Paracetamol tablet and preparation method thereof

A technology for acetaminophen tablets and acetaminophen, which is applied to the field of acetaminophen tablets and their preparation, can solve problems such as splits, and achieve the effects of high dissolution rate, improved appearance qualification rate, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

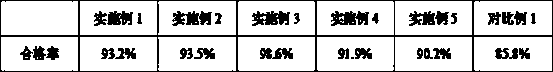

Examples

Embodiment 1

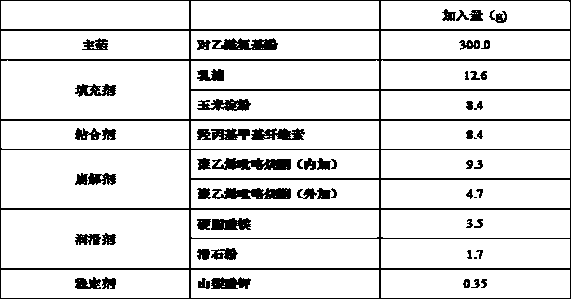

[0019] Example 1: To prepare 1000 pieces of acetaminophen tablets (specification 0.3g), the following components were used:

[0020]

[0021] Preparation method: fully mix acetaminophen with corn starch and lactose, and micronize the resulting mixture to obtain fine powder mixture I with a particle size of 1-75 microns; similarly process hydroxypropyl methylcellulose Micronization treatment to obtain a fine powder with a particle size of 1-75 microns. Accurately weigh the specified amount of the fine powder and add it to a 20% ethanol solution and stir thoroughly to obtain a binder solution with a concentration of 3%. Weigh the formula amount Potassium sorbate was added to the binder solution, stirred and dissolved to obtain binder solution II; the remaining auxiliary materials were respectively crushed through a 100-mesh sieve, and set aside; the mixture I was mixed with the internally added cross-linked polyvinylpyrrolidone to obtain Mixture III: Slowly add the mixture II...

Embodiment 2

[0022] Example 2: To prepare 1000 pieces of acetaminophen tablets (specification 0.3g), use the following components

[0023]

[0024] Preparation method: fully mix acetaminophen with corn starch and lactose, and micronize the resulting mixture to obtain fine powder mixture I with a particle size of 1-75 microns; similarly process hydroxypropyl methylcellulose Micronization treatment to obtain a fine powder with a particle size of 1-75 microns. Accurately weigh the specified amount of the fine powder and add it to a 20% ethanol solution and stir thoroughly to obtain a binder solution with a concentration of 3%. Weigh the formula amount Potassium sorbate was added to the binder solution, stirred and dissolved to obtain binder solution II; the remaining auxiliary materials were respectively crushed through a 100-mesh sieve, and set aside; the mixture I was mixed with the internally added cross-linked polyvinylpyrrolidone to obtain Mixture III; slowly add the mixture III to th...

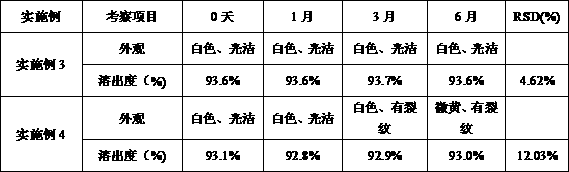

Embodiment 3

[0025] Example 3 To prepare 1000 pieces of acetaminophen tablets (specification 0.3g), use the following components

[0026]

[0027] Preparation method: fully mix acetaminophen with corn starch and lactose, and micronize the resulting mixture to obtain fine powder mixture I with a particle size of 1-75 microns; similarly process hydroxypropyl methylcellulose Micronization treatment to obtain a fine powder with a particle size of 1-75 microns. Accurately weigh the specified amount of the fine powder and add it to a 20% ethanol solution and stir thoroughly to obtain a binder solution with a concentration of 3%. Weigh the formula amount Potassium sorbate was added to the binder solution, stirred and dissolved to obtain binder solution II; the remaining auxiliary materials were respectively crushed through a 100-mesh sieve, and set aside; the mixture I was mixed with the internally added cross-linked polyvinylpyrrolidone to obtain Mixture III; slowly add the mixture III to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com