A kind of preparation method of bulk neodymium iron boron

A NdFeB, bulk technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the poor performance consistency of sintered magnets, aggravate the volatilization of NdFeB rare earth components, and affect the consistency of magnetic properties of magnets In order to achieve the effect of good consistency of magnet performance, reduce the ratio of appearance defects, and improve the appearance pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036](1) Use a vacuum intermediate frequency melting furnace to smelt metals such as neodymium (Nd), praseodymium neodymium (PrNd), pure iron (Fe), boron iron (B-Fe), cobalt (Co) into an alloy liquid, and use a rapid-setting process The alloy liquid is thrown into cast pieces, and the composition of the cast pieces is Nd25Pr6Dy0.3Fe66.43Co0.5B1Ga0.1Cu0.12AL0.3Nb0.25 (weight percent), in order to suppress the grain growth, a certain amount of zirconium (Zr );

[0037] (2) Put the cast pieces into the hydrogen smashing furnace. After vacuuming ≤10pa, rush into hydrogen to start hydrogen absorption. The hydrogen absorption pressure is controlled at 170-200kPa. After the hydrogen absorption is saturated, heat it to 600±5℃ for dehydrogenation. After the dehydrogenation is completed Filled with Ar gas to replace hydrogen, and finally cooled by fan;

[0038] (3) The powder in step 2 is ground with a 400-type jet mill, and the average particle size (D[3,2]) of the powder is 3.3-3.4 ...

Embodiment 2

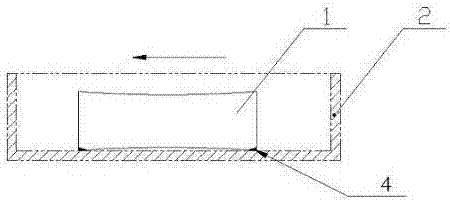

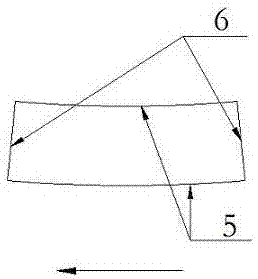

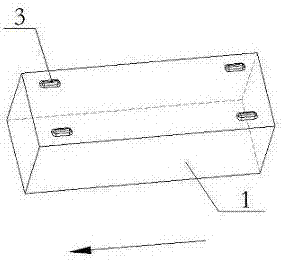

[0043] This example is exactly the same as Example 1 in steps, (1)-(3), and uses a batch of powder with the same preparation batch. (4) see image 3 , compact design, mold design and mold making, compact size is 55.8mmX53.2mmX158.5mm, 4 orderly bumps are designed on the surface of 55.8mmX158.5mm, bump size 4mmX10mmX0.2mm; bump orientation The directional spacing is 90mm and the die width directional spacing is 25mm, and the distances between the bumps and the two sides of the green compact are 13.4mm and 29.25mm respectively; then the mold is designed and manufactured; compared with Example 1, the difference between this example is only in The height of the bump is lowered to 0.2mm; all 200kg of powder is pressed, and (5)-(6) are exactly the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com