Carbon-system far-infrared radiation electric hot plate and manufacturing method thereof

A technology of far-infrared radiation and electric heating plate, applied in the direction of electric heating device, ohmic resistance heating, ohmic resistance heating parts, etc. Poor heat dissipation and other problems, to achieve good far-infrared radiation effect, good electrical conductivity, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

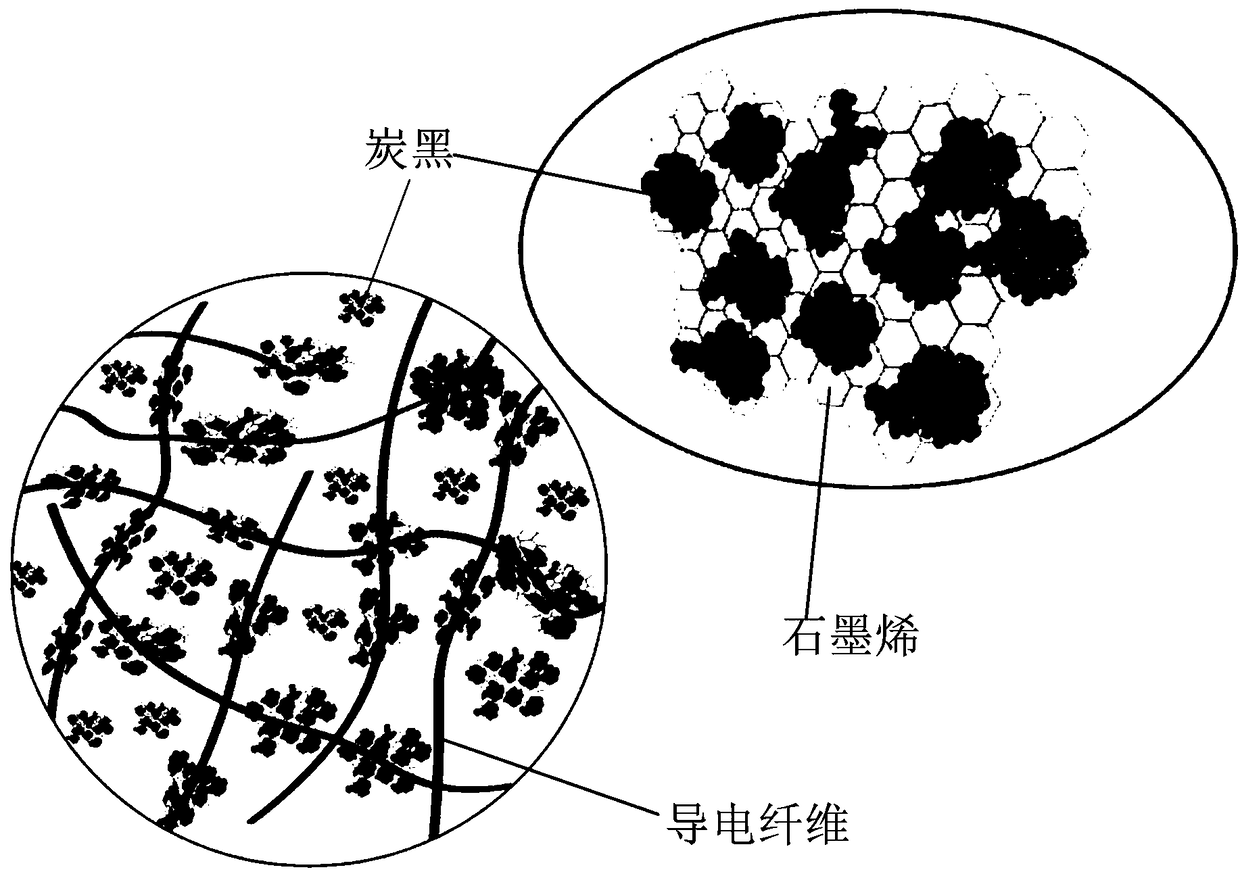

[0042] The carbon-based far-infrared radiation electric heating plate of the present invention mainly includes a substrate, and the thickness of the substrate is generally 5-30 mm. The substrate can be made into different shapes as needed, such as rectangular, square, circular, elliptical, irregular, etc. There may be patterns on the substrate, or there may be no patterns. The size of the substrate can be adjusted as needed. Positive and negative electrodes are provided inside the substrate, and the positive and negative electrodes are located on the same plane perpendicular to the thickness, preferably at 1 / 2 of the thickness of the substrate, and wires are provided on the positive and negative electrodes. The outer layer of the substrate can be further wrapped with an insulating layer or / and a protective layer as an intermediate layer. For example, only the insulating layer can be wrapped on the outer layer of the substrate, or only the protective layer can be wrapped on the...

Embodiment 2

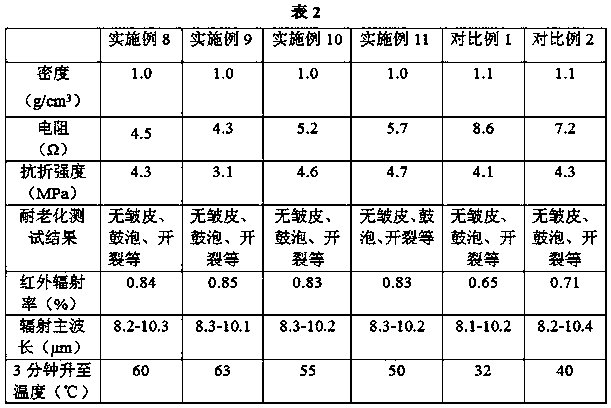

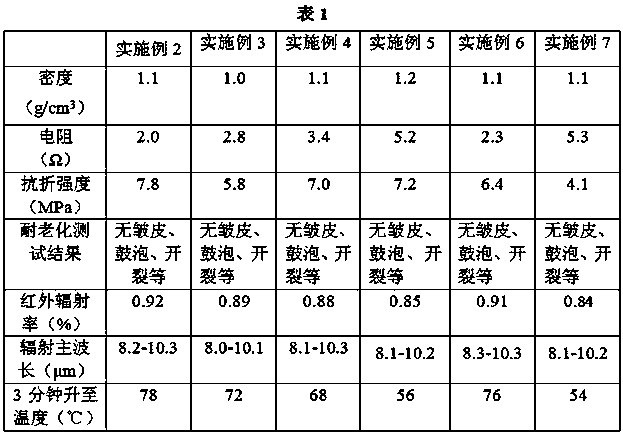

[0047] The structure of the electric heating plate is the same as in Example 1. The substrate is made of a carbon-based far-infrared radiation electric heating composition. The amount of each raw material is 20 parts by weight of graphene, 30 parts of carbon black, 8 parts of conductive fiber, 60 parts of composite ceramic powder, and 50 parts of binding agent. The conductive fiber is graphite fiber, the composite ceramic powder is a mixture of corundum, quartz, titanium dioxide and limestone, and the binder is epoxy resin.

[0048] The preparation method is as follows:

[0049] 1. Add graphite fiber with corundum (100 microns) grinding media for ball milling, the number of ball milling revolutions is 200 revolutions / min, and the time is 1 hour.

[0050] 2. Wash the ball-milled graphite fiber with distilled water for later use; add KH550 to distilled water to prepare a 3vol.% silane coupling agent solution, adjust the pH of the solution to 4, add graphite fiber and graphene to the s...

Embodiment 3

[0058] The structure of the electric heating plate is the same as in Example 1. The substrate is made of a carbon-based far-infrared radiation electric heating composition. The amount of each raw material is 15 parts by weight of graphene, 10 parts of carbon black, 6 parts of conductive fiber, 50 parts of composite ceramic powder, and 35 parts of binding agent. The conductive fiber is graphite fiber, the composite ceramic powder is a mixture of corundum, quartz, titanium dioxide and limestone, and the binder is phenolic resin.

[0059] The preparation method is as follows:

[0060] 1. Add graphite fiber with titanium dioxide (20 microns) grinding media for ball milling, the number of ball milling revolutions is 200 revolutions / min, and the time is 1 hour.

[0061] 2. Wash the ball-milled graphite fiber with distilled water for later use; add KH550 to distilled water to prepare a silane coupling agent solution with a concentration of 3vol.%, adjust the pH of the solution to 6, add gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com