Treatment method of thick oil sewage

A technology of heavy oil sewage and treatment method, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of improving purification performance, improving treatment effect, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Test conditions:

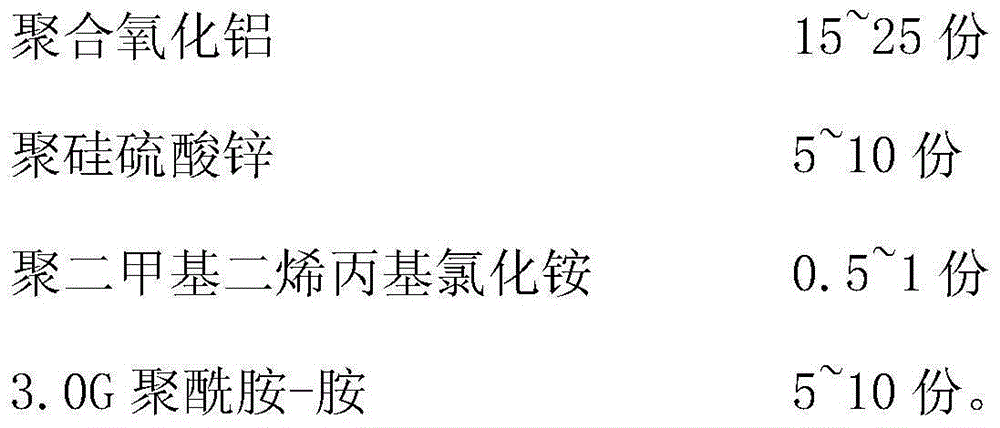

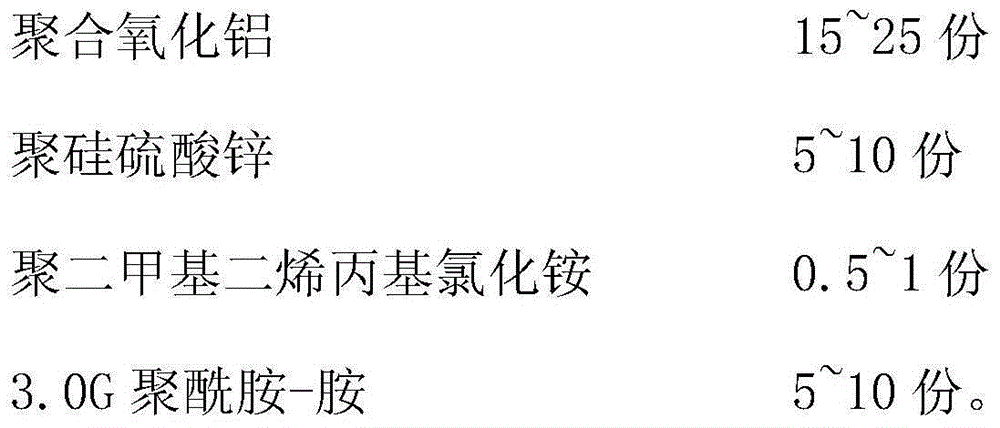

[0038] The CODCr of the heavy oil sewage raw water is 336mg / L, and the heavy oil sewage coagulant and polyaluminum sulfate are respectively added to the cyclone reactor for coagulation treatment. 7 parts of zinc, 0.7 parts of polydimethyldiallyl ammonium chloride, and 7 parts of 3.0G polyamide-amine were prepared, and the pH during the coagulation process was adjusted to 3.5. After coagulation treatment, the effluent CODCr decreased to 175mg / L, the biodegradability of sewage increased from less than 0.2 to 0.29.

[0039] The anaerobic biochemical treatment is carried out in the anaerobic biological reaction tank, and the anaerobic biological reaction tank is equipped with a submersible submersible plug flow stirrer and a suspended composite biological filler.

[0040] In the biochemical treatment, the contact oxidation biological reaction tank is provided with a suspended composite biological filler and a diaphragm aerator; the submerged submersible ...

Embodiment 2

[0044] In the coagulation removal treatment, the coagulant is prepared from 15 parts of polymeric alumina, 5 parts of polysilicon sulfate, 0.5 parts of polydimethyldiallyl ammonium chloride, and 5 parts of 3.0G polyamide-amine. Except that the pH in the process is 3, other processes are the same as in Example 1, and the CODCr of the final activated sludge reaction tank effluent is 30 mg / L.

Embodiment 3

[0046] In the coagulation removal treatment, the coagulant is prepared from 25 parts of polymeric alumina, 10 parts of polysilicon sulfate, 1 part of polydimethyldiallyl ammonium chloride, and 10 parts of 3.0G polyamide-amine. Except that the pH in the process was 4, other processes were the same as in Example 1, and the CODCr of the final activated sludge reaction tank effluent was 31 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com