Method for graft modification of silks

A graft modification, silk technology, applied in textiles and papermaking, fiber processing, animal fibers, etc., can solve the problems of poor durability of wear resistance, easy to harden silk, etc., and achieve high hydrolysis efficiency and high bonding firmness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

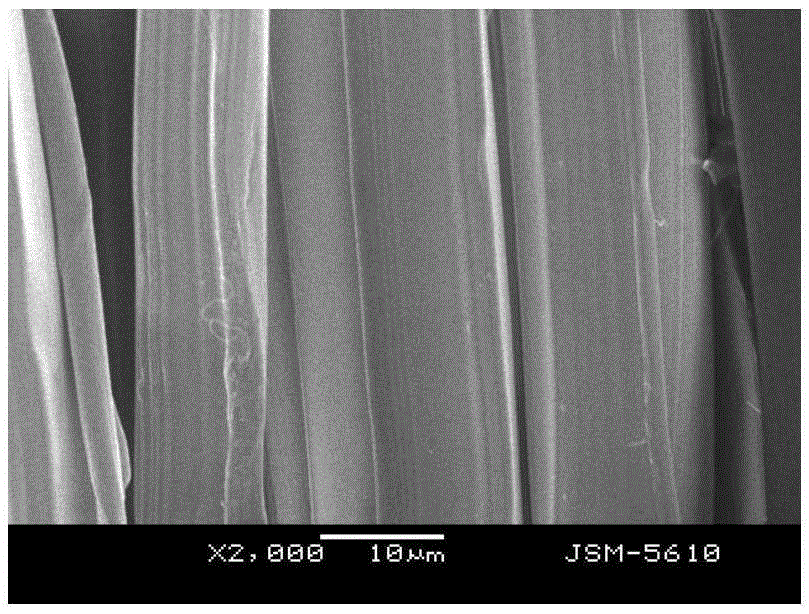

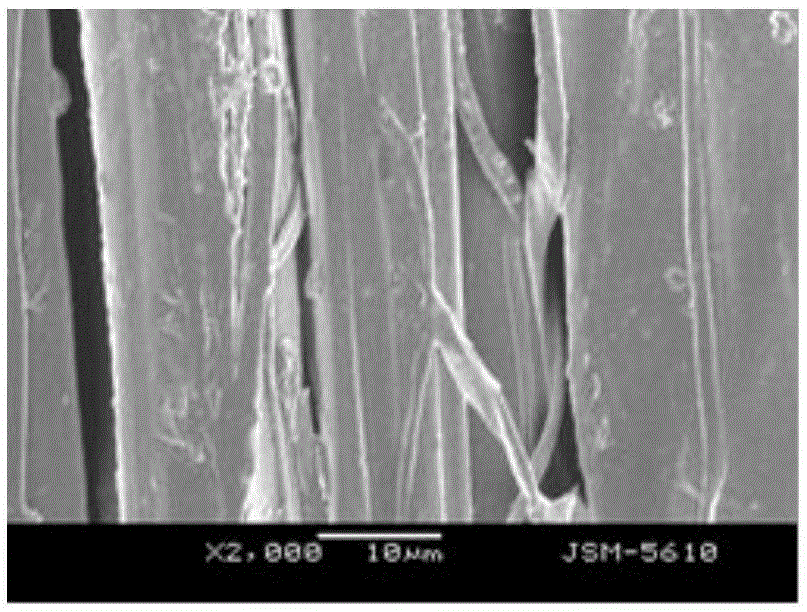

Image

Examples

Embodiment 1

[0021] A method for grafting and modifying silk, comprising the steps of:

[0022] Pretreatment step: the silk to be modified is degummed first, then washed twice with ethanol and water respectively, and then dried at a constant temperature of 55°C for 12 hours. Wherein, the degumming method adopts the soap alkali method, and the pH value of the lye is 10;

[0023] Step A: Use tetrahydrofuran as solvent and 1g of poly-N-isopropylacrylamide-co-acrylic acid polymer as solute to prepare 0.02L of a 50g / L solution, add 0.02g of catalyst 4-dimethylaminopyridine, and Stir the reaction for 1h;

[0024] Step B: Use tetrahydrofuran as a solvent and 0.1 g of N,N'-dicyclohexylcarbodiimide as a solute to prepare a 50 g / L solution, and immerse 2 g of silk that has undergone a pretreatment step into the liquid surface. 1:10, stirred and reacted at room temperature for 1h;

[0025] Step C: Pour the solution prepared in Step A into the container of Step B, and stir and react at room tempera...

Embodiment 2

[0028] A method for grafting and modifying silk, comprising the steps of:

[0029] Pretreatment step: degumming the silk to be modified, then washing it with ethanol and water three times respectively, and then drying at a constant temperature of 35°C for 24 hours. Wherein, the degumming method adopts the soap alkali method, and the pH value of the lye is 9.5;

[0030] Step A: with toluene as solvent, with 0.5g PMEO 2 MA-b-PAA polymer is used as solute, and 0.01L of 50g / L solution is prepared, 0.02g of catalyst 4-dimethylaminopyridine is added, and the reaction is stirred at room temperature for 1.5h;

[0031] Step B: Use toluene as the solvent and 0.2g of N,N'-dicyclohexylcarbodiimide as the solute to make a 50g / L solution, and immerse 1g of silk that has undergone the pretreatment step into the liquid surface. 1:14, stirring reaction at room temperature for 1.5h;

[0032] Step C: Pour the solution prepared in Step A into the container of Step B, and stir and react at room...

Embodiment 3

[0035] A method for grafting and modifying silk, comprising the steps of:

[0036] Pretreatment step: the silk to be modified is degummed first, then washed with ethanol, water, ethanol and water four times in sequence, and then dried at a constant temperature of 45°C for 18 hours. Wherein, the degumming method adopts the soap alkali method, and the pH value of the lye is 10.5;

[0037] Step A: with tetrahydrofuran as solvent, with 0.5g PMEO 2 MA-b-PAA polymer is used as the solute, and 0.02L of 25g / L solution is prepared, 0.01g of catalyst 4-dimethylaminopyridine is added, and the reaction is stirred at room temperature for 2h;

[0038] Step B: Use tetrahydrofuran as a solvent and 0.2g of N,N'-diisopropylcarbodiimide as a solute to prepare 0.002L of a 100g / L solution, and immerse 1g of silk that has undergone a pretreatment step into the liquid surface , the solution-bath ratio is 1:22, stirring and reacting at room temperature for 2h;

[0039] Step C: Pour the solution pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com