Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Improve appearance pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

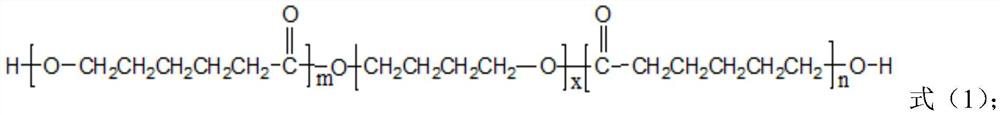

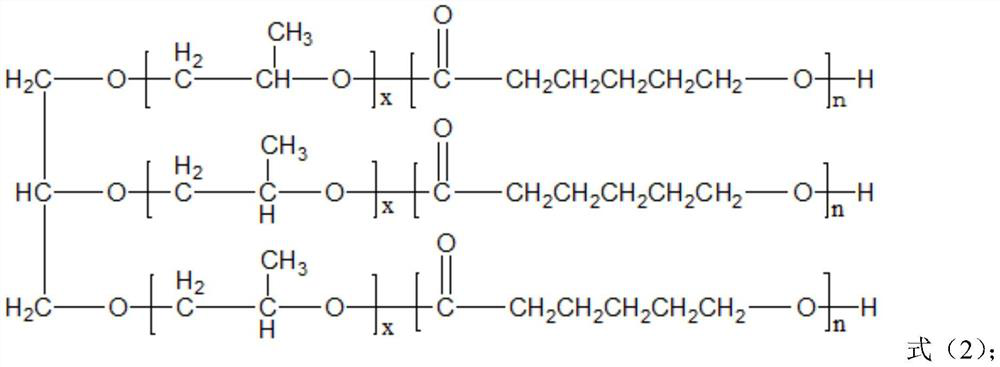

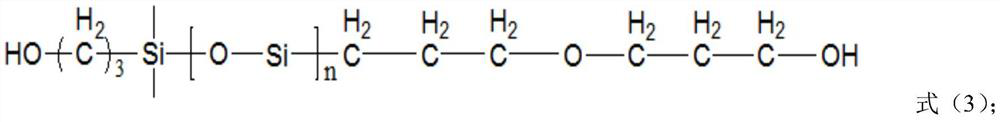

Polyurethane damping cushion with high cold resistance and preparation method thereof

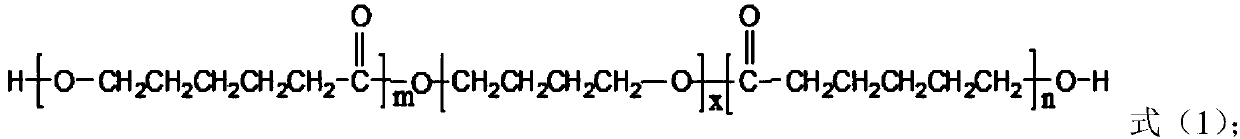

ActiveCN107602817ADisruption of regularityImprove low temperature performanceSide reactionCaprolactone

The invention provides a polyurethane damping cushion with high cold resistance and a preparation method thereof. The polyurethane damping cushion is prepared in the manner of crosslinking a componentA with a component B; the component A is a polyalcohol composition and comprises the following raw materials: caprolactone modified polyether polyol, polyether polyol, hydroxyl terminated polybutadiene, primary hydroxyl terminated siloxane, a chain extender, a catalyst, a foam stabilizer and a foaming agent; the component B is NCO-terminated isocyanate prepolymer and comprises the following raw materials: caprolactone modified polyether polyol, 4,4-diphenylmethane diisocyanate and a side reaction inhibitor. The polyurethane damping cushion with high cold resistance prepared according to the invention has excellent damping property, excellent dynamic fatigue resistance and obviously improved low-temperature performance and can be applied to the field of construction of the Moscow-Kazan high-speed rails and the rails in cold areas, such as, Northern Europe and Siberia and the field of automobile damping in extreme cold areas.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

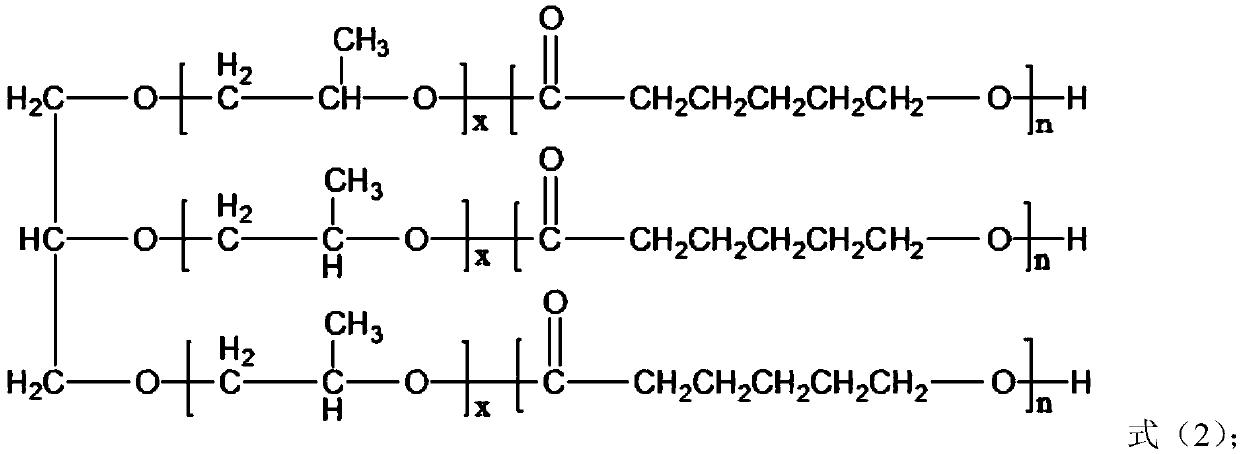

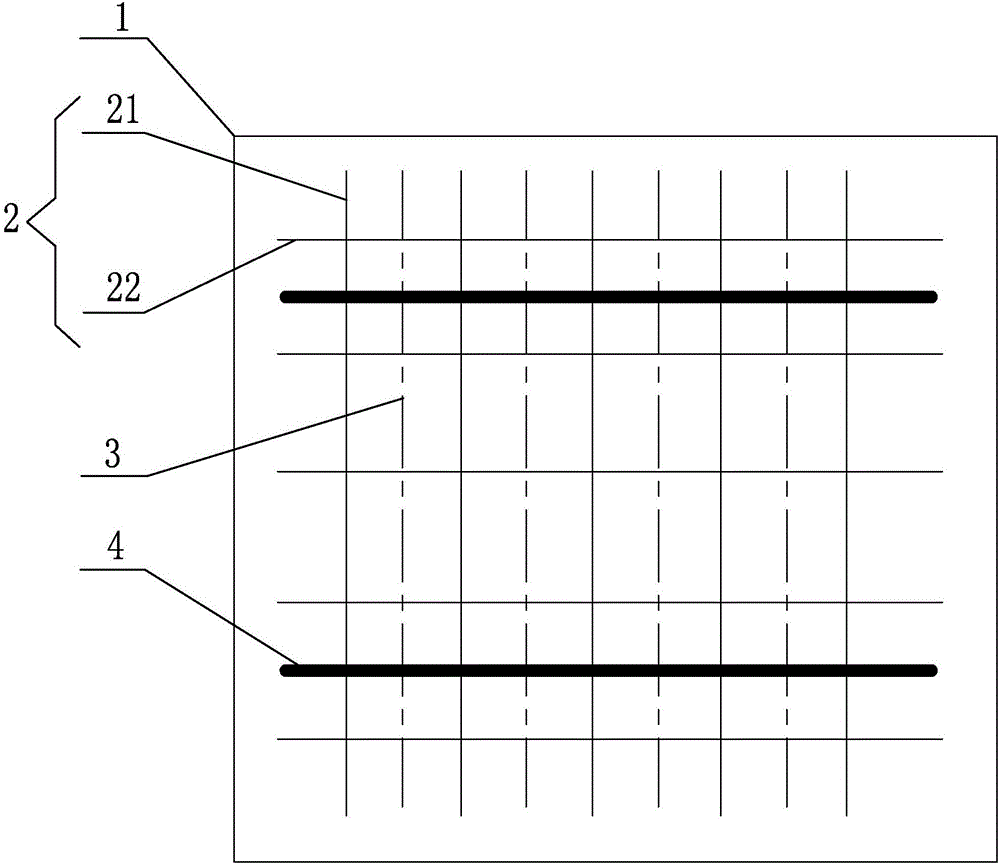

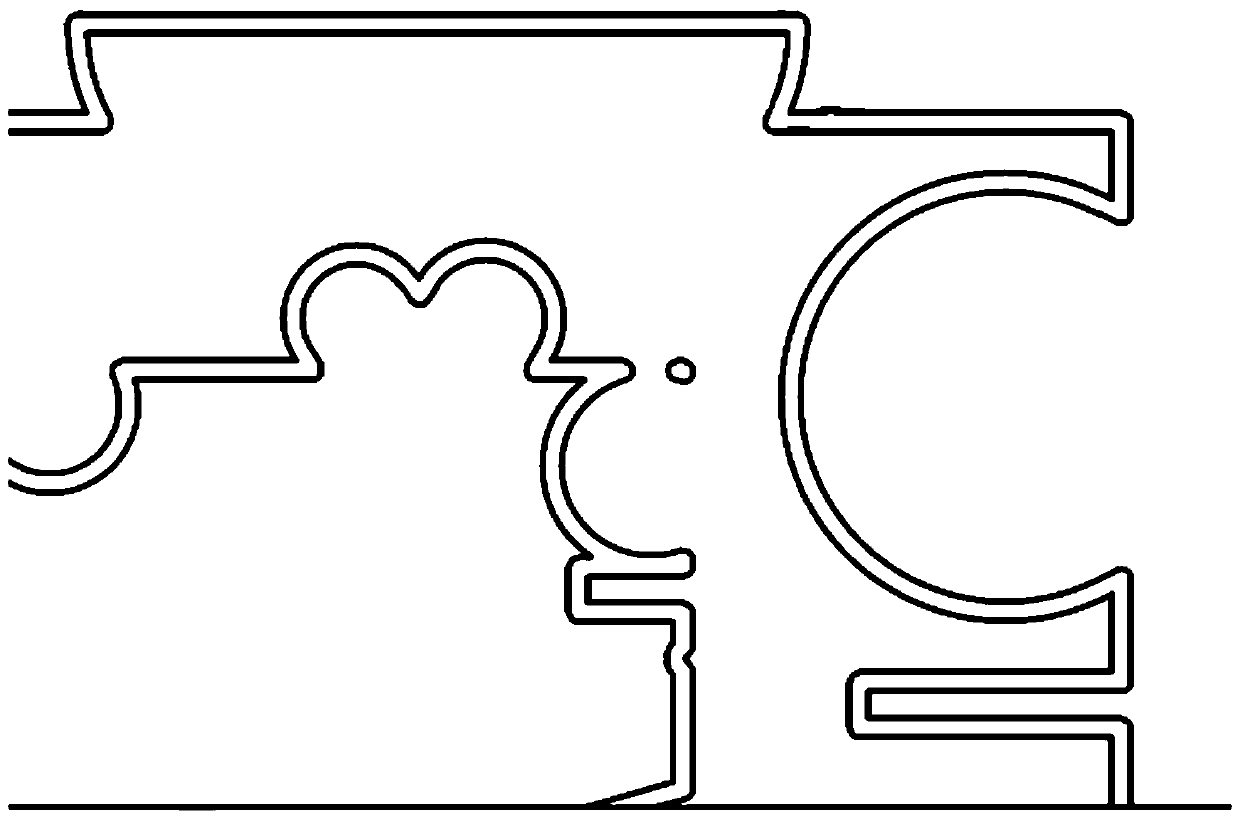

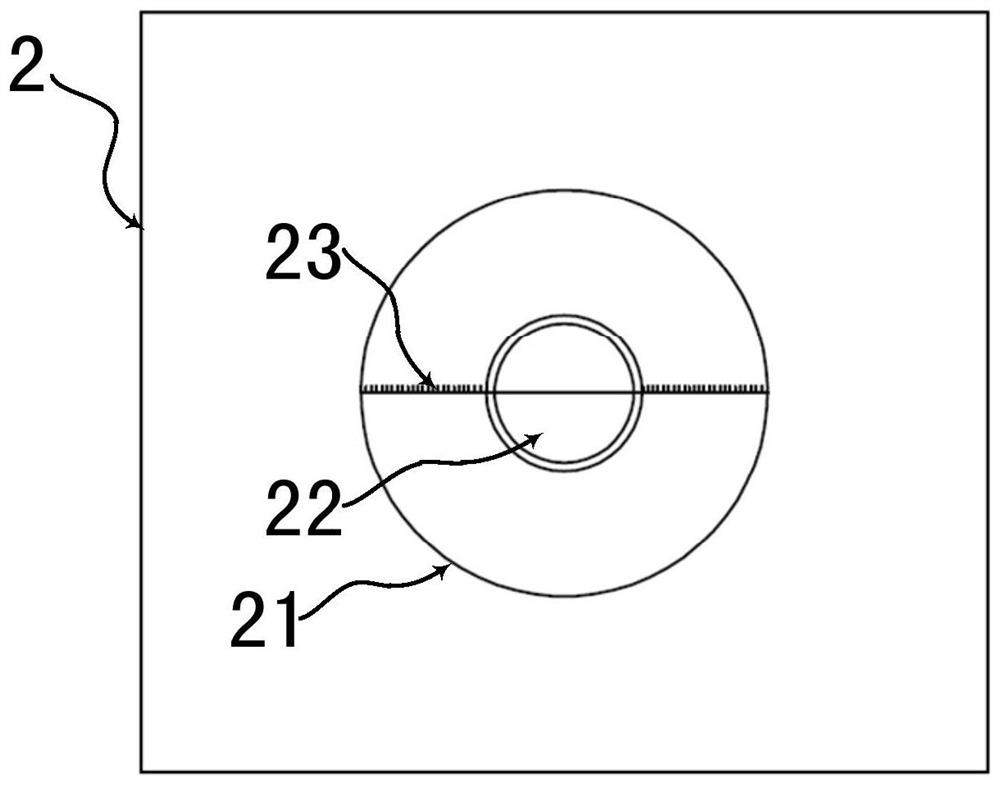

Crystalline silicon solar battery positive electrode screen printing plate

InactiveCN105977346AReduce widthIncrease aspect ratioFinal product manufactureScreen printersScreen printingYarn

The invention discloses a crystalline silicon solar battery positive electrode screen printing plate and belongs to the technical field of a solar battery. The crystalline silicon solar battery positive electrode screen printing plate comprises a screen frame and a plurality of mesh yarns arranged on the screen frame, wherein the mesh yarns are coated with a latex film layer, the latex film layer is provided with a positive electrode pattern, and the positive electrode pattern comprises a plurality of crossed primary grid wires and secondary grid wires; the mesh yarns comprise a plurality of vertical mesh yarns and transversal mesh yarns which are vertically crossed, the vertical mesh yarns are successively arranged on the screen frame in parallel at equal intervals, the transversal mesh yarns are successively arranged on the screen frame in parallel at equal intervals, and the interval between adjacent two vertical mesh yarns and the interval between adjacent two transversal mesh yarns are the same; and the primary grid wires are arranged in parallel between adjacent two transversal mesh yarns, the secondary grid wires are arranged in parallel between adjacent two vertical mesh yarns, and the quantity of the primary grid wires is smaller than that of the secondary grid wires. The solar battery positive electrode screen printing plate, while improving the electrode conductivity, improves the photoelectric conversion efficiency of a battery, can reduce EL broken grid proportion of a secondary grid at the same time, and improves the appearance qualified rate of the battery.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH CO LTD

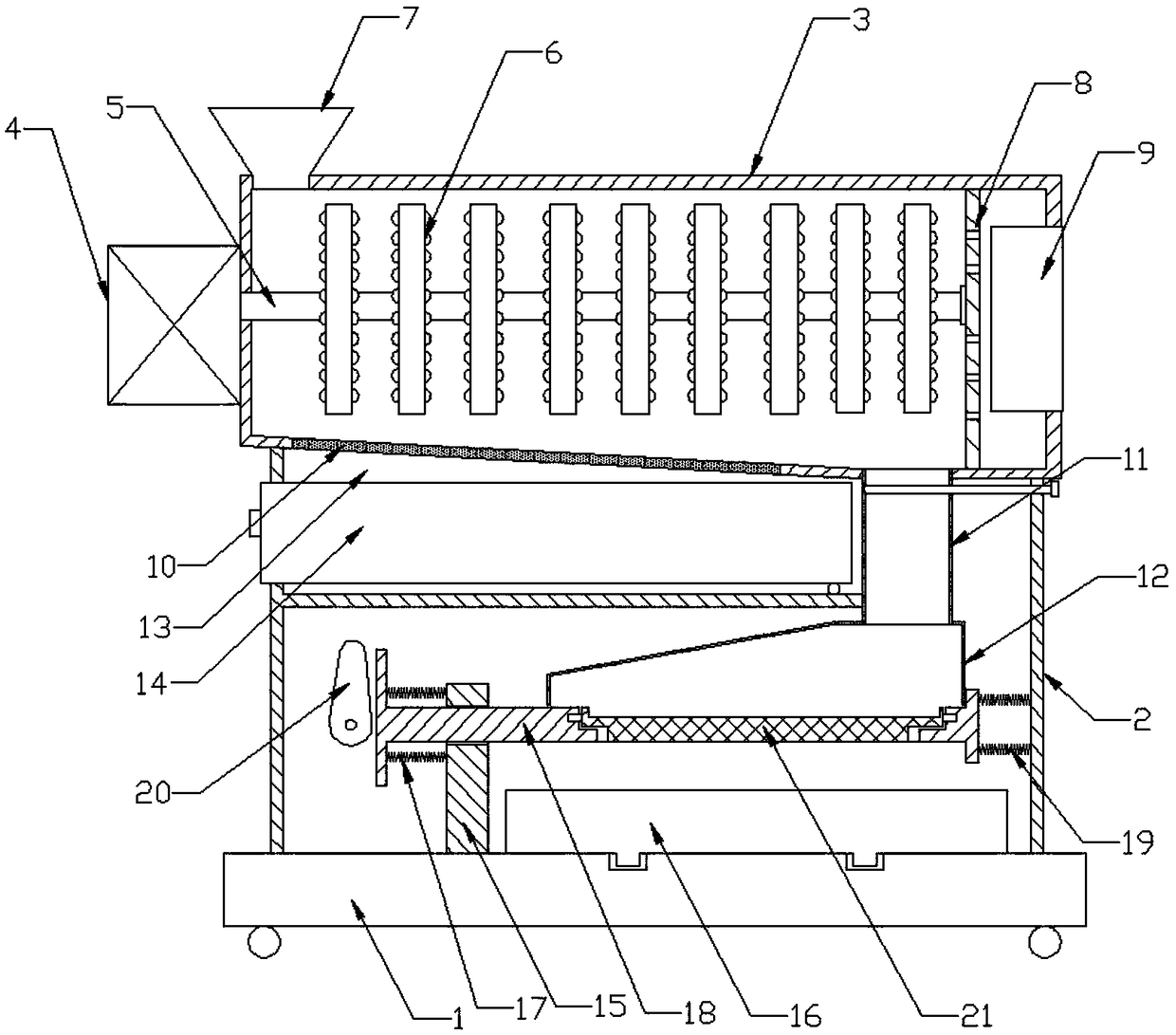

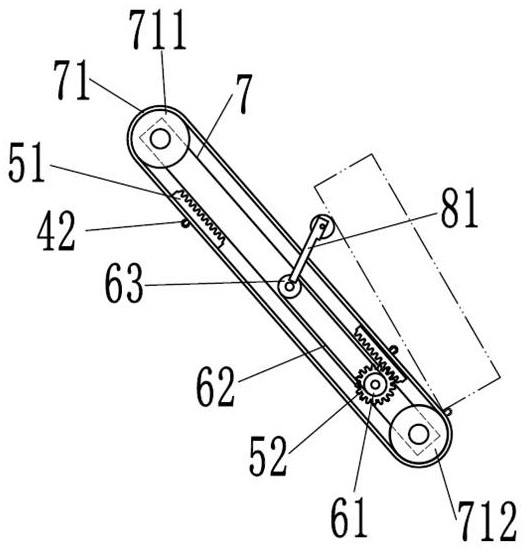

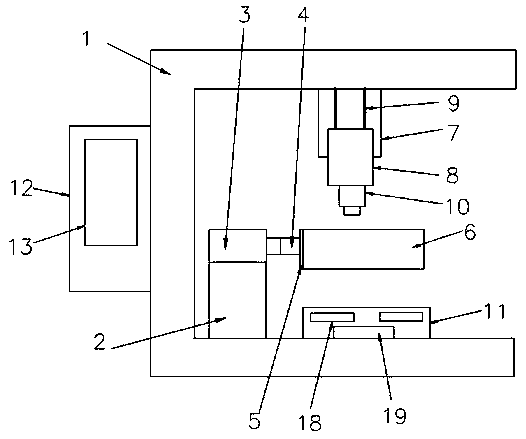

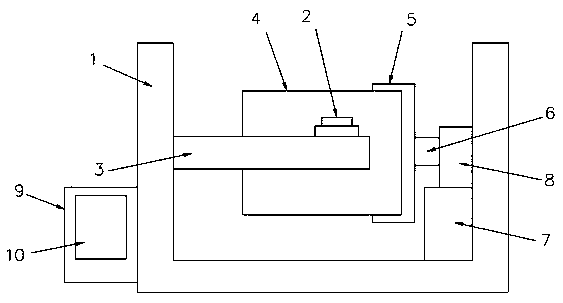

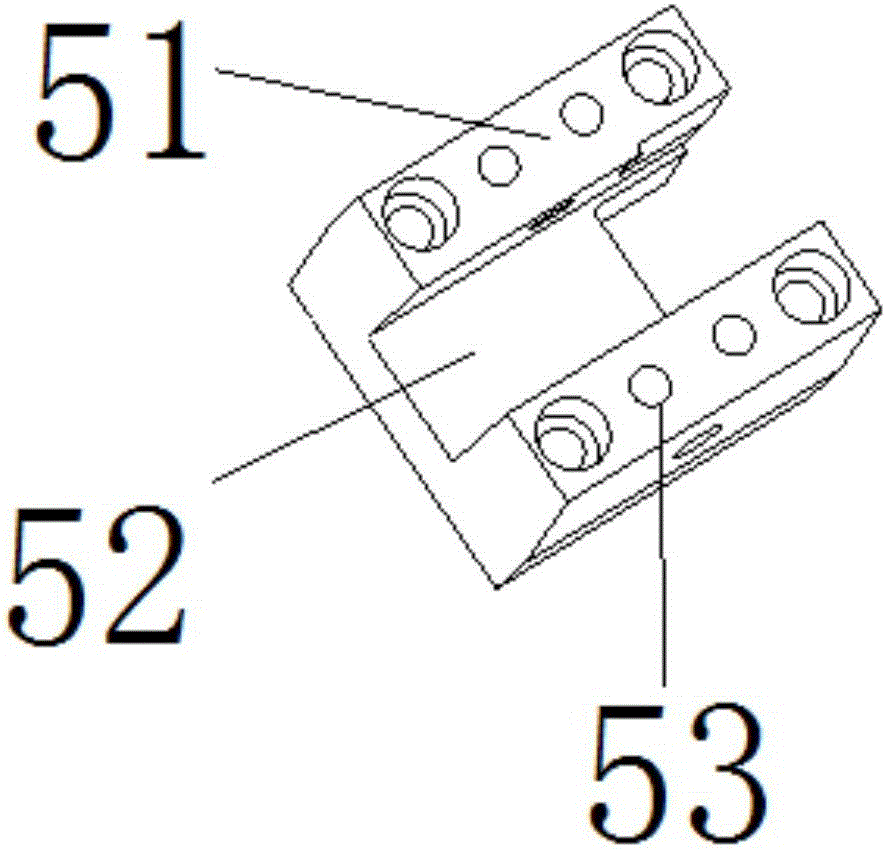

Grinding and sorting all-in-one machine for wear-resistant ball production

InactiveCN108940826AImprove appearance pass ratePrevent slipping outSievingScreeningWear resistantPulp and paper industry

The invention discloses a grinding and sorting all-in-one machine for wear-resistant ball production. The machine comprises a base, the top of the base is connected with a sorting chamber, the top ofthe sorting chamber is connected with a grinding cylinder, and the left side of the top of the grinding cylinder is connected with a feeding hopper, and a fan is embedded in the right side wall of thegrinding cylinder, a filter screen is arranged on the left side of the bottom of the grinding cylinder, and a material conveying pipe is connected to the right side of the bottom of the grinding cylinder, the top of the left side of the inner cavity of the sorting chamber is provided with a waste collecting cavity, and the top of the base is connected with a fixing plate and a collecting box, theleft side wall of the fixing plate is connected with a first spring, and the left end of the first spring is connected with a movable plate, a cam is arranged on the left side of the movable plate, and a sieve tray is embedded in the movable plate. The machine is reasonable in structural design and is beneficial to improving the appearance percent of pass of the wear-resistant ball, dust impurities generated during grinding can be timely guided into the waste collecting box through the filter screen, non-performing products that the volume of the product is too large is screened out, the product quality is improved, and the processing efficiency of the wear-resistant ball is improved through the integrated design of the device.

Owner:NINGGUO ZHENGXING WEAR RESISTANT MATERIALS

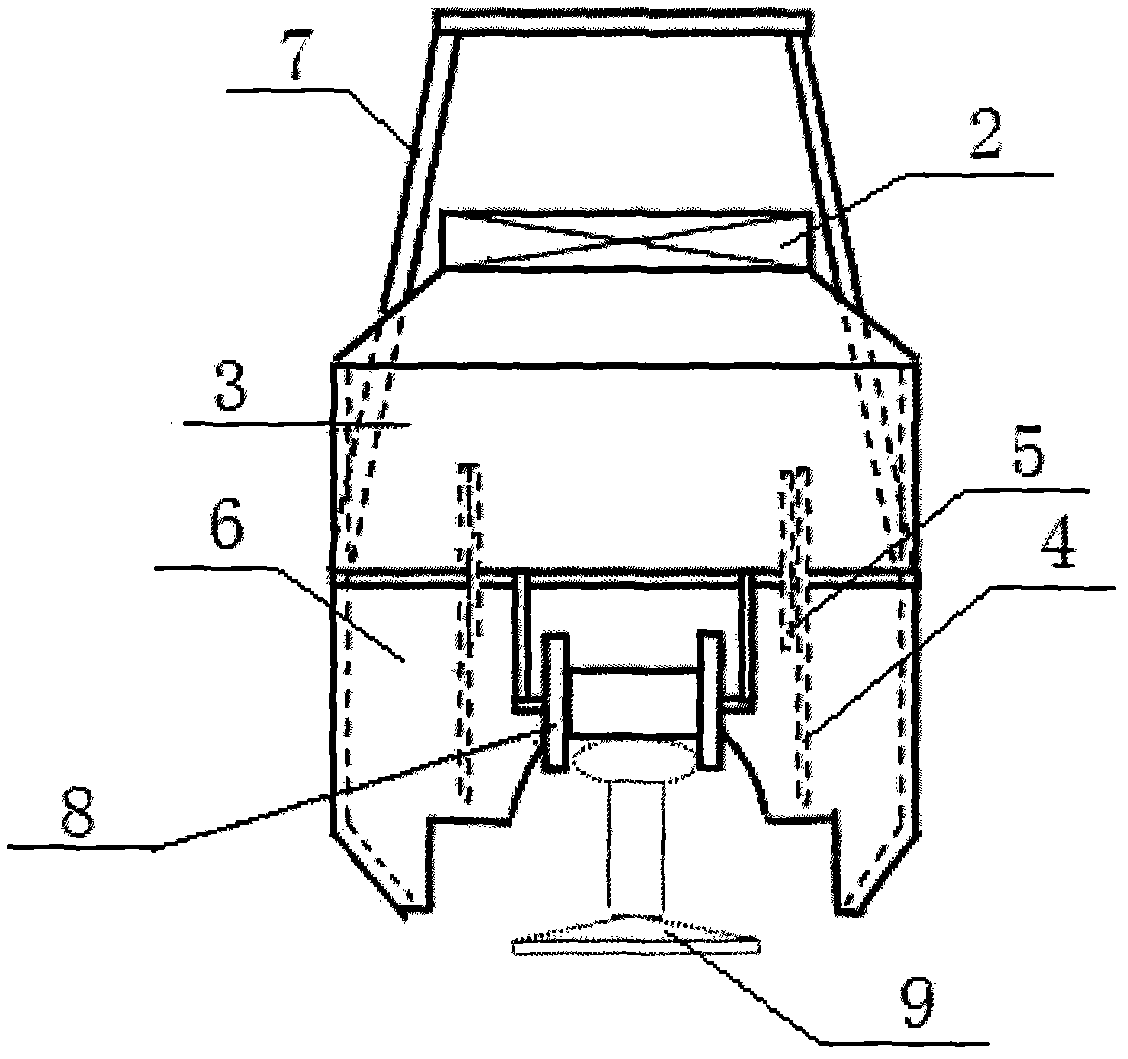

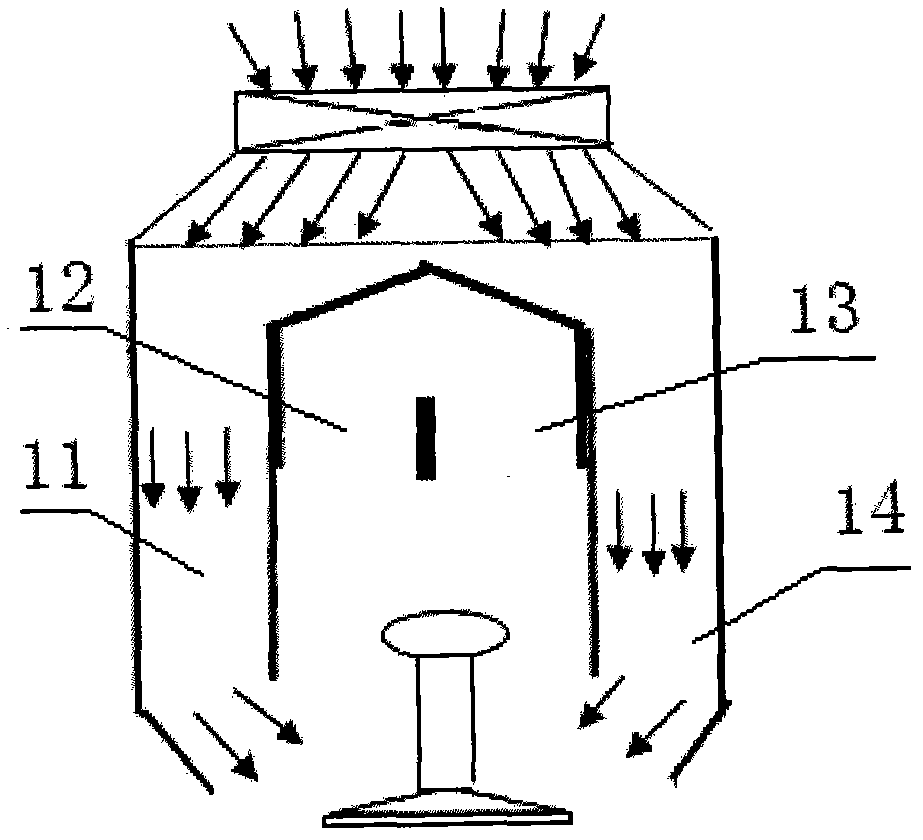

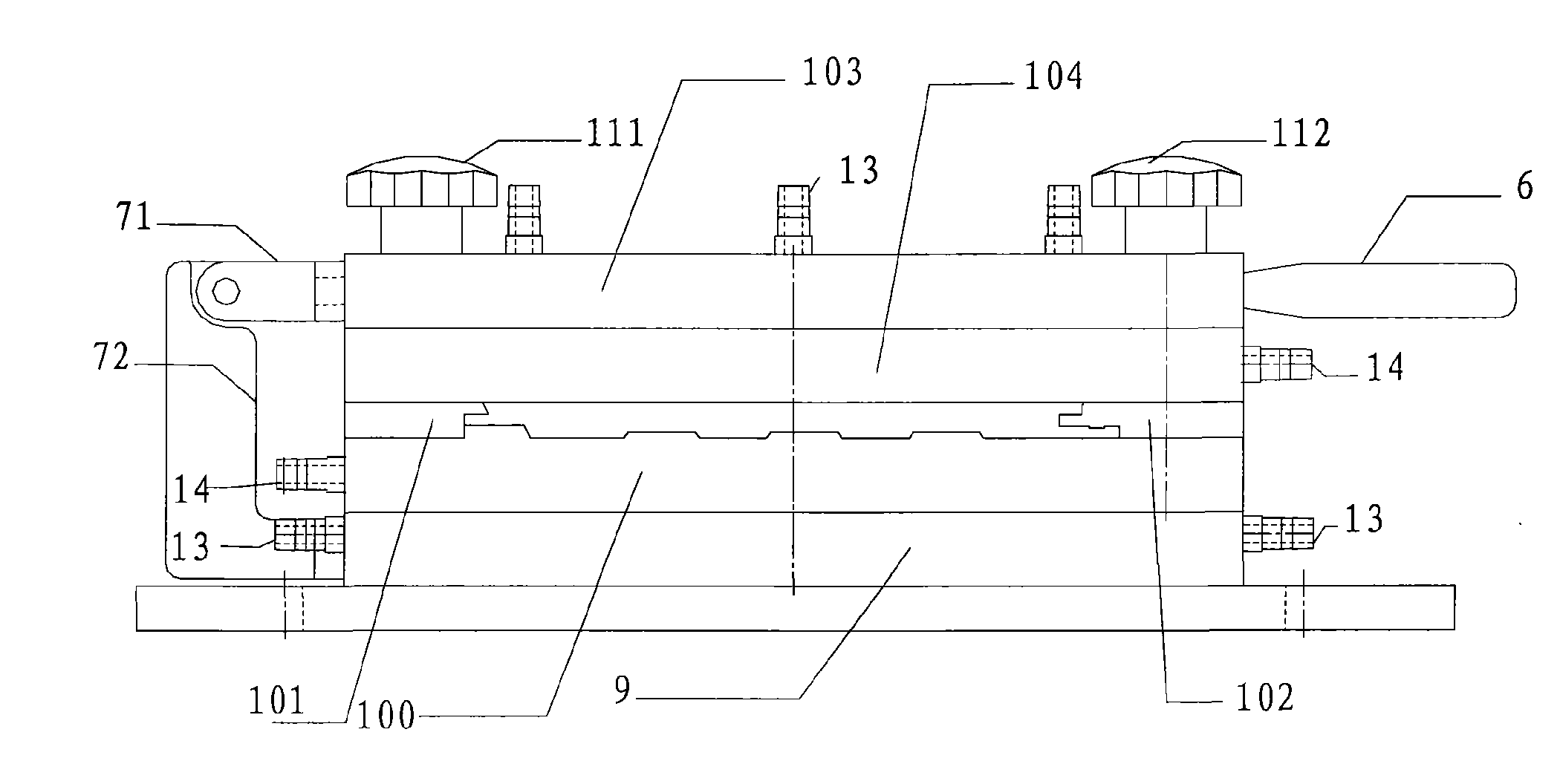

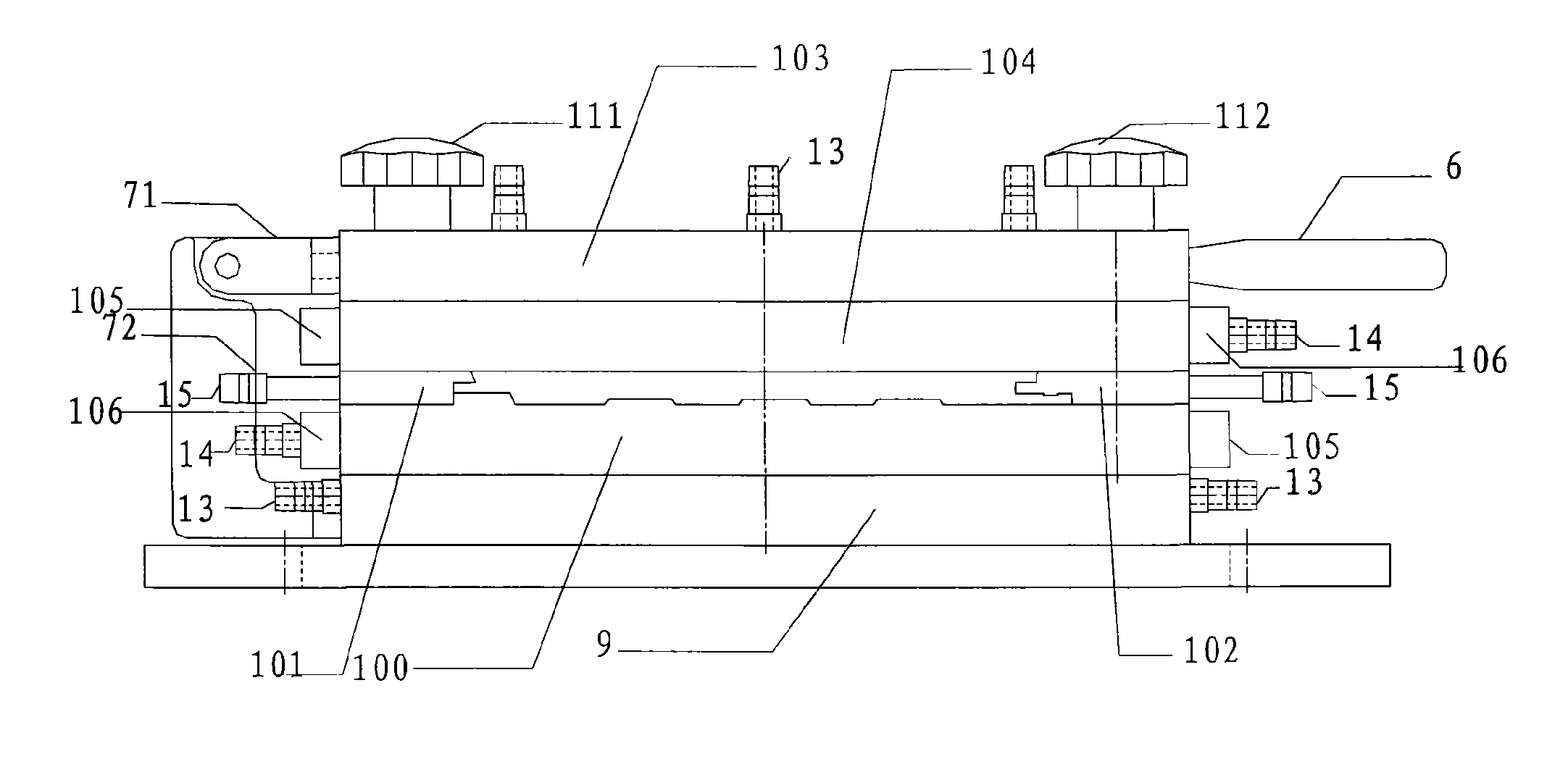

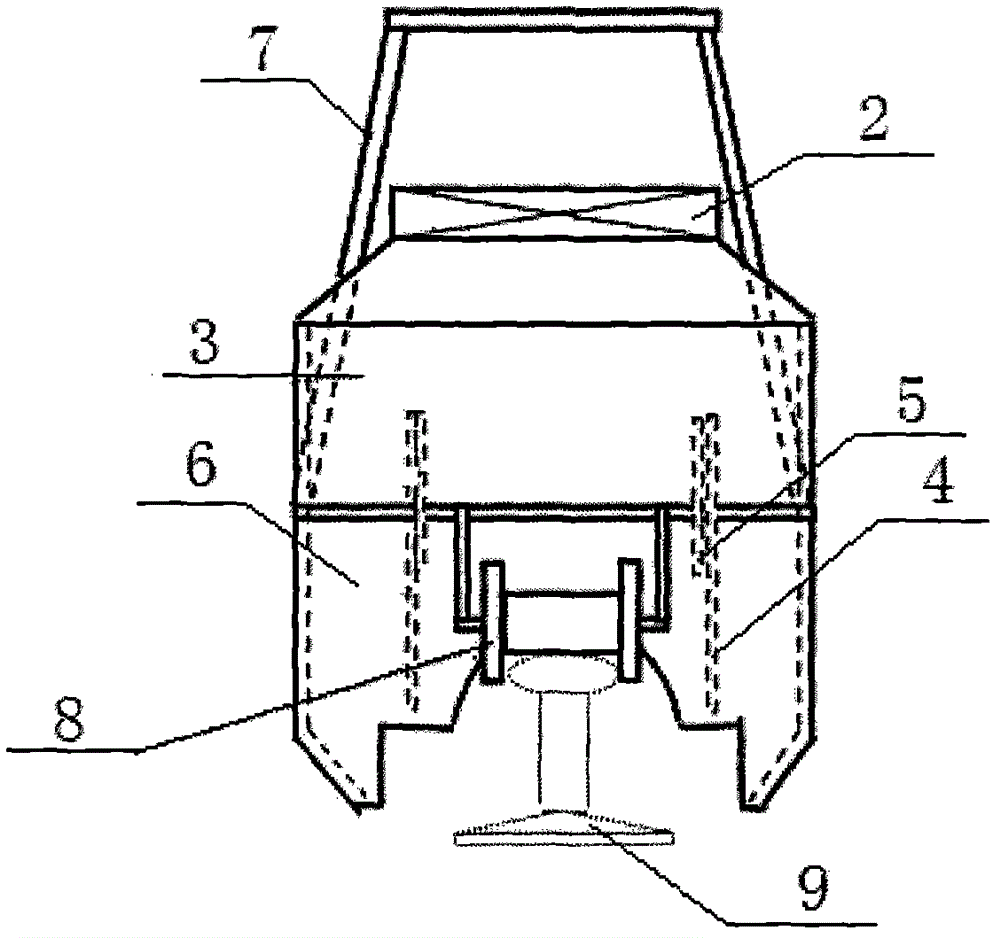

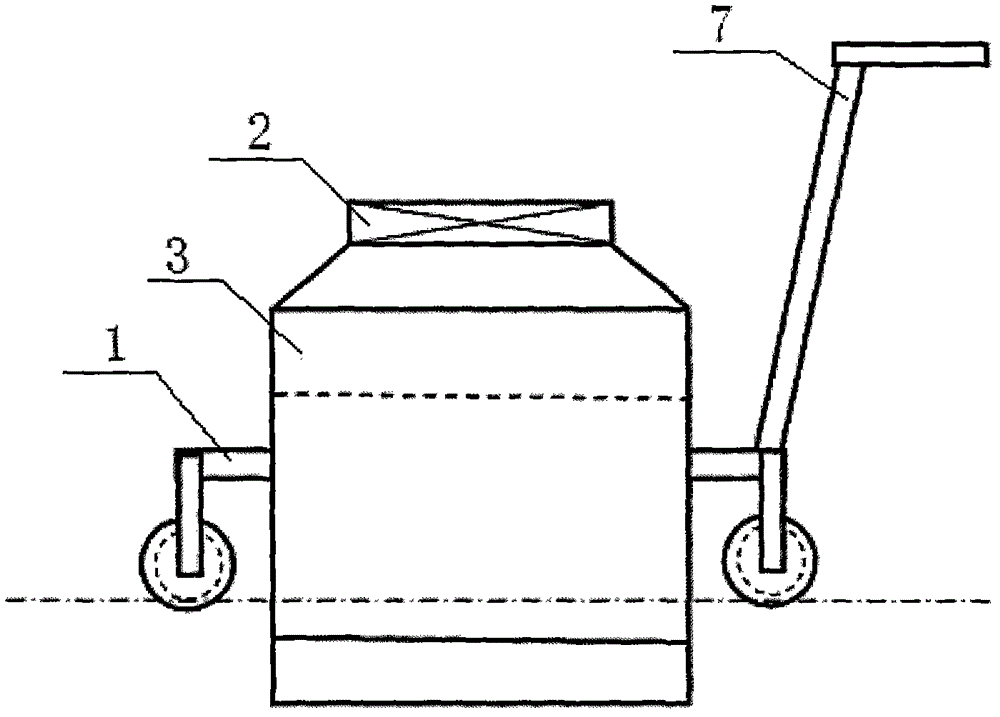

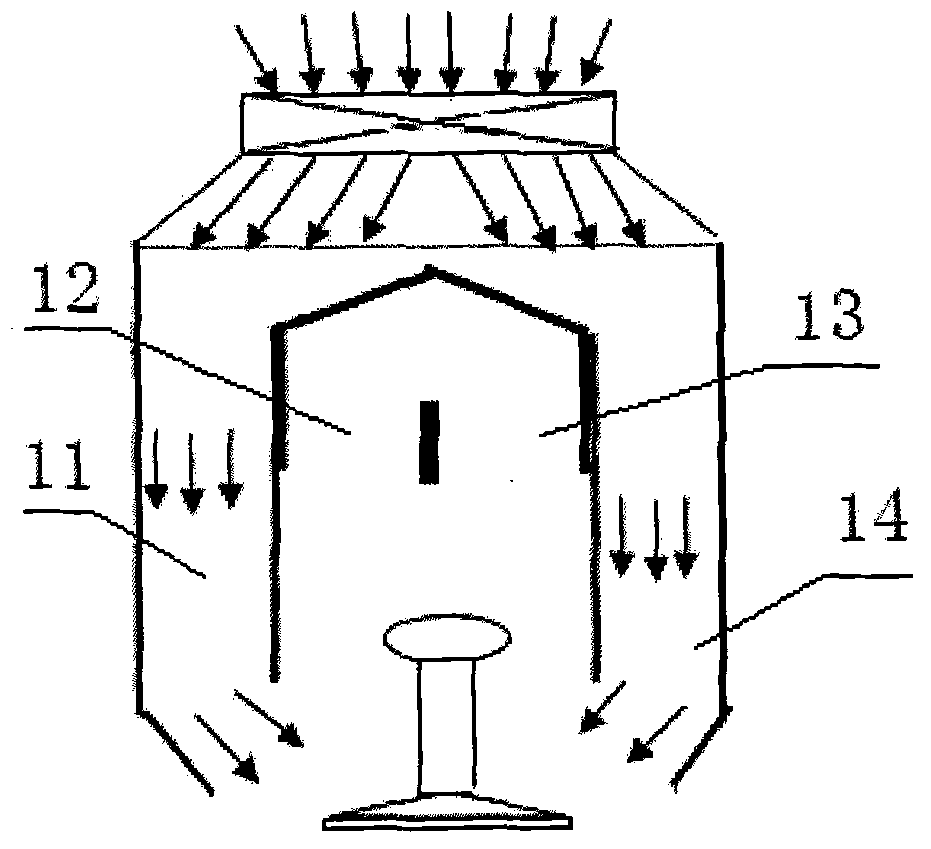

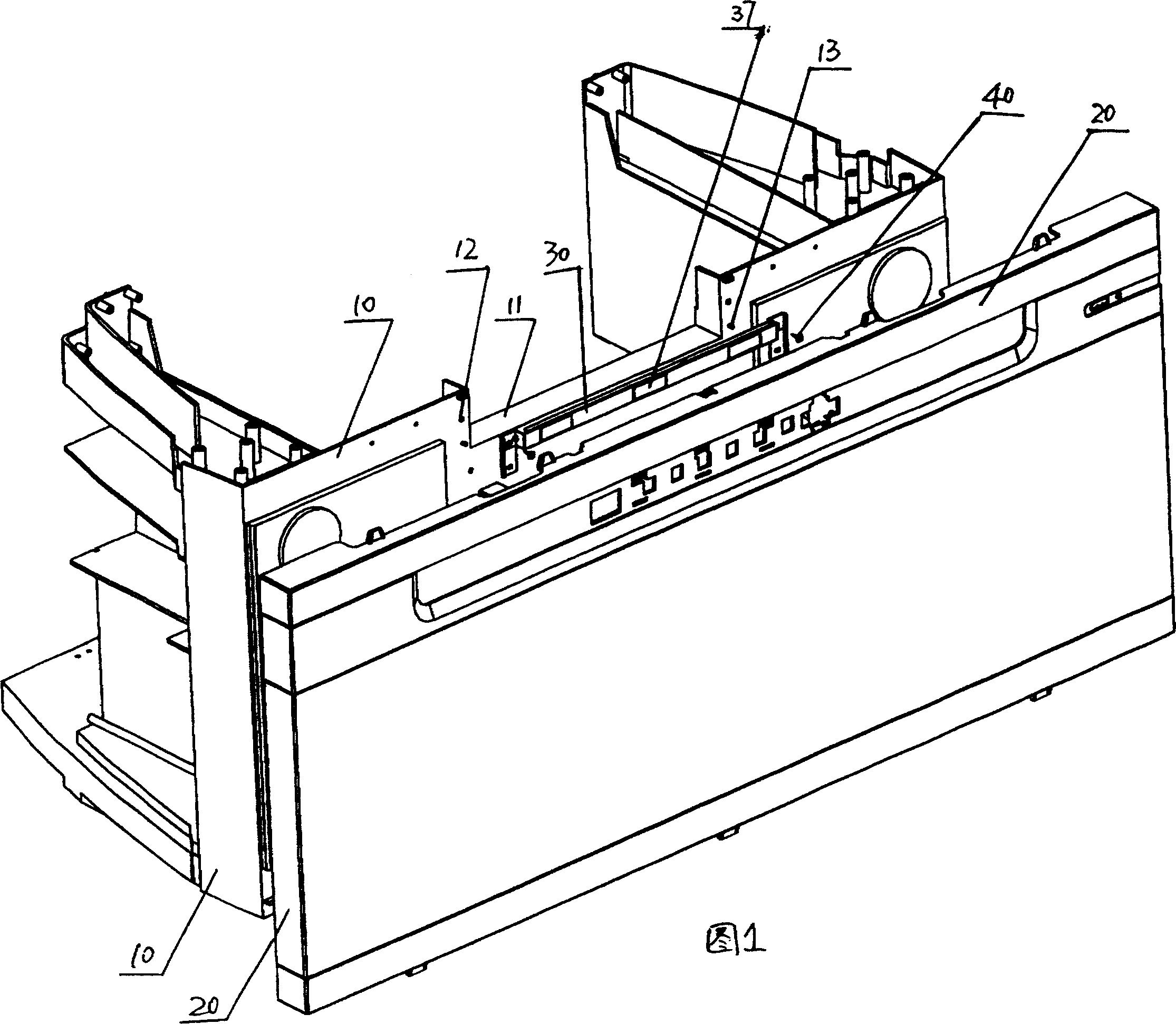

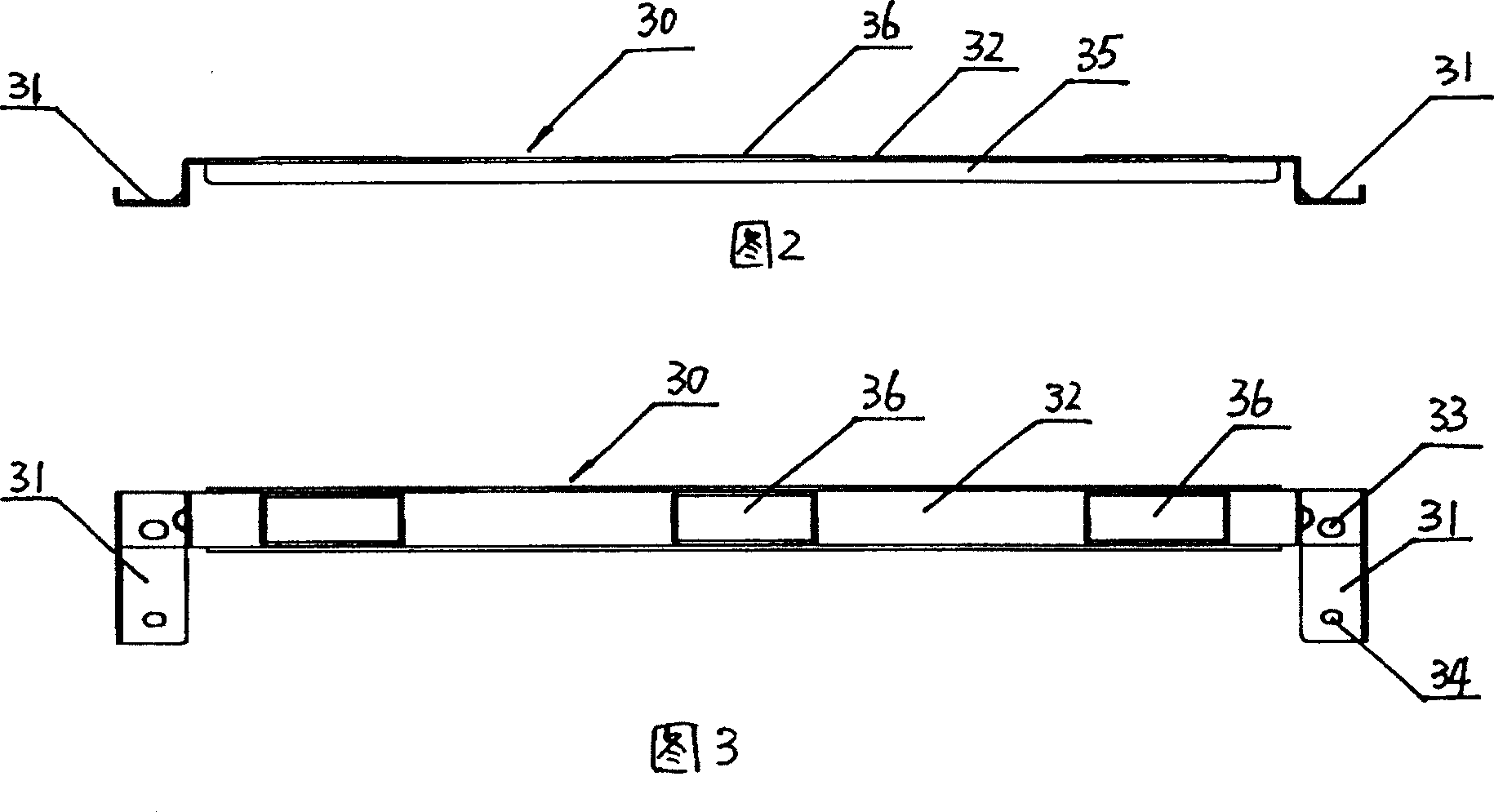

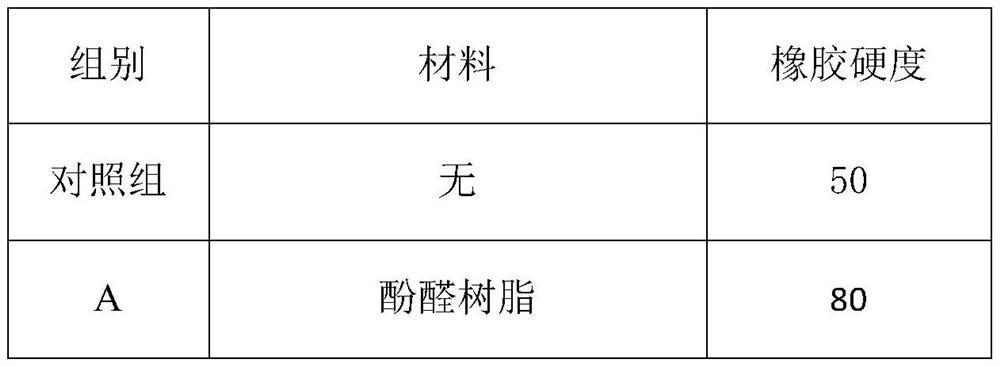

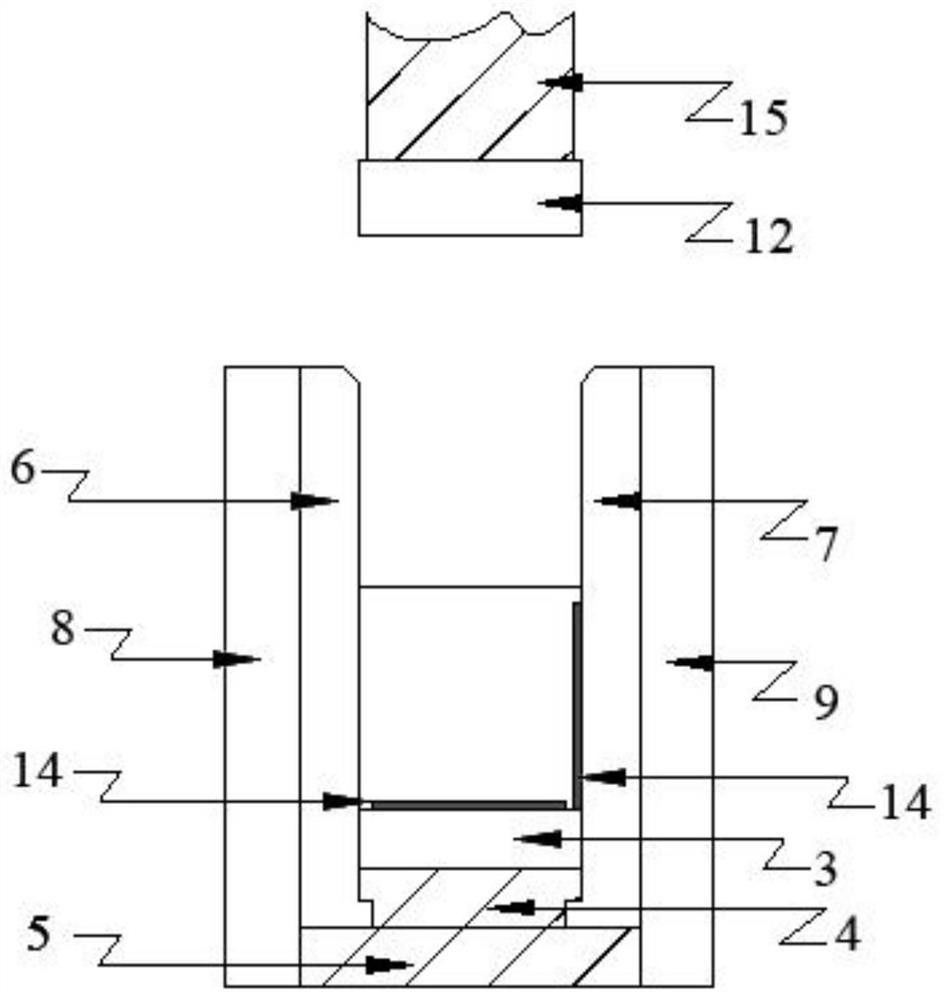

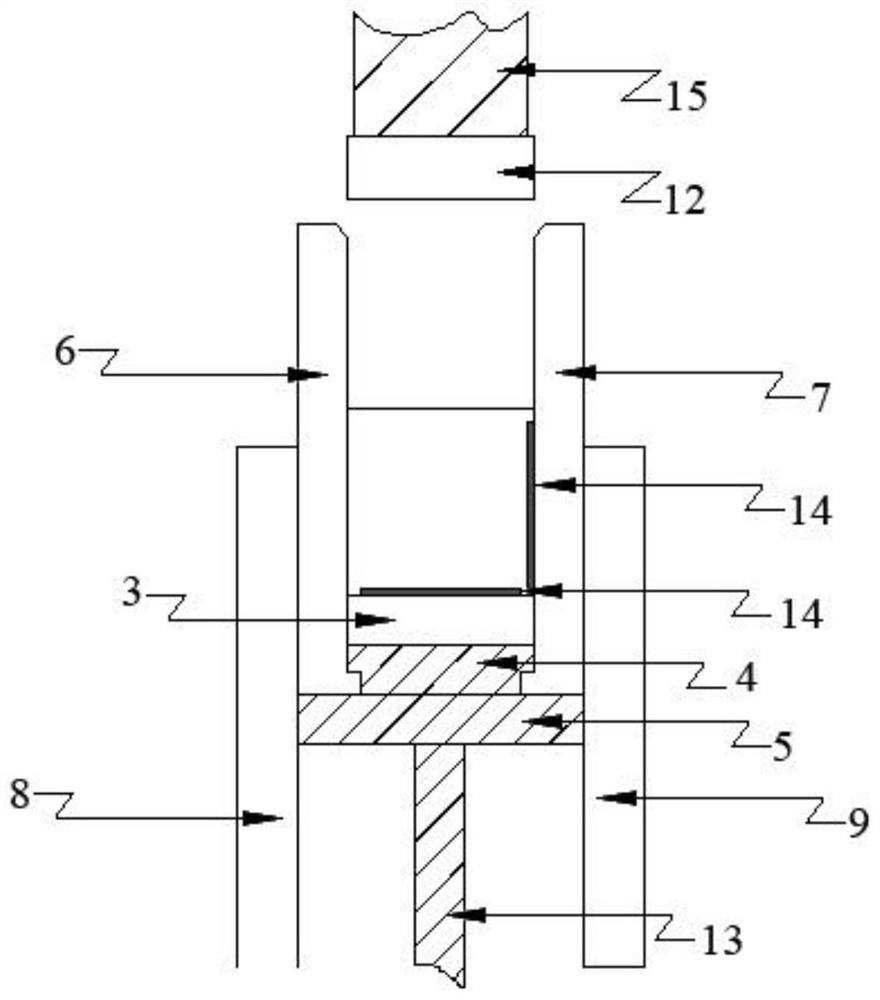

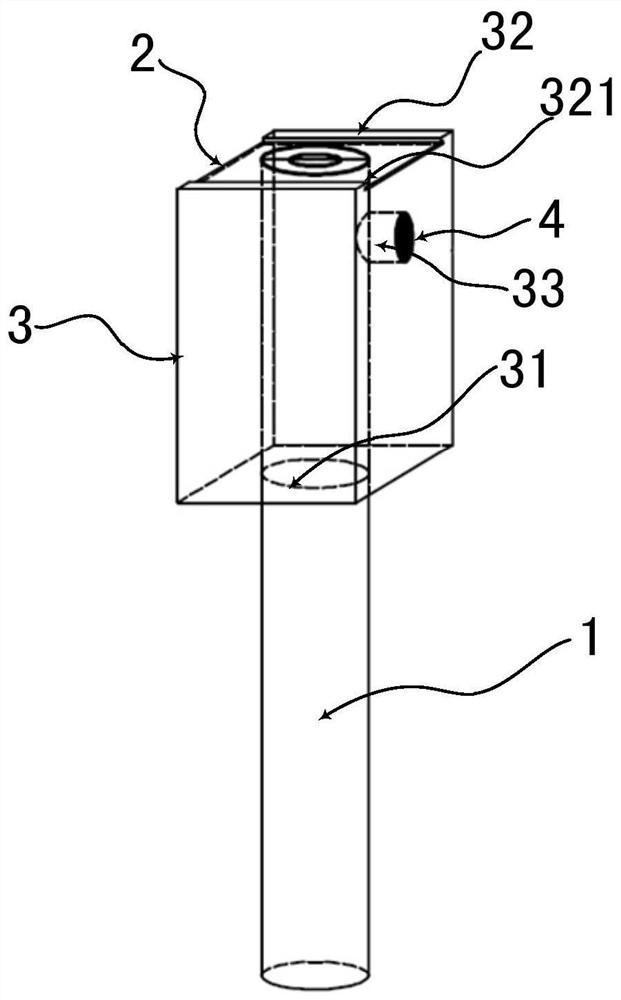

Cooler for cooling on-site welded joint of long steel rail and using method for cooler

InactiveCN102409585AGuarantee welding qualityGuarantee the quality of heat treatmentRailway track constructionAir volumeThermal deformation

The invention discloses a cooler for cooling an on-site welded joint of a long steel rail and a using method for the cooler. The cooler is characterized by comprising a walking support, a cooling fan and a cooling wind path distributing device, wherein the cooling wind path distributing device is fixed on the walking support; the cooling fan is arranged on the top of the cooling wind path distributing device; the cooling wind path distributing device has a bottomless empty tank shape; the lower part of the tank body is inwardly folded; wind path partitioning boards and a wind path switch are arranged in the tank; the wind path partitioning boards partition the tank body into a plurality of vertical spaces; and the tops of the wind path partitioning boards are moveably connected with the wind path switch. The using method comprises the following steps of: pushing the cooling wind path distributing device which is connected with an external power supply along the steel rail to a position above the on-site welded joint; turning on a switch of the cooling fan; distributing wind generated by the cooling fan to a part required to be cooled according to a certain sequence and a certain wind amount; and making the center of the cooling wind path distributing device uniformly swing within a range of 10cm around the welded joint so as to fulfill the aim of uniform cooling. The appearance of the welded joint is corrected by using a rule of thermal deformation in the cooling process, so that the appearance qualification rate of the welded joint is improved, the appearance polishing workload is reduced, and the product quality is improved.

Owner:中铁二十二局集团第二工程有限公司 +1

Method for cooling and sizing plastic profiles and device for realizing same

The invention discloses a method for cooling and sizing plastic profiles and a device for realizing same. The method comprises the following steps: firstly, the plastic profiles are extruded by an extruder, and then the first cooling and sizing are carried out on a first section of dry-type shaper by vacuum forming and injecting cooling water to a cooling hole; secondly, an open-type cooling tankis added behind the first section of dry-type shaper, the cooling tank is internally filled with coolants, and the plastic profiles are dissipated of heat and cooled by the coolants; and thirdly, a second section dry-type shaper is added behind the open-type cooling tank, the plastic profiles enter the second section of dry-type shaper after being dissipated of heat and cooled in the open-type cooling tank, and then second vacuum sizing and cooling are carried out. The existing dry-type shaper of the invention is divided into two parts for using, is matched with the open-type water tank reasonably simultaneously, which changes the view that improvement of cooling and sizing effect by a big margin can be realized only in the condition that the dry-type shaper is connected with other specialcooling devices. The invention is especially suitable for processing hollow plastic profiles similar with PVC buckles and the like.

Owner:成都市新湖装饰材料有限公司

Radiator core surface treatment equipment

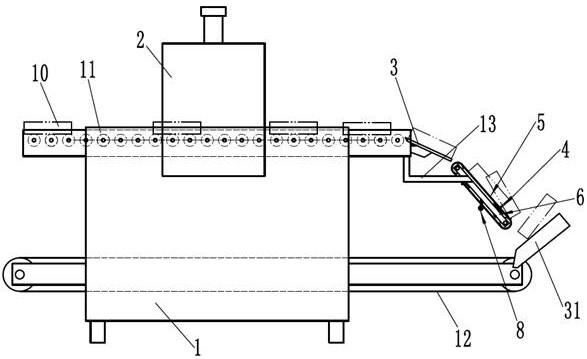

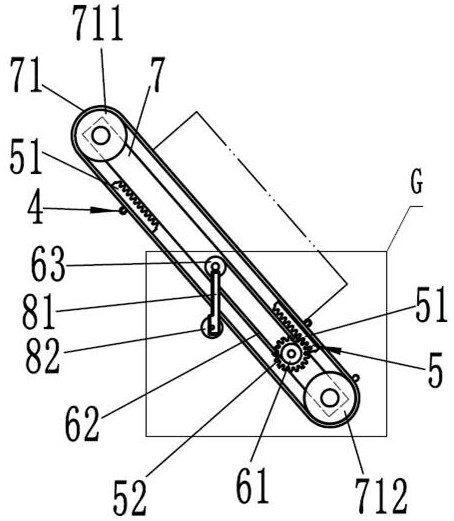

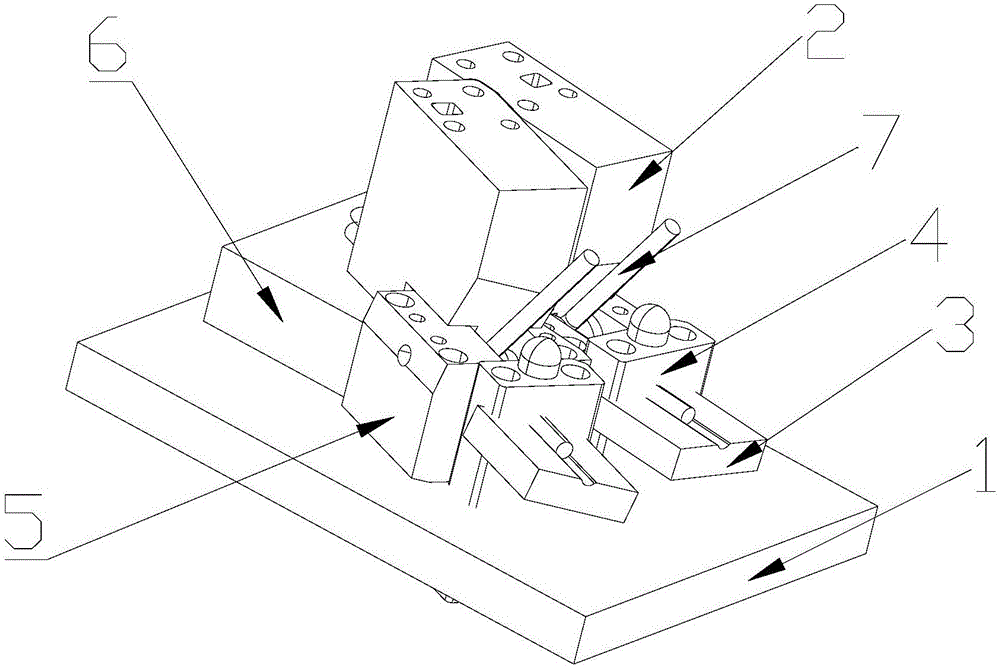

ActiveCN113104551AImprove processing efficiencyImprove appearance pass rateConveyorsGrinding feedersSlide platePhysics

The invention discloses radiator core surface treatment equipment. The equipment comprises a rack, a first conveying mechanism, a second conveying mechanism, a polishing machine, a sliding plate mechanism and an overturning device, wherein the first conveying mechanism and the second conveying mechanism are arranged at the upper end and the lower end of the rack respectively, the polishing machine is arranged at the upper end of the rack and located on one side of the first conveying mechanism, the sliding plate mechanism comprises an upper sliding plate and a lower sliding plate, the upper sliding plate is installed at the right end of the first conveying mechanism, the lower sliding plate is installed at the right end of the second conveying mechanism, the overturning device is installed at the right end of the first conveying mechanism and located between the upper sliding plate and the lower sliding plate, and an overturning mechanism can drive a radiating core to turn over. The equipment can improve the working efficiency, and can reduce the surface contact between the personnel and the radiating core, and therefore the yield is higher.

Owner:WENZHOU POLYTECHNIC

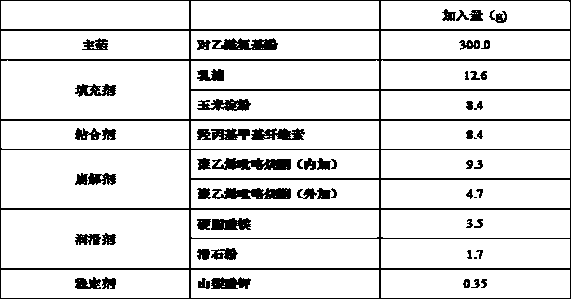

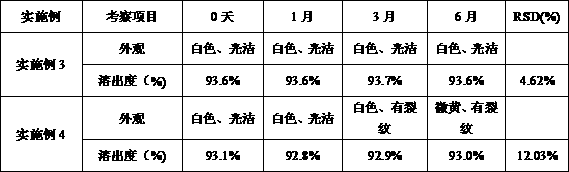

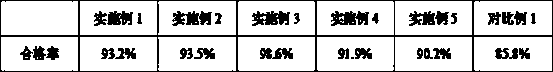

Paracetamol tablet and preparation method thereof

PendingCN111297813AImprove appearance pass rateSmooth appearanceOrganic active ingredientsAntipyreticTabletingOrganic chemistry

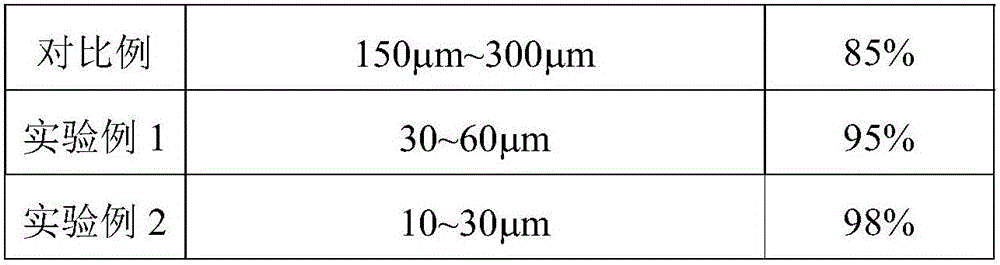

The invention discloses a paracetamol tablet. The paracetamol tablet is composed of paracetamol, a filler, a binder, a disintegrating agent, a lubricant and a stabilizer, wherein when an appropriate amount of stabilizer is added into the binder, the stability of the dissolution rate can be significantly improved. The invention also discloses a preparation method of the paracetamol tablet. The method uses a micronization technology to process the raw and auxiliary materials, so that the fusion of the raw and auxiliary materials can be improved, the tabletting time can be shortened, and the production costs can be saved. The finally prepared paracetamol tablet has a bright and clean appearance, a high dissolution rate, good stability and easy storage, and is suitable for large-scale industrial production.

Owner:GANSU LANYAO PHARMA CO LTD

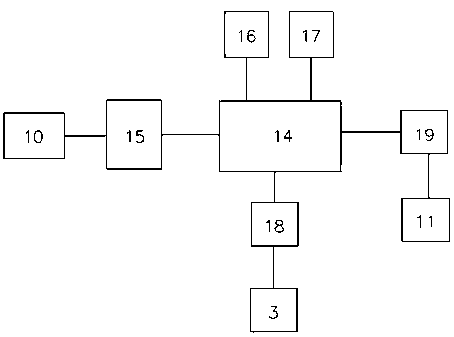

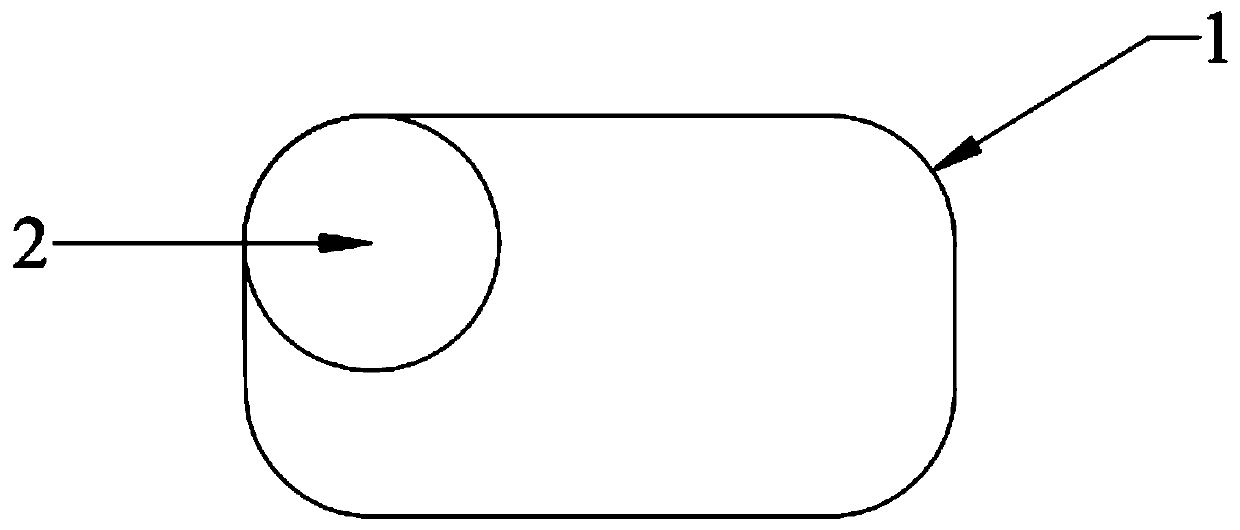

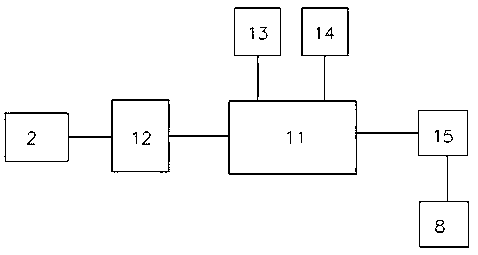

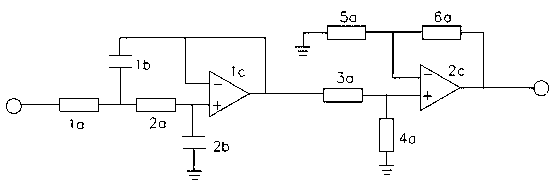

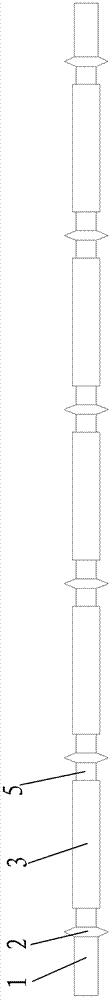

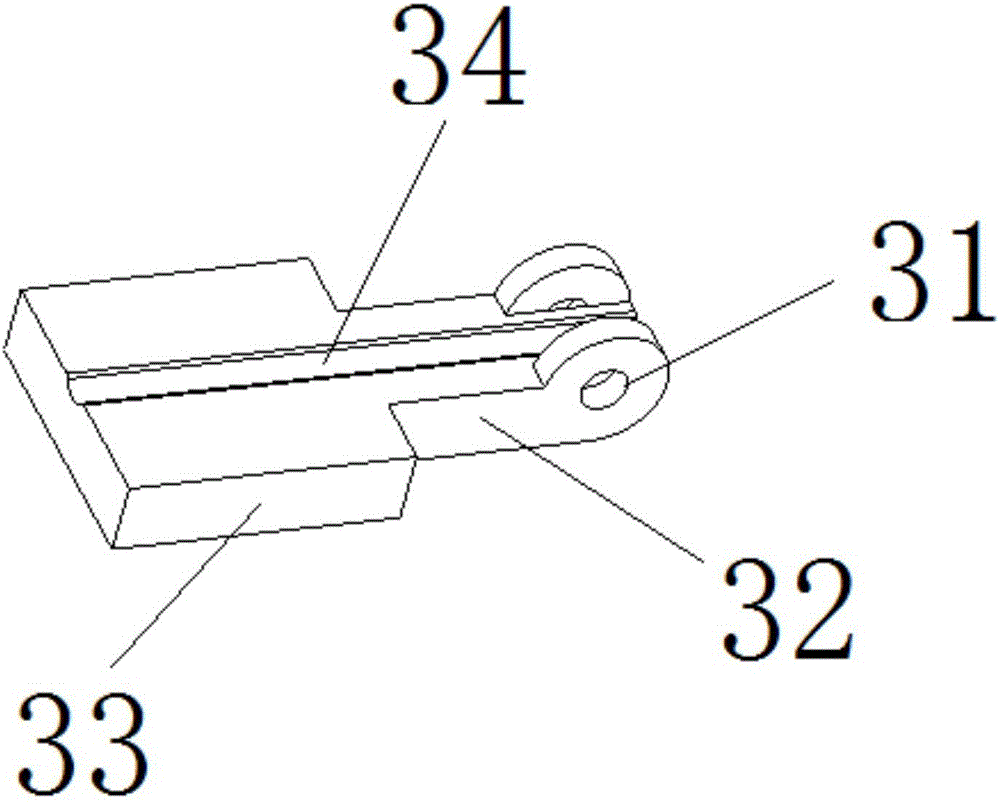

Shaft-type part appearance detection method based on linear camera

InactiveCN108872244AImprove appearance pass rateSimple structure and principleOptically investigating flaws/contaminationComputer terminalEngineering

The invention discloses a shaft-type part appearance detection method based on a linear camera. The shaft-type part appearance detection method comprises a fixed support, wherein the fixed support adopts a U-shaped structure, the fixed support is provided with a motor fixing frame, a rotating motor is installed on the motor fixing frame, a motor shaft of the rotating motor is connected with a rotating shaft, the outer end part of the rotating shaft is fixed on the center of a fixed plate, the fixed plate is installed on one side end surface of the to-be-detected shaft-type part, the to-be-detected shaft-type part is transversely arranged and is parallel to the ground, the inner side of the top of the fixed support is provided with a camera support and a switching plate, the camera supportis longitudinally provided with a channel, one end of the switching plate is fixedly connected with a bolt on the channel of the camera support, the other end is fixedly connected with a linear camera, the linear camera is arranged above the to-be-detected shaft-type part, the inner side of the bottom of the fixed support is provided with a backlight source, and the outer wall of the fixed supportis also provided with a monitoring terminal. The shaft-type part appearance detection method is simple in structure principle, capable of efficiently and precisely detecting the appearance of the shaft-type part, high in working efficiency, and capable of increasing the appearance qualification rate of the shaft-type part at the same time.

Owner:无锡九霄科技有限公司

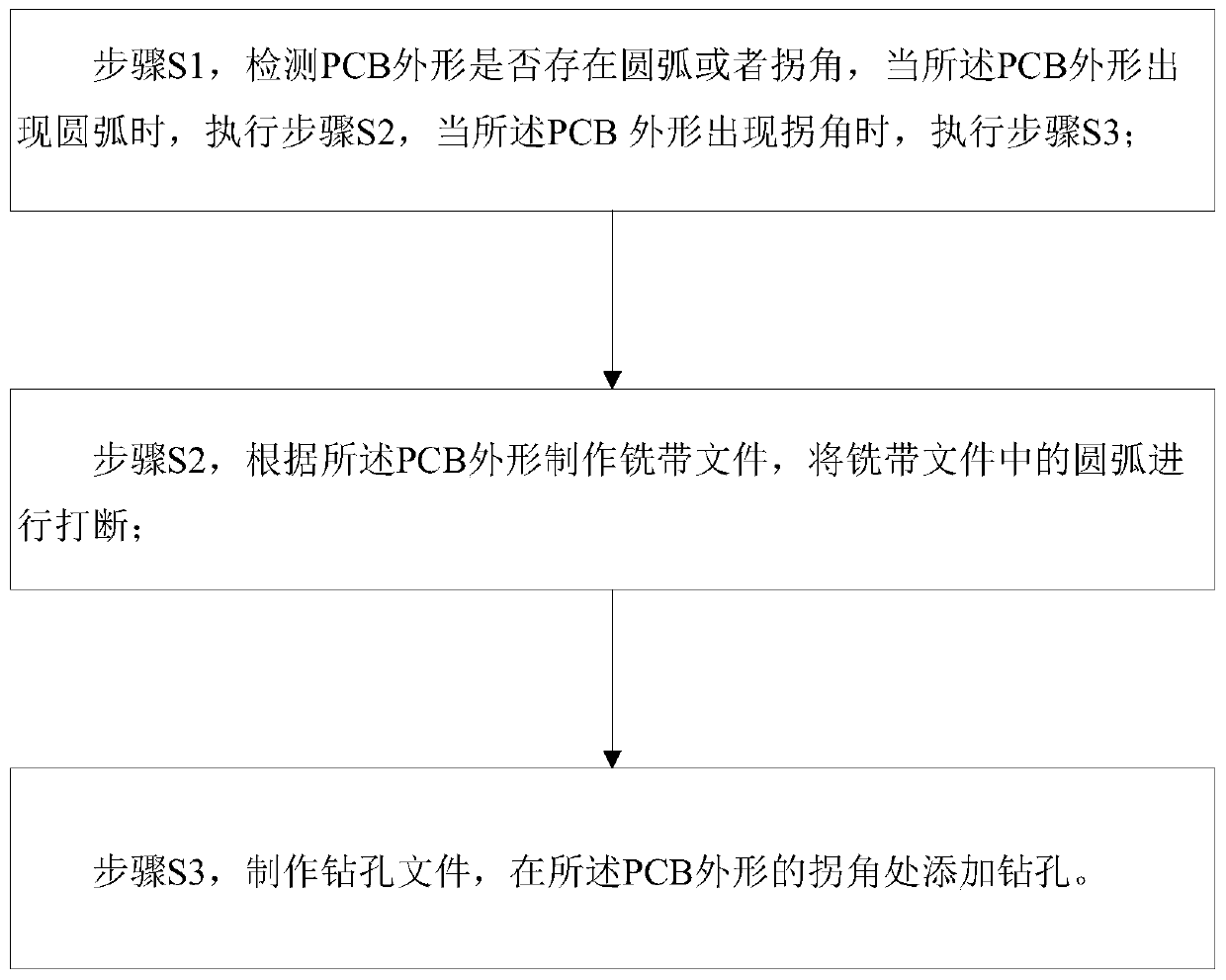

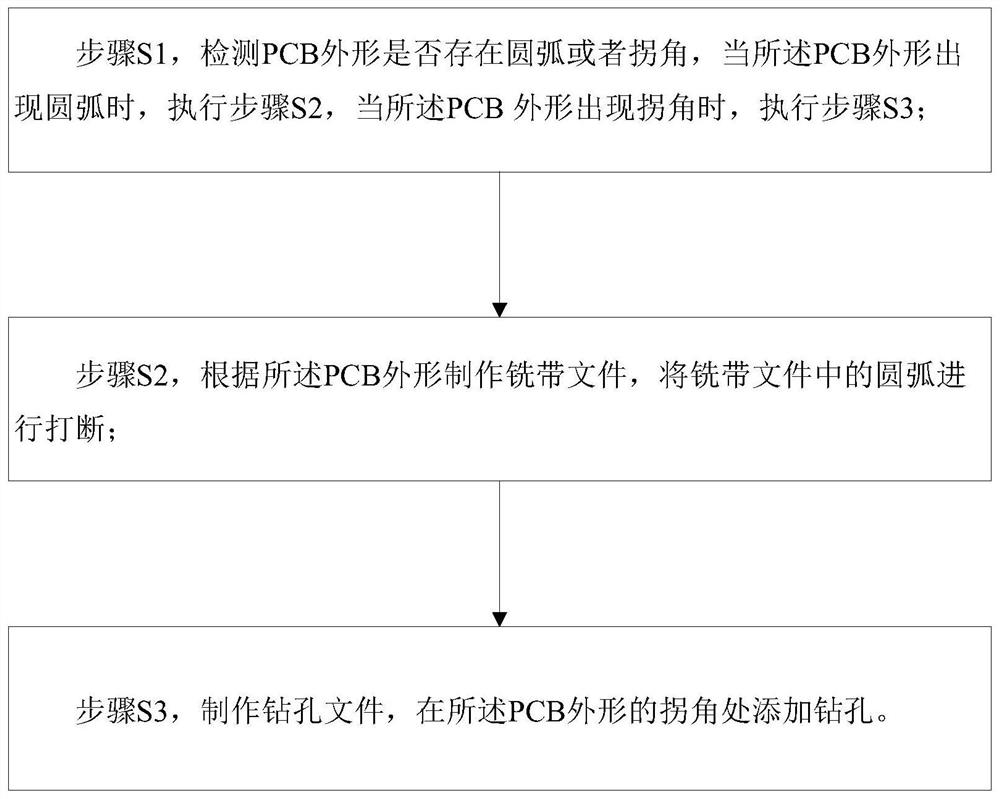

PCB outline machining method and device and readable storage medium

The invention discloses a PCB outline machining method and device and a readable storage medium. The method comprises the following steps of S1, detecting whether an arc or a corner exists on the outline of a PCB or not, when the arc exists on the outline of the PCB, executing a step S2, and when the corner exists on the outline of the PCB, executing a step S3; S2, making a milling tape file according to the outline of the PCB, and breaking the arc in the milling tape file; and S3, making a drilling file, and adding a drilling hole at the corner of the outline of the PCB. According to the method, by detecting whether the arc and the corner exist on the outline or not, the arc is automatically broken, the drilling hole is automatically added at the corner, manual intervention can be directly reduced, the error probability is reduced, the working efficiency is improved, the operation time of workers is shortened, the labor cost is greatly saved, and the percent of pass of the outlines isimproved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +1

A method for removing nodules on the hearth roll of a heat treatment furnace on-line

ActiveCN104896963BThe impact of reducing productivityThe generation of solutionIncrustation removal devicesNumerical controlMaterial resources

Owner:贝斯山钢(山东)钢板有限公司

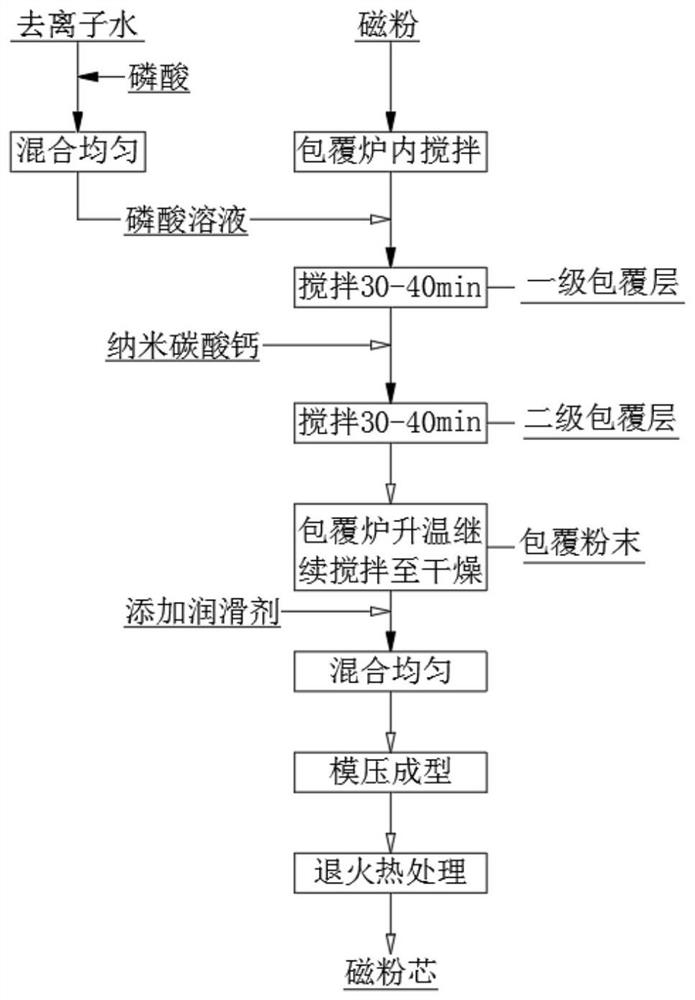

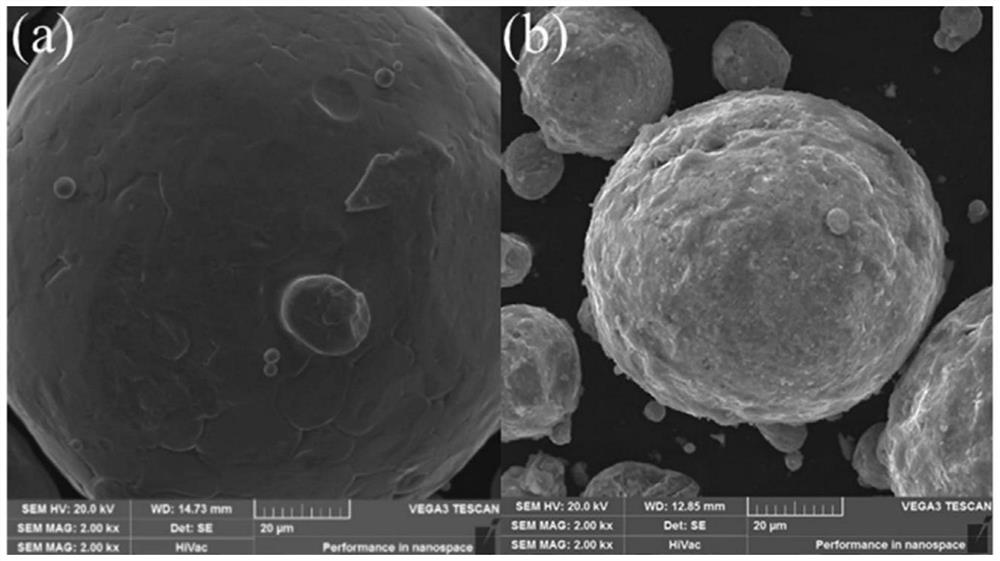

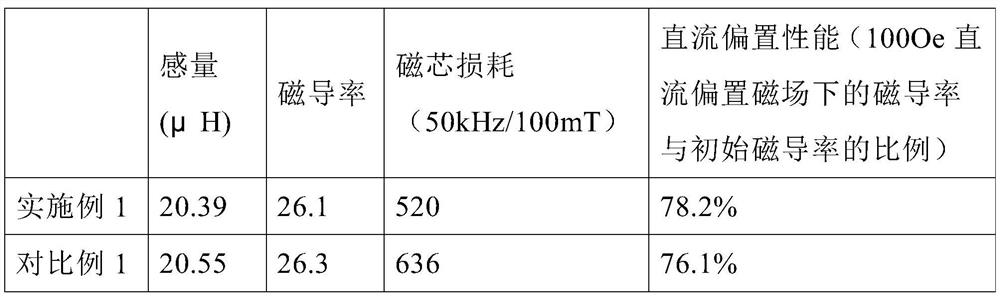

Method for secondary coating of a magnetic powder core with phosphoric acid and nano calcium carbonate

ActiveCN112185641AImprove insulation performanceReduce dosageInorganic material magnetismInductances/transformers/magnets manufactureO-Phosphoric AcidWeather resistance

The invention discloses a method for secondary coating of a magnetic powder core with phosphoric acid and nano calcium carbonate, which comprises the following steps: stirring and mixing magnetic powder and a phosphoric acid solution, reacting to obtain a Fe(H2PO4)2 primary coating layer on the surface of the magnetic powder, adding nano calcium carbonate, stirring and mixing, and reacting to obtain a Ca(H2PO4)2 secondary coating layer on the surface of the magnetic powder. According to the invention, double-layer coating is carried out on the surface of the magnetic powder, and nano calcium carbonate with high resistivity is filled among magnetic powder particles, so that the insulativity is very good; the use amount of insulators achieving the same insulation effect is small, and the direct-current bias performance is good; the used coating binding material is inorganic materials such as nano calcium carbonate and monocalcium phosphate Ca(H2PO4)2 generated by reaction, the binding performance is good, the forming is easy, the appearance qualification rate is high, meanwhile, the weather resistance is greatly improved, and the cost is greatly reduced; and the preparation equipmentis simple, easy to operate, low in cost and particularly suitable for industrial large-batch and large-scale production.

Owner:JIANGXI AITE MAGNETS +1

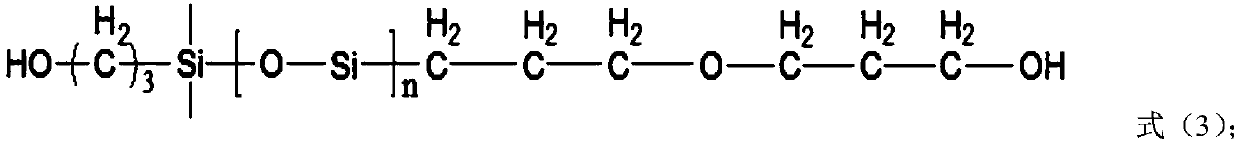

A kind of high cold-resistant polyurethane shock-absorbing pad and preparation method thereof

ActiveCN107602817BImprove shock absorptionExcellent dynamic fatigue resistancePolymer sciencePtru catalyst

The invention provides a high cold-resistant polyurethane shock-absorbing pad and a preparation method thereof. The polyurethane shock absorber is formed by mixing and crosslinking components A and B; wherein, component A is a polyol composition, including the following raw materials: caprolactone-modified polyether polyol, polyether polyol, terminal Hydroxy polybutadiene, terminal primary hydroxyl siloxane, chain extender, catalyst, foam stabilizer, foaming agent; B component is NCO blocked isocyanate prepolymer, including the following raw materials: caprolactone modified polyether Polyols, 4,4-diphenylmethane diisocyanate, side reaction inhibitors. The high cold-resistant polyurethane shock-absorbing pad prepared by the invention has good shock-absorbing performance and excellent dynamic fatigue resistance, and the low-temperature performance is significantly improved, and can be used in the construction fields of Moscow-Kazan high-speed railway and railways in cold regions such as Northern Europe and Siberia. And the field of automobile shock absorption in extremely cold regions.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

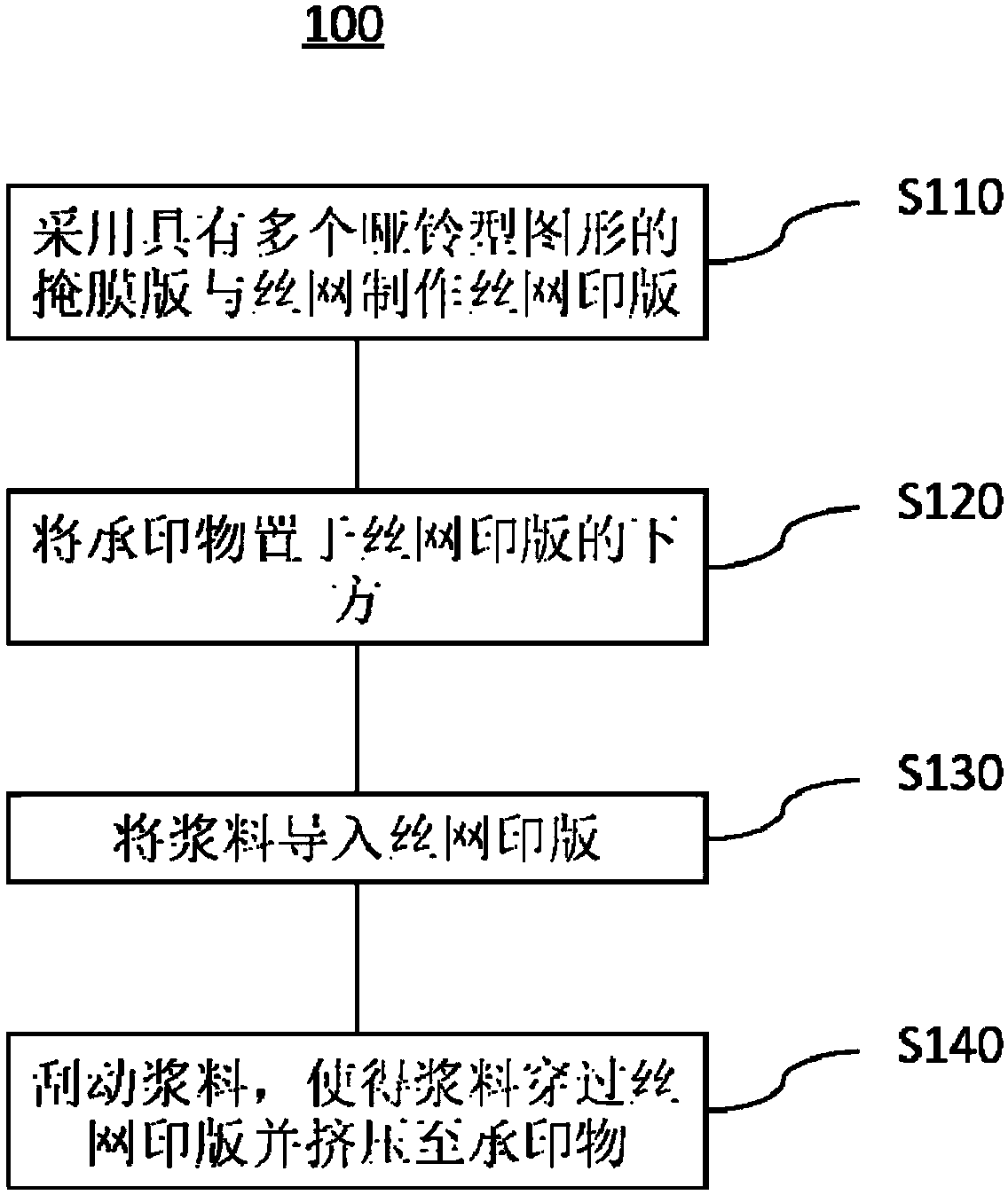

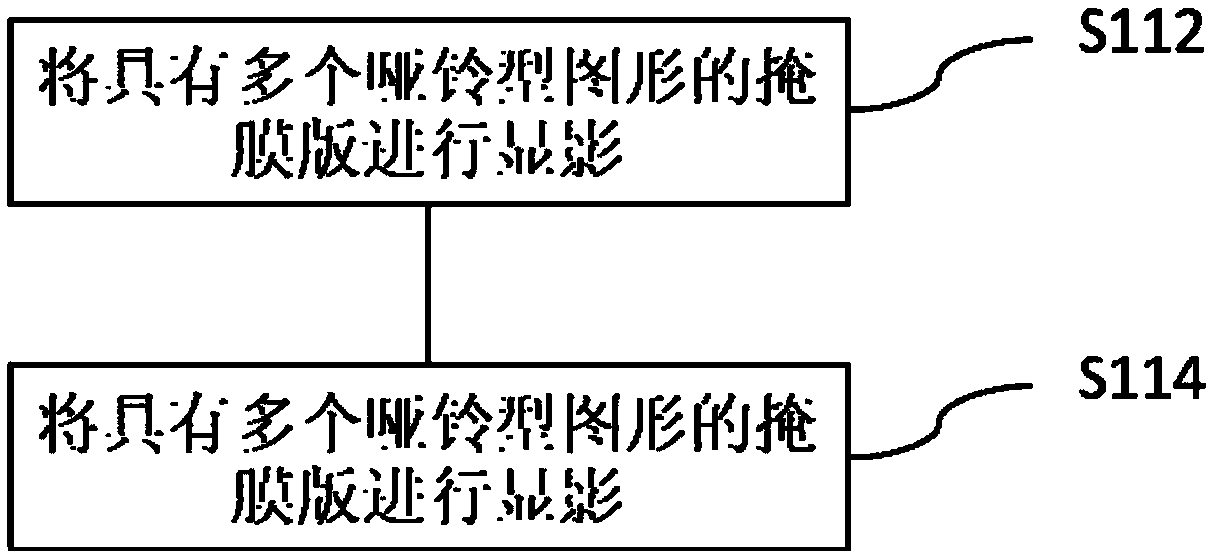

A screen printing method and resistor

InactiveCN108987009AGood consistency of resistance valueImprove appearance pass rateResistor manufactureOther printing apparatusScreen printingSlurry

The invention provides a screen printing method and a resistor, which relate to the field of patch resistors. A screen printing method comprises the steps of placing a substrate under a screen printing plate, wherein the screen printing plate is made of a mask plate having a plurality of dumbbell-shaped patterns, introducing a slurry into the screen printing plate, scraping the slurry so that theslurry passes through the screen printing plate and is squeezed to the substrate. By using the screen printing method, the resistor with good consistency of resistance value and high qualified rate ofproduct appearance can be obtained.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS +1

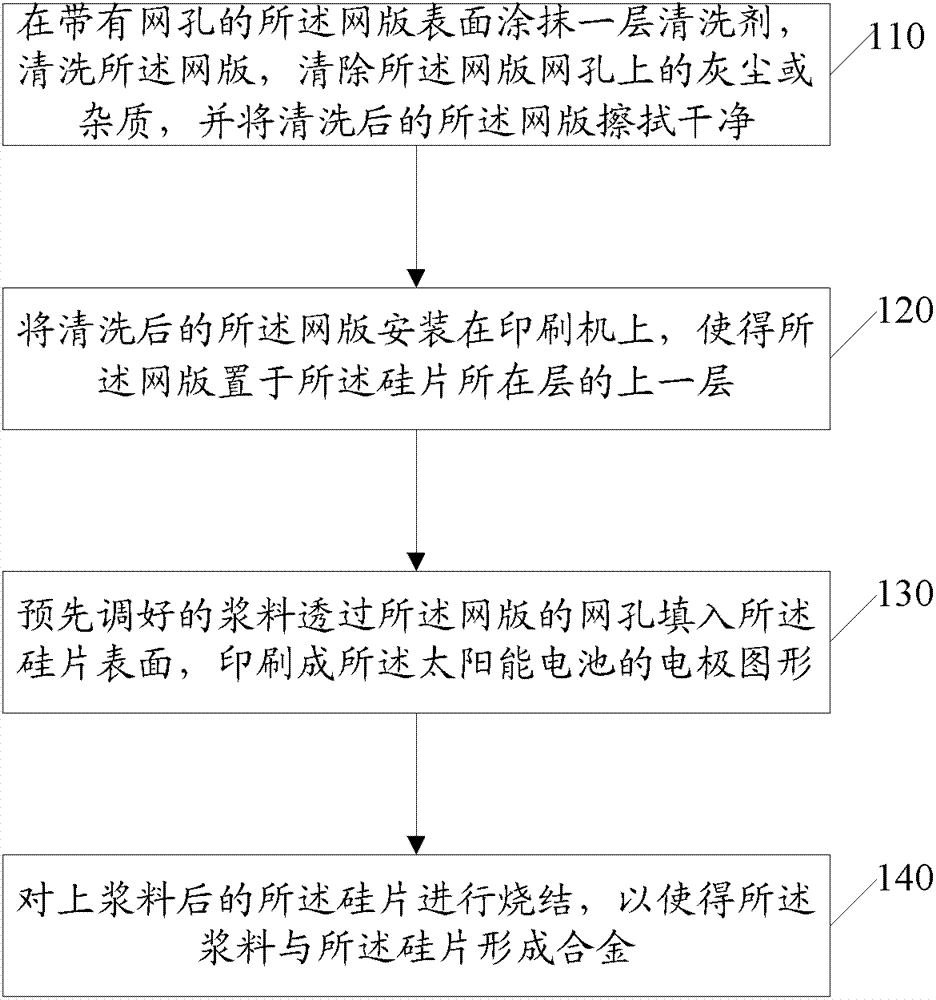

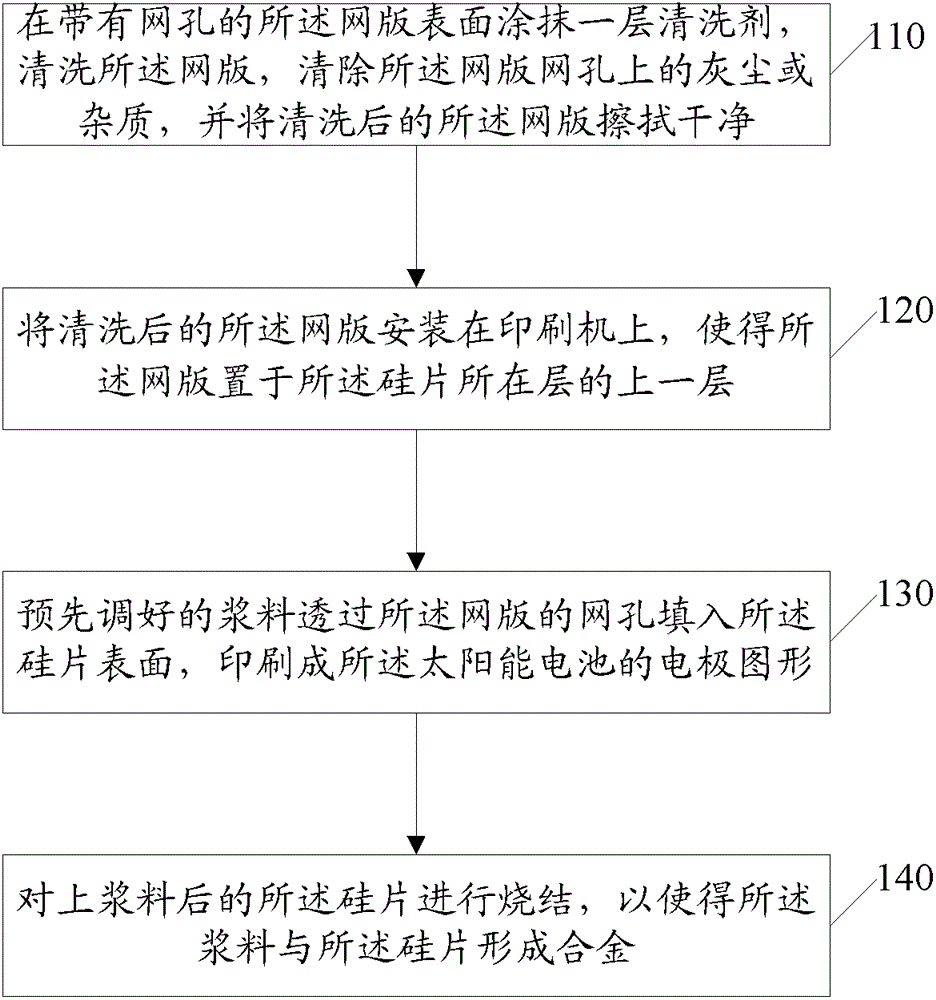

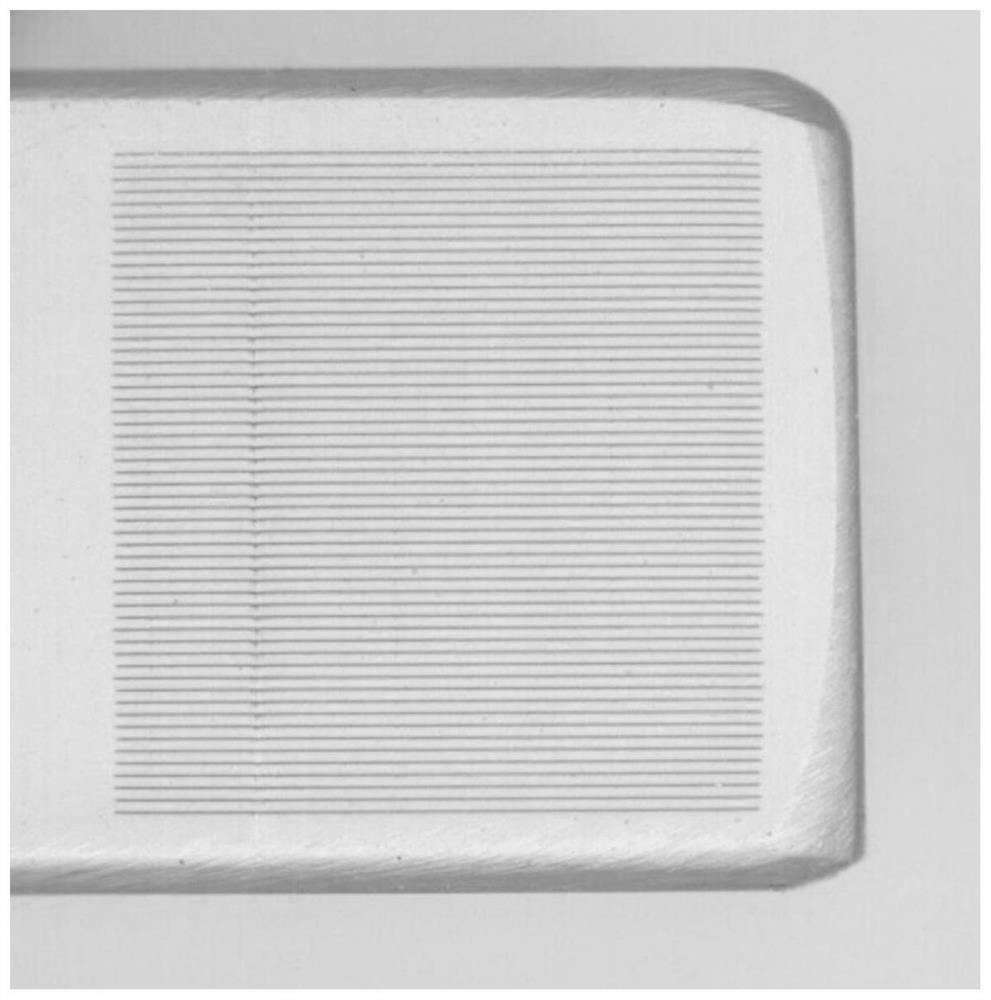

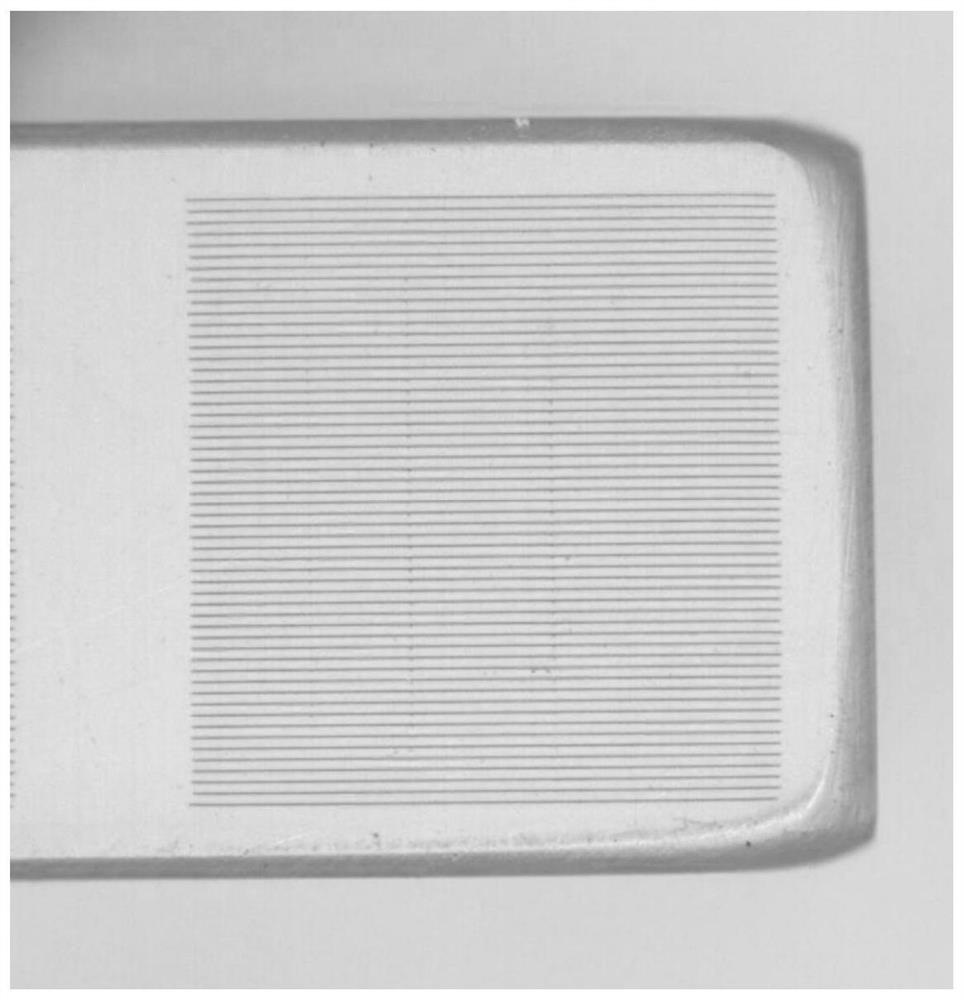

Optimizing process method of screen printing screen plate

ActiveCN103094400AImprove printing qualityImprove appearance pass rateScreen printersRenewable energy productsScreen printingEngineering

The invention discloses an optimizing process method of a screen printing screen plate. The method is used for printing a silicon wafer of a solar cell. The method includes that a layer of cleaning agents is coated on the surface of a screen plate with a hole, the screen plate is washed, dust or impurities in the hole of the screen plate are removed, the screen plate after being cleaned is wiped clean, the screen plate after being cleaned is installed on a printing machine, the screen plate is placed on a layer above the layer where the silicon wafer is located, slurry which is well mixed in advance is filled in the surface of the silicon wafer through the hole of the screen plate to be printed into the pattern of an electrode of the solar cell, and the silicon wafer with the slurry is sintered to enable the slurry and the silicon wafer to form alloy. Therefore, gate broken and other bad printing occasions occurring in screen plate printing are reduced, printing quality of the screen plate is improved, and the qualified rate of the appearance of the solar cell is improved.

Owner:JETION SOLAR HLDG

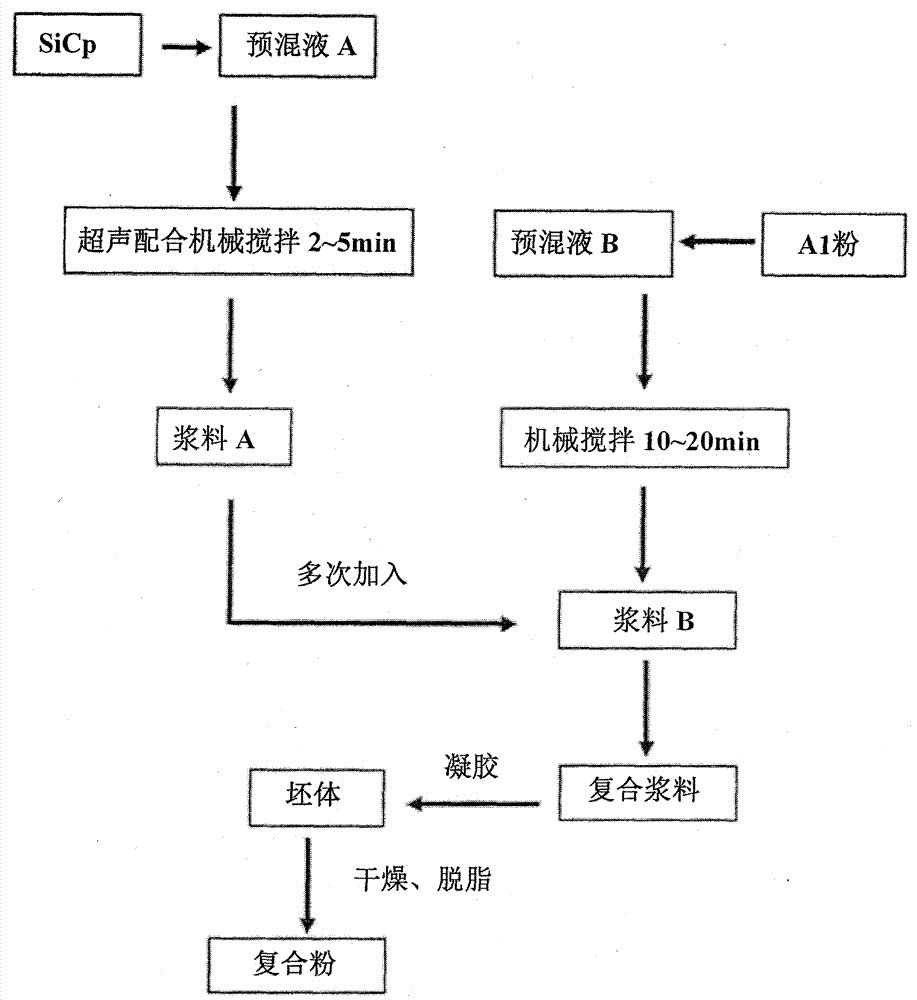

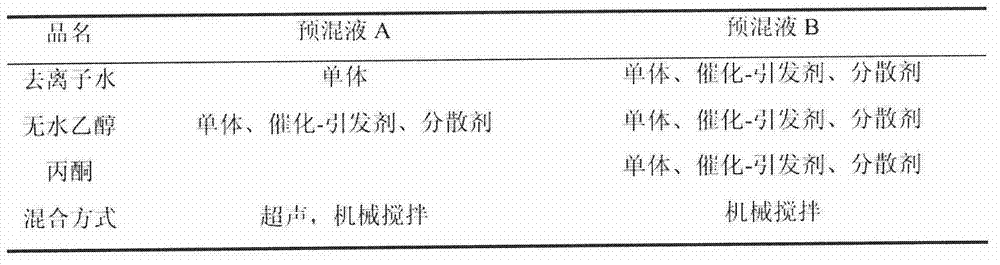

Gel method preparation process for SiC/Al composite powder

InactiveCN104841944AImprove uniformityImprove the use performance and product appearance qualification rateInstabilityGel method

The invention discloses a gel method preparation process for SiC / Al composite powder. The gel method preparation process for the SiC / Al composite powder includes the following steps that a premixed solution A and a premixed solution B with certain components are obtained through wet method mixing; 7.24 parts of SiC powder is added into the premixed solution A and stirred for 2-5 min through an ultrasonic blending machine, and a slurry A is obtained; 6.73 parts of Al powder is added into the premixed solution B and stirred for 10-20 min mechanically, and a slurry B is obtained; the slurry A is added into the slurry B multiple times and mixed for 20-30 min, then catalysts-initiators for catalyzing gel component gel-clot reaction are added, the slurry is promoted to be solidified to form a wet blank, and the process is less than 30 s; after the wet blank is dried and degreased, two-phase uniformly dispersed composite powder is obtained. Instability of mechanical properties caused by enhanced phase agglomeration in the composite materials is avoided, the enhanced phase proportion in the composite powder can be adjusted within the range of 5-38 percent, and the application range is enlarged.

Owner:SHENYANG LIGONG UNIV

Ferrite bead and preparation method thereof

ActiveCN106816264AAvoid depositionImprove appearance pass rateInductances/transformers/magnets manufactureFixed signal inductancesMetal coatingAfter treatment

The invention discloses a ferrite bead and a preparation method thereof. The method for preparing the ferrite bead comprises the following steps: S1, preparing a ferrite bead semi-finished product, wherein a magnet in the ferrite bead semi-finished product is formed by sintering a ferrite material, and a silver electrode is arranged on the magnet; S2, performing high-temperature treatment on the ferrite bead semi-finished product in a furnace with the oxygen volume fraction being 60-95% at the temperature of 400-600 DEG C for 2-10 hours, and performing furnace cooling after treatment is ended; and S3, performing electroplating treatment on the ferrite bead semi-finished product treated in S2, and depositing a metal coating on the electrode of the ferrite bead semi-finished product, thereby obtaining the ferrite bead. According to the preparation method disclosed by the invention, the appearance yield of the prepared product can be improved, and the manufacturing cost is low.

Owner:SHENZHEN SUNLORD ELECTRONICS

A kind of repair method of roasting furnace

ActiveCN109855430BReduced safety risk of cloggingInsulation against direct scour erosionLinings repairGas emission reductionGlass fiberFiber

The invention discloses a roaster repairing method. The roaster repairing method specifically comprises the following steps that a high-pressure water gun is used for cleaning the surface of a roaster, a hidden and infirm coating on the surface of the roaster is removed, and a firm coating is reserved; silica sol is sprayed through the high-pressure water gun; a spraying machine is used for spraying a first layer of spraying materials on the pretreated roaster surface; when the first layer of spraying materials are thick, a layer of glass fiber or carbon fiber is sprayed to the first layer ofspraying materials; after the first layer of spraying materials are dried, the spraying machine is used for spraying a second layer of spraying materials; and after the second layer of spraying materials are dried, if fine cracks are generated, the spraying machine is used for spraying the first layer of spraying materials, and slight cracks are filled. Through successful application of the disclosed roaster repairing method, safety risks caused by fire path blockage during roasting are effectively reduced, the labor intensity of personnel is effectively reduced, generation of roasting waste blocks can be reduced as well, the natural gas consumption rate during roasting is reduced, and the effect is obvious in the aspects of energy saving and consumption reducing.

Owner:安阳市上鑫炉业有限公司

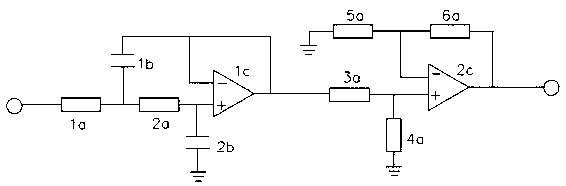

Endoscopic cavity component appearance detection method based on line-scan digital camera

InactiveCN108663372AEasy to analyze and judgeImprove efficiencyOptically investigating flaws/contaminationComputer terminalEngineering

The invention discloses an endoscopic cavity component appearance detection method based on a line-scan digital camera. According to the method, a fixing bracket and a line-scan digital camera are mounted; the fixing bracket is of a U-shaped structure; a camera fixing column is mounted on the left side inside the fixing bracket; the camera fixing column is arranged perpendicular to the inner wallof the fixing bracket; one end of the camera fixing column extends into the inner cavity of a component to be detected; the component to be detected is of a hollow structure; the line-scan digital camera is fixedly mounted at one end of the camera fixing column; the right end of the component to be detected is fixed inside a clamping ring; a rotating shaft is fixedly connected with the middle of the outer side of the clamping ring; the rotating shaft is connected with a rotating motor which is arranged on a motor fixing rack; the motor fixing rack is mounted on the right side inside the fixingbracket; a monitoring terminal is mounted on the outer wall of the fixing bracket. The endoscopic cavity component appearance detection method is simple in structure principle and convenient to use,high-efficiency and high-precision detection on the appearance of the inner wall of an endoscopic cavity component can be achieved, the working efficiency is improved, and meanwhile, the component appearance pass percent can be increased.

Owner:无锡九霄科技有限公司

Cooler for cooling on-site welded joint of long steel rail and using method for cooler

InactiveCN102409585BGuarantee welding qualityGuarantee the quality of heat treatmentRailway track constructionThermal deformationEngineering

The invention discloses a cooler for cooling an on-site welded joint of a long steel rail and a using method for the cooler. The cooler is characterized by comprising a walking support, a cooling fan and a cooling wind path distributing device, wherein the cooling wind path distributing device is fixed on the walking support; the cooling fan is arranged on the top of the cooling wind path distributing device; the cooling wind path distributing device has a bottomless empty tank shape; the lower part of the tank body is inwardly folded; wind path partitioning boards and a wind path switch are arranged in the tank; the wind path partitioning boards partition the tank body into a plurality of vertical spaces; and the tops of the wind path partitioning boards are moveably connected with the wind path switch. The using method comprises the following steps of: pushing the cooling wind path distributing device which is connected with an external power supply along the steel rail to a position above the on-site welded joint; turning on a switch of the cooling fan; distributing wind generated by the cooling fan to a part required to be cooled according to a certain sequence and a certain wind amount; and making the center of the cooling wind path distributing device uniformly swing within a range of 10cm around the welded joint so as to fulfill the aim of uniform cooling. The appearance of the welded joint is corrected by using a rule of thermal deformation in the cooling process, so that the appearance qualification rate of the welded joint is improved, the appearance polishing workload is reduced, and the product quality is improved.

Owner:中铁二十二局集团第二工程有限公司 +1

Method, device and readable storage medium for processing pcb shape

ActiveCN109822294BSave operating timeReduce manual interventionProcess engineeringMechanical engineering

The invention discloses a PCB shape processing method, device and readable storage medium. The method includes: step S1, detecting whether there is a circular arc or a corner in the PCB shape, and when the PCB shape has a circular arc, execute step S2, when When a corner appears in the PCB shape, execute step S3; step S2, make a milling tape file according to the PCB shape, and interrupt the arc in the milling tape file; step S3, make a drilling file, and insert Add drill holes at the corners of the . When the present invention detects whether there are circular arcs and corners in the shape, the circular arc is automatically interrupted, and drilling holes are automatically added at the corners, which can directly reduce manual intervention, reduce the probability of error, improve work efficiency, shorten the operating time of personnel, and greatly save Reduce labor costs and improve the appearance qualification rate.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +1

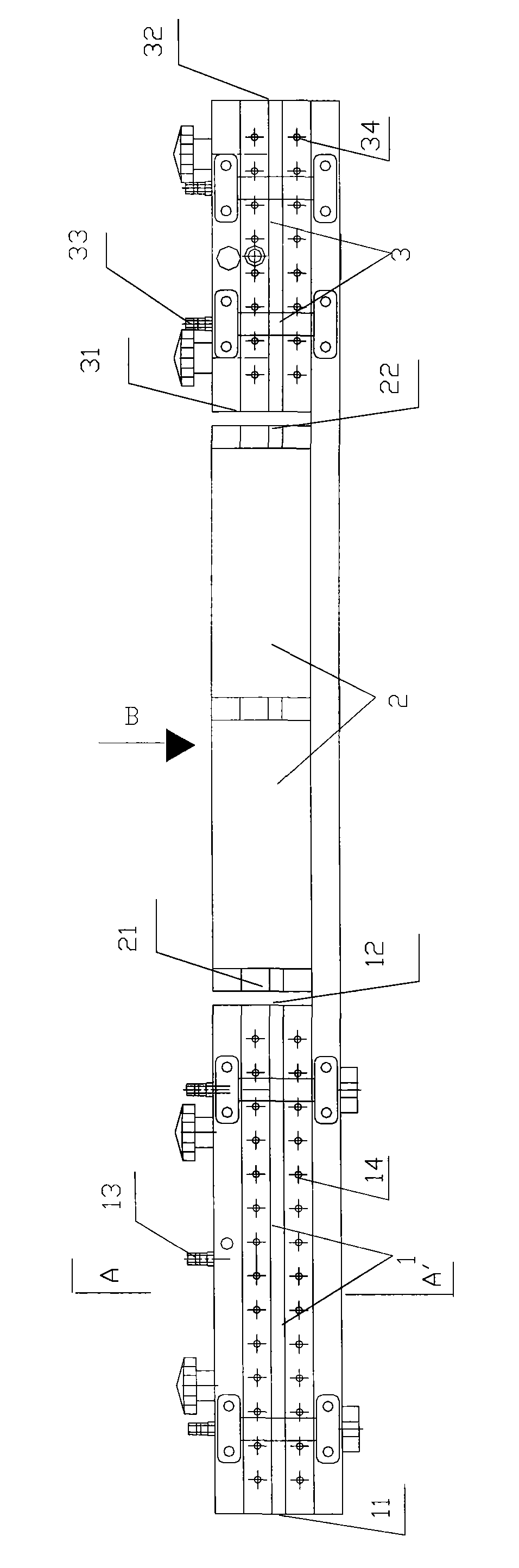

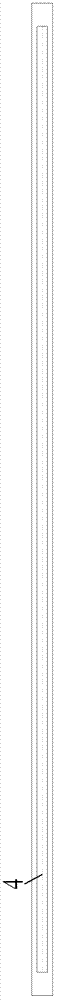

Transmission and air-drying structure of polycrystalline silicon wafer flocking machine

ActiveCN103000747BImprove appearance pass rateFinal product manufactureSemiconductor devicesAir knifeEngineering physics

The invention discloses a transmission and air-drying structure of a polycrystalline silicon wafer flocking machine. The transmission and air-drying structure comprises a rotatable transmission shaft, joints, rollers and downwind openings. The joints are equidistantly arranged along the axial direction of the transmission shaft, radial sizes of the joints are identical, the middle of a connecting shaft section between each two joints is circumferentially protruded to form the corresponding roller, the axial length of each roller is larger than the side length of a polycrystalline silicon wafer, the circular or long and narrow downwind openings are arranged below the rollers, and the polycrystalline silicon wafer is in linear contact with the rollers. The lower surface of the polycrystalline silicon wafer can be quickly air-dried under the action of air knives blown out from the downwind openings after the polycrystalline silicon wafer is discharged from a flocking groove, roller marks are prevented, and the appearance qualified rate of the manufactured polycrystalline silicon wafer is increased.

Owner:NANTONG SHENGYANG ELECTRIC CO LTD

Distortion of front faceplate protected back projective TV set

InactiveCN1333588CCan be increased by degreesImprove appearance pass rateTelevision system detailsPicture reproducers using projection devicesEngineeringDistortion

The invention includes base of back projector at bottom and front faceplate fixed on the base. U shaped trough is made on the middle of upper part of the base. Characters are that a sheet metal bracket in inverse U shape for supporting front faceplate is fixed on the said U-shaped trough; upper and middle parts of the front faceplate are fixed on the sheet metal bracket. By sheet metal bracket with good rigidity being added, the disclosed structure enhances rigidity of the front faceplate at middle part. The said projector provides large quantity of anti pressing on the front faceplate, and no happening ridgy distortion so as to raise acceptability for appearance of the front faceplate, and make users more satisfaction.

Owner:HISENSE +1

A method of manufacturing an axial diode

ActiveCN110085541BLow costImprove appearance pass rateSolid-state devicesSemiconductor/solid-state device manufacturingWaferingElectrical testing

The invention discloses a manufacturing method of an axial diode, comprising the following steps: 1. Wafer cutting→2. Welding and assembling→3. High-temperature welding→4. Plastic sealing and forming→5. Lead-free electroplating→6. Electrical test braiding →7. Laser printing →8. Packaging. Due to the laser printing method for printing, the original 5H cooking work before lead-free electroplating is avoided. At the same time, consumables such as ink for ink printing and printing molds are no longer required to be purchased, which can reduce product costs and improve product appearance. Improve the product appearance quality level, improve the product appearance production pass rate by more than 1%, reduce product costs, and greatly improve the product appearance quality, thereby improving product quality.

Owner:QIANGMAO ELECTRONICS WUXI CO LTD

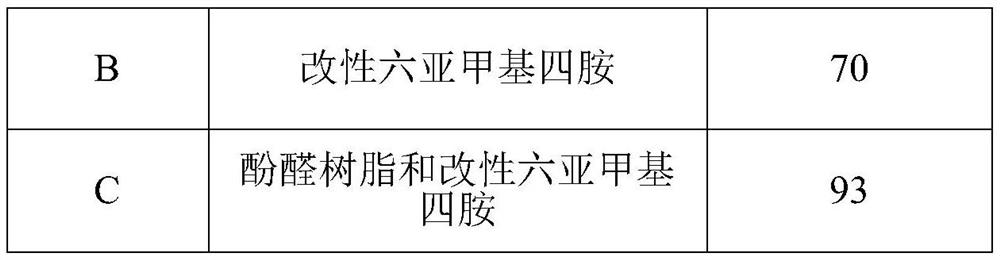

Formula of high-hardness easy-to-produce nitrile rubber

PendingCN114524980ATraffic density increasedHardness drop rate reducedRubber materialPolymer science

The invention discloses a high-hardness easy-to-produce nitrile rubber formula, and relates to the technical field of rubber production research. The formula of the NBR comprises the following raw materials: 33.0 parts of NBR + PVC rubber and plastic alloy; 36.0 parts of carbon black; 1.7 parts of a softening agent; 3.0 parts of an active agent; 2.9 parts of an anti-aging agent; 1.2 parts of a vulcanization accelerator; 3.0 parts of phenolic resin; and 0.6 part of modified hexamethylenetetramine. According to the high-hardness easy-to-produce NBR formula disclosed by the invention, when the high-hardness easy-to-produce NBR formula is used for producing rubber, the addition amount of carbon black is properly reduced, the fluidity requirement of a rubber material is reasonably adjusted, phenolic resin and modified hexamethylenetetramine are added, and the material and rubber macromolecules are chemically crosslinked during high-temperature vulcanization, so that the crosslinking density is increased, and the hardness reaches 90 degrees or above; and after the product is heated, the hardness reduction rate is greatly reduced.

Owner:CHONGQING LINGFENG RUBBER PROD

An optimized processing method for screen printing screen

ActiveCN103094400BImprove printing qualityImprove appearance pass rateFinal product manufactureScreen printersScreen printingAlloy

The invention discloses an optimizing process method of a screen printing screen plate. The method is used for printing a silicon wafer of a solar cell. The method includes that a layer of cleaning agents is coated on the surface of a screen plate with a hole, the screen plate is washed, dust or impurities in the hole of the screen plate are removed, the screen plate after being cleaned is wiped clean, the screen plate after being cleaned is installed on a printing machine, the screen plate is placed on a layer above the layer where the silicon wafer is located, slurry which is well mixed in advance is filled in the surface of the silicon wafer through the hole of the screen plate to be printed into the pattern of an electrode of the solar cell, and the silicon wafer with the slurry is sintered to enable the slurry and the silicon wafer to form alloy. Therefore, gate broken and other bad printing occasions occurring in screen plate printing are reduced, printing quality of the screen plate is improved, and the qualified rate of the appearance of the solar cell is improved.

Owner:JETION SOLAR HLDG

A kind of preparation method of bulk neodymium iron boron

ActiveCN106601400BSmall amount of deformationSmooth degassingInductances/transformers/magnets manufactureMagnetic materialsHydrogen contentEngineering

The invention relates to a preparation method for chunk neodymium iron boron. The preparation method is characterized by comprising the steps of designing multiple convex points which are distributed in a central symmetry manner on an upper pressing surface of a pressing blank during designing the pressing blank of a chunk magnet; designing concave points, corresponding to the convex points designed on the upper pressing surface of the pressing blank, on a surface, corresponding to the upper pressing surface of the pressing blank, of a die when the die is designed; installing the die, and completing powder weighing, pressing, packaging and isostatic pressing to obtain the pressing blank which can be put into a sintering furnace; and enabling the surface, having the convex points, of the pressing blank to be in contact with a sintering basin, forming an interval between the magnet and the sintering basin, and completing sintering. The preparation method has the advantages as follows: by increasing the convex points on the surface of the chunk magnet, the friction force between the magnet and the sintering basin is reduced in the sintering process, and the magnet deformation is lowered; and meanwhile, smooth degasification of the magnet in the sintering process is realized, so that carbon and hydrogen contents in the magnet are reduced, thereby improving the brittleness and magnetic property of the magnet.

Owner:BAOTOU YUNSHENG STRONG MAGNETIC MATERIAL +1

Preparation method of large-size metal-skin refractory bricks and movable mold of large-size metal-skin refractory bricks

ActiveCN113635433APress evenlyEven force up and downDischarging arrangementMould auxillary partsFire brickRefractory

The invention discloses a preparation method of large-size metal-skin refractory bricks and a mold of the large-size metal-skin refractory bricks, and belongs to the technical field of refractory materials. The mold comprises a mold sleeve, mold base plates, a mold bottom plate, a mold false bottom, a mold bottom supporting plate, mold movable side plates, mold side plates, mold end plates and a mold cover plate. According to the method, the refractory bricks are designed to be stressed up and down, so that the pressing stress uniformity is improved, sufficient pressure is guaranteed, and cracking is avoided; the metal skin wrapping firmness is improved by designing a metal skin special-shaped claw; metal skin is protected through a special mold; the mold movable side plates and the metal skin achieve synchronous movement, so that metal skin deformation or friction scratches are avoided; and meanwhile, a grinding tool is protected, and the service life of the grinding tool is prolonged, so that the preparation qualification rate and production efficiency are improved.

Owner:YINGKOU PUNAI MAGNESIUM MATERIALS CO LTD

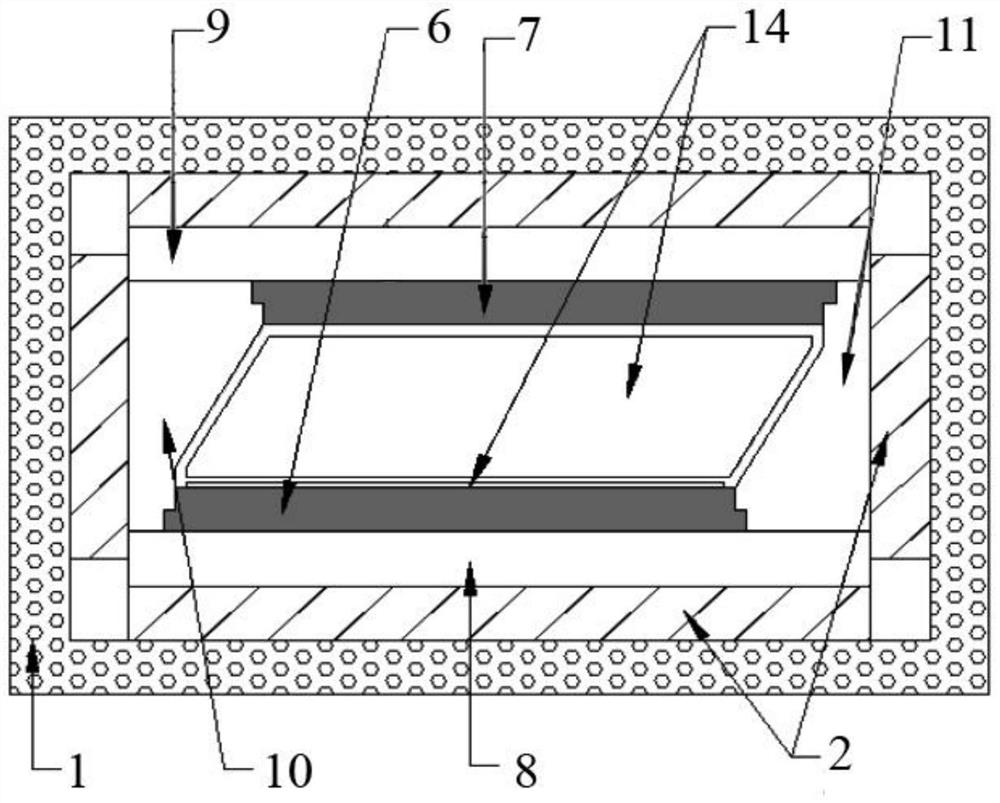

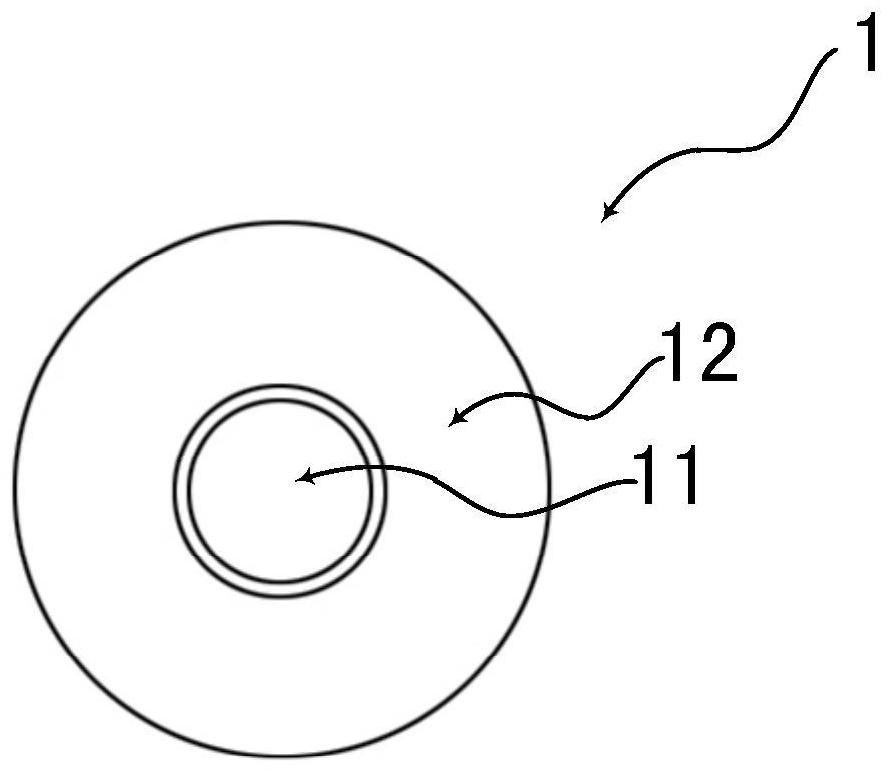

End face pattern centering detection device for coaxial core filter rod

ActiveCN112212808BPrevent tamperingImprove detection stabilityUsing optical meansStructural engineeringMechanical engineering

The invention provides an end face pattern centering degree detection device for a coaxial core filter rod. The coaxial core filter rod includes an inner core and an outer core wrapped around the outer circumference of the inner core. The end surface pattern centering degree detection device includes: contrast transparent The standard outer core pattern that is the same as the end face pattern of the outer core and the standard inner core pattern located at the center of the standard outer core pattern are printed on the control transparent sheet; The central hole through which the filter rod passes, the diameter of the central hole is adapted to the diameter of the coaxial core filter rod, and the main body of the device has a clamping structure for adding a contrast transparent sheet, so that the contrast transparent sheet is vertically sealed in the central hole on a port. Through the device for detecting the centering degree of the end face pattern of the coaxial core filter rod of the present invention, the inspector can quickly and accurately detect the centering degree of the inner core of the coaxial core filter rod in the appearance inspection of the coaxial core filter rod.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Plate turnover forming device for inclined tubes

The invention discloses a plate turnover forming device for inclined tubes. The plate turnover forming device comprises a base and one or more forming mechanisms, wherein each forming mechanism comprises a forming press plate, a turning plate, an ejector block and a rotating shaft block; the ejector block and the rotating shaft block are fixed on the base; the turning plate is rotationally connected with the rotating shaft block; the ejector block is arranged at the end part of the rotating shaft block, and propped against the turning plate in a process of movement; the whole turning plate is platy; a first groove matched with the shape of an inclined tube product is formed in the middle part of the turning plate; a second groove matched with the shape of the inclined tube product is formed in the lower part of the forming press plate; and under the control of an upper die, the forming press plate drives the inclined tube product to move downward. The plate turnover forming device is simple in structure, and has the advantages that the forming mode is changed from traditional point contact to surface contact, thereby ensuring uniform stress when the inclined tube product is formed; stress points are distributed on the whole surface of the inclined tube product, so that abrasion to the inclined tube product can be reduced to the greatest extent; the operation is convenient, the product appearance qualification ratio is improved, and the die maintenance cost is saved; and meanwhile, the plate turnover forming device is easily maintained by field staff and the working efficiency is improved.

Owner:SUZHOU VICTORY PRECISION MFG

A grinding process and preparation method for large-scale products of multilayer ceramic capacitors

ActiveCN112975583BQuality improvementImprove appearance pass rateCeramic shaping apparatusCapacitor manufactureCeramic capacitorElectronic component

The invention relates to the field of electronic component manufacturing, in particular to a grinding process and preparation method for large-scale products of multilayer ceramic capacitors. The grinding process includes the following process steps: S100, medium temperature treatment before sintering of the product: the treatment temperature is 625-725°C; S200, fine grinding on the machine after the medium temperature treatment: the grinding medium is white corundum powder, and the product and white The volume ratio of corundum powder is 1:2; its operation curve is: 4.5-5.5h at a speed of 4-8rpm, 4.5-5.5h at a speed of 14-18rpm, and 40-50h at a speed of 23-27rpm. It improves the overall quality of the product, ensures the consistency of the product, and improves the appearance qualification rate of the product; the internal micro-cracks of the product are reduced, and the loss tangent value is reduced; the surface smoothness of the product is increased, and the pressure resistance and reliability of the product are improved . Moreover, the production efficiency is improved, and a large-scale batch production of products is realized.

Owner:厦门华信安电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com