Graphene composite fiber far infrared anion flexible conductive heating board and production technology

A far-infrared negative ion, graphene composite technology, applied in electric heating devices, ohmic resistance heating, electrical components and other directions, can solve the problems of inflexible electric heating plates, polyester electric heating films easy to burn, uneven heating, etc., to achieve uniform heating, The effect of enhancing thermal conductivity and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

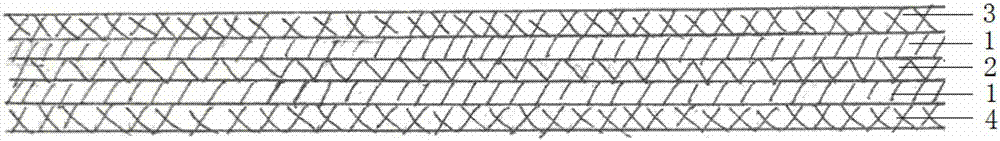

Image

Examples

Embodiment 1

[0038]In this embodiment, the manufacturing process of the graphene composite fiber far-infrared negative ion flexible conductive heating plate is referred to the Chinese invention patent application (publication number: CN103982937A). The difference is that the graphene nanometer far-infrared negative ion composite fiber conductive heating film The production process is as follows:

[0039] The Chinese invention patent application (application number 201710096589.3) is used to prepare the graphene nano far-infrared negative ion composite fiber conductive heating film, and the graphene nano far infrared negative ion composite fiber conductive heating film is used as the main body of the heating core.

[0040] Graphene nanometer far-infrared negative ion composite fiber conductive heating film, comprising plant fiber pulp, graphene powder glue, nanometer bamboo charcoal fiber powder (or nanometer far-infrared negative ion powder) and fiber diffusing agent, by weight parts, plant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com