Styrene waste gas treatment device and method

A treatment device and technology for styrene, applied in gas treatment, chemical instruments and methods, separation methods, etc., to achieve low energy consumption, efficient removal and resource utilization, and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] use as figure 1 The shown device treats the aromatics extraction device and discharges high-concentration styrene waste gas from time to time, and the volume content of each component in the waste gas is 589 mg / m styrene 3 , Benzene 412mg / m 3 , toluene 367mg / m 3 , Xylene 268mg / m 3 , other hydrocarbons 2870mg / m 3 . Other hydrocarbons mainly include alkanes, olefins and a small amount of aromatics and halogenated hydrocarbons. The total gas flow rate is 100-300m 3 / h, the temperature is lower than 20°C, the absorption unit adopts a spray tower, the superficial velocity is 2.0m / s, the overall size is Φ3600×8500mm, the quantity is 2, the absorbent is diesel, the consumption is 10.5t / h, and the material of the absorption unit is 304 stainless steel; organic gas separation membrane parameters: material PMOS, filling capacity 40m 2 , absorbent volatile matter / nitrogen separation coefficient 38.5, absorbent volatile oxygen separation coefficient 20.4, permeation flux 1.2...

Embodiment 2

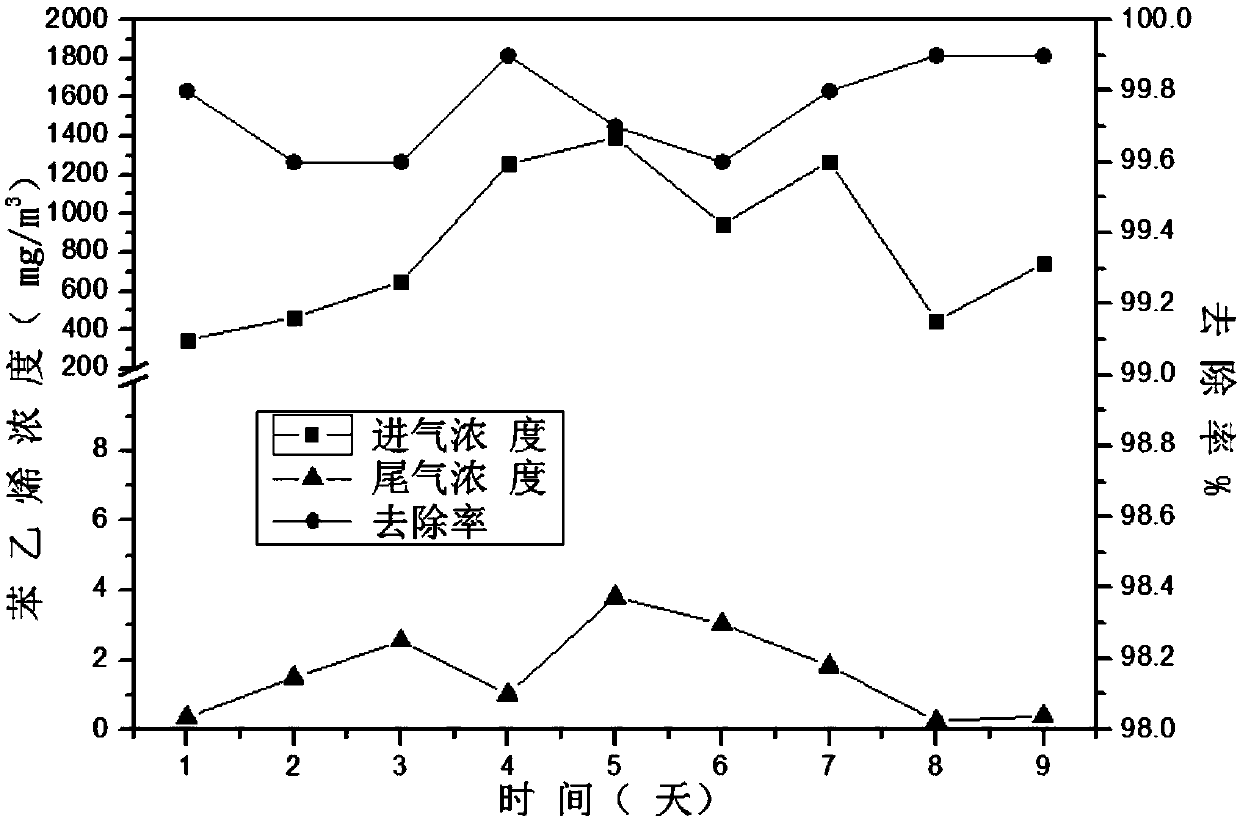

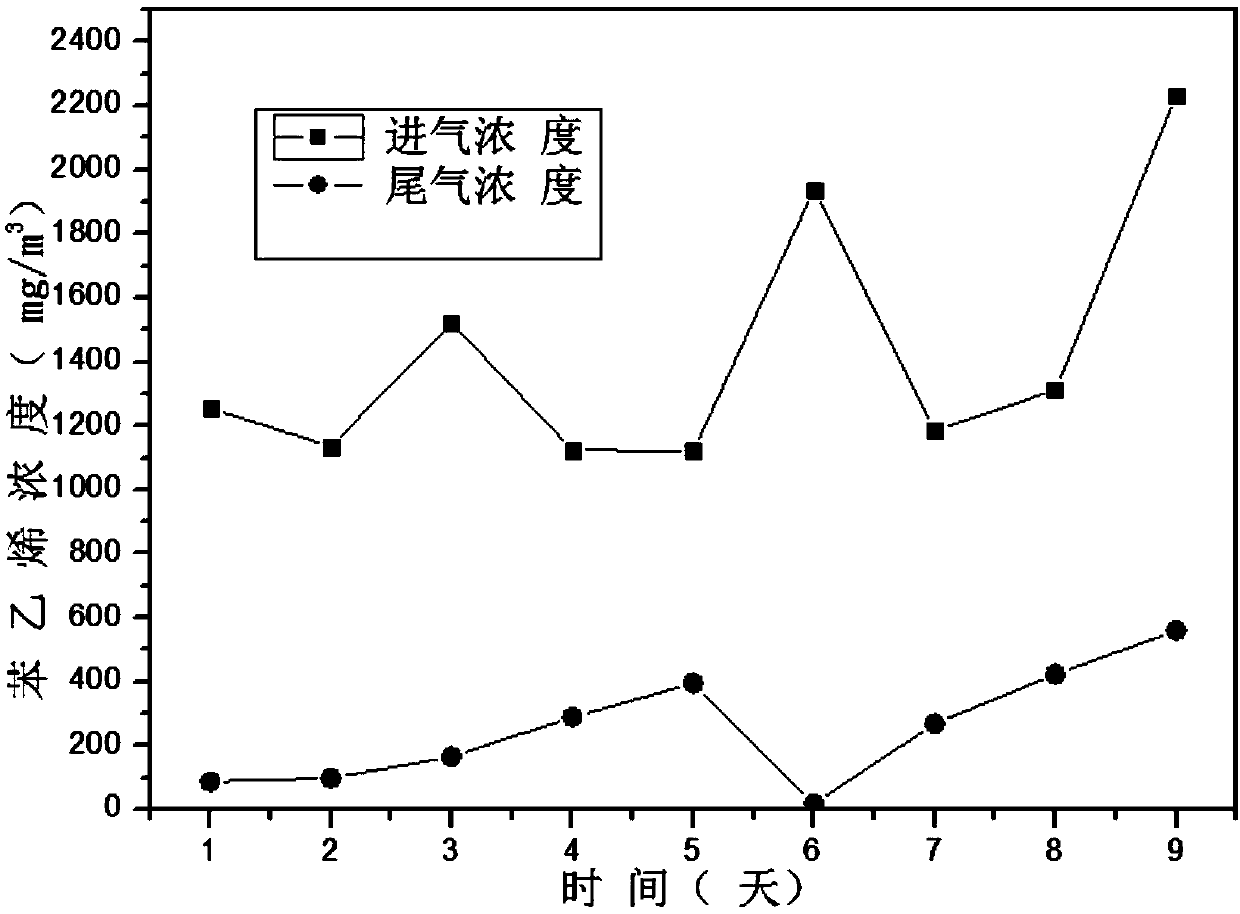

[0062] use as figure 1 The device shown in the figure treats the waste gas discharged from the breathing valve of the styrene storage tank in the rubber factory, and the volume content of each component in the waste gas is styrene 1868mg / m 3 , Benzene 438mg / m 3 , toluene 548mg / m 3 , Xylene 63mg / m 3 , other hydrocarbons below 200mg / m 3 . Other hydrocarbons mainly include alkanes, olefins, and a small amount of aromatics and halogenated hydrocarbons. The total amount is relatively small and no specific analysis is made. The total flow of gas flow is 200m 3 / h, temperature 70°C (±5°C), absorption unit adopts packed tower, superficial velocity 1.40m / s, external dimension Φ2600×4500mm, quantity 2, absorbent adopts sulfolane after low temperature precooling, dosage 4t / h, absorption unit material stainless steel; organic gas separation membrane parameters: material PDMS, filling capacity 26m 2 , absorbent volatile matter / nitrogen separation coefficient 31.5, absorbent volatil...

Embodiment 3

[0070] use as figure 1 The shown device treats styrene car loading platform waste gas, the volume content of each component in the waste gas is styrene 347-1368mg / m 3 , other hydrocarbons below 200mg / m 3 . Other hydrocarbons mainly include volatiles of benzene series and polymerization inhibitors, the total amount is small and no specific analysis is made. The total flow of gas flow is 200m 3 / h, temperature 0°C (±5°C), absorption unit adopts packed tower, superficial velocity 1.36m / s, external dimension Φ3600×4200mm, quantity 2, absorbent adopts low-temperature pre-cooled dimethyl sulfoxide, Add a small amount of polymerization inhibitor, the dosage is 6t / h, the material of the absorption unit is stainless steel; the parameters of the organic gas separation membrane: the material is PDMS, and the filling volume is 40m 2 , absorbent volatile matter / nitrogen separation coefficient 31.5, absorbent volatile oxygen separation coefficient 18.6, permeation flux 1.85-2.10m 3 / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com