Water-filled flood bags for emergency flood control

a flood control and flood bag technology, applied in the direction of doors/windows, coastline protection, door/window protective devices, etc., can solve the problems of insufficient time to fill sandbags, inability to quickly respond to floodwater, and inability to fill sandbags in time, so as to minimize the damage of the floodwater, the effect of minimizing the damage of the cell and minimizing the punctur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

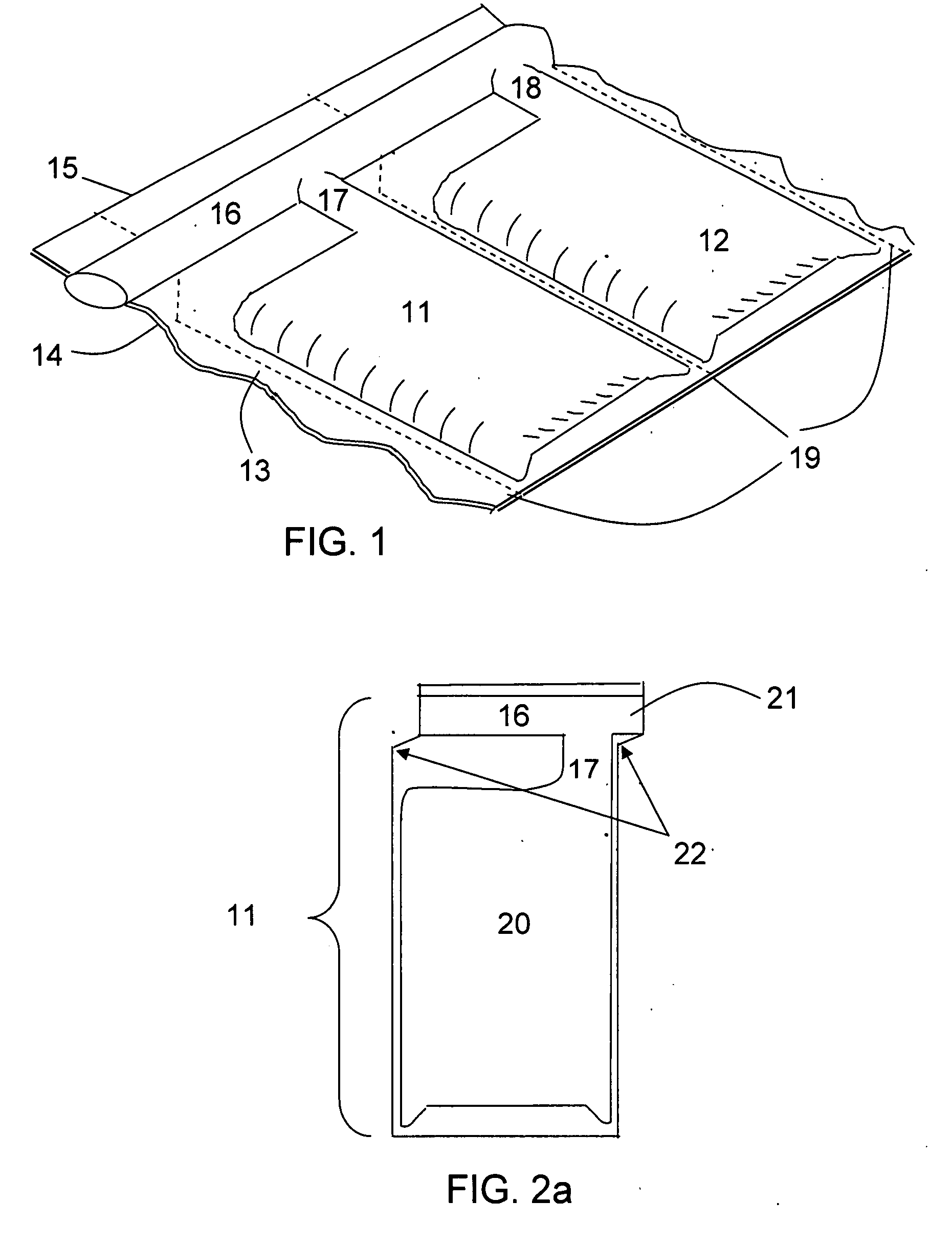

[0056]FIG. 1 illustrates a perspective view of two exemplary hollow chambers or flood bags 11 and 12 that are part of a continuous sheet of such bags, in accordance with an embodiment of the present invention. The present embodiment, Embodiment 1, comprises two flood bags 11 and 12 that are shown as part of a continuous series of such bags that can be wound into a roll or coil or folded similar to an accordion. Flood bags 11 and 12 are formed between two layers 13 and 14 of plastic sheeting. The material anticipated for use is polyethylene but other types of impermeable plastic fabric or sheeting may be substituted such as, but not limited to, rubberized cloth or canvas. Plastic layers 13 and 14 may be separate sheets of plastic or a single sheet of plastic folded along an edge 15 to form layers 13 and 14. The fabric used to form flood bags 11 and 12 is thick enough to be somewhat puncture resistant such as, but not limited to, 10-mil polyethylene sheeting. However, when in use bags...

embodiment 2

[0080]FIG. 11 is an end-view perspective showing how flood bags 91, 92, 93, and 94, as illustrated by way of example in FIG. 9, can be folded to form two rows of tandem flood bags with bags 91 and 92 toward the front and bags 93 and 94 partially obscured to the rear, in accordance with an embodiment of the present invention. This is similar to the method in which two rows of tandem bags are formed in Embodiment 2 as illustrated in FIGS. 6, 7, and 8a, 8b and 8c. However, in the present embodiment, bottom flaps 97a and 97b are sealed to each other longitudinally along a centerline 1110, by a method such as, but not limited to gluing, welding, or stitching, so that each row of flood bags is attached to the other at fill-tube 95 at the top and at centerline 1110 at the bottom. By allowing extra slack in a bottom panel 1120 a connecting membrane is created between the bottoms of flood bags 91, 92, 93 and 94 allowing the bags to spread somewhat apart to form an “A-frame” structure that ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com