Iron tailing activation method and multi-solid-waste iron tailing concrete

A technology for waste concrete and iron tailings, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as time-consuming and cost-consuming, resource-consuming, and average effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

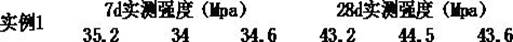

Embodiment 1

[0026] An iron tailings activation method, the multi-solid waste admixture includes the following raw materials in parts by weight, 30 parts of iron tailings powder, 10 parts of calcium phase admixture, 10 parts of aluminum phase admixture, 5 parts of composite activator, 1 part of grinding aid.

[0027] The calcium phase admixture is calcium carbide slag with a CaO content of 68%;

[0028] The aluminum phase admixture is coal gangue, Al 2 o 3 Content 28%;

[0029] The composite activator is a mixture of NaOH solution with a mass fraction of 30% and liquid sodium silicate with a modulus of 2.2-2.5 and a Baume degree of 38-45Be in a ratio of 1:2;

[0030] The grinding aid is triethanolamine.

[0031] A method for activating iron tailings, comprising the following steps:

[0032] Step 1: Mix a certain amount of iron tailings powder, calcium phase admixture and aluminum phase admixture in a ratio of 3:1:1, place it in an industrial microwave oven with a frequency of 2450MHz,...

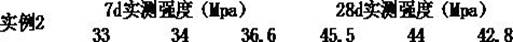

Embodiment 2

[0045] An iron tailings activation method, the multi-solid waste admixture includes the following raw materials in parts by weight, 20 parts of iron tailings powder, 10 parts of calcium phase admixture, 10 parts of aluminum phase admixture, 4 parts of composite activator, 2 parts of grinding aid.

[0046]The calcium phase admixture is papermaking white mud, with a CaO content of 42%;

[0047] The aluminum phase admixture is lithium slag, Al 2 o 3 Content 21%;

[0048] The composite activator is a mixture of NaOH solution with a mass fraction of 30% and liquid sodium silicate with a modulus of 2.2-2.5 and a Baume degree of 38-45Be in a ratio of 1:2;

[0049] The grinding aid is desulfurized gypsum.

[0050] A method for activating iron tailings, comprising the following steps:

[0051] Step 1: Mix a certain amount of iron tailings powder, calcium-phase admixture and aluminum-phase admixture in a ratio of 2:1:1, place it in an industrial microwave oven with a frequency of 2...

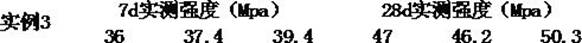

Embodiment 3

[0064] An iron tailings activation method, the multi-solid waste admixture includes the following raw materials in parts by weight, 20 parts of iron tailings powder, 15 parts of calcium phase admixture, 15 parts of aluminum phase admixture, 4 parts of composite activator, 2 parts of grinding aid.

[0065] The calcium phase admixture is desulfurization ash 62%;

[0066] The aluminum phase admixture is ceramic powder 36%;

[0067] The composite activator is a mixture of NaOH solution with a mass fraction of 30% and liquid sodium silicate with a modulus of 2.2-2.5 and a Baume degree of 38-45Be in a ratio of 1:2;

[0068] The grinding aid is one or a mixture of triethanolamine and desulfurized gypsum.

[0069] A method for activating iron tailings, comprising the following steps:

[0070] Step 1: Mix a certain amount of iron tailings powder, calcium-phase admixture and aluminum-phase admixture in a ratio of 4:3:3, place it in an industrial microwave oven with a frequency of 245...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com