Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Help break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

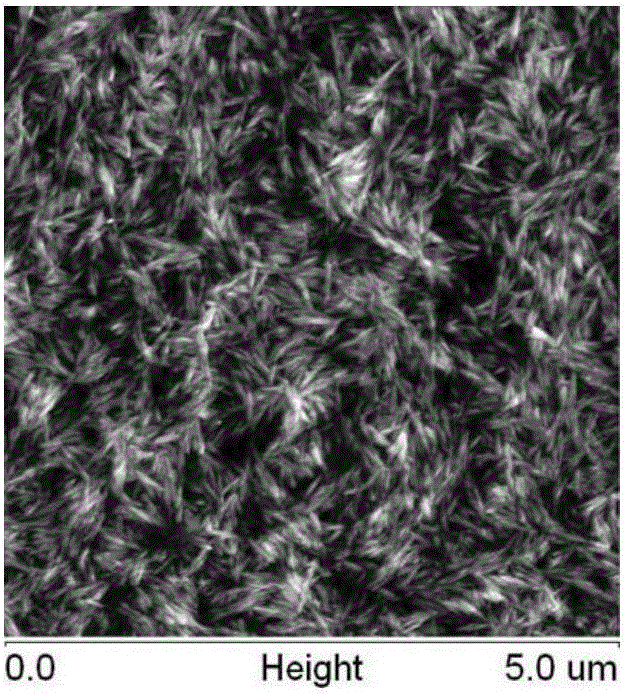

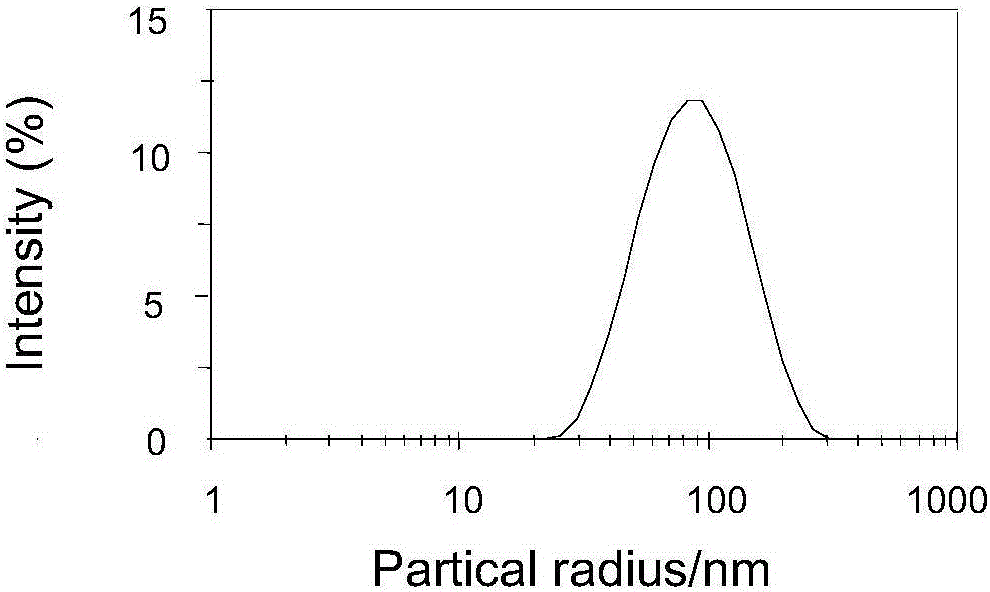

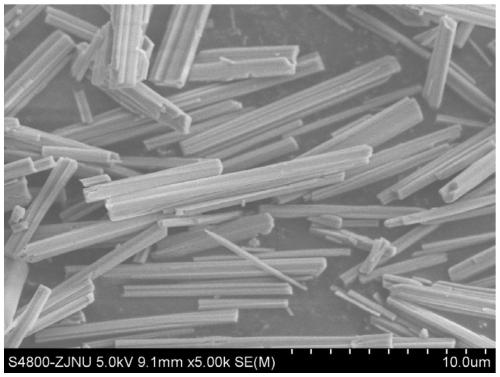

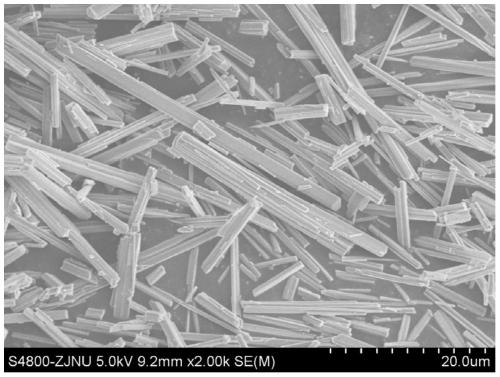

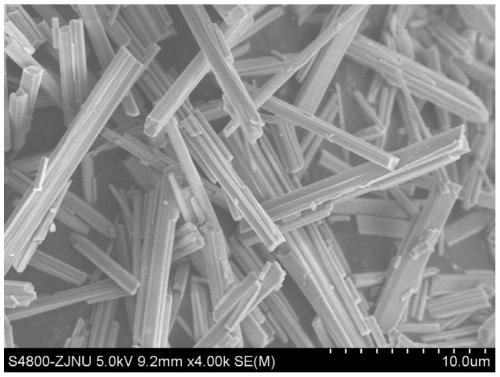

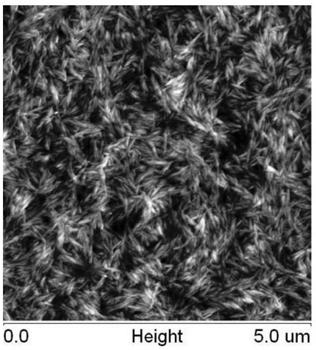

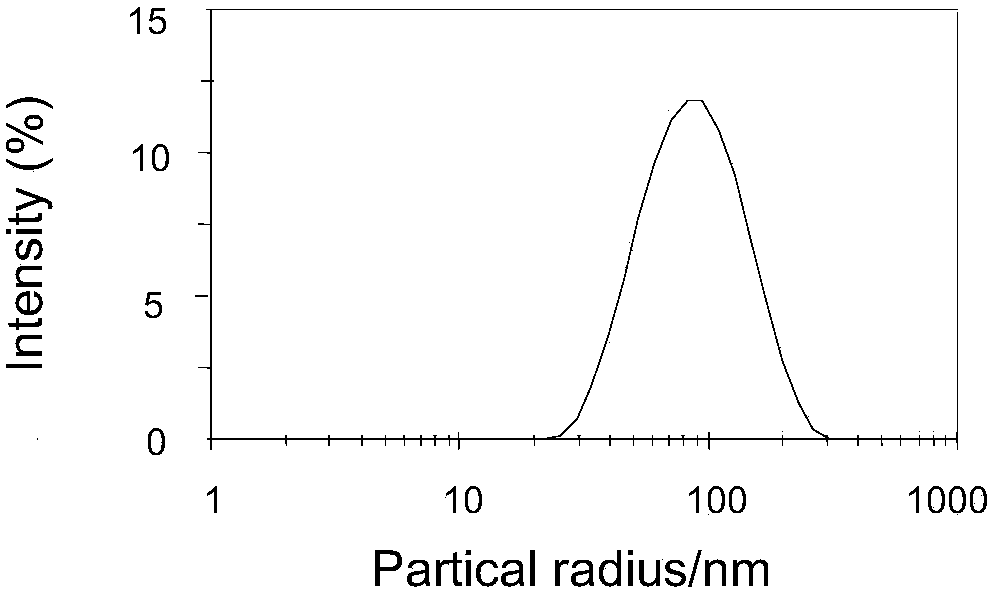

Efficient cellulose nanocrystalline preparing method

ActiveCN105777913AHigh yieldImproved particle size distributionPulp properties modificationWashing/displacing pulp-treating liquorsInorganic saltsCellulose

The invention provides an efficient and quick cellulose nanocrystalline preparing method.According to the method, a cellulose raw material is pretreated with aqueous alkali and then subjected to acidolysis, and inorganic salt containing metal ions is added during acidolysis to serve as a promoter to promote acidolysis reaction.Reaction condition is mild and easy to control, raw materials needed by reaction are simple and easy to obtain, and the method can be widely applied to preparation of cellulose nanocrystalline from various cellulose raw materials.

Owner:QINGDAO UNIV OF SCI & TECH

Raw material for increasing quality of low-rank coal by present tamping coke oven

ActiveCN104327873ASolve the low utilizationSolve the problem of overcapacity in the coking industrySpecial form destructive distillationEngineeringActive ingredient

The invention provides a raw material for increasing quality of low-rank coal by a resent tamping coke oven. The raw material comprises low-rank coal and an auxiliary agent. The auxiliary agent is an organic binder with weightlessness being less than 50% under destructive distillation isolated from the air at 850 DEG C. Preferably, the organic binder is asphaltene with softening point being greater than 100 DEG C. By using the raw material as a raw material for increasing quality of low-rank coal by the use of a tamping coke oven, the problem that present tamping coke ovens have low availability and excess capacity exists in the coking industry is solved, and the problem that application of low-rank coal is limited because there is no large-scale industrial equipment is also solved. After the auxiliary agent is mixed with low-rank coal, active ingredients in the auxiliary agent are beneficial to degradation of high-molecular polymers in the low-rank coal at high temperature and fracture of macromolecules in the low-rank coal. Thus, output of oil gas is raised during the technological process, and the total output of oil gas is increased by more than 10%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

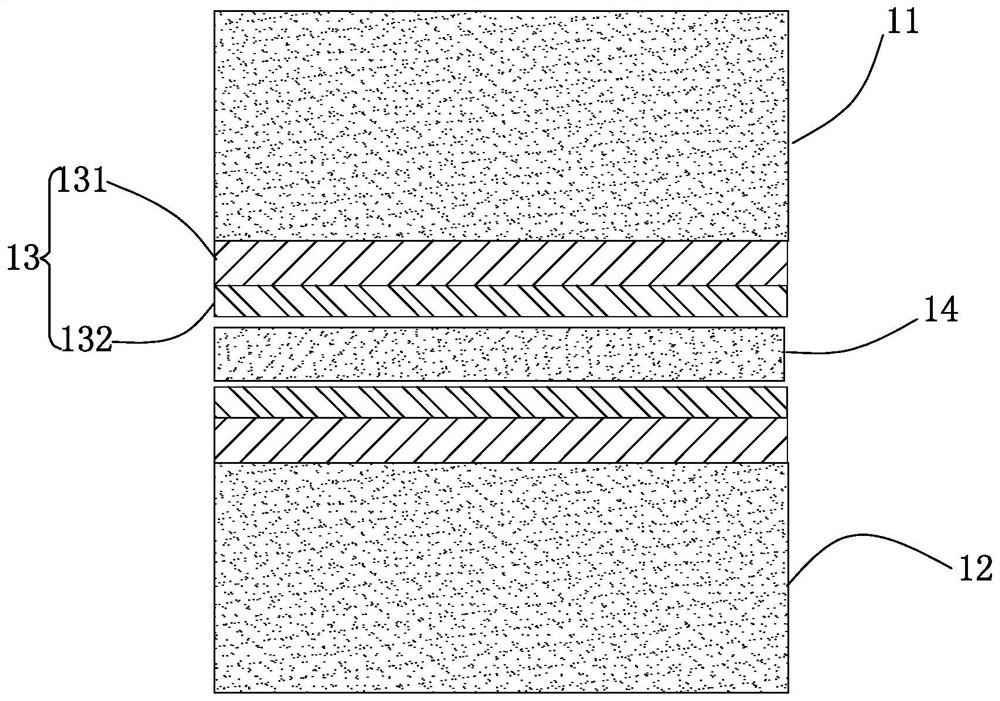

Moulded coal raw material suitable for low rank coal upgrading technology

ActiveCN104479709ASolve the low utilizationImprove qualitySpecial form destructive distillationBriquetteCoal water

The invention provides a moulded coal raw material suitable for low rank coal upgrading technology, the moulded coal raw material includes a low rank coal moulded coal body formed by low rank coal and an additive, the additive is an organic binder, air isolation destructive distillation weight loss of the organic binder at 850 DEG C is less than 50%; the moulded coal raw material also includes a non low rank moulded coal layer externally coating the low rank coal moulded coal body, the non low rank moulded coal layer is prepared from one or a plurality of medium rank coal, high rank coal or medium-high rank coal, and the adding amount of the low rank coal is 60-80wt% of the moulded coal raw material. The moulded coal raw material not only solves the problems of low using degree of a stamped coke oven and excess production capacity of coking industry in the prior art, and solves the problems of restricted application due to no large-scale industrial equipment in view of the low rank coal, after the additive is mixed with the low rank coal, effective components in the additive contribute to degradation of polymer in low rank coal at high temperature and fracture of polymer in the low rank coal so as to improve the oil and gas yield in technical process.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Purification method of high purity quartz sand tailings

The invention provides a purification method of high purity quartz sand tailings. The method includes: ore grinding: taking the tailings generated in the high purity quartz sand production process asthe raw material, and carrying out ball milling and sieving; strong magnetic separation: performing strong magnetic separation by a magnetic separator to remove strong magnetic substances in the quartz sand; acid leaching: performing acid leaching treatment, then conducting filtering and ultrapure water flushing; calcination: conducting high temperature calcination for 2-4h; water quenching: performing water quenching for 3-5min to break the junction of a quartz matrix and impurities; secondary acid leaching: repeating the above acid leaching process to remove feldspar and other impurities inthe quartz sand; and cleaning: conducting flushing with ultrapure water, and performing filtering and drying to obtain a purified and processed product of quartz sand tailings. The method provided bythe invention adopts mixed acid to cooperate a leaching aid to replace the traditional acid leaching process, improves the leaching rate of quartz sand, and reduces the dosage of acid in the acid leaching process. The quartz sand tailings treated by the technology have a silica content up to 99.9% or above, which reaches the standard of high-purity quartz sand.

Owner:江苏凯达石英股份有限公司

Coking process raw materials

The present invention provides coking process raw materials, which comprise low-rank coal and an auxiliary agent, wherein the auxiliary agent is an organic binder with air isolated dry distillation weightlessness of less than 50% at a temperature of 850 DEG C, and preferably the organic binder is asphaltene with a softening point of more than 100 DEG C. According to the present invention, with the raw materials, the problems of low existing stamp-charging coke oven utilization rate and excess coking industry production capacity are solved, and the problem that the application of the low-rank coal is limited due to no large-scale industrial equipment is solved; and after the auxiliary agent and the low-rank coal are mixed, the degradation of the macromolecule polymer in the low-rank coal at the high temperature and the breaking of the macromolecule in the low-rank coal are easily achieved through the effective components in the auxiliary agent so as to improve the oil gas yield during the process, wherein the total amount of the oil gas is increased by more than or equal to 10%.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Coking process containing low-rank coal

ActiveCN104263395ASolve application limitationsSolve the low utilizationSpecial form destructive distillationIndustrial equipmentCoke oven

The invention discloses a coking process containing low-rank coal. The coking process comprises the following steps: (1) crushing low-rank coal, and mixing with an auxiliary agent to form a low-rank coal raw material; (2) firstly performing pressure forming on one or more of crushed middle-rank coal, high-rank coal or intermediate-high-rank coal to form a non-low-rank-coal type coal bed; and adding the low-rank coal raw material on the non-low-rank-coal type coal bed, and continuously performing pressure forming on the low-rank coal raw material to form a low-rank coal type coal bed which is positioned on the non-low-rank-coal type coal bed so as to form a final molded coal raw material; and (3) pushing the molded coal raw material into a coke oven for coking, wherein the weight loss of the auxiliary agent caused by destructive distillation in isolating air at 850 DEG C is less than that of 50% of an organic binding agent. By adopting the coking process containing the low-rank coal disclosed by the invention, the problems of low availability of an existing tamping coke oven and excess capacity in the coking industry can be solved, and the problem that the application of the low-rank coal is limited because no large-scale industrial equipment is provided also can be solved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

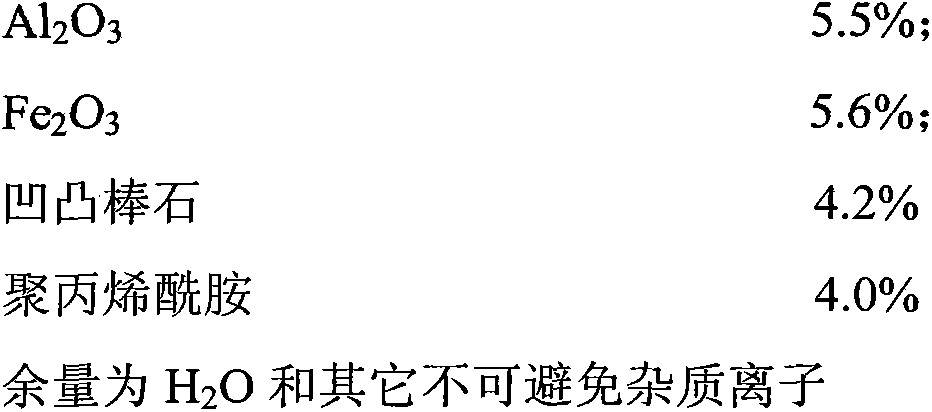

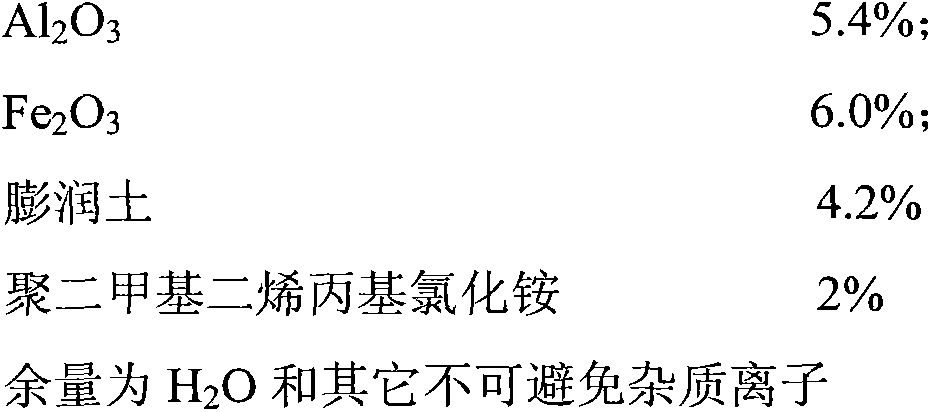

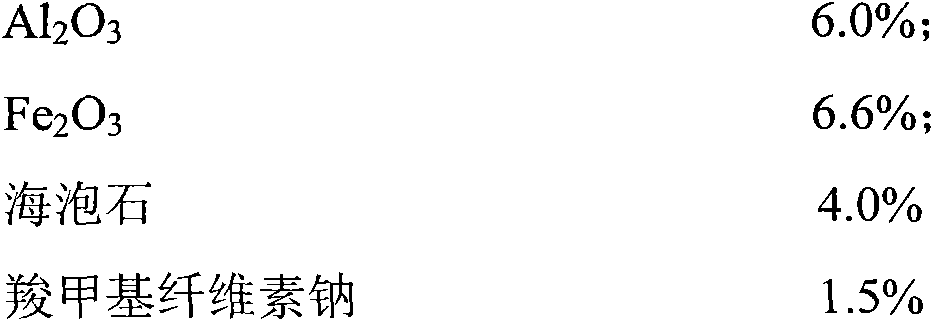

Method for preparing multi-component flocculant and co-producing composite white carbon black by using red mud

ActiveCN103922448AWide variety of sourcesSolve the problem that cannot coexist stablySilicaWater/sewage treatment by flocculation/precipitationRed mudResource utilization

The present invention discloses a method for preparing a multi-component flocculant and co-producing composite white carbon black by using red mud, and belongs to eth field of resource utilization of red mud. The technical problem solved by the present invention is to provide a method for preparing a red mud base multi-component flocculant and co-producing composite white carbon black, wherein the method has characteristics of easily available raw material, large scale production and low cost. The technical scheme comprises: 1, carrying out acid leaching on red mud; 2, mixing the acid leaching solution and a telomer to prepare a polymerization aluminum-iron inorganic flocculant; 3, mixing the polymerization aluminum-iron inorganic flocculant, a mineral material and a polymer material to prepare a red mud base multi-component flocculant; and 4, drying the acid leaching residue obtained in the step 1 for 2-12 h at a temperature of 150-600 DEG C to prepare the composite white carbon black.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Method for extracting DHA algae oil from algae cells

ActiveCN104388178AAvoid the problem of not completely breaking down the cell wallHelp breakFatty-oils/fats productionHigh pressureCell wall

The invention relates to a method for extracting DHA algae oil from algae cells. The method comprises the following steps: (1) centrifuging and spray-drying algae cell fermentation broth to prepare algae cell dry powder, then uniformly mixing the algae cell dry powder with absolute ethanol, and carrying out high-pressure homogenizing cell wall breaking to prepare a wall-broken ethanol solution; (2) distilling the wall-broken ethanol solution at a low temperature in vacuum, removing ethanol to prepare wall-broken bacteria; and (3) carrying out CO2 supercritical extraction on the wall-broken bacteria to obtain DHA algae oil. According to the method, the algae cell dry powder is soaked by the absolute ethanol before high-pressure homogenizing cell wall breaking, so that the extraction rate can be greatly increased.

Owner:SHANDONG BAILONG CHUANGYUAN BIO TECH

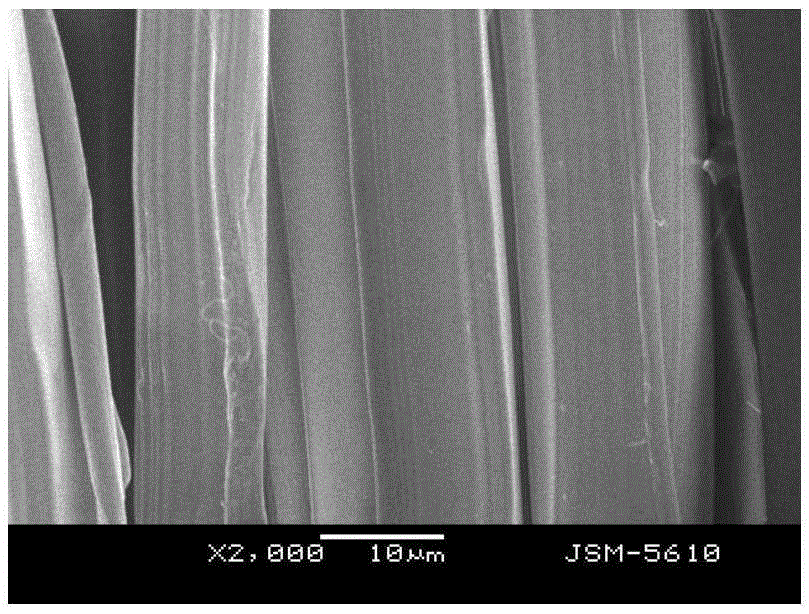

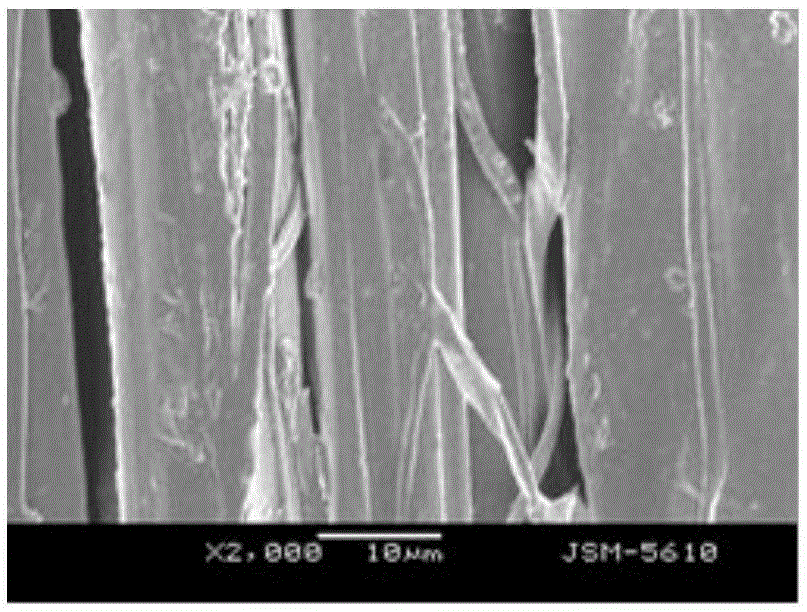

Method for graft modification of silks

The invention relates to the field of spinning, and discloses a method for graft modification of silks. 4-dimethylamino pyridine is used as a catalyst, carbodiimide is used as a condensing agent, a polymer containing carboxyl is activated and then reacts with amidogen of the silks, and the polymer is bound to the silks. The carbodiimide is used as the condensing agent, the carboxyl is activated and then acts with the amidogen of the silks to form an amido bond, the reaction condition is mild, modification is different from traditional physical absorption modification, and the made modified silks have the advantages of being high in filling power, good in durability, high in wear resistance, high in fastness and not prone to loss in the using process.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

Urea intercalation modified kaolin filling polypropylene composite material and preparation method thereof

The invention discloses a urea intercalation modified kaolin filling polypropylene composite material which comprises the following components in parts by weight: 60-80 parts of PP resin, 3-20 parts of urea intercalation kaolin, 20-40 parts of a flame retardant, 0.1-0.5 part of a coupling agent and 0.1-0.2 part of an antioxidant. The invention further discloses a preparation method of the urea intercalation modified kaolin filling polypropylene composite material. The urea intercalation modified kaolin filling polypropylene composite material prepared by the invention has performance advantages of both the PP and intercalation kaolin, and has excellent mechanical property, flowing property, increased toughness, high heat resistance, excellent flame-retardant effect and simple process and is low in cost.

Owner:GUANGXI TEACHERS EDUCATION UNIV

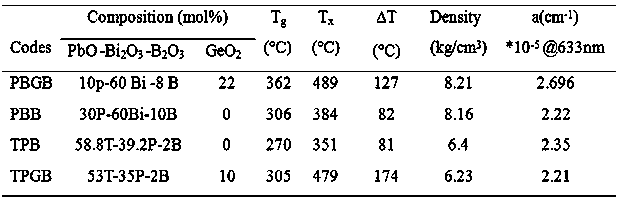

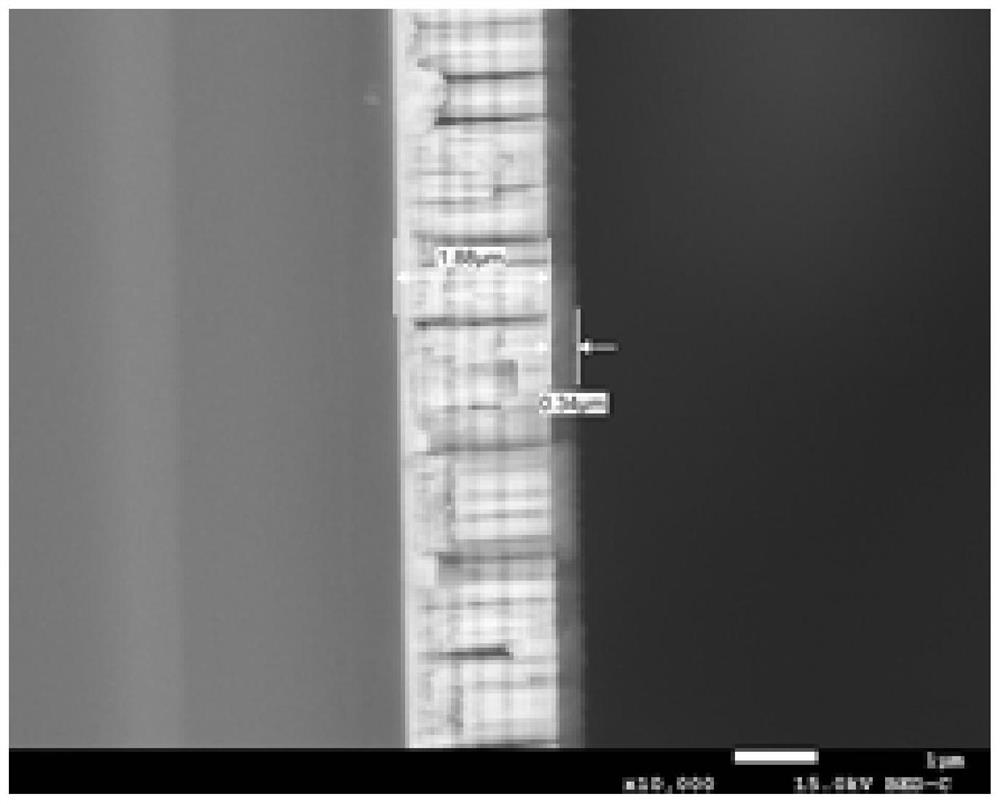

Method for directly writing magneto-optic waveguide on diamagnetic photosensitive glass by using femtosecond laser

InactiveCN107765367AGood opticsPermanently change physical propertiesOptical light guidesFemto second laserRefractive index

The invention discloses a method for directly writing a magneto-optic waveguide on diamagnetic photosensitive glass by using femtosecond laser. A micro channel pattern is drawn and imported through software, and a 40X objective lens and a 520-micron slit are used to focus laser in a direction orthogonal to the surface of well-polished glass and the transmission of a laser beam. Scanning is repeated 4-12 times at the repetition rate of 100kHz, at the power of 0.1-0.5W and at the current of 21-25A, and the depth of irradiation is 170 microns. A magneto-optic waveguide can be obtained through movement at the pulse energy of 150-350nJ and at the speed of 1.5mm / min according to a set scanning pattern. After ultrasonic concussion cleaning, annealing is carried out for 2 hours at 260-290 DEG C. The magneto-optic waveguide obtained is 150-500 microns wide, and the refractive index increases by 3-9*10<-2>. The method provides a carrier with good magneto-optical property for the magneto-optic waveguide, reduces the complexity of the magneto-optical waveguide structure, and improves the sensitivity and speed of magnetic field response of devices. The method is simple and nontoxic, consumes less energy, and has a wide range of application.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

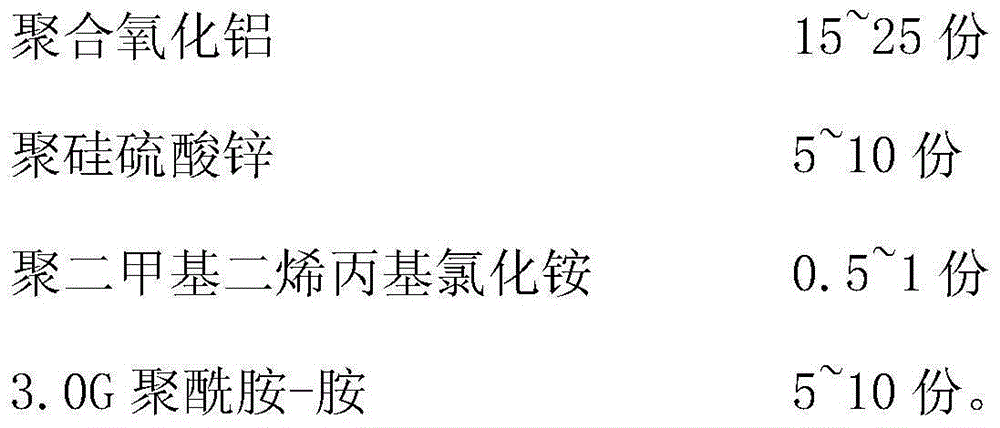

Treatment method of thick oil sewage

InactiveCN105217895AImprove biodegradabilityReduce CODCr contentWaste water treatment from quariesWater contaminantsSuspended particlesEmulsion

The invention provides a treatment method of thick oil sewage. According to the treatment method, thick oil sewage raw water is subjected to coagulation treatment, anaerobic biochemical treatment and biochemical treatment in sequence, and effluent reaches an emission standard. The method is used for treating thick oil wastewater in an oil field and can effectively improve the biodegradability of the thick oil wastewater and greatly reduce the CODCr content of the thick oil wastewater. A coagulating agent used during the coagulation treatment is high-temperature-resistant, the selective adsorption distribution of the coagulating agent on a thick oil-water interface is helpful for breaking and eliminating oil-water micro emulsion, and a synergistic effect principle is used for improving the emulsion breaking and oil removing performance of the coagulating agent and improving the purification performance by virtue of an effect of coagulating solid suspended particles and colloid particles; and after coagulation treatment, the CODCr of the effluent is reduced to 190-160mg / L, and the biodegradability of the sewage is improved from less than 0.2 to between 0.25 and 0.35.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

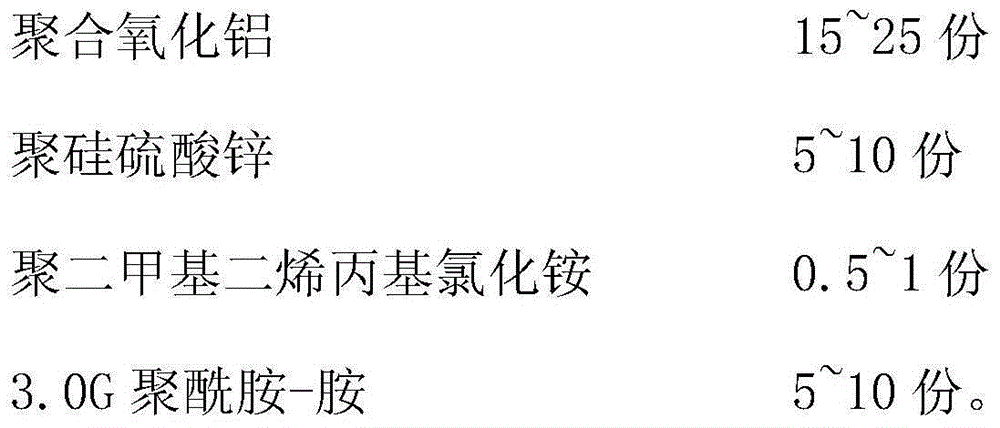

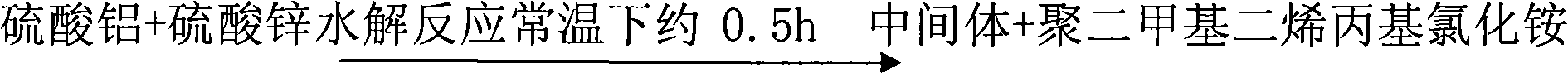

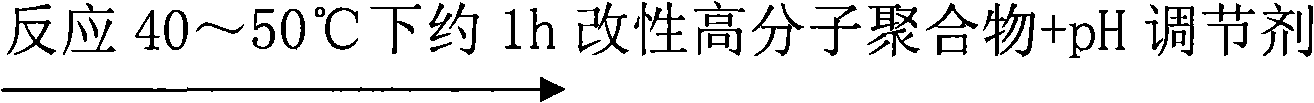

Novel oilfield sewage disposal coagulant

ActiveCN101323474ASimple processing technologyImprove floc morphologyWater/sewage treatment by flocculation/precipitationDimethyldiazeneChemistry

The invention provides a novel oil field sewage disposal coagulant and relates to the oil field sewage disposal agent. The weight percentage of the coagulant is as follows: 10 to 20 percent of aluminum sulphate, 2 to 10 percent of zinc sulphate, 0.2 to 0.5 percent of PDMDAAC and the rest is water. The coagulant is used for purifying sewage containing hydrogen sulfide and oil, and high-temperature thick-oil sewage. The preparation method is comprises the following steps: 10 to 20 percent of aluminum sulphate and 2 to 10 percent of zinc sulphate are added into water and after the aluminum sulphate and zinc sulphate are completely dissolved, the 0.2 to 0.5 percent of PDMDAAC is added, and then the mixed solution is stirred evenly to adjust the pH value to 3 to 4 to so as to obtain the coagulant. With the same purified water quantity, the oil and suspended matter in the purified water are reduced dramatically with the coagulant, and the formed flocs is thicker and the settlement speed is quicker, and the impact on the purified water quality by the water quantity fluctuation can be reduced to a certain extent.

Owner:PETROCHINA CO LTD

Briquette raw material for coking technique

ActiveCN104263396ASolve the low utilizationSolve the problem of overcapacity in the coking industrySpecial form destructive distillationCoal briquetteCoke oven

The invention provides a briquette raw material for a coking technique, which comprises a low-rank coal briquette layer formed by low-rank coal and an assistant, and a non-low-rank coal briquette layer formed by one or more of medium-rank coal, high-rank coal and medium-high-low coal, wherein the assistant is an organic binder of which the weight loss is less than 50% when being carbonized at 850 DEG C in the absence of air; the low-rank coal briquette layer is arranged on the non-low-rank coal briquette layer; and the low-rank coal accounts for 50-80 wt% of the briquette raw material. When being used for coking treatment, the briquette raw material solves the problems of low availability and surplus productivity of coking industry in the existing tamping cokery, and also solves the problem of limited application due to no large-scale industrialized equipment for low-rank coal. After the assistant and low-rank coal are mixed, the effective component in the assistant is beneficial to degradation of high-molecular polymers in the low-rank coal at high temperature and also beneficial to rupture of high polymers in the low-rank coal, thereby enhancing the oil gas yield in the technical process.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

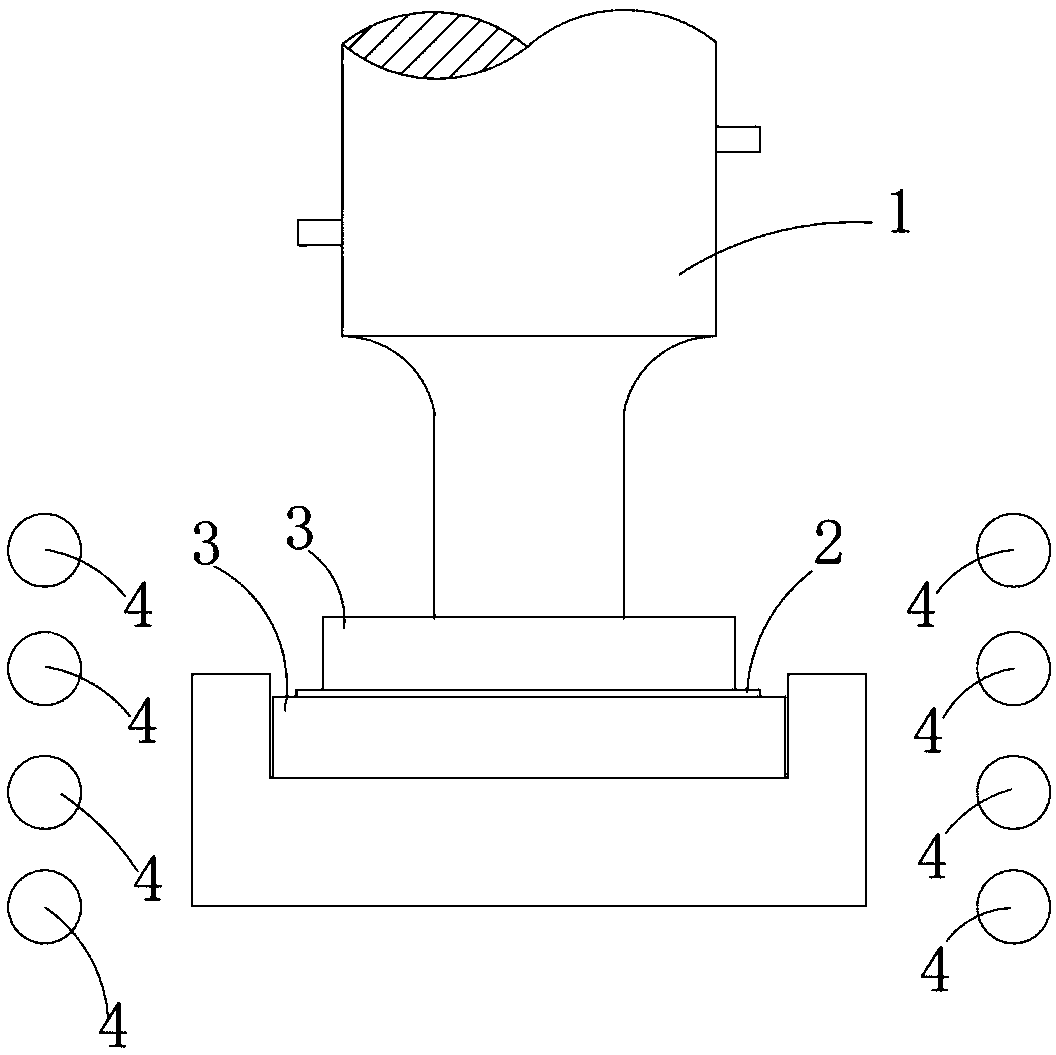

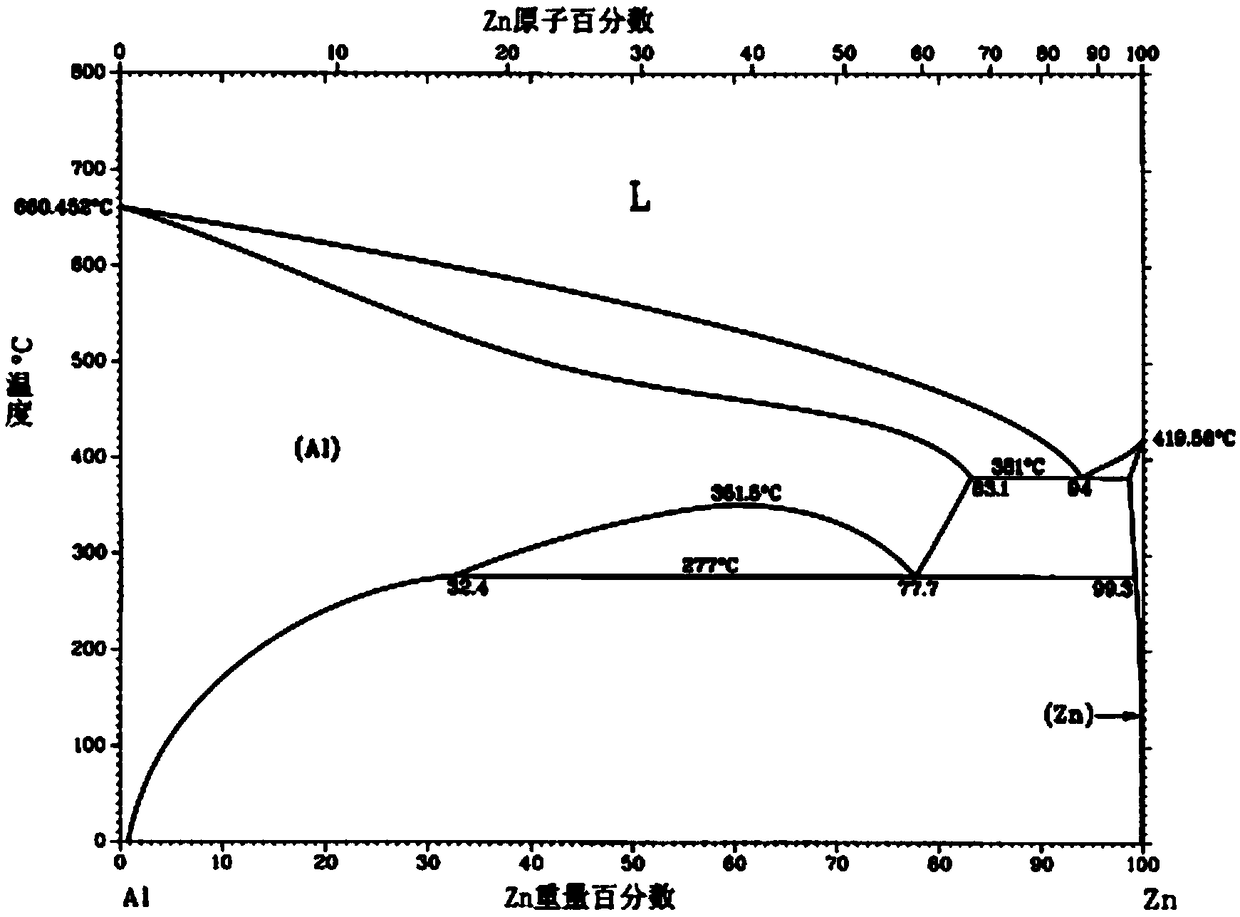

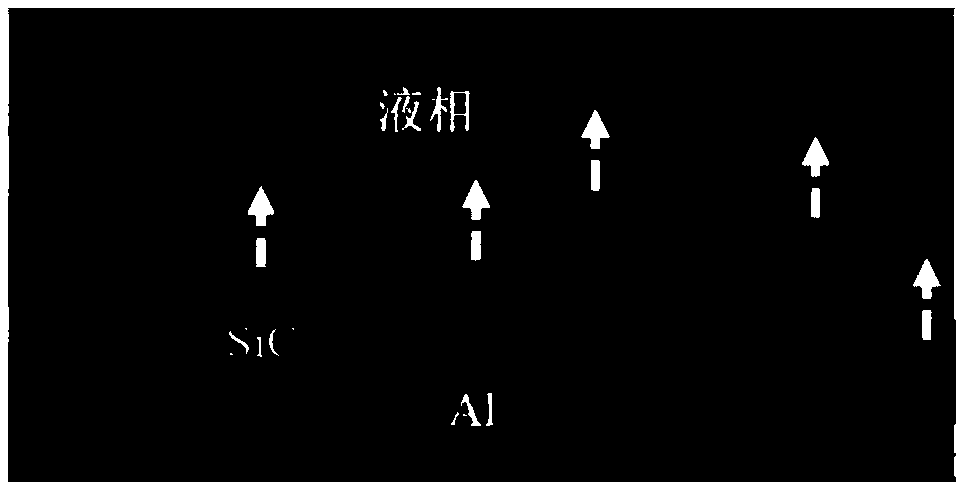

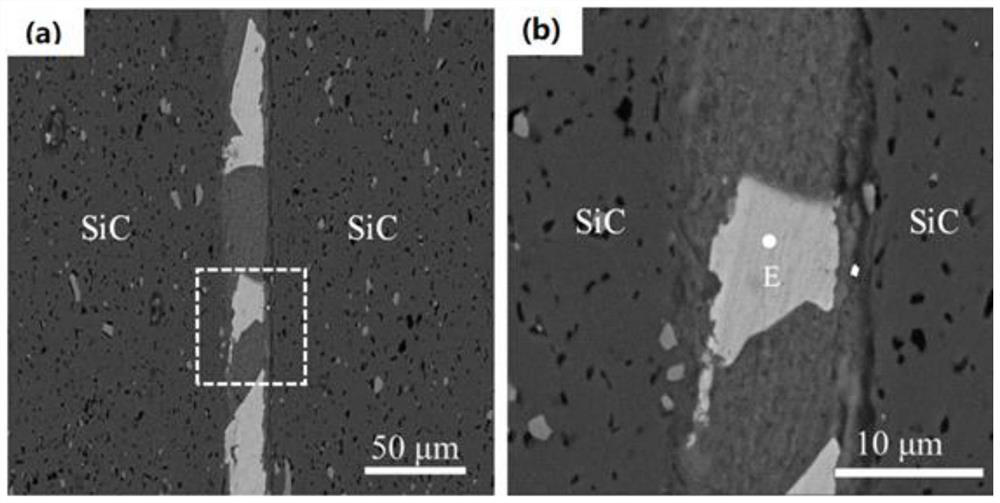

Ultrasound-assisted auxiliary welding method for silicon carbide particle-reinforced aluminum matrix composite (SiCp-Al) with pure Zn as intermediate reaction material layer

ActiveCN109365985AImprove the mechanical properties of jointsShort welding timeNon-electric welding apparatusUltrasonic weldingSolid solution

The invention discloses an ultrasound-assisted auxiliary welding method for a silicon carbide particle-reinforced aluminum matrix composite (SiCp-Al) with pure Zn as an intermediate reaction materiallayer. The base metal to be welded is 40%-55% of the silicon carbide particle-reinforced aluminum matrix composite, pure zinc foil is selected as the intermediate reaction material layer according tothe design conditions of the intermediate reaction material layer, the choice of the pure zinc foil as the intermediate reaction material layer is beneficial for reducing the welding temperature, andan all silicon carbide (SiC) particle-reinforced alpha-Al solid solution joint is more easily obtained. Under appropriate ultrasound time and connecting temperature conditions, the all SiC particle-reinforced alpha-Al solid solution joint is obtained by combining the process method of primary ultrasonic welding and secondary ultrasonic heat preservation, welding is completed in an atmospheric environment without brazing filler metal assistance, greening and environmental protection are achieved, the welding time is short, the mechanical properties of the joint are high, and the welding effectis good.

Owner:东莞市新玛博创超声波科技有限公司

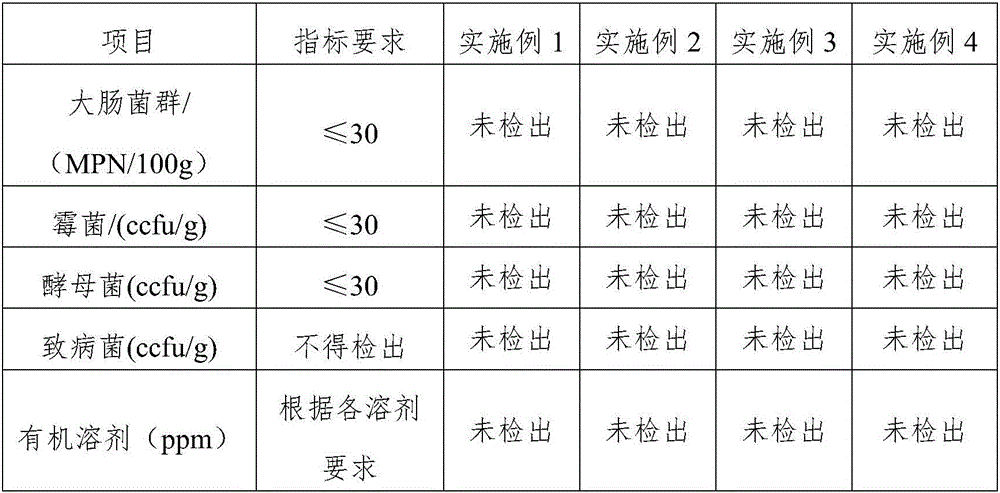

Production method for extracting tea oil through aqueous enzymatic method

InactiveCN106190524AQuick releaseGuaranteed qualified microbiological contentFatty-oils/fats refiningFatty-oils/fats productionAcetic acidMicroorganism

The invention discloses a production method for extracting tea oil through an aqueous enzymatic method. Under proper pH, mixed enzyme is added, vibrating extraction is conducted in a glacial acetic acid-sodium chloride solution, osmotic pressure is formed by means of enzymolysis and a sodium chloride solution so that tea oil in tea seed kernels can be quickly released, then the tea oil is sterilized and dried, and the tea oil is obtained. The tea seed oil extraction yield is high, the content of microorganisms in the tea oil reaches the standard, no organic solvent residues exist, and the method is suitable for large-scale popularization.

Owner:贵州石阡佛顶山野生油茶油业有限公司

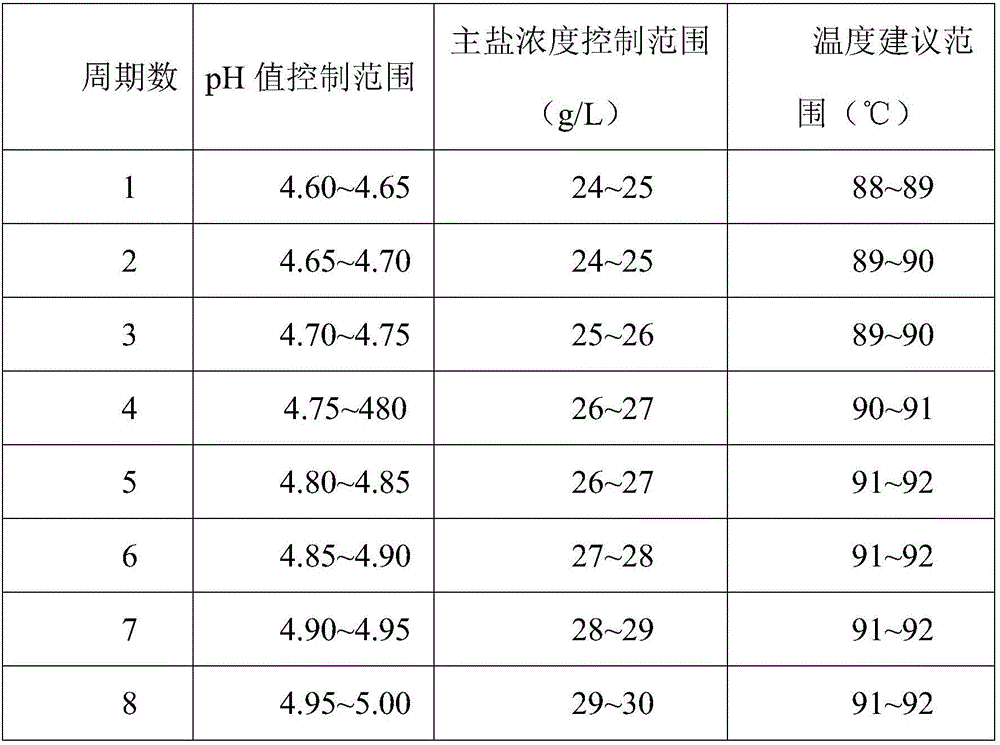

A kind of method of chemically plating high-phosphorus nickel-phosphorus alloy

ActiveCN106048567BIncrease deposition rateHigh phosphorus contentLiquid/solution decomposition chemical coatingAlloyINCREASED EFFECT

The present invention discloses a method for chemically plating a high-phosphorus nickel-phosphorus alloy. According to the present invention, the compounding of two organic nitrogen-containing compounds such as benzotriazole and benzimidazole can provide accelerating and stabilizing effects for the citric acid system chemical plating high-phosphorus nickel-phosphorus alloy, wherein N-2-hydroxyethyl ethylenediamine triacetic acid provides a phosphorus increasing effect for the citric acid system chemical plating high-phosphorus nickel-phosphorus alloy plating layer, is successfully applied in the aluminum alloy chemical plating high-phosphorus nickel-phosphorus alloy production in practice, and achieves the good effect; with the application of the method to perform laboratory plating, the plating liquid service life can achieve 8 metal cycles, the average plating rate is 10.3 [mu]m / h, and the average phosphorus content in the plating layer is 11.6%; and compared with the traditional process, the method of the present invention has the following characteristics that the plating liquid service life is increased by 60%, the plating speed is increased by 25%, and the phosphorus content in the plating layer is increased by 10.5%.

Owner:GUIZHOU UNIV

Method and device for culturing edible fungi after inoculation

PendingCN109699401AAvoid risk of carryover to culture flasksImprove cultivation efficiencyMixersCultivating equipmentsBiotechnologyBottle

The invention relates to the technical field of edible fungi culture, particularly relates to a method for culturing edible fungi after inoculation and also relates to a device used in the culture method. The method comprises the following steps of: inoculating solid strain blocks to a culture bottle, stirring and crushing solid strain blocks by using a stirring device, continuing culturing, or after inoculating and growing for a period of time, stirring and crushing solid strain blocks, continuing culturing, or after the culture bottle is well cultured, stirring and crushing by adopting the stirring device before solid strain blocks are inoculated to a next-stage seed tank, and inoculating the seed tank. According to the method and device, the telescopic stirring device is adopted to achieve the purpose of stirring and crushing strain blocks or materials in the culture bottle and preventing strain blocks or materials from being infected by miscellaneous bacteria. The stirring device is convenient to take and place, the operation is convenient, and the problem in the prior art that a stirring paddle cannot be matched with a triangular bottle because the size of the stirring paddleis not proper is solved.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

A coking process containing low-rank coal

ActiveCN104263395BSolve application limitationsLow costSpecial form destructive distillationIndustrial equipmentProcess engineering

The invention discloses a coking process containing low-rank coal. The coking process comprises the following steps: (1) crushing low-rank coal, and mixing with an auxiliary agent to form a low-rank coal raw material; (2) firstly performing pressure forming on one or more of crushed middle-rank coal, high-rank coal or intermediate-high-rank coal to form a non-low-rank-coal type coal bed; and adding the low-rank coal raw material on the non-low-rank-coal type coal bed, and continuously performing pressure forming on the low-rank coal raw material to form a low-rank coal type coal bed which is positioned on the non-low-rank-coal type coal bed so as to form a final molded coal raw material; and (3) pushing the molded coal raw material into a coke oven for coking, wherein the weight loss of the auxiliary agent caused by destructive distillation in isolating air at 850 DEG C is less than that of 50% of an organic binding agent. By adopting the coking process containing the low-rank coal disclosed by the invention, the problems of low availability of an existing tamping coke oven and excess capacity in the coking industry can be solved, and the problem that the application of the low-rank coal is limited because no large-scale industrial equipment is provided also can be solved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Model coal raw material for increasing quality of low-rank coal of tamping coke oven

ActiveCN104327871ASolve application limitationsSolve excess capacitySolid fuelsSpecial form destructive distillationIndustrial equipmentProcess engineering

The invention provides a model coal raw material for increasing quality of low-rank coal of a tamping coke oven. The model coal raw material comprises a low-rank model coal layer formed by low-rank coal and an auxiliary agent. The auxiliary agent is an organic binder with weightlessness being less than 50% under destructive distillation isolated from the air at 850 DEG C. The model coal raw material also comprises a non-low-rank model coal layer formed by one or more selected from medium-rank coal, high-rank coal or medium / high-rank coal. By mass, the addition amount of the low-rank coal is 50-80 wt% of mass of the model coal raw material. By using the raw material as the model coal raw material for increasing quality of low-rank coal of the tamping coke oven, the problem that present tamping coke ovens have low availability and excess capacity exists in the coking industry is solved, and the problem that application of low-rank coal is limited because there is no large-scale industrial equipment is also solved. After the auxiliary agent is mixed with low-rank coal, active ingredients in the auxiliary agent are beneficial to degradation of high-molecular polymers in the low-rank coal at high temperature and fracture of macromolecules in the low-rank coal. Thus, output of oil gas is raised during the technological process.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Coking technology of low-rank coal briquette raw material containing biomass

ActiveCN105733623ANot easy to pulverizeEasy to focusBiofuelsSpecial form destructive distillationBiomassAgriculture

The invention discloses a coking technology of a low-rank coal briquette raw material containing biomass. Firstly the low-rank coal briquette raw material containing the biomass is moulded, and then the raw material is coked. The raw material mainly comprises a low-rank coal briquette body formed of a low rank coal and the biomass, and a non-low-rank coal briquette layer covering the low-rank coal briquette body. The non-low-rank coal briquette layer is made of one or several coals selected from a medium rank coal, a high rank coal or a medium-high rank coal. The coking technology of the low-rank coal briquette raw material containing the biomass solves the problems that the availability of a present stamping charging coke oven is low, and the production power in the coking industry is excess, and solves the problem that the application of the low-rank coal is limited due to no large scale industrial devices. The availability of biomass energy such as straws and agriculture and forestry residues is improved, a new sludge processing mode is developed, and the influence of leachate generated by sludge sanitary landfills on the surrounding environment is solved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Low-rank coal coking process

ActiveCN105400533ASolve application limitationsSolve the low utilizationSpecial form destructive distillationWeightlessnessIndustrial equipment

The present invention discloses a low-rank coal coking process, which comprises: (1) crushing low-rank coal, mixing the crushed low-rank coal and an auxiliary agent, and carrying out stamp-charging molding on the raw material coal by using stamp-charging equipment; and (2) pushing the molded raw material coal into a coke oven, coking, and collecting the overflowed crude coal gas, tar and crude benzene mixture while obtaining the byproduct coke, wherein the coking temperature is controlled at more than 800 DEG C, the coking time is not less than 15 h, and the auxiliary agent is an organic binder with air isolated dry distillation weightlessness of less than 50% at a temperature of 850 DEG C. According to the present invention, with the low-rank coal coking process, the problems of low existing stamp-charging coke oven utilization rate and excess coking industry production capacity are solved, and the problem that the application of the low-rank coal is limited due to no large-scale industrial equipment is solved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for chemically plating high-phosphorus nickel-phosphorus alloy

ActiveCN106048567AIncrease deposition rateHigh phosphorus contentLiquid/solution decomposition chemical coatingChemical platingNitrogen

The present invention discloses a method for chemically plating a high-phosphorus nickel-phosphorus alloy. According to the present invention, the compounding of two organic nitrogen-containing compounds such as benzotriazole and benzimidazole can provide accelerating and stabilizing effects for the citric acid system chemical plating high-phosphorus nickel-phosphorus alloy, wherein N-2-hydroxyethyl ethylenediamine triacetic acid provides a phosphorus increasing effect for the citric acid system chemical plating high-phosphorus nickel-phosphorus alloy plating layer, is successfully applied in the aluminum alloy chemical plating high-phosphorus nickel-phosphorus alloy production in practice, and achieves the good effect; with the application of the method to perform laboratory plating, the plating liquid service life can achieve 8 metal cycles, the average plating rate is 10.3 [mu]m / h, and the average phosphorus content in the plating layer is 11.6%; and compared with the traditional process, the method of the present invention has the following characteristics that the plating liquid service life is increased by 60%, the plating speed is increased by 25%, and the phosphorus content in the plating layer is increased by 10.5%.

Owner:GUIZHOU UNIV

Moulded coal raw material suitable for coking technology

ActiveCN104479710ASolve application limitationsLow costSpecial form destructive distillationIndustrial equipmentCoke oven

The invention provides a moulded coal raw material suitable for coking technology, the moulded coal raw material includes a low rank coal moulded coal body formed by low rank coal and an additive, the additive is an organic binder, air isolation destructive distillation weight loss of the organic binder at 850 DEG C is less than 50%; the moulded coal raw material also includes a non low rank moulded coal layer externally coating the low rank coal moulded coal body, the non low rank moulded coal layer is prepared from one or a plurality of medium rank coal, high rank coal or medium-high rank coal, and the adding amount of the low rank coal is 50-75wt% of the moulded coal raw material. The moulded coal raw material not only solves the problems of low using degree of a stamped coke oven and excess production capacity of coking industry in the prior art, and solves the problems of restricted application due to no large-scale industrial equipment in view of the low rank coal, after the additive is mixed with the low rank coal, effective components in the additive contribute to degradation of polymer in low rank coal at high temperature and fracture of polymer in the low rank coal so as to improve the oil and gas yield in technical process.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Powder metallurgical aluminum base material and manufacturing method thereof

The invention relates to a powder metallurgical aluminum base material. According to the raw material powder, the powder metallurgical aluminum base material comprises, by mass percentage, 0.001%-3% of magnesium hydride powder and the balance aluminum substrate powder. The aluminum substrate powder is aluminum elementary substance powder or aluminum alloy powder or aluminum-based composite material powder. The invention further relates to a manufacturing method of the powder metallurgical aluminum base material. The manufacturing method comprises the following steps of (a) powder mixing; (b) forming; (c) sintering; and (d) thermal treatment. The powder metallurgical aluminum base material is low in sintering deformation. The manufacturing method is simple in technology and high in production efficiency, and is suitable for mass production.

Owner:NBTM NEW MATERIALS GRP

Process for carrying out quality improvement on coal raw material containing low-rank coal by using stamp-charging coke oven

ActiveCN105400531ASolve application limitationsFocusSpecial form destructive distillationIndustrial equipmentWeightlessness

The present invention discloses a process for carrying out quality improvement on a coal raw material containing low-rank coal by using a stamp-charging coke oven. The process comprises: (1) crushing low-rank coal, mixing the crushed low-rank coal and an auxiliary agent to form a low-rank coal raw material, mixing the obtained low-rank coal raw material and a crushed non-low-rank coal raw material to form a raw material coal, and carrying out stamp-charging molding on the raw material coal by using stamp-charging equipment, wherein the low-rank coal is one or a plurality of materials selected from medium-rank coal, high-rank coal and medium-high-rank coal; and (2) pushing the molded raw material coal into a coke oven, carrying out quality improvement, and collecting the overflowed crude coal gas, tar and crude benzene mixture while obtaining the byproduct coke, wherein the quality improvement temperature is controlled at more than 800 DEG C, the time is not less than 15 h, and the auxiliary agent is an organic binder with air isolated dry distillation weightlessness of less than 50% at a temperature of 850 DEG C. According to the present invention, the process that the coal raw material containing the low-rank coal is subjected to quality improvement by using the stamp-charging coke oven is used, such that the problems of low existing stamp-charging coke oven utilization rate and excess coking industry production capacity are solved, and the problem that the application of the low-rank coal is limited due to no large-scale industrial equipment is solved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Brazing method for silicon carbide ceramics

ActiveCN112975032AImprove wettabilityImprove bindingSoldering apparatusCarbide siliconUltimate tensile strength

The invention discloses a brazing method for silicon carbide ceramics. The brazing method comprises the following steps: carrying out surface treatment on the silicon carbide ceramics; depositing a first metal layer on the surface of the silicon carbide ceramics by adopting a vapor deposition method, and then depositing a second metal layer on the surface of the first metal layer to obtain the silicon carbide ceramics deposited with double metal layers, wherein the material of the first metal layer is selected from one of Ni, Ti, Fe or Zr, and material of the second metal layer is selected from Al; placing the silicon carbide ceramics needing to be connected in a vacuum sintering furnace, then placing a pure Al foil between the silicon carbide ceramics needing to be connected, starting heating when vacuum in the furnace reaches 10 <-1 > Pa, increasing the temperature to 600-800 DEG C, and conducting heat preservation for 10-60 min; and after heat preservation is finished, performing cooling to room temperature along with the furnace to obtain the silicon carbide ceramics subjected to brazing connection. According to the brazing method for the silicon carbide ceramics, the wettability of aluminum-based brazing filler metal to the silicon carbide material can be improved, the brazing temperature can be reduced, and the bonding strength of a brazed joint can be improved.

Owner:浙江浙能兰溪发电有限责任公司 +1

Molybdenum carbide catalyst as well as preparation method and application thereof

ActiveCN111111730AOptimize electronic structureHigh catalytic activityPhysical/chemical process catalystsOrganic compound preparationCelluloseBenzene

The invention belongs to the technical field of polyurethane preparation, and particularly relates to a molybdenum carbide catalyst, a preparation method of the molybdenum carbide catalyst, biologicalpolyol prepared through catalysis of the molybdenum carbide catalyst and polyurethane prepared from the biological polyol. The molybdenum carbide catalyst prepared by the method can be used for simultaneously breaking chemical bonds in cellulose, hemicellulose and lignin in biological straw; the biological straw is converted from a solid state into the biological polyol which is high in reactionactivity and contains hydroxyl and benzene rings; further, the biological polyol is applied to the preparation of the polyurethane; According to the method, a process route for preparing the polyurethane by taking the biological straw as the raw materials is realized, the problems of low straw filling amount and poor polyurethane performance when the polyurethane is prepared by taking the biological straw as the raw material in the prior art are solved, and the prepared polyurethane has the advantages of low heat conductivity coefficient, good heat preservation performance, high compression strength and the like.

Owner:ZHEJIANG NORMAL UNIVERSITY

A kind of efficient preparation method of cellulose nanocrystal

ActiveCN105777913BLoose structureIncreased Response AccessibilityPulp properties modificationWashing/displacing pulp-treating liquorsCelluloseInorganic salts

The invention provides an efficient and quick cellulose nanocrystalline preparing method.According to the method, a cellulose raw material is pretreated with aqueous alkali and then subjected to acidolysis, and inorganic salt containing metal ions is added during acidolysis to serve as a promoter to promote acidolysis reaction.Reaction condition is mild and easy to control, raw materials needed by reaction are simple and easy to obtain, and the method can be widely applied to preparation of cellulose nanocrystalline from various cellulose raw materials.

Owner:QINGDAO UNIV OF SCI & TECH

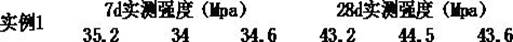

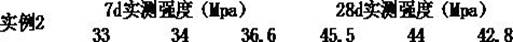

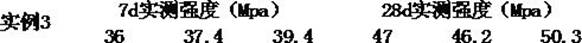

Iron tailing activation method and multi-solid-waste iron tailing concrete

InactiveCN113149500AImprove activity indexHelp breakSolid waste managementEnvironmental engineeringWater reducer

The invention belongs to the technical field of building material and solid waste resource utilization, and relates to an iron tailing activation method and iron tailing-containing multi-solid-waste concrete. A multi-solid-waste admixture comprises 20-30 parts of iron tailing powder, 10-15 parts of a calcium phase admixture, 10-15 parts of an aluminum phase admixture, 4-5 parts of a composite activator, and 1-2 parts of a grinding aid. The multi-solid-waste admixture is used as an auxiliary cementing material, and each cubic meter of the multi-solid-waste concrete is prepared from the following components in proportion: 310-336 kg of cement, 144-170 kg of the multi-solid-waste admixture, 492-517 kg of machine-made sand, 221-281 kg of natural sand, 1020-1055 kg of machine-made stone, 1.2-1.5% of an air-entraining and water-reducing agent (with respect to the total amount of the cementing material) and 177-186 kg of water. The iron tailings are activated in a composite activation mode of microwave irradiation, mechanical grinding and chemical excitation, the activity index of the admixture can be well increased, a large amount of solid waste is used, the comprehensive utilization rate of the iron tailings is increased, consumption of natural resources is reduced, and the concrete is more environmentally friendly.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com