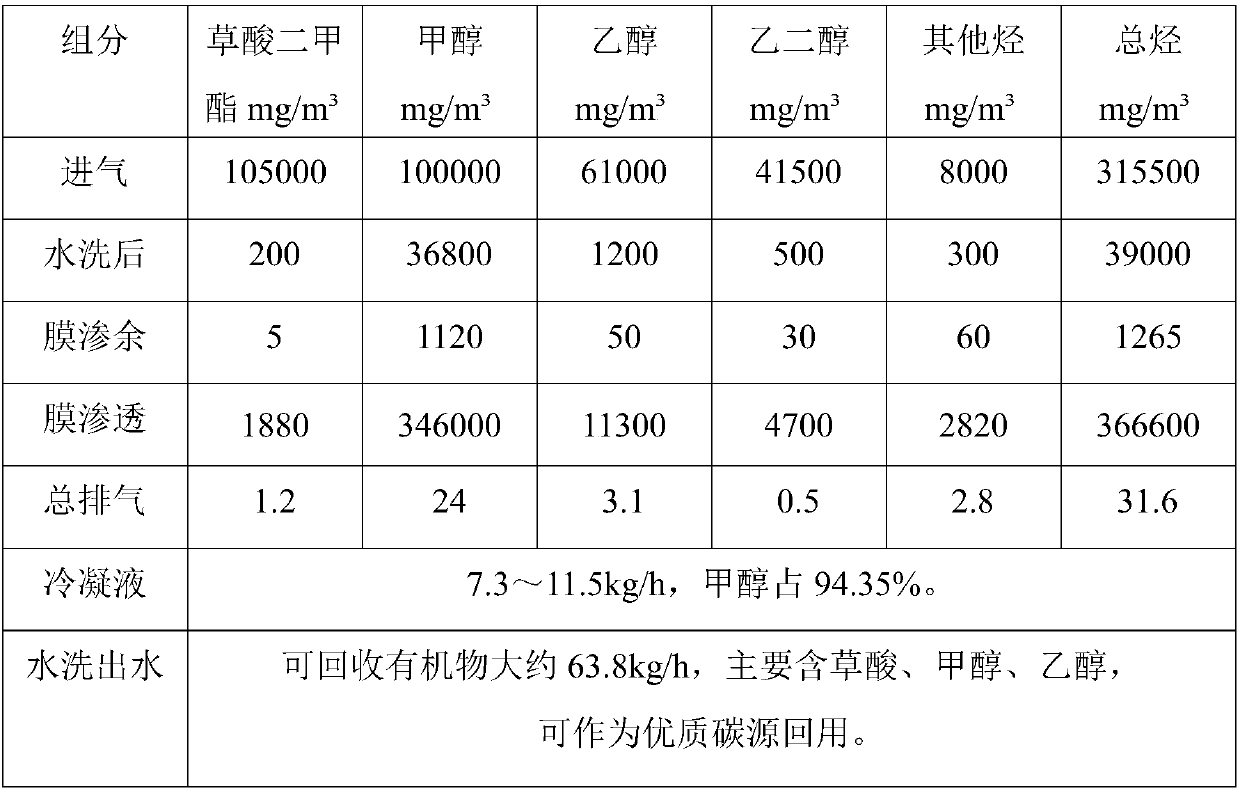

Coal-to-olefin industrial exhaust gas comprehensive treatment device and method

ActiveCN110339687AEfficient processing and resource utilizationImprove explosion protectionGas treatmentDispersed particle separationExhaust gasCoal chemical industry

The invention relates to a coal-to-olefin industrial exhaust gas comprehensive treatment device and method. The coal-to-olefin industrial exhaust gas comprehensive treatment device and method are mainly applied to treatment and resource utilization of exhaust gas emitted in organized and unorganized modes by tank areas, platforms and production devices in the field of coal chemical industry. Specifically, a washing process and three organic exhaust gas recovery techniques of membrane separation, condensation and adsorption are innovated, optimized and coupled to form the coal-to-olefin industrial exhaust gas treatment method. The method does not include the heating step or the heat production step, the explosion-proof property and safety are high. In the washing process, soluble organic matter is recovered, the acidity is reduced, the temperature is decreased, then resource utilization is conducted through a combination process of membrane separation, condensation and adsorption, and thus the requirements of resource utilization and emission on standard are met. According to the coal-to-olefin industrial exhaust gas comprehensive treatment device and method, the difficult problem of coal-to-olefin exhaust gas treatment is solved, organic exhaust gas emitted by industrial devices, the tank areas, the vehicle-loading platforms and the like in the coal-to-olefin field can be efficiently removed and subjected to resource utilization, and the coal-to-olefin industrial exhaust gas comprehensive treatment device and method have application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for glue pouring of battery box of electric vehicle

InactiveCN105826589AImprove shock absorptionImprove explosion protectionFinal product manufactureSmall-sized cells cases/jacketsElectrical batteryAutomotive battery

The invention relates to a method for glue pouring of a battery box of an electric vehicle. The method comprises the steps of stirring glue stock firstly, wherein double-component pouring sealant poured into an agitator is evenly stirred with a low-speed stirrer; conducting glue pouring, wherein the agitator is placed on a base of a hydraulic discharging machine, a glue pouring pipe is connected to a valve on the lower portion of the agitator, the glue outlet end of the glue pouring pipe is aimed at the battery box glue pouring area for glue pouring, the valve on the lower portion of the agitator is switched on to start the hydraulic discharging machine, and the glue stock in the agitator is poured into the battery box glue pouring area for glue pouring till glue pouring weight reaches a required value; conducting curing finally, wherein after glue in the battery box glue pouring area flows steadily, glue is placed in the glue curing area to be cured for several hours at room temperature. According to the method, stirring and glue pouring are achieved automatically with machines, time and labor are saved, labor intensity is relieved, production efficiency is improved, the produced battery box has high shock absorption capacity, anti-explosion performance and inflaming-retarding performance are improved greatly, and the service life of a battery is prolonged.

Owner:浙江伊卡新能源汽车有限公司

Overpressure preventing water outlet mechanism of warm water boiler

The invention discloses an overpressure preventing water outlet mechanism of a warm water boiler. The overpressure preventing water outlet mechanism comprises an inner container (1) and a water outlet pipe (2), a water outlet motor (3) is installed on the outside of the side edge of the inner container (1), an active magnetic material (4) is installed on a motor shaft of the water outlet motor (3), a passive metal material (6) which is opposite to the active magnetic material (4) is installed in the water outlet pipe (2), a water outlet impeller (7) is arranged on the passive metal material (6), and an air vent (5) is disposed on the upper portion of the inner container (1). According to the overpressure preventing water outlet mechanism of the warm water boiler, the active magnetic material is driven to drive the passive metal material to correspondingly rotate, the water outlet impeller is driven to enable a liquid in the inner container to flow out along the water outlet pipe, and the water outlet is smooth and gentle; the air vent is arranged on the upper portion of the inner container, so that steam pressure in the inner container can be released by the air vent, the overpressure of the inner container is effectively prevented, and the liquid in the inner container can be heated to be boiled; and accordingly technical performances of water outlet, heating, anti-explosion, safety and the like of the warm water boiler are improved.

Owner:瑞安市华仕力环保设备股份有限公司

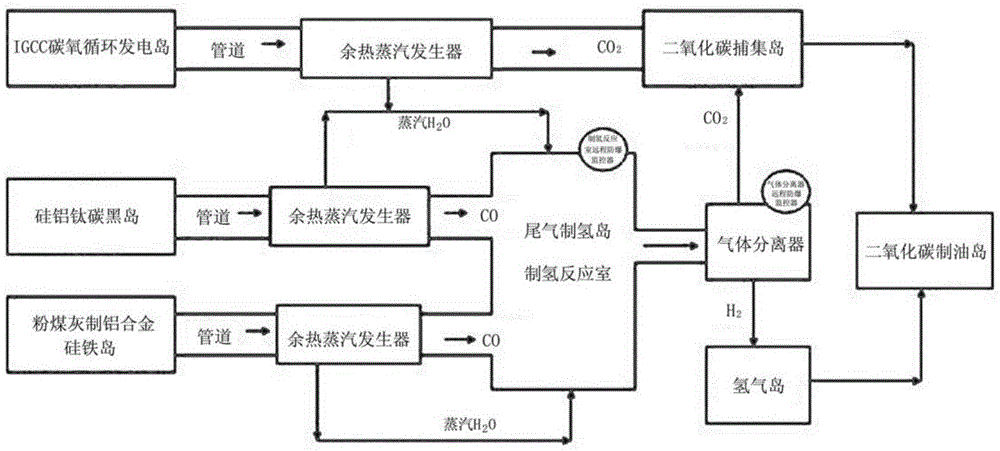

Process and device for preparing graphene tire by coproduction

ActiveCN105666904AIncrease puncture resistanceImprove explosion protectionHydrogenWaste processingJet aeroplaneFerrosilicon

The invention relates to the field of tires and particularly relates to a process and device for preparing a graphene tire by coproduction. By coproducing electric oil aluminum alloy ferrosilicon by a coal-based graphene tire, graphene tire production and tail gas pollution emission management, IGCC power generation and oil production are integrated together to realize industrialized application. The process and the device, provided by the invention, have the beneficial effects that firstly, graphene automobile tires, motorcycle tires, tractor tires, bicycle tires, industrial tires and airplane safety tires can be produced at a low cost;; particularly, the anti-puncturing and anti-explosion properties of the tires can be improved, the resistance is increased and the service life is prolonged; secondly, an aluminum alloy can be prepared by using produced carbon black and coal ash and hydrogen is prepared from tail gas produced by the ferrosilicon at a low cost; carbon dioxide collected from the IGCC power generation is used for preparing oil at a low cost; and thirdly, the problems of coal power carbon dioxide emission and fly ash environment pollution are controlled from the source, and the carbon dioxide and the fly ash are 100% utilized.

Owner:程礼华

Film uncovering self-cleaning explosion-proof camera shooing device for coal mine robot and cleaning method

ActiveCN109483594APrecise positioningAccurate image captureTelevision system detailsColor television detailsCleaning methodsEngineering

The invention discloses a film uncovering self-cleaning explosion-proof camera shooing device for a coal mine robot and a cleaning method, wherein the film uncovering self-cleaning explosion-proof camera shooing device and the cleaning method are suitable for coal mine underground. An explosion-proof box is internally of a sealing structure of through hole plug screw positioning and sealing ring sealing; the explosion-proof box is internally divided into an upper cavity and a lower cavity; an explosion-proof camera is fixed into the upper cavity, and window glass is arranged at the position, at a lens of the explosion-proof camera, of the explosion-proof box; the lower cavity comprises a left cavity and a right cavity, the left cavity is internally provided with a controller and a driver which are mutually connected, and a motor is arranged in the right cavity; and a rotating shaft of the motor extends out of the explosion-proof box to be provided with a three-fork halberd hook claw, and the lengths of three hook rods of the three-fork halberd hook claw are not the same. The film uncovering self-cleaning explosion-proof camera shooing device has the advantages of reasonable design,compact structure, convenient use and maintenance, high automation degree and the like.

Owner:CHINA UNIV OF MINING & TECH

Double-side defense anti-explosion assembly wallboard

PendingCN111794401AStrong anti-crack and explosion-proof abilityImprove anti-seepage performanceFire proofingShock proofingFiberConstruction engineering

The invention discloses a double-side defense anti-explosion assembly wallboard and belongs to anti-explosion engineering. The double-side defense anti-explosion assembly wallboard comprises an anti-explosion wallboard, a sandwich decompression defense wallboard, a base plate, an L-shaped connection plate, a clamping groove, an anti-explosion plate decompression hole, an anti-explosion protectivecoating, a connection ribbed plate, a connection groove, a sandwich plate decompression hole, a sandwich plate decompression cavity, a fire-insulation anti-explosion reinforced fiber net layer and built-in decompression energy dissipation fireproof cotton. A double-side defense anti-explosion form is adopted for the double-side defense anti-explosion assembly wallboard, anti-crack anti-explosion ability is high, anti-seepage ability is high, and certain explosion impact resistance is achieved while certain strength of the overall structure is ensured. Meanwhile, an assembly mode is adopted forthe double-side defense anti-explosion assembly wallboard, installation operation is simplified significantly, assembled speed is high, the industrialization process can be promoted, construction issimpler, industrial disassembly is very convenient, and explosion impact energy can be absorbed to the greatest extent.

Owner:张延年

Breathing apparatus for normal pressure storage tank

InactiveCN101613024AImprove explosion protectionImprove security usageLarge containersCorrosionFan blade

The invention discloses a breathing apparatus for a normal pressure storage tank, which relates to a self-cleaning type breathing apparatus. The breathing apparatus is arranged on the top of the normal pressure storage tank and comprises a fan blade box internally provided with fan blades and a driving mechanism thereof, a sliding bearing connecting mechanism in driving connection with the fan blades, a pass burble spiral scraper in driving connection with the sliding bearing connecting mechanism, a ventilating pipe group running through the mechanism and a ventilating pipe of the normal pressure storage tank, wherein the pass burble spiral scraper is formed by forming micropores on a burble spiral scraper. The breathing apparatus for the normal pressure storage tank adopts the self-cleaning breathing apparatus which is driven by wind energy and has self-cleaning function to achieve the aims of ensuring the balance between the pressure in the tank and the atmospheric pressure in the process of lifting the liquid surface in the storage tank, preventing breathing holes and pipelines from being blocked, improving the anti-explosion and corrosion resisting capabilities, and simultaneously improving the safe using rate of the apparatus, and reducing the production and maintenance cost.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

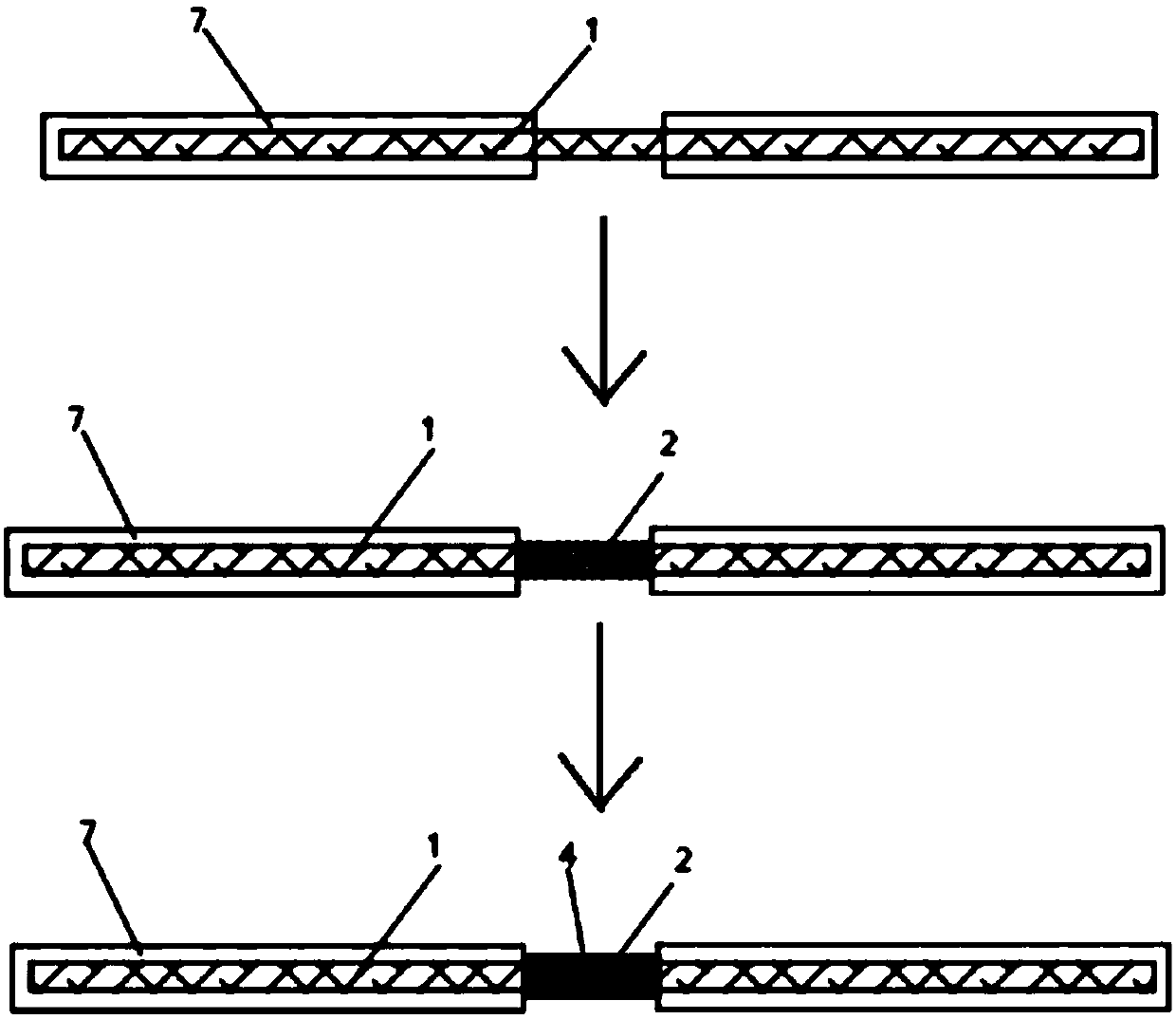

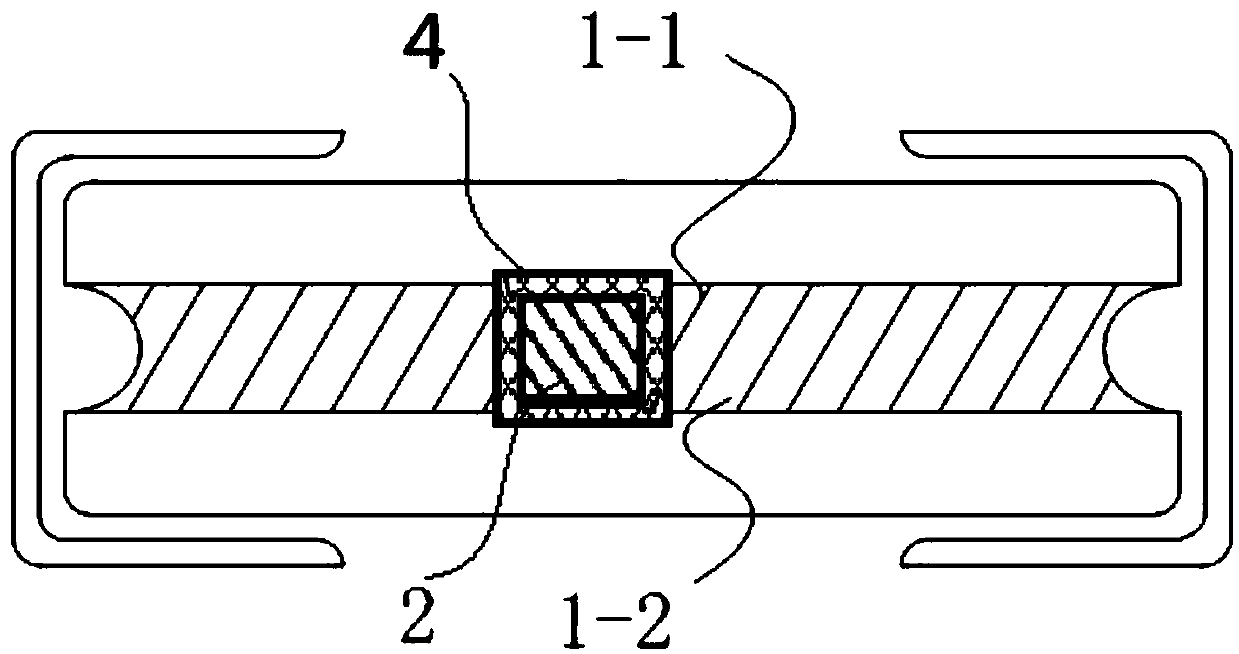

Ultrathin high-performance protection element and production method

ActiveCN107689314AReduce thicknessImprove explosion protectionEmergency protective devicesWire wrapLightning surges

The invention provides an ultrathin high-performance protection element and a production method. The ultrathin high-performance protection element comprises an encapsulated layer, a melt and electrodes, wherein the melt is disposed in the encapsulated layer, the melt comprises a metal fuse wire, two ends of the metal fuse wire are respectively connected with electrodes fixed on two ends of the encapsulated layer, a part of the metal fuse wire wraps a co-melt, the co-melt is coated with an wrapping layer, and the wrapping layer is a macromolecular polymer material. The ultrathin high-performance protection element of the invention is light in weight, thin in thickness, small in size, explosion-proof, excellent in lightning surge resistance and precise in fusion.

Owner:NANJING SART SCI & TECH DEV

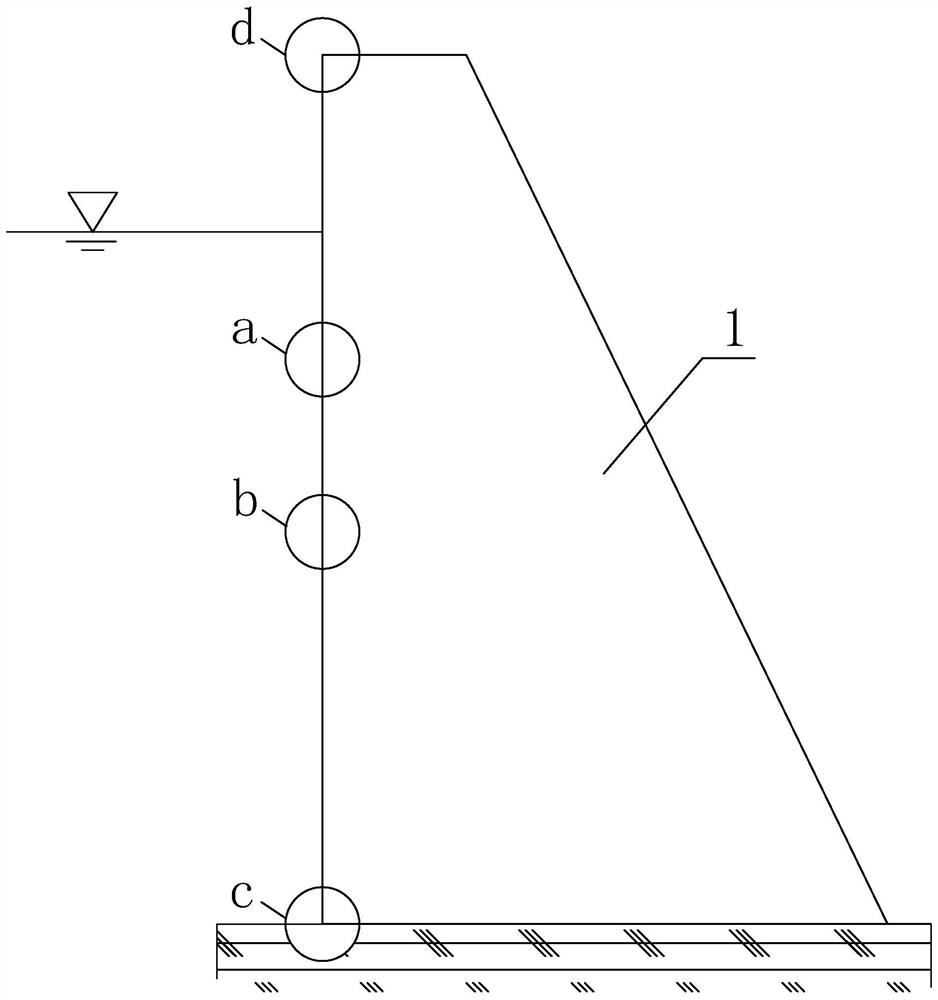

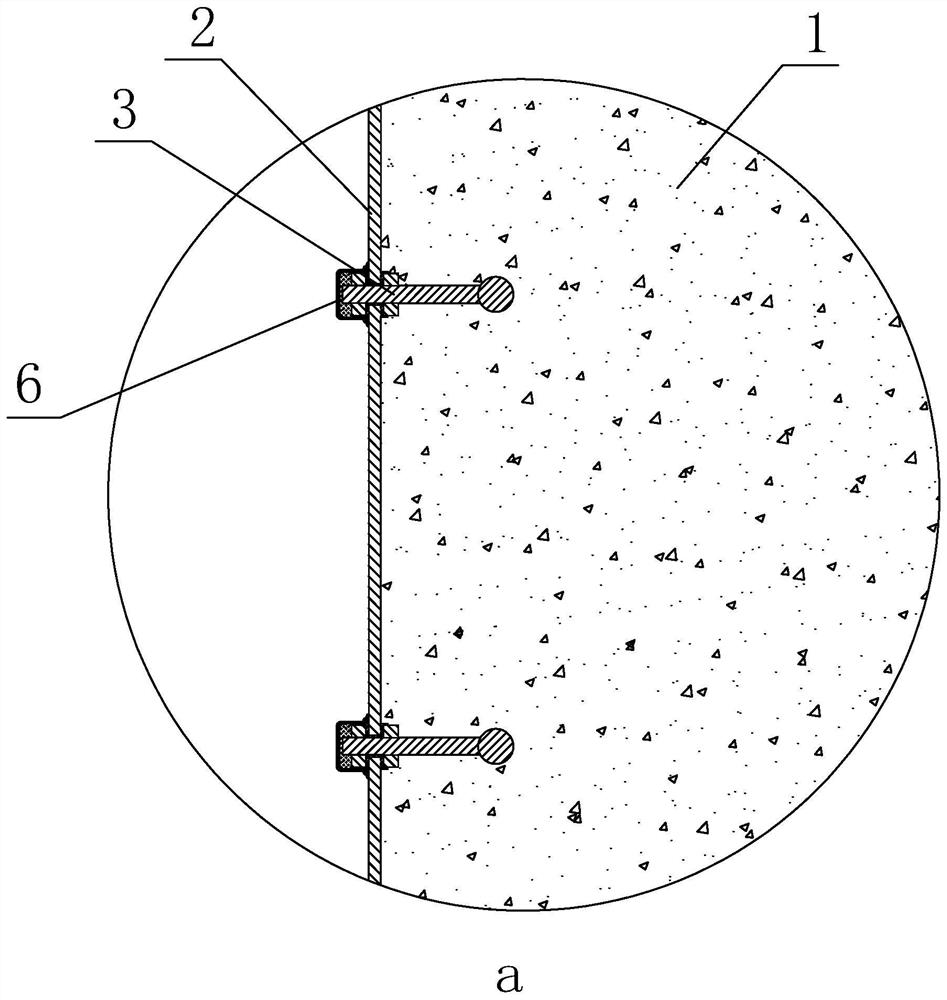

Stainless steel panel and concrete combined anti-seepage structure and construction method thereof

InactiveCN112301963ASolve temperature deformationOvercome temperature deformationWall damsArchitectural engineeringStructural engineering

The invention relates to the field of hydraulic engineering construction, in particular to a stainless steel panel and concrete combined anti-seepage structure and a construction method thereof. The stainless steel panel and concrete combined anti-seepage structure is characterized in that the stainless steel panel and concrete combined anti-seepage structure comprises a concrete dam body, a stainless steel panel and a connecting component, the stainless steel panel is attached to the water side of the concrete dam body, and the stainless steel panel is fixedly connected with the concrete dambody through the connecting component. The stainless steel panel has the advantages of corrosion resistance, high strength, impact resistance, high ductility, explosion prevention, shock resistance and the like, is high in corrosion resistance in a humid environment and a water environment, can be maintenance-free, and has high cost performance when being used for seepage prevention of a water conservancy project; and the stainless steel panel is arranged on the near-water side of the dam body, so that the leakage problems of concrete temperature stress cracks, construction joints, contractionjoints, pores and the like of a concrete water retaining structure of a water conservancy project are solved, the stainless steel panel and a concrete body in the component have super-strong durability, and the overall appearance, the impact resistance and the durability are remarkably improved.

Owner:FUJIAN LUGANG GRP CO LTD +1

LNG skid-mounted station control system and installation method

PendingCN111176235AReduced mobilityGuaranteed mobilityTotal factory controlProgramme total factory controlCommunication interfaceStation

The invention provides an LNG skid-mounted station control system and an installation method. The system comprises a plurality of skid-mounted blocks arranged at an LNG skid-mounted station, the skidis connected with an instrument and a valve; an I / O module is arranged on the skid; the I / O module comprises a redundant communication interface and an I / O card. The instrument valve is connected to the skid in a point-to-point mode through an I / O clamping piece, the skid is connected with an I / O bus through the redundant communication interface and then is connected into the communication interface of a DCS control unit. The method comprises the steps that the I / O module is arranged on the skid, and the I / O module is installed in an explosion-proof box; the I / O module is arranged on the skid,and the the I / O module is installed in the explosion-proof box; and the redundant communication interface in the I / O module is connected to then I / O bus and then is connected to the DCS control unit.The pay-off number is greatly reduced, the field construction is simplified, the construction period is shortened, the engineering cost is reduced, the I / O module is arranged in the explosion-proof box and the explosion-proof and reliability of the skid are improved.

Owner:合肥万豪能源设备有限责任公司

Heat storage type water-electricity separation heating mechanism

The invention discloses a heat storage type water-electricity separation heating mechanism applied to warm and hot water heater. The heat storage type water-electricity separation heating mechanism comprises a water pipe (1) and a heating pipe (2), and the heating pipe (2) is arranged outside the water pipe (1) while the water pipe (1) and the heating pipe (2) are both arranged inside a heat transfer body (3). The heat transfer body (3) is made of aluminum alloy. The heat storage type water-electricity separation heating mechanism enables the heating pipe and water mediums inside the water pipe to be heated separately and indirectly, the heat transfer body is used for transferring heat and heat can be effectively accumulated instead of being wasted, so that drinking water heating inside the water pipe can be quickened, heat preservation can be achieved effectively and the heat utilization rate is high. Due to the fact that the surface of the heating pipe is not in contact with the drinking water, the heating pipe cannot be eroded, further the drinking water can be clean and health, the service life of the heating pipe is prolonged, personal safety can be guaranteed due to water-electricity separation heating, potential hazards can be eliminated, and heating, anti-explosion and safety technical performances of the warm and hot water heater can be improved significantly.

Owner:瑞安市华仕力环保设备股份有限公司

Thermal-insulation glass protective film

InactiveCN105347691AImprove heat insulationImprove insulation effectCoatingsThermal insulationAntibacterial property

The invention discloses a thermal-insulation glass protective film which is composed of the following ingredients in parts by weight: 8.8 parts of styrene, 1-2 parts of dipropylene glycol butyl ether, 1.2 parts of albite, 0.4 part of rubella iron oxide, 1.3 parts of sodium propionate, 1.2 parts of triethoxyvinylsilane, 1.3 parts of sodium peroxide and 3.4 parts of propylene glycol monomethyl ether acetate. The thermal-insulation glass protective film can improve the heat-insulating property, insulation property, cold resistance, explosionproof property, corrosion resistance, antibacterial property and anti-static property of glass.

Owner:CHANGSHU SEDY INLAY GLASS PROD

Novel flame-retardant explosion-proof glass

The invention discloses novel flame-retardant explosion-proof glass. The novel flame-retardant explosion-proof glass comprises, by weight, 50 to 70 parts of cassava vinasse, 10 to 20 parts of sheep manure, 10 to 30 parts of chicken manure, 10 to 20 parts of decomposed fallen leaves, 12 to 18 parts of rice chaff, 10 to 15 parts of rapeseed cakes, 5 to 10 parts of potassium sulfate, 8 to 17 parts ofhumic acid, 8 to 12 parts of sodium selenite, 5 to 10 parts of a silane coupling agent, 5 to 12 parts of calcium carbonate, 2 to 8 parts of a biological agent and 5 to 11 parts of a rooting agent. The flame-retardant explosion-proof glass is reasonable in formula, uses simple and easily available raw materials, and has high explosion resistance and shock resistance, and good mechanical strength,wear resistance, acid resistant and alkali resistance.

Owner:ANHUI WEINI ENERGY STORAGE TECH CO LTD

Heat insulation and heat preservation glass film

InactiveCN105331091AImprove heat insulationImprove insulation effectExplosion protectionThermal insulation

The invention discloses a heat insulation and heat preservation glass film. The heat insulation and heat preservation glass film is prepared from, by weight, 17 parts of polyurethane resin, 1-2 parts of dialkyl-alkylene diol phenyl ether, 1.6 parts of lauraminopropionate, 1.3 parts of methyl methacrylate, 2.5 parts of modified polysiloxane, 1.3 parts of zinc oxide, 1.2 parts of allyl heptanoate and 3.4 parts of methyl methyacrlate. The heat insulation and heat preservation glass film can improve the properties of heat insulation, heat preservation, cold resistance, explosion protection, corrosion resistance, antibiosis and static prevention of glass.

Owner:CHANGSHU SEDY INLAY GLASS PROD

Glass protective film

The invention discloses a glass protective film which is prepared from, by weight, 7.9 parts of butyl rubber, 1-2 parts of dibutyl phthalate, 0.2 part of acrylic acid, 1.3 parts of light calcium carbonate, 2.4 parts of ethylene distearamide, 1.2 parts of fatty alcohol-polyoxyethylene ether, 1.3 parts of methyltrimethoxysilane and 2.3 parts of 1,4-cyclohexynol. The glass protective film can improve the heat-isolation, heat-preservation, cold-resistant, anti-explosion, anti-corrosion, anti-bacterial and anti-static performance of glass.

Owner:CHANGSHU SEDY INLAY GLASS PROD

A kind of process and its device for preparing graphene tire through joint production

ActiveCN105666904BIncrease puncture resistanceImprove explosion protectionHydrogenWaste processingFerrosiliconCogeneration

Owner:程礼华

Explosion-proof laser radar

PendingCN111487601AExpand the effective rangeReduce lossElectromagnetic wave reradiationGlass coverRadar

The invention relates to the technical field of radar explosion prevention, and particularly relates to an explosion-proof laser radar. A multiple stable explosion-proof protection structure composedof a glass cover, an upper cover plate, a lower cover plate, an upper pull plate, a lower pull plate, a connecting mechanism and the like is arranged outside a laser body so that the laser radar can be safely applied to dangerous environments with an explosive gas and the like. And meanwhile, a window on the connecting mechanism is matched with the laser body so that transmission losses during laser emission and receiving of laser radar operation can be effectively reduced, and laser detection efficiency is improved.

Owner:海隆石油集团(上海)信息技术有限公司 +1

Method for manufacturing vibration isolator

ActiveCN103467784BImprove carrying capacityGood damping energy dissipation capacityCoatingsStearic acidNoise reduction

The invention discloses a method for manufacturing a vibration isolator. The method is as below: first dipcoating 5-10 rubber layers on a whisker surface of tetrpod-like zinc oxide; taking 100 parts by weight of plasticated natural rubber; adding 10-15 parts by weight of the tetrpod-like zinc oxide with rubber layers dip-coated on the whisker surface, 3-5 parts by weight of nano zinc oxide, 0.3-0.8 parts by weight of stearic acid, 15-20 parts by weight of spray carbon black, 1-3 parts by weight of an antioxidant N-phenyl-beta-naphthylamine, 2-3 parts by weight of sulfur and 0.3-0.8 part by weight of an accelerator disulfide benzothiazole; mixing evenly; injecting the mixture into a metal mold cavity of a molding machine injection isolator by an injection molding machine; and vulcanizing the mixture at 150-160 DEG C for 15-20 min to obtain the isolator product. The isolator manufactured by the manufacturing method provided by the invention has strong carrying capacity and high damping dissipation energy, good noise reduction and isolation performance and obvious effects.

Owner:ANHUI HUAJING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com