A grinding process and preparation method for large-scale products of multilayer ceramic capacitors

A multi-layer ceramic and grinding process technology, applied in capacitor manufacturing, capacitors, ceramic molding machines, etc., can solve problems such as affecting product performance and quality, electrode extraction cannot be guaranteed, and the surface is easily contaminated by foreign objects, so as to improve the appearance of qualified rate, achieve large-scale mass production, and prevent the effect of product surface discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

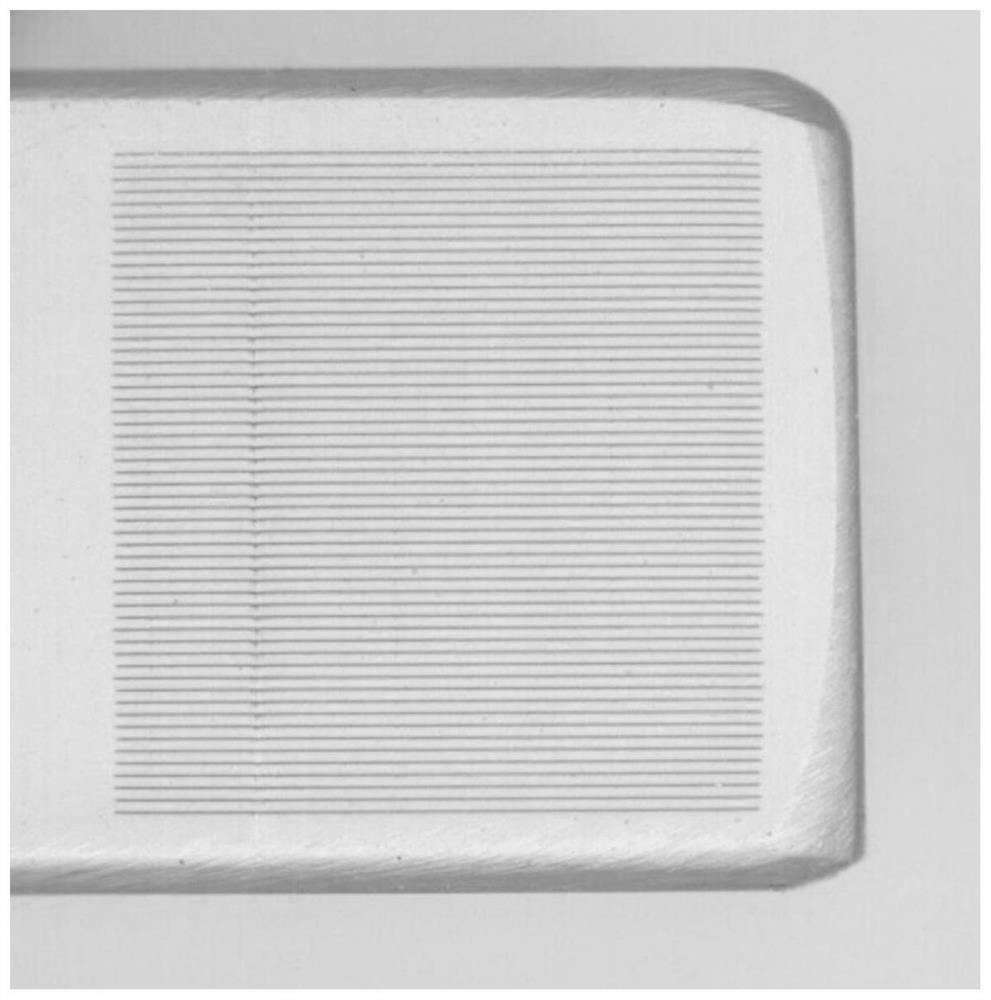

[0085] The experimental product before sintering was roughly ground with manual sandpaper in advance, and 12 edges and eight corners were manually rough-ground with 1000 mesh SiC sandpaper, so that the 12 edges and eight corners of the product had a certain arc, and The product is undamaged. The appearance of the product after coarse grinding is as figure 1shown.

[0086] 1. The product is subjected to medium temperature treatment before sintering

[0087] The experimental product after coarse grinding of sandpaper is treated at a medium temperature of 725°C, and its operation curve is: the first program segment is from 30 °C to 120 °C at a constant speed, and the heating time is 3 hours; the second program segment is from 120 °C to 150 °C at a uniform speed , the heating time is 6h; the third program segment is from 150℃ to 210℃ at a constant speed, and the heating time is 6h; the fourth program segment is from 210℃ to 280℃, and the heating time is 6h; the fifth program seg...

Embodiment 2

[0096] The experimental product before sintering was roughly ground with manual sandpaper in advance, and 12 edges and eight corners were manually rough-ground with 1000 mesh SiC sandpaper, so that the 12 edges and eight corners of the product had a certain arc, and The product is undamaged.

[0097] 1. The product is subjected to medium temperature treatment before sintering

[0098] The experimental product after coarse grinding of sandpaper is treated at a medium temperature of 625°C, and its operation curve is: the first program segment is from 30 °C to 120 °C, and the heating time is 3 hours; the second program segment is from 120 °C to 150 °C , the heating time is 6h; the third program segment is from 150℃ to 210℃ at a constant speed, and the heating time is 6h; the fourth program segment is from 210℃ to 280℃, and the heating time is 6h; the fifth program segment is 280℃, The holding time is 2 hours; the sixth program section is to raise the temperature from 280°C to 62...

Embodiment 3

[0107] The experimental product before sintering was roughly ground with manual sandpaper in advance, and the 12 edges and eight corners were manually rough ground with 1000 mesh SiC sandpaper, so that the 12 edges and eight corners of the product had a certain arc. And the product is not damaged.

[0108] 1. The product is subjected to medium temperature treatment before sintering

[0109] The experimental product after coarse grinding of sandpaper is treated at a medium temperature of 675°C, and its operation curve is: the first program segment is from 30 °C to 120 °C at a constant speed, and the heating time is 3 hours; the second program segment is from 120 °C to 150 °C at a uniform speed , the heating time is 6h; the third program segment is from 150℃ to 210℃ at a constant speed, and the heating time is 6h; the fourth program segment is from 210℃ to 280℃, and the heating time is 6h; the fifth program segment is 280℃, The holding time is 2 hours; the sixth program section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com