A kind of efficient preparation method of cellulose nanocrystal

A cellulose and nanocrystal technology, applied in the post-processing of cellulose pulp, fiber raw material processing, papermaking, etc., can solve problems such as no pretreatment steps, improve reaction accessibility, and improve acid hydrolysis reaction efficiency. , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

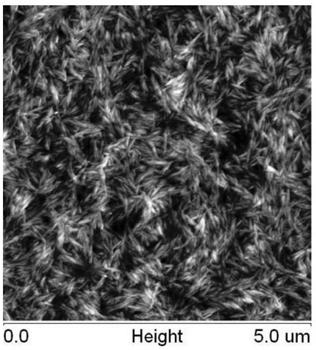

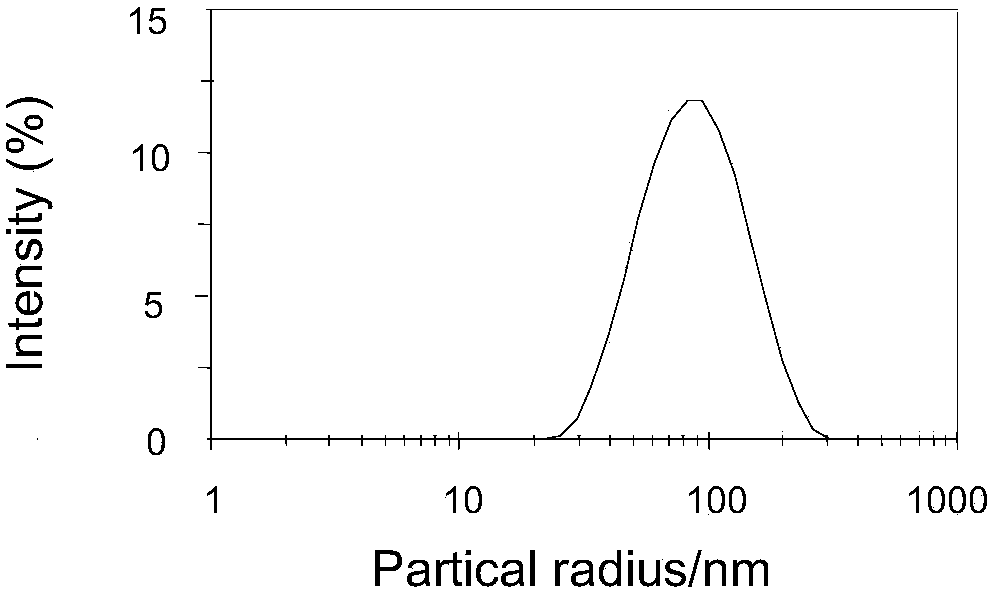

[0035] Break 5 grams of pulp cellulose into cotton wool with a mixer, add 250ml, 4wt% NaOH solution, soak for 24 hours, then use deionized water to filter and wash it to neutral, and take this alkali-pretreated fiber prime, add 0.078 g CuSO 4 ·5H 2 0, add 90 milliliters of 64wt% sulfuric acid again, after stirring at 50 DEG C for 40min, add deionized water to terminate the reaction, after the solution is left to stand, centrifuge with a high-speed centrifuge for 10min at a speed of 8000rpm / min, then the precipitate is washed, Separate again until the supernatant becomes cloudy. The obtained cellulose nanocrystal suspension was ultrasonicated to obtain a stable cellulose nanocrystal suspension. The average size of the obtained cellulose crystal grains was measured to be about 160 nm, the yield was 77%, and the PDI was 1.5.

Embodiment 2

[0037] The types of raw materials used, the dosage and the process flow are the same as in Example 1, except that the soaking time of pulp cellulose in NaOH solution is extended to 72 hours to obtain a stable suspension of cellulose nanocrystals. The size is about 150 nm, the yield is 81%, and the PDI is 1.4.

Embodiment 3

[0039] After soaking 5g of α-cellulose with 250ml, 4wt% NaOH solution for 48 hours, filter and wash with deionized water until neutral, take this alkali-pretreated cellulose, add 0.078 gram of CuSO 4 ·5H 2 O, add 100 ml of 64wt% sulfuric acid, stir at 50°C for 1.5h, add deionized water to terminate the reaction, after the solution is allowed to stand, centrifuge at a speed of 8000rpm / min for 10min with a high-speed centrifuge, and then wash the precipitate , and separated again until the supernatant became cloudy. The obtained cellulose nanocrystal suspension was ultrasonicated to obtain a stable cellulose nanocrystal suspension with an average particle size of about 200 nm, a yield of 83%, and a PDI of 1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com