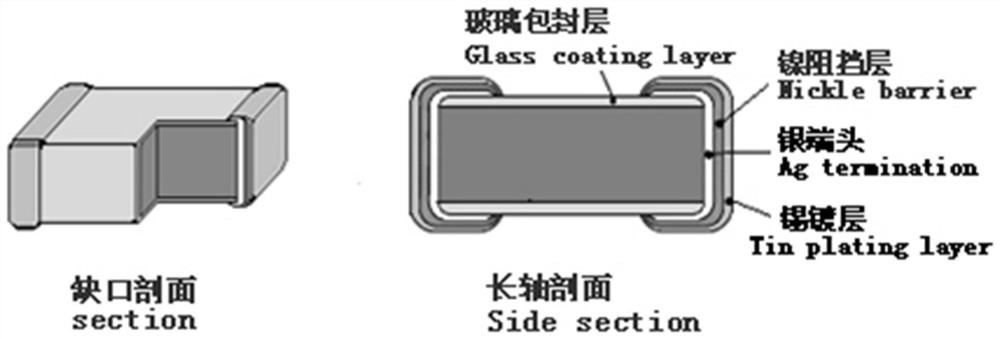

High-reliability chip NTC (Negative Temperature Coefficient) thermistor material as well as preparation method and application thereof

A thermistor and reliability technology, applied in the field of high-reliability chip NTC thermistor materials and their preparation, can solve problems such as poor consistency of NTC thermistors, and achieve improved oxidation resistance, high stability, and stability. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

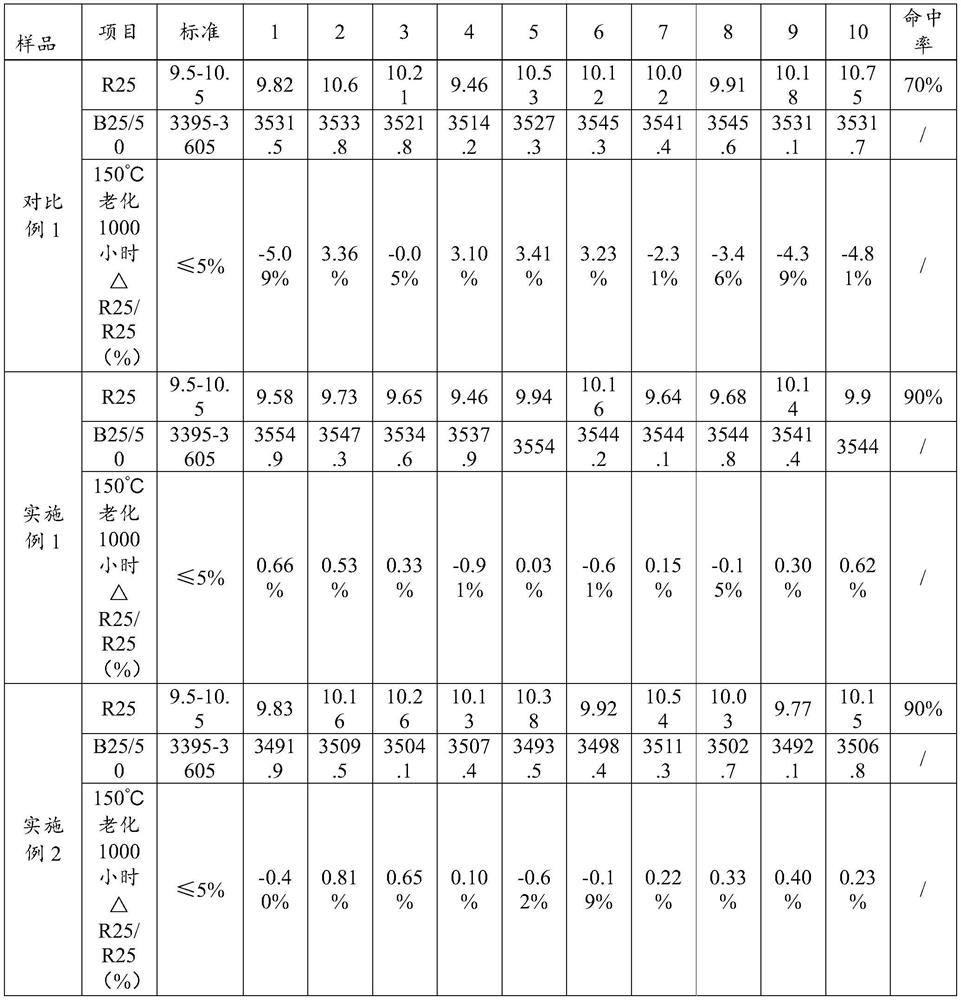

Embodiment 1

[0024] An embodiment of the high-reliability chip NTC thermistor material of the present invention, the material in this embodiment, by weight percentage, includes the following components: 42.4% Mn 3 o 4 , 39.7% Co 3 o 4 , 9.6% Ni 2 o 3 , 7.8% ZnO, 0.5% La 2 o 3 .

[0025] Its preparation method is as follows:

[0026] (1) Weigh Mn according to the formula ratio 3 o 4 、Co 3 o 4 、Ni 2 o 3 , ZnO, La 2 o 3 Mix the ingredients, put the weighed mixed powder and water into the ball mill jar at a weight ratio of 1:1.5, and ball mill for 24 hours at a rate of 30 rpm;

[0027] (2) After the ball mill is cooled, transfer the ball-milled slurry to a tray and place it in an oven at 250°C for drying;

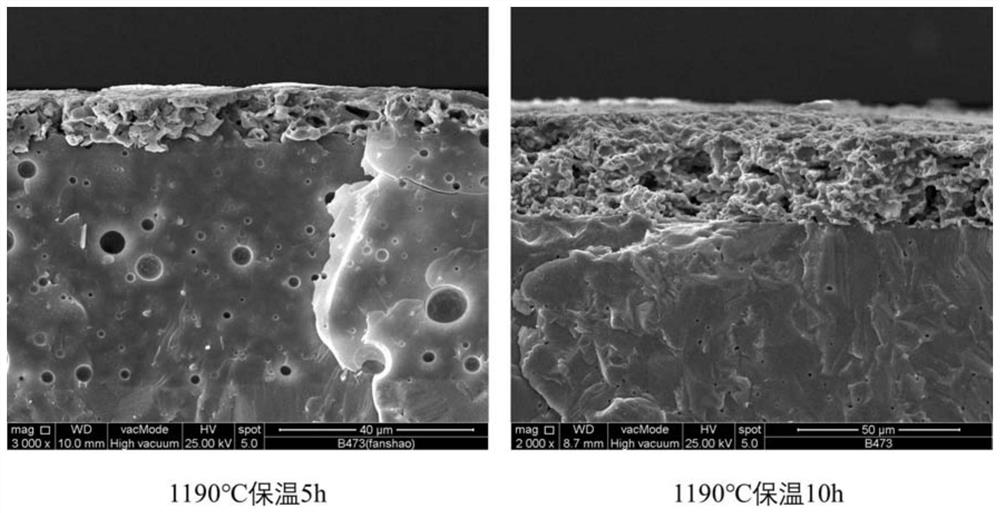

[0028] (3) The dried material is crushed and placed in the muffle furnace for pre-firing, and the dried material is crushed and placed in the muffle furnace for pre-firing, in order to improve the consistency of the high-resistance porcelain powder pre-synthesis process and ...

Embodiment 2

[0033] An embodiment of the high-reliability chip NTC thermistor material of the present invention, the material in this embodiment, by weight percentage, includes the following components: 45.3% Mn 3 o 4 , 37.7% Co 3 o 4 , 8.7% Ni 2 o 3 , 7.5% ZnO, 0.8% La 2 o 3 .

[0034] Its preparation method is as follows:

[0035] (1) Weigh Mn according to the formula ratio 3 o 4 、Co 3 o 4 、Ni 2 o 3 , ZnO, La 2 o 3 Mix the ingredients, put the weighed mixed powder and water into the ball mill jar at a weight ratio of 1:1.5, and ball mill for 24 hours at a rate of 30 rpm;

[0036] (2) After the ball mill is cooled, transfer the ball-milled slurry to a tray and place it in an oven at 250°C for drying;

[0037] (3) The dried material is crushed and placed in the muffle furnace for pre-firing, and the dried material is crushed and placed in the muffle furnace for pre-firing, in order to improve the consistency of the high-resistance porcelain powder pre-synthesis process and ...

Embodiment 3

[0042] An embodiment of the high-reliability chip NTC thermistor material of the present invention, the material in this embodiment, by weight percentage, includes the following components: 50.5% Mn 3 o 4 , 35.2% Co 3 o 4 , 8.2% Ni 2 o 3 , 5.1% ZnO, 1.0% La 2 o 3 .

[0043] Its preparation method is as follows:

[0044] (1) Weigh Mn according to the formula ratio 3 o 4 、Co 3 o 4 、Ni 2 o 3 , ZnO, La 2 o 3 Mix the ingredients, put the weighed mixed powder and water into the ball mill jar at a weight ratio of 1:1.5, and ball mill for 24 hours at a rate of 30 rpm;

[0045] (2) After the ball mill is cooled, transfer the ball-milled slurry to a tray and place it in an oven at 250°C for drying;

[0046] (3) The dried material is crushed and placed in the muffle furnace for pre-firing, and the dried material is crushed and placed in the muffle furnace for pre-firing, in order to improve the consistency of the high-resistance porcelain powder pre-synthesis process and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com