Transmission and air-drying structure of polycrystalline silicon wafer flocking machine

A technology of polycrystalline silicon wafers and transmission structures, which is applied in the manufacturing of final products, sustainable manufacturing/processing, electrical components, etc., can solve the problems of small contact area between polycrystalline silicon wafers and rollers, affecting the appearance qualification rate of polycrystalline silicon wafers, and improve the appearance qualification. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

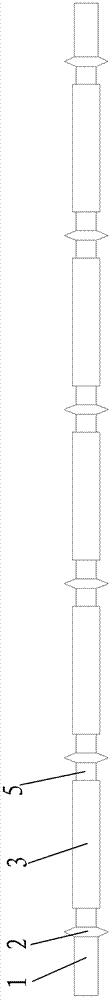

[0011] see figure 1 As shown, the transmission shaft 1 can rotate continuously. In practice, multiple rows of parallel transmission shafts with the same height are arranged to drive the polysilicon wafer forward when rotating. Connecting joints such as 2 are evenly arranged in the axial direction of the transmission shaft 1. Sections such as 2 separate the transmission shaft 1 into a plurality of equal-length transmission shaft segments such as 5, and the middle part of each transmission shaft segment such as 5 protrudes outwards along the circumferential direction to form rollers such as 3, and the rollers such as 3 The axial length is greater than the side length of the polysilicon wafer, so that the long-line contact between the rollers such as 3 and the polysilicon wafer has changed the traditional way of supporting and driving the polysilicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com