A screen printing method and resistor

A technology of screen printing and screen printing, which is applied in the fields of resistors, printing, and resistor manufacturing. It can solve the problems of poor consistency of resistor resistance and low pass rate of product appearance, and achieve good consistency of resistor resistance and high product quality. The effect of high appearance pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

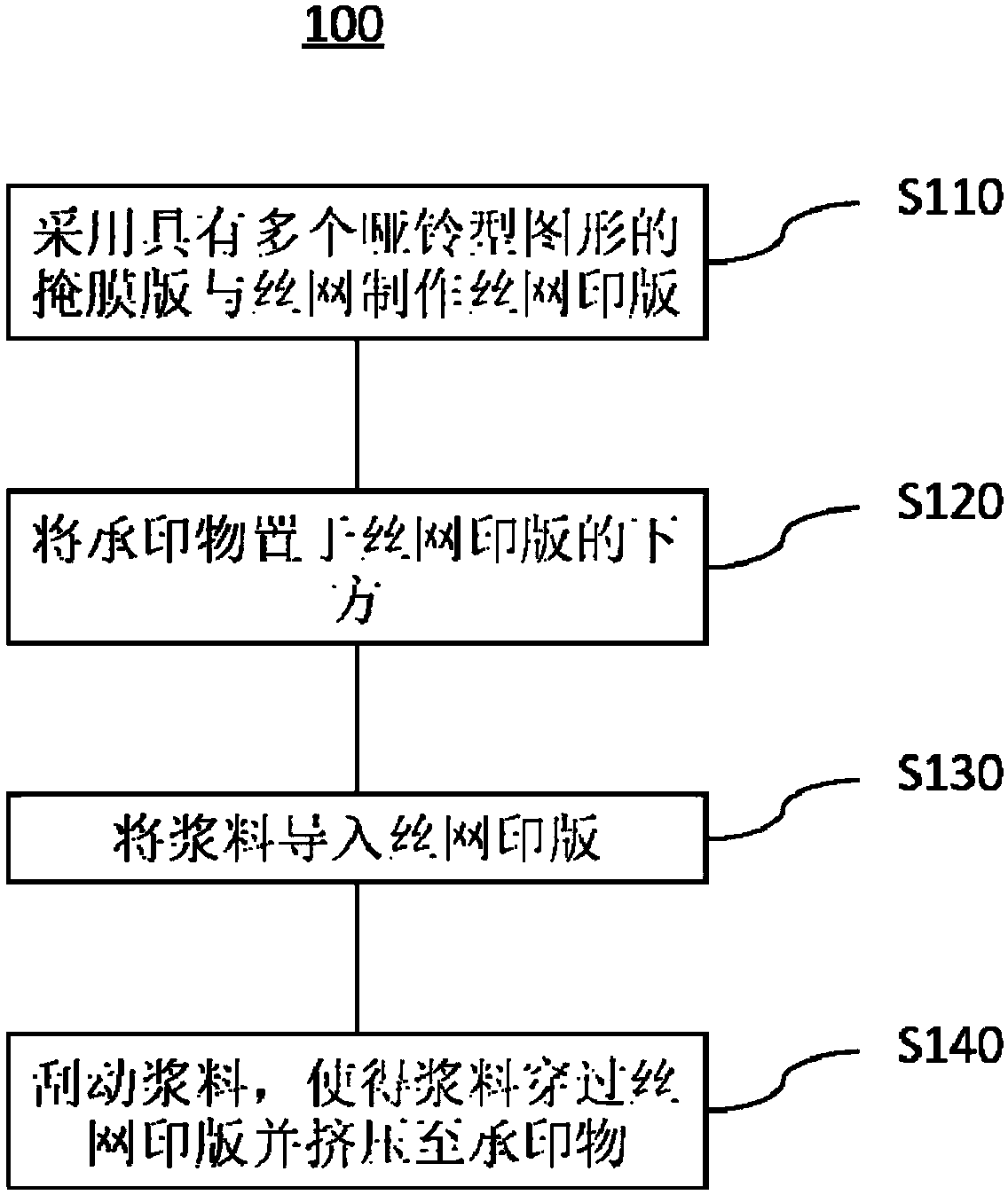

[0047] see figure 1 , figure 1 It is a flow chart of the screen printing method 100 provided in the first embodiment. The screen printing method 100 is mainly used in the production of chip resistors, and is a printing method that has the advantages of flexible and diverse printing methods, large printing area, and is not limited by the size and shape of the substrate. The screen printing method 100 provided in this embodiment can produce products with good consistency in resistance value and high pass rate of product appearance.

[0048] The steps of screen printing method 100 include:

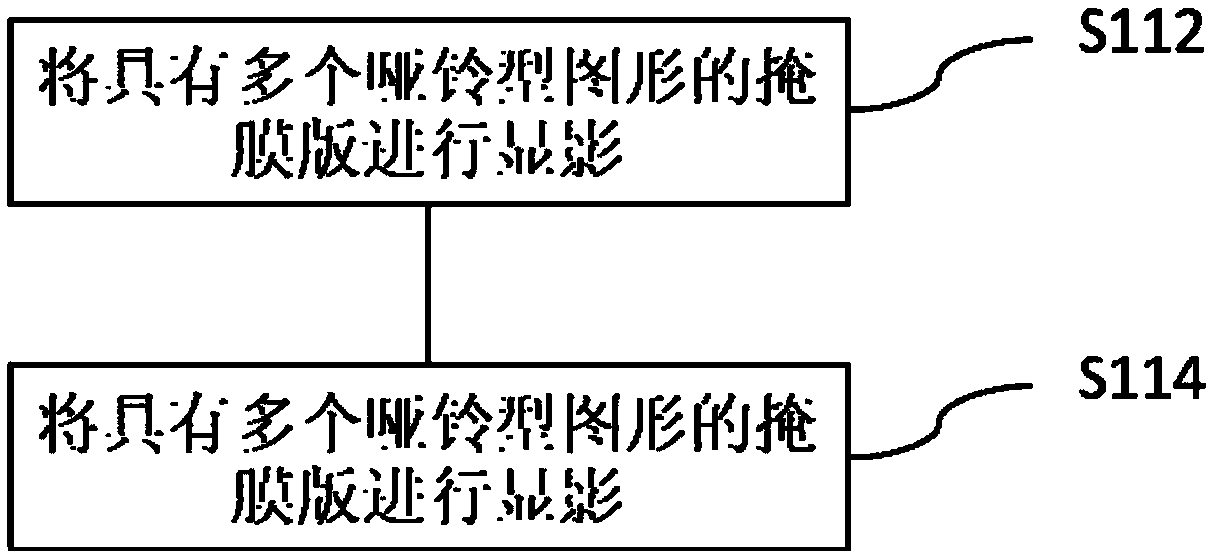

[0049] In step S110, a screen printing plate is made by using a mask plate with a plurality of dumbbell-shaped figures and a screen.

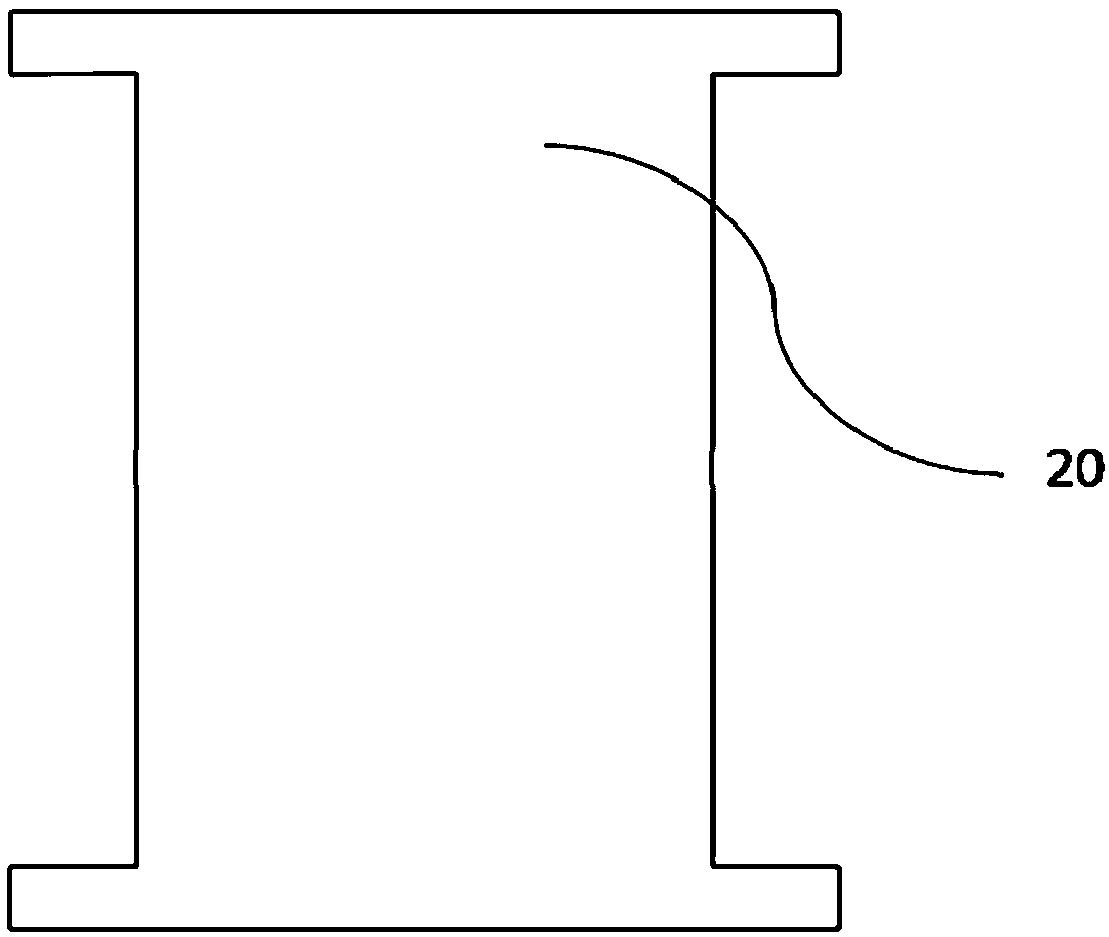

[0050] see figure 2 , figure 2 Shown is a schematic diagram of the dumbbell-shaped mask plate 20 provided by Embodiment 1 of the present invention. The dumbbell-shaped mask 20 has a dumbbell-shaped body in a rectangular shape and four corners in a smal...

Embodiment 2

[0075] see Figure 5 , Figure 5 Shown is a three-dimensional schematic diagram of the resistor 10 provided by Embodiment 2 of the present invention. The resistor 10 is approximately in the shape of a cuboid, and is manufactured by the provided screen printing method 100 using the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com