Nano-composite current-conducting electric heating film and production method thereof

A nano-composite and electrothermal film technology, applied in the field of materials, can solve problems such as poor product uniformity, and achieve the effects of low cost, high heat, and high electrothermal conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

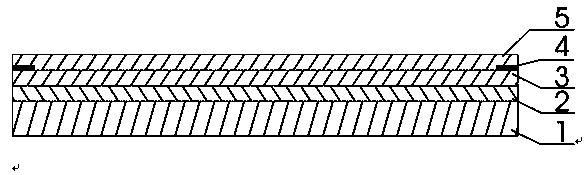

[0056] A method for preparing a nanocomposite conduction electric heating film without an insulating layer, comprising the following steps:

[0057] 1) Select PET (polyethylene terephthalate) film as the substrate layer 1;

[0058] 2) setting of the diversion layer 2: a diversion layer (ITO (indium oxide) transparent conductive film) is vacuum evaporated on the substrate layer 1, its thickness is 100nm, and the sheet resistance (film resistance) is 15 ohms / port , and the diversion layer 2 is entirely covered on the substrate layer;

[0059] 3) Setting of the conductive heating layer 3: by screen printing, a conductive heating ink layer 3 (composed of carbon paste ink, purchased from Shenzhen Baojiayi Technology Co., Ltd.) is completely covered and printed on the guide layer 2 ), the printing thickness is controlled at 0.05mm, and the sheet resistance is 100 ohms / port;

[0060] 4) Electrode setting: Silver paste electrodes (composed of silver paste ink, purchased from Shenzhe...

Embodiment 3

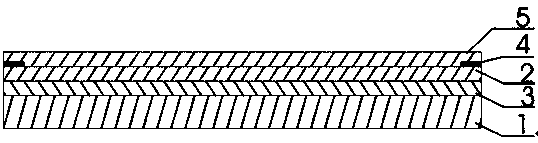

[0066] A preparation method of a nanocomposite conduction electric heating film with an insulating layer, comprising the following steps:

[0067] 1) Select PI (polyimide) film as the substrate layer 1;

[0068] 2) Setting of diversion layer 2: a diversion layer (carbon series conductive ink layer (composition of carbon paste ink, Shenzhen Baojiayi Technology Co., Ltd.) is printed on the substrate layer by gravure printing, which passes through The ink filled with carbon nanotubes is made into gravure printing ink), the guide layer 2 only plays a conductive role, does not generate heat, or the efficiency of heating is low, the sheet resistance is 20 ohms / port, and the overall coverage is on the The entire surface of the PI film;

[0069] 3) The setting of the conductive heating layer 3: making the conductive heating layer 3 above the flow guide layer, which is the same as step 3) of Example 1;

[0070] 4) Setting of electrodes 4: firstly make conductive silver paste at both ...

Embodiment 4

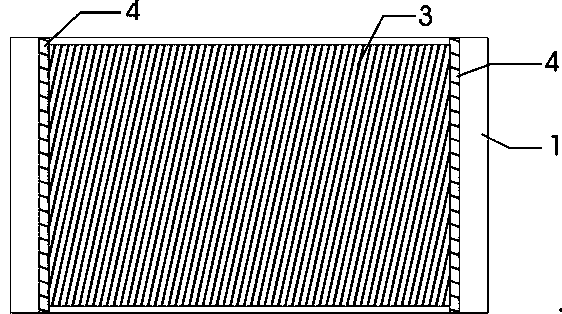

[0073] A preparation method of a nanocomposite conduction electric heating film with uniform through holes, comprising the following steps:

[0074] Step 1), step 2), step 3), step 4), step 5) are identical with embodiment 3;

[0075] 6) Punching the above-mentioned nanocomposite electrothermal film with an insulating layer, such as Figure 4 , Figure 5 or Image 6 As shown, the above layers are all pierced, and the shape of the hole is round, oval or square, which becomes a through hole, so as to obtain a nanocomposite conductive electric heating film with uniform through holes, which can be applied to wood boards, plastics, ceramic tiles, In the interlayer of pavement materials, due to the existence of through holes, good stress penetration can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com