Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152results about How to "High electrothermal conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

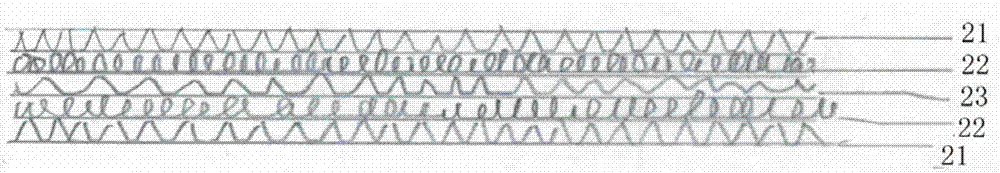

Preparation method of carbon fiber fabric for electric heating

InactiveCN109457430ASoft touchUniform textureHeating/cooling textile fabricsVegetal fibresElectric heatingElectricity

The invention relates to a preparation method of carbon fiber fabric for electric heating, which comprises the steps of (1)weaving raw fabric with carbon fiber yarns by means of spinning and weaving;(2) using a self-made treating agent to pad the raw fabric so that carbonization yield is increased, the surface of the raw fabric is etched and carbonization time is shortened; (3) pre-oxidizing thetreated raw fabric at 200-300 DEG C; (4) carbonizing the pre-oxidized fabric at the low temperature of 600-900 DEG C; (5) carbonizing the fabric, which is carbonized at the low temperature, at the high temperature of 1200-1800 DEG C to obtain carbon fiber fabric which is soft, low in resistance and suitable for electric heating.

Owner:嘉兴纳科新材料有限公司

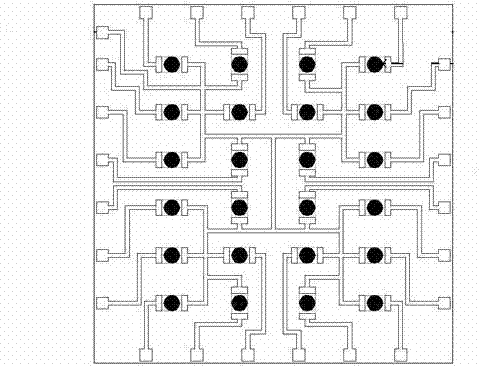

Dielectric Al/CuO composite film energetic electric ignition bridge and ignition bridge array

The invention discloses a dielectric Al / CuO composite film energetic electric ignition bridge and an ignition bridge array. The bridge body of the ignition bridge is formed by overlapping an upper electrode, a lower electrode and a dielectric layer; two layers of metal films with the same size and different directions serve as the upper electrode and the lower electrode; an Al / CuO composite film layer with the same size and direction as the upper electrode metal film is sandwiched between the two layers of metal films to serve as the dielectric layer; partial Al / CuO composite film layer is coated and overlapped on the lower electrode metal film; and the upper electrode metal film is completely coated and overlapped on the Al / CuO composite film layer. In the ignition array taking the dielectric Al / CuO composite film energetic electric ignition bridge as a basic unit, a plurality of dielectric Al / CuO composite film energetic electric ignition bridges are connected through leads preparedfrom Au metal films or Cu metal films to form the ignition array. The invention has the advantages of high safety, high ignition capacity and good compatibility.

Owner:NANJING UNIV OF SCI & TECH

Carbon material electrical heating membrane and preparing method

InactiveCN1770930AHigh electrothermal conversion rateSignificant power saving effectHeating element materialsElectricityGraphite

This invention discloses one carbon materials generating film and its process method, which makes use of one micro carbon powder, conductive carbon powder excellent electricity and thermal property and adds proper stabilizer, adhesive agent and disperser to make flexible electricity film materials. Comparing with current technique, the invention product is of high conversion efficiency and good saving effect and can product low temperature, middle temperature type with highest temperature of 350 degrees and its voltage is between 3.6V to 650V with wide utility range and with simple process.

Owner:贵州航天江南工业贸易有限公司 +1

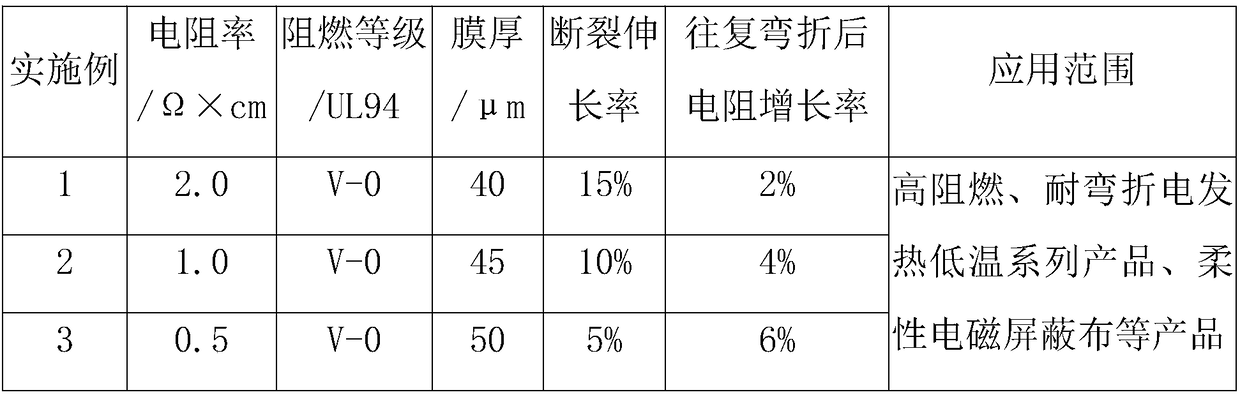

Graphene flame-retardant elastic composite, composite film and preparing method of composite film

The invention provides a graphene flame-retardant elastic composite. The composite is characterized by being prepared from, by mass, 0.5-10% of graphene microchips, 20-35% of fire retardant, 10-30% ofthermoplastic elastomer, 30-60% of solvent and 0.1-1.5% of auxiliaries. In addition, the invention further provides a composite film containing the graphene flame-retardant elastic composite and a preparing method of the composite film. The composite obtained with the thermoplastic elastomer, the fire retardant and the solvent with different elasticity moduli as the film forming materials and thegraphene microchips as the conductive filler has the advantages of flame retardance, high conductivity, bendability, high adhesiveness and the like, and therefore the composite film prepared from thecomposite also has the advantages of flame retardance, high conductivity, bendability, high adhesiveness and the like, and the composite film can be applied in the fields of electromagnetic shielding, far infrared electric heating products, flexible conductive electrodes and the like, is wide in application range, and effectively overcome the problems that an existing electric heating film product is poor in bending resistance and potential safety hazards such as spontaneous combustion are caused by local overheating.

Owner:中金态和(武汉)石墨烯科技股份有限公司

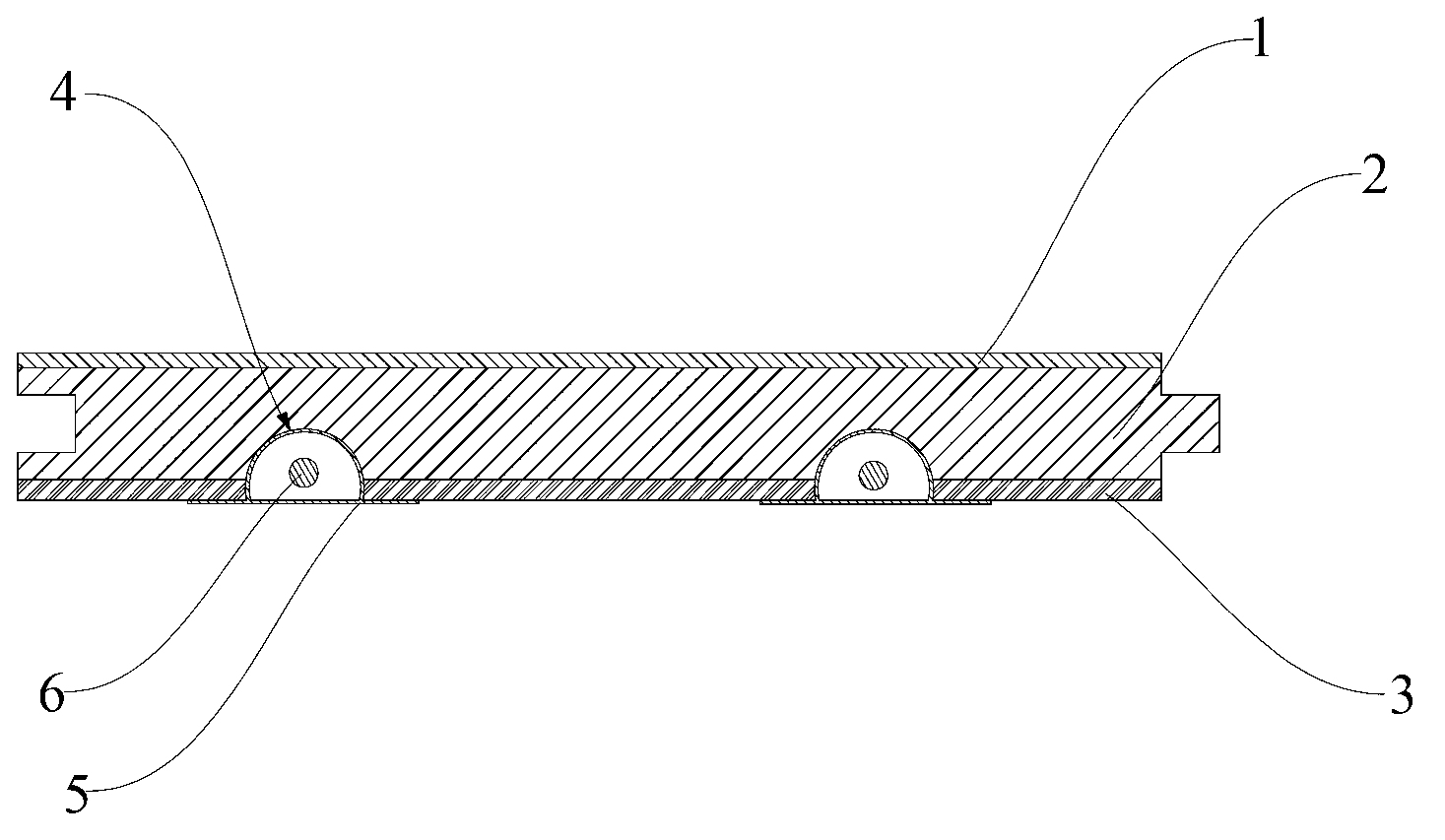

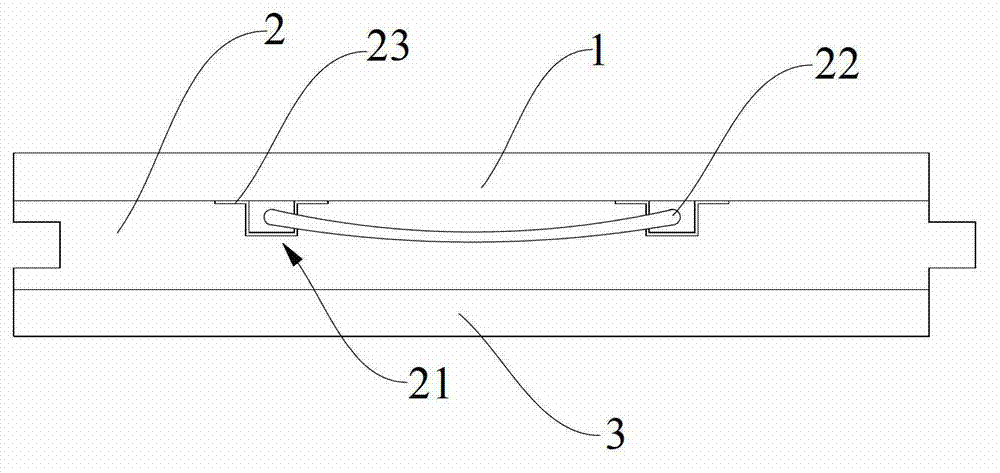

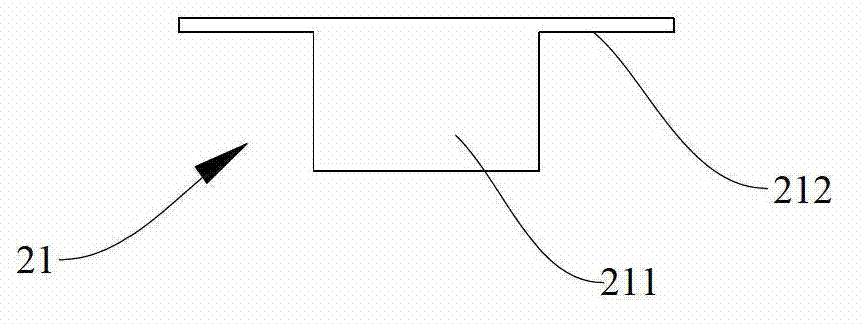

Heat energy floor

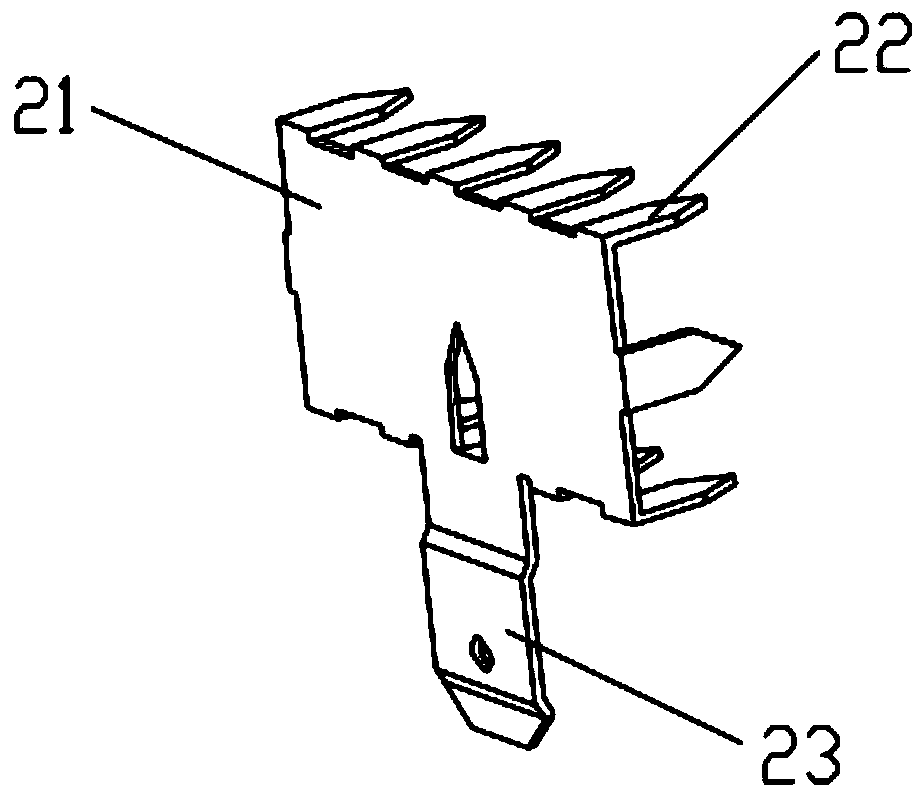

ActiveCN103062825AWith health functionImprove stress resistanceLighting and heating apparatusElectric heating systemMetallic materialsElectrical connection

The invention provides a heat energy floor. At least one winding displacement groove is arranged at the bottom of a floor along the length direction; the winding displacement groove is internally provided with a metal material heat-conducting frame; the metal material heat-conducting frame comprises an arc-shaped arch-shaped bracket with a vertical section which is chord-shaped and is located below, and a supporting plate located below the arch-shaped bracket; an opening is arranged at the position below the arch-shaped bracket, which corresponds to a chord on the arc-shaped section; the supporting plate covers the opening; a hollow cavity with two open ends is formed by the arch-shaped bracket and the supporting plate; the outer surface of the arch-shaped bracket at least has several parts which are respectively contacted with the surface of the inner wall of the winding displacement groove; at least one winding displacement groove is internally further provided with an electric heating wire; and the electric heating wire penetrates through the hollow cavity of the metal material heat-conducting frame and is electrically connected with a power supply. The heat energy floor disclosed by the invention has the advantages of strong anti-pressure ability, good heating effect, convenience in machining, and simple structure, is applicable to various fields, and has a very good application prospect.

Owner:苏州卡尔玛智能暖居科技有限公司

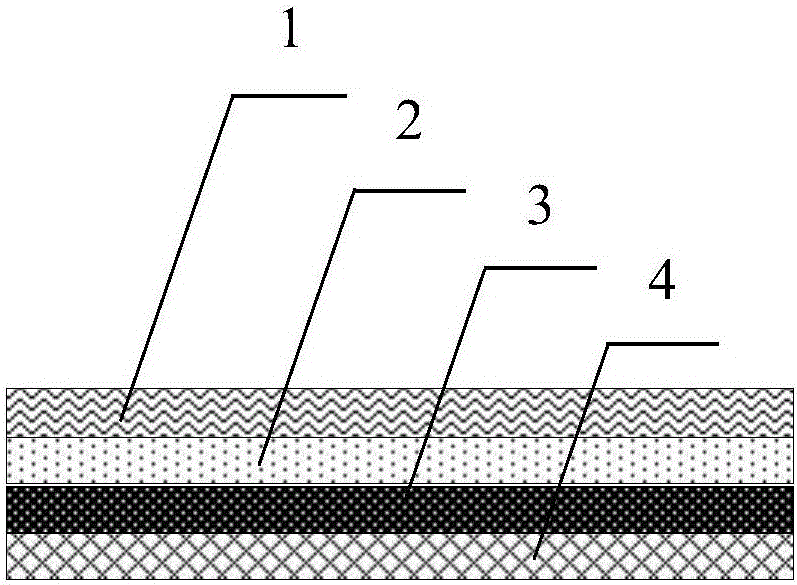

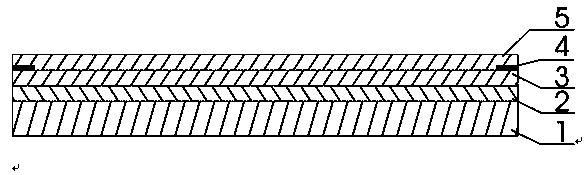

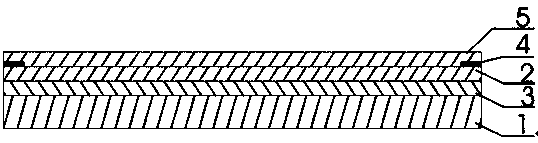

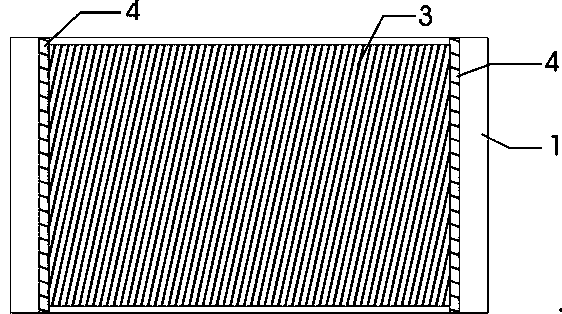

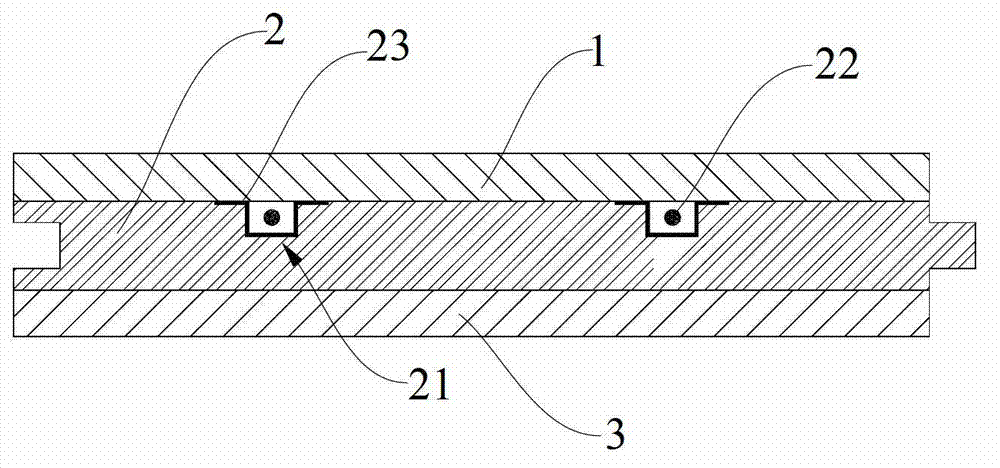

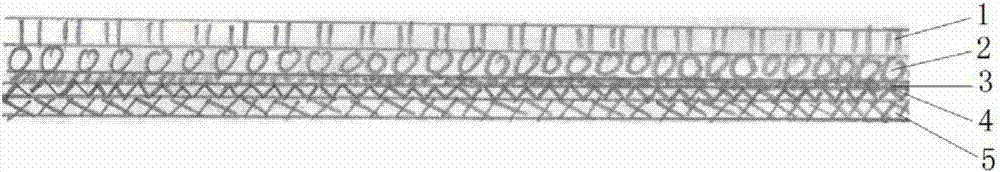

Flexible far-infrared heating film, preparation method thereof and far-infrared blanket produced through same

ActiveCN102984833AHigh electrothermal conversion rateIncrease profitHeating element materialsEngineeringHardness

The invention discloses a flexible far-infrared heating film, a preparation method thereof and a far-infrared blanket produced through same and relates to the technical field of heating films. The heating film comprises a far-infrared heating layer, wherein electrodes are arranged on two sides of the heating film, the extension direction of the electrodes is identical with the extension direction of the far-infrared heating layer, a flexible insulating layer is attached to the positive and the negative of the far-infrared heating layer respectively, metal shielding layers are attached to outsides of two flexible insulating layers, the far-infrared heating layer comprises, by weight, 3-5 parts of conductive ink and 1-3 parts of far-infrared emitting agent and the conductive ink and the far-infrared emitting agent are mixed to form the far-infrared heating layer. The technical problems that in the prior art, the far-infrared heating device is high in hardness, instable in emitted far-infrared heating rays and poor in safety performance are solved. The heating film and the far-infrared blanket produced through the heating film are good in flexibility, stable in emitted far-infrared heating rays and good in use safety performance.

Owner:SHANDONG LEKANG ELECTRICAL TECH

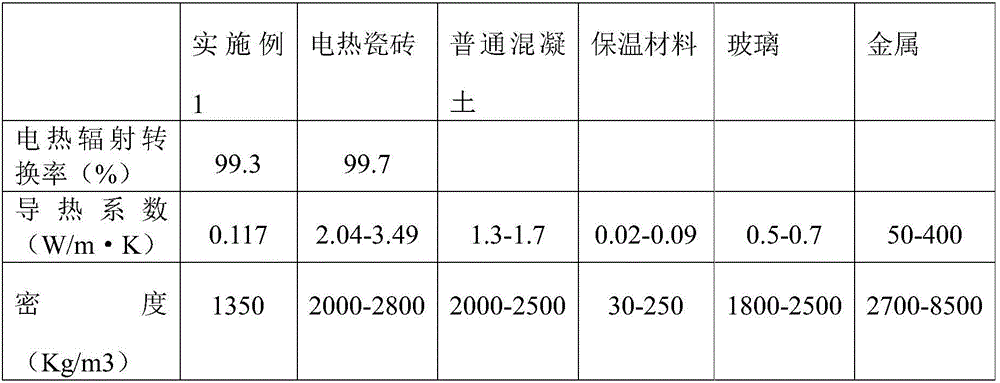

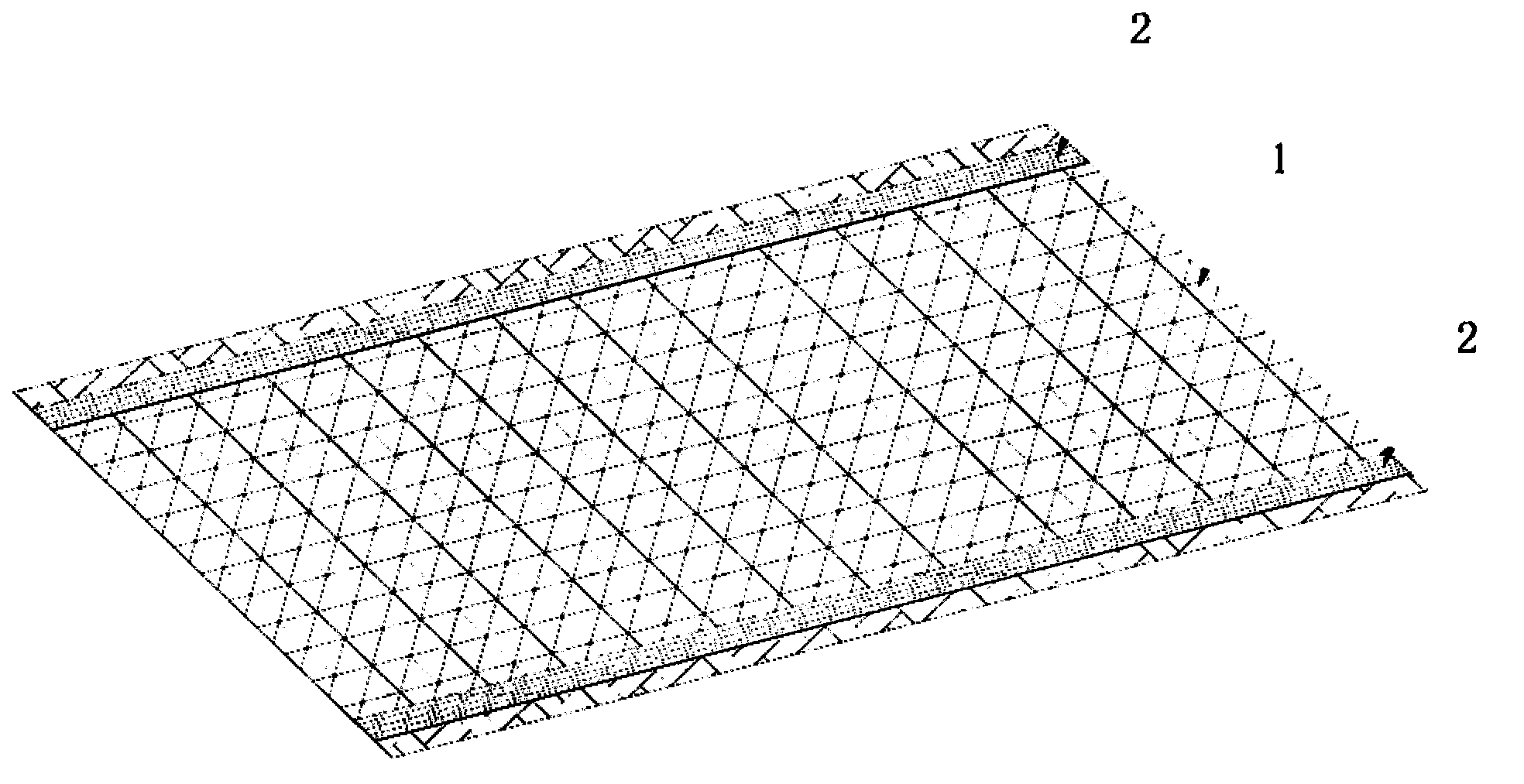

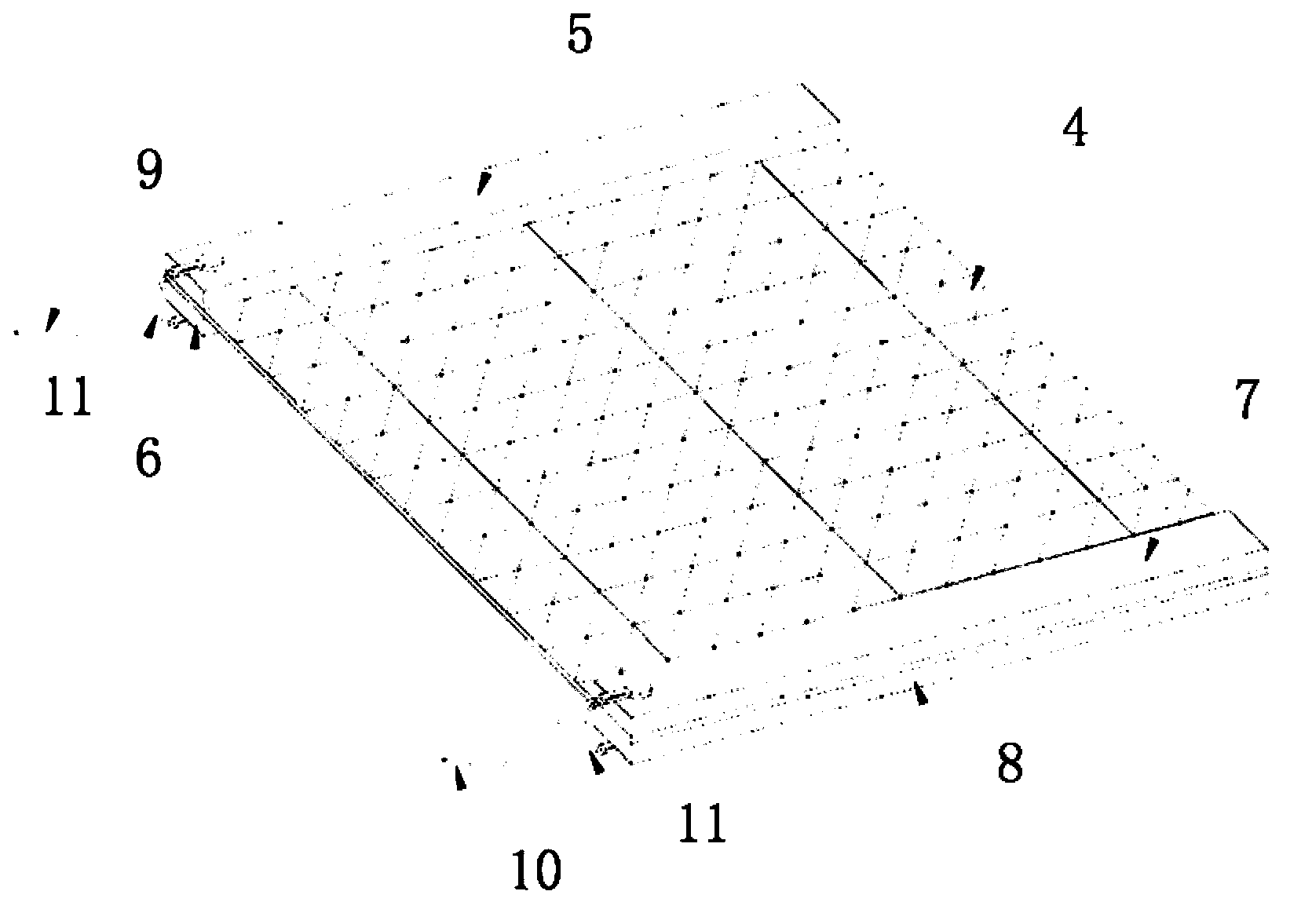

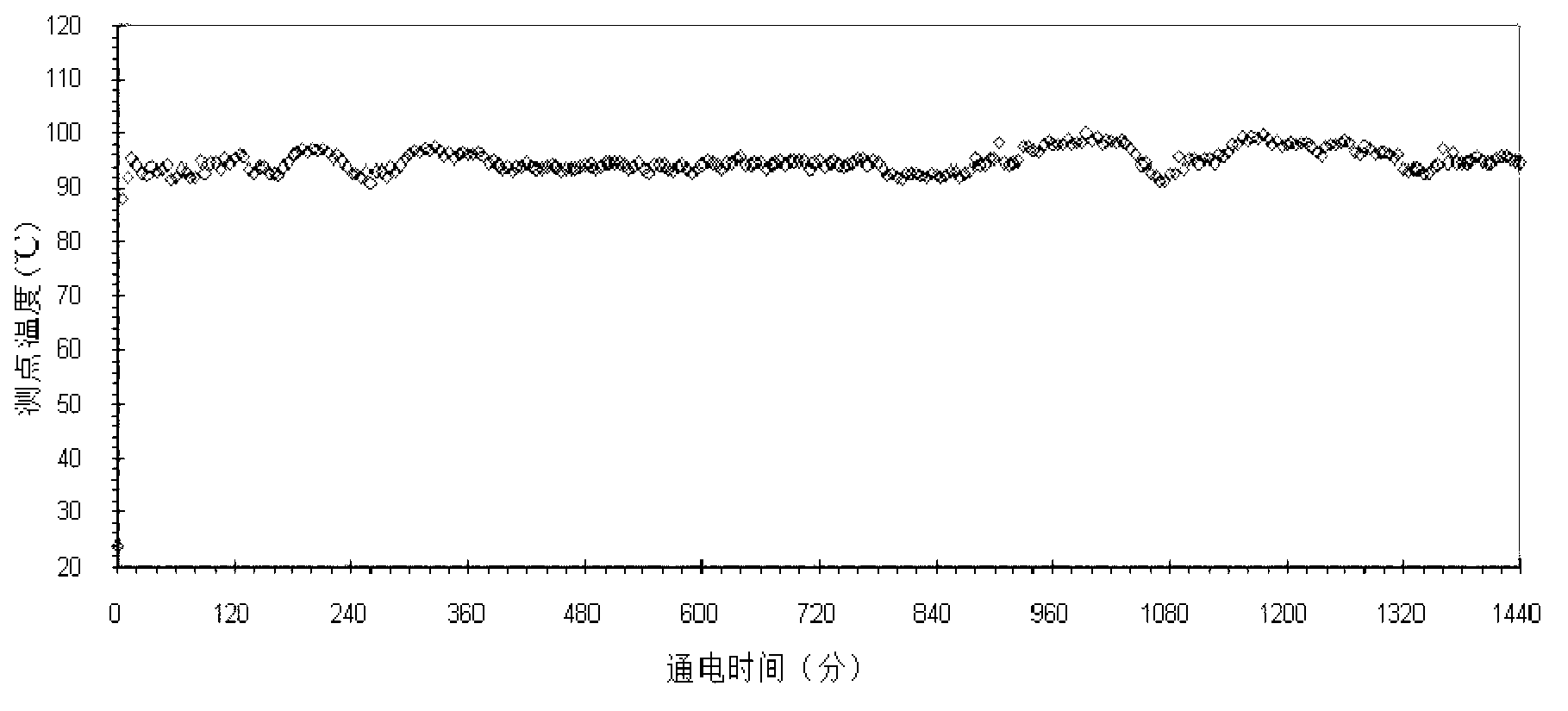

Low-temperature far-infrared integral electric heating tender porcelain decorative material and preparation method thereof

ActiveCN106592902ARich and colorful decorative functionsWith electric heating functionCovering/liningsLaminationElectricityEmulsion

The invention belongs to the technical field of building inner wall decorative materials and relates to a low-temperature far-infrared integral electric heating tender porcelain decorative material and a preparation method thereof. The low-temperature far-infrared integral electric heating tender porcelain decorative material is composed of a soft porcelain layer, a heat conductive waterproof layer, an electric heating layer and a heat preservation layer in sequence. The preparation method of the integral electric heating tender porcelain decorative material comprises the following steps that a silicone-acrylate emulsion, medical stone powder and cement and the like are prepared into slurry, and the slurry is poured into a mould, and after drying is conduced, the soft porcelain layer is obtained; then the surface of the soft porcelain layer is coated with waterborne polyurethane heat conductive insulating glue and conductive resin, and after drying is conducted in sequence, the heat conductive waterproof layer and the electric heating layer are obtained; and finally, a glass fabric is sufficiently immersed through waterborne polyurethane glue and covered on the electric heating layer, and after drying is conducted, the electric heating tender porcelain decorative material is obtained. The obtained electric heating tender porcelain decorative material has decorative and electric heating functions, has the properties of sterilization and bacteriostasis, releasing beneficial far infrared rays and being excellent in water and pollution resistance, and can work for a long time at the temperature ranging from minus 20 DEGC to 35 DEGC.

Owner:WUHAN WEIJUN IMPORT & EXPORT TRADE CO LTD

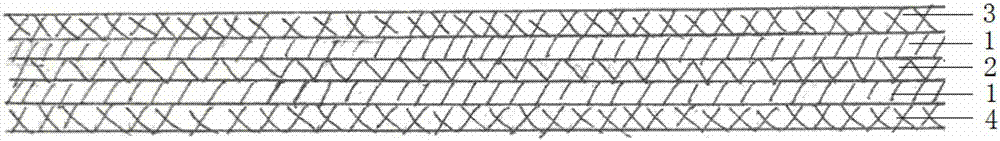

Macromolecule composite electric heating material, preparation method thereof and application thereof

ActiveCN103269528AEffective distributionHigh electrothermal conversion rateWoven fabricsHeating element materialsCarbon fibersMetal fibers

The invention provides a macromolecule composite electric heating material, a preparation method of the macromolecule composite electric heating material and application of the macromolecule composite electric heating material. The macromolecule composite electric heating material is characterized by comprising a macromolecule composite electric heating coating and a substrate used for bearing the macromolecule composite electric heating coating. The macromolecule composite electric heating coating comprises, by weight parts, 100 parts of macromolecule resin base materials, 1-50 parts of conductive filler, 1-30 parts of auxiliaries and 100-600 parts of solvent, wherein the conductive filler is one or more of conductive carbon black, conductive graphite, carbon fibers, metal powder and metal fibers, and the base materials are thin and flexible materials which are suitable for being coated by coating-type objects. The macromolecule composite electric heating material is applicable to the low-temperature heating field at the temperature of 0DEG C-160DEG C, and particularly applicable to the aspects such as heating of buildings, heating and heat preservation of animals and plants, baking and drying of objects and far infrared physiotherapy health care.

Owner:李春学

Stone needle thermal therapy new material and use thereof

InactiveCN101744717AHigh electrothermal conversion rateGood energy saving effectDevices for heating/cooling reflex pointsElectrotherapyRheumatismConductive materials

The invention provides a stone needle thermal therapy new material and application thereof. The stone needle thermal therapy new material is characterized in that a natural stone needle powder body with nanometer fineness is selected and compounded in a conductive material, and the mixture is processed to form the stone needle thermal therapy new material. The material can be processed into various stone needle thermal therapy products, the stone needle thermal therapy material can further achieve the physical therapy effect when the products are used under the condition of heating by external power energy, and the stone needle thermal therapy material not only contains a plurality of microelements, but also has a far-infrared radiation function; and the stone needle thermal therapy material is heated through rubbing to generate ultrasonic pulses (3,698 times / 20-2,000 / hz), can also generate anions and has obvious effects of resisting bacteria, increasing blood oxygen level, removing peculiar smell, losing weight, enlarging chest, and treating neurasthenia, insomnia, scapulohumeral periarthritis, rheumatism, rheumatoid arthritis, amyotrophy caused by chronic nerve diseases and chronic diseases such as tendovaginitis of fingers, wrists and the like which are easily generated for persons who use computers for a long time. The stone needle thermal therapy new material has the characteristics of simple process, wide use, easy purchase of raw materials and low cost.

Owner:范瑞彬

Nano-composite current-conducting electric heating film and production method thereof

InactiveCN103974471AImprove heating efficiencyHigh electrothermal conversion rateOhmic-resistance heatingPunchingPrinting ink

The invention relates to a nano-composite current-conducting electric heating film and a production method thereof, and belongs to the technical field of materials. The nano-composite current-conducting electric heating film comprises a substrate layer, a current conducting layer is arranged on the substrate layer, a conductive heating layer is arranged on the current conducting layer, and each of two upper ends of the conductive heating layer is provided with an electrode. The nano current conducting layer and the conductive heating layer are introduced to be composited to obtain a nano conductive heating unit, the entire surface serves as one conductive heating unit, the current flows evenly on the entire surface, and poor uniformity of the film due to the printing technology and problems of printing ink is avoided; effect of punching and cutting in any place on the surface without affect conduction and heating is achieved.

Owner:KMT纳米科技(香港)有限公司

Preparation method of graphene carbon fiber conductive paper for fuel cell electrodes

ActiveCN106930151AImprove conductivityImprove thermal conductivitySpecial paperWater-repelling agents additionPorosityFiber

The invention relates to the field of porous diffusion forming materials for fuel cell electrodes, specifically a base material for manufacturing a porous diffusion layer of a fuel cell electrode, as well as a preparation method and a production method of graphene carbon fiber conductive paper. The method adopts graphene powder, short chopped carbon fibers and plant fiber raw wood pulp, wherein graphene powder mixed liquid, short chopped carbon fiber mixed liquid and plant fiber mixed liquid are prepared into pulp, the pulp diluted by mixing with water is put onto a screen box for papermaking, the made paper is conveyed via a blanket, dried in a drying cylinder and rolled by a paper rolling device, and the required graphene carbon fiber conductive paper is thus obtained. The graphene carbon fiber conductive paper is 80-100 grams per square meter, the porosity is 20-40%, and the conductive sheet resistance is 3-10 ohms per square centimeter. The graphene carbon fiber conductive paper can be produced in batch on a common papermaking machine, and meets the requirement for manufacturing porous diffusion layer electrodes of fuel cells.

Owner:北京绿能嘉业新能源有限公司

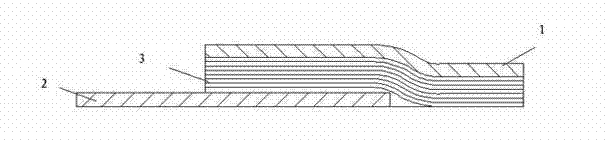

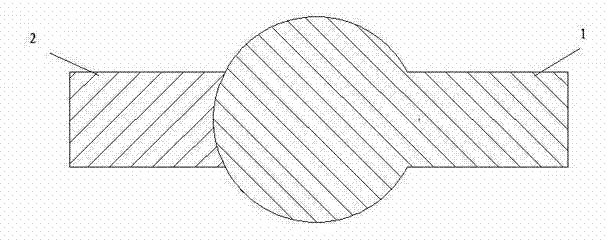

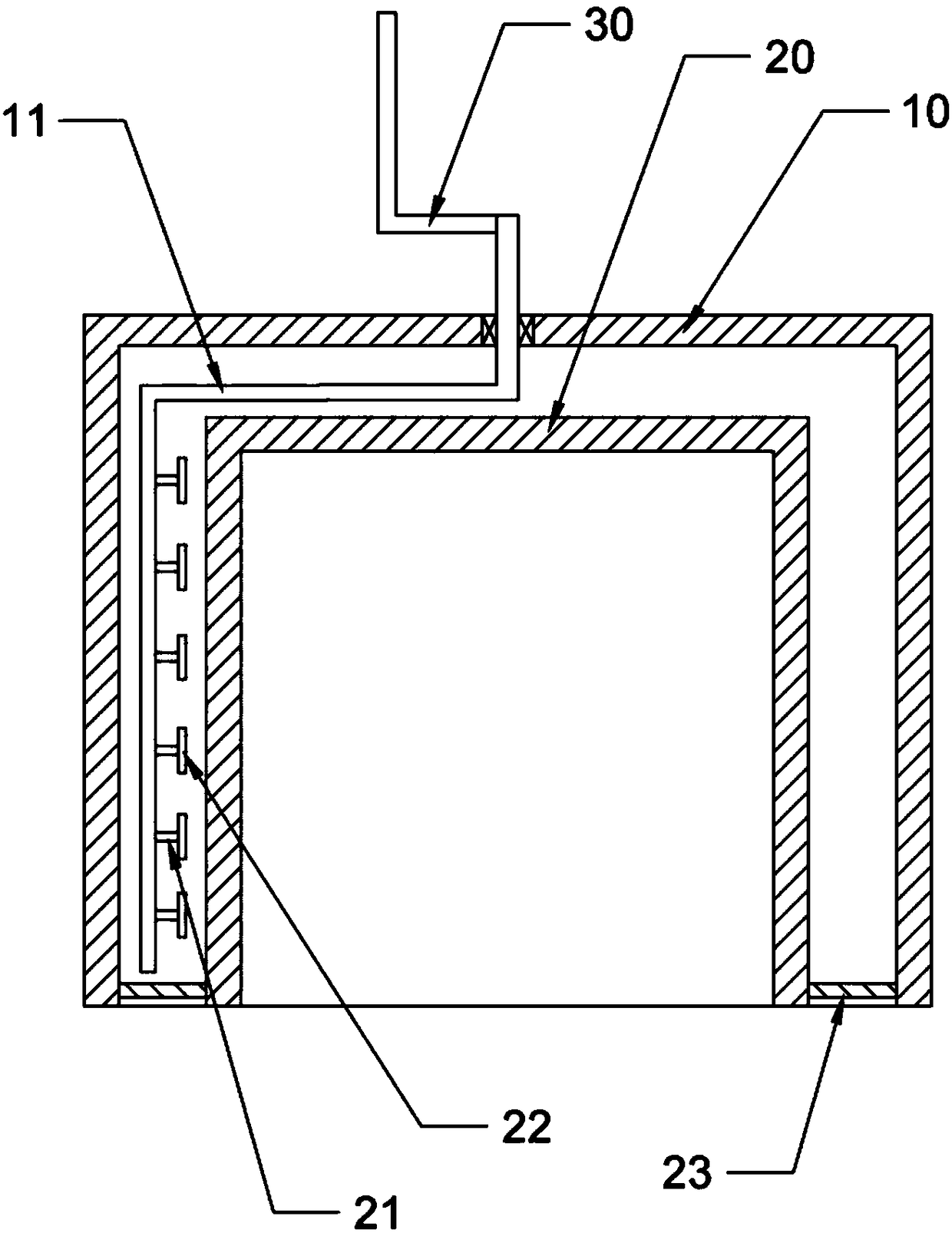

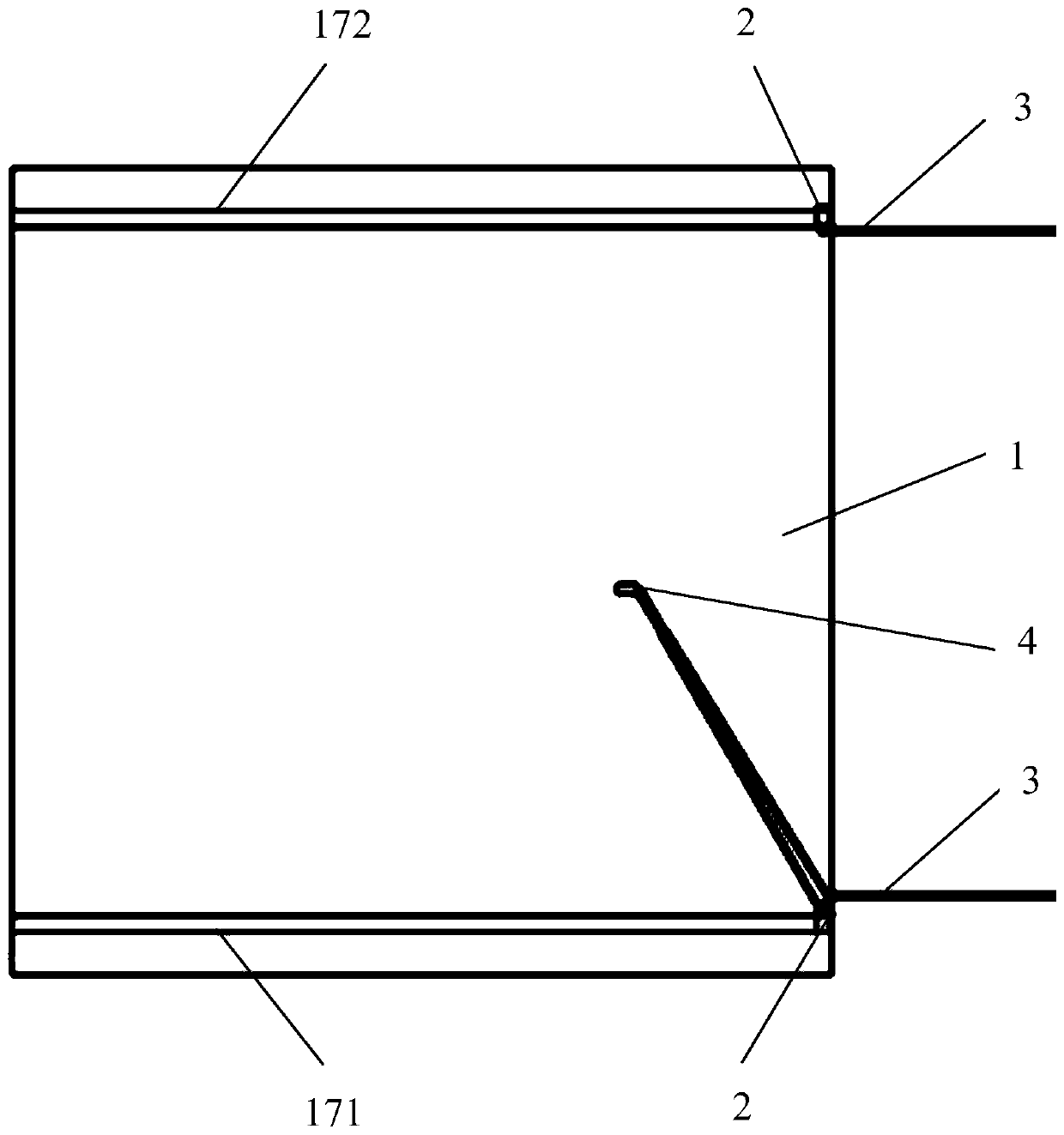

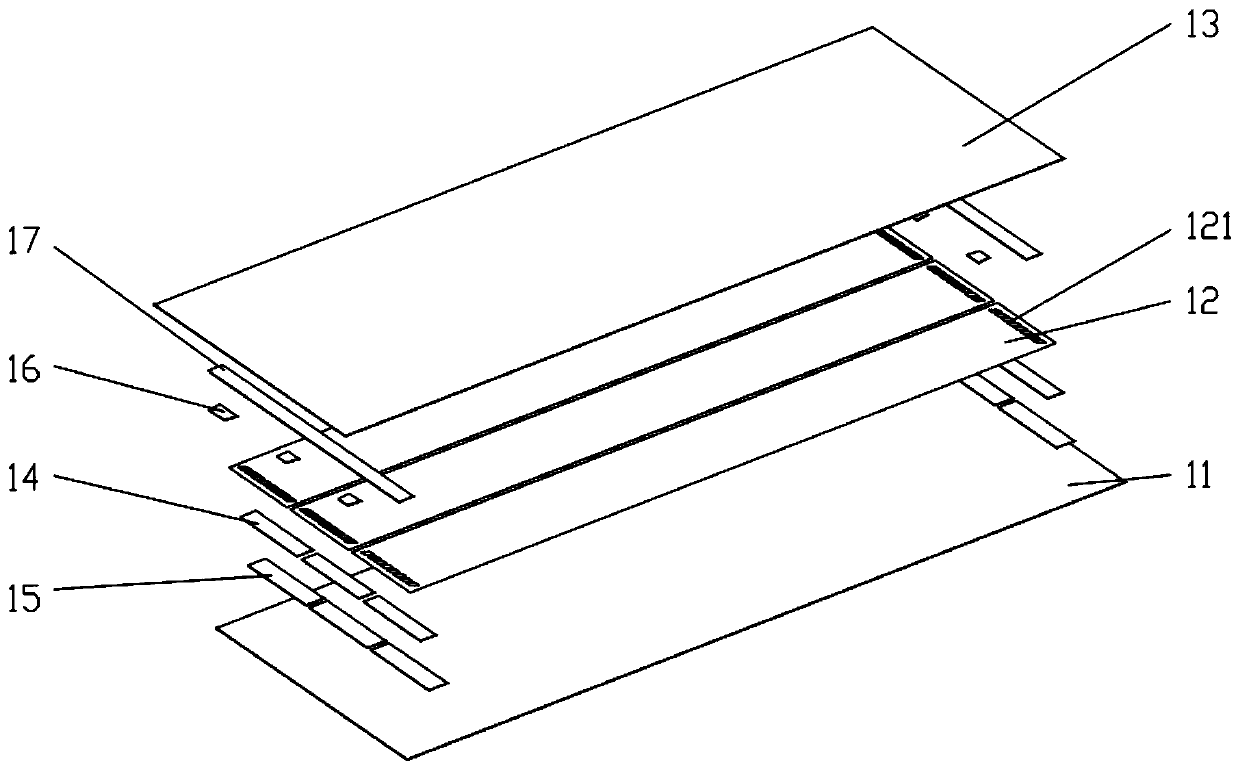

Spontaneous heating multilayer solid wood composite floor

ActiveCN102829507AImprove insulation performanceSimple structureLighting and heating apparatusElectric heating systemSolid woodHeat conducting

The invention provides a spontaneous heating multilayer solid wood composite floor. The spontaneous heating multilayer solid wood composite floor comprises a top layer, a bottom layer and an interlayer between the top layer and the bottom layer, wherein at least one flat cable slot is arranged on the interlayer in the longitude direction thereof, and the at least one flat cable slot is equipped with an electrical heating coil therein which is connected with the power supply through the flat cable slot. The electrical heating coil is a kind of carbon nanocoil which is made from a carbon nano composite material. The wall surface of the at least one flat cable slot is equipped with metal material heat conducting layer. The spontaneous heating multilayer solid wood composite floor provided by the invention has simply structure and is easy to be installed by way of machining a flat cable slot on the interlayer and arranging carbon nanocoil in the flat cable slot, and the heat conducting layer on the surface of the flat cable slot is capable of uniformly conducting heat to the floor surface because the carbon nanocoil has very high electricity-heat transfer efficiency, so that the composite floor provided by the invention has low energy consumption, is very safe and suitable for office, household and other various of sites, and has extensive application.

Owner:SUZHOU KANG CARBON WARM HOME TECH CO LTD

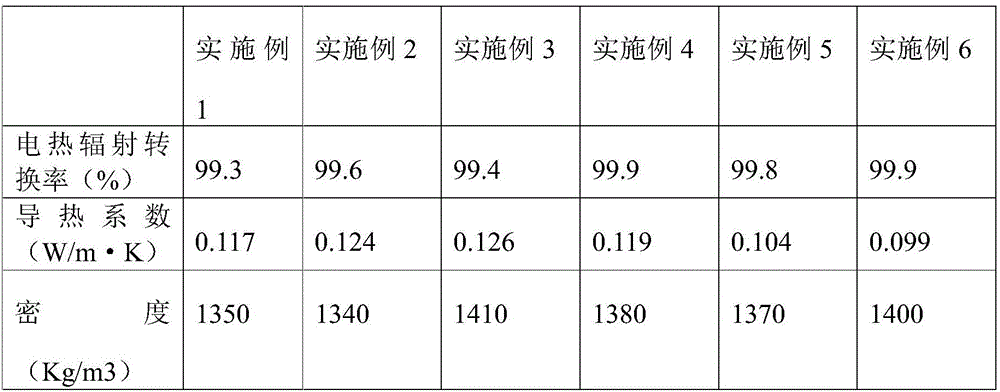

Manufacturing process of graphene nanometer far-infrared negative ion electrothermal film

InactiveCN109423130AImprove thermal conductivityImprove conductivityLamination ancillary operationsLaminationWire gauzeScreen printing

The invention relates to the field of manufacturing of electrothermal films and manufacturing of electrothermal products, and particularly relates to a manufacturing process of a graphene nanometer far-infrared negative ion electrothermal film. Biaxially oriented stretching film is coated in front and back sides of a graphene aqueous carbon nanometer electrical heating material layer, a nanometerfar-infrared negative ion ink layer is printed on the oriented stretching film on the front side of the graphene aqueous carbon nanometer electrical heating material layer by a silk screen, and a reflective film aluminum powder ink layer is printed on the oriented stretching film on the back side of the graphene aqueous carbon nanometer electrical heating material layer by the silk screen. The manufacturing process fully utilizes the characteristic that graphene has excellent electrical conductivity and thermal conductivity; multi-layer graphene powder is selected to be combined with carbon nanotube powder; other auxiliary materials and diluents are fully combined, wrapped and added; a conductive heating liquid is prepared by roller grinding and filtration; and after dilution is performed,the electrothermal film can be used for printing and spraying on various substrates to form a conductive heating product.

Owner:北京绿能嘉业新能源有限公司

Graphene composite fiber far infrared anion flexible conductive heating board and production technology

InactiveCN107105528AGood electrical conductivityHigh electrothermal conversion rateOhmic-resistance heatingCvd grapheneCarbon nanotube

The invention belongs to the field of producing a heating board through an electric heating material and particularly relates to a graphene composite fiber far infrared anion flexible conductive heating board and a production technology. The conductive heating board comprises hot melt adhesive film, a heating core, a decoration layer and a balance layer. The specific structure is as follows that the hot melt adhesive film is arranged on the top of the balance layer; the heating core is arranged on the top of the hot melt adhesive film; the hot melt adhesive film is arranged on the top of the heating core; the decoration layer is arranged on the top of the hot melt adhesive film; and the heating core is graphene nano far infrared anion composite fiber conductive heating film. In order to save energy and exert a demand that functions of the conductive heating board need to be expanded, according to the graphene composite fiber far infrared anion flexible conductive heating board and the production technology, the present advanced graphene raw material is taken as a heating unit, the graphene material is acknowledged that the electric conductivity and the thermal conductivity are the best, the electric conductivity and the thermal conductivity of the graphene material are higher than those of the electric heating materials such as carbon fibers and carbon nano tubes, and the electric heating conversion rate and the far infrared radiation of the graphene material are high.

Owner:北京绿能嘉业新能源有限公司

Graphene far-infrared heating negative-ion light wave plate and manufacturing method thereof

InactiveCN107079746APromote photosynthesisImprove germination rateClimate change adaptationGlass/slag layered productsFiberInsulation layer

The invention belongs to the field of functional materials and electric heating elements and particularly relates to a graphene far-infrared heating negative-ion light wave plate and a manufacturing method thereof. The graphene far-infrared heating negative-ion light wave plate comprises a front-side plate, a heating plate, a heat insulation layer, a reflective layer and a rear cover plate which are sequentially arranged in the up-and-down order, wherein the heating plate is provided with glass fiber cloth, a resin adhesive layer and a graphene nano far-infrared negative-ion composite fiber conductive heating film, and the resin adhesive layer and the glass fiber cloth are sequentially arranged at the upper part and the lower part of the graphene nano far-infrared negative-ion composite fiber conductive heating film. As far-infrared transmitted waves and crop-absorbed sunlight have the consistent nutrition wavelength for photosynthesis, photosynthesis of crops can be promoted, the germination rate and the emergence rate of the crops are improved, the growth cycle is shortened, accordingly, maturation of the crops is quickened, and the growth environment can be regulated and controlled and the temperature and the humidity can be controlled according to different growth cycles of the crops.

Owner:北京绿能嘉业新能源有限公司

Graphene nano far infrared negative ion composite fiber conductive heating plate and production process

InactiveCN107197549AImprove conductivityHigh electrothermal conversion rateNon-macromolecular organic additionPaper/cardboardFiberCarbon fibers

The invention belongs to the field of a heating plate made from an electric heating material, and particularly relates to a graphene nano far infrared negative ion composite fiber conductive heating plate and a production process. The conductive heating plate comprises an impregnated glass fiber fabric layer, a heating core and an impregnated glass fiber fabric layer; the impregnated glass fiber fabric layer and the impregnated glass fiber fabric layer are respectively arranged at the top and the bottom of the heating core; and the heating core is a graphene nano far infrared negative ion composite fiber conductive heating film. In order to save energy better and play the requirement of the conductive heating plate for expanding functions, according to the invention, graphene advanced nowadays is used as a raw material; and as a heating body, the graphene material is a recognized material with the best electrical conductivity and thermal conductivity, is superior to electric heating materials such as carbon fibers, carbon nanotubes and the like, and is higher in electric-thermal conversion rate and stronger in far infrared radiation.

Owner:北京绿能嘉业新能源有限公司

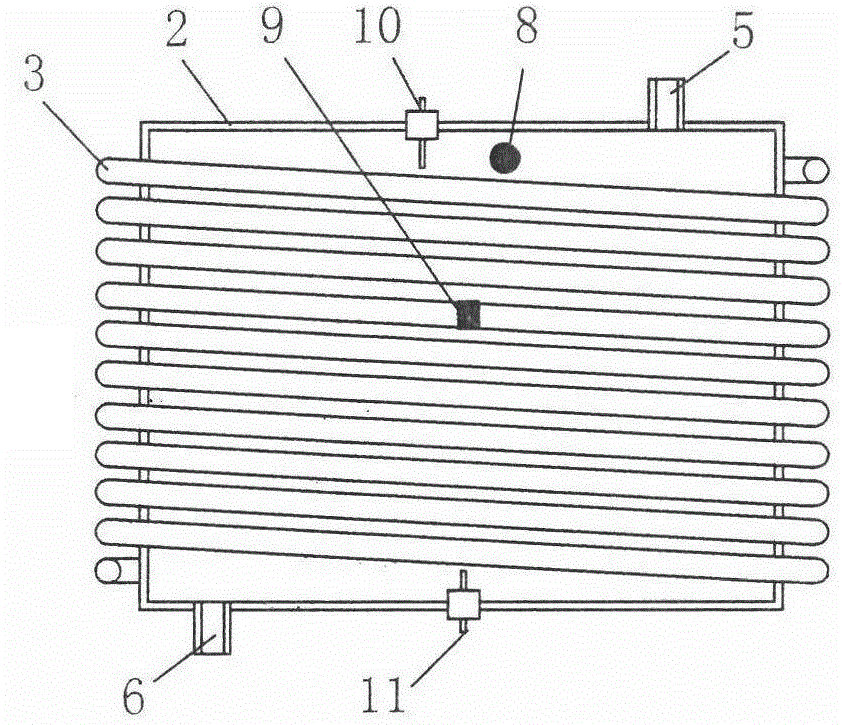

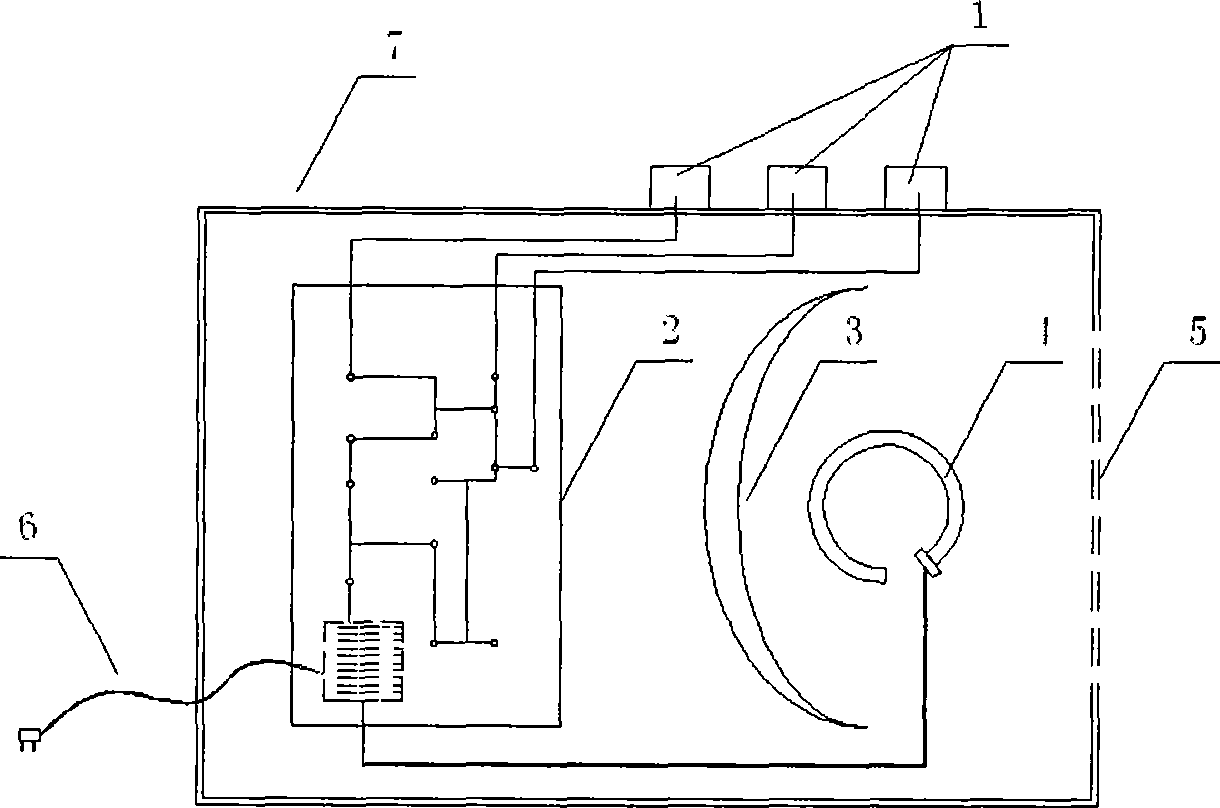

Scale-free and radiation-free technology of intelligent electromagnetic energy water heater

InactiveCN105485893AStable jobGuaranteed to workScale removal and water softeningWater heatersCapacitanceElectromagnetic radiation

The invention discloses a scale-free and radiation-free technology of an intelligent electromagnetic energy water heater. Heating is carried out in a high-frequency electromagnetic induction manner, and electricity is saved by 1 / 4 or near 1 / 3 compared with a common electric heating tube water heater. As heating coils are not in contact with water, the combustible-gas inflammable possibility, the combustible gas explosive possibility and the carbon monoxide poisoning possibility can be avoided, and therefore safety is quite high. After several years of long-term experimenting, the working frequency and the waveform of the water heater are changed, and scale is effectively eliminated; the water temperature can be controlled to the accurate temperature with the temperature error of + / -0.5 DEG C through the PID adjustment technology and the self-adaptive technology; multiple intelligent technologies such as various intelligent functions including WiFi, voices, a Bluetooth network, a wireless panel and the like are adopted; the water-cooling cooling technology of a water inlet tank is used, and therefore stable work of a high-power electronic device is guaranteed; and a shell is made of a flame-retardant and insulating material, the interior is made of an anti-radiation material, the resistance-capacitance absorption technology is adopted for the interior, and the electromagnetic radiation value is reduced to be zero. The electromagnetic-energy, radiation-free and scale-free technology is suitable for water heaters, induction cookers, water dispensers, winter heating and the like, and can be further applied to hospitals, touring, civil boilers and industrial boilers, and the market is quite large.

Owner:CHENGDU YINDING TECH

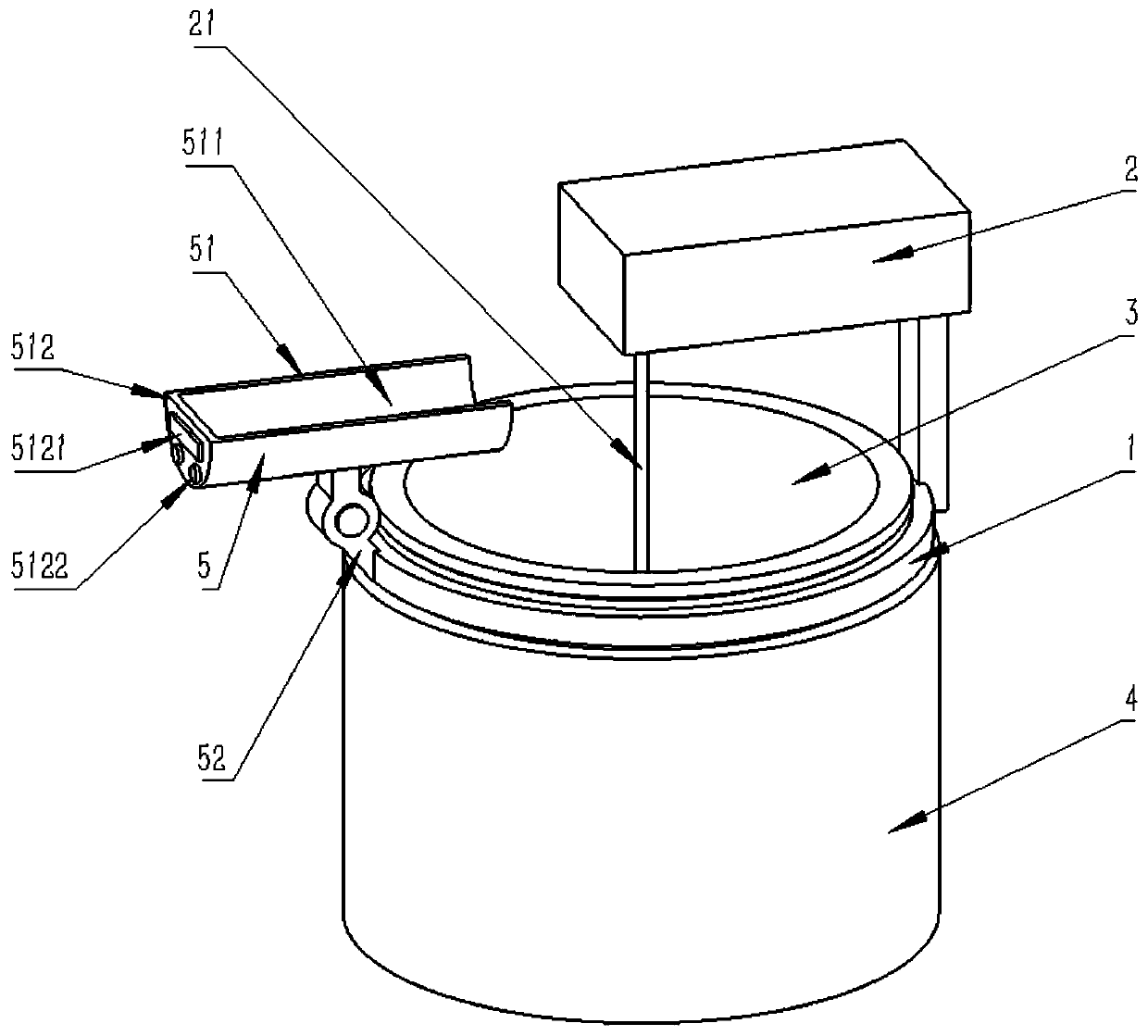

Warming equipment of capacitor

ActiveCN108198687AImprove the heating effectImprove insulation effectCapacitorsInduction current sourcesCapacitorThermal expansion

The invention relates to the field of a capacitor. Aiming at the technical problem that an existing capacity cannot be used in an extremely cold temperature, warming equipment of a capacitor is provided. The warming equipment comprises a shell, a heat preservation cover, a support rod and a handle, wherein an installation hole is formed in the shell, the heat preservation cover is fixedly arrangedin the shell, an installation cavity is formed between the heat preservation cover and the shell, a friction bottom layer is arranged on an outer surface of the heat preservation cover, the support rod is arranged in the installation cavity, the support rod has a shape matched with the shape of the outer surface of the heat preservation cover, the support rod is rotatably arranged in the installation hole, the support rod rotates around the heat preservation cover in the installation cavity by taking the installation hole as a circle center, a fixed rod made of a thermal expansion and cold shrinkage material is arranged on the support rod, one end of the fixed rod is fixedly connected with the support rod, a friction body is fixedly arranged at the other end of the fixed rod and generatesfriction with the friction bottom layer to generate heat, and the handle is arranged outside the shell and is used for driving the support rod to rotate.

Owner:宁波隆锐机械制造有限公司

Dynamic infrared spectrum physiotherapy equipment

The invention discloses a dynamic infrared spectrum physical therapeutic instrument, which mainly comprises a dynamic output power adjusting device and an infrared radiation device, wherein the dynamic output power adjusting device adjusts the working voltage or current of the infrared radiation device to make the output power of the infrared radiation device generate dynamic change and make the heating temperature of the infrared radiation device dynamically fluctuate, so that total radiant flux, flux density and radiation wavelength peak value of the infrared radiation are also dynamically changed. The dynamic spectrum of the dynamic infrared spectrum physical therapeutic instrument can make microvibration of the infrared energy and infrared particles resonant with microvibration of cells of a human body to strengthen the effects of health care, treatment and cosmetology. The dynamic output power adjusting device can adopt music to follow circuits, so that the fluctuation caused by the voltage or current adjustment has musical rhythm, and the physical therapy and the musical therapy can be cooperated to strengthen comprehensive curative effect.

Owner:易智强

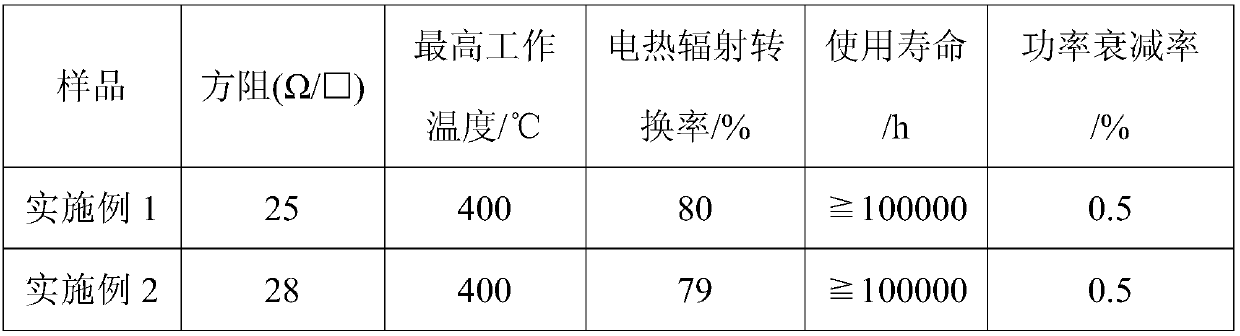

Electric heating printing ink as well as preparation method and application thereof

InactiveCN109517445AReduce contact resistanceImprove far-infrared radiation rateInksHeating element materialsMass ratioWorking temperature

The invention provides electric heating printing ink as well as a preparation method and application thereof. The electric heating printing ink contains the following components in parts by mass: 2-10parts of a conductive filler, 1-9.9 parts of a dispersing agent, 30-50 parts of resin and 30-55 parts of a solvent, wherein the conductive filler is conductive carbon black containing graphene and further contains functional elements, the mass ratio of carbon to oxygen in graphene is (20-60) to 1, and the functional elements at least include Fe, Si and Al. The electric heating printing ink provided by the invention has the advantages of high electric heat conversion rate and electric heat radiation conversion rate, stable conductivity and long service life, the power attenuation is reduced, the resistance is adjustable and is minimally 5 omega / formula (shown in the description), the electric heat radiation conversion rate maximally can be 80%, the power attenuation minimally can be 0.5%,the service life minimally can be over 100000h, and the working temperature minimally can be 400 DEG C.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

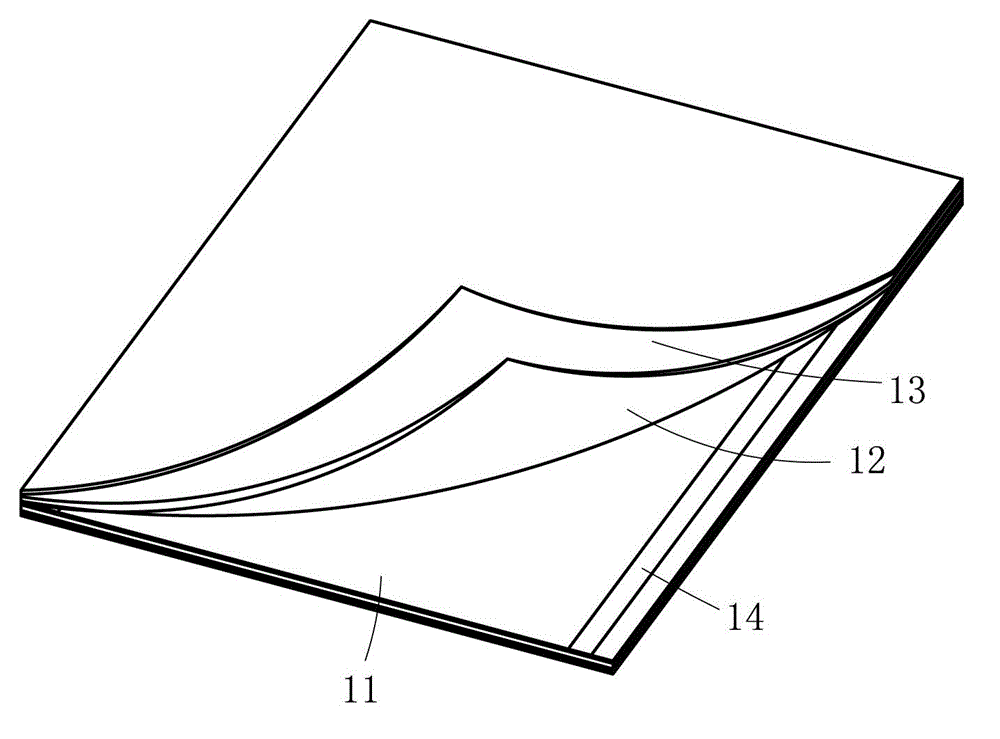

Novel nano-carbon-fiber heating floor and preparation method thereof

ActiveCN105155815AImprove conductivityHigh strengthLighting and heating apparatusElectric heating systemCarbon fibersInsulation layer

The invention provides a novel nano-carbon-fiber heating floor and a preparation method thereof. The preparation method comprises the following steps: (1) placing nano polyacrylonitrile fibers prepared by electrostatic spinning in a roasting oven, performing heat treatment by using air as a medium, and performing carbonization treatment under nitrogen environment so as to obtain carbonized nano polyacrylonitrile fibers; (2) stirring plant protoplasm fibers and a cationic surface active agent under a closed condition and normal temperature till a uniform mixture is obtained, adding the carbonized nano polyacrylonitrile fibers and nano graphite powder in the mixture, stirring the carbonized nano polyacrylonitrile fibers, the nano graphite powder and the mixture at a high speed, and preparing sheet type flexible macromolecule materials by a hot-pressing technology; (3) fixing metal-sheet electrodes at both ends of the sheet type flexible macromolecule materials by a silver solution so as to form a conductive heating layer; and (4) shearing a solid-wood layer, an insulation layer, the conductive heating layer, a temperature control layer, another solid-wood layer and a surface treatment layer with appropriate sizes from bottom to top, and performing combination so as to form the nano-carbon-fiber heating floor.

Owner:浙江康辉木业有限公司

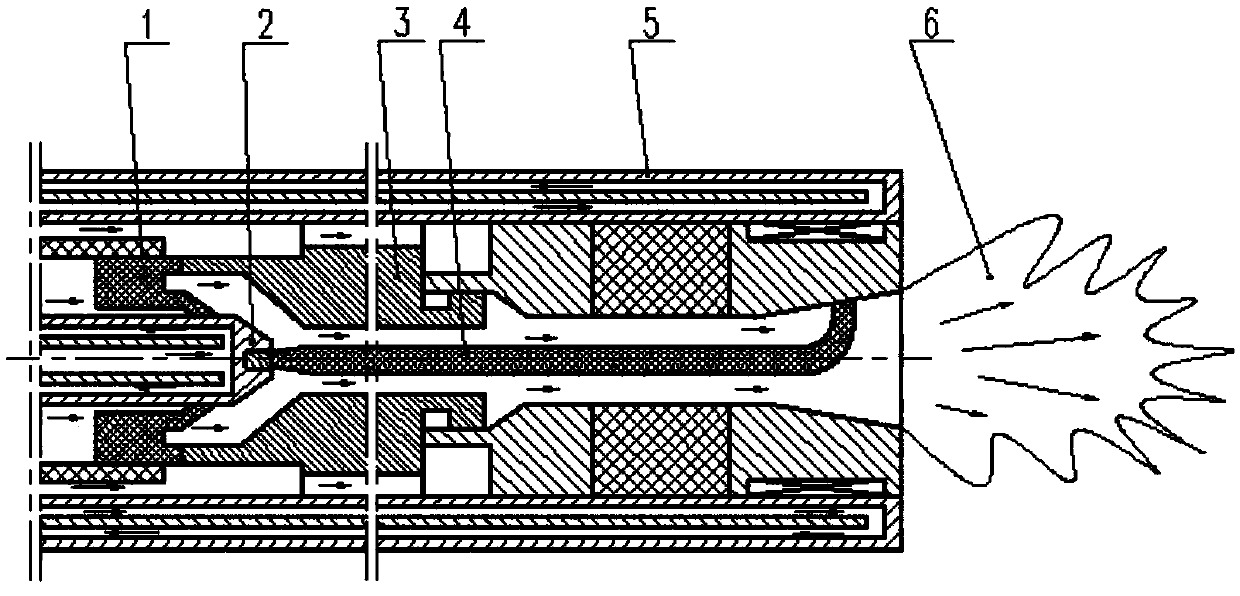

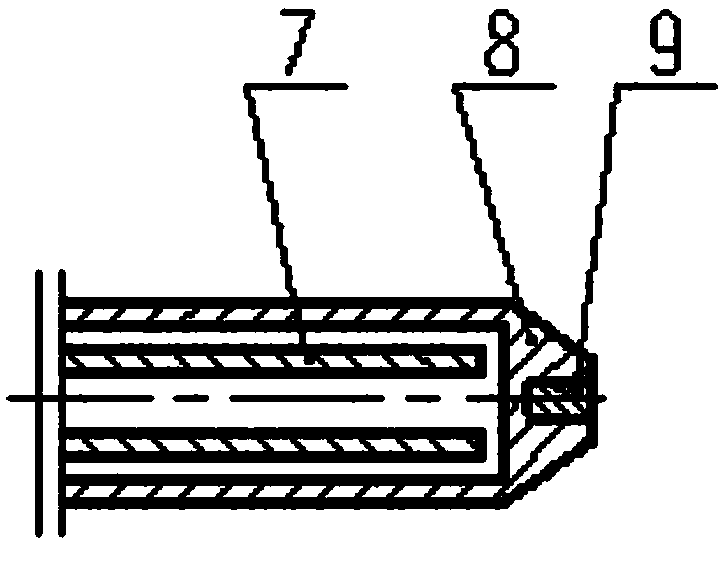

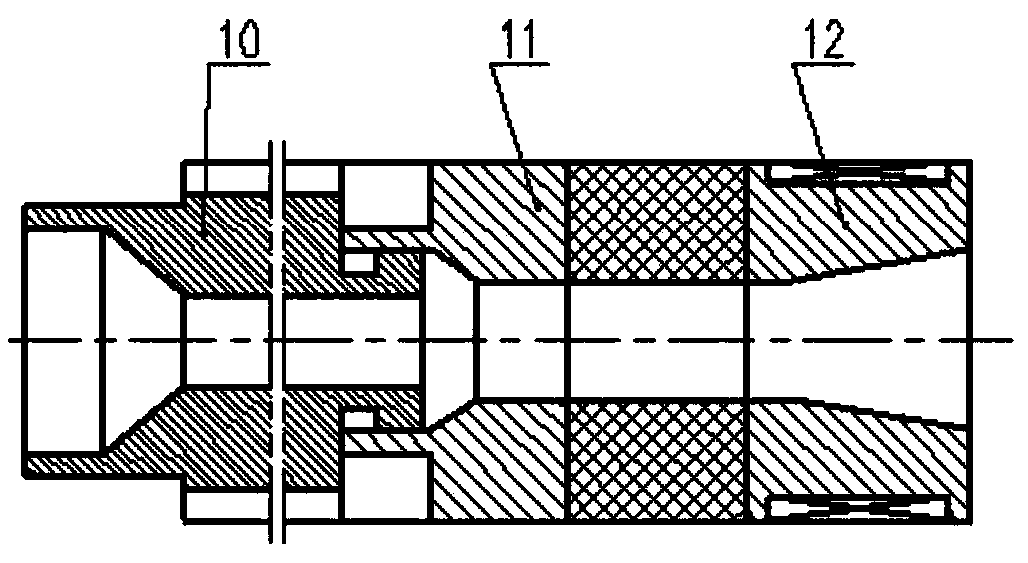

Magnetic rotating arc plasma generator

The invention relates to a magnetic rotating arc plasma generator, and belongs to the technical field of plasma generators. The magnetic rotating arc plasma generator comprises a cathode, a magnetic rotating arc anode, a rotational flow ring and an anode water channel, and is characterized in that the cathode and the magnetic rotating arc anode are arranged in a coaxial manner; the magnetic rotating arc anode comprises an arc starting anode, a transition anode and a main anode, the transition anode comprises a conducting section and an insulating section, and the main anode comprises an electromagnetic coil and a main anode body. The magnetic rotating arc anode is in the shape of a special-shaped circular tube on the whole, one end of the magnetic rotating arc anode is in the shape of a bell mouth, and the middle of the magnetic rotating arc anode is provided with a through hole. The air flow generates a rotational flow through the rotational flow ring, the electromagnetic coil generates an electromagnetic field, the rotational flow and the electromagnetic field compress the arc together and drive the arc to rotate, thereby enabling the root of the arc to rotate with a high speed on the main anode. The magnetic rotating arc plasma generator has the advantages of high arc voltage, low operating current, high electric-thermal conversion efficiency, small electrode ablation amount, small fluctuation range of arc voltage, wide power adjustment range, low operation cost, good disassembly and assembly characteristic, high practicability and the like.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD

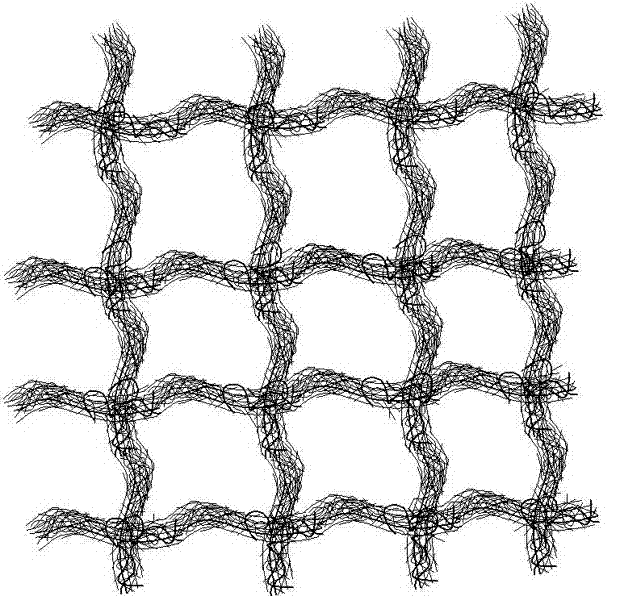

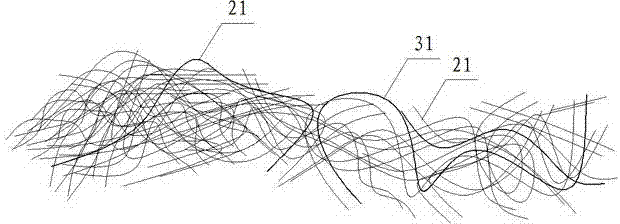

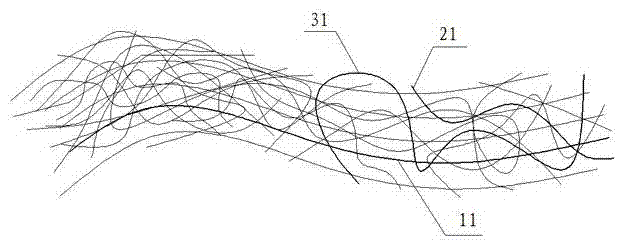

Metal-wire-containing electric heating fabric suitable for severe environment

ActiveCN103194842ASimple structureReduce thicknessFibre treatmentOhmic-resistance heatingElectric heatingYarn

The invention relates to metal-wire-containing electric heating fabric suitable for a severe environment. A main body is formed by spinning yarns, an electric channel formed by metal wires and capable of heating after power is on is arranged in the main body, and various function layers can be arranged on the fabric surface according to requirements. The electric heating fabric has high mechanical performance and electric heating performance, can prevent water effectively, is resistant to high temperature and low temperature, suitable for various severe environments, good in internal electrical conductivity and small in resistance. An electrical characteristic and a heating characteristic of the fabric can be adjusted effectively by adjusting the tensioning degree or compact degree of the fabric. The fabric is suitable for heat preservation and heating of devices under various outdoor situations, especially long-distance electric heating snow removing and ice removing of tracks.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

Graphene heating film

PendingCN111163540ABlock direct contactPrevent vulcanization reactionOhmic-resistance heatingSilver electrodeGraphite

The invention relates to the technical field of graphene material application, and particularly discloses a graphene heating film. The graphene heating film comprises a heating film body, and the heating film body comprises a carrier and a plurality of rectangular surface-shaped graphene heating coatings coated on the carrier, and a polymer insulating film is thermally coated on the graphene heating coatings; silver electrode strips are arranged at the bottoms of the two ends of each graphene heating coating, and graphene strips for preventing the silver electrode strips from making contact with the carrier are arranged between the silver electrode strips and the carrier. The adjacent graphene heating coatings are connected in parallel through the electrode connecting sections, electrode current-carrying strips are arranged on the upper surfaces of the graphene heating coatings and the electrode connecting sections, and the electrode current-carrying strips are clamped between the graphene heating coatings and the polymer insulating films; connection terminals are arranged at the two ends of the heating film body, penetrate through the current-carrying strips and are fixed to the heating film body, heating is uniform, heating efficiency is high, safety is high, the service life is long, and production monitoring and rear end machining are easy and convenient.

Owner:FOSHAN SHUNDE SANBEI ELECTRONICS CO LTD

Nonmetallic heating filament and preparation method thereof

The invention discloses a nonmetallic heating filament and a preparation method thereof. The nonmetallic heating filament is made by taking a polyester / cotton yarn as a base material, coating a layer of a heating conductive polymeric compound coating on the external surface of the base material and finally drying the coating, wherein, a heating conductive polymeric compound is carbon composite conductive carbon paste, and the carbon composite conductive carbon paste comprises the following components in parts by weight: 1-2 parts of acrylic resin, 1-2 parts of polyurethane resin, 0.5-1 part of carbon black, 0.5-1 part of graphite, 0.1 part of a levelling agent and 0.1 part of a defoaming agent. The preparation method of the nonmetallic heating filament comprises the following steps: paying-off the yarn, soaking the yarn into the paste, shaping, drying, measuring resistance and taking-up the yarn. In the invention, the heating conductive polymeric compound is taken as a heating material and voltage is added to two ends of the heating conductive polymeric compound so that the heating conductive polymeric compound can radiate energy outwards in a far infrared manner, and a far infrared ray has thermal action, thus achieving the heating purpose.

Owner:韩奎

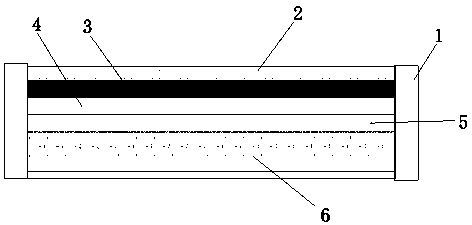

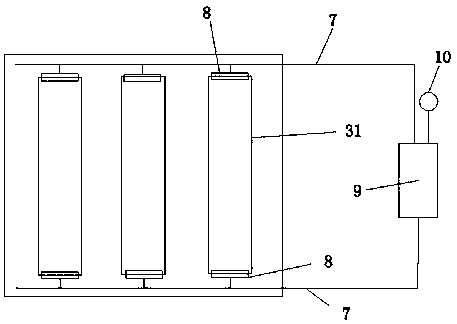

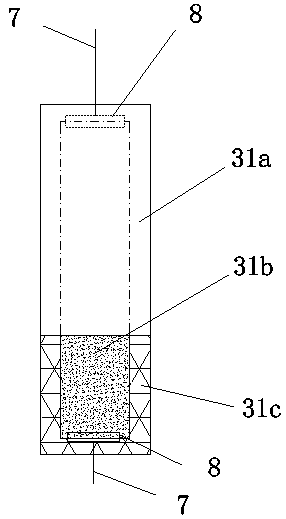

Intelligent far-infrared heating mattress

PendingCN108784120AFast feverImprove efficiencyStuffed mattressesSpring mattressesPower controllerThermal insulation

The invention relates to an intelligent far-infrared heating mattress which is characterized by comprising a mattress frame, an elastic permeable layer, a heating layer, a thermal insulation and reflection layer, a protective layer and a spring; the elastic permeable layer is fixed on the mattress frame, the heating layer is arranged under the elastic permeable layer, the thermal insulation and reflection layer is arranged under the heating layer, the protective layer is arranged under the thermal insulation and reflection layer, and the spring is arranged under the protective layer; the heating layer is formed by connecting a plurality of strip-shaped heating bodies in parallel through a lead; each of the plurality of strip-shaped heating bodies consists of a first insulating layer, a graphene heating layer, electrodes and a second insulating layer, the graphene heating layer is rectangular, the first insulating layer and the second insulating layer seal and wrap the graphene heatinglayer, the electrodes are connected with the two short sides of the graphene heating layer and are also connected with a power supply controller through the lead, and a temperature sensor is also connected with the power supply controller. The intelligent far-infrared heating mattress provided by the invention has the beneficial effects of high heating speed, high heating efficiency, energy conservation, environmental protection, lower manufacturing cost, good heat transfer effect and the like.

Owner:浙江融墨科技有限公司

Pollution-free manufacturing method for surface electric heating elements

InactiveCN103716925AHigh electrothermal conversion rateSmall thermal inertiaOhmic-resistance heatingMagnesium Acetate TetrahydrateFluoroboric acid

A pollution-free manufacturing method for surface electric heating elements is characterized in that a formula of a surface modification solution comprises, by weight, 100g of stannous fluoroboric acid, 1-1.2g of antimony trifluoride, 0.2-0.4g of cupric acetate monohydrate, 0.2-0.4g of magnesium acetate tetrahydrate, a proper amount of hydrofluoric acid and a proper amount of acetic acid, and 100-500ml of distilled water. The pollution-free manufacturing method for the surface electric heating elements comprises the steps of (1) preparing the surface modification solution, wherein the distilled water is acidized through the acetic acid, the stannous fluoroboric acid, the cupric acetate monohydrate and the magnesium acetate tetrahydrate are weighed, stirred and melted in the acidized distilled water respectively, antimony trifluoride is quickly weighed, stirred and added in the acidized distilled water, the mixture is stirred, and all the solutions are mixed evenly, sealed and stored at a shady, cool and ventilating place for use; (2) cleaning base materials; (3) feeding the base materials into a surface modification furnace which is 550-650 DEG C to carry out surface modification on the base materials; (4) brushing silver paste at proper positions of radiant faces, and carrying out mechanical wire leading; (5) powering on to carry out aging by using voltages 1.25 times using voltages. The pollution-free manufacturing method for the surface electric heating elements is suitable for manufacturing the pollution-free surface electric heating elements.

Owner:信跃珍

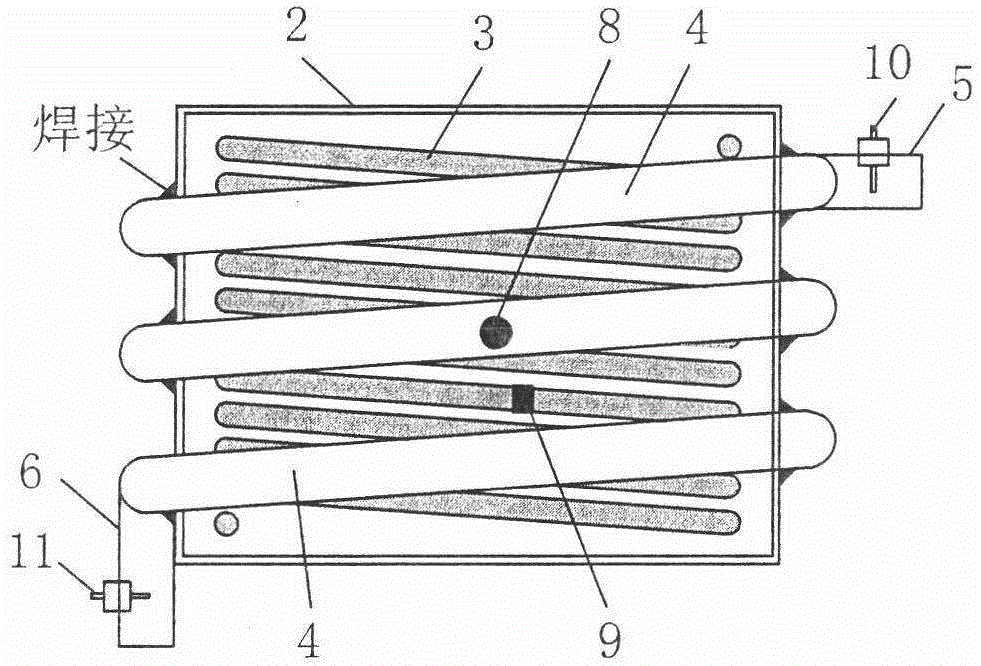

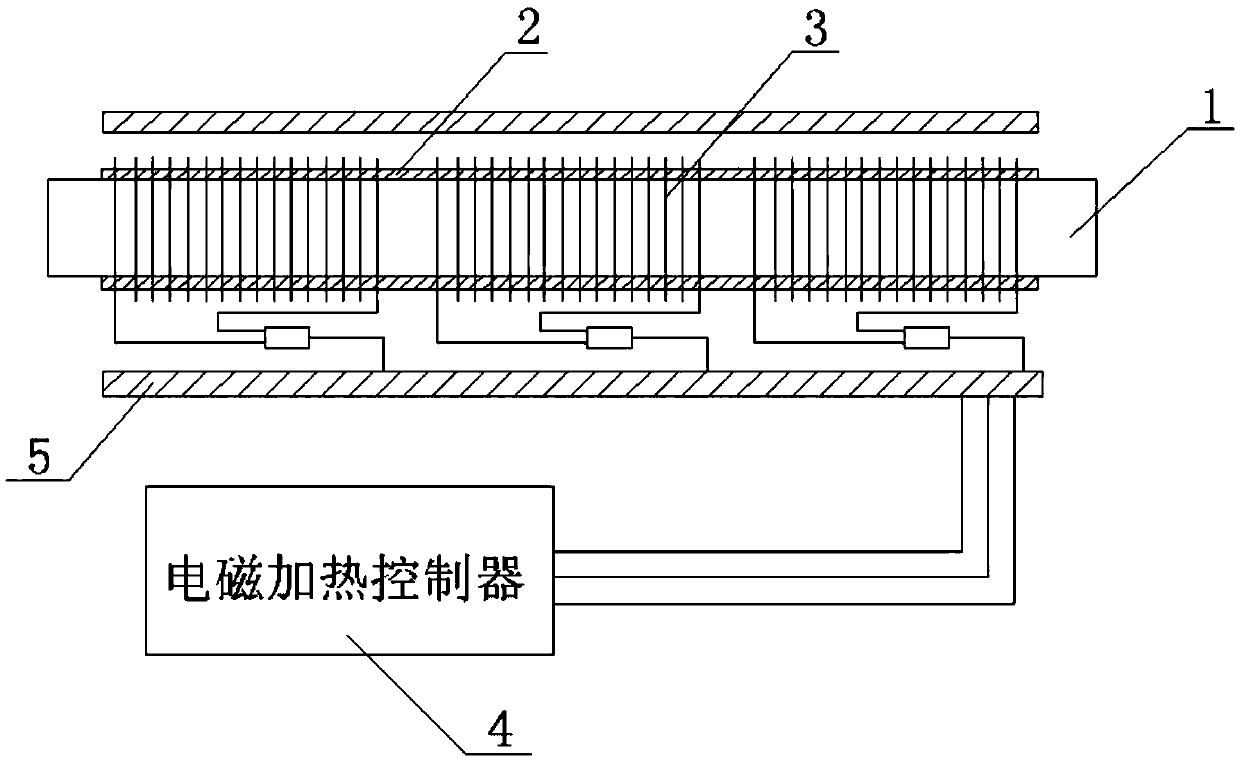

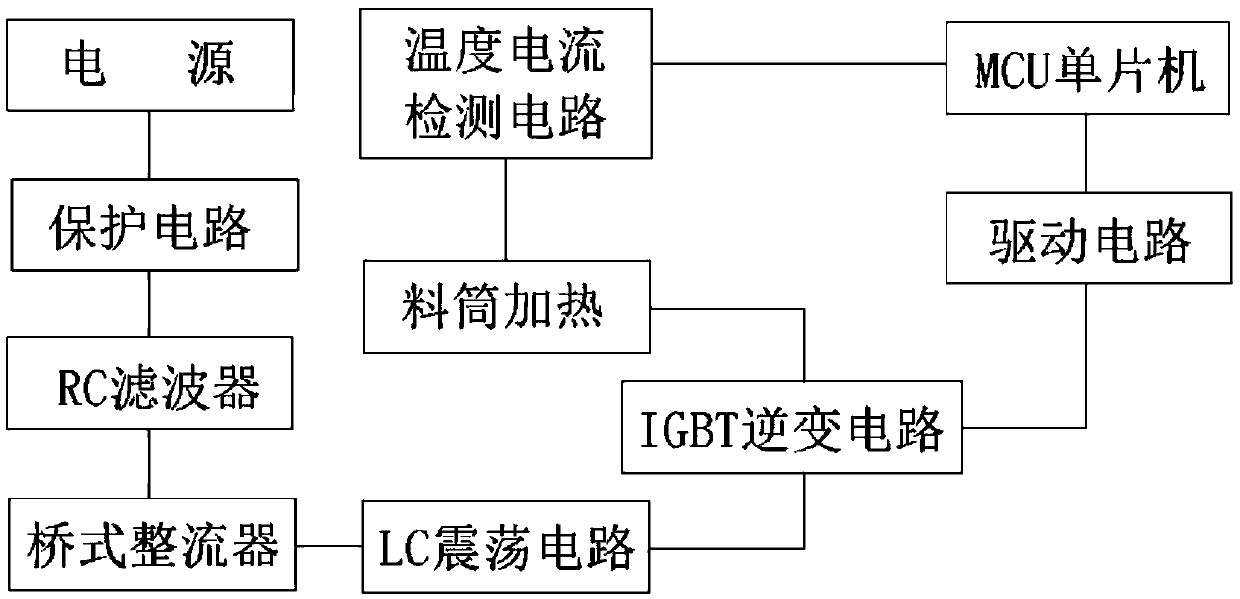

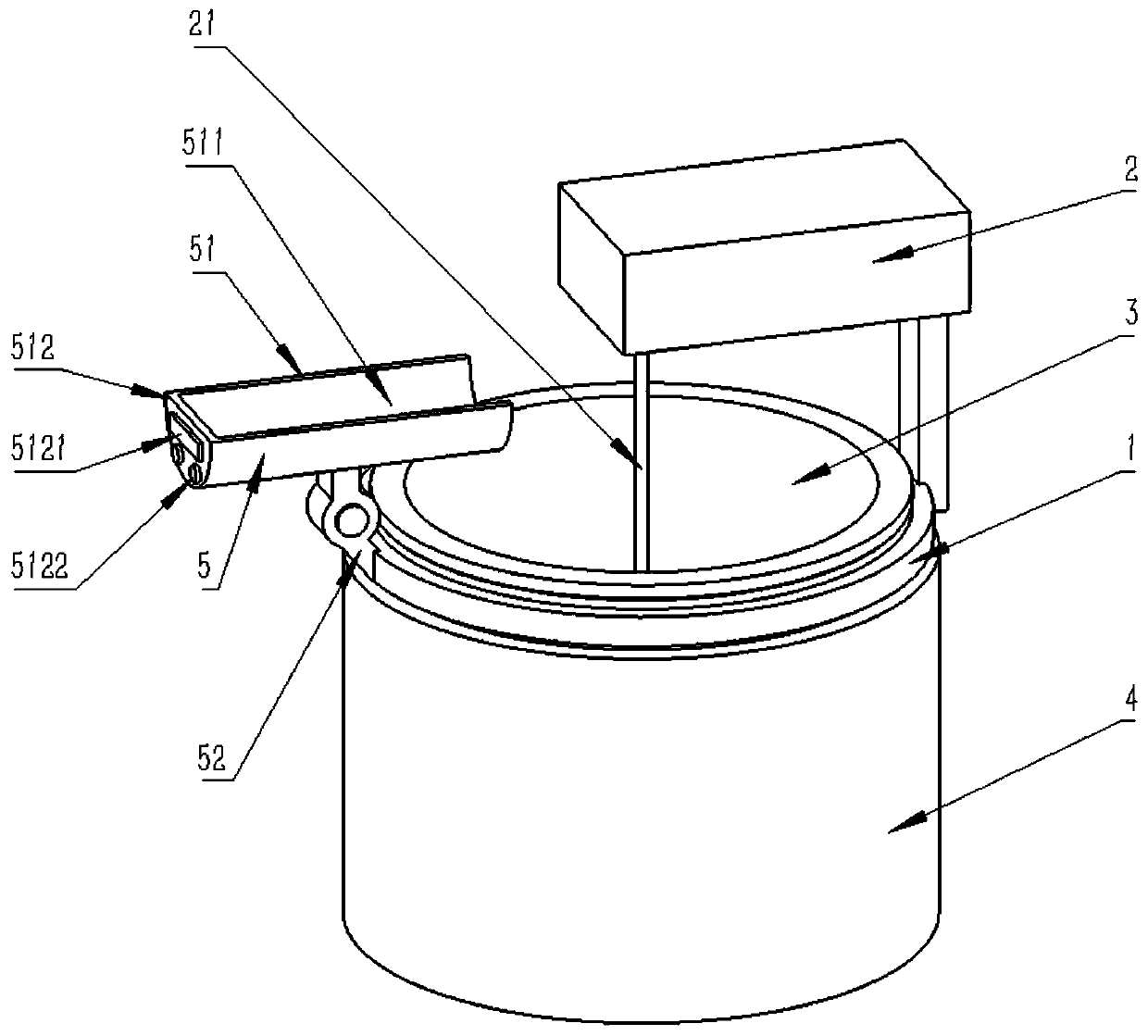

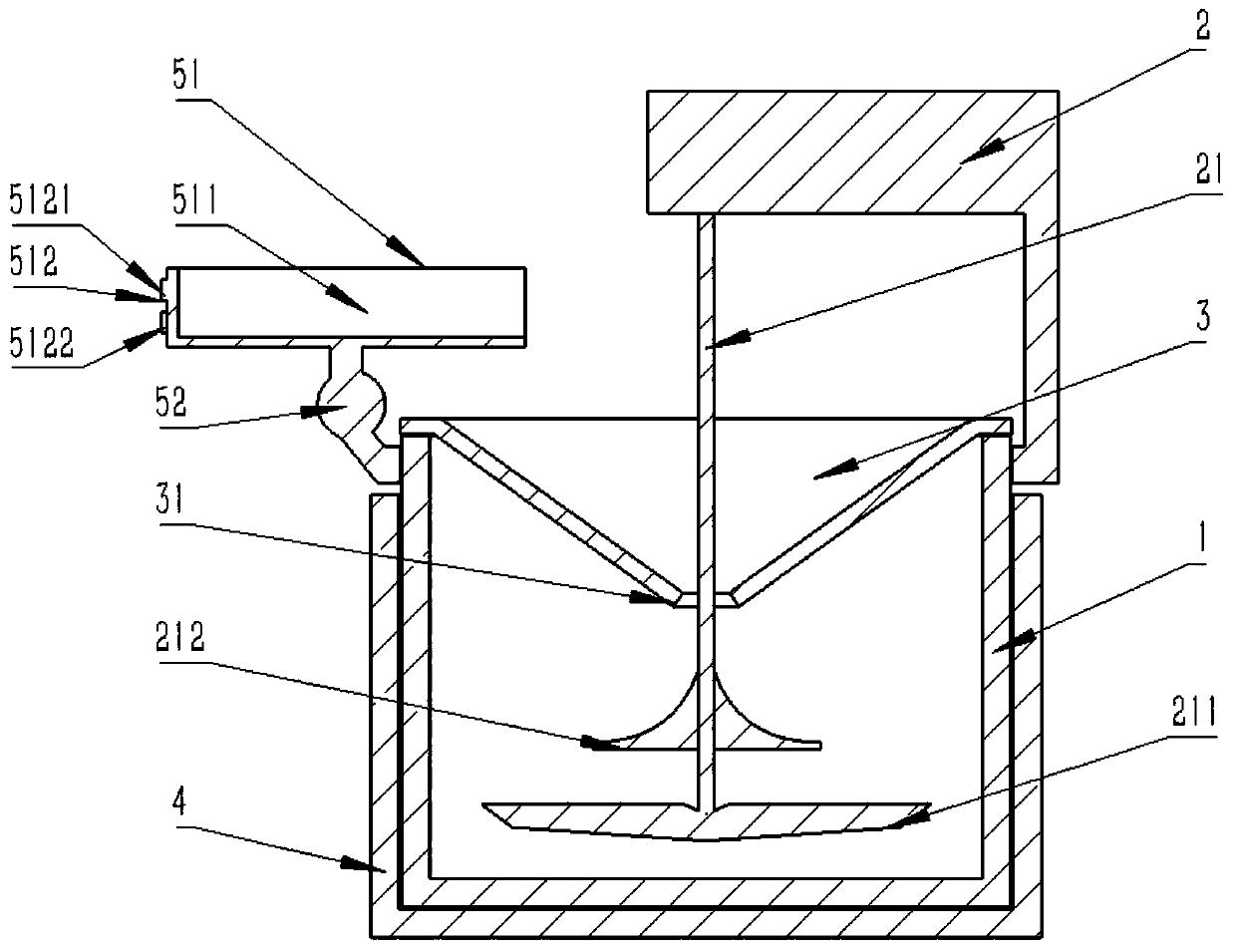

Electromagnetic induction heating system for injection molding machine

InactiveCN105365175AReduce pollutionFast heatingOhmic-resistance heatingInduction heating controlThermal insulationClosed loop

The invention discloses an electromagnetic induction heating system for an injection molding machine. The electromagnetic induction heating system comprises an electromagnetic heating barrel and an electromagnetic heating controller; the electromagnetic heating barrel comprises a charging barrel in the innermost layer, thermal-insulation cotton in the middle layer and winding electromagnetic induction coils in the outmost layer; and the electromagnetic heating controller comprises an RC filter, a bridge rectifier, an LC oscillating circuit and an IGBT inverter circuit, and the IGBT inverter circuit is connected with a plurality of electromagnetic induction coils which are in parallel connection. Due to the fact that the electromagnetic heating controller is connected with the electromagnetic induction coils of the electromagnetic heating barrel, quick heating and closed-loop control on heating temperature are achieved. The electromagnetic induction heating system for the injection molding machine has the advantages of being short in preheating time, high in heating speed, high in electric heating converting rate, small in environment pollution and simple to replace and maintain. In addition, the heating temperature is easy to control, energy conservation and environment friendliness are achieved.

Owner:ANHUI QINGLONGQUAN PRINTING TECH CO LTD

Electric heating coating and preparation method thereof

InactiveCN109913075AHigh electrothermal conversion rateExtended service lifeFireproof paintsAnti-corrosive paintsDissolutionPolymer

The invention provides an electric heating coating on one hand, wherein the electric heating coating comprises the following raw materials by weight: 0.1-5 parts of graphene, 40-60 parts of metal oxide, 5-20 parts of non-metal oxide, 5-20 parts of organic semiconductor materials and 5-20 parts of high-molecular polymer. The invention provides a method for manufacturing an electrothermal coating, wherein the method comprises the following steps: S1, mixing graphene with the high-molecular polymer at a design ratio; S2, heating up the mixture to 80-180 DEG C for full dissolution; and S3, addingthe metal oxide, the non-metal oxide and the organic semiconductor materials into the mixture according to the design ratio, and continuously heating and stirring for 10-30 min. The electrothermal coating provided by the invention has advantages of high electrothermal conversion rate, nano-plane heating, no attenuation, acid and alkali corrosion resistance, availability to preparation in harsh environments with strong corrosion, and long service life.

Owner:秾源科技(北京)有限公司

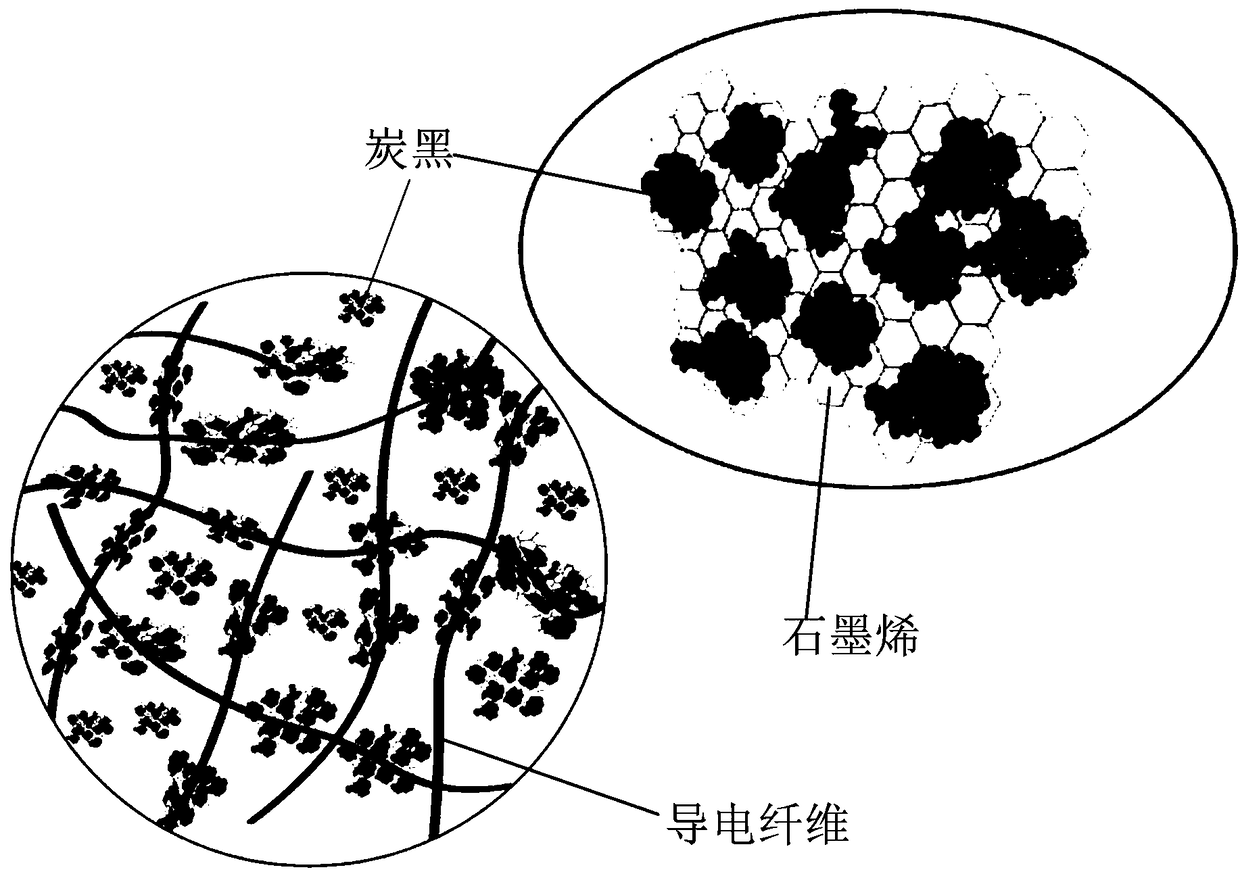

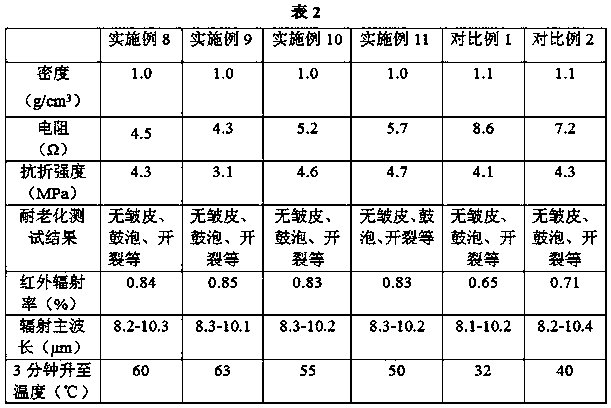

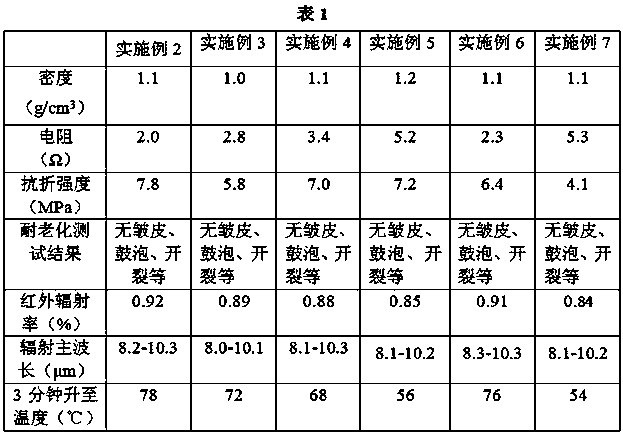

Carbon-system far-infrared radiation electric hot plate and manufacturing method thereof

ActiveCN108574998AIncreasing the thicknessHeat dissipation is slowOhmic-resistance electrodesHeating element materialsFiberComposite ceramic

The invention discloses a carbon-system far-infrared radiation electric hot plate and a manufacturing method thereof. The electric hot plate comprises a carbon-system far-infrared radiant electric hotsubstrate. The substrate is made of a carbon-system far-infrared radiant electric hot composition. The carbon-system far-infrared radiant electric hot composition comprises a carbon-system three-dimensional conductive network body, a composite ceramic powder and a binder. The carbon-system three-dimensional conductive network body is formed by a conductive fiber whose surface is grafted with graphene and carbon black whose surface is grafted with acrylamide through electrostatic adsorption. The electric hot plate possesses a high far-infrared radiation effect and a high release negative ion effect. An infrared radiation wavelength is 8-10nm and the wavelength is similar to an organism. The conductivity of the electric hot plate is good, and the electric hot plate has a high electro-thermal conversion rate, a small resistance, a fast temperature rise speed, a high heat storage capability and good heat dissipation performance, and can be used under a 36V voltage. A good heating effect is reached and safety is high. Besides, the electric hot plate has excellent characteristics of flame retardance, acid resistance, alkali resistance, antibacterial mould prevention, ageing resistance,environmental protection, decorativeness and the like.

Owner:广州东铝轻合金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com