Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

189results about "Wall dams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

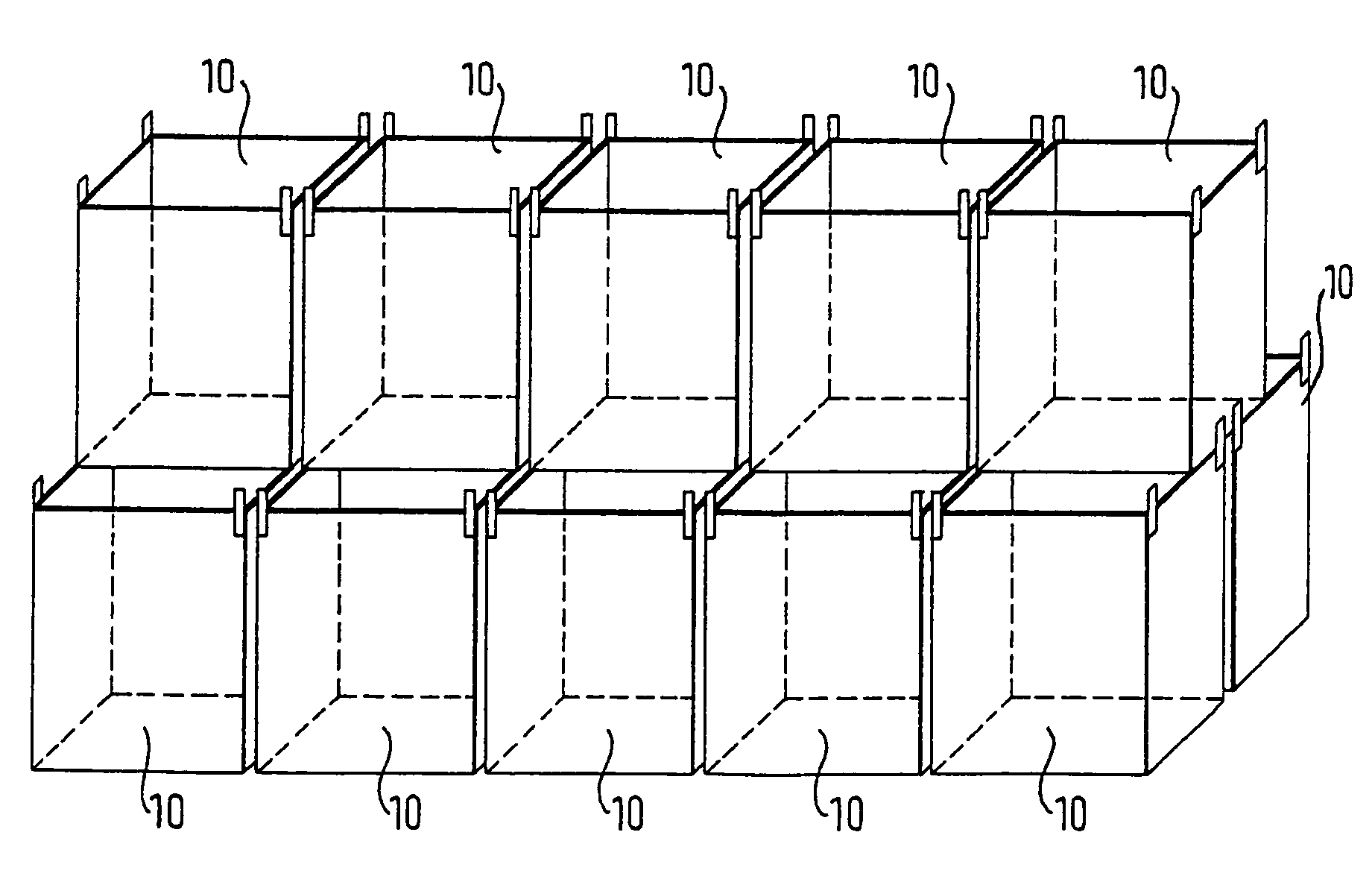

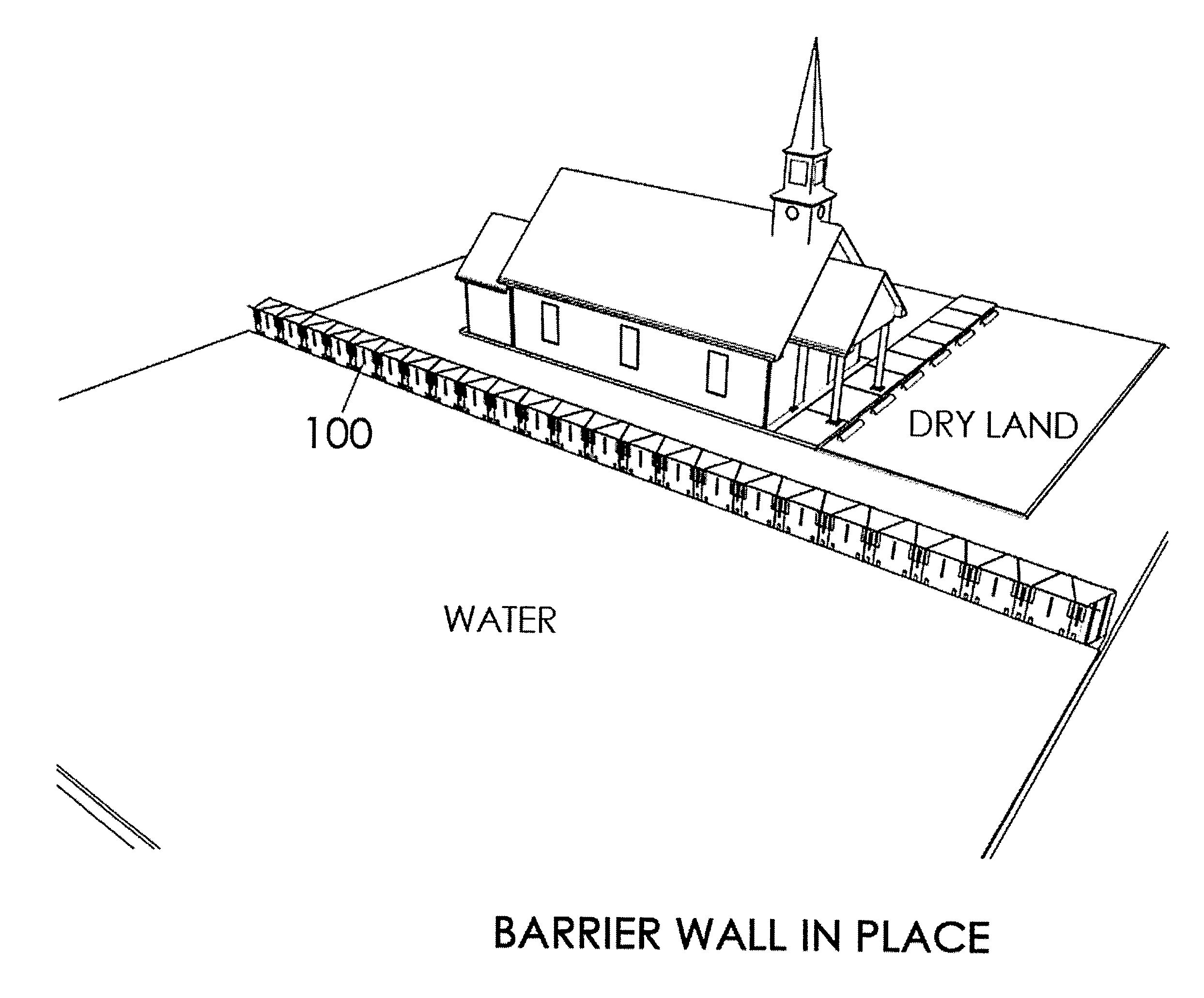

Flood control system

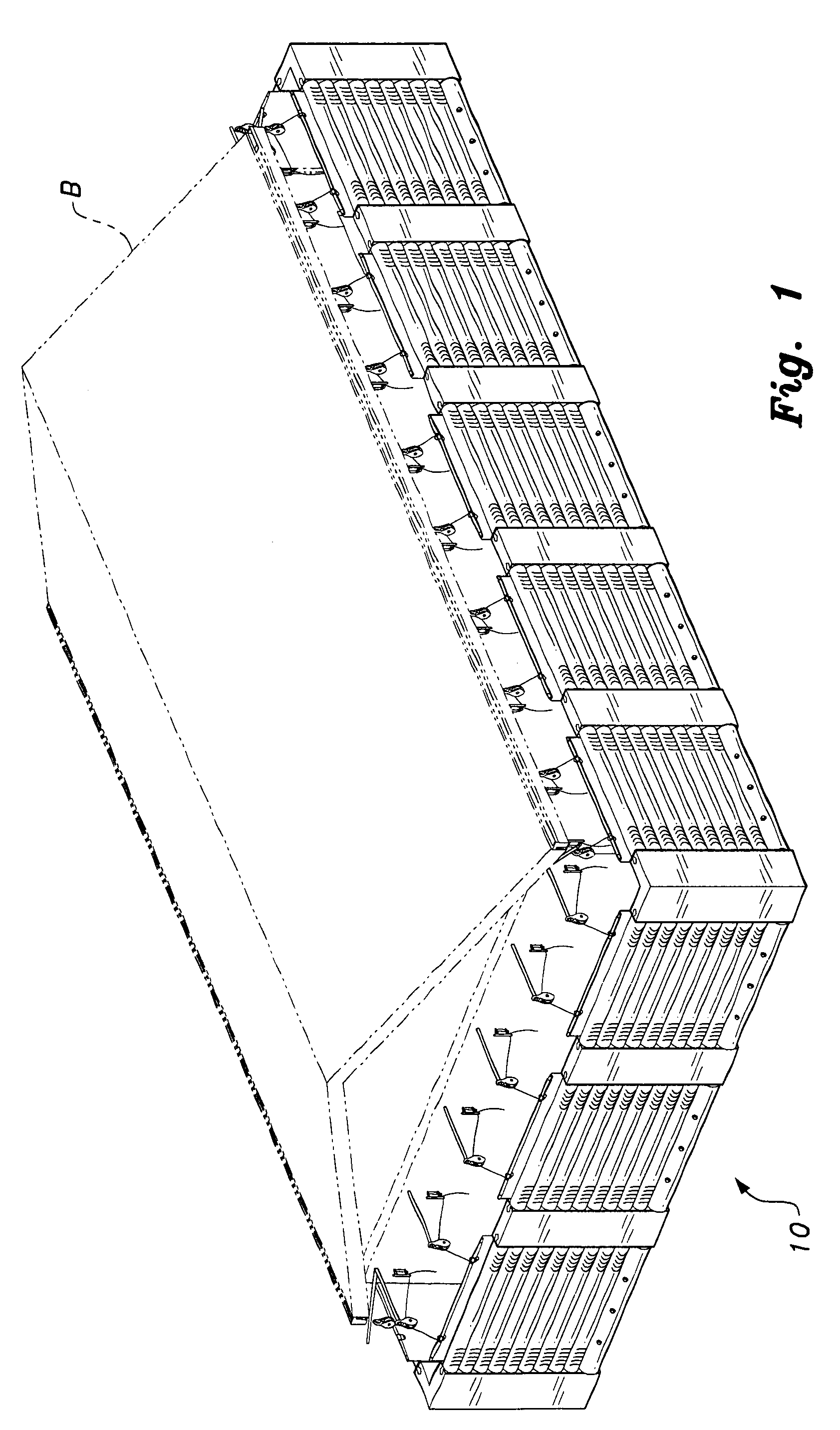

A flood control system, in one aspect involving providing a plurality of substantially rigid containers, at least some of the containers having a top portion, a bottom portion and substantially rigid sidewalls operably connecting the top and bottom portions, the sidewalls being configured to withstand compressive forces between the top portion and the bottom portion; and positioning the plurality of substantially rigid containers at a selected location proximate a body of water, at least some of the substantially rigid containers being positioned at the selected location in a substantially abutting relationship to form a barrier.

Owner:TOBOR & GOLDSTEIN

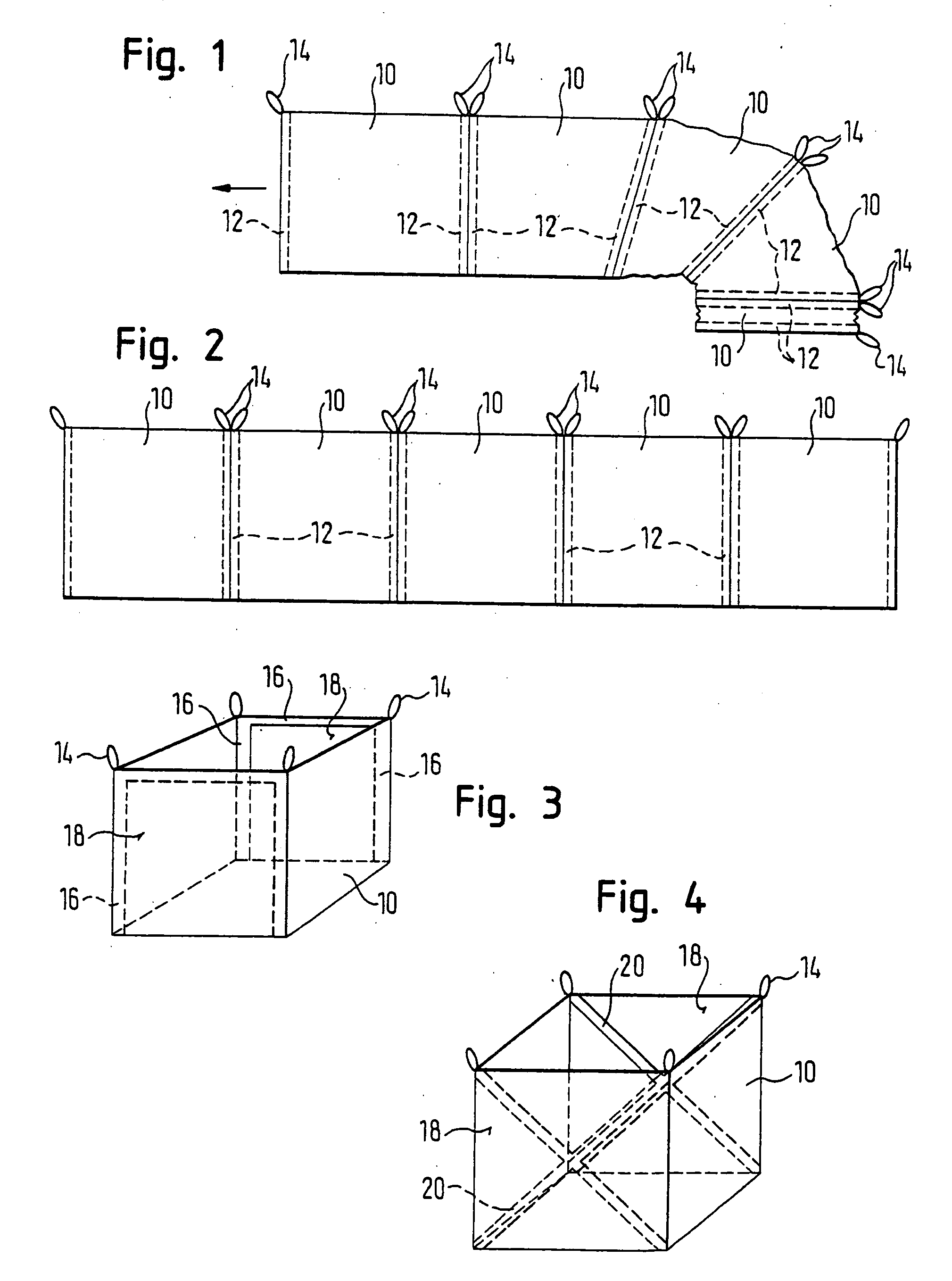

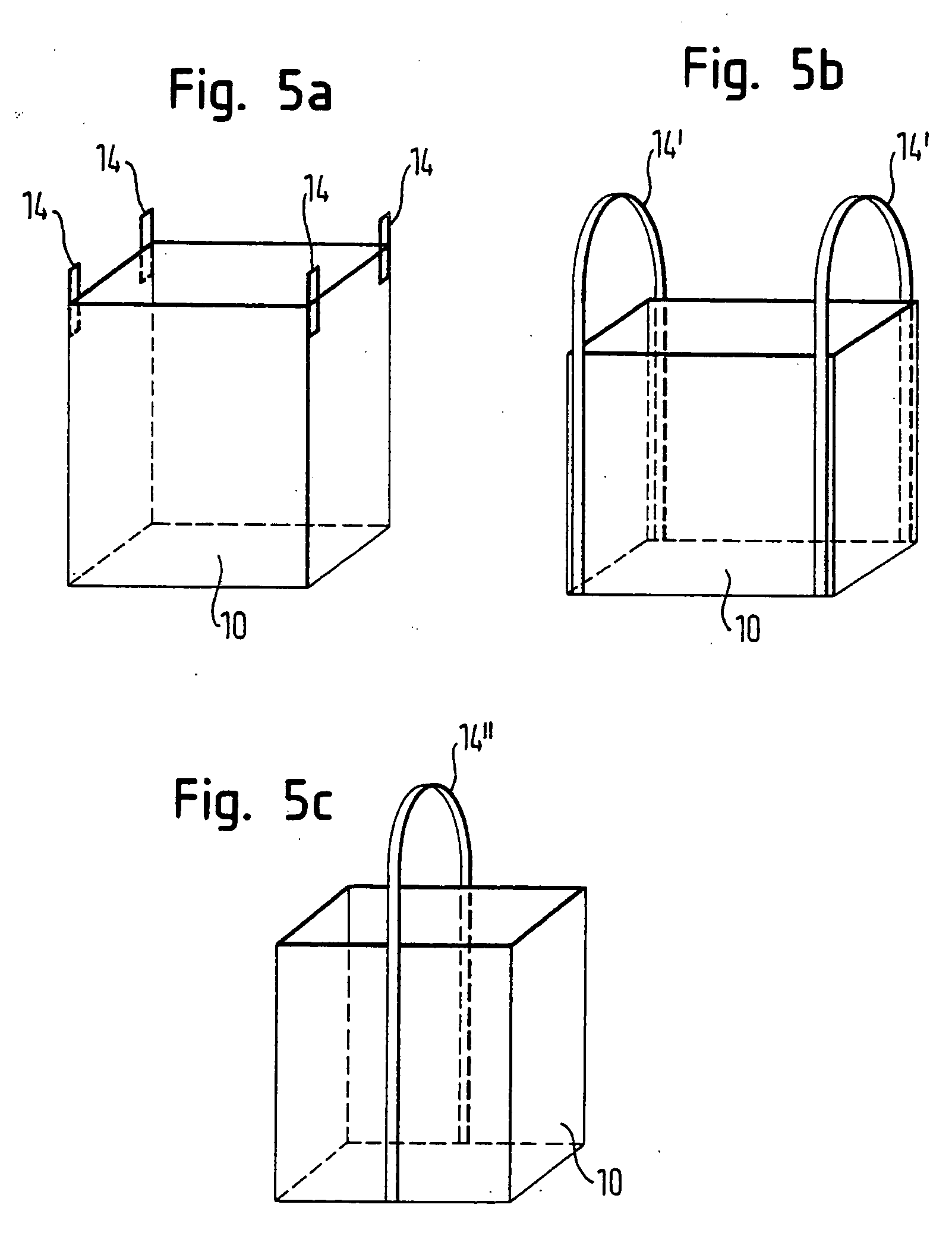

Flood protection

The invention relates to flood protection comprising a plurality of fillable sacks made of flexible fabric material, with mutually adjacent coupling sides of adjacent sacks being connected to one another in a coupling region and with at least one stiffening structure being associated with each coupling region and extending from the base region of the sacks up to their upper marginal region.

Owner:DISASTER RELIEF & INNOVATIVE PROTECTION SYST LLC

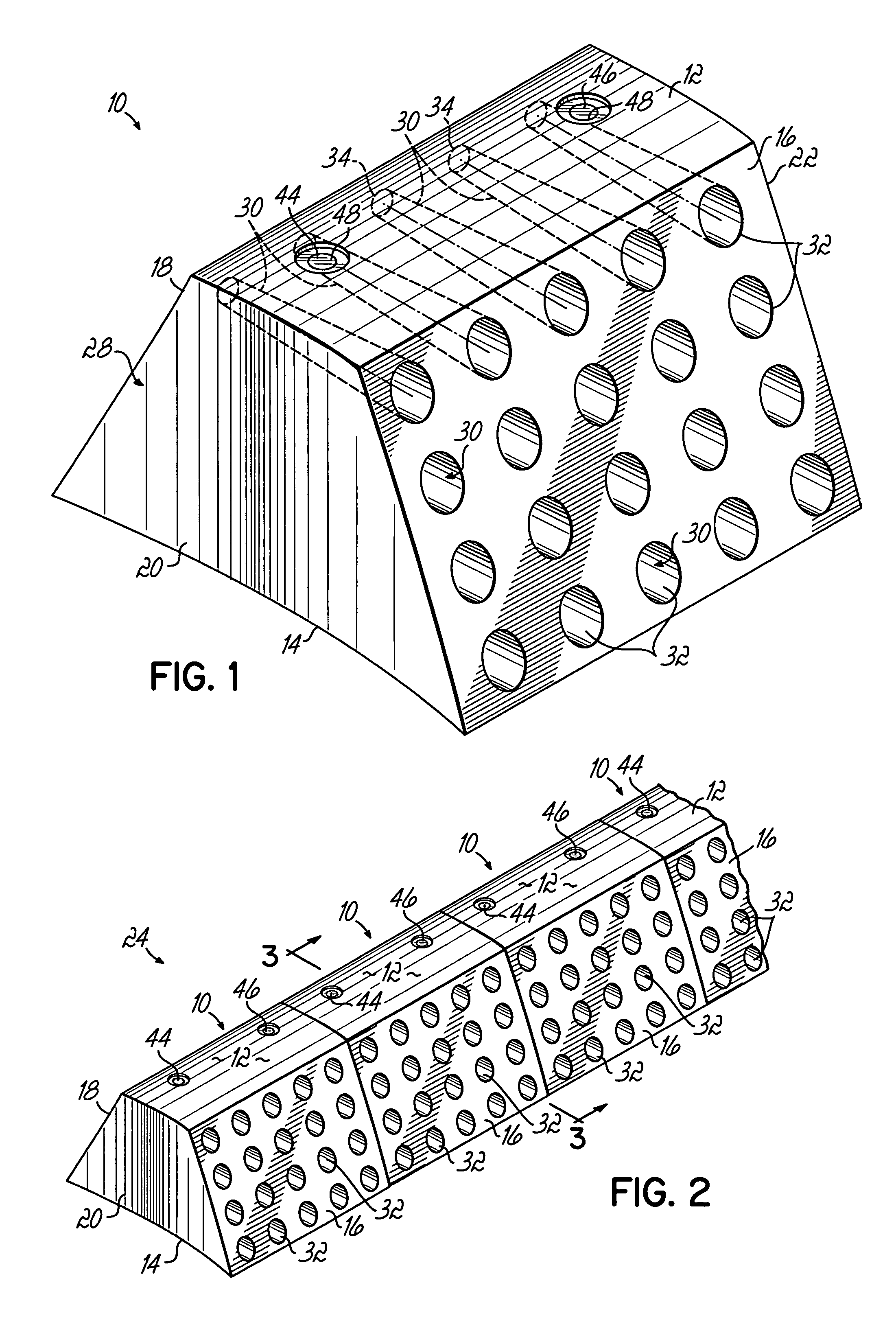

Shoreline erosion barrier

A barrier for reducing erosion along shorelines includes a barrier body formed as a unitary, molded plastic structure. In one embodiment, the barrier body has at least one elongate passage extending through it, between oppositely disposed first and second sides, and an interior reservoir. A port formed into the barrier body communicates with the interior reservoir to facilitate filling the reservoir with material to thereby add weight to the barrier. The barrier further includes at least one anchor formed into a side of the barrier body and associated with the passage to control shrinkage of the barrier body as it is being molded. In another embodiment, a method of making the barrier body includes placing plastic material in a mold, manipulating the mold to distribute the plastic material within the mold and thereby form the barrier body as a unitary piece, and reducing the shrinkage of the molded barrier body with the anchor.

Owner:GRANGER PLASTICS

Flood protection

Owner:DISASTER RELIEF & INNOVATIVE PROTECTION SYST LLC

Beach stabilizing blocks

A device and method for stabilization of beaches and building walls, patios and similar simple structures consisting of blocks with trapezoidal or rectangular shapes which have staking or interlocking means of interconnecting blocks and where the top has an open area allowing fill by slurries of water and sand, gravel or clay and the escape of clarified water during and after filling.

Owner:GIBBS RICHARD A

Flood levee and barrier module and system

A levee and barrier module for fluid control and containment is provided including an outer module shell and a module-to-module connection system to attach adjacent outer shells. The outer module shell, being in the general shape of a prism or prism with curvilinear section, is formed by opposing side walls and two opposing end walls, and is configured to enclose or support filler material. The two opposing end walls are configured with end apertures. The outer module shell defines a top aperture and a bottom aperture. When modules are placed end to end in a levee structure the end apertures allow filler material communication horizontally between adjacent modules. The bottom aperture allows filler material communication with the earth below the module. The top aperture allows filler material to be added to the module, as well as visual observation of, and maintenance of, the amount of contained filler material.

Owner:BOUDREAUX JR JAMES C

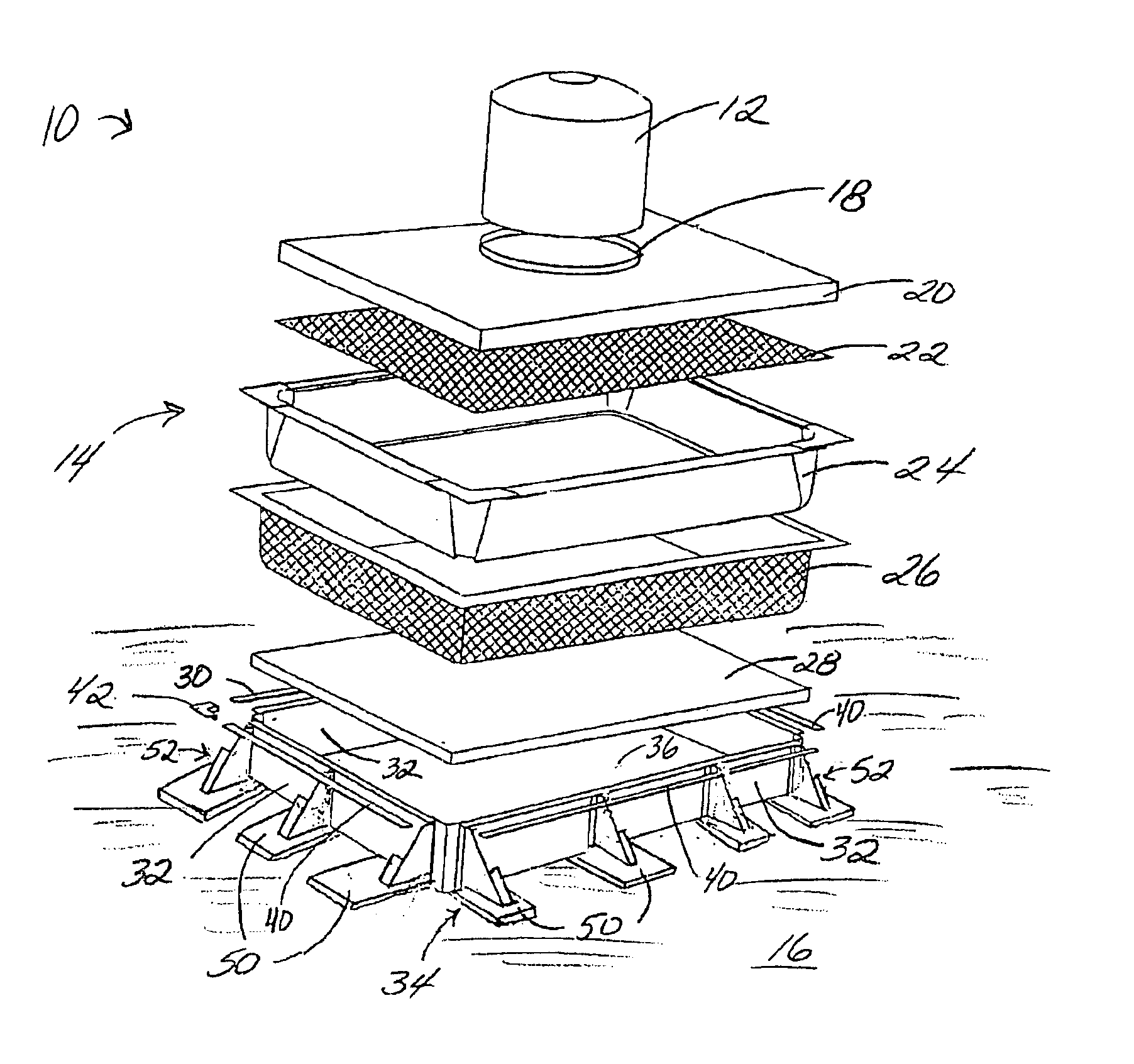

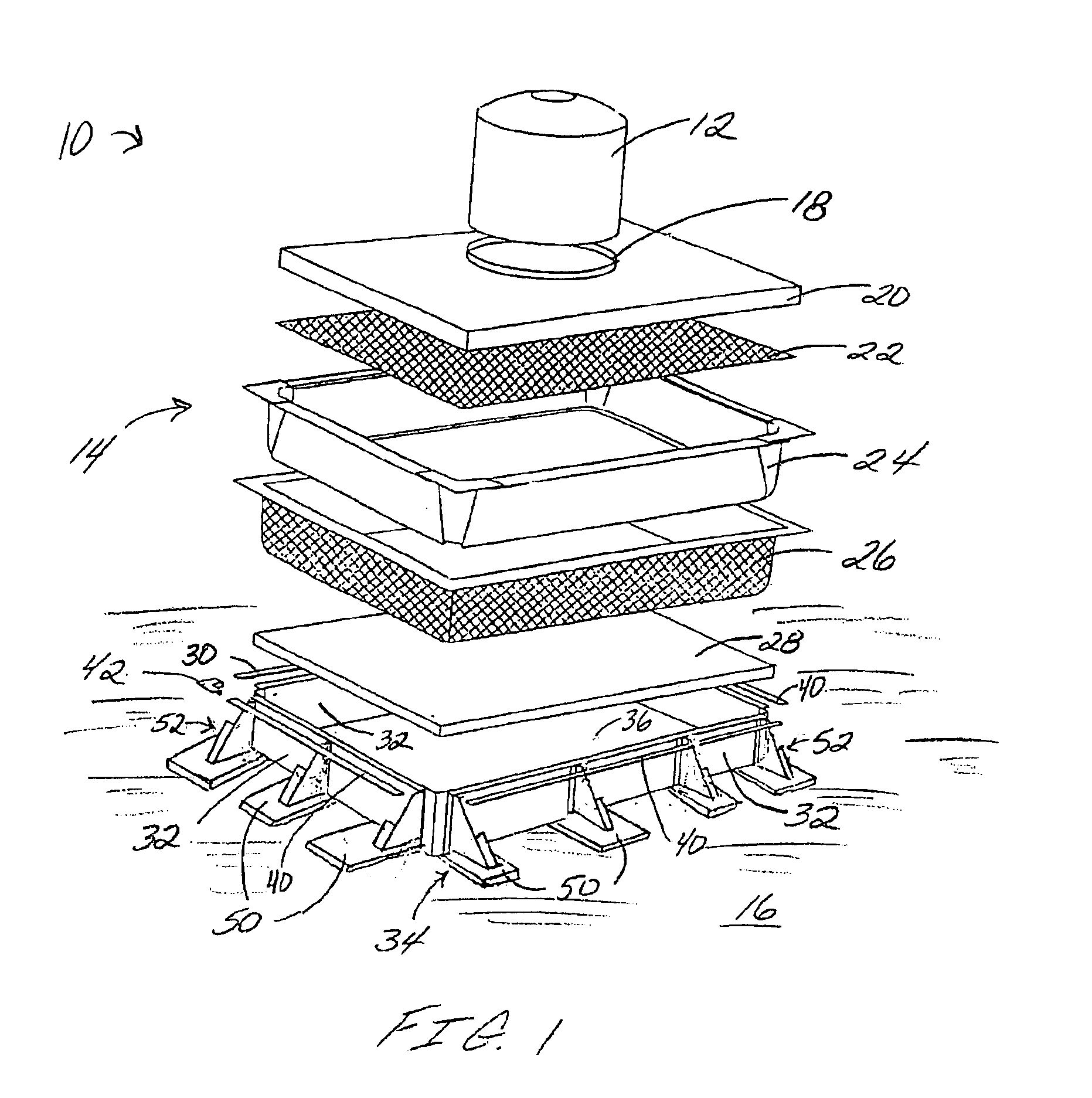

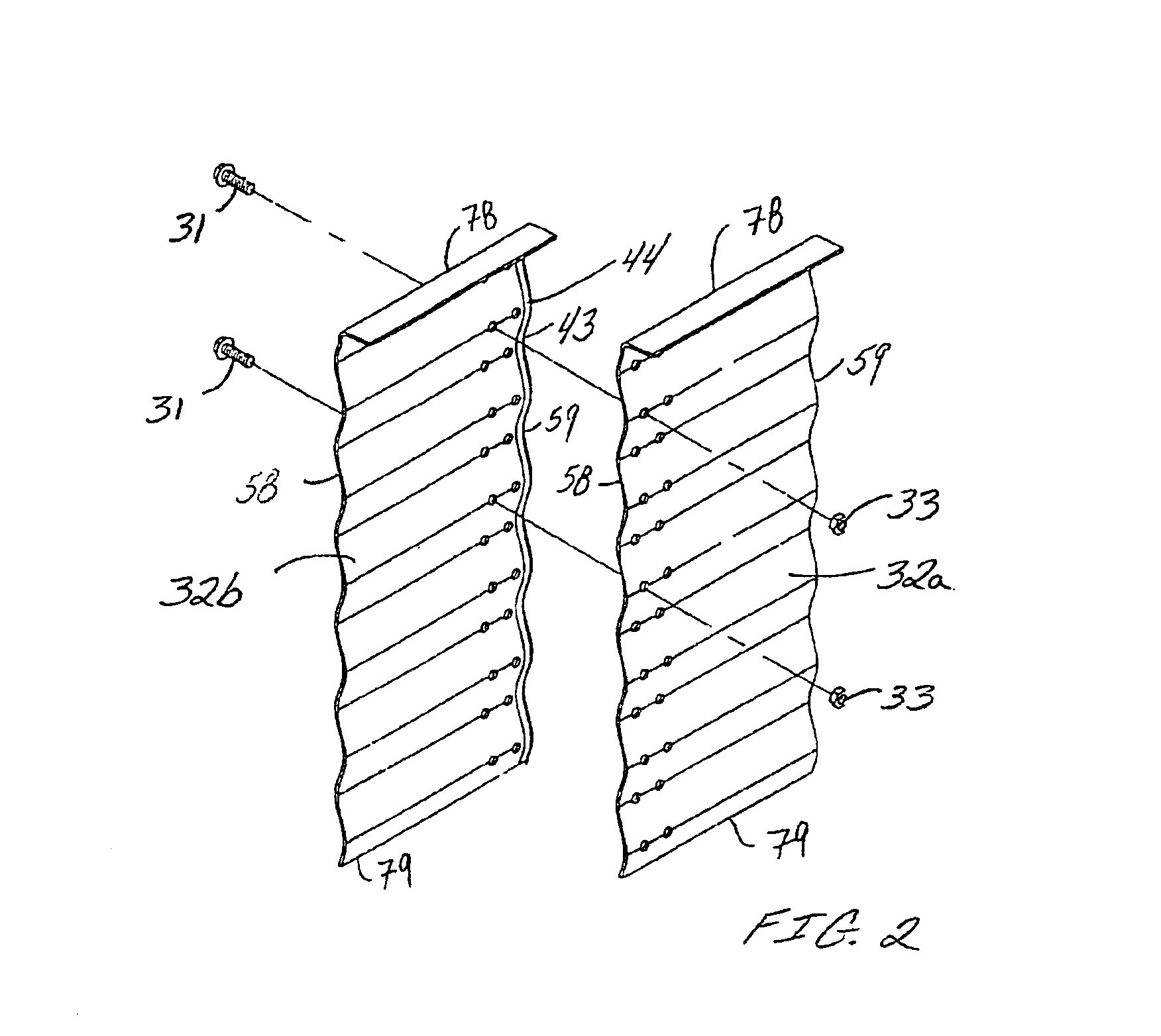

Zero ground disturbance system

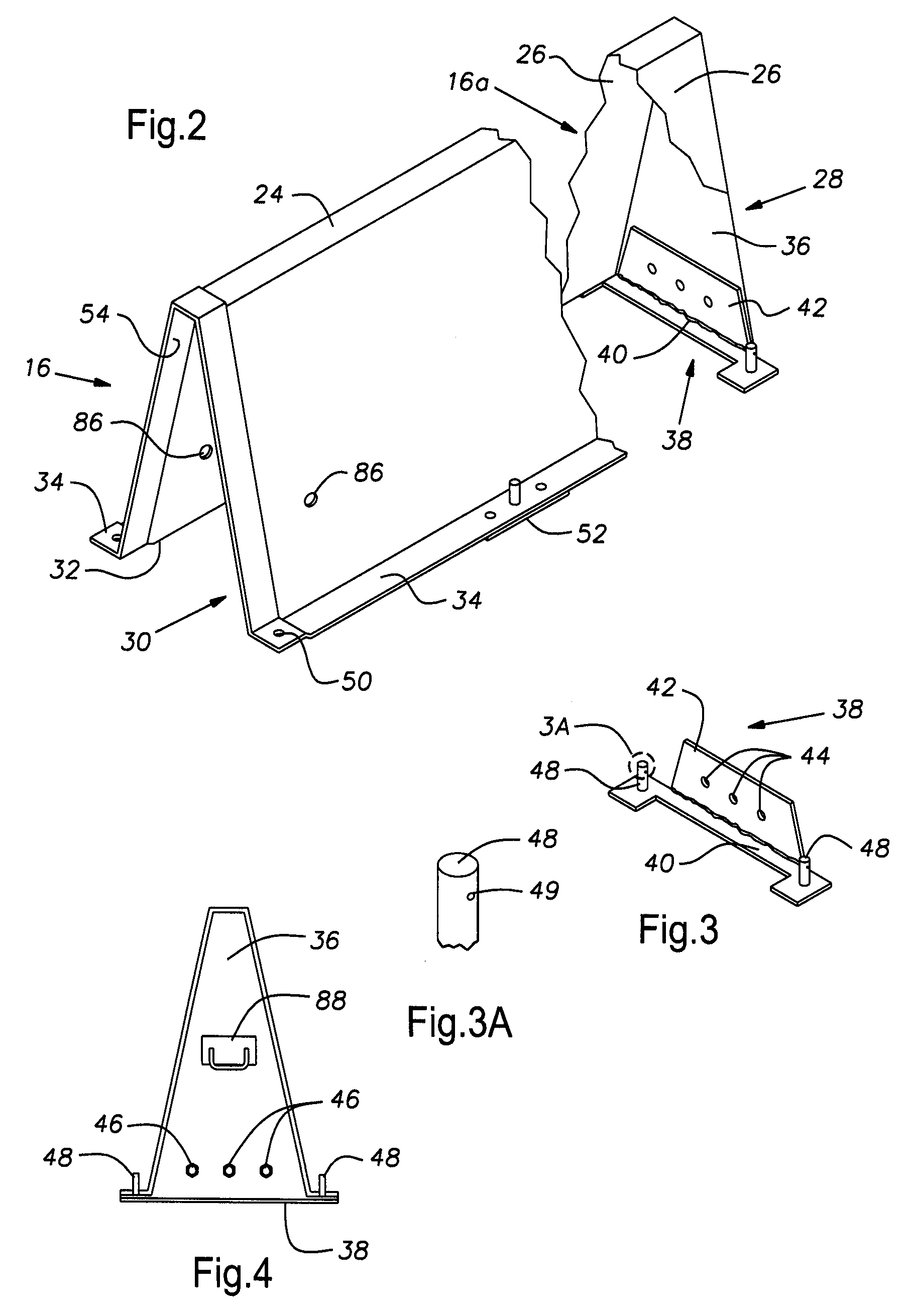

ActiveUS6854926B2Increase stiffnessNot compromise stabilityBarrages/weirsSolid waste disposalEngineeringBending moment

A zero ground disturbance dike apparatus and method for the secondary containment of harmful chemicals that are stored in primary storage vessels, wherein the dike apparatus does not require the drilling of postholes or the setting of support posts in concrete. Sections of dike walls are attached to bracing assemblies, each bracing assembly being comprised of a brace and a base plate. Braces are configured to support the assembled wall sections and to provide resistance against the outwardly force exerted by material that is released from the primary storage vessel. Base plates attached to the braces assist in resisting bending moments that may be created about the base of the dike apparatus. The brace assembly also preferably includes at least one base support channel for additional base plate stiffness and support cables to further resist the outwardly forces exerted against the dike apparatus by said released materials.

Owner:GLOBALFOUNDRIES US INC +1

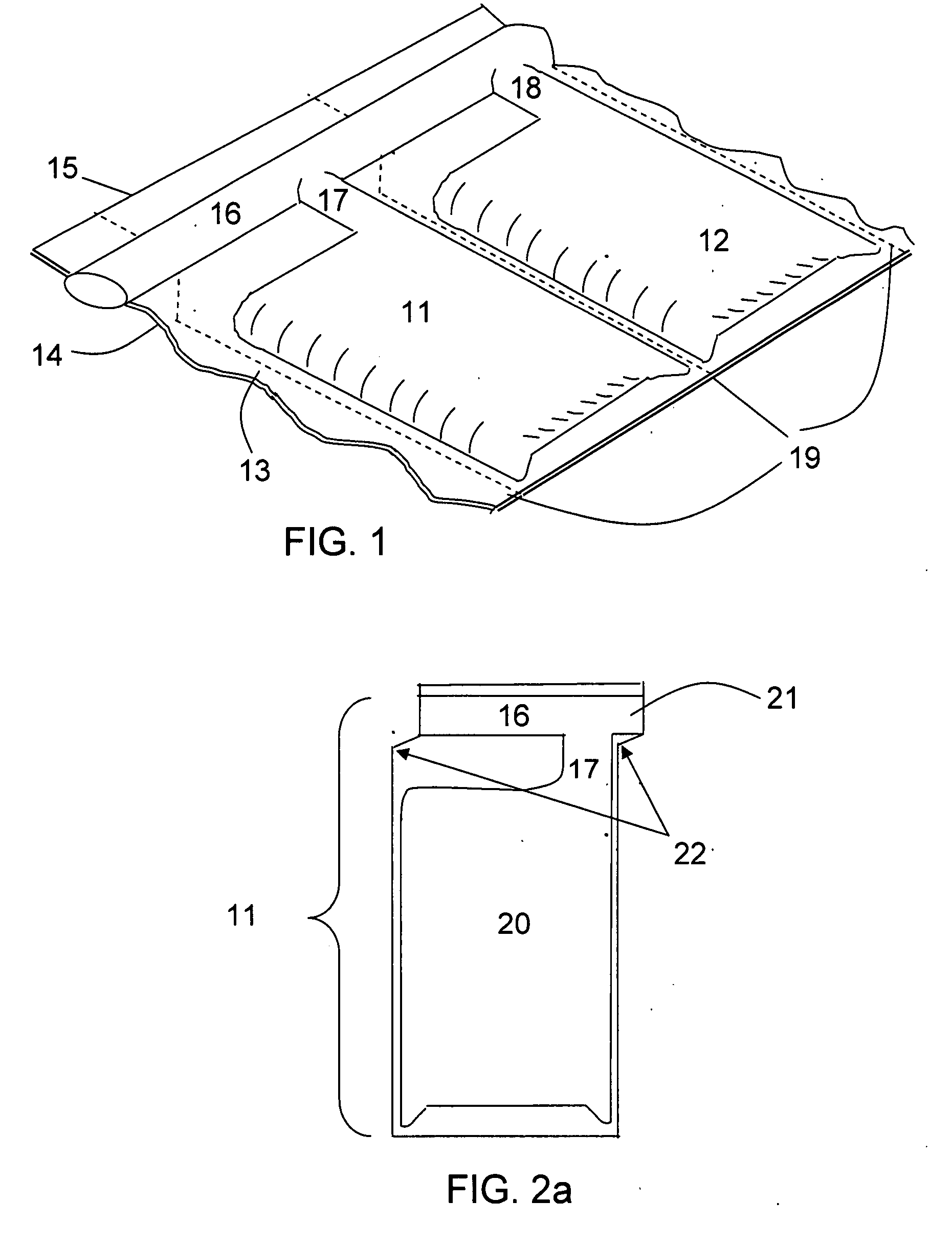

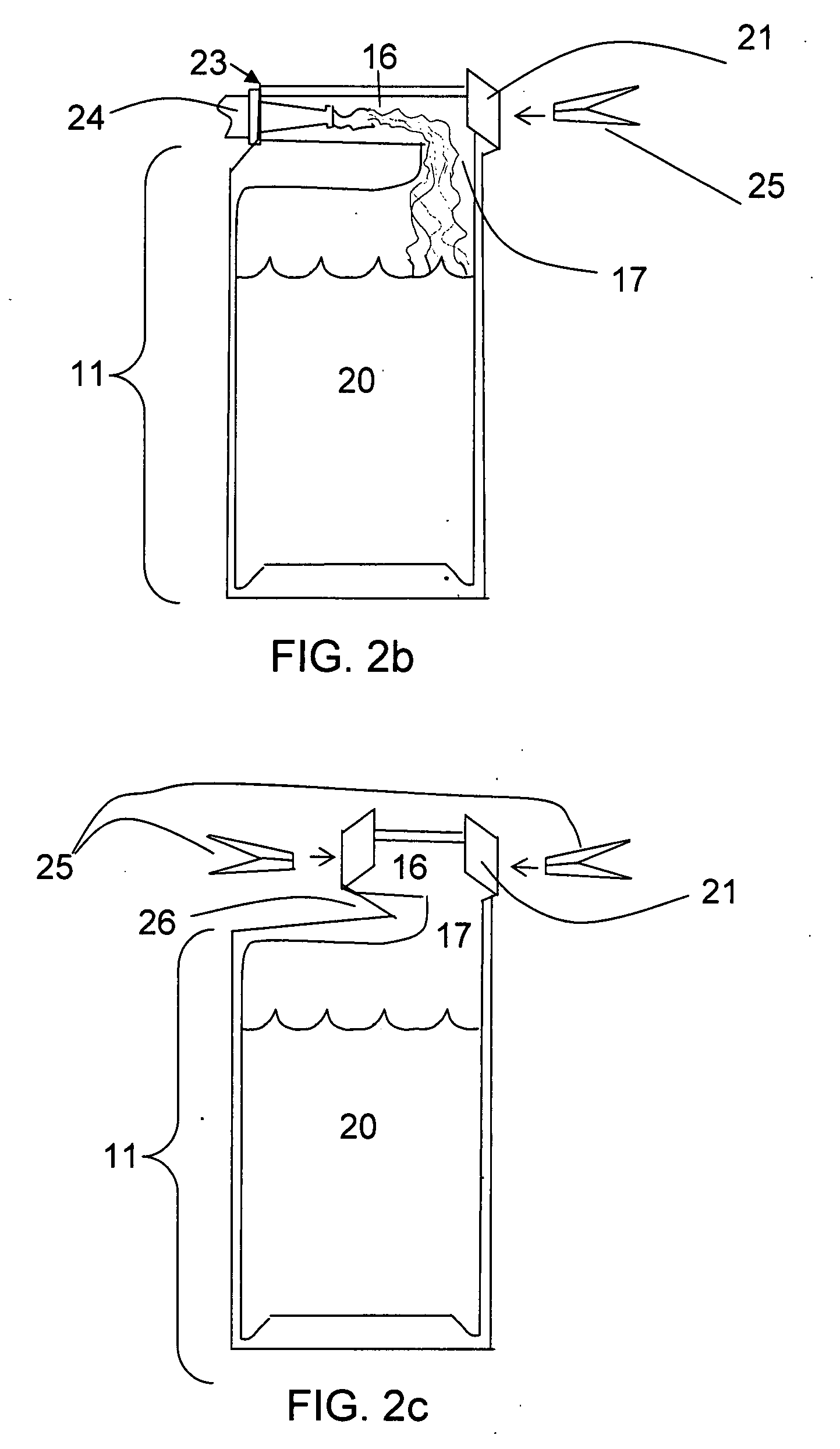

Water-filled flood bags for emergency flood control

InactiveUS20070243021A1Minimize puncturingBarrages/weirsDoor/window protective devicesEngineeringFlood control

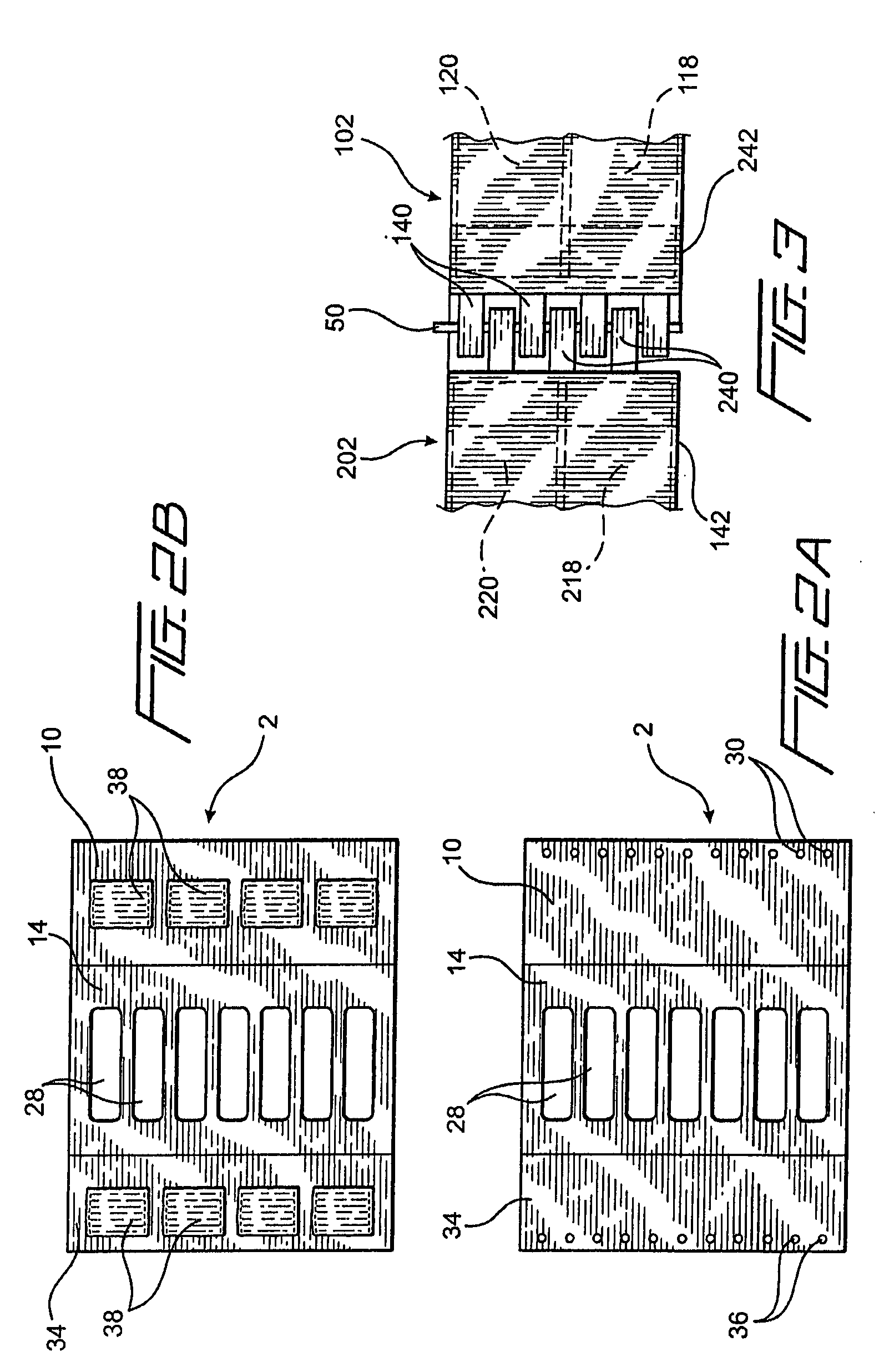

An emergency flood control apparatus is described that includes a row of a plurality of vertically separated cells horizontally arranged formed between at least two continuous sheets of impermeable flexible material, a continuous horizontal tube formed between the sheets and disposed at an end of the cells, and a plurality of necks disposed perpendicularly between the tube and the cells, the necks connecting each of the cells to the horizontal tube in a manner such that the cells may be filled with fluid from the tube at substantially the same time.

Owner:TYLER TIM RICHARD

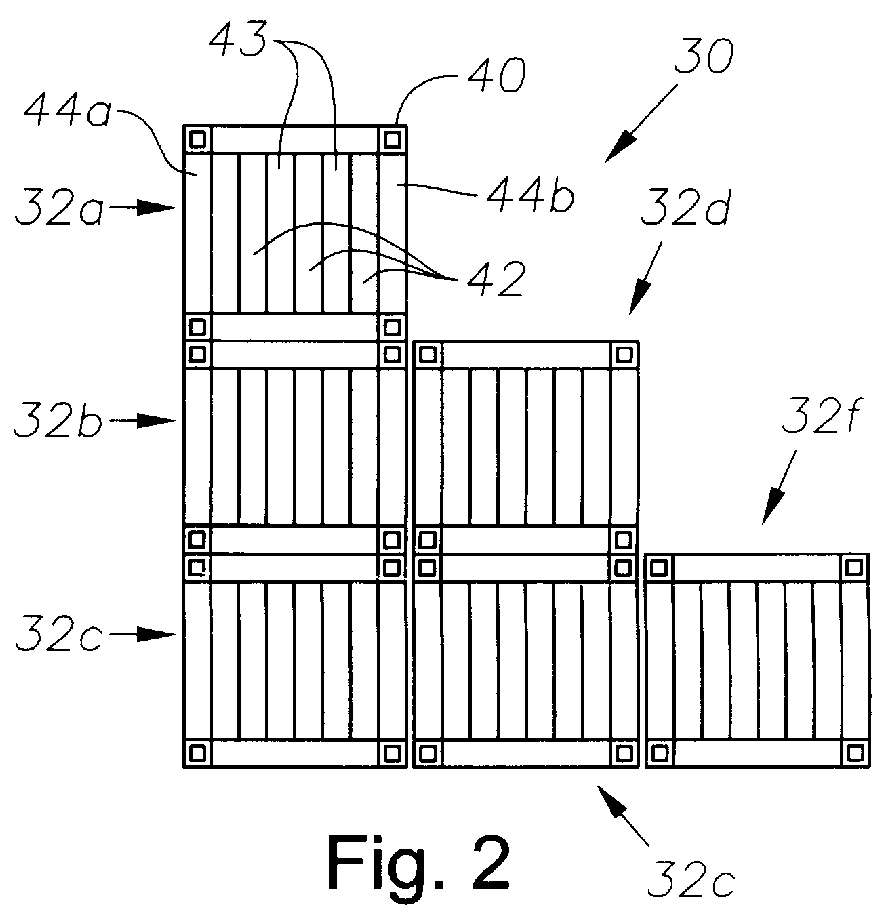

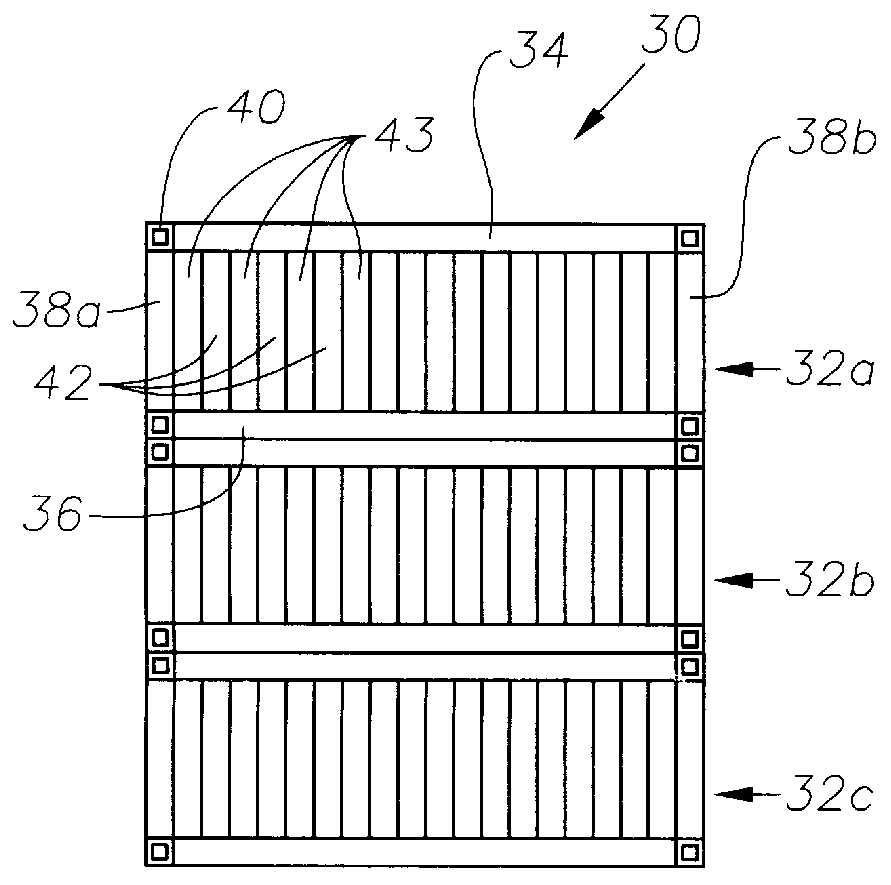

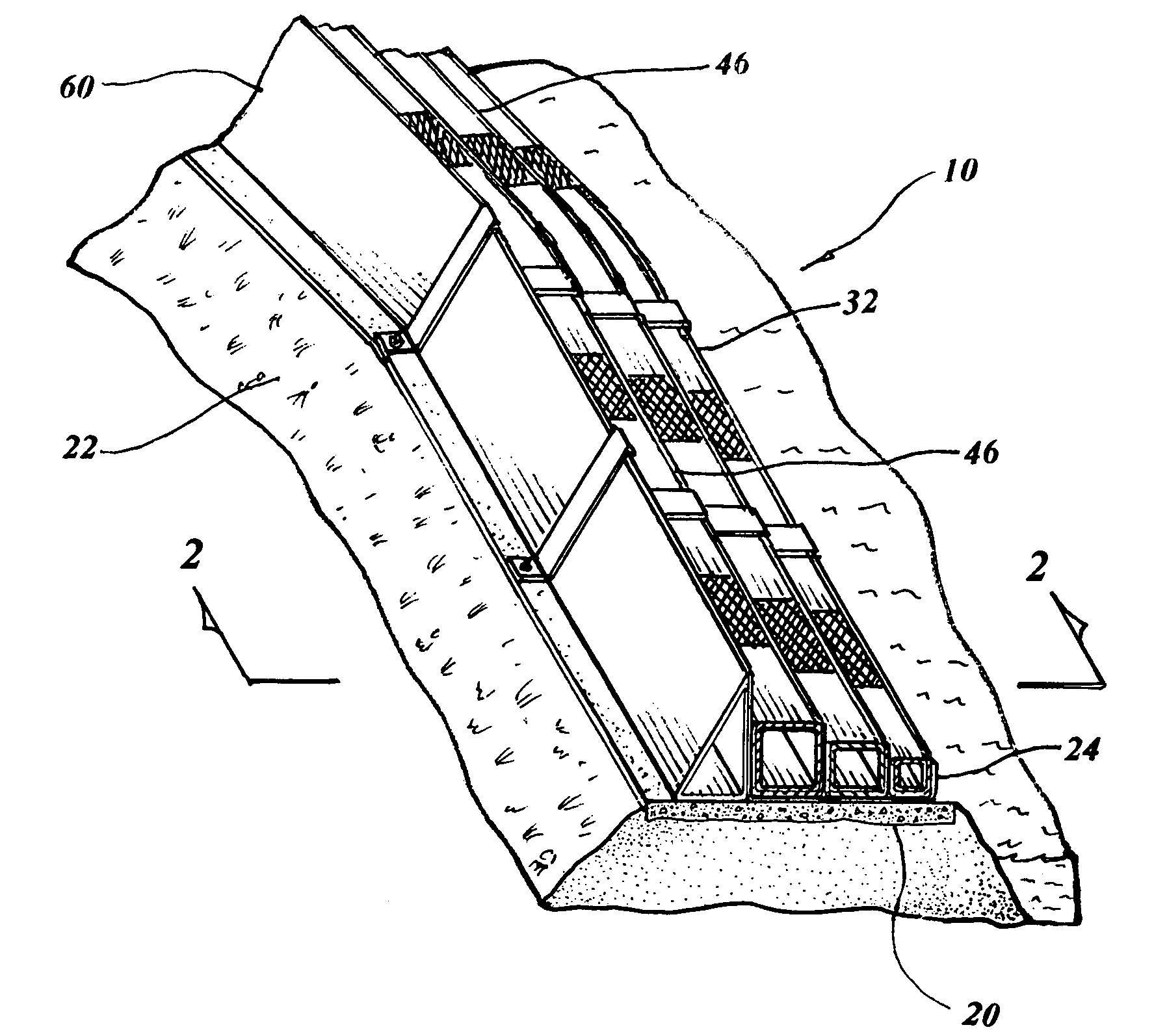

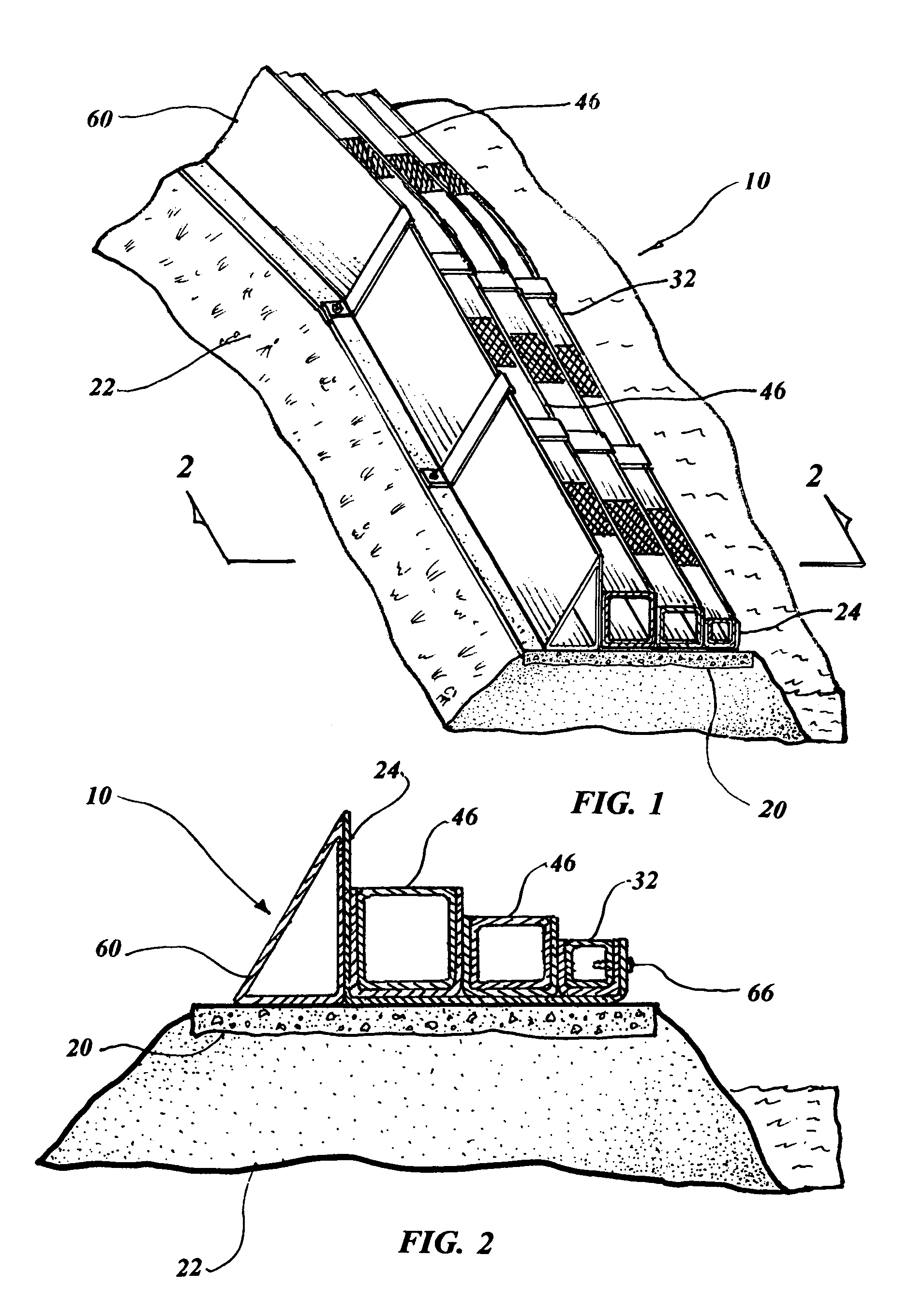

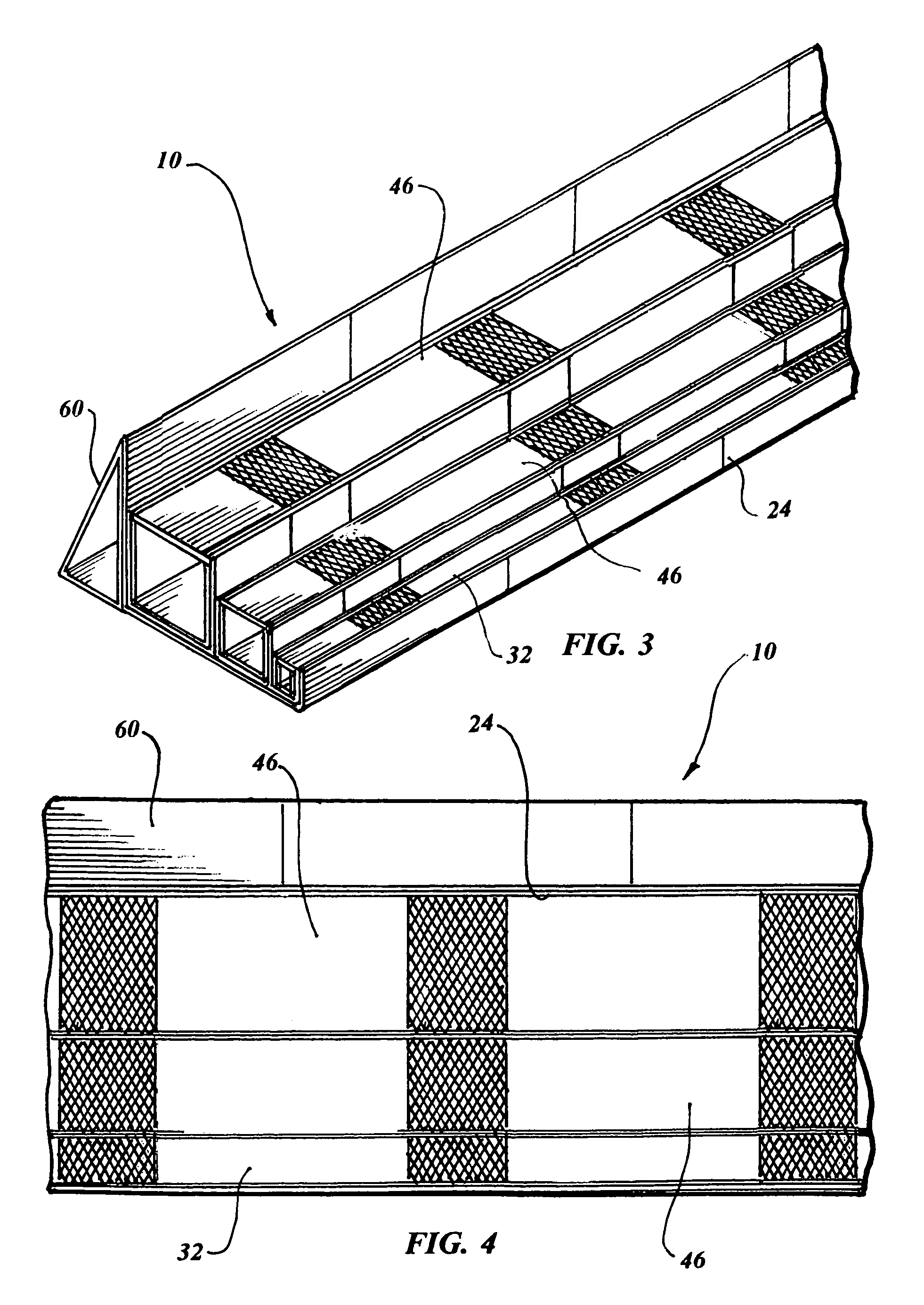

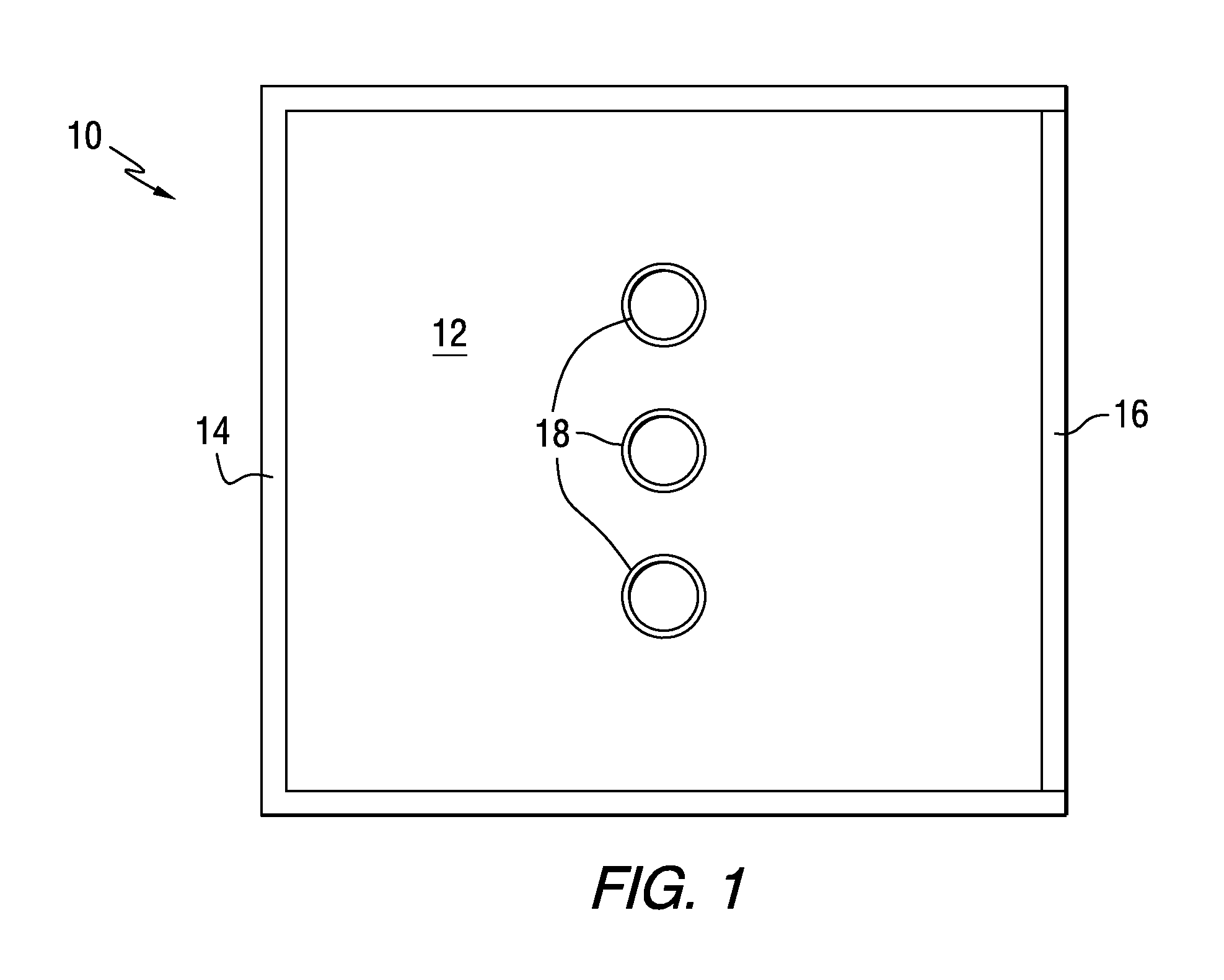

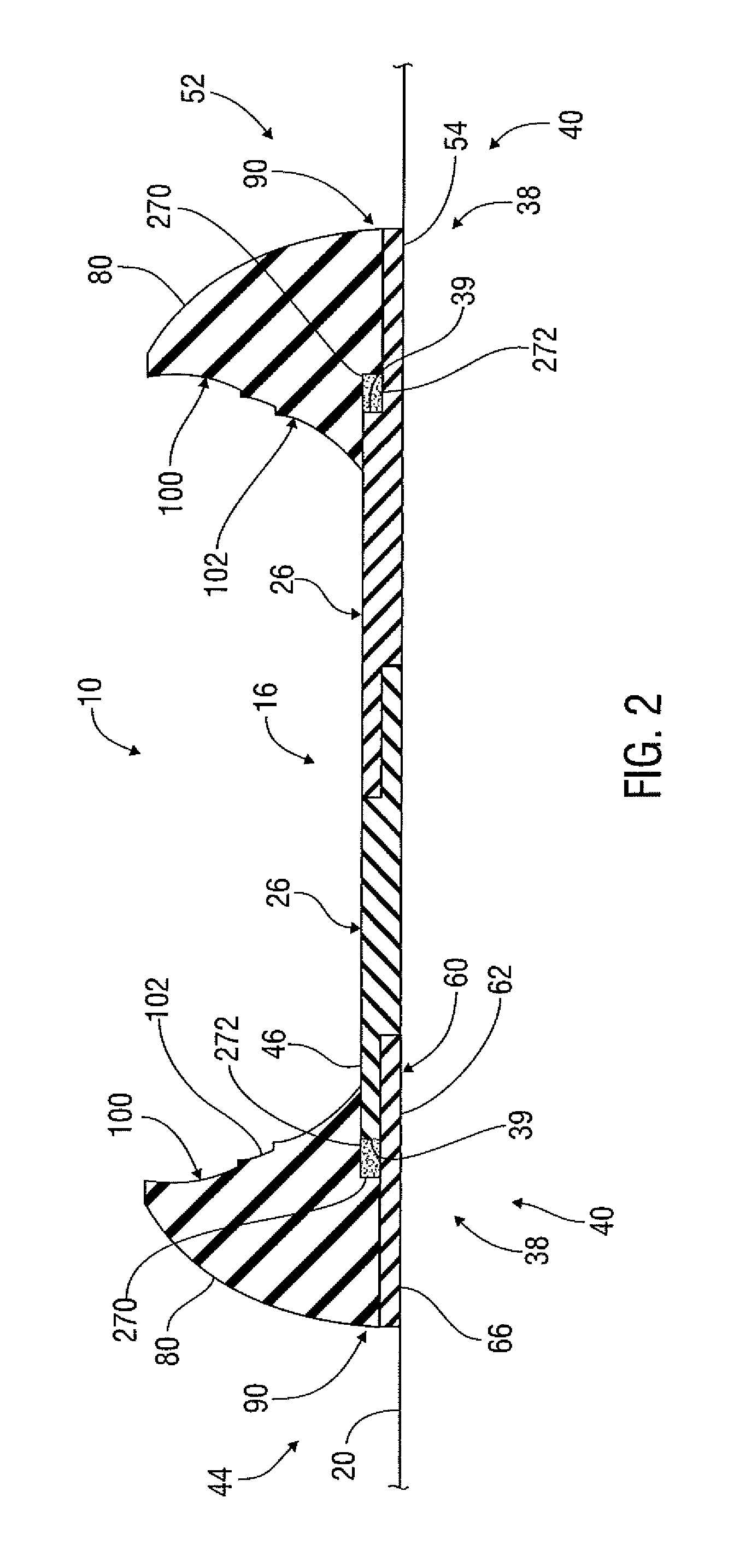

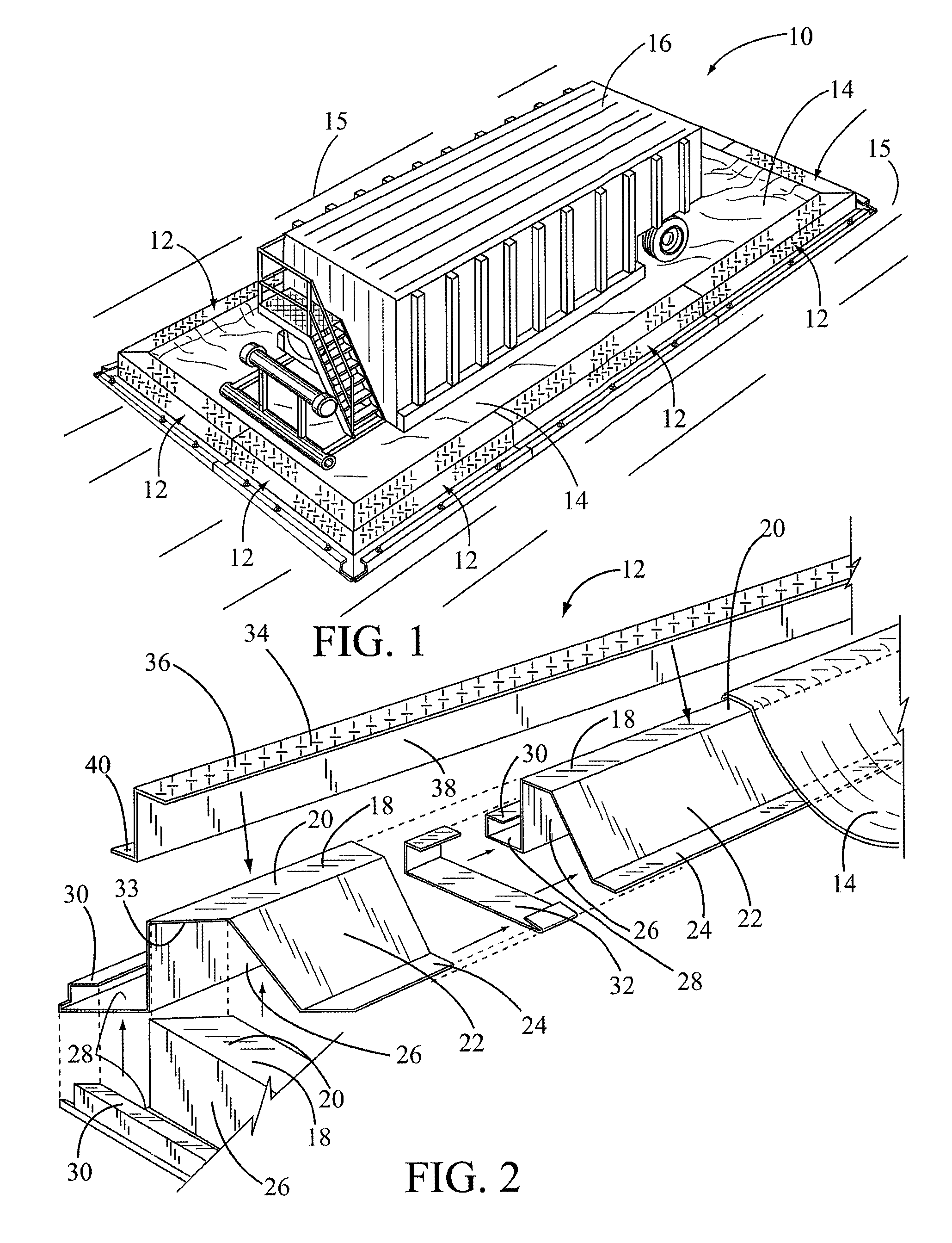

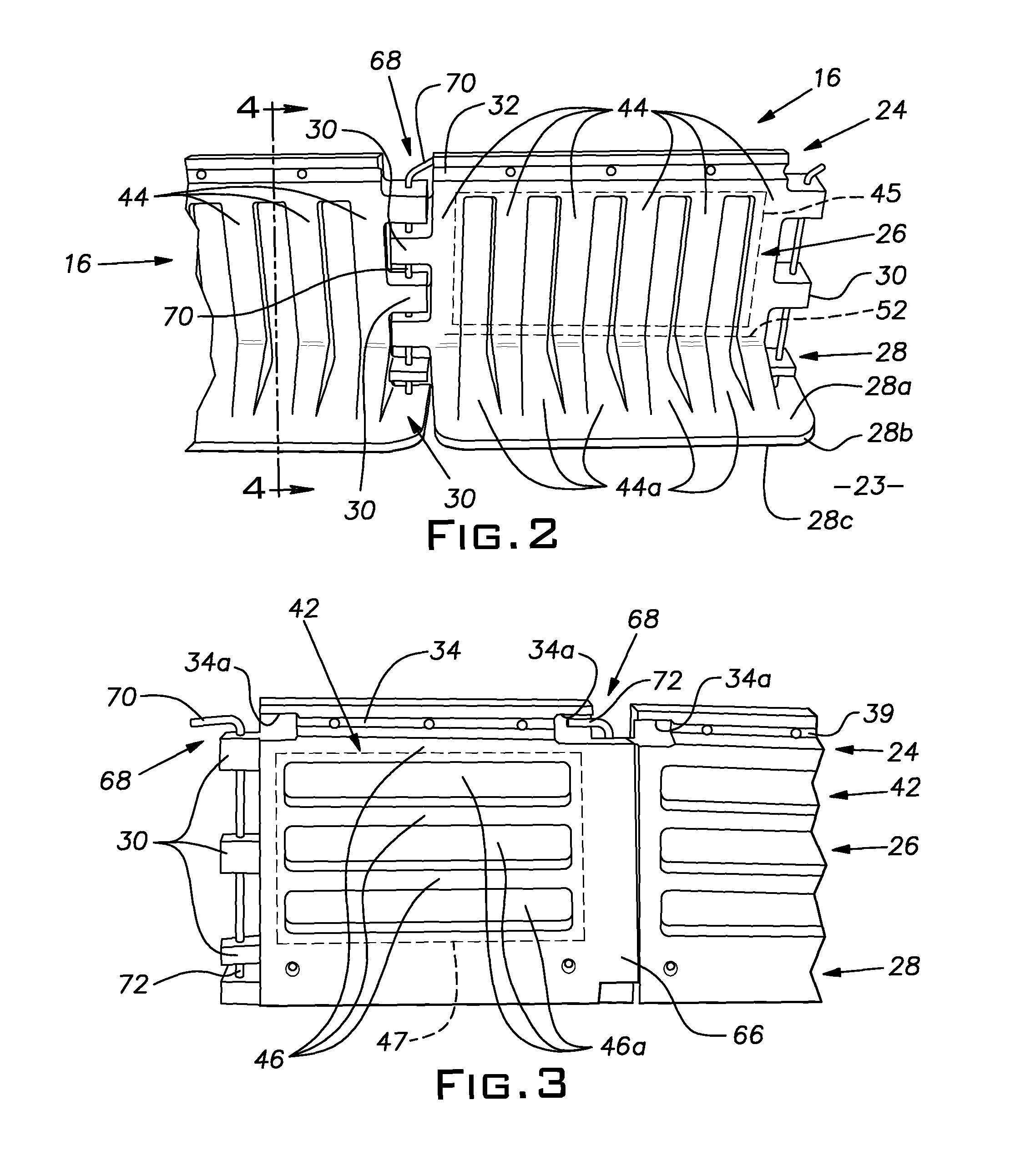

Sectionalized flood control barrier

InactiveUS7214005B1Provide stabilityEvenly dispersedBarrages/weirsBreakwatersEngineeringPrimary channel

A sectionalized flood control barrier (10) for mounting on top of a levee or a river bank to prevent flooding. The barrier (10) consists of a footing (20) with a series of support channels (24) that are butted end to end attached to the footing. The support shells are sealed watertight at the interface with each other and also to the footing. A series of primary channel bridge assemblies (32) and secondary channel assemblies (46) are disposed within the support channels (24) and are also butted end to end. Wind protectors (60) contiguously engage each support channel (24) and rest upon the footing for diverting the wind over the barrier. Stepped fastening risers (62) are attached to the footing on each end and over the channel assemblies, and wind protectors hold them securely in place.

Owner:DAVIS GEORGE T

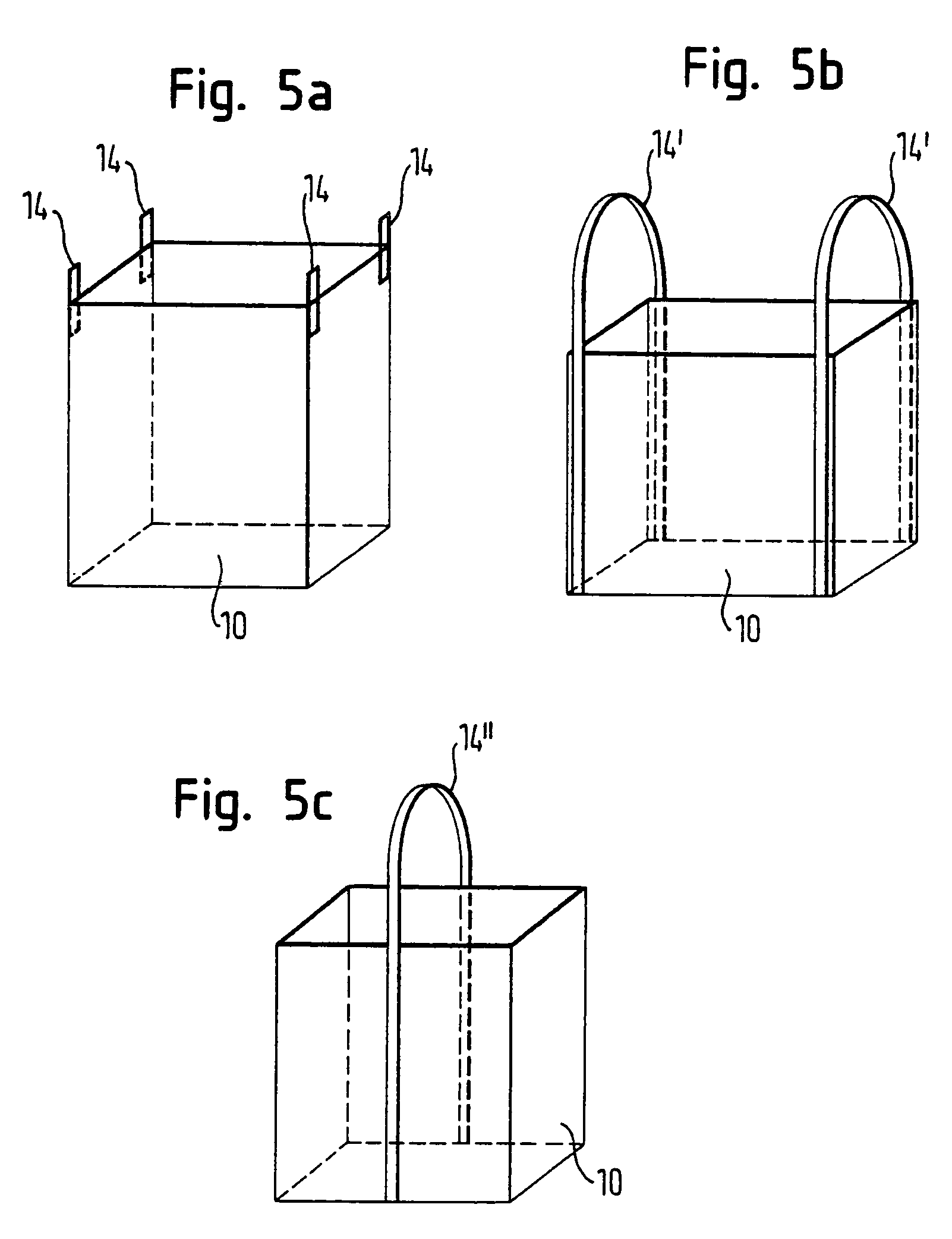

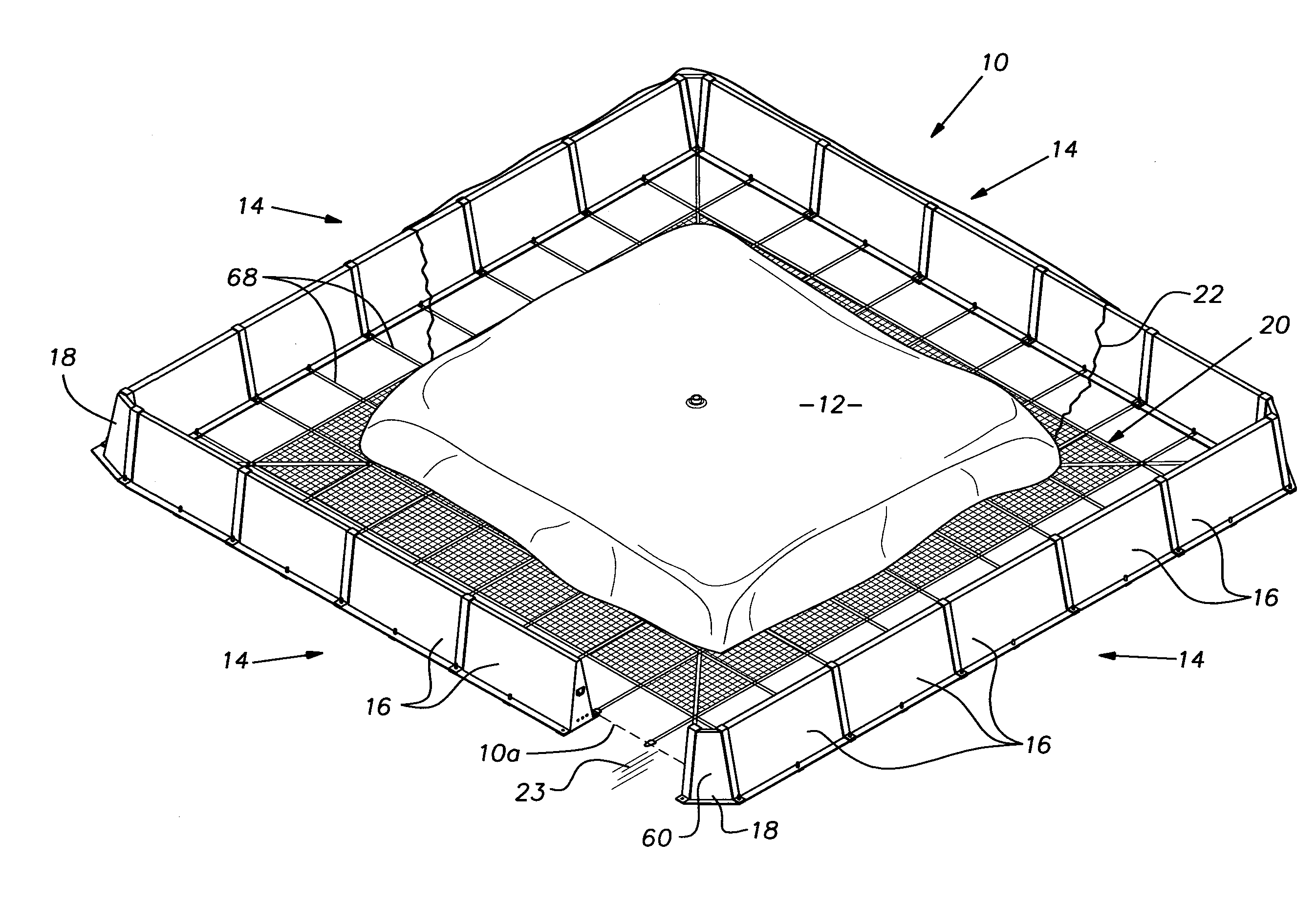

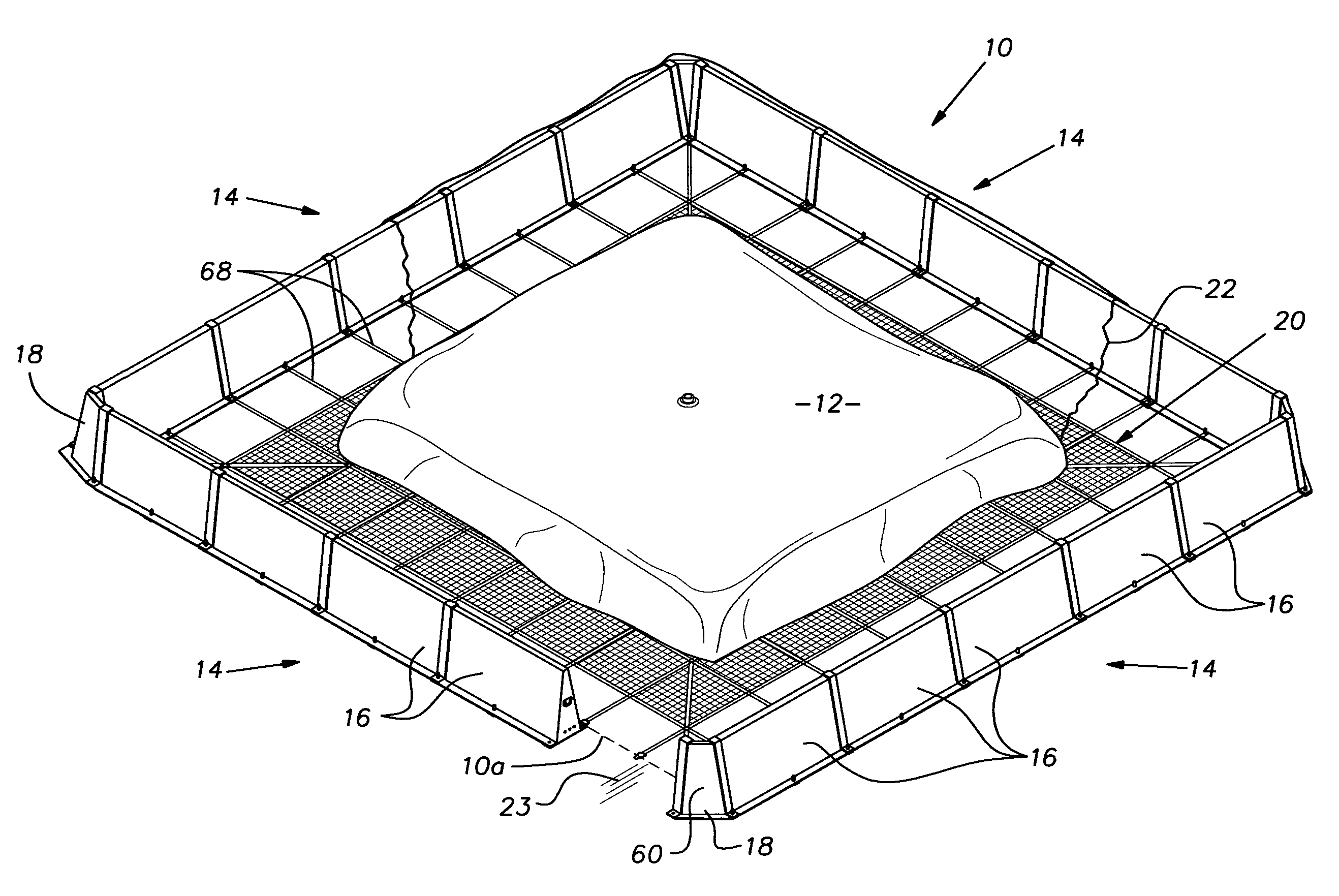

Deployable containment system

ActiveUS20090041543A1Reduce weightPrecise positioningBarrages/weirsLarge containersWaste managementEngineering

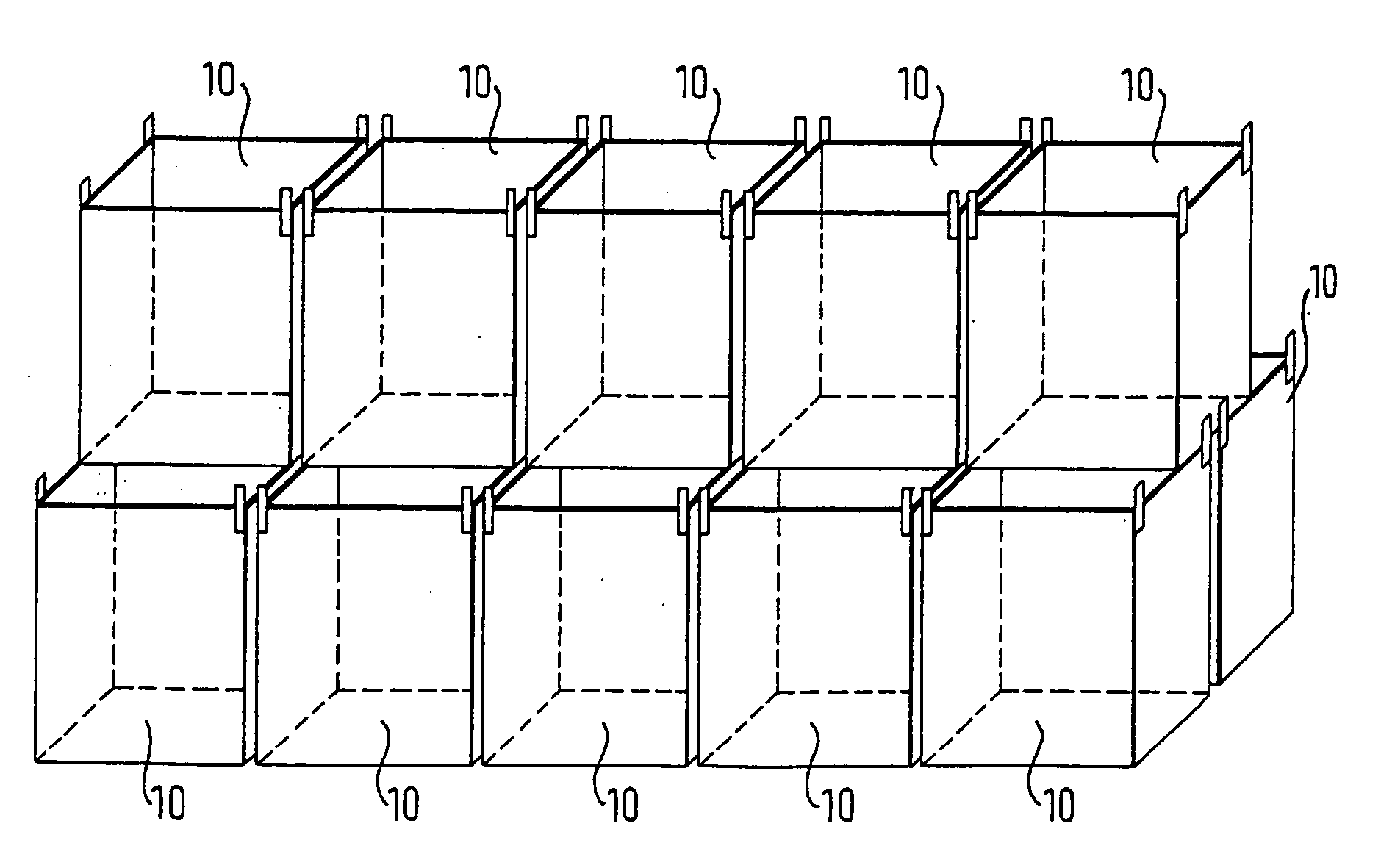

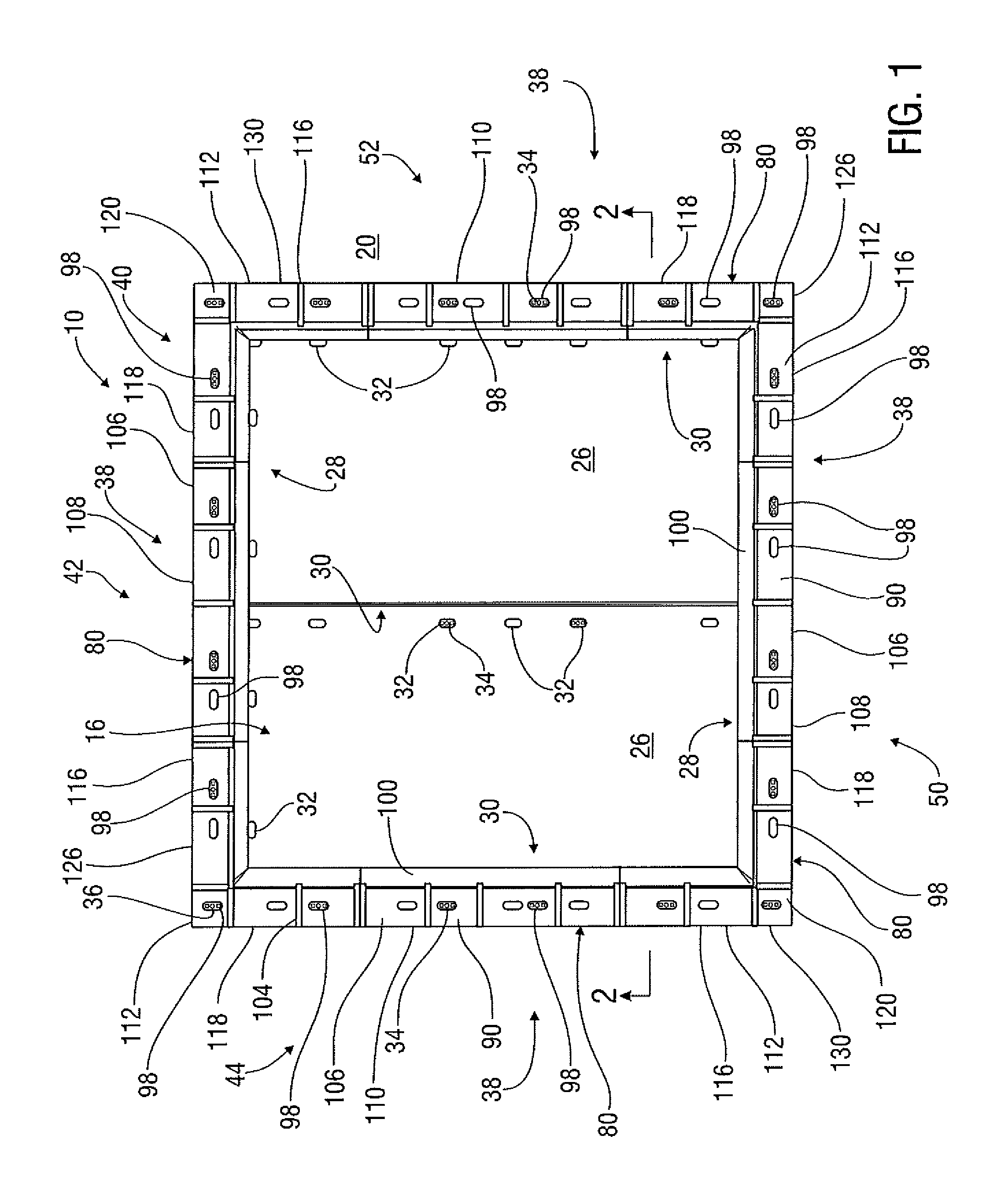

A modular dike assembly includes strut and corner members that may be interconnected to form a barrier or dike wall surrounding a primary container. The strut members are stackable for convenience in transporting the system and an alignment web is provided for defining the interior perimeter of the closed barrier or dike wall and to secure assembled members together.

Owner:POLYSTAR

Flood prevention device

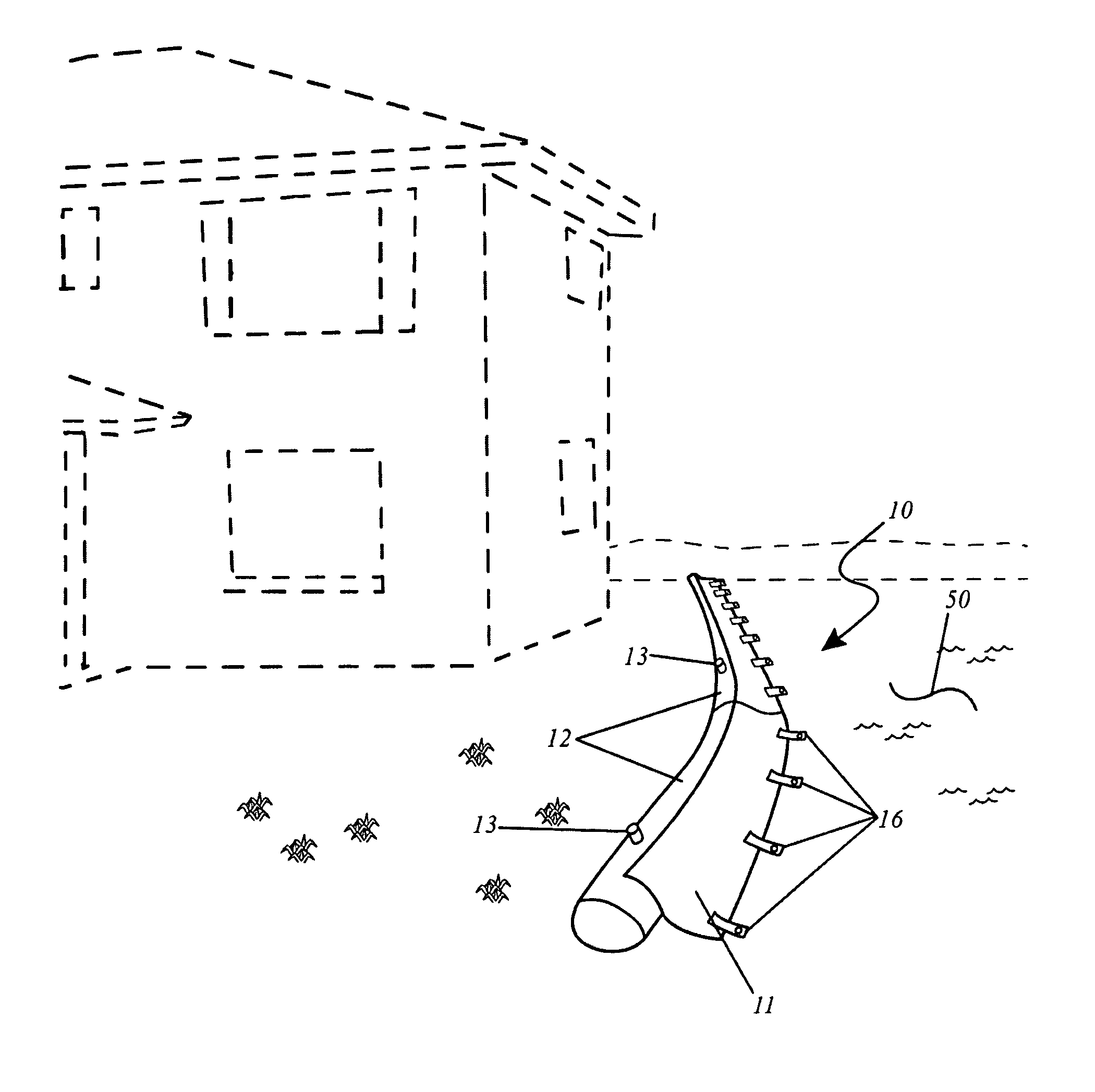

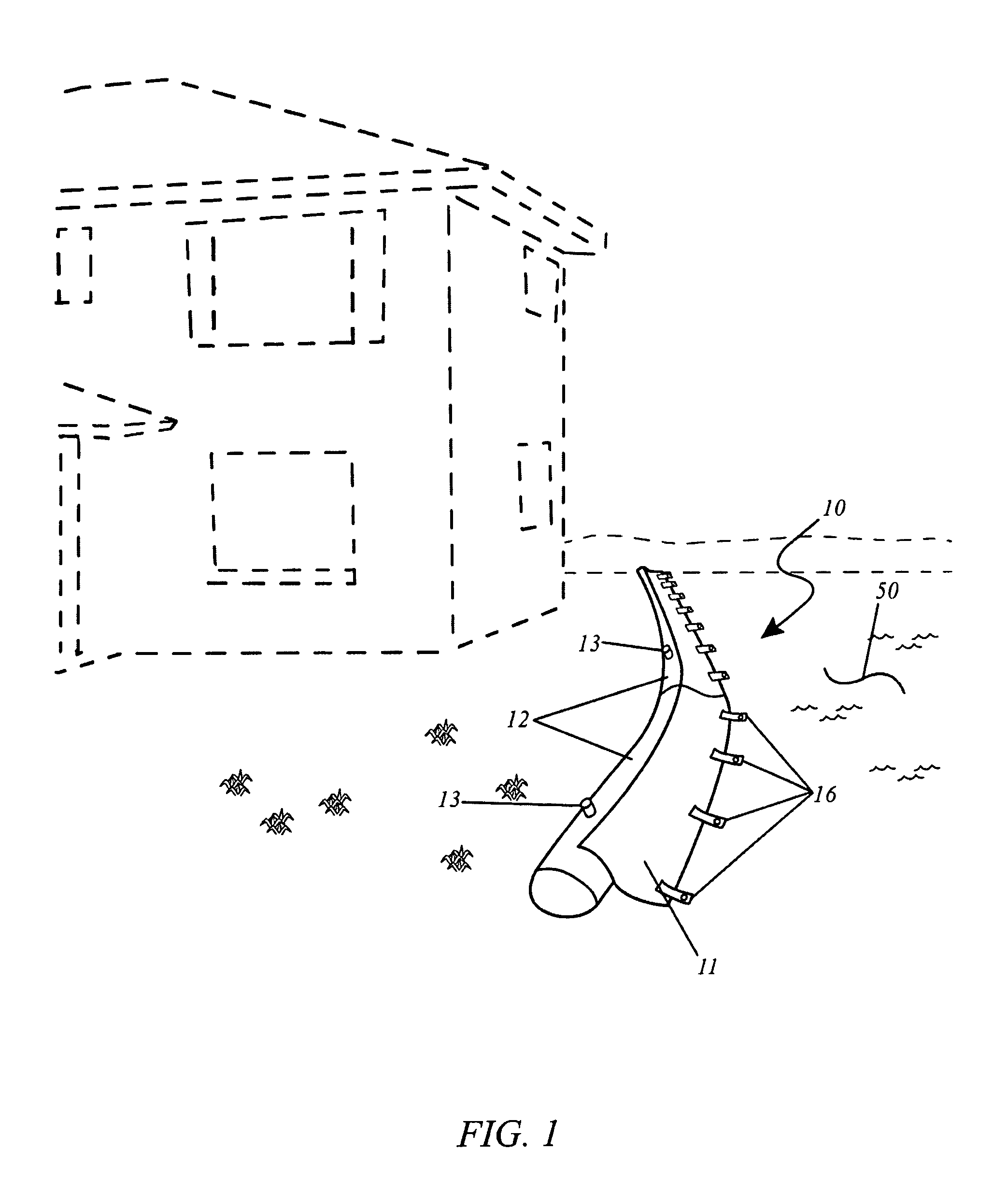

The flood prevention device includes a plurality of barrier walls interconnected around a structure or area to be protected. Each barrier wall includes a base sand tube adapted to be filled with sand. At least one gill tube may be stacked atop the sand tube and stitched together to form a wall of desired height. Each gill tube includes a plurality of reinforced gills adapted to permit water flow to fill the gill tube. A hanging tube is operatively disposed above each wall. A pulley mooring system may be disposed on the sides of the structure with one end operatively attached to interlocking poles disposed in the hanging tubes. Opposing sides of each barrier wall include interlocks that may be selectively attached to a locking corner track or a locking extender track to form the overall barrier. Once assembled, the flood prevention device may be lifted or rapidly deployed by the pulley mooring system.

Owner:STEWART TOMMY D +1

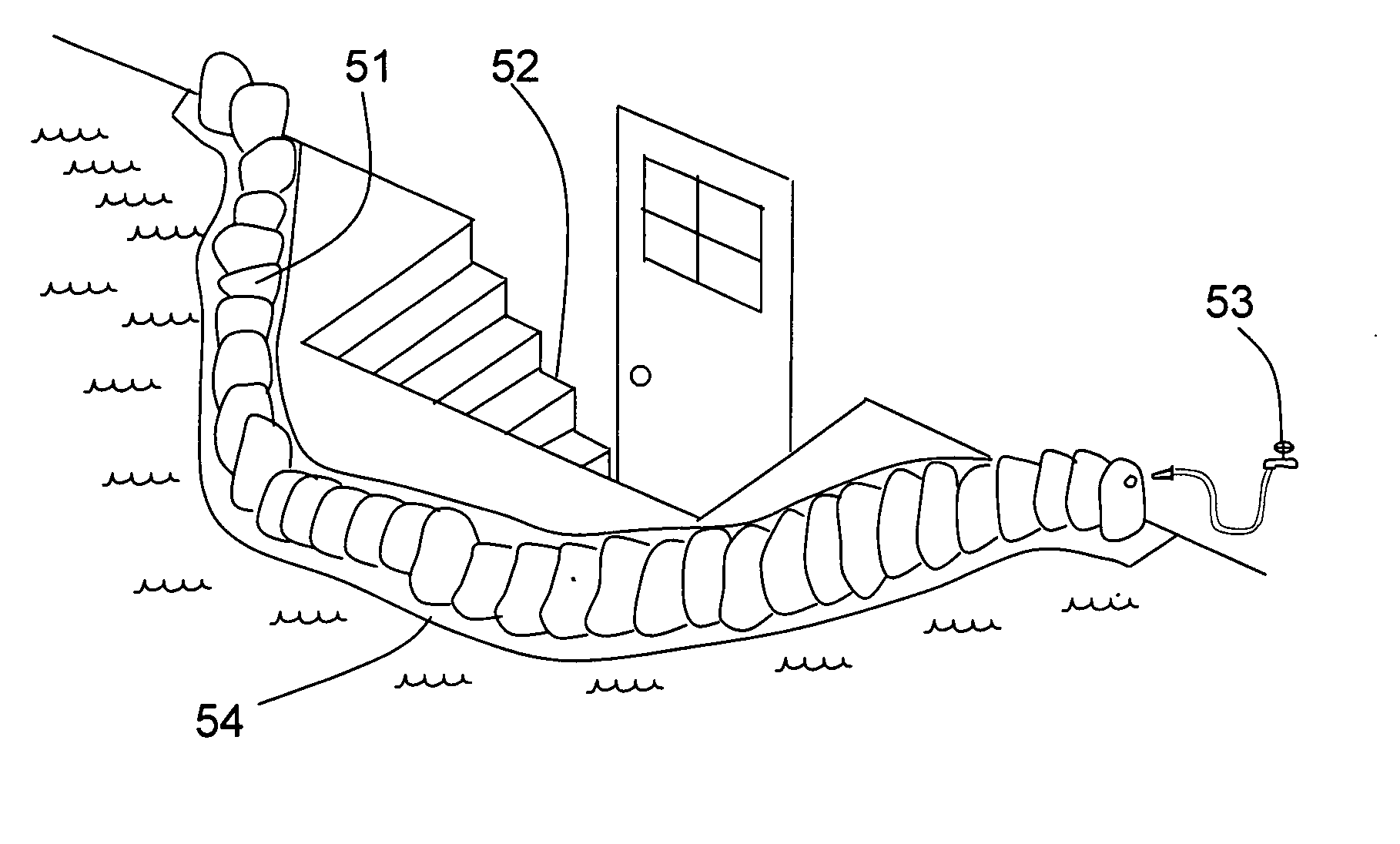

Residential flood control unit

The present invention comprises an apparatus that is designed to hold back flood waters via a series of interconnected long flexible tubular units. Each unit is connected to each other via a sleeve and has a weighted flap portion for additional anchoring. Each unit has its own fill tube and drain plug and is designed to retain water or other liquid to provide an impervious water barrier when in deployment.

Owner:SMITH CLARENCE E

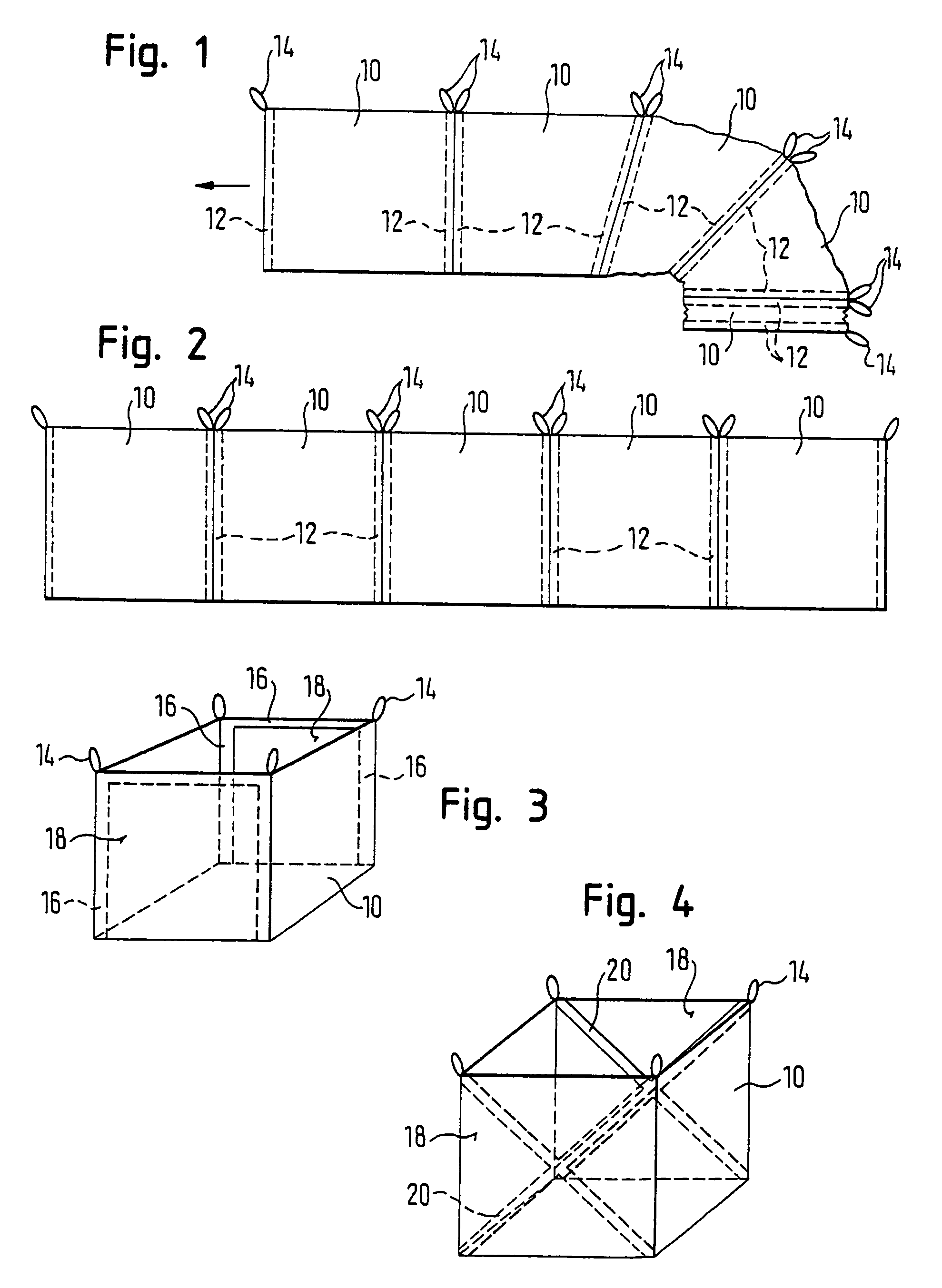

Sectional interlocking barrier bags

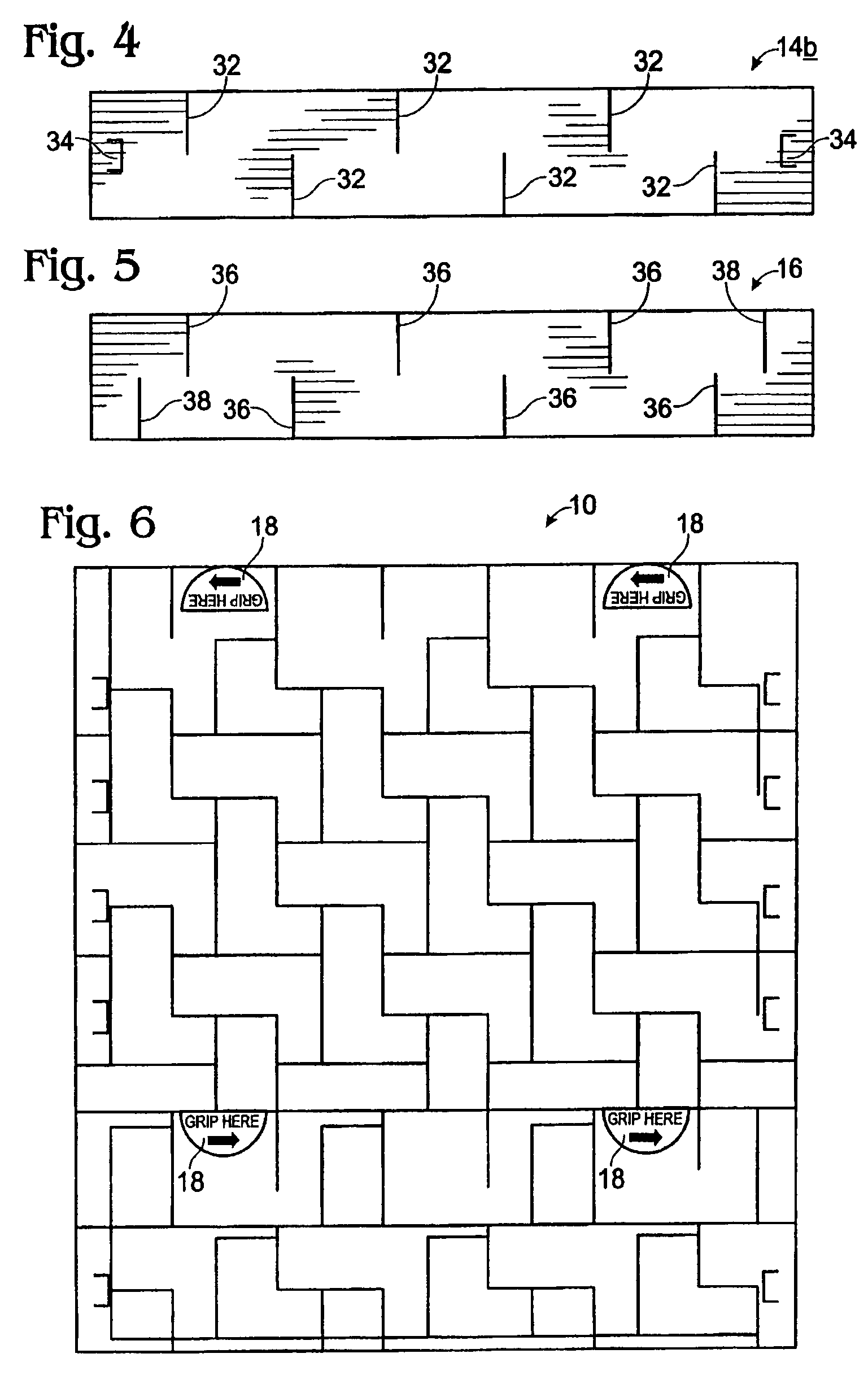

InactiveUS7329069B2Secure structureWider and stronger water-fight structureBarrages/weirsBagsEngineeringParticulate material

A bag made from a length of material (10) divided into a series of three or more substantially equal sized sections (12, 14, 16, 18, 20). Every other section is filled with sand (14, 18), or other particulate material and there is an unfilled section (12, 20) at each end.

Owner:SLATER +1

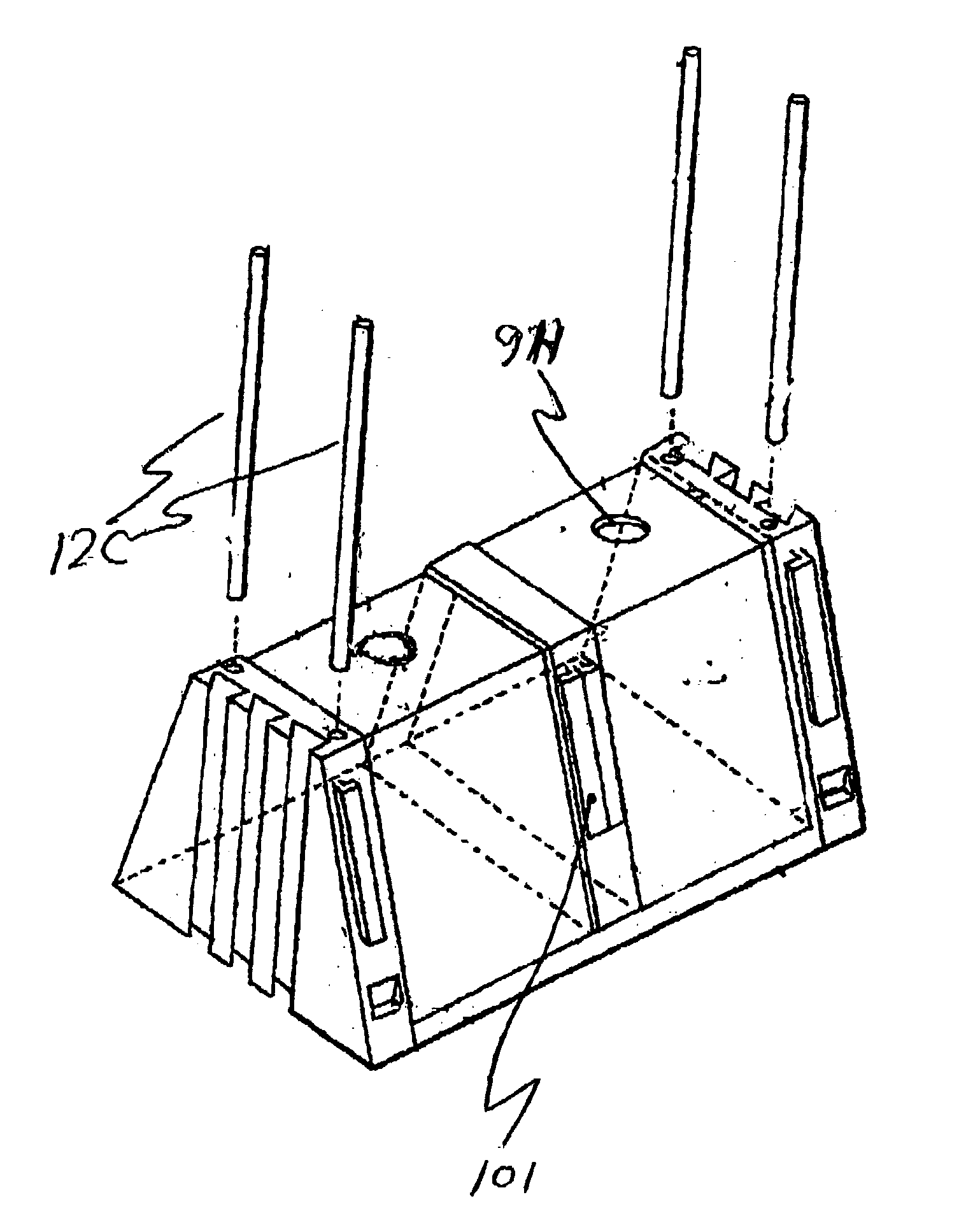

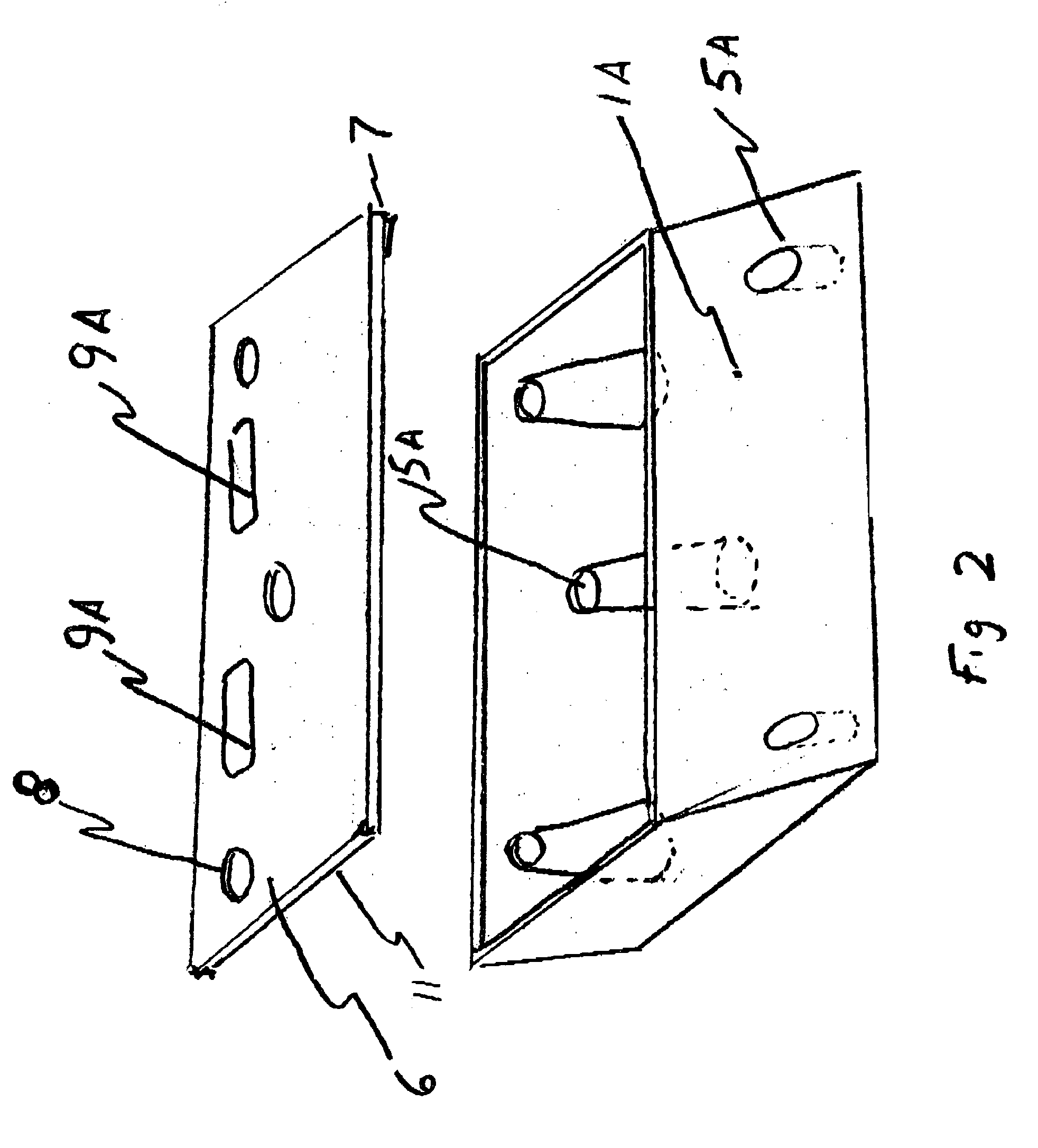

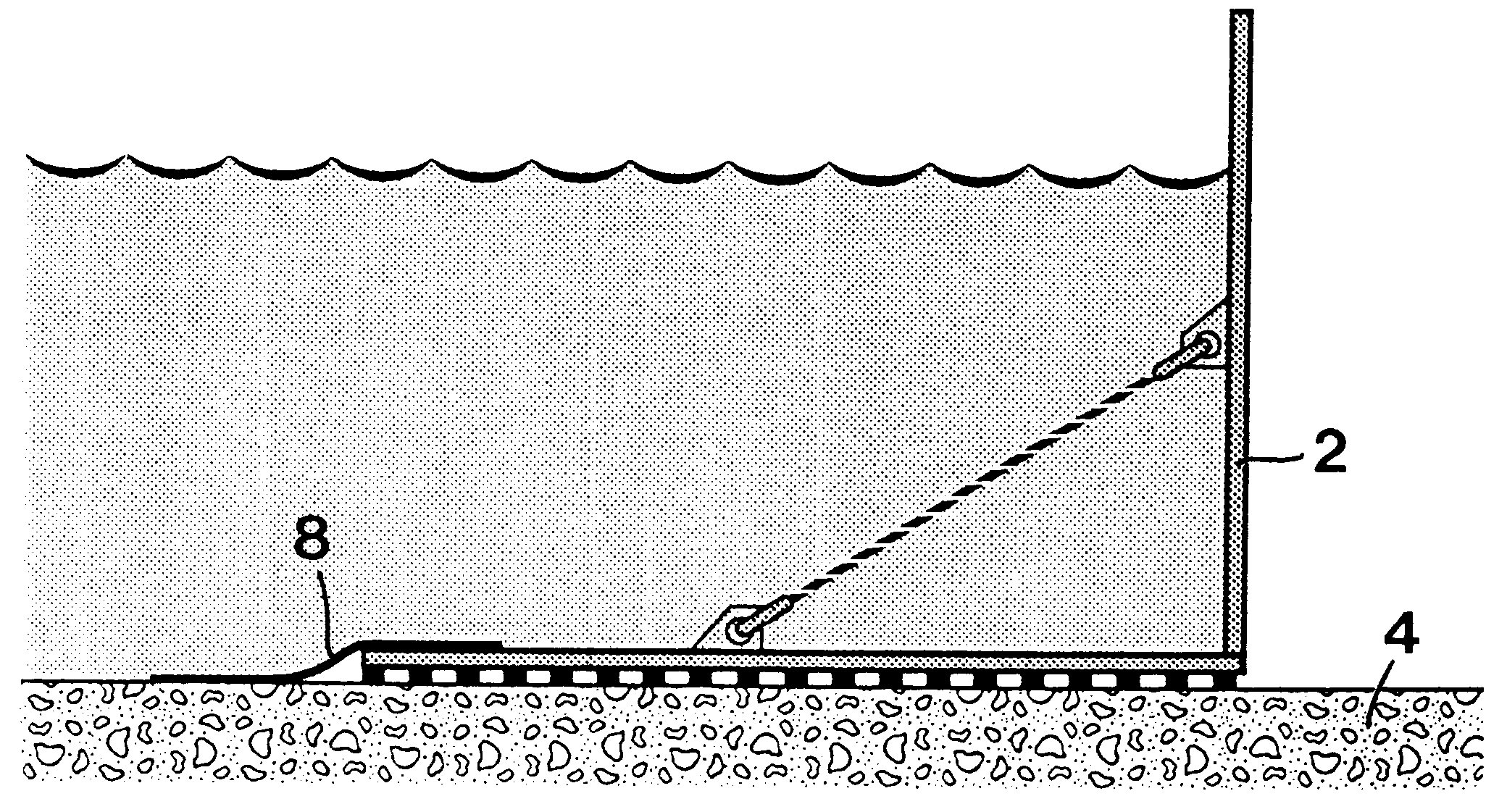

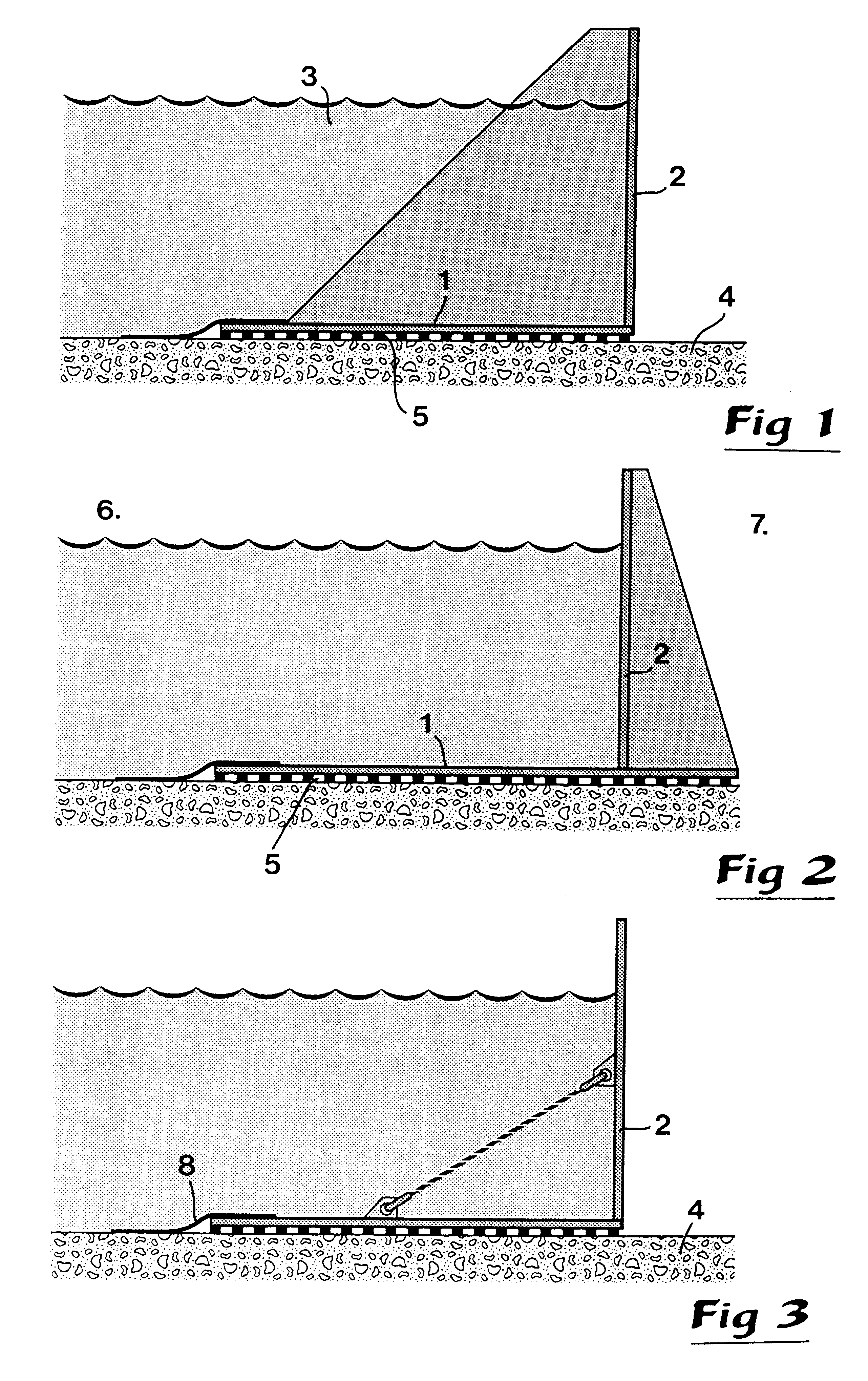

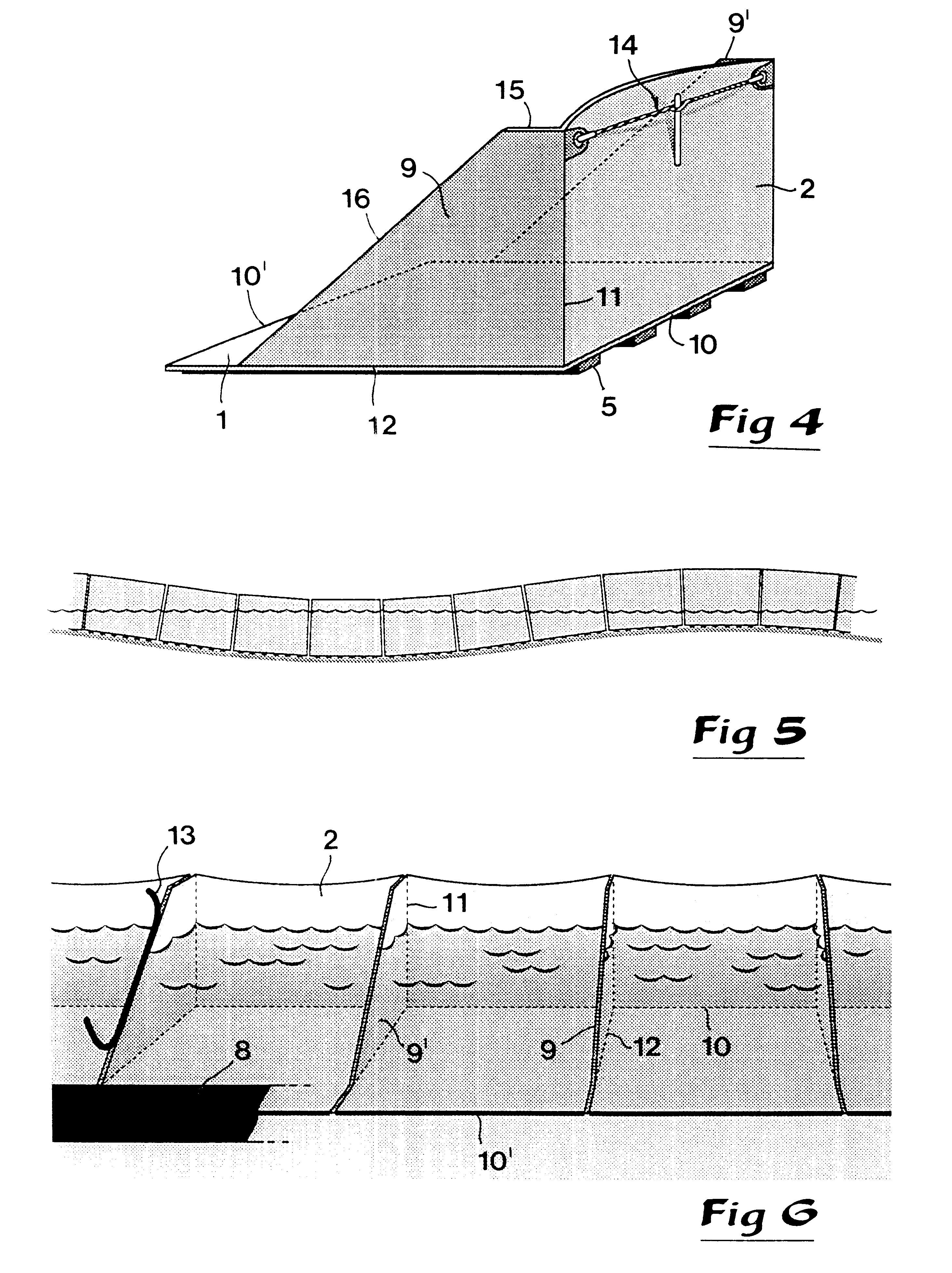

Damming device for erecting a liquid-damming protective bank

A damming device for forming a liquid-damming protective bank comprises at least one first board (1), in the active state laying, intended to be urged by the liquid against the surface and thereby anchoring the device, as well as at least a second board (2), in the active state up-right, intended to dam the liquid. There are liquid-draining means (5) on the bottom side of the anchoring board (1). Devices (9, 9') act between the two boards (1, 2) with the purpose of inhibiting tilting of the damming board (2) from the active position in the direction towards the dry the side, when liquid simultaneously affects the anchoring board (1) with a vertical force and the damming board (2) with a horizontal force.

Owner:MELIN SIGURD

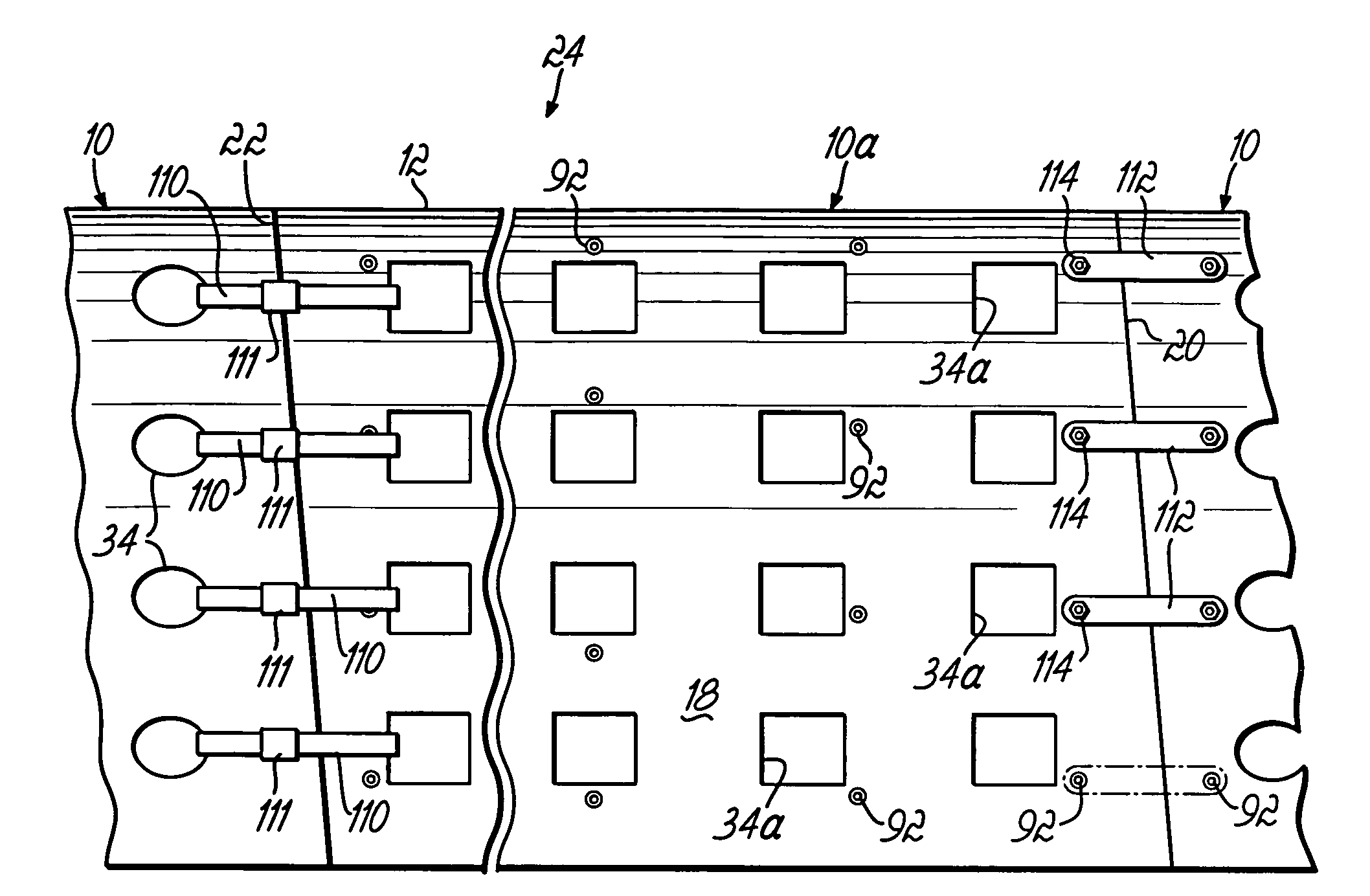

Deployable containment system

ActiveUS7614825B2Reduce weightPrecise positioningBarrages/weirsLarge containersModularityWaste management

Owner:POLYSTAR

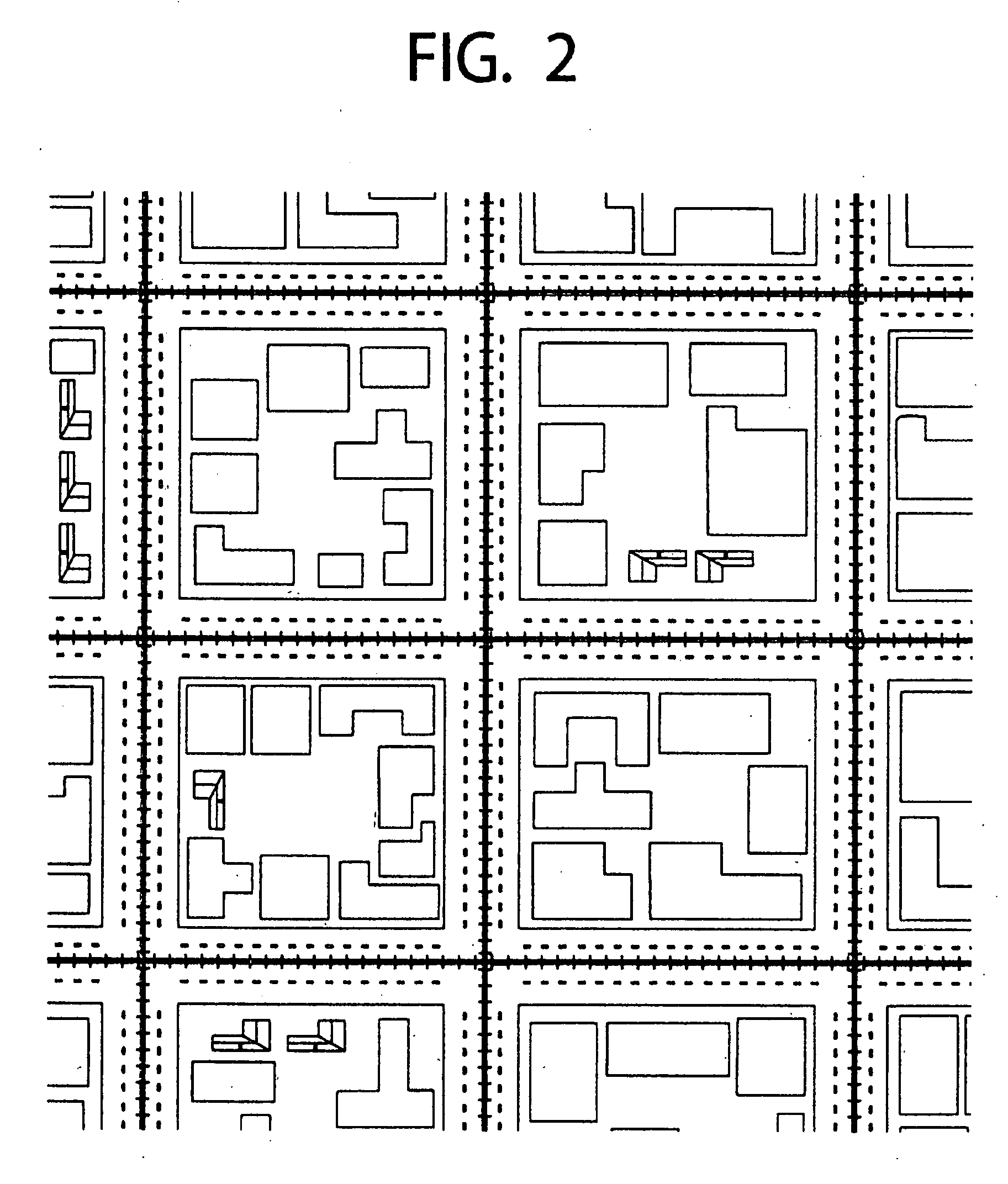

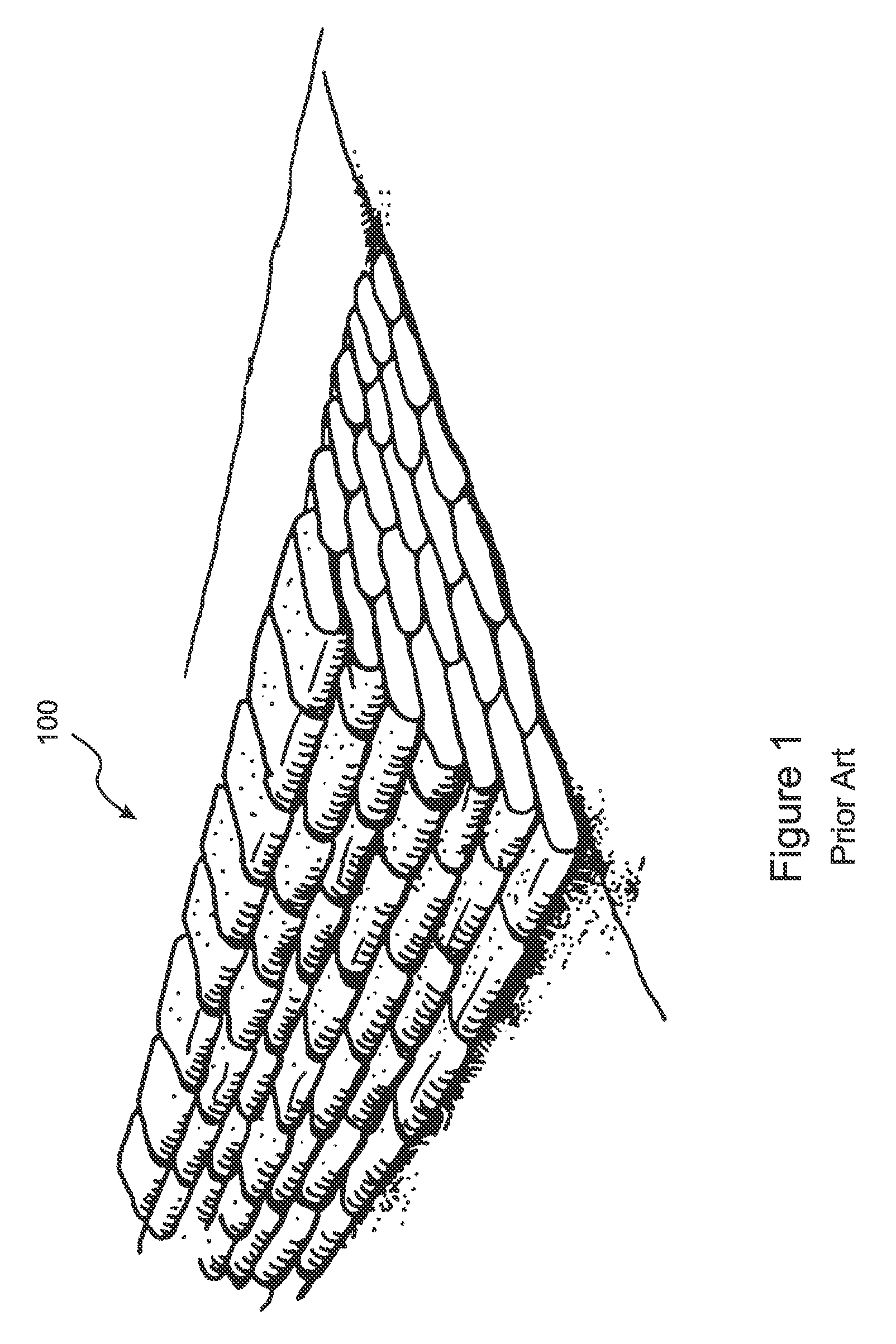

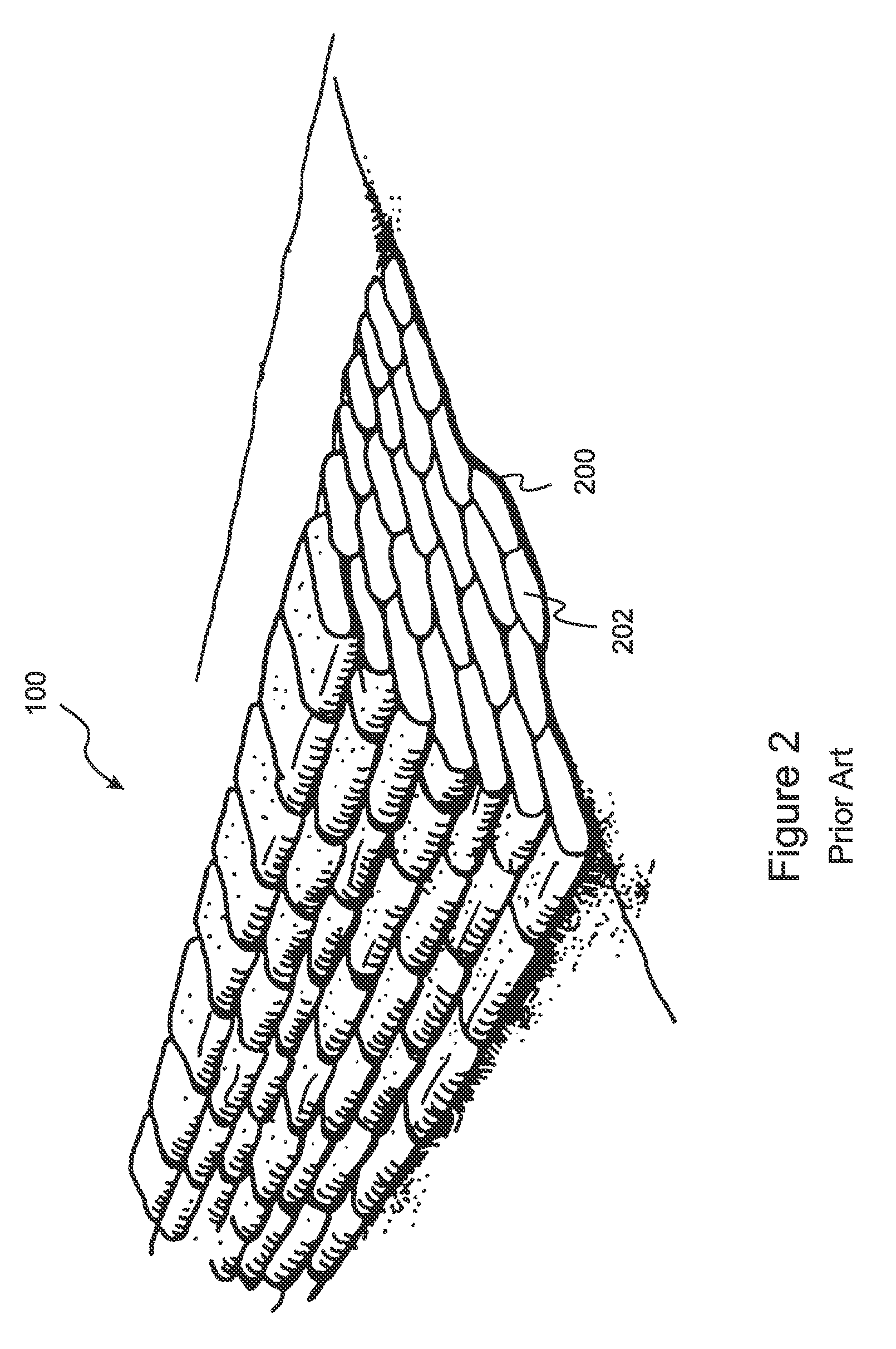

Fluent material confinement system

A fluent material confinement system configured to receive a granular fluent material to form a temporary barrier structure is disclosed, wherein the fluent material confinement system includes a plurality strips, the plurality of strips including a plurality of lengthwise strips and a plurality of widthwise strips coupled with each other to define a plurality of open cells, wherein the plurality of lengthwise strips includes at least one wider lengthwise strip configured to extend into cells of a next-lowest fluent material confinement system when the fluent material confinement system is stacked on the next-lowest fluent material confinement system, and a stacking error indicator associated with the wider lengthwise strip, wherein the stacking error indicator is configured to be effective in low visibility conditions to indicate to a user a location of an error in stacking of the fluent material confinement system on the next-lowest fluent material confinement system.

Owner:GEOCELL SYST

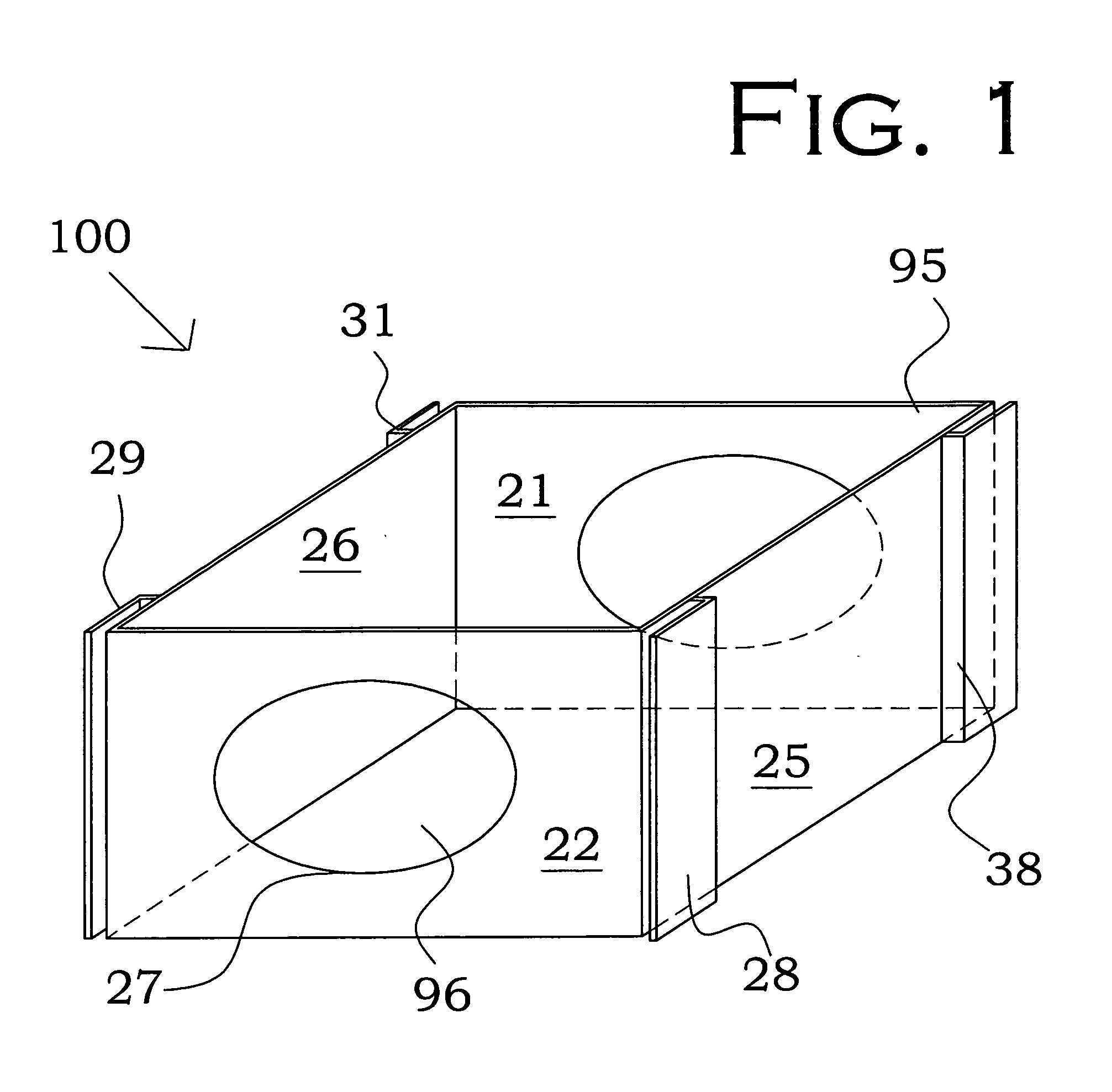

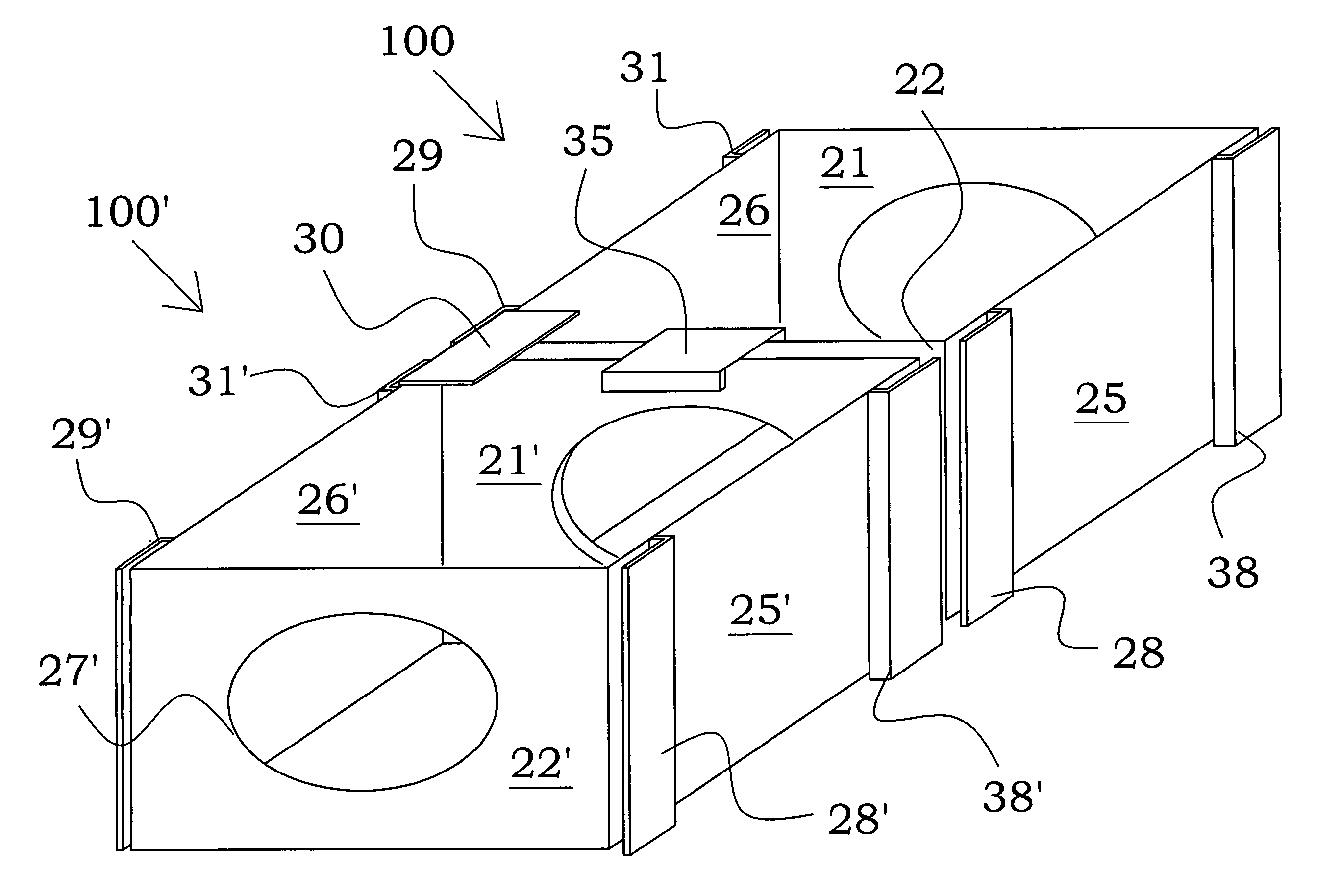

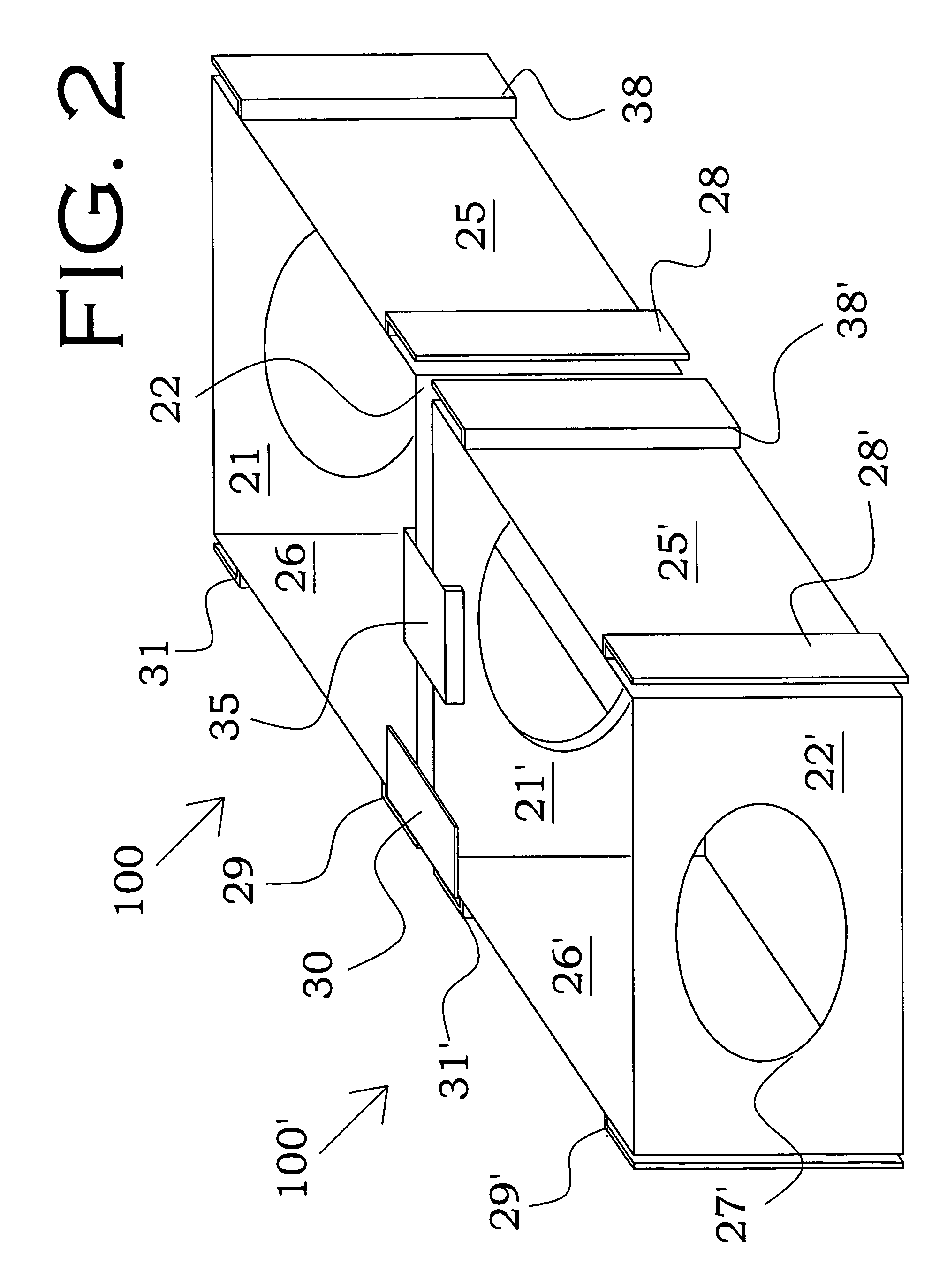

Flood levee and barrier module and system

A levee and barrier module for fluid control and containment is provided including an outer module shell and a module-to-module connection system to attach adjacent outer shells. The outer module shell, being in the general shape of a prism or prism with curvilinear section, is formed by opposing side walls and two opposing end walls, and is configured to enclose or support filler material. The two opposing end walls are configured with end apertures. The outer module shell defines a top aperture and a bottom aperture. When modules are placed end to end in a levee structure the end apertures allow filler material communication horizontally between adjacent modules. The bottom aperture allows filler material communication with the earth below the module. The top aperture allows filler material to be added to the module, as well as visual observation of, and maintenance of, the amount of contained filler material.

Owner:BOUDREAUX JR JAMES C

Berms for protective liners

Owner:NEW PIG CORP

Roadway-levee

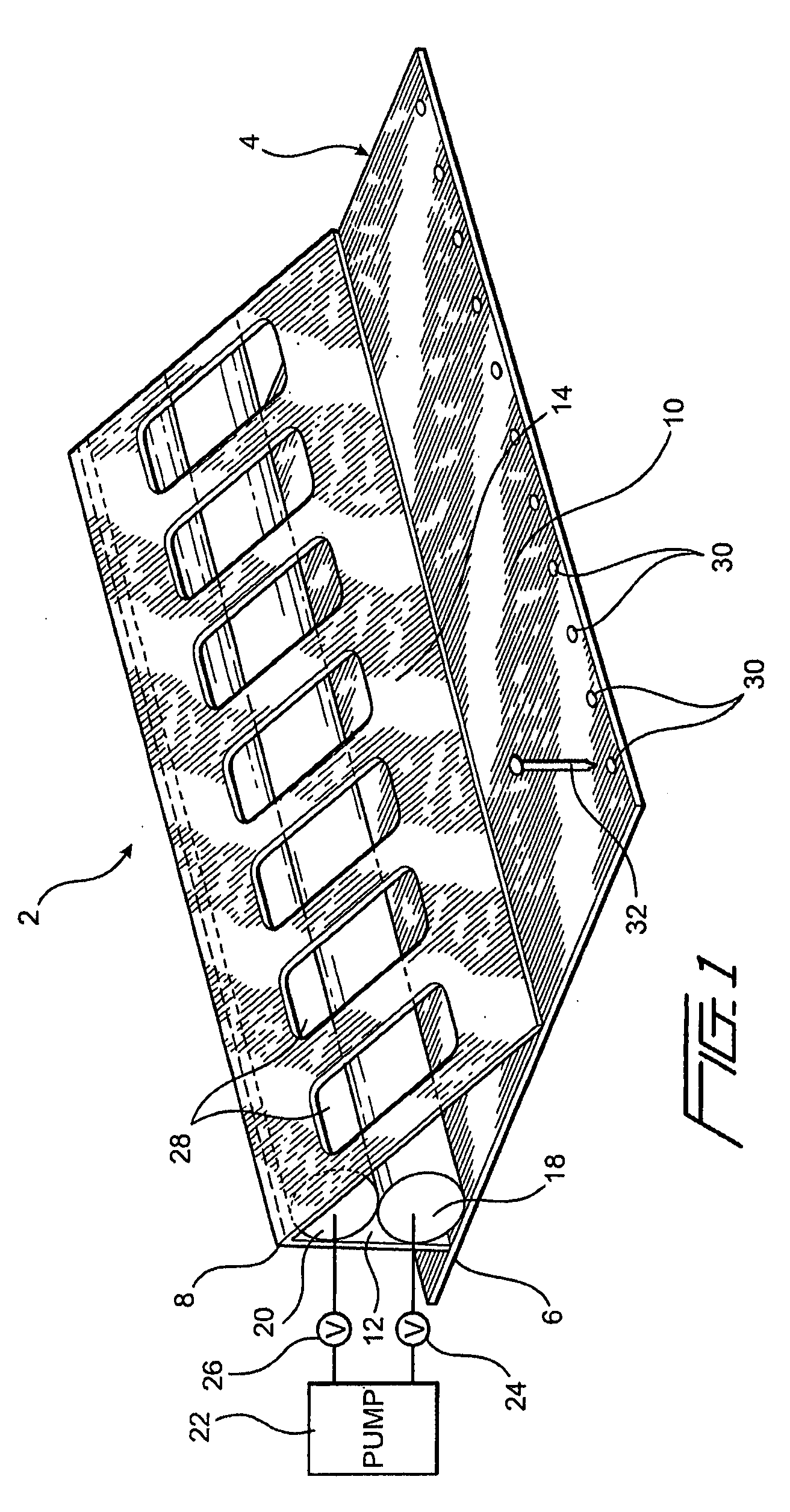

A water or flood control and containment system is provided having foundations, sealed bases, supporting structure, and pumping system that gives the user control over water containment and movement either to reduce the water hazard or to store water. The bases are secured and sealed to paved surfaces with foundations that have been preset into the street or other prepared foundation. When deployed on multiple adjacent streets, roadway levee creates a compartmented barrier containment system that mitigates flooding and storm surges. The invention is to be removed and stored off site when not in use.

Owner:BONDS RONALD SCOTT

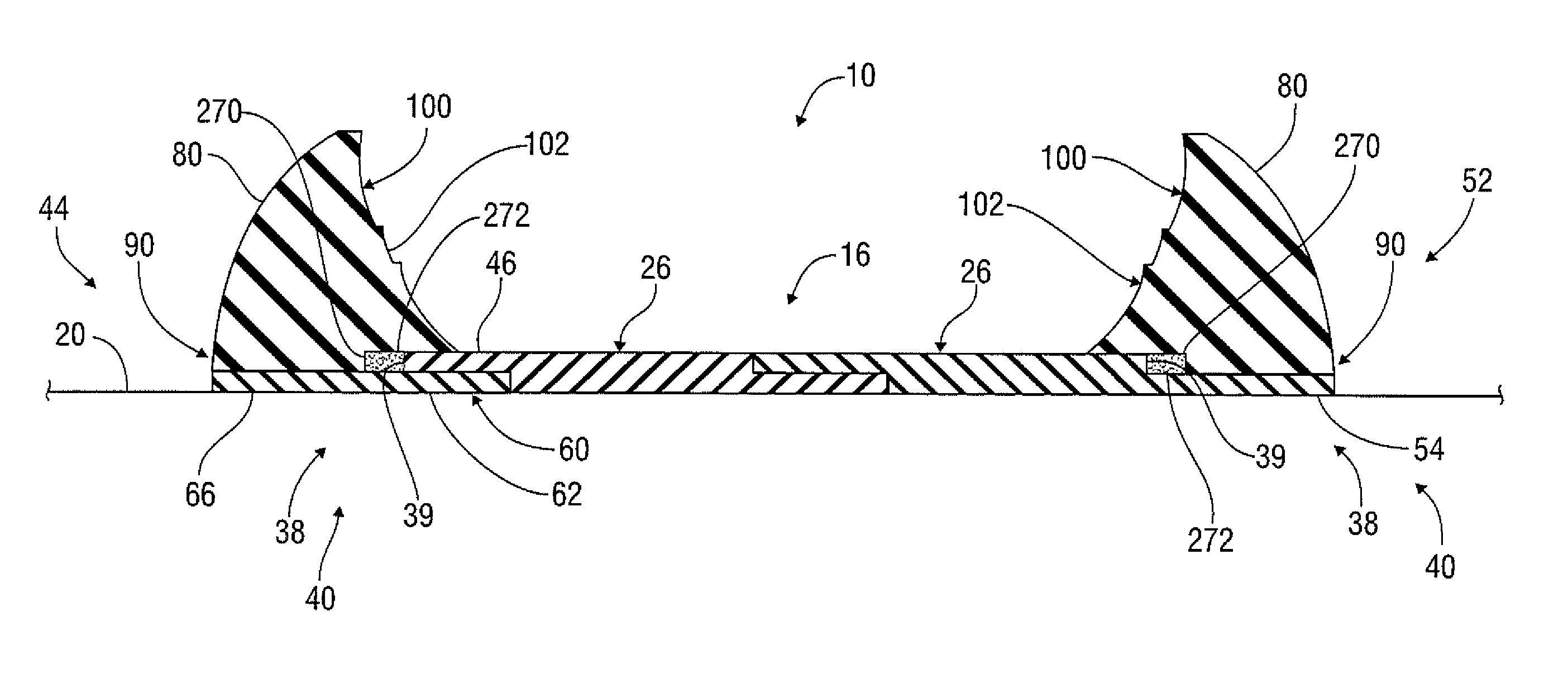

Flood Wall

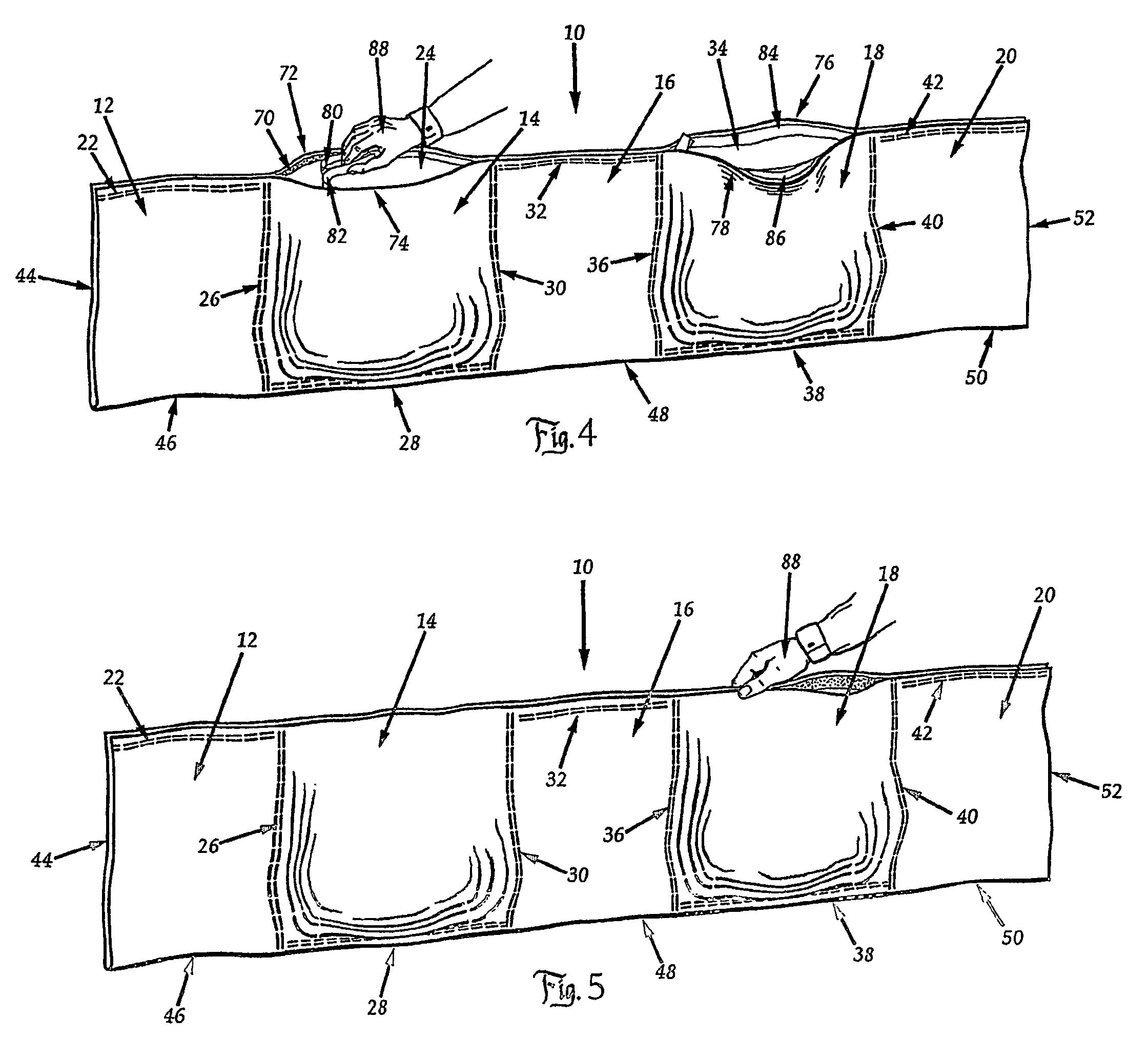

A portable, inflatable flood wall is characterized by a sheet of synthetic plastic material which is folded back on itself to define a chamber between bottom, rear and front portions of the sheet and within which at least one inflatable bladder is secured. When the bladder is inflated, the rear portion of the sheet is erected to a vertical position which prevents water from passing beyond the sheet. The front portion preferably contains a plurality of openings to allow water to enter the chamber. The weight of the water on the bottom portion of the sheet serves to hold the wall in place. A plurality of such walls may be connected in end-to-end relation to construct a wall of a desired length.

Owner:SALEMIE BERNARD

Flood wall

A portable, inflatable flood wall is characterized by a sheet of synthetic plastic material which is folded back on itself to define a chamber between bottom, rear and front portions of the sheet and within which at least one inflatable bladder is secured. When the bladder is inflated, the rear portion of the sheet is erected to a vertical position which prevents water from passing beyond the sheet. The front portion preferably contains a plurality of openings to allow water to enter the chamber. The weight of the water on the bottom portion of the sheet serves to hold the wall in place. A plurality of such walls may be connected in end-to-end relation to construct a wall of a desired length.

Owner:SALEMIE BERNARD

Liquid containment system for use with load-supporting surfaces

Owner:NEWPARK MATS & INTEGRATED SERVICES

Hazardous spill ground containment system

ActiveUS8636445B1Prevent movementSecurely holdBarrages/weirsWater cleaningMetal frameworkEngineering

A hazardous spill ground containment system having a plurality portable metal frame sections. The frame sections are used to create an angular shaped containment frame received over various types of ground surfaces. The frame sections can be made to different lengths and heights and are used for holding in place a heavy duty liner on top of the ground surface. The liner is adapted for receiving various types of equipment, tanks and containers holding toxic chemicals and the like hazardous materials. The metal frame sections include an elongated, metal, A-shaped lower frame member and an elongated, metal, Z-shaped upper frame member for receiving and holding a side of the liner securely in place.

Owner:WILLIAMS FLOYD E

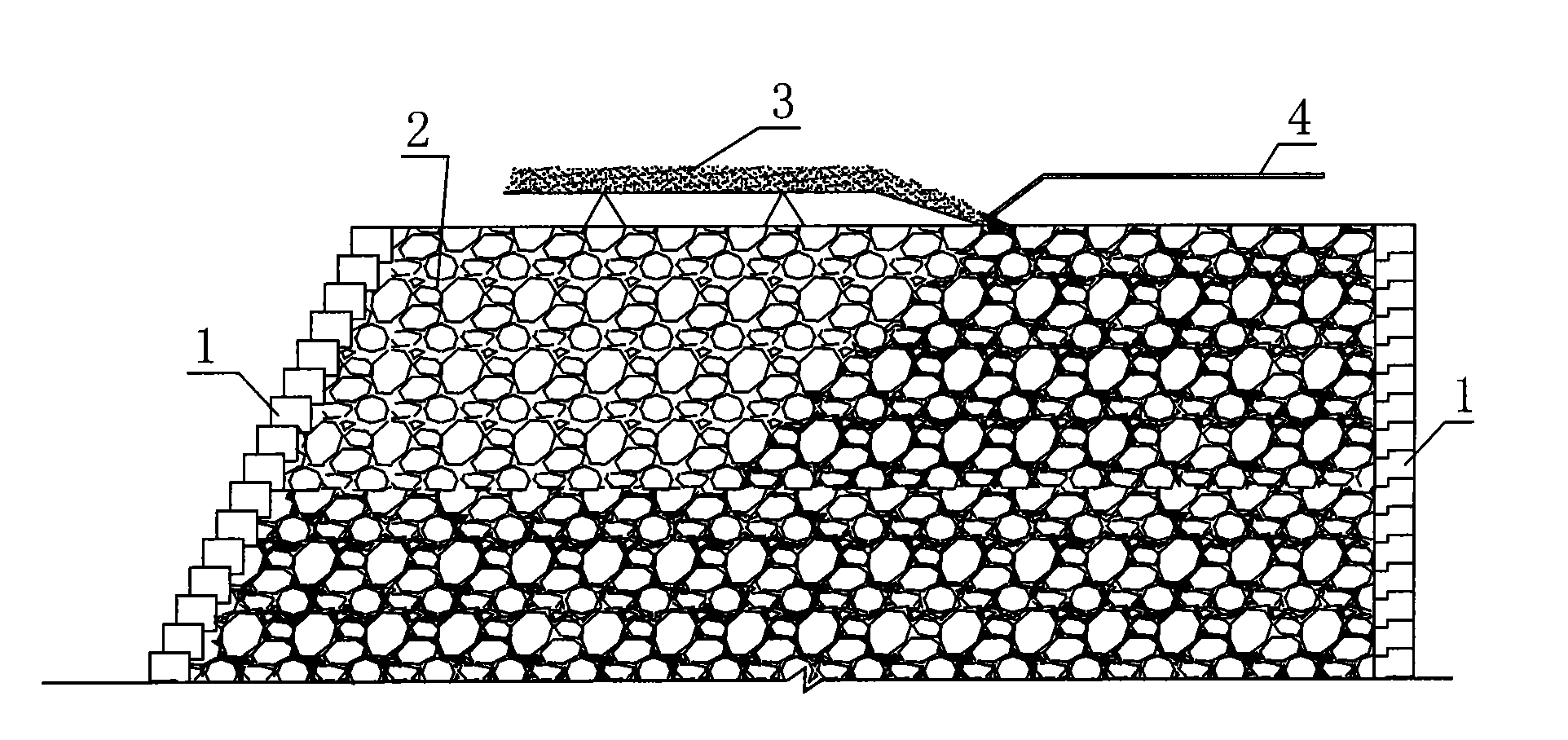

Construction method for filling mortar combined stone dam

ActiveCN101581088AIncrease self-impermeabilityTake advantage ofFoundation engineeringWall damsDiameter controlFly ash

The invention discloses a construction method for filling a mortar combined stone dam, which combines a mortar grouting and filling method and a rock-fill dam filling construction process, and solves the problems that a stone masonry structure is inconvenient to use mechanical construction and has low working efficiency, and a rock-fill dam has higher requirement on grain diameters of filling stones, lower material source utilization rate, high manufacturing cost and the like. The construction method comprises the following steps: filling stones in a dam shell till reaching the thickness requirement of a filling layer, flattening the stones, and then carrying out mortar sand removal operation on the top surface of the filling layer, namely directly filling previously prepared cement mortar or cement mixed mortar doped with admixture fly ash into the screened sand quantitatively supplied by a mortar conveying device in gaps of the filled stones through the mortar conveying device to form the mortar combined stone dam similar to the mortar masonry stone dam. The process flow is simple, the application range is wide, the maximum block diameter control and grade matching requirements are not needed, the stone source is abundant, the thickness of the filling layer is large, the roller compaction is not needed, the construction speed is high, the working efficiency is high, the construction cost is reduced, and the formed dam mortar masonry is compact and has good quality.

Owner:沈阳乾玉水利有限公司

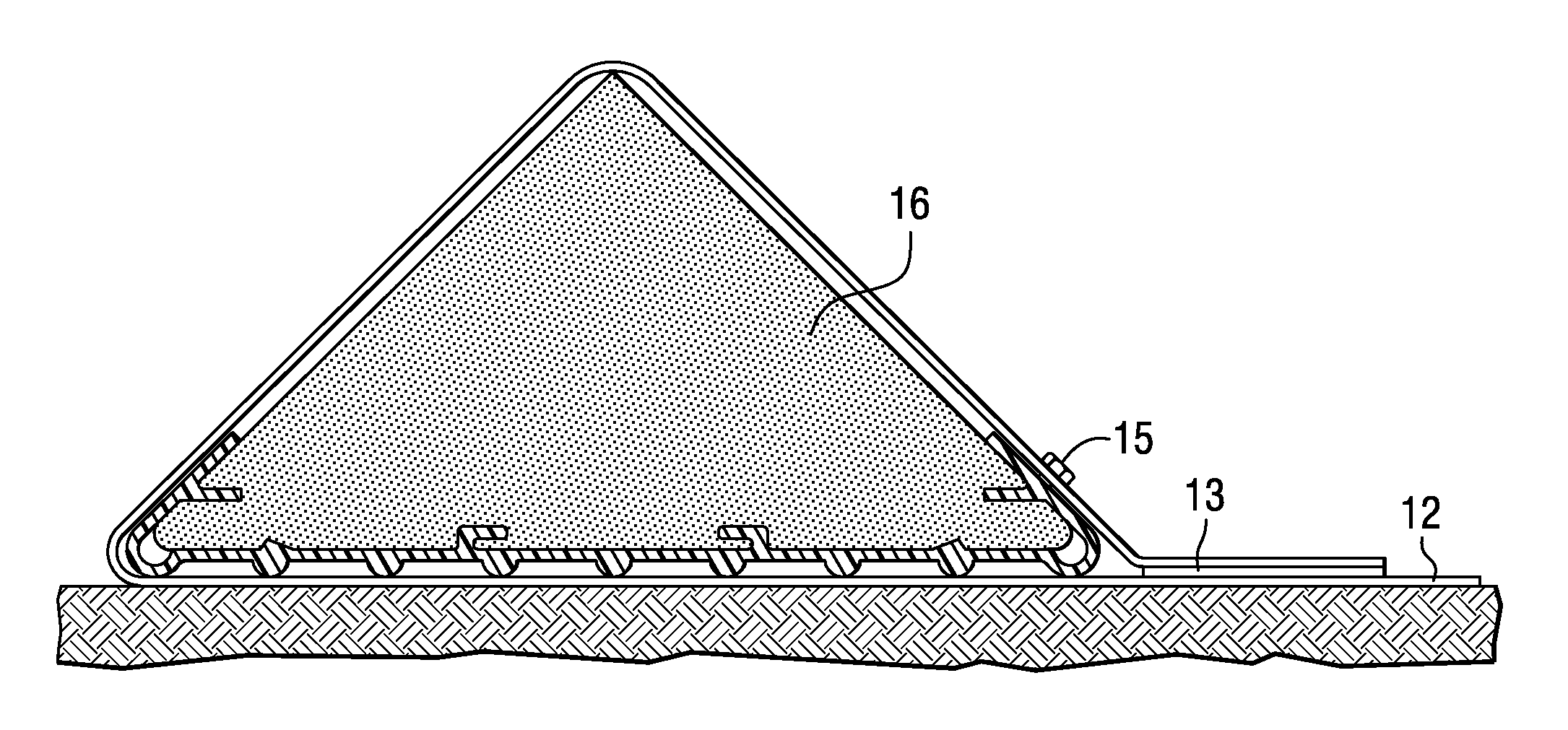

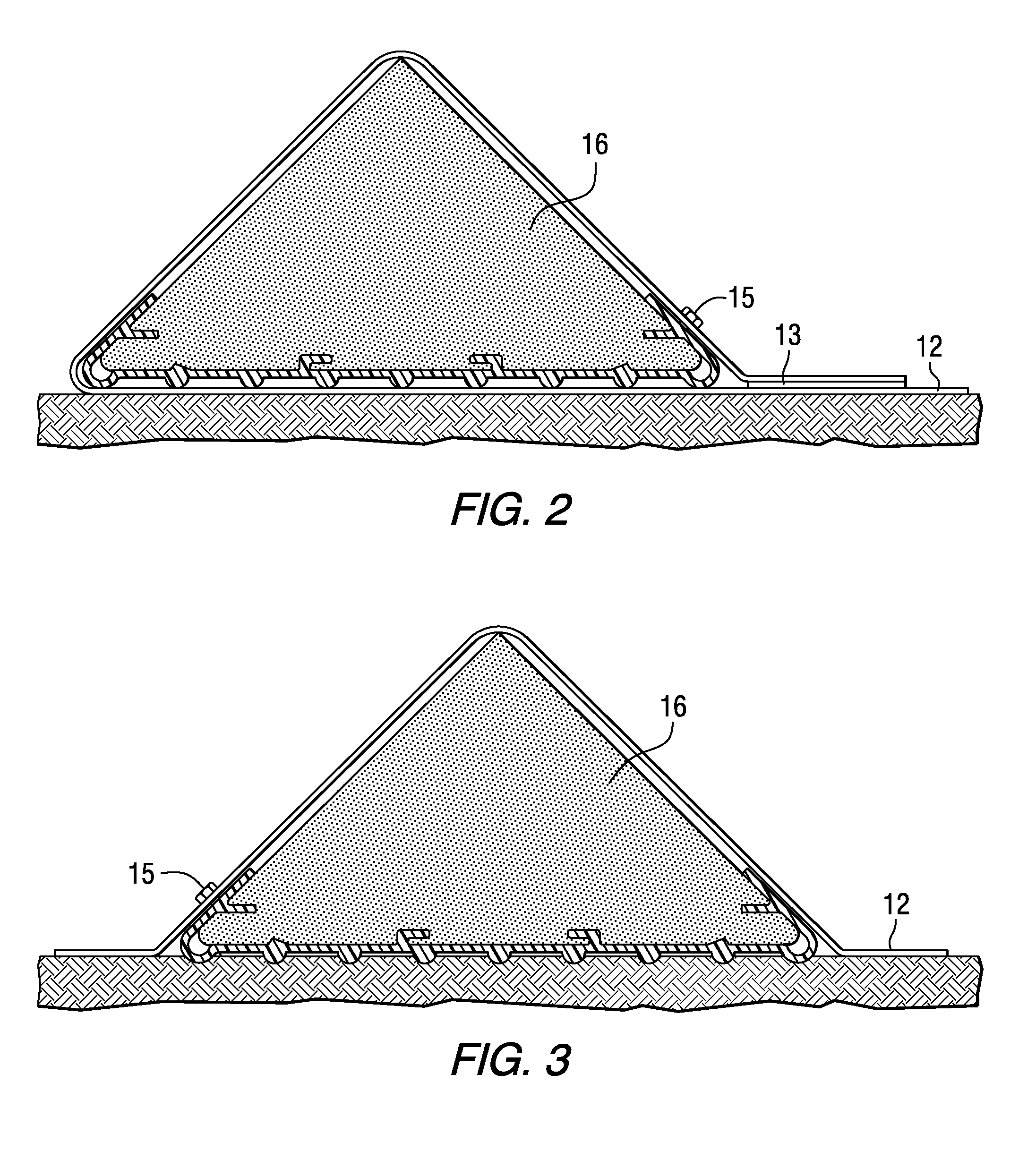

Portable water-inflatable barrier

ActiveUS8956077B2Simple and inexpensive to removeResist punctureBarrages/weirsButtress damsNanofiberWater barrier

A portable, water-filled barrier emulates a sandbag dike or wall without requiring sand or intensive labor to install. The barrier is made of a light, flexible material that can include nanofiber. Some embodiments are formed from a plurality of interlocked water-filled cells, with a forward-facing water barrier sheet. Other embodiments are unitary shells that are internally divided into cells, with internal openings that permit water to flow between cells. Automatic valves can seal the filled cells, so that a punctured cell will not cause cells below and behind to deflate. A row or rows of cells can project below the base into a stabilizing trench. Cells can include internal or external rods or plates that support the horizontal structure. Embodiments can be initially filled with air, positioned, and then filled with water while the air escapes through a pressure valve. Barrier end structures can enable interlocking of adjacent units.

Owner:ABELES GARY E

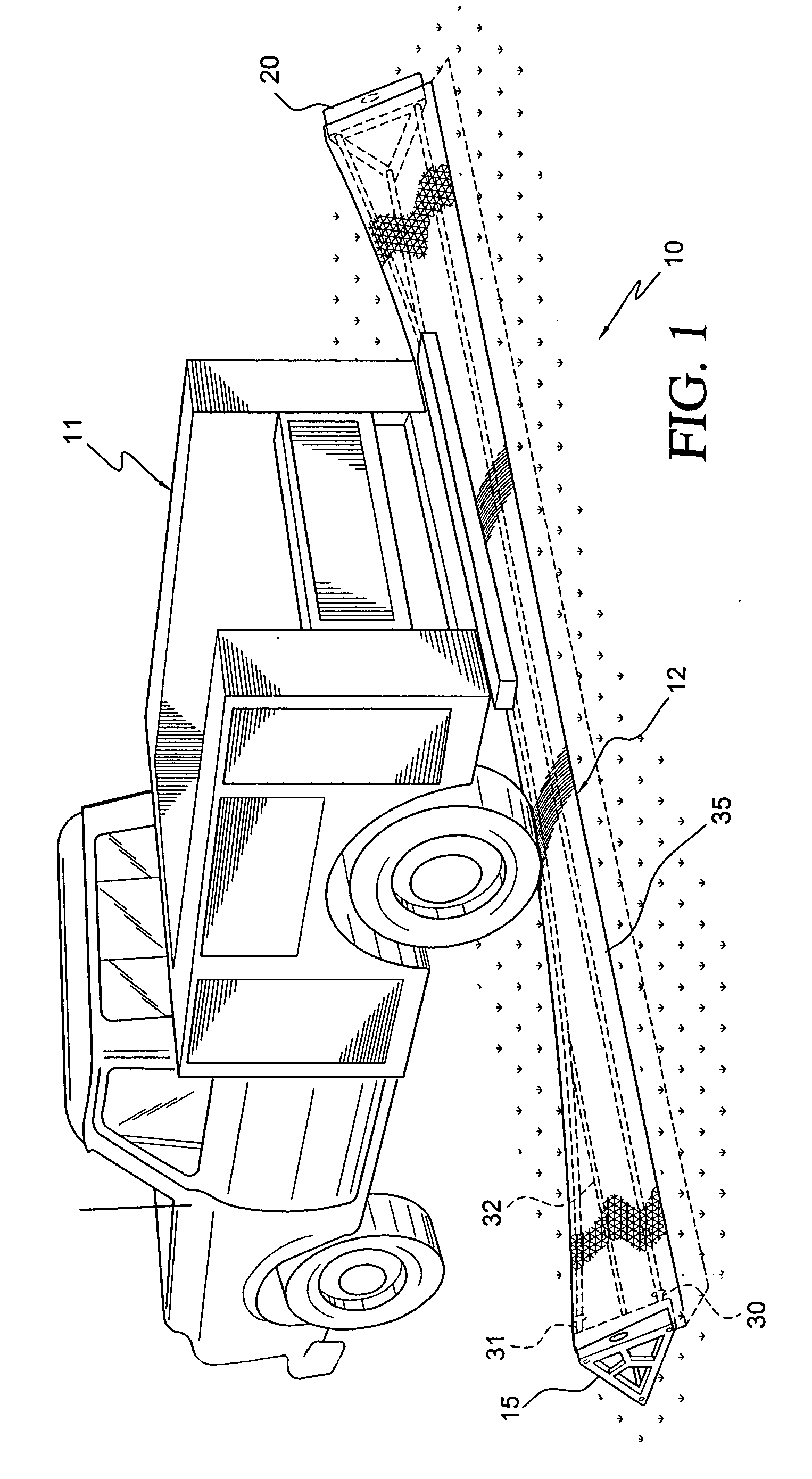

Silt fencing system

InactiveUS20090022552A1Easy to transportEasy to bendBarrages/weirsProtective constructionEngineeringTruck

A transportable and reusable silt fencing system for use at a construction site to prevent sediment and soil erosion comprises tension rods, a male section, a female section, and a fencing material having sleeve supports for the rods to slide in and support the fencing material. The tension rods are collapsible. The rods collapse when a truck drives over the fence, but re-assume their original form once the truck has passed. If a fence longer than the fencing section is required, additional fencing sections may be attached by connecting a male section of one fence section with the female section of another fence section.

Owner:BERENYI GARY

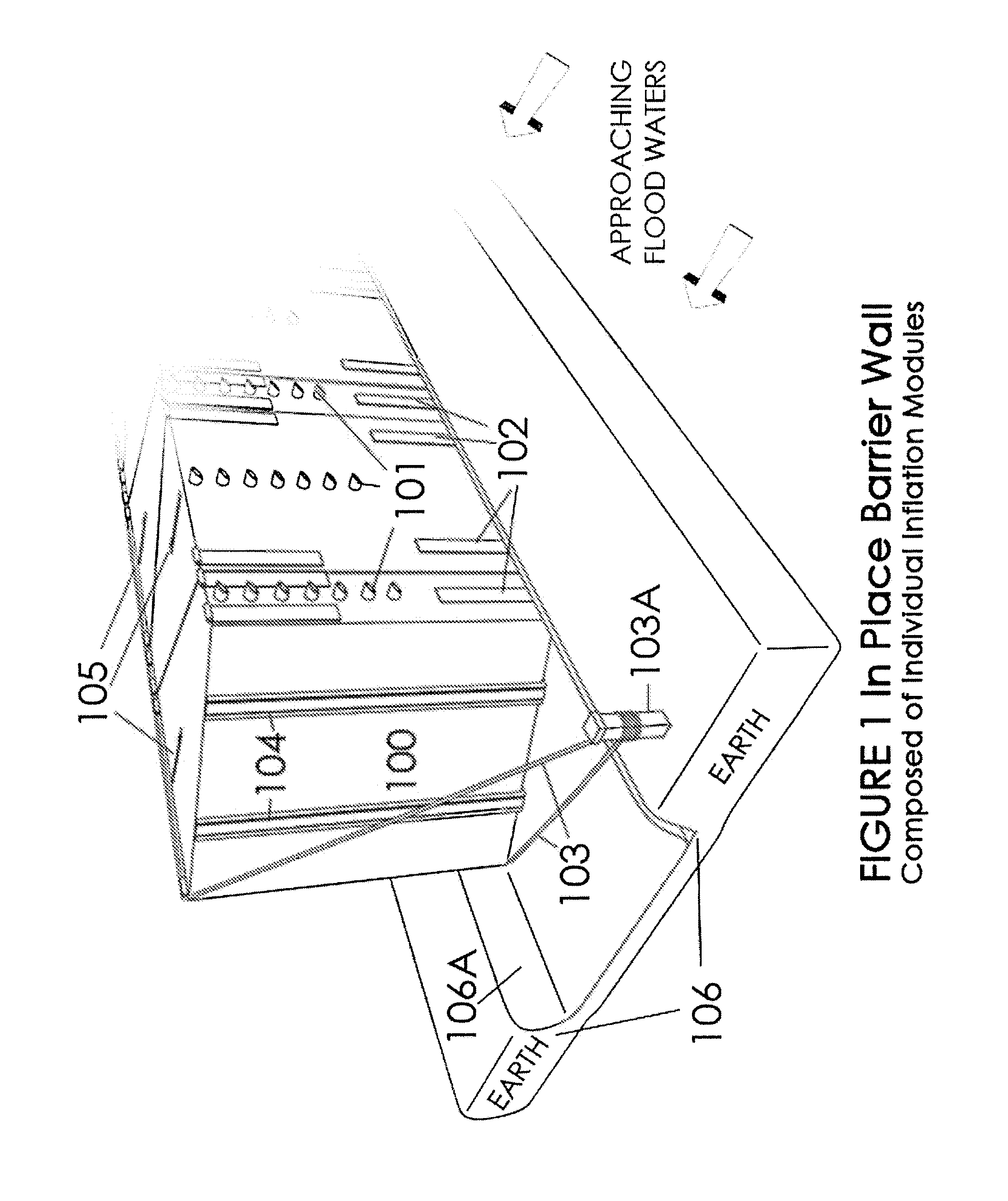

Rapid Deployment, Self-Inflating, Interlocking, Modular Flood-Water Barrier Wall System

InactiveUS20120207545A1Restrict water seepageEnhance and assure sealingBarrages/weirsAutomatic exchangesEngineeringFlood water

The water barrier is comprised of a number of interconnected modules, that contain expansive material (such as polymer powder). Each module has inlets that allow rising water to enter the interior volume of the module so that it inflates from a flattened configuration to a four sided shape. The shape is wedge shaped and the modules are alternated so that the narrow end of the module is toward the rising water on one module and the wide end is next to the rising water on the adjacent module, so that pressure from the rising water is transferred to adjacent modules from module to module and ultimately to an anchoring system.

Owner:CASSIDY CLARENCE A

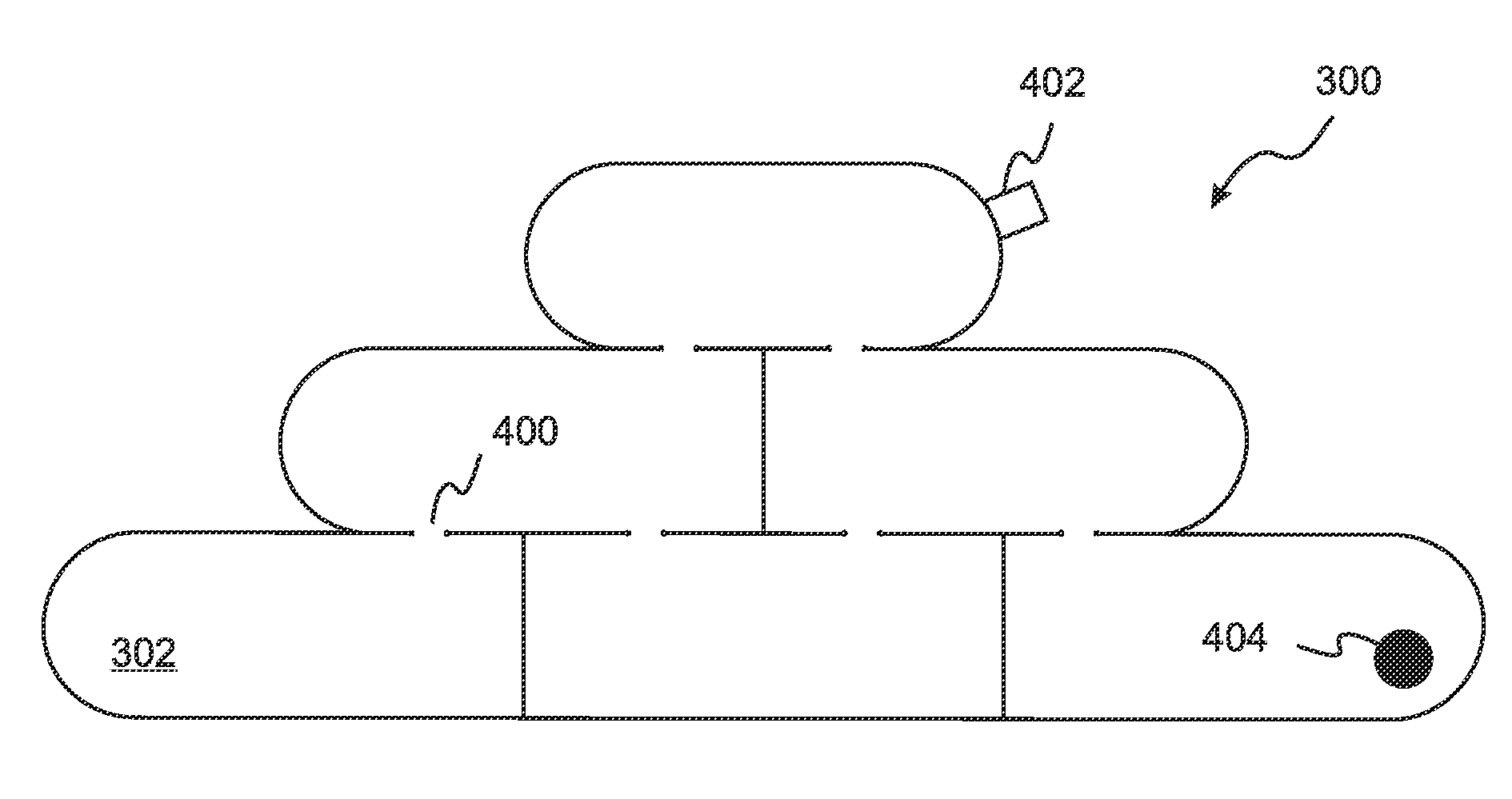

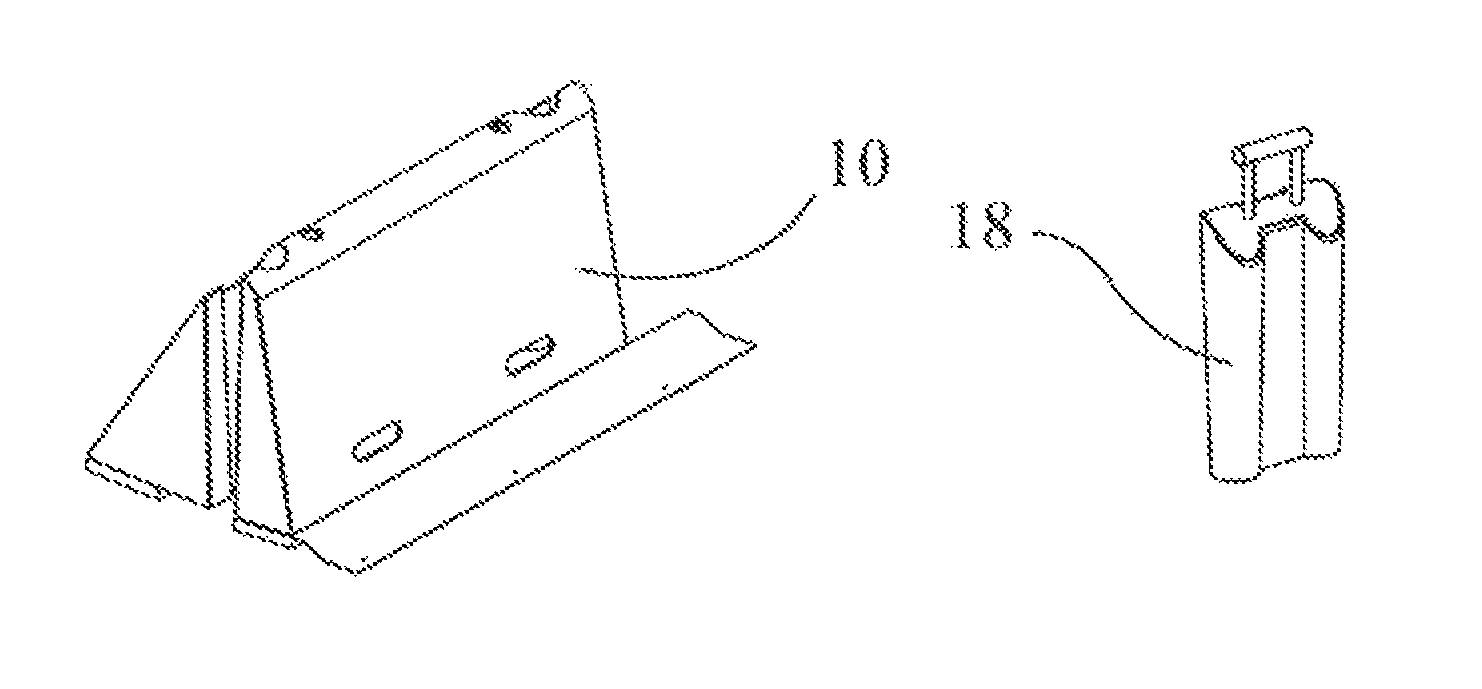

Self-filling modular barrier

A flood barrier comprises hollow self-filling units (10, 12, 14, 16) placed end-to-end and connected at their ends by downwardly tapered bilobal (46) keys inserted into sockets (26, 28) at the ends of the units, wherein the keys incorporate concrete or other ballast for negative buoyancy.

Owner:BU INNOVATIONS LTD

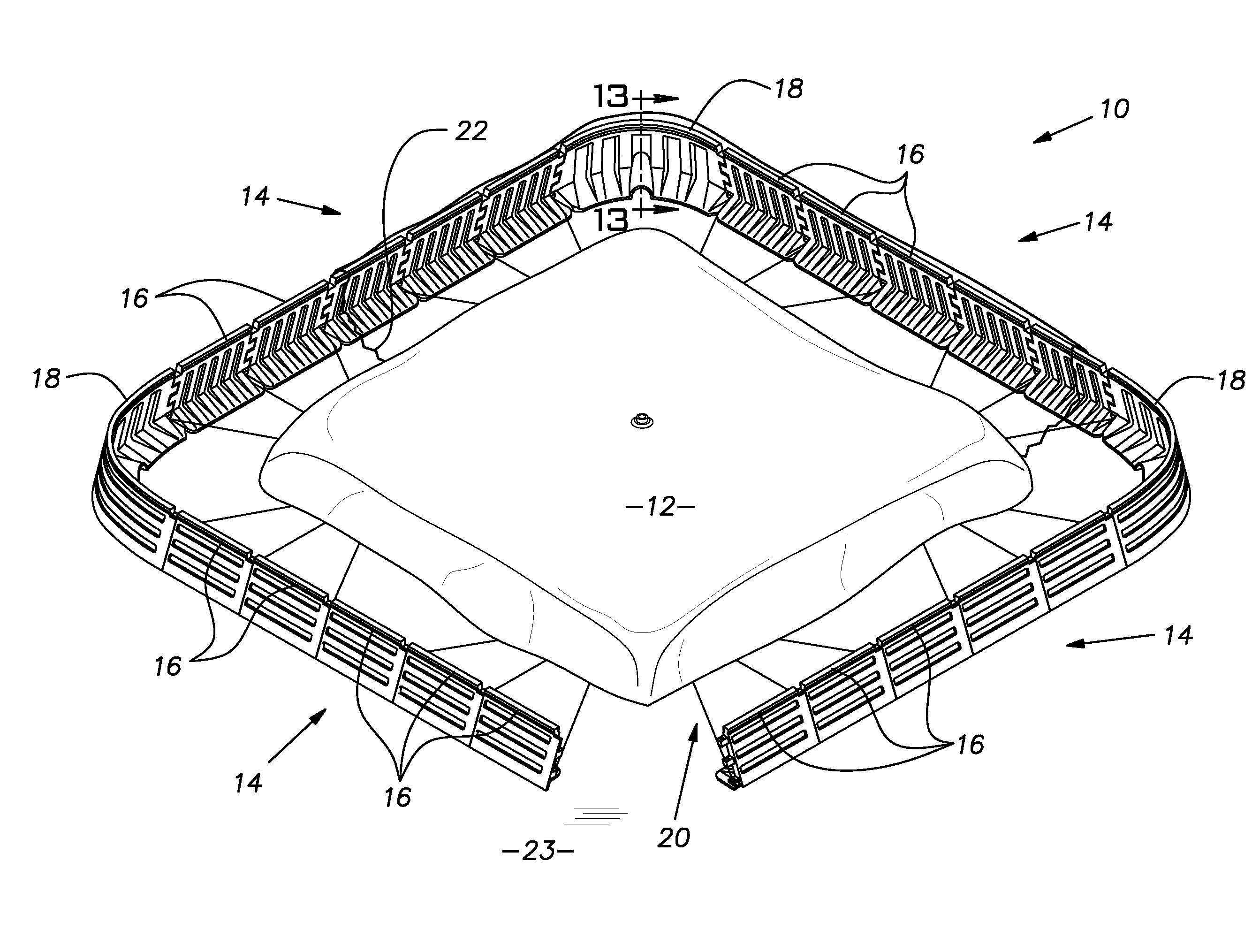

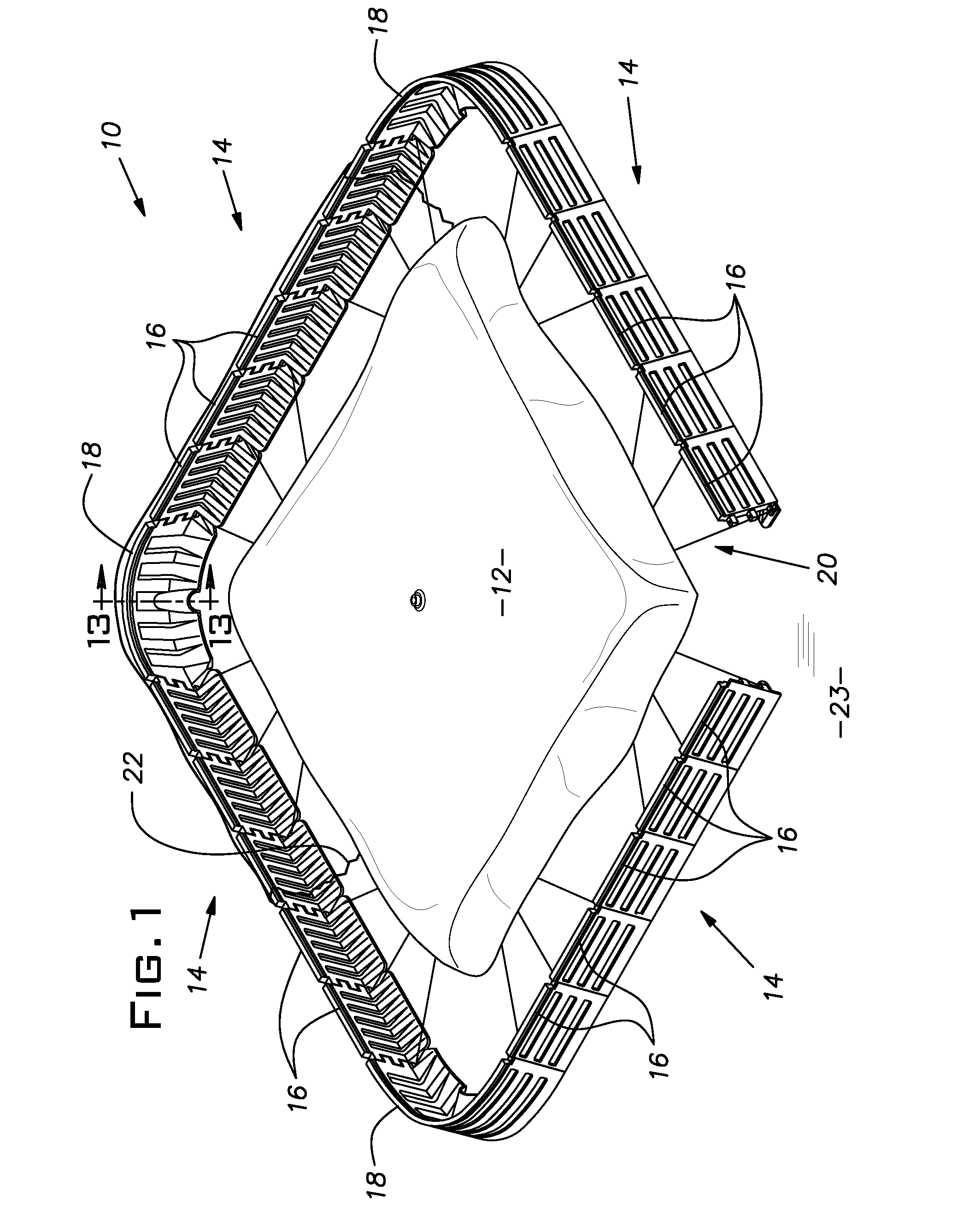

Containment system

ActiveUS8540456B2Easy to assembleReduce manufacturing costBarrages/weirsButtress damsAcute angleEngineering

A modular dike or barrier assembly includes straight and curved members that may be interconnected to form a barrier or dike wall surrounding a primary container. The members are hollow and include opposed side walls having integrally formed reinforcing ribs. The side walls extend at an acute angle relative to the base of the barrier to contain and redirect a surge flow directed toward the dike or barrier assembly. The interior surfaces of the side walls are closely spaced at locations spaced from the ribs and tend to abut for added wall reinforcement upon application of wall deflecting loads.

Owner:POLYSTAR

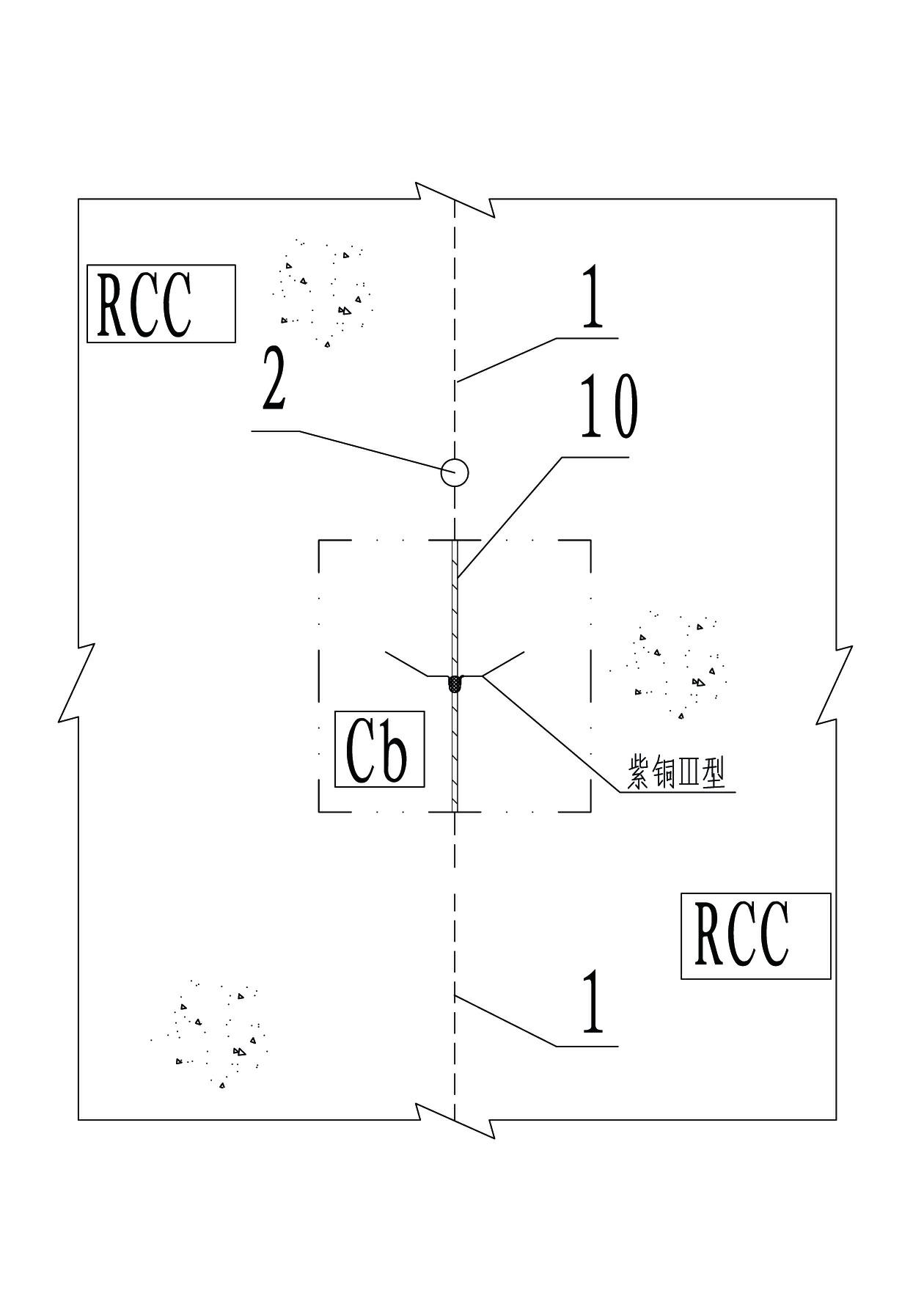

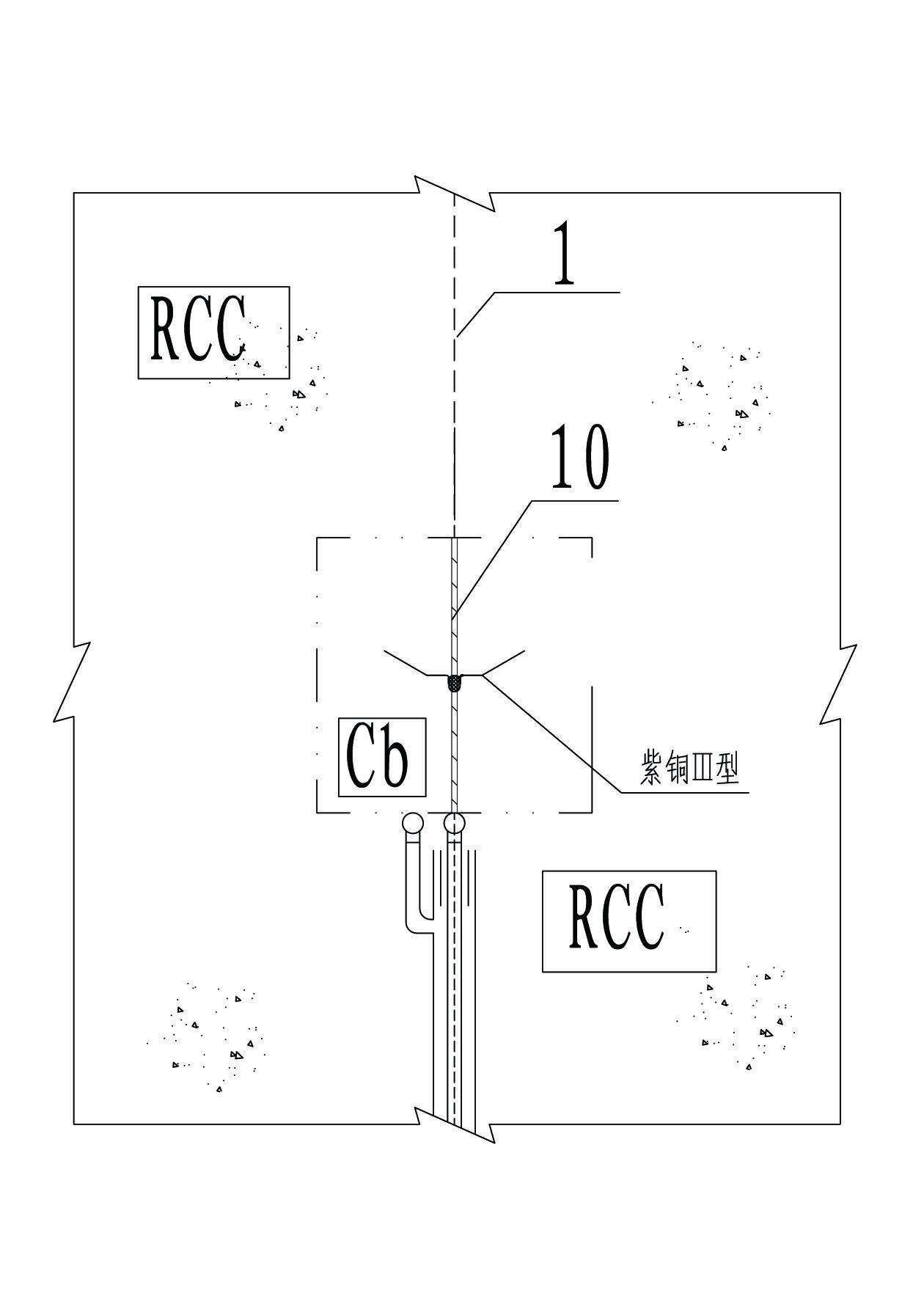

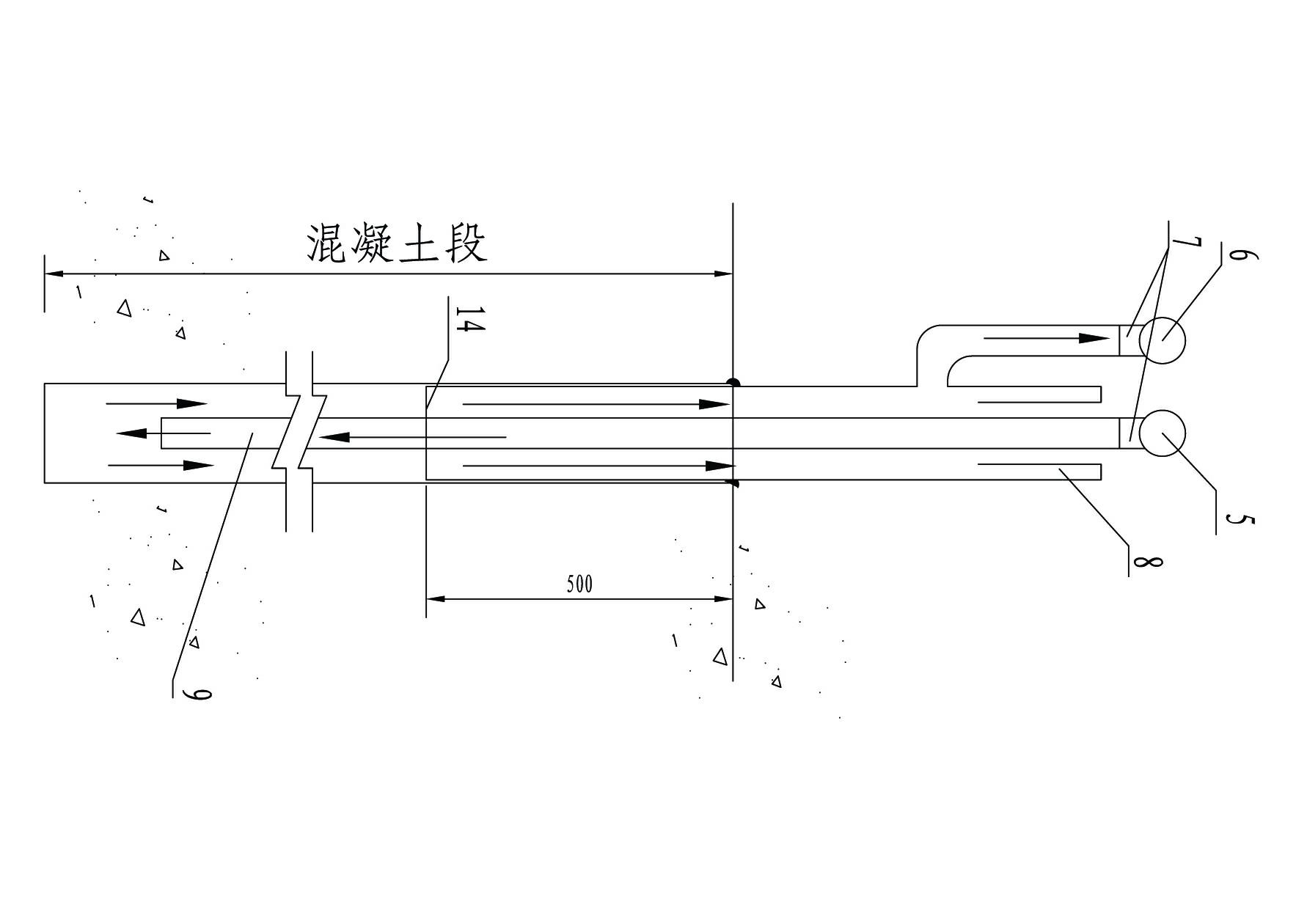

Roller compacted concrete dam and slit forming method thereof

ActiveCN102108692AEasy to operateSimple structureFoundation engineeringWall damsHydroelectricityGrout

The invention discloses a roller compacted concrete dam and a slit forming method thereof. The method comprises the following steps: pouring roller compacted concrete according to a conventional construction process, upwards guiding a vertical grout stop copper sheet together with the rise of a roller compacted layer, and drilling an induction hole in interval of concrete after a raising layer is upwards guided; arranging a grouting pipeline in the induction hole; and then arranging a horizontal grout stop copper sheet and the vertical grout stop copper sheet above the grouting pipeline, repeating the processes, and grouting a transverse slit through the grouting pipeline after the temperature of the roller compacted concrete is reduced to a stable temperature so as to form a roller compacted concrete transverse slit surface for transferring pressure and shearing force. Hoisting equipment is not needed, the warehouse surface construction is simple and convenient, and the transverse slit surface can transfer the pressure and the shearing force; and the method basically has no influence on the construction of large-scale roller compacted concrete of a warehouse surface, and is particularly suitable for slit formation of the roller compacted concrete dam with the transverse slit for transferring the pressure or the shearing force among the dam sections and the slit formation of a roller compacted concrete arch dam in the industries of water conservancy and hydroelectricity.

Owner:POWERCHINA ZHONGNAN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com